Page 1

®

Donut Robot

Mark V

Operator’s Manual

and

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Tel: (206) 322-5474

Fax: (206) 322-5425

Toll Free (US): 1-800-578-2547

E-mail: service@belshaw.com

www.belshaw.com

Page 2

Donut Robot

Mark V

Operator’s Manual

Belshaw Bros., Inc.

814 44

Phone: (206) 322-5474 Fax: (206) 322-5425

E-mail: service@belshaw.com http://www.belshaw.com

th

Street NW, Suite 103

Auburn, WA 98001 USA

Page 3

Page 4

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

IMPORTANT

Keep this manual for reference purposes.

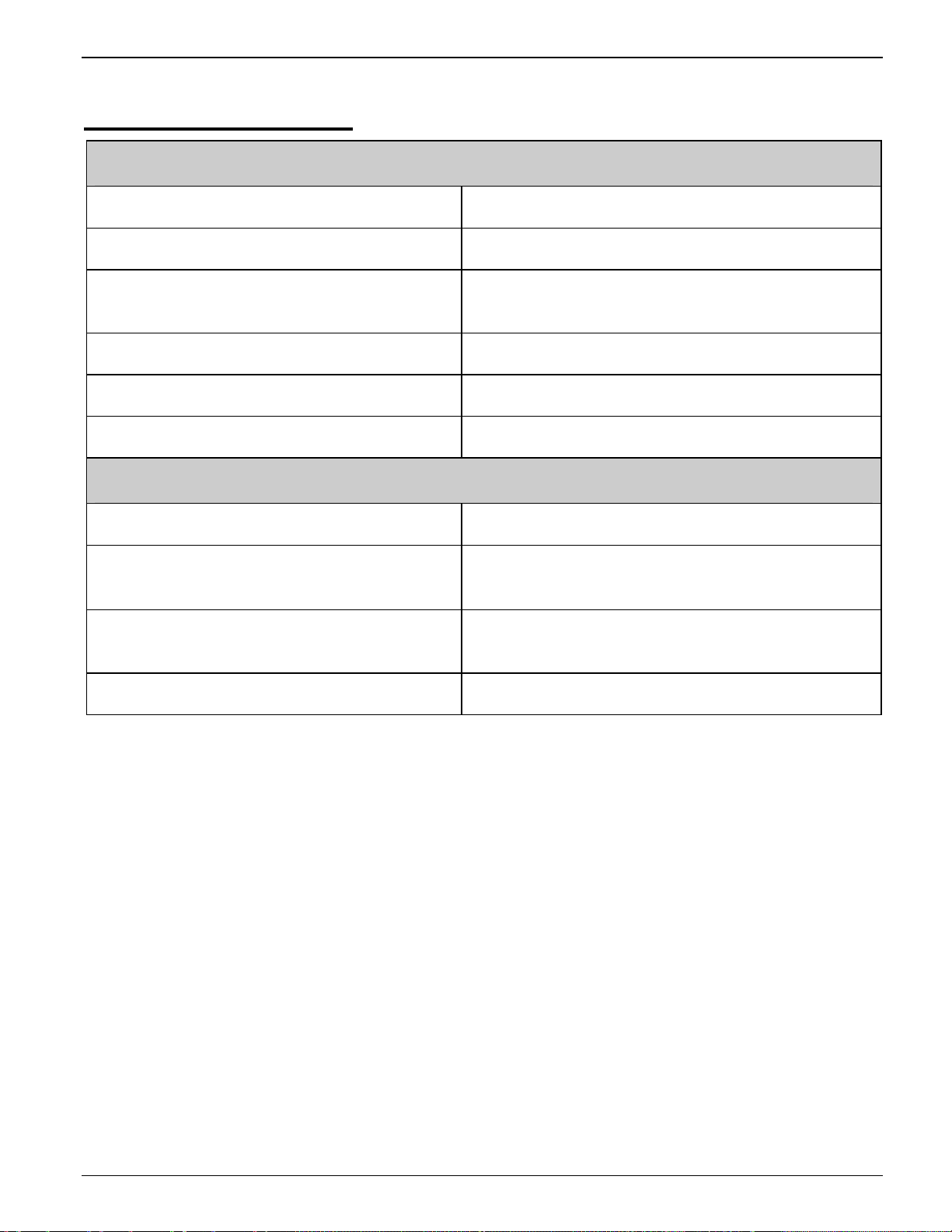

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

011708

MN-1022EN

Belshaw Bros., Inc.

