Page 1

Snack Master

®

Multi-Purpose Fryer

Operator’s Manual

Belshaw Bros., Inc.

814 44

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

th

Street Northwest, Suite 103

Auburn, WA 98001 USA

Page 2

Page 3

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. The freight company has

accepted the responsibility for the safe delivery

of our machines. For your protection, inspect

the machine to see that no parts are bent,

scratched, or otherwise damaged. If any damage

has occurred in shipping, file a freight claim with

the shipping company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

092308

MN-1012EN

Belshaw Bros., Inc.

814 44th Street Northwest, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Page 4

Page 5

Contents

Contents

1 Operation 1

2 Cleaning 4

Cleaning the Conveyor and the Kettle 5

Removing the Shortening 5

Washing 6

Rinsing 7

Drying 8

3 Maintenance 9

Daily 9

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN iii

Page 6

Preface

The Snack Master fryer is designed to

automatically fry fresh cut tortilla chip and other

frozen snack food products utilizing a fully

submerging conveyor.

The Snack Master fryer is designed to be used on

a flat, stationary table or countertop. A specially

designed table come as an option with the full

fryer system. The operator must work safely at

all times and read this manual and follow its

instructions and warnings.

The Snack Master produces only 71.5 dB(A) of

equivalent A-weighted sound pressure at

workstations. This has been determined during a

dry run of the machine, using a Bruel & Kjaer

sound level meter, type 2236.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

Snack Master will prevent production delays and

injuries.

To use the Snack Master fryer safely, heed the

following warnings and all other warnings that

appear in this manual:

• Make sure the machine is secured to the

work surface. Doing so will prevent the

machine from moving or falling, which

could cause serious injury.

• Never let water and hot shortening come

in contact. Moisture causes hot

shortening to spatter, which may cause

serious burns.

• Hot shortening can cause serious burns.

Make sure that the system and the

shortening are cool before attempting

any adjustment, repair, disassembly, or

cleaning.

• To avoid electrocution or other injury,

unplug the machine before attempting

any adjustment, repair, disassembly, or

cleaning.

• To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

• Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

clean the area immediately. Materials on

the floor can cause people to slip or fall,

resulting in serious injury or loss of life.

• To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

• To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

• Make sure that all electrical cords are

routed so that no one will trip over them.

• Do not overfill the kettle with

shortening. If shortening overflows the

kettle, it could cause serious burns or

could cause someone to slip on the floor

and be seriously injured.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-xxxxEN Snack Master OM

Page 7

1 Operation

WARNING

Do not operate fryer without cover on

place. Doing so may expose operator to

steam and pinch points

Read each step completely before doing what it

tells you to do.

1. If necessary, place lower conveyor in

kettle. Ensure that the conveyor drive is

placed in the conveyor drive sprocket.

Place the upper conveyor on top of lower

conveyor. Make sure that the upper

conveyor drive sprocket ride on the lower

conveyor drive chain.

2. Plug in the fryer power cord or turn on

main supply breaker.

3. Insure that the Emergency Stop is not

activated by pull out.

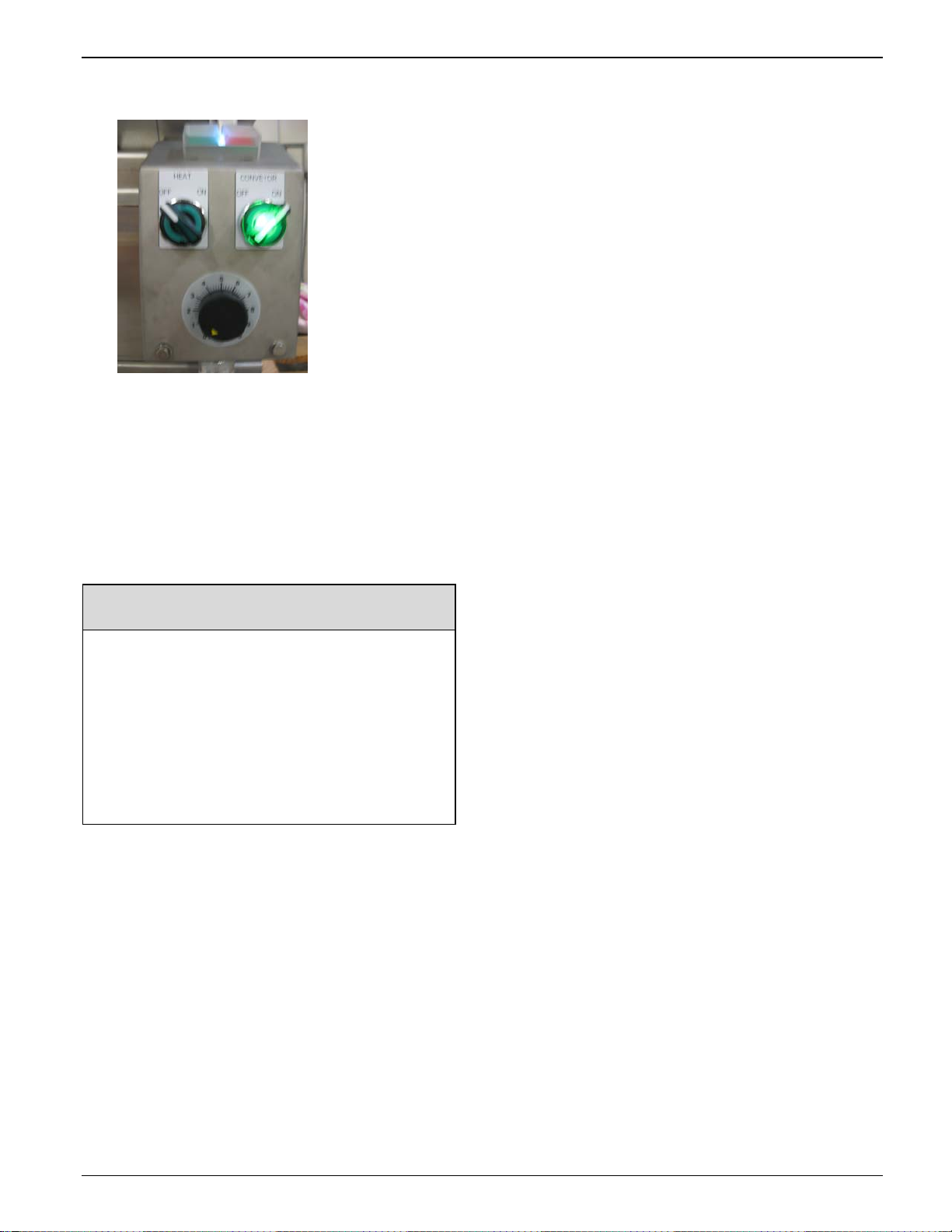

4. Check that the control power switch on

the back of the fryer heater head is on.

