Page 1

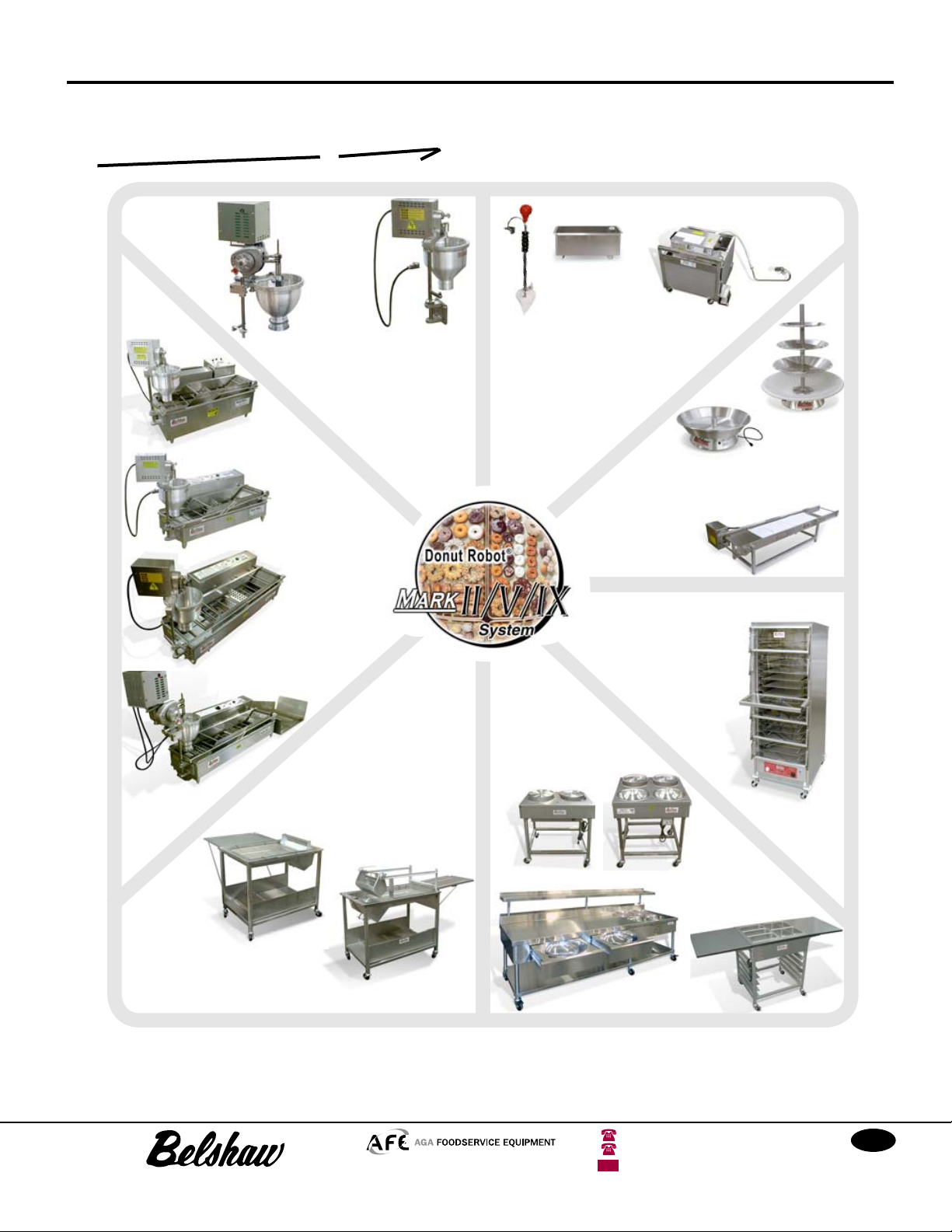

DONUT PRODUCTION SYSTEMS

BAKERY AND RETAIL EQUIPMENT GUIDE

Worldwide Leader in the Design, Manufacture, Installation, Training and Service of Donut Production Equipment

®

Mark II, V and IX Donut Robot

Systems

Donut Robot® Automatic Systems – Mark II, Mark V, & Mark IX

are the most highly requested systems

produced by Belshaw. Designed for retail

bakeries and concessions, these systems’

popularity arises from the labor savings

and convenience of allowing the operator

to perform multiple tasks while the machine

fries, turns and dispenses completely on its

own. Additionally, the Donut Robot® has

proven very popular for exhibition-style

baking.