814 44

th

Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

E-mail: service@belshaw.com http://www.belshaw.com

Page 5

Page 6

Contents

1 Operation 1

Making Cake Donuts 1

Making Yeast-Raised Donuts 2

2 Cleaning 5

Cleaning the Hopper and the Plunger 5

Cleaning the Conveyor and the Kettle 6

3 Maintenance 11

Lubricating 11

Taking Care of the Plunger, Hopper, and Cylinder 12

4 Related Products 13

FT-42 Feed Table 13

Roto Cooler 16

Icing Finishing Tree and Roto Cooler 17

Sugaring Tray and Roto Cooler 18

Filter Flo Siphon 19

Shortening Reserve Tank 22

5 Donut-Making Helps 23

Tips on Making Quality Cake Donuts 23

Calculating Correct Water Temperature 24

Ratios of Plunger Sizes to Donut Weights 24

Temperature Conversion 24

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN iii

Page 7

Preface

The Donut Robot Mark V is designed to

automatically cut and fry cake donut products,

and to fry yeast-raised donut products. It is not

designed to cut or fry any other products. The

Mark V uses electrical elements to heat

shortening in its kettle.

The Mark V is designed to be used on a flat,

stationary table or countertop, with the operator

standing opposite the heater head of the machine.

The operator must work safely at all times and

read this manual and follow its instructions and

warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

Donut Robot Mark V will prevent production

delays and injuries.

To use the Mark V safely, heed the following

warnings and all other warnings that appear in

this manual:

Make sure the machine is secured to the

work surface. Doing so will prevent the

machine from moving or falling, which

could cause serious injury.

Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

Do not overfill the kettle with

shortening. If shortening overflows the

kettle, it could cause serious burns or

could cause someone to slip on the floor

and be seriously injured.

Hot shortening can cause serious burns.

Make sure that the system and the

shortening are cool before attempting

any adjustment, repair, disassembly, or

cleaning.

To avoid electrocution or other injury,

unplug the machine before attempting

any adjustment, repair, disassembly, or

cleaning.

To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

Make sure that all electrical cords are

routed so that no one will trip over them.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

iv MN-1022EN Donut Robot Mark V OM

Page 8

1 Operation

For general information on donut production,

refer to Section 5, “Donut-Making Helps.”

WARNING

Read each step completely before doing what it

tells you to do.

Making Cake Donuts

1. If necessary, install the swing column,

connect the swing connecting rod, install the

cutter head, and install the hopper and the

plunger.

2. When the shortening reaches the correct

frying temperature, it should reach the

middle of the flight bars.

Shortening expands as it increases in

temperature. This means that unless the

shortening is at frying temperature when you

put it in the kettle, you should put it in

gradually. Let the shortening in the kettle

heat up before you add more.

Put shortening in the kettle using one of

these methods:

Pre-melt shortening in a pan on the stove

and carefully pour it into the kettle.

Use the optional EZ Melt to melt

shortening and transfer it to the kettle.

See your EZ Melt manual.

WARNING

Hot shortening causes severe burns.

Air spaces can cause the shortening to

overheat and catch on fire.

