Page 1

MONO-TWIN Tilting automatic spiral mixer

Supplied and serviced by

BELSHAW ADAMATIC BAKERY GROUP

1-800-578-2547

www.belshaw-adamatic.com

info@belshaw-adamatic.com

MONO-TWIN

MONO-TWIN

Tilting automatic spiral mixer

MONO-TWIN 200 A - rest position.

These photos and this document are not contractually binding.

MONO-TWIN 200 A - unloading position.

Page 2

MONO-TWIN Tilting automatic spiral mixer

The MONO-TWIN mixer consists of an ISE/F spiral mixer permanently installed on a hydraulic cylinder elevator,

designed to vertically raise the entire structure and tip the dough contained in the bowl on the right or left side as

required by the user. According to the model chosen, the opposed unloading heights allow the machine to be combined with volumetric dividers and/or deposit the dough on a work bench, feeding one or two production lines, according to requirements.

Versatile as regards use and highly compact, the MONO-TWIN has been designed and produced to reduce overall

working dimensions to a minimum, at the same time guaranteeing all requirements in terms of dependability, quality performance, mechanical solidity and safety, hallmarks of the Esmach mixers.

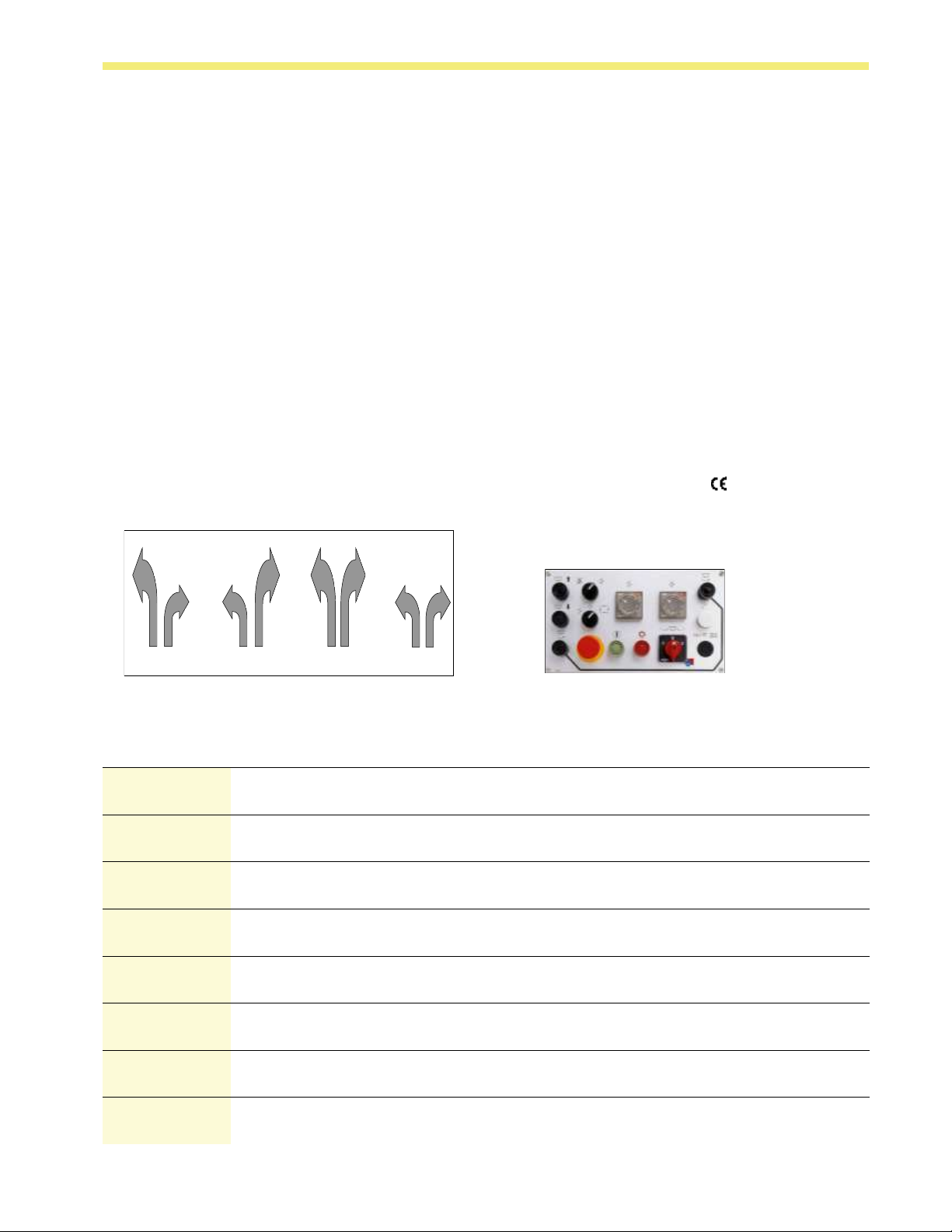

The MONO-TWIN comes in 2 versions – with mixing capacity of 160 and 200 kg – and 4 models, which differ due to

