Page 1

DONUT ROBOT®

Mark II Gas • Mark II GP Gas

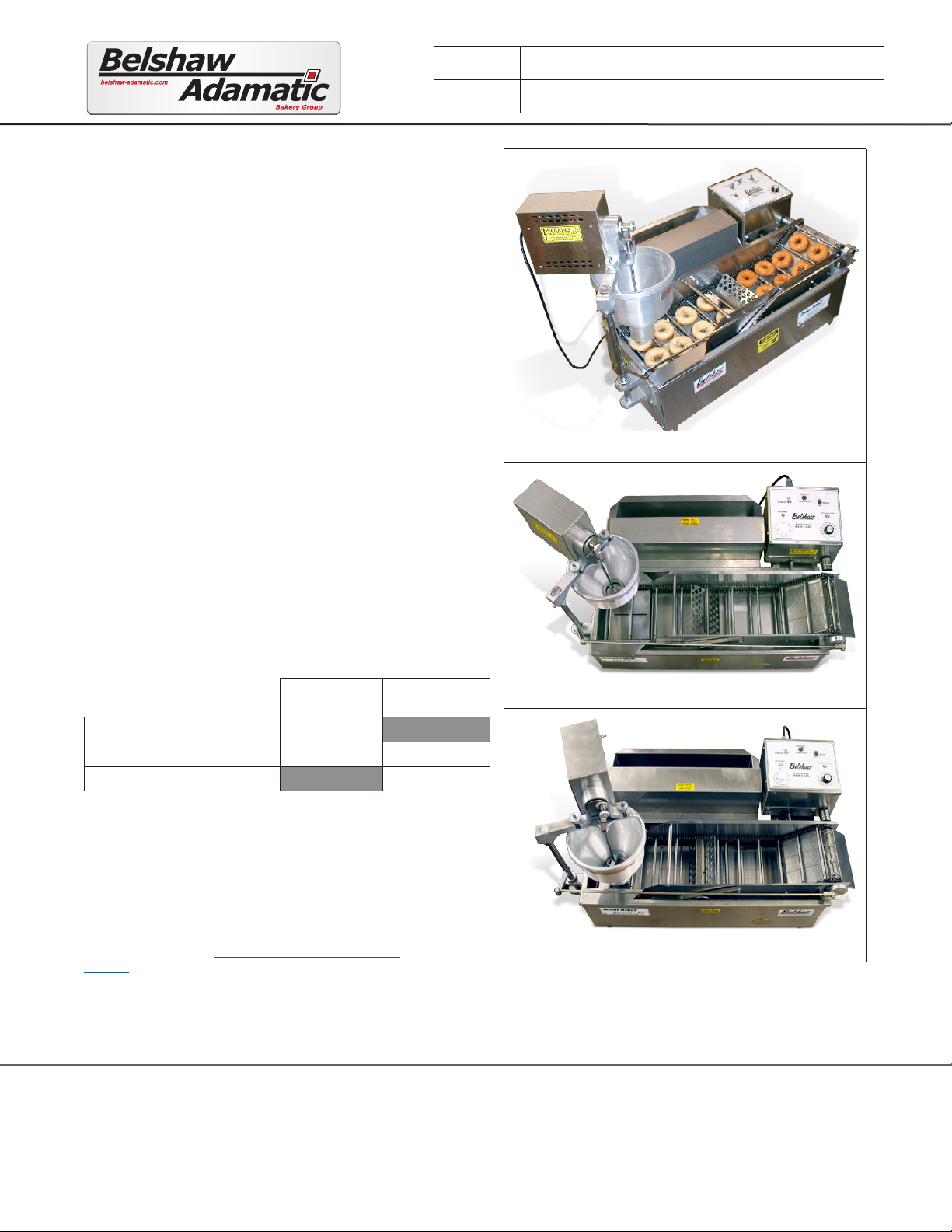

Belshaw Adamatic's Donut Robot® Mark II Gas / Mark II GP

Gas Fryers deposit, fry, turn, and dispense cake donuts

and mini donuts automatically. These fryers use the same

cake donut depositor and the same conveyor as Donut

®

electric models, and produce donuts of the same

Robot

high quality. Training and labor requirements are low, while

consistent donuts are produced time after time by a single

person. Donut Robot® fryers have been shown to reduce

oil use by up to 50% in comparison with kettle fryers. In

addition, Donut Robot® fryers are fun to watch and are sure

to attract passers by – generating foot traffic and impulse

buys.

The Donut Robot® fries each donut for the same amount

•

of time, producing donuts that are nearly identical. Donut

size is adjustable within a generous range. Frying time and

shortening temperature can also be adjusted to suit the

product.