3. Turn the heating element to the desired

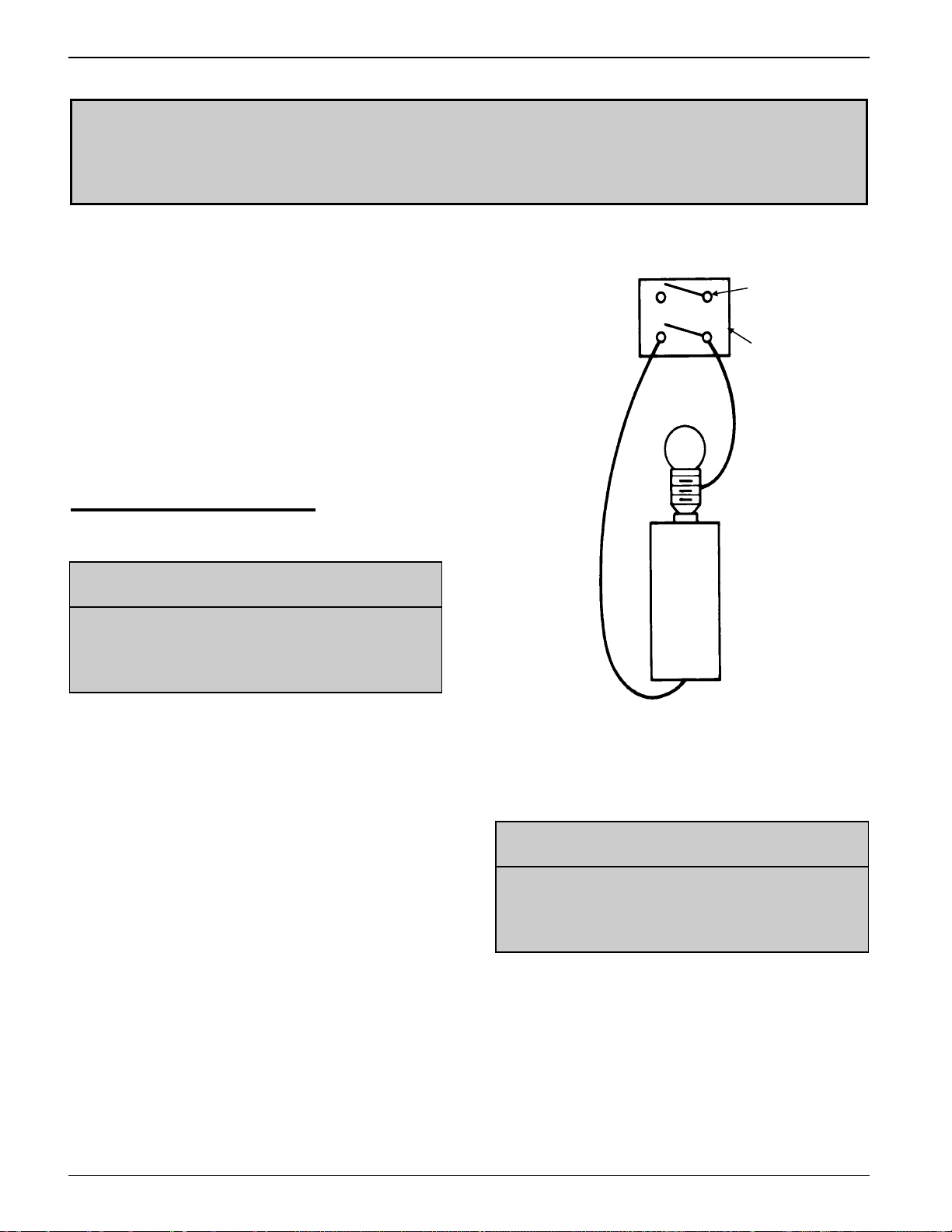

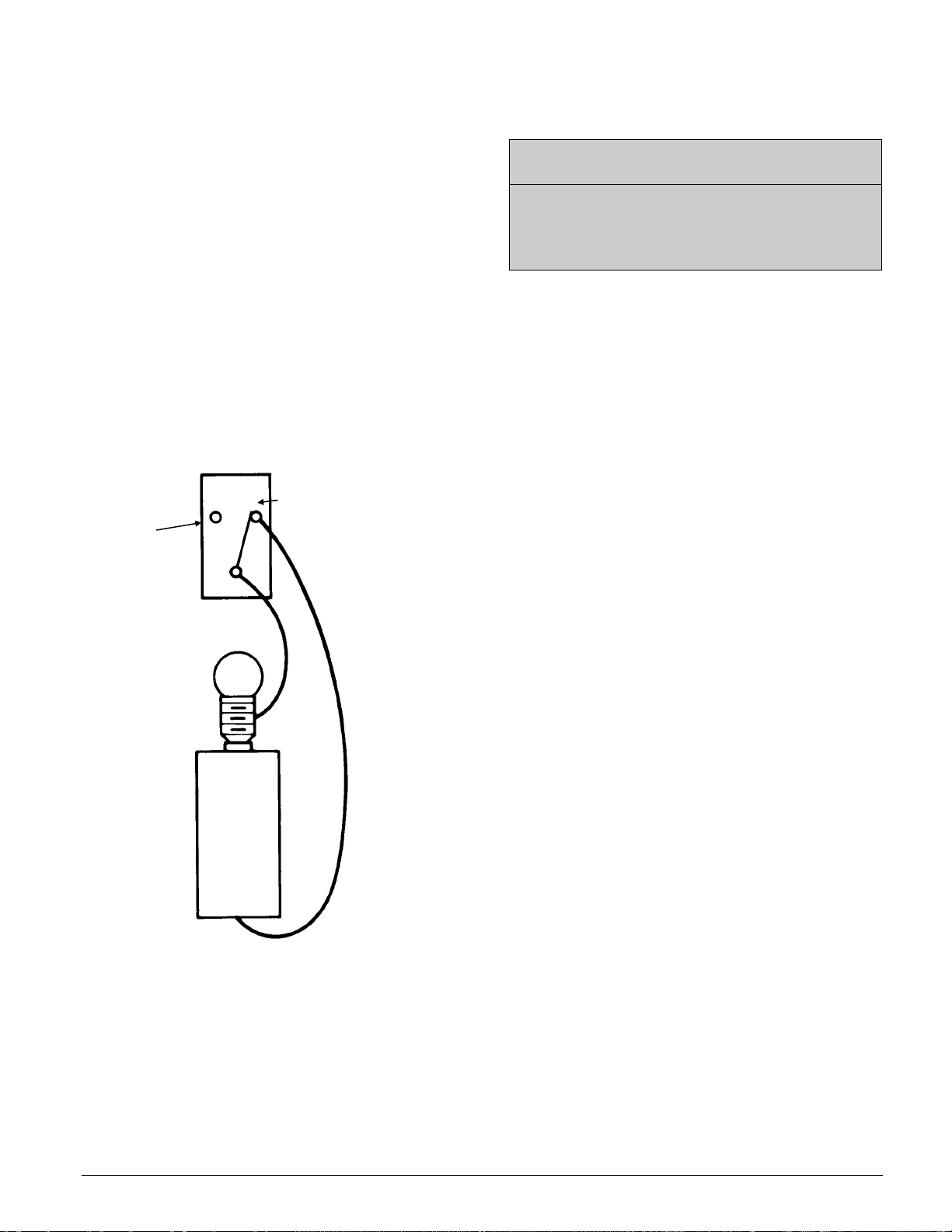

temperature. Two pilot lights will come on.

The one on top of the heater head indicates

that the heating element has been turned on

(that the thermostat is set above 200F/

93C). The one on the front of the heater

head indicates that the shortening has not yet

reached the desired temperature. This light

will go out if the high temperature limit

control breaks the circuit.

Note: If the high temperature limit control

does break the circuit, push the red reset

button on the back of the heater head.

4. Wait for the shortening to reach the desired

temperature. When it does, the pilot light on

the front of the heater head will go out. DO

NOT run the conveyor until all the

shortening has melted.

5. If you are using the optional Shortening

Reserve Tank, fill it with shortening. Then

position it on the conveyor side panels either

ahead of or behind the turner, but not above

it. The heat of the fryer will melt the

shortening in the tank.