5. Press the green SYSTEM button on the

control box to ready fryer.

Put cover and infeed chute in place

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN 1

Page 8

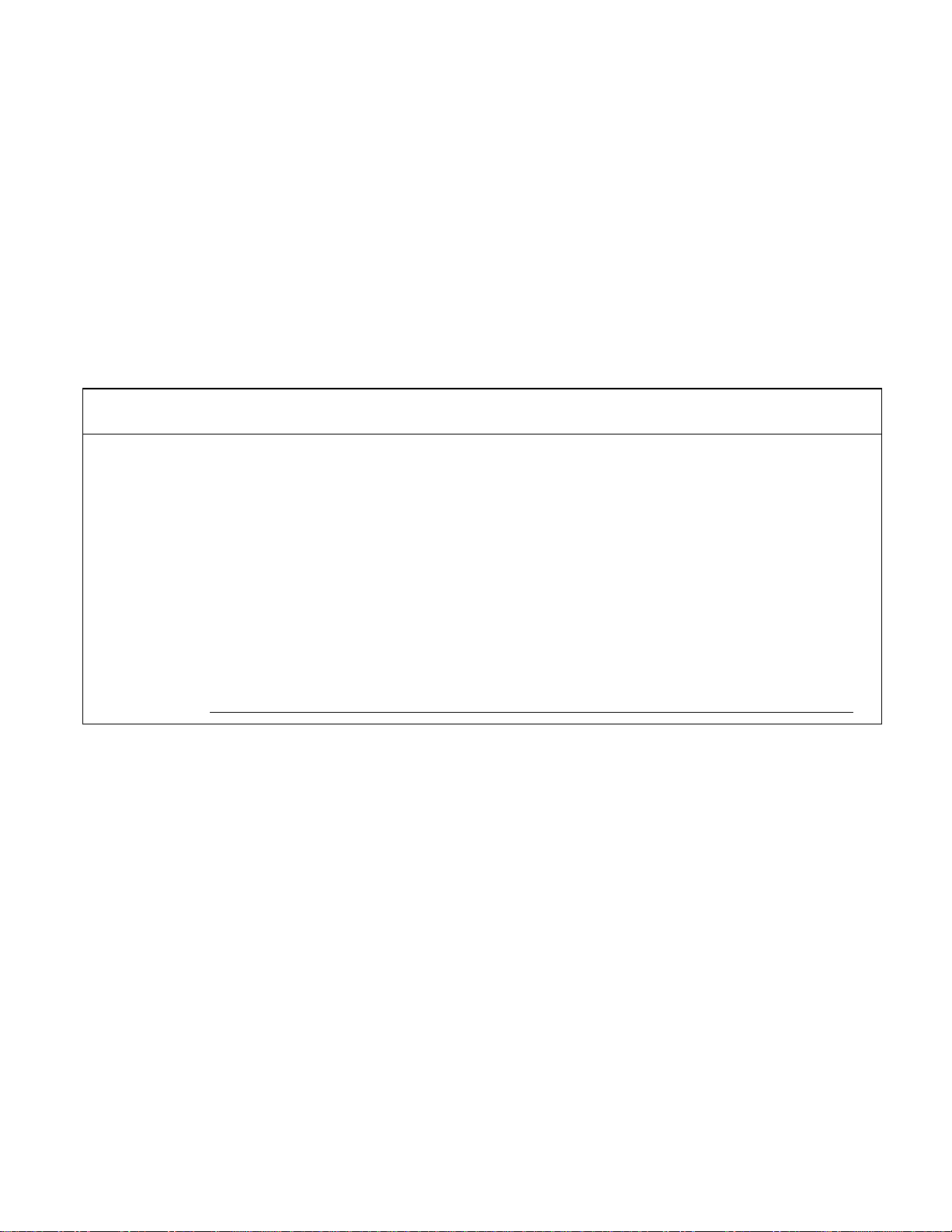

6. Set the temperature to the desired

temperature turning the temperature dial

above 200°F/93°C.