Models are available for natural gas or propane (specify

•

when ordering)

Type DONUT ROBOT

Models Mark II Gas • Mark II GP Gas

®

Automatic Fryers

Donut Robot® Mark II Gas with Donuts

MODEL SELECTION

For standard size donuts: Donut Robot Mark II Gas

•

For mini donuts: Donut Robot Mark II GP Gas

•

For standard size donuts AND mini donuts: Donut Robot

•

Mark II Gas with Mini Donut Hopper/Plunger Kit, Item

#MK-1502-1

CAPACITY ESTIMATES

STANDARD

DONUTS

Mark II Gas

Mark II Gas (with Mini Donut Kit)

Mark II GP Gas

Estimates are based on full capacity at frying times of

•

95 seconds for standard donuts and 60 seconds for mini

donuts. Capacity may vary depending on frying time,

product size, and frying temperature.

37 Dozen/hour

37 Dozen/hour 109 Dozen/hour

YEAST-RAISED DONUTS

The Donut Robot® Mark II Gas makes excellent

•

yeast-raised donuts with the addition of accessories

including FT42 Feed Table, Proofing Trays, and Proofing

Cloths. For details see "Equipment for Mark II and Mark V

systems".

MINI

DONUTS

153 Dozen/hour

Donut Robot® Mark II Gas

Donut Robot® Mark II GP Gas

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP S.P.A.

CONTACT

800.578.2547 (USA/Canada)

(+1) 206.322.5474 Worldwide

info@belshaw.com

© 2015 Current version available at www.belshaw-adamatic.com

WEB

www.belshaw-adamatic.com

Page 1 of 2

Page 2

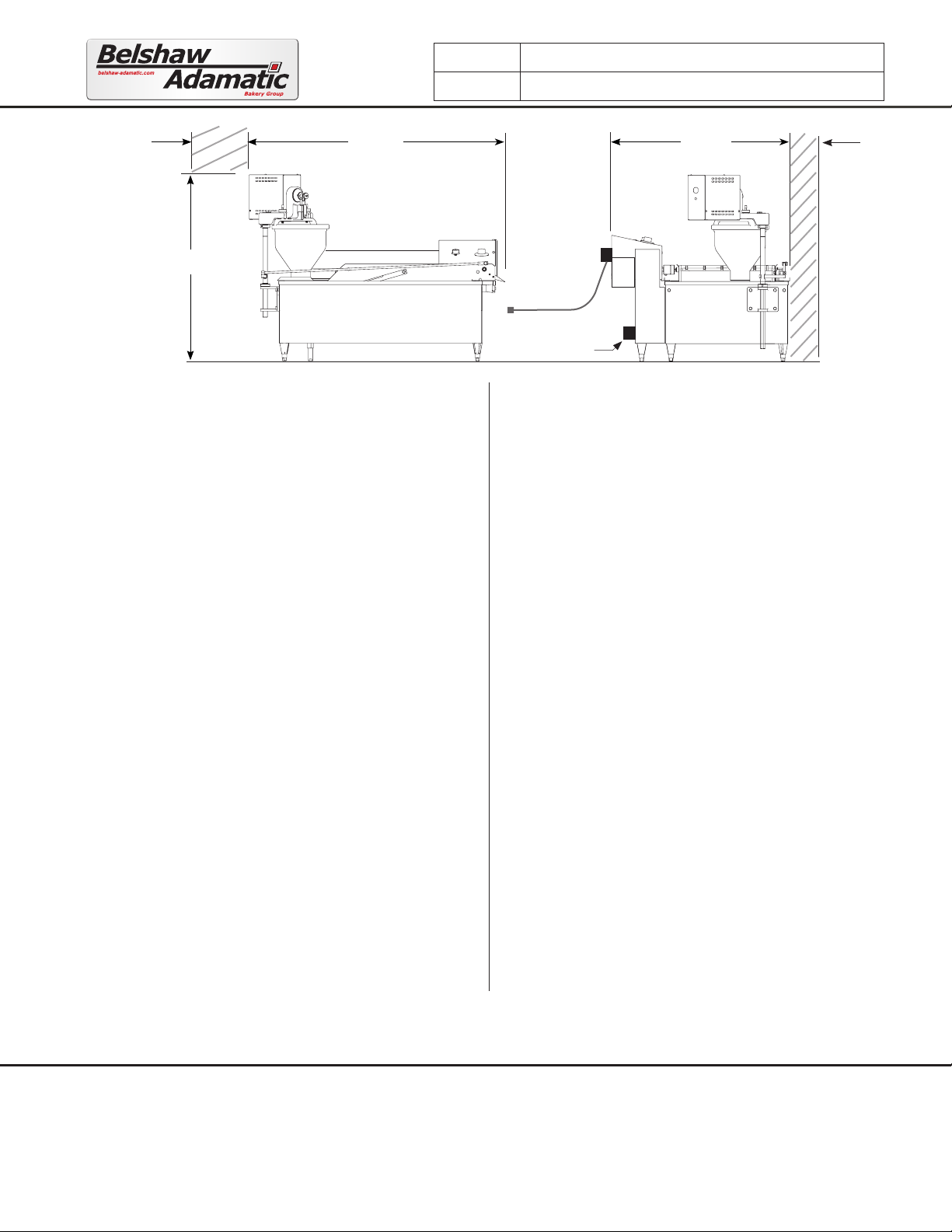

CLEARANCE:

12 INCH (30 CM)

FOR DEPOSITOR

TO SWING

OUTWARD

41” (104 cm)

Type DONUT ROBOT

®

Automatic Fryers

Models Mark II Gas • Mark II GP Gas

30” (52 cm)

CLEARANCE:

2” (5 CM) TO

CONSTRUCTION

ON ALL SIDES

30”

(76 cm)

STANDARD FEATURES

Specify when ordering: Liquid Propane OR Natural Gas

•

Automatic cake donut depositor, synchronized with fryer conveyor

•

Stainless steel materials with some aluminum components

•

On Mark II Gas, stainless steel 'Plain' donut plunger, 1-9/16" (39.7mm)

•

diameter. 'Star' plunger is optional, see below. Deposits 2 standard size

donuts per conveyor row.

On Mark II GP Gas, stainless steel double 1" (25.4mm) diameter

•

plunger. Deposits 4 mini donuts per conveyor row.

Stainless steel conveyor with flight bar system for advancing donuts

•

On Mark II Gas, the conveyor's flight bars are spaced 3¾" (95mm) from

•

center to center for standard size donuts. Flight bars are round, 3/8"

(9.5mm) diameter.

On Mark II GP Gas, the conveyor's flight bars are spaced 3" (76mm)

•

from center-to-center for mini donuts. Flight bars are 3/8" (9.5mm)

diameter.

Aluminum hopper with 10 lbs (4.5kg) batter capacity

•

Batter weight adjustment dial - allows variation from small to large

•

donuts

Automatic turning of donuts mechanically synchronized with fryer

•

Automatic dispensing of fried donuts onto collection device such as

•

Roto-Cooler

Frying time dial sets frying times from approximately 55 to 360 seconds

•

Temperature adjustment (thermostat)

•

High temperature limit switch – cuts gas and electricity at approximately

•

450°F (232°C)

Half-speed switch that reduces automatic cake donut deposits to 1

•

donut per conveyor row instead of 2. For GP models, 2 per row instead

of 4.

Not compatible with Belshaw Adamatic's 'Insider' Clean Air Ventless

•

Cabinet

No drain is included; use optional accessory Filter-Flo Siphon

•

OPTIONS

For Mark II Gas: 1-9/16" Star Plunger. Makes ring donuts with a star

•

shape around the center hole.

Mini donut conversion kit (Item#MK-1502-1). This kit includes mini

•

donut hopper and double plunger, for depositing 4 mini donuts per

conveyor row (as used on GP model). Changeover from standard to

mini donuts and back again takes less than one minute.

Natural Gas and Propane models available (specify at time of ordering)

•

POWER

CONNECTION

96" (2.43m)

½" GAS PIPE

CONNECTION

P

G

VENTILATION AND FIRE SUPPRESSION

Customer is responsible for installation of ventilation hood and/or

•

fire suppression as required by local codes.

ACCESSORIES

Filter-Flo Siphon (Item #DR42-1048). Durable large siphon with

•

heat resistant handle and cone filter, for filtering shortening.

Roto-Cooler (Item #22104). Revolving white polyethylene tray

•

for collecting donuts as they are dispensed from fryer

Shortening Reserve Tank (Item #MKV-1012) Small s/s

•

container for holding oil or shortening above the fryer, with a

valve for allowing refills to fryer

FT42 Extended Height Feed Table with trays and cloths for

•

raised donut production

Proofer, icer, glazer and donut collection rack also available

•

ELECTRICAL DATA

120 V, 50/60 Hz, 1 ph, 0.36 kW, 3 A

•

240 V, 50/60 Hz, 1 ph, 0.36 kW, 1.5 A

•

(Electrical supply is necessary to power the conveyor and

depositor)

GAS DATA

Gas connection: 1/2" NPT (Female)

•

Capacity: 40,000 BTU/hr

•

Water Column

•

- Natural Gas @ 5-13 inches W.C.

- Propane Gas @ 11-14 inches W.C.

CLEARANCE

2 inches (5 cm) between machine and all construction

•

12 inches (30 cm) at infeed for depositor to swing out

•

24 inches (61 cm) at outfeed for Roto-Cooler or other receptacle

•

FRYING AREA AND SHORTENING CAPACITY

Frying area: 32"L x 12"W x 4"D (81 x 30.5 x10 cm)

•

Volume: 6.6 gallons (25.2 liter)

•

Weight: 49.4 lbs (22.5 kg)

•

SHIPPING DATA

Shipped in 2 cartons. Freight class: 85

Fryer carton: 56"x36"x36", 185 lbs (142x91x91cm, 84 kg)

•

Depositor carton: 16"x16"x22", 25 lbs (41x41x56 cm ,11 kg)

•

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP S.P.A.

CONTACT

800.578.2547 (USA/Canada)

(+1) 206.322.5474 Worldwide

info@belshaw.com

© 2015 Current version available at www.belshaw-adamatic.com

WEB

www.belshaw-adamatic.com

Page 2 of 2

Loading...

Loading...