Mark II, V and IX systems fry 2 full-size (or

4 miniature) donuts across each conveyor

row. The Mark II system will produce up to

43 dozen donuts per hour, while the Mark

V and Mark IX systems produce up to 63

dozen per hour using a longer fryer. Mark II,

V and IX Donut Robot® Systems include the

accessory equipment required to prepare,

fry and fi nish donuts. They include:

◆ Automatic Fryer

◆ Shortening Filter or Reserve Tank

◆ Roto-Cooler / Finishing Tree

(rotates as it collects donuts from fryer)

◆ Icer

◆ Feed Table

yeast-raised donuts into fryer)

(automatically inserts

Below: Belshaw Donut Robot® Mark II

Cake & Yeast System (Typical)

Donut Robot® Mark II, with

Feed Table

Roto-Cooler

EZMelt Melter-Filter

HG18-E Z Glazer

H&I -2 Icing Table

EP18-24 Proofer

(Cake Donut Cutter not shown)

◆ Proofer for yeast-raised products

◆ Glazer

◆ Mixer (7 qt / 6.6 L)

◆ Jelly Filler

PART OF AGA FOODSERVICE GROUP

Above:Belshaw Donut Robot®

Mark II Cake Donut System

(Typical)

Donut Robot® Mark II, with

Filter-Flo® Siphon & Filter

Shortening Reserve Tank

Roto-Cooler

These systems are also compatible with

Belshaw’s Insider ventless hood cabinet.

The guide over the page will help to select

the components that make up a Mark II,

Mark V or Mark IX donut system. For

specifi cations of Mark II, Mark V, and Mark

IX fryers, as well as equipment for building

a complete system, see the Automatic

Fryers section of the

Retail Products Guide

4

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144-4590 USA

W http://www.belshaw.com 800-578-2547 (USA/Canada) 206-322-5474 (International)

Belshaw Bakery and

.

©2002 Belshaw Bros, Inc. Rev.4/ 02

FAX

206-322-5425

Page 2

DONUT PRODUCTION SYSTEMS

Donut Robot® Mark II, V & IX Systems

Building a system

Typ e N

automatic

Cake Donut

Depositor

Gas Mark II

Mark II

Mark V

Donut Robot

Cake Donut

Depositor

The Donut Robot® depositor is

standard on Mark II and Mark

V. Type N is standard on Mark

IX. Both are automatic.

Fryer

Donut Robot®

Mark II, V or IX.

Choose ‘GP’

models for

mini-donuts

Mark IX

®

Donut

Depositor

Glazer

Glaze a full screen of

donuts at a time. Reduce

lifting with ‘Easylift’

FOR BELSHAW DONUT ROBOT® MARK II, V OR IX

Shortening Reserve Tank

EZ Melt

Filter-Flo® Siphon

SF fi lter cleans and recycles

shortening; EZMelt melts,

pumps and fi lters

Sugaring

Tra y

Shortening

Filter

Collect, cool and display donuts

after frying. Load yeast-raised

donuts into the fryer.

Fryer

Accessories

Feed Table

Proofer

Take the guess work

out of proofi ng any

Icer

Make a full variety of

donuts with this choice

of icing methods

yeast-raised product

EP18-24

Finishing

Tre e

FT-2

Manufactured by

HG Standard

H&I-2

HG Easylift

PART OF AGA FO ODSERV ICE GRO UP

H&I-4

Donut Finishing

Center

H&I-6

Icing and Finishing Table

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

5

Page 3

AUTOMATIC FRYERS

BAKERY AND RETAIL EQUIPMENT GUIDE

Worldwide Leader in the Design, Manufacture, Installation, Training and Service of Donut Production Equipment

Donut Robot® Mark II - Mark IX

PART OF AGA FOODSERVICE GROUP

Donut Robot® Series Automatic Fryers deposit, fry,

turn, and dispense cake and yeast-raised donuts

- automatically - improving donut quality and

reducing costs. Training and labor requirements

are substantially reduced while quality, repeatable

donuts are produced time after time. Additionally,

Donut Robot

®

fryers have been shown to reduce

shortening use by up to 50%.

®

Donut Robot

Series Automatic Fryers are built

with exhibition style production in mind – improving

foot traffi c and customer loyalty. For locations

where exterior ventilation is impractical, the

“Insider” custom kiosk, without exterior ducting, is

the solution.

Donut Robot

®

Mark II

Belshaw offers several machines with capacity from 200 to 1500 donuts per hour. Production is even higher for miniature

donuts. If less production is needed at any time, a simple switch cuts cake donut production instantly by half.

Belshaw can tailor a complete system to your specifi c needs. The Donut Systems section of the

Equipment Guide

shows examples of systems built with Donut Robot® fryers.

Belshaw Bakery and Retail

18

Donut Robot® GAS Mark II

Donut Robot

®

Mark IX

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144-4590 USA

W http://www.belshaw.com 800-578-2547 (USA/Canada) 206-322-5474 (International)

Donut Robot® Mark VI

©2002 Belshaw Bros, Inc. Rev.4/ 02

Donut Robot® Mark V

FAX

206-322-5425

Page 4

AUTOMATIC FRYERS

LI STE D

C US

U

L

U

L

NSF

Donut Robot® Mark II - Mark IX

PRODUCT INFORMATION

Electric heating is standard; Mark II and Mark II GP are available either

gas-heated or electric-heated.