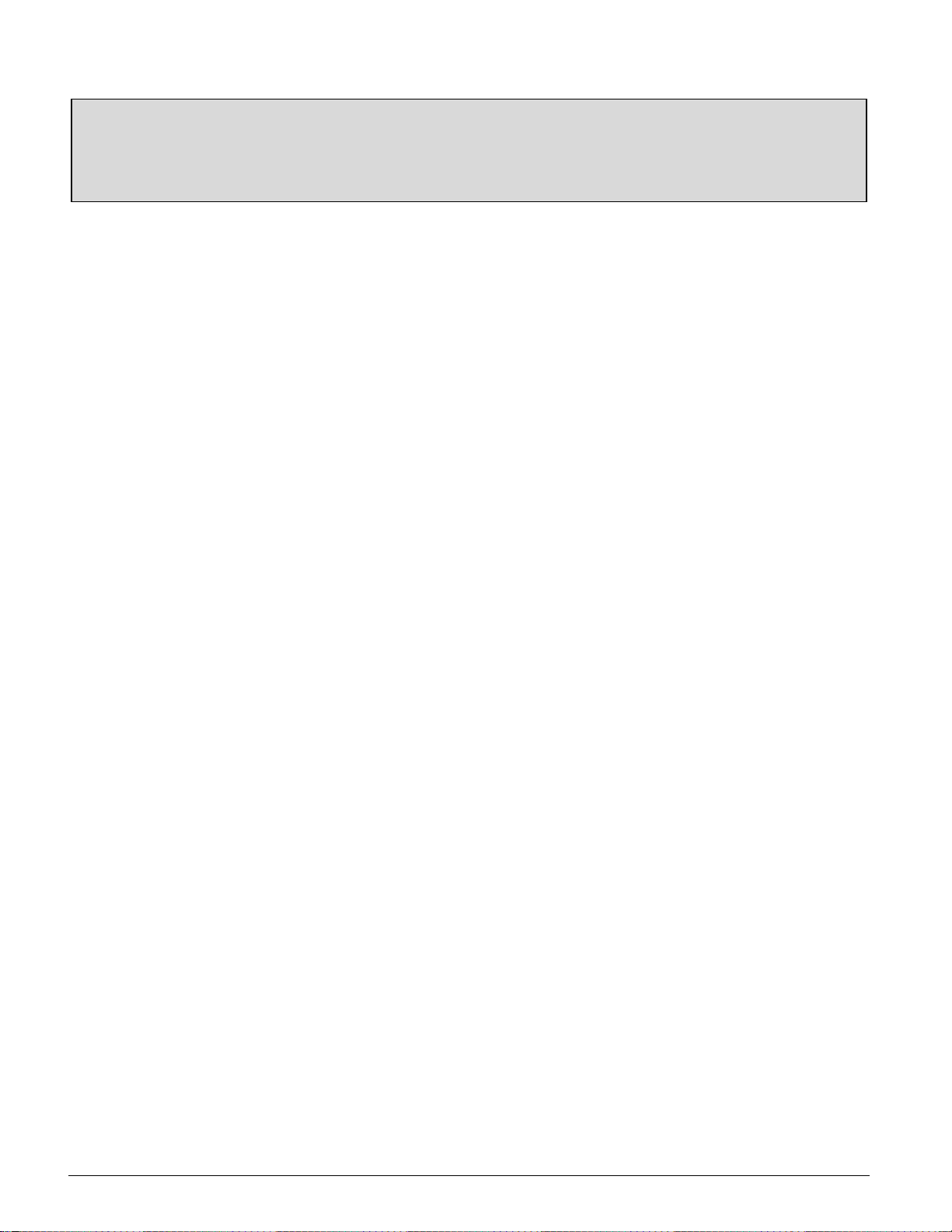

7. Turn HEAT selector switch to on the

control box to the on position. The lamp

in the selector switch is on to indicate

that the fryer heat has been turned The

pilot light on top of the heater head cycles

on when the elements are on and heating

the shortening

conveyor.

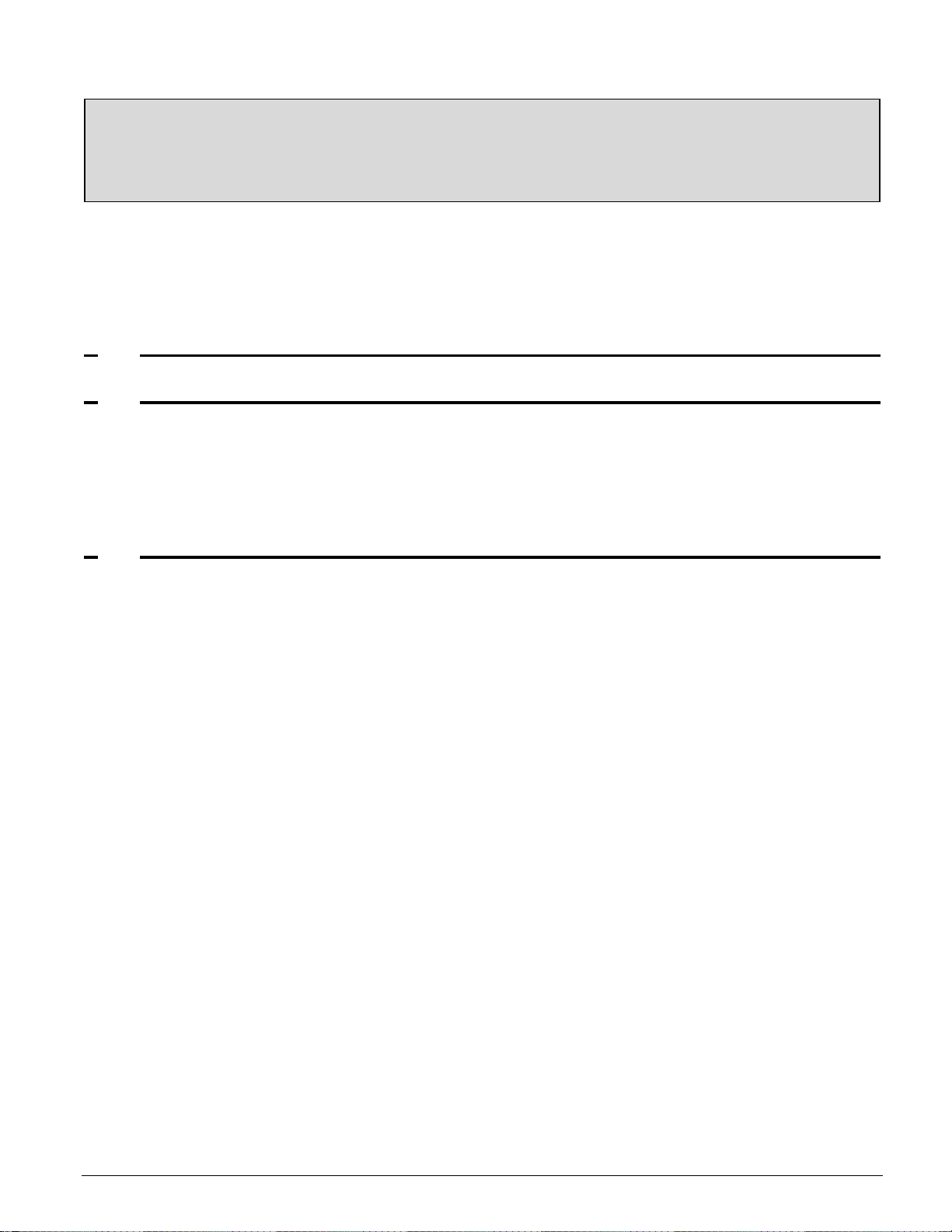

NOTE

The proper shortening level may change

based on the product being fried

• Pre-melt shortening in a pan on the stove

and carefully pour it into the kettle.

