Page 1

belshaw-adamatic.com

SNACK

1-800-578-2547 ▪ info@belshaw-adamatic.com ▪ www.belshaw-adamatic.com

MASTER

Frying System

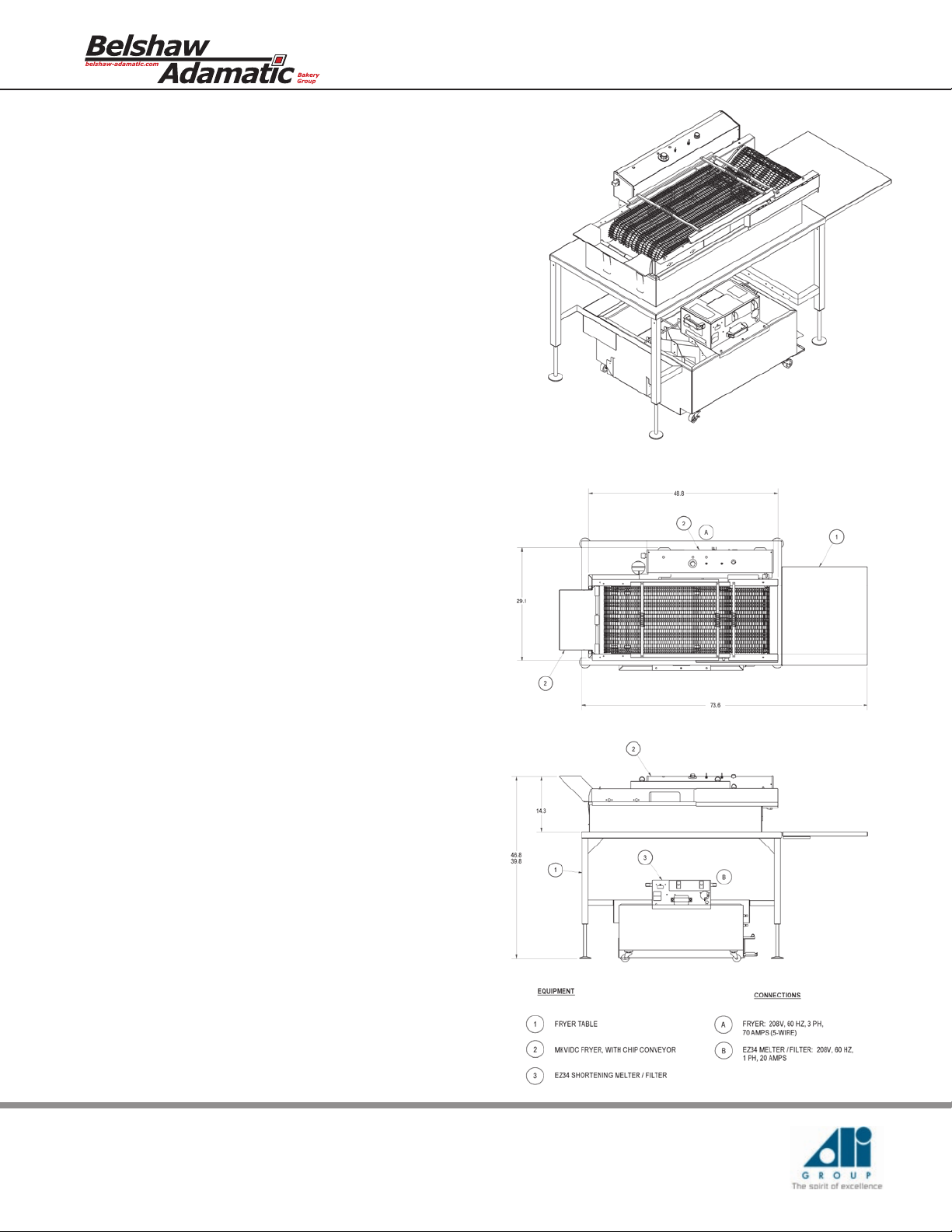

Above: Snack Master frying system with fryer,

lter, support table and receptacle bin.

For restaurants, bars, supermarkets, convenience stores and anywhere fresh food

is consumed

Includes fryer, support table, and ltering system

Customers can watch, sample, and buy – hot ′n fresh

For tortilla chips, chicken nuggets, mozzarella sticks, falafel and more

No standing over an open fryer

Capacity approx 140 lbs (64 kg) tortilla chips per hour

Compact footprint 72” x 32”

Belshaw Adamatic Bakery Group’s Snack Master automated frying system produces fresh tortilla

chips, chicken nuggets, mozzarella sticks and other similar products. The frying system can be put

on view to encourage sample tasting and on-the-spot purchases. No specic skills are required to

operate the system. The operator lls the entry chute, and a consistent nished product exits at

the other end. The submerging conveyor guides the chips between two conveyor belts through the

length of the fryer under the surface of the oil. An exit conveyor drops the chips into a basket or

receptacle. The operator can top up frying oil using the ltering system's foot switch, while the fryer

is running.

BELSHAW ADAMATIC BAKERY GROUP Fryers, ovens, bread lines and donut equipment

206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Page 2

Features – Fryer

Fast-recovery heating elements ▪

Removable conveyor ▪

Close weave conveyor belting ▪

Tilt up elements for cleaning kettle ▪

Thermostat control ▪

Variable speed, from 1 - 7 Min frying time ▪

Oil rell indicator ▪

Emergency stop switch ▪

3-phase power ▪

Oil drain and valve ▪

Stainless steel construction (some aluminum components) ▪

Features – Filtering System

Heavy duty stainless steel frame and casters ▪

Heavy duty pump & motor ▪

Fixed connection rell hose to fryer ▪

Detachable rinse hose with plated steel nozzle and safety grip ▪

Reusable long life synthetic lter ▪

Heavy duty, moisture repellent foot switch for pump ▪

Heating element and thermostat factory set to 200°F/93°C ▪

High-temperature limit switch ▪

Oil capacity 250 lbs (113 kg) ▪

SNACKMASTER

Note: Fryer includes cover not shown in diagrams.

Frying System

Features – Support Table

Fold-down table exension ▪

Guide rails for lter system ▪

Lock down bolts for fryer ▪

All stainless steel ▪

Production Capacity

Approximately 140 lbs (64 kg) tortilla chips per hour. ▪

Notes: ▪

Output depends on how fast the variable speed conveyor is set to run.

Fryer must be loaded regularly -

When loaded regularly, a second person may be required to bag or otherwise handle the nished product.

Fryer dimensions

Fryer length: 49” (1.25m) ▪

Fryer length with removable infeed chute in place: 56” (1.42m) ▪

Fryer width: 29” (74cm) ▪

Fryer height: 17” (43cm) with cover, not including exhaust ▪

vent)

Oil capacity: 106 lbs (48 kg) ▪

Overall system dimensions:

Table length: 72” (1.83m) ▪

Table width: 32” (81cm) ▪

Overall system height: 43”-50” (1.09m-1.27m). Height ▪

depends on table leg adjustment up to 7” (18cm)

Electrical

Fryer: 208/240V-60-3, 70 Amps (5-wire) ▪

Filter: 208V-60-1, 20 Amps ▪

BELSHAW ADAMATIC BAKERY GROUP Fryers, ovens, bread lines and donut equipment

206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2009 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Loading...

Loading...