‘GP’ models designate mini-donut specifi c machines, with hopper/plunger

and conveyor adapted for rapid production of mini donuts.

All models feature frying time and temperature adjustment. Mark II and

above feature a switch that reduces automatic cake donut deposits to one

donut per conveyor row (normal is two donuts per row).

All models feature electrically powered conveyors. See table at bottom of

page for available voltages.

The Donut Robot® automatic cake donut depositor is standard on Mark

I, II and V. It accomodates Donut Robot® plain, mini, star, or french cake

plungers and attachments. A 1-9/16” (40mm) star plunger is supplied on

new machines, unless another plunger is requested.

Mark IV and Mark VI use either Type ‘F’ (semi-automatic) or Donut

Robot® (automatic) cake donut depositors.

Type ‘N’ (automatic) is standard on Mark IX. See Donut Depositor

section of

DONUT ROBOT

C

Bakery and Retail Product Guide

®

MARK II - IX

A B

[Drawings show Donut Robot cake donut depositor]

for depositor details.

DOZENS

PER

HOUR

200

175

150

125

100

75

50

25

Mark I

DONUT ROBOT® PRODUCTION

Based on fr ying times of 90 seconds

for standa rd donuts and 55 seconds

for mini donu ts. Production will

vary depending on product

size, fry ing temper ature and

composition of donut.

126

63

Mark IX

®

LISTED

S

I

F

S

A

L

C

®

CLASSIFIED TO

NSF 4 - 1992

Mark IV

I

E

D

US

87

Mark VI

Mark I GP

63

43

17

Mark II

Mark V

SANITATION

100

Mark II GP

285

196

Mark V GP

MINI DONUTS

ONLY

NSF

®

STANDARD

FEATURES

MODEL

MARK I

MARK II

MARK IV

MARK V

MARK VI

MARK IX

OPTIONAL

Electric

Heat

Gas Heat GP model

DIMENSIONS AND POWER

Shipping

A x B x C

in cm lbs/kg lbs/kg KW A KW A KW A KW A KW A BTU/hr kPa N.GAS PROP.

MARK I 35 x 14 x 23 89 x 34 x 57 100/45 14/6.4 1.2 10.0 1.5 7.4/6.4

MARK II 41 x 21 x 25 104 x 52 x 62 136/62 35/16 4.3/5.7 21.0/24.0 4.5/5.7 12.5/14.2 4.4/5.2 6.7/7.3 5.8/6.8 7.6/8.2

MARK II (Gas) 41 x 23 x 30 104 x 58 x 62 150/67 35/16 0.36 3.0 40,000 12.9 3.5 in 10 in

MARK IV 41 x 28 x 24 104 x 71 x 62 172/78 70/32 7.2/9.5 20.0/23.2 8.0/9.5 12.0/14.0 8.0/9.5

MARK V 52 x 20 x 24 133 x 52 x 62 200/91 50/23 7.3/9.4 35.2 7.3/9.4 20.3/23.0 7.9/9.4 11.9/13.8

MARK VI 52 x 28 x 24 133 x 71 x 62 294/133 106/48 12.1/15.2 33.6/37.1 12.0/14.2 18.0/20.9 15.3/18.7

MARK IX 53 x 21 x 35 133 x 52 x 89 250/113 50/23 7.6/9.8 36.5/40.8 7.6/9.8 21.1/24.4 8.3/9.8 12.5/14.6

weight

Fryer

capacity

Note: details about Donut Robot® Mark I can be found in the Donut Systems section of the Product Guide.

Electric

Conveyor

120 V 208/240 V 380/415 V (Export)

Donut

Robot

Depositor

Type F

Depositor

Type N

Depositor

Dimensions taken with Donut Robot cake donut depositor on all models.

208/240 V

50/60Hz/3ph

Feed Table

(for raised

donuts)

Multiple

Turners

440/480 V

50/60Hz/3ph

Submerger

INSIDER™

Ventless

Cabinet

GAS

OUTPUT50/60Hz/1ph 50/60Hz/1ph 50/60Hz/3ph

Automatic

proofer

(TM-VI)

COLUMN

Manufactured by

PART OF AGA FO ODSERV ICE GRO UP

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

19

Page 5

AUTOMATIC FRYERS

BAKERY AND RETAIL EQUIPMENT GUIDE

Worldwide Leader in the Design, Manufacture, Installation, Training and Service of Donut Production Equipment

Accessories for Donut Robot® Mark II, Mark V, & Mark IX

COLLECTING AND COOLING DONUTS

Sugaring Tray

Roto-Cooler

Roto-Cooler

with Finishing Tree

Belshaw’s three

to collect, hold and cool donuts fried on Donut Robot® Mark II, V

and IX fryers. They are rotating round trays, attractively fi nished,

and powered by a connection to the fryer.