8. When the shortening reaches the correct

temperature, verify the shortening level.

Shortening expands as it increases in

temperature. This means that unless the

shortening is at frying temperature when

you put it in the kettle, you should put it

in gradually. Let the shortening in the

kettle heat up before you add more.

Proper shortening level is checked using

the level indicators on the lower

• Use the optional EZ Melt to melt

shortening and transfer it to the kettle.

See your EZ Melt manual.

WARNING

Hot shortening causes severe burns.

• Put solid shortening into the kettle,

packing it tightly around the elements

and bulbs.

WARNING

Air spaces can cause the shortening to

overheat and catch on fire.

8. Wait for the shortening to reach the desired

temperature. When it does, the pilot light on

the top of the heater head will go out. DO

NOT run the conveyor until all the

shortening has melted.

9. Choose the appropriate fry time for your

product using the fry time control knob on

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-xxxxEN Snack Master OM

Page 9

the control box .

10. . Turn on the conveyor drive using the

selector switch on the control box.

Note: If the conveyor becomes jammed, a

warning buzzer will sound about a minute

later and stop when the conveyor is turned

off. The conveyor drive is impedanceprotected so it will not burn out due to

jamming.

hood. Place a food bin at the at feed to catch

product as it comes out the outfeed conveyor.

WARNING

If the conveyor becomes jammed:

1. Turn off the conveyor drive and the

heater.

2. Allow the system to cool down.

HOT SHORTENING IS DANGEROUS.

3. Determine the cause of the jamming.

4. Clear it.

5. Restart the system.

11. Continue adding shortening to the kettle to

maintain the proper shortening level (see

step 2). There are two ways to do this:

• Melt some shortening in a pan on the

stove and carefully pour it into the kettle.

• If you are using the optional EZ Melt,

transfer more shortening from it. See

your EZ Melt manual.

12. To cook product, drop on infeed chute.

Beware of steam exiting out from under the

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN 3

Page 10

2 Cleaning

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor can

cause serious injury or loss of life.

WARNING

To avoid electrocuting yourself or

damaging the machine, never allow water,

steam, shortening, cleaning solution, or any

other liquid to enter the heater.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-xxxxEN Snack Master OM

Page 11

Cleaning the Conveyor and

the Kettle

There are four basic steps to cleaning the

conveyor and the fryer kettle: removing the

shortening, washing, rinsing, and drying. You

must perform all four steps and perform them in

the order listed.

Removing the Shortening

WARNING

To avoid being burned or electrocuted,

disconnect the machine from the power

source before cleaning the fryer.

1. Disconnect the machine from the power

source.

main drive shaft coupling from the

conveyor drive coupling. The lower

conveyor weighs 60 pounds/27.2KG. to

prevent injury it is recommended that

two people are used to lift the lower

conveyor. Slide one piece of wood under

the conveyor and lay it across the top of

the kettle. Lift the other end of the

conveyor and do the same with the other

piece of wood. The conveyor will now

be resting on the two pieces of wood.

Let the shortening drain off of the

conveyor and into the kettle

2. Let the shortening cool to 100°F/38°C.

3. Remove the conveyor assembly as follows:

a. Obtain two pieces of wood, at least 1” x

1” x 15” (2.5 cm x 2.5 cm x 38 cm).

b. Remove cover from fryer.

WARNING

To prevent injury it is recommended that

two people are used for lifting the upper

and lower conveyors

c. Lift upper conveyor assembly from the

lower conveyor. The upper conveyor

weighs 36 pound/16.3 KG. To prevent

injury it is recommend that two people

are used lift the upper conveyor. Turn

slightly clockwise and rest on lower

conveyor to allow excess shortening to

drain off the conveyor and into the

kettle. After shortening has drained off

remove completely.

c. Lift the lowerr conveyor and pull it away

from the heater head to disengage the

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN 5

Page 12

WARNING

All parts must be dried thoroughly.

Moisture causes hot shortening to spatter,

which may cause serious injury.

4. After the shortening has drained off of the

conveyor assembly, set the conveyor

assembly aside.

9. Check again to see that the shortening in the

kettle has cooled to 100°F/38°C.

10. Remove the shortening from the kettle using

one of these methods:

• Using the drain valve, drain shortening

into optional EZ-Melt Shortening filter.

• Using the drain valve, drain shortening

into metal bucket. The method will

require some means to remove

impurities from the shortening

• Using a small saucepan or a metal

pitcher, scoop as much of the shortening

as you can into one or more large metal

buckets. Then lift the kettle out of the

fryer case and carefully pour the rest of

the shortening into a metal bucket. Be

careful not to disturb the sediment that

has accumulated in the bottom of the

kettle.

WARNING

Do not allow the shortening to overflow the

buckets. Shortening will get on the floor,

and if the shortening is not cool enough,

you may be burned.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Shortening on the

floor can cause serious injury or loss of life.

11. Return the kettle to the fryer case, if you

have removed it.

12. Tilt the heater assembly down.

13. Brush off any carbon that has accumulated

on the heating element. Accumulated

carbon can cause corrosion and ineffective

heating.

14. Tilt the heater head assembly back, raising

the heating element out of the kettle.