6. Disengage the swing connecting rod from

the swing column throw arm and swing the

hopper away from over the fryer.

Put solid shortening into the kettle,

packing it tightly around the elements

and bulbs.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 1

7. Adjust the size selector dial on the cutter

head’s crankshaft assembly. This dial

regulates the donut weight. The higher the

setting, the larger the donuts will be. Adjust

the dial setting as follows:

Page 9

a. Unscrew the dial lock nut 1/2 turn.

b. Turn the dial to the desired position, as

indicated by the marks on the crank

plate.

c. Tighten the dial in place with the lock

nut. Tighten it using your fingers only.

8. Put dough into the hopper. Prime the hopper

to expel any air that may be trapped in the

bottom of it. To prime the hopper:

a. Hold a mixing bowl under the cutter.

b. Hold down the prime switch on the

cutter head and run the cutter until it has

dropped two or three donuts into the

bowl.

Note: Holding down the prime switch

causes the cutter to run continuously

without the normal delay between cuts.

c. Put the dough in the bowl back in the

hopper.

9. Return the hopper into position over the

fryer and reconnect the swing connecting

rod to the swing column throw arm.

10. Choose the appropriate fry time for your

product using the fry time control knob on

the heater head.

11. Using the switch on the heater head, select

the number of donutsone or twoyou want

to cut during each swing cycle of the hopper.

12. Turn on the cutter using the power switch on

the cutter head.

WARNING

If the conveyor becomes jammed: 1. Turn

off the conveyor drive and the heater. 2.

Allow the system to cool down. HOT

SHORTENING IS DANGEROUS.

3. Determine the cause of the jamming.

4. Clear it. 5. Restart the system.

14. Continue adding shortening to the kettle to

maintain the proper shortening level (see

step 2). There are three ways to do this:

Melt some shortening in a pan on the

stove and carefully pour it into the kettle.

If you are using the optional EZ Melt,

transfer more shortening from it. See

your EZ Melt manual.

If you are using the optional Shortening

Reserve Tank, push open the supply

valve.

15. Continue adding dough to the hopper as

needed. You can add dough to the hopper

without priming it again as long as it does

not become empty. If the hopper does

become empty, you must prime it again.

16. When you fill the hopper for the last time,

you will want to use all of the dough in the

hopper. To do so, push the dough to the

bottom of the hopper using a rubber scraper

or spatula. Be careful not to jam the scraper

in the donut cutter.

13. Turn on the conveyor drive using the power

switch on the heater head.

Note: If the conveyor becomes jammed, a

warning buzzer will sound about a minute

later and stop when the conveyor is turned

off. The conveyor drive is impedanceprotected so it will not burn out due to

jamming.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

2 MN-1022EN Donut Robot Mark V OM

To avoid injury, never put your hand in or

under the hopper while the machine is on.

Making Yeast-Raised

Donuts

1. Remove the hopper and plunger, the cutter

head, and the swing column, if they are

installed.

WARNING

Page 10

2. When the shortening reaches the correct

frying temperature, it should reach the

middle of the flight bars.

Shortening expands as it increases in

temperature. This means that unless the

shortening is at frying temperature when you

put it in the kettle, you should put it in

gradually. Let the shortening in the kettle

heat up before you add more.

Put shortening in the kettle using one of

these methods:

Pre-melt shortening in a pan on the stove

and carefully pour it into the kettle.

Use the optional EZ Melt to melt

shortening and transfer it to the kettle.

See your EZ Melt manual.

WARNING

Hot shortening causes severe burns.

Put solid shortening into the kettle,

packing it tightly around the elements

and bulbs.

WARNING

4. Wait for the shortening to reach the desired

temperature. When it does, the pilot light on

the front of the heater head will go out. DO

NOT run the conveyor until all the

shortening has melted.

5. If you are using the optional Shortening

Reserve Tank, fill it with shortening. Then

position it on the conveyor side panels either

ahead of or behind the turner, but not above

it. The heat of the fryer will melt the

shortening in the tank.