The standard

donuts, giving the operator plenty of time to complete other jobs

before transferring the contents. The tray is white polyethylene

and easy to clean.

The stainless steel

allows the operator to coat donuts with cinnamon sugar and other

fl avors on the spot without a separate fi nishing table.

Roto- Cooler With Finishing Tree

The

icing, decorating and display center. Each of the top three trays

have two sections for a greater selection of icings and toppings.

One person can quickly decorate donuts to create an endless

variety, fi nished to order, right on the spot.

Roto-Cooler

Roto-Cooler

Sugaring Tray

versions are the most practical way

is large enough to hold in excess o f 75

is smaller and deeper, and

makes a complete donut

TRANSFER DIRECT TO ICER OR GLAZER

The RL-18 Rack

Loader is a labor

saver for operators

using Belshaw’s HI18

batch icer and/or

HG18 hand glazer.

Donuts are collected

onto glazing screens,

ready for direct

transfer onto the icer

or glazer.

PART OF AGA FOODSERVICE GROUP

Rack

Loader

Glazing

Screen

INSERTING YEAST-RAISED DONUTS INTO THE FRYER

The

FT-2 Feed Table

box such as Belshaw’s EP18/24. The donuts are laid on a Proofi ng

Cloth and Proofi ng Tray before proofi ng, then transferred onto the

FT-2. The Feed Table advances in time with the fryer and drops the

proofed donuts automatically. The process allows the donut maker

to move about rather than standing in front of the fryer.

FT-2 Feed Table

20

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144-4590 USA

W http://www.belshaw.com 800-578-2547 (USA/Canada) 206-322-5474 (International)

accepts yeast-raised donuts from a proof

Proofi ng Tray

Proofi ng Cloths

LONGER LIFE SHORTENING

Filter-Flo Siphon

Shortening

Reserve Tank

The Filter-Flo is a heavy

duty siphon that removes

and fi lters shortening. One

squeeze of the bulb starts the fl ow

which can empty a Mark II in about

fi ve minutes. A reusable cloth fi lter

cleans as liquid passes through.

The Shortening Reserve Tank melts

and holds new shortening ready for

adding to the fryer as needed.

©2002 Belshaw Bros, Inc. Rev.4/ 02

FAX

206-322-5425

Page 6

AUTOMATIC FRYERS

NSF

DIMENSIONS AND POWER

Accessories for Mark II, Mark V, & Mark IX Fryers

OVERALL DIMENSIONS

MODEL

FILTER-FLO SIPHON 4 x 6.5 x 23 10 x 17 x 59 3 1.5

ROTO-COOLER 24 x 24 x 7 61 x 61 x 18 16 7.5

SUGARING TRAY 17 x 17 x 7 43 x 43 x 18 14 6.5

ROTO-COOLER & FINISHING TREE 24 x 24 x 31 61 x 61 x 79 28 12.5

RACK LOADER (RL-18) 21 x 29 x 10 53 x 74 x 25 25 11.5

FT-2 FEED TABLE 52 x 19 x 12 132 x 49 x 30 41 19

Width x Depth x Height

in. cm. lbs. kg. V A W

APPROX SHIPPING

WEIGHT

CONSTRUCTION

MODEL CONSTRUCTION

Siphon tube and valve are nickel plated steel. Clamp is aluminum alloy.

FILTER-FLO SIPHON

SHORTENING RESERVE TANK All parts are stainless steel.

FT-2 FEED TABLE

ROTO-COOLER

Filters are flannel cloth, filter ring is powder coated steel, handle is high

density plastic.

Stainless steel chains and hooks. Other parts stainless steel and cast

aluminum alloy.

Tray is high density polyethylene. Base is spun, polished, heavy gauge

aluminum

ELECTRICAL DATA

110V, 50/60Hz,1ph

(connected to fryer)

110V, 50/60Hz,1ph

(connected to fryer)

110V, 50/60Hz,1ph

(connected to fryer)

110V, 50/60Hz,1ph

(connected to fryer)

NSF

0.3 A 35 W

0.3 A 35 W

0.3 A 35 W

0.6 A 70 W

®

SUGARING TRAY Tray and base are spun polished, heavy gauge aluminum

ROTO-COOLER & FINISHING TREE

RACK LOADER (RL-18)

Manufactured by

Lower tray is high density polyethylene. Upper trays and base are

spun, polished, heavy gauge aluminum

Loader is all stainless steel. Glazing screens (available separately) are

nickel plated steel.

PART OF AGA FO ODSERV ICE GRO UP

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

21

Loading...

Loading...