15. Lift the kettle out of the fryer case. Remove

and dispose of the remaining shortening and

the accumulated sediment. Dry the outside

of the kettle.

16. Put the kettle back in the fryer case.

17. Tilt the heater head assembly down.

WARNING

Do not use plastic buckets for shortening

storage. If the shortening is not cool

enough, the buckets will melt; possibly

causing you to be burned, and causing

shortening to get on the floor.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 MN-xxxxEN Snack Master OM

19. Install the conveyor assembly.

Washing

1. Pour hot water into the kettle, up to the

normal level of the shortening. Add about

2 oz/59 ml of trisodium phosphate or other

appropriate cleaner.

2. Connect the machine to the power source.

Heat the solution to 200°F/93°C. Turn on

the conveyor. Keep the solution at this

temperature for 15-20 minutes.

Page 13

3. Turn off the conveyor and scrub the soiled

parts while the solution is under heat. Do

not use any abrasive cleaners or scrapers.

4. Turn off the heater and disconnect the

machine from the power source. Allow the

cleaning solution to cool to 100°F/38°C.

5. Remove the conveyors and tilt the heater

head back as you did before.

6. Remove the cleaning solution from the

kettle using one of these methods:

• Using the drain, valve drain the cleaning

solution into metal buckets When the

cleaning solution has stopped draining,

carefully carry the buckets to the sink

and slowly pour the solution into the

sink.

• Using a small saucepan or a metal

pitcher, scoop as much of the cleaning

solution as you can into one or more

large metal buckets. Then lift the kettle

out of the fryer case and carefully pour

the rest of the cleaning solution into a

metal bucket. Carefully carry the

buckets to the sink and slowly pour the

solution into the sink.

WARNING

Thoroughly clean and dry the floor if

cleaning solution is spilled. Liquid on the

floor can cause serious injury or loss of life.

7. Lift the kettle out of the fryer case.

8. Rinse the kettle thoroughly and dry it on the

outside.

9. Install the kettle, tilt the heater head

assembly down, and install the conveyor

assembly as before.

Rinsing

1. Pour clean water into the kettle, up to the

normal level of the shortening.

2. Connect the machine to the power source.

Heat the water to 200°F/93°C.

3. Run the conveyor for 5-10 minutes.

4. Turn off the heater and disconnect the

machine from the power source. Allow the

water to cool to 100°F/38°C.

5. Lift the conveyor assembly out of the fryer

case. Tilt the heater head assembly back.

WARNING

Do not use plastic buckets. If the cleaning

solution is not cool enough, the buckets will

melt; possibly causing you to be burned,

and causing cleaning solution to get on the

floor.

WARNING

Do not allow the cleaning solution to

overflow the buckets. Cleaning solution

will get on the floor, and if the solution is

not cool enough, you may be burned.

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN 7

6. Remove the water from the kettle using one

of these methods:

• Using the drain valve, drain the cleaning

solution into metal buckets. When the

water has stopped draining, carefully

carry the buckets to the sink and slowly

pour the water into the sink.

• Using a small saucepan or a metal

pitcher, scoop as much of the water as

you can into one or more large metal

buckets. Then lift the kettle out of the

fryer case and carefully pour the rest of

the water into a metal bucket. Carefully

carry the buckets to the sink and slowly

pour the water into the sink.

Page 14

WARNING

Do not use plastic buckets. If the water is

not cool enough, the buckets will melt;

possibly causing you to be burned, and

causing water to get on the floor.

WARNING

Do not allow the water to overflow the

buckets. Water will get on the floor, and if

the water is not cool enough, you may be

burned.

WARNING

4. If your kettle has the optional drain

assembly, close the drain valve.

Thoroughly clean and dry the floor if water

is spilled. Water on the floor can cause

serious injury or loss of life.

Drying

1. Thoroughly dry all parts, including the

conveyor, the heating element(s), the inside

of the kettle, and the drain.

WARNING

All parts must be dried thoroughly.

Failure to dry the kettle, conveyor, and all

parts of the Donut Robot completely will

cause spattering or an eruption.

Shortening will spatter or overflow the

fryer and may result in fire, injury, or

death.

2. Assemble the Snack Master as before.

3. Make sure no water is in the drain or drain

tube.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

8 MN-xxxxEN Snack Master OM

Page 15

3 Maintenance

WARNING

To avoid being burned, electrocuted, or

otherwise injured, always unplug the

machine and allow it to cool down before

making adjustments, clearing obstructions,

lubricating, cleaning, or disassembling.

Daily

Before using the machine each day, inspect the

upper and lower conveyors for damage.

Belshaw Bros., Inc. www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Snack Master OM MN-xxxxEN 9

Page 16

Page 17

Snack Master

Multi-Purpose Fryer

Technical Supplement

Belshaw Bros., Inc.

814 44

Phone: (206) 322-5474 Fax: (206) 322-5425

E-mail: service@belshaw.com http://www.belshaw.com

th

Street Northwest, Suite 103

Auburn, WA 98001 USA

Page 18

Page 19

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. The freight company has

accepted the responsibility for the safe delivery

of our machines. For your protection, inspect

the machine to see that no parts are bent,

scratched, or otherwise damaged. If any damage

has occurred in shipping, file a freight claim with

the shipping company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

0205

MN-1013EN

Belshaw Bros., Inc.

th

814 44

Street Northwest, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

E-mail: service@belshaw.com http://www.belshaw.com

Page 20

Page 21

Contents

1 Installation 1

Unpacking the Fryer 2

Initial Cleaning 2

Assembling the Fryer 2

Leveling and Securing the Fryer 4

Moving the Fryer 4

2 Maintenance 5

Lubricating 6

Checking the Thermostat 7

3 Troubleshooting 8

Snack Master 8

4 Electrical Components 15

Continuity Testing 15

5 Appendix 20

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN iii

Page 22

Preface

This technical supplement to the Snack Master

Operator’s Manual contains much information

that users and service persons may find helpful:

Detailed maintenance procedures for the

Snack Master

Detailed troubleshooting guides for the

Snack Master

Parts lists and assembly drawings of the

Mark II

Wiring diagrams of the Snack Master

Instructions on the testing and

calibration of electrical components

Information to make your donut

production easier

Remember that this is a supplement, not the

official operator’s manual. You use this

supplement at your own risk. While we have

made every effort to inform you of how to

behave safely, Belshaw denies any liability for

the use of the information contained herein.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

iv MN-1013EN Snack Master TS

Page 23

1 Installation

To help familiarize you with the major parts of

your Snack Master, please study the

photographs below.

