Page 1

belshaw-adamatic.com

Providers of quality bakery equipment for more than 80 years

1-800-578-2547 ▪ info@belshaw-adamatic.com ▪ www.belshaw-adamatic.com

‘INSIDER’

Clean-Air Cabinet and Frying System

The Insider is Belshaw’s distinctive new

donut frying system that elimates the need

for an exhaust hood. With its ability to

operate in indoors, the Insider offers unique

benets:

Customers in high trafc areas can watch

the Insider frying donuts automatically.

The operator has only to mix batter, ll

the Donut Robot® hopper and bag donuts

from the Roto-Cooler, a revolving tray

that collects the donuts automatically.

The Insider can be easily moved from one

place to another. The hood is built-in and

there is no exterior ductwork.

The Insider eliminates the purchase

and installation cost of standard hood

ventilators.

The Insider is designed to attract the

interest of passers-by. With its large

window viewing area and attractive

appearance the Insider has great

merchandising potential.

The Insider comprehensively addresses

re prevention, clean air, and sanitation

requirements. The system meets national

and local safety standards. Cabinet and

fryers are tested by ETL to UL-197, CSA

C22.2 and NSF-4 standards.

Belshaw Insider

Donut Robot® Mark V GP)

Companion Equipment for Insider

(Shown with

Components of Insider with Donut

Robot® fryer system:

Clean-Air Cabinet ▪ , on legs or casters

Donut Robot® Mark II or Mark II GP ▪

with extended drain and valve.

Roto-Cooler ▪

EZMelt 18 ▪ Melter-Filter. The EZMelt can

be placed inside the cabinet, below the

fryer. It will quickly empty, lter and rell

the shortening in the fryer

Donut Finishing Center ▪ , for buyers

wanting to produce variety donuts with

icings, sprinkles, etc

Shortening Reserve Tank ▪ for melting

and topping up fryer shortening, if EZ

Melt is not used

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2010 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Donut Robot Mark II / Mark II GP EZ Melt 18

Roto-Cooler Donut Finishing Center

Page 2

Features - Cabinet

All stainless steel, plated steel and aluminum construction, ▪

except removable lexan viewing windows.

Full clean-air recycling system, with fan-assisted grease lter, ▪

electronic lter, and odor lters.

Integrated 8-switch interlock system to ensure ventilation is ▪

active. Fryer is otherwise shut down.

5-nozzle re prevention/suppression system. Operates automati- ▪

cally using 3 sensors; also operates manually from pull station.

Legs (w/adjustable feet) or casters, according to buyer ▪

specication

Frying Equipment

Donut Robot ▪

®

Mark II for standard donuts, or Mark II GP for

mini-donuts.

Roto-Cooler for cooling and collecting donuts ▪

EZ Melt 18 oil-recycling system. ▪

Donut Finishing Center or H&I icer for icing and nishing. ▪

Shortening Reserve Tank for adding shortening, (not needed if ▪

EZMelt is used).