the height and position of the unloading points, as shown in the diagram of combinations.

Construction

Steel mixer and elevator structure.

Dual-cycle anti-corrosion treatment, using epoxy powders

(food contact).

Bowl, column, spiral and safety grid made of stainless steel.

Spiral automatically stops when grid is opened.

24V low voltage control panel.

Motors protected against short circuits by thermal switches.

Two working speeds for bowl and spiral.

Device for inverting bowl rotation direction in first speed.

Electrical system housed inside central stainless steel box

Electromechanical instrumentation. Repeatable work cycle,

set via two timers with automatic switch from first to second

speed. Possibility of working in manual mode.

Elevator up-down movements with “hold-to-run” controls.

Button for rotation of spiral and bowl (up) or bowl only

(down), after tipping, to facilitate detachment of the mixture.

Electrical power supply: V.400/3/50 Hz (different voltages on

request).

mounted on adjustable support, with integrated control panel.

This machine complies regulations.

POSSIBLE COMBINATIONS

Type A Type B Type E Type H

MODEL

MONO-TWIN 160 H 01550802

MONO-TWIN 160 E 01550702

MONO-TWIN 160 A 01550502

MONO-TWIN 160 B 01550602

MONO-TWIN 200 H 01550402

MONO-TWIN 200 E 01550302

MONO-TWIN 200 A 01550102

MONO-TWIN 200 B 01550202

Ref. Description

Spiral mixer with approx. kg. 160 dough capacity (approx. kg. 100

flour capacity). Bowl diameter mm 900.

Version with unloading on bench on both sides.

Spiral mixer with approx. kg. 160 dough capacity (approx. kg. 100

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on both sides.

Spiral mixer with approx. kg. 160 dough capacity (approx. kg. 100

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on left, on bench on right.

Spiral mixer with approx. kg. 160 dough capacity (approx. kg. 100

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on right, on bench on left.

Spiral mixer with approx. kg. 200 dough capacity (approx. kg. 125

flour capacity). Bowl diameter mm 900.

Version with unloading on bench on both sides.

Spiral mixer with approx. kg. 200 dough capacity (approx. kg. 125

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on both sides.

Spiral mixer with approx. kg. 200 dough capacity (approx. kg. 125

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on left, on bench on right.

Spiral mixer with approx. kg. 200 dough capacity (approx. kg. 125

flour capacity). Bowl diameter mm 900.

Version with unloading on divider on right, on bench on left.

Control panel

FOR UNLOADING HEIGHTS, CONFORM STRICTLY TO THE MEASURES INDICATED AT THE FOLLOWING PAGE

Page 3

MONO-TWIN Tilting automatic spiral mixer

1

2

TIPO D I ABBIN AM ENTO

TYPE OF COUPLIN G

AB

DATI TE CNI CI -TECHNI CAL FEATURE S MONO -TWIN 160/200

A

B

C

D

E

mm

mm

mm

mm

mm

F 160 / 200 mm

G

H

I

mm

mm

mm

DIMENSI ONI MINIME PORTE D'ACCESSO

MINI MUM DI ME NSIONS OF E NTRANCE DO ORS

TIPO DI SCARICO DELLA VASCA-BOWL UNLOADING TYPE

1

3000

1740

/

/

2620

940/1000

1250

200

1690

TIPO DI ABBINAMENTO-TYPE OF COUPLING

ABEH

E

mm 2580x1400 2080x1400

POTENZA INSTALLATA-INSTALLED POWER kW

POTENZA MAX ASSORBITA-MAX ABSORBED POWER kW

PESO-WEIGHT kg 1270

1210

CONNESSIONE ELETTRICA-PLUG COUPLING

9

7,9

3PH+Gr

H

2

/

/

1200

2460

2120

940/1000

1250

200

1690

1150

Loading...

Loading...