Figure 1-1. Donut Robot Mark II.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 1

Page 24

Figure 1-1. Donut Robot Mark II.

Unpacking the Fryer

The Snack Master may come with a optional

table and EZ Melt Shortening Filter.To unpack

the equipement, first transport all the pieces to

the work area.:

1. Remove all crating and packing material

from the equipment.

2. Remove the cover and the conveyors from

the fryer.

3. Disconnect the control box power cord

5. Remove the clevis pins that hold the heater

head in place, and lift the heater head out of

the fryer.

6. Coil the power cord and carry the heater

head to the workstation.

7. Move the fryer case and kettle to the

workstation.

Initial Cleaning

WARNING

Never let water and hot shortening come in

contact. Moisture causes hot shortening to

spatter, which may cause serious injury.

Prior to use, make sure any parts you have

washed are dry.

After cleaning, assemble the fryer and cutter as

explained below.

Assembling the Fryer

1. If the optional table is used, place the table

in place and level.

2. Place the fryer case the table or on a flat,

stationary surface.

2. Screw the fryer’s legs in as far as they will

go.

3. Set the kettle into the fryer case. The end of

the kettle that has the locating pin must be

placed at the outfeed end of the fryer case.

The lip of the kettle should fit securely over

the edge of the case.

Thoroughly clean your Snack Master before

using it. Remove all packing materials. Use

household dishwashing detergent. Do not use

strong alkali cleaners such as lye, soda ash, or

trisodium phosphate. Thoroughly dry and

lubricate parts to prevent rusting.

Refer to the Cleaning section in the Operator's

Manual for detailed cleaning instructions.

WARNING

To avoid electrocution or damaging the

machine, never allow water, steam,

cleaning solution, or other liquid to enter

the cutter head or heater head assemblies.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

2 MN-1013EN Snack Master TS

4. Install the heater head assembly as follows:

a. Align the holes in the heater head end

caps with the holes in the heater head

mounting brackets.

b. Slide the clevis pins through the holes so

that the pinheads are on the outsides.

c. Insert the hairpin clips into the holes in

the clevis pins.

5. Lower the heater head assembly into

position so the thermostat bulb bracket rests

on or very near the bottom of the kettle.

6. Install the lower conveyor assembly as

follows:

a. Hold the conveyor at an angle and slide

the conveyor drive coupling over the

main drive shaft coupling. The conveyor

Page 25

coupling has a notch in it. Turn the

conveyor coupling until the head of the

socket head screw in the drive coupling

can slide into this notch.

Figure 1-1

b. Set the upper conveyor on to the lower

conveyor so that the upper conveyor

drive sprocket engages with the drive

chain on the lower conveyor.

Figure 1-2..

7. Be sure your power source matches the

specifications on the data plate. Connect the

machine to the power source.

8. Turn on the conveyor only and check to see

that it operates smoothly. The power switch

for the conveyor drive is on the control box

at the fryer infeed.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 3

Page 26

Leveling and Securing the

Fryer

Check to see if the fryer is level. If it is not,

adjust the heights of the legs. Be sure that all six

legs rest on the work surface when the fryer is

level.

Bolt the fryer to the work surface as follows:

1. There are brackets on the ends of the fryer

case. Each has a hole in it. Mark the

locations of the holes on the work surface.

2. Drill holes through the work surface.

3. Insert bolts through the holes.

4. Tighten nuts onto the bolts to ensure that the

Snack Master will not move.

Moving the Fryer

If you ever want to move the fryer to a different

workstation, follow this procedure:

1. Turn off the machine and disconnect it from

the power source. Unplug the cutter head

power cord.

2. Allow the machine and the shortening to

cool.

WARNING

Do not touch hot shortening. It can cause

serious burns.

3. Remove the shortening from the fryer as

explained in “Removing the Shortening” in

Section 3.

4. To avoid dropping the machine or getting

shortening on the floor wipe excess

shortening off of the fryer and the conveyor.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Materials on the floor

can cause people to slip or fall, resulting in

serious injury or loss of life.

5. Set aside the conveyors.

6. Remove the clevis pins that hold the heater

head in place. Remove the heater head from

the fryer.

7. To prevent tripping, coil the power cord.

Move the heater head to the new

workstation.

10. Move the fryer to its new location.

11. Install the heater head.

12. Move and install the conveyors.

16. Level and secure the fryer.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

4 MN-1013EN Snack Master TS

Page 27

2 Maintenance

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 5

Page 28

WARNING

To avoid being burned, electrocuted, or

otherwise injured, always unplug the

machine and allow it to cool down before

making adjustments, clearing obstructions,

lubricating, cleaning, or disassembling.

Lubricating

Yearly

Lubricate the conveyor drive motor as explained

below. To help you better understand where to

lubricate, refer to the Parts Drawings.

1. Disconnect the machine from the power

source.

2. Remove the back cover of the heater head.

3. Unscrew the two bolts that connect the

conveyor drive assembly to the bottom of

the heater head.

Daily

Before using the machine each day, inspect the

upper and lower conveyors for damage.

Figure 2-1. Lubricating the Connecting Rod.

Weekly

1. Remove the heater head cover and lightly

coat the gear teeth with multi-purpose

grease. Replace the cover. See Figure 2-1.

CAUTION

Be gentle with all parts of the conveyor

drive assembly, especially when pulling the

assembly out of the heater head and

putting it back in the heater head..