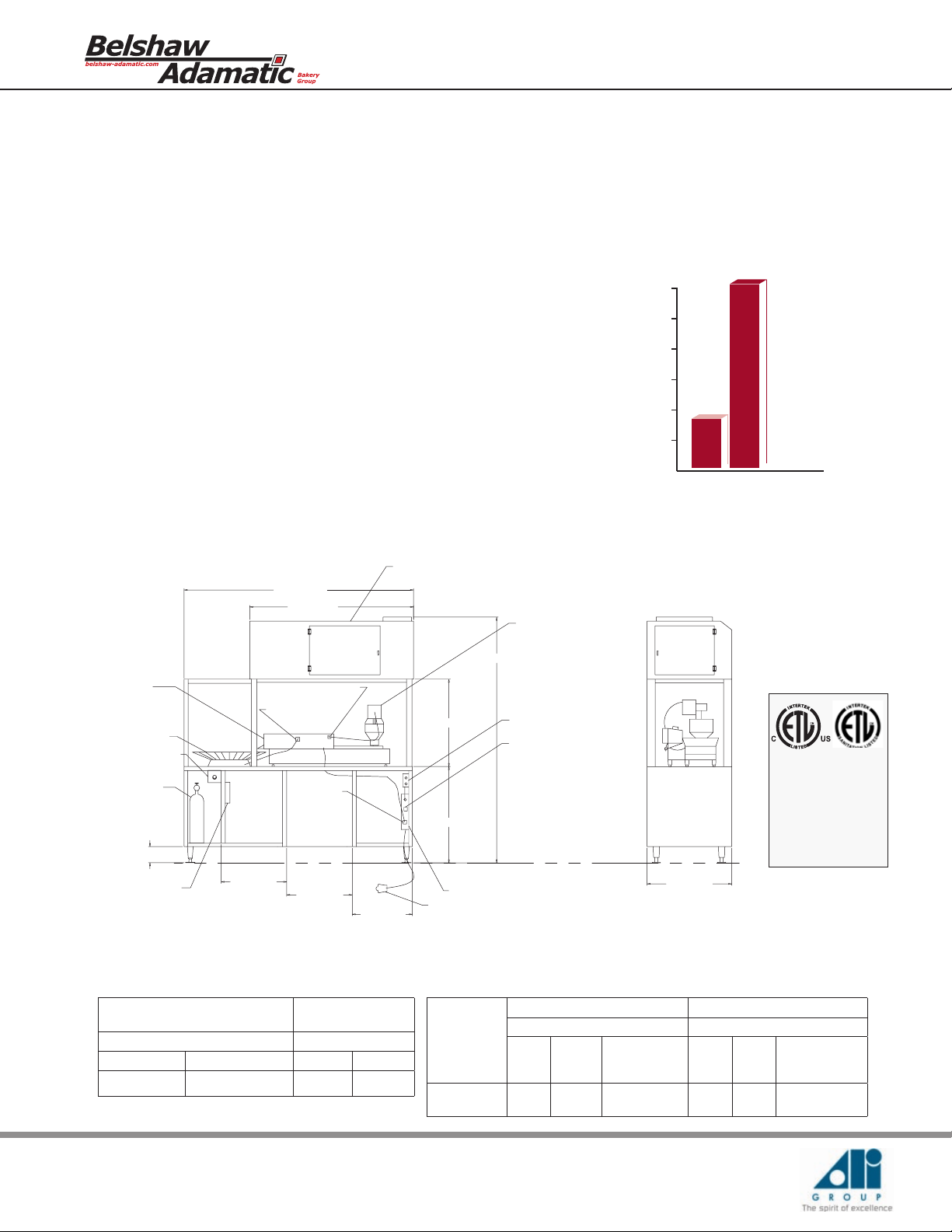

INSIDER

PRODUCTION CHART FOR

FRYER SELECTION

Based on frying times of 95 seconds for

standard donuts and 60 seconds for mini

donuts. Production will vary depending

on product size, frying temperature and

composition of donut.

DOZENS

PER HOUR

150

125

100

42

Mark II G P

153

• CHOOSE GP

MODEL FOR

MINI DONUTS

75

50

25

Mark II

Insider Assembly

84"(214 cm)

60"(133 cm)

REAR VIEW

FRYER

MKII,

ROTO COOLER

FIRE SUPPRESSION

MANUAL PULL

STATION

WET FIRE

SUPPRESSION

CYLINDE R

6"(15 cm)

SUPPRESSION

CONTROL BO X

,

FIRE

DONUT CUTTER PLU G

ROTO COOLER

24"(81 cm)

PLU G

24"(81 cm)

FRYER

PLU G

22"(56 cm)

Dimensions And Weight

OVERALL DIMENSIONS APPROX SHIPPING

Width x Depth x Height (Cabinet only)

in. cm lbs. kg

84” x 31” x 90” 214 x 78 x 229 cm 1150 522

WEIGHT

INSIDE R

HOOD/CLEAN-AIR ASSEMBLY

90"(229 cm)

32"(81 cm)

AUXILIARY RECEPTACLE

35"(89 cm)

ELECTRICAL ENCLOSURE

POWER CORD

(6 FT/1.83m)

Connector type: See Electrical Data Tabl e

Electrical Data

CABINET,

FRYER &

AUXILIARY

EQUIPMENT

Mark II

Mark II GP

1 - PHASE 60 Hz 3 - PHASE 60 Hz

(3-pole, 4-wire, neutral required) (4-pole, 5-wire, neutral required)

208 V 240 V CONNECTOR 208 V 240 V CONNECTOR

6.7 KW 8.7 KW NEMA#14-50p 5.1 KW 6.5 KW I.E.C. 309-60P

DONUT CUTTER

STOP/START SWITCH

BF

AR

CO

K N

31"(79 cm)

T

ETL certied to UL-197,

CSA C22.2 and NSF-4.

Certication applies

to Insider with Donut

Robot Mark II

(Pin &

Sleeve)

BELSHAW ADAMATIC BAKERY GROUP 206-322-5474 ▪ 800-578-2547 ▪ info@belshaw-adamatic.com

814 44th St NW, Suite 103, Auburn, WA 98001 USA • www.belshaw-adamatic.com

©2010 Belshaw Adamatic Bakery Group Specications are subject to change without notice.

Loading...

Loading...