Damaging the parts could stop production.

4. Carefully pull the motor out of the heater

head. See Figure 2-3.

Figure 2-3. Removing the Conveyor Drive

Motor.

Figure 2-1. Lubricating the Drive Gears.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

6 MN-1013EN Snack Master TS

Page 29

5. Apply 4 to 6 drops of SAE 30 machine oil

through the lubricating hole in the bearing

cap until the felt pad is saturated. See

Figure 2-4.

Figure 2-4. Lubricating the Conveyor Drive

Motor.

6. Carefully put the motor back in the heater

head, bolt the motor to the heater head, and

replace the back cover of the heater head.

Checking the Thermostat

If the quality of your product decreases, check

the accuracy of the thermostat. Heat some

shortening in the fryer, measure the temperature

of the shortening using a thermometer you know

to be accurate, and compare this reading to the

thermostat setting If you need to calibrate the

thermostat, consult the “Electrical Components”

section.

If you ever want to test the continuity of the

thermostat or any of the switches on your Snack

Master, refer to the “Electrical Components”

section.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 7

Page 30

3 Troubleshooting

This section is designed as an aid in

troubleshooting with the Snack Master. It is

not a substitute for a qualified technician. You

may encounter a problem with your machine that

is not covered in this section, or you may try the

remedies suggested here and find that they do not

solve the problem. If this happens, call your

dealer or another qualified technician. Also, call

your dealer if you need a replacement part.

If your dealer cannot help you, please call

Belshaw Bros. When you call, please specify the

following:

The model name of the machine.

The serial number of the machine.

The voltage, phase, and cycle of the

machine.

If your machine needs to be repaired, consult

your dealer or another local, qualified technician.

If they cannot repair your machine, Belshaw can

provide factory service. First call Belshaw for a

return goods authorization. Then send your

machine to the Belshaw factory, freight prepaid,

with instructions for service, your phone number,

and the name of the person to contact when a

cost estimate is calculated. In most cases, the

machine can be shipped back, freight collect,

within five days. Ship the machine to:

To avoid down time, call to see whether a loaner

machine is available while your machine is being

serviced.

CAUTION

If you perform repairs yourself or have

them performed by anyone other than a

service technician authorized by Belshaw

Bros., you do so at your own risk.

Snack Master

Following is a troubleshooting chart to help

identify and solve problems with the Snack

Master.

WARNING

To avoid being burned, electrocuted, or

otherwise injured, unplug the machine and

allow it to cool before disassembling,

repairing, or wiring.

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

8 MN-1013EN Snack Master TS

Page 31

THE PRODUCT IS UNDERCOOKED.

Possible Causes What To Do

The shortening is not hot enough. Increase the temperature setting.

The conveyor is moving too quickly. Decrease the speed of the conveyor, using the

conveyor speed knob located on the control box.”

The thermostat reads inaccurately. Calibrate the thermostat.

THE PRODUCT IS OVERCOOKED.

Possible Causes What To Do

The shortening is too hot. Decrease the temperature setting.

The conveyor is moving too slowly. Increase the speed of the conveyor, using the

conveyor speed knob located on the control box

The thermostat reads inaccurately. Calibrate the thermostat.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 9

Page 32

PRODUCT DOES NOT MOVE THROUGH CONVEYOR.

Possible Causes What To Do

Product is to small for spacing between

conveyors.

Product is to large for spacing between

conveyors

The shortening level is too low. Add shortening to reach the proper level.

The fryer is not level. Level the fryer.

Add shorten to insure contact with both upper and

lower conveyor.

Use smaller product

WARNING

Before doing any of the following, turn off the

machine and allow the shortening to cool.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

10 MN-1013EN Snack Master TS

Page 33

THE HEATING ELEMENT FAILS TO MAINTAIN THE PROPER

TEMPERATURE.

Possible Causes What To Do

The input voltage is incorrect. Supply the correct power as specified on the data

plate.

Sediment has accumulated around the

thermostat bulb.

Clean to remove the sediment. (Clean the Donut

The thermostat has been calibrated incorrectly. Recalibrate the thermostat.

The thermostat is defective.

Replace the thermostat.

To avoid being burned or otherwise injured, turn

off the machine and allow the shortening to cool.

Robot regularly and thoroughly.)

To avoid being burned, electrocuted, or otherwise

injured, turn off the machine, allow the

shortening to cool, and disconnect the machine

from the power source.

WARNING

WARNING

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 11

Page 34

THE CONVEYOR IS JAMMED.

Possible Causes What To Do

Cooked food particles are wedged between a

chain opening and a sprocket tooth.

The conveyor drive shaft and the drive motor

shaft are out of alignment.

To avoid being burned or otherwise injured,

before doing any of the following, turn off the

machine and allow the shortening to cool.

Clean to remove the food particles. Clean the Snack

Master regularly and thoroughly.

Remove the cover of the drive assembly. Loosen the

four mounting spacers so the drive assembly can be

moved. Align the motor shaft with the conveyor

shaft. When they are aligned, tighten the mounting

spacers. Replace the cover.

THE MOTOR OVERHEATS.

Possible Causes What To Do

The power requirements of the machine do not

match the power source.

Supply the correct power as specified on the data

plate.

WARNING

The motor is binding. Repair or replace the motor.

The motor is defective. Repair or replace the motor.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

12 MN-1013EN Snack Master TS

To avoid being burned, electrocuted, or otherwise

injured, before doing the following, turn off the

machine, allow the shortening to cool, and

disconnect the machine from the power source.

WARNING

Page 35

THE ELEMENT WILL NOT HEAT, AND THE CONVEYOR WILL NOT RUN.

Possible Causes What To Do

The power cord is not plugged in, or the outlet

has no power.

The power cord is defective. Replace the power cord.

Connect the machine to a good power source.

WARNING

To avoid being burned, electrocuted, or otherwise

injured, before doing any of the following, turn

off the machine, allow the shortening to cool, and

disconnect the machine from the power source.

THE ELEMENT WILL NOT HEAT, BUT THE CONVEYOR RUNS.

Possible Causes What To Do

The high temperature limit control switch has

been tripped.

The thermostat has been calibrated incorrectly. Recalibrate the thermostat.

Push the red reset button on the back panel of the

heater head.

WARNING

The high temperature limit control is defective. Replace the high temperature limit control.

The thermostat is defective. Replace the thermostat.

The contactor for the heating is defective. Replace the contactor.

The connections to the contactor are bad. Rewire the connections to the contactor.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 13

To avoid being burned, electrocuted, or otherwise

injured, before doing any of the following, turn

off the machine, allow the shortening to cool, and

disconnect the machine from the power source.

Page 36

THE ELEMENT HEATS, BUT THE CONVEYOR WILL NOT RUN.

Possible Causes What To Do

The input voltage is incorrect. Supply the correct power as specified on the data

plate.

The circuit breaker has been tripped. Reset it by moving the white switch on the back of

the heater head to “off” and then to “on.” If the

conveyor still will not run, see that the power source

agrees with the specifications on the data plate. If

the problem persists, see below.

There is a short circuit. Find it and repair it. (First see “The circuit breaker

The wiring harness in the conveyor drive

assembly is not connected.

The conveyor drive power switch is defective. Replace the switch.

The nylon brake dog is binding on the conveyor

brake motor.

The brake motor is defective. Replace the brake motor.

To avoid being burned, electrocuted, or otherwise

injured, before doing any of the following, turn

off the machine, allow the shortening to cool, and

disconnect the machine from the power source.

has been tripped” above.)

Check the connection of the pin connector from the

conveyor drive assembly to the socket connector in

the heater head enclosure. Make sure the pins in the

pin housing are securely seated in the housing.

If the brake dog is worn, replace it. If it is too tight,

loosen it. If the spring is weak or missing, replace it.

WARNING

An internal wire is interfering with the nylon

brake dog.

The conveyor is jammed. Clear the obstruction.

The couplings are not engaged. Engage the couplings.

The conveyor drive coupling is slipping. Tighten the two set screws.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

14 MN-1013EN Snack Master TS

Move the wire.

Page 37

4 Electrical Components

This section explains how to test the continuity

of electrical components in the Snack Master.

These include the toggle switches, the

microswitches, and the thermostat.

The section also contains a document by the

Robertshaw Controls Company, the maker of the

thermostat we use in the Donut Robot Mark II.

It explains how to check, adjust, and recalibrate

the thermostat.

switch terminals

toggle switch

Continuity Testing

To test the continuity of a toggle switch:

WARNING

To avoid the possibility of electric shock,

disconnect the machine from the power

source before testing.

1. Disconnect the machine from the power

source.

2. Disconnect the terminal wires from the

switch.

3. Obtain a continuity tester or a volt-ohm

meter. If neither of these instruments is

available, make a continuity tester using a

battery and a bulb. (See Figure 4-1.)

4. Connect the wires of the continuity tester to

the switch terminals, as shown in Figure C1, and test the switch in the ON and OFF

positions. The switch should show

continuity only when in the ON position.

+

battery

_

Figure 4-1. Toggle Switch Continuity Test.

To test the continuity of a microswitch:

WARNING

To avoid the possibility of electric shock,

disconnect the machine from the power

source before testing.

1. Disconnect the machine from the power

supply.

2. Disconnect the terminal wires from the

switch.

3. Obtain a continuity tester or a volt-ohm

meter. If neither of these instruments is

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 15

Page 38

available, make a continuity tester using a

battery and a bulb. (See Figure 4-2.)

4. Connect one wire of the continuity tester to

the microswitch’s common (COM) terminal

and the other wire to the normally open

(NO) terminal, as shown in Figure 4-2. The

switch should show continuity only when

the microswitch actuator arm is depressed.

5. To test the normally closed (NC) terminal,

move the wire from the normally open (NO)

terminal to the normally closed terminal.

Now the switch should show continuity only

when the actuator arm is not depressed.

switch

terminals

NC NO

COM

microswitch

To test the continuity of the thermostat:

WARNING

To avoid the possibility of electric shock,

disconnect the machine from the power

source before testing.

1. Disconnect the machine from the power

supply.

2. Disconnect the terminal wires from the

thermostat.

3. Connect the continuity tester across the B

terminals indicated in Figure 4-3. This set

of contacts should be closed whenever the

thermostat is on. To test, start with the

thermostat in the OFF position. Then turn

the thermostat up until you hear a distinct

click (at about the 175F/79C setting). At

this time, there should be continuity across

the B terminals.

+

battery

Figure 5-2. Microswitch Continuity Test.

4. Connect the continuity tester across the A

terminals. Start with the thermostat in the

OFF position and turn the thermostat up

until you hear a distinct click. If there is no

continuity (the indicator or light does not

come on), proceed to step 5.

5. With the continuity tester still connected,

turn the thermostat knob to OFF and remove

the knob. There is an adjusting screw in the

center of the knob stem. Turn it counterclockwise until there is continuity. If there

is no continuity (the indicator or light does

not come on), then the thermostat is

defective. If there is continuity, proceed to

step 6.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

16 MN-1013EN Snack Master TS

Page 39

6. Immerse the thermostat sensing bulb in a

pan of boiling water and set the thermostat

at about 212F/100C. The continuity

tester’s indicator or light should go off. If

the indicator or light does not go off,

increase the temperature setting of the

thermostat until it does. Then recalibrate the

thermostat according to the manufacturer’s

instructions. If the indicator or light will not

go off at any setting or recalibration, then

the thermostat is defective.

“B” terminals

“A” terminals

Figure 5-3. Thermostat Terminals.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Snack Master TS MN-xxxxEN 17

Page 40

5 Appendix

See Parts List Drawing Insert Page.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

20 MN-xxEN Snack Master TS

Loading...

Loading...