6. Install your Feed Table and load proof cloths

on it. Refer to Appendix A, “Related

Products,” for complete installation and

operation instructions for the Feed Table.

7. Choose the appropriate fry time for your

product using the fry time control knob on

the heater head.

8. Turn on the conveyor drive using the power

switch on the heater head.

Note: If the conveyor becomes jammed, a

warning buzzer will sound about a minute

later and stop when the conveyor is turned

off. The conveyor drive is impedanceprotected so it will not burn out due to

jamming.

Air spaces can cause the shortening to

overheat and catch on fire.

3. Turn the heating element to the desired

temperature. Two pilot lights will come on.

The one on top of the heater head indicates

that the heating element has been turned on

(that the thermostat is set above 200F/

93C). The one on the front of the heater

head indicates that the shortening has not yet

reached the desired temperature. This light

will go out if the high temperature limit

control breaks the circuit.

Note: If the high temperature limit control

does break the circuit, push the red reset

button on the back of the heater head.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 3

If the conveyor becomes jammed: 1. Turn

off the conveyor drive and the heater. 2.

Allow the system to cool down. HOT

SHORTENING IS DANGEROUS.

3. Determine the cause of the jamming.

4. Clear it. 5. Restart the system.

9. Continue adding shortening to the kettle to

maintain the proper shortening level (see

step 2). There are three ways to do this:

Melt some shortening in a pan on the

stove and carefully pour it into the kettle.

WARNING

Page 11

If you are using the optional EZ Melt,

transfer more shortening from it. See

your EZ Melt manual.

If you are using the optional Shortening

Reserve Tank, push open the supply

valve.

10. Continue loading proof cloths onto the Feed

Table as needed.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

4 MN-1022EN Donut Robot Mark V OM

Page 12

2 Cleaning

WARNING

Thoroughly clean and dry the floor if

shortening, water, or other materials are

spilled. Materials spilled on the floor can

cause serious injury or loss of life.

WARNING

To avoid electrocuting yourself or

damaging the machine, never allow water,

steam, shortening, cleaning solution, or any

other liquid to enter the heater head or

cutter head assemblies.

Cleaning the Hopper and

the Plunger

You must clean the hopper and the plunger daily,

or after each use. Follow these general

guidelines:

Use household dishwashing detergent.

Do not use strong alkali cleaners such as

lye, soda ash, or trisodium phosphate, as

these discolor and corrode aluminum.

Wash, dry, and lubricate parts

thoroughly to prevent rusting.

When washing parts by hand, wash each

part separately; do not put any other

utensil or dish in the sink with the part

being washed.

To clean the hopper and the plunger:

1. Unplug the cutter head power cord.

2. Remove the plunger and the hopper. To do

so, reverse the procedures found in steps 2

and 3 of “Assembling the Cutter” in Section

1 of the Technical Supplement.

3. Pre-soak the parts, if necessary, to loosen

stubborn or dried-on deposits.

4. Wash the hopper and the plunger separately

in hot water and a detergent recommended

for aluminum. Use a non-scratching plastic

scouring cloth to remove soil and restore

luster.

5. Rinse the hopper and the plunger separately

in clear, hot water (170-190F/77-88C).

6. Dry each part completely.

7. Dip the plunger and the hopper cylinder in

mineral oil or liquid shortening to prevent

rust and sticking.

8. Wipe the cutter head assembly with a soft

cloth dampened with hot water and an

appropriate cleaner. Wipe it with another

damp cloth to remove the cleaner. Wipe it

dry.

CAUTION

To avoid electrocuting yourself or

damaging the machine, never immerse the

cutter head.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 5

Page 13

Cleaning the Conveyor and

the Kettle

There are four basic steps to cleaning the

conveyor and the fryer kettle: removing the

shortening, washing, rinsing, and drying. You

must perform all four steps and perform them in

the order listed.

Removing the Shortening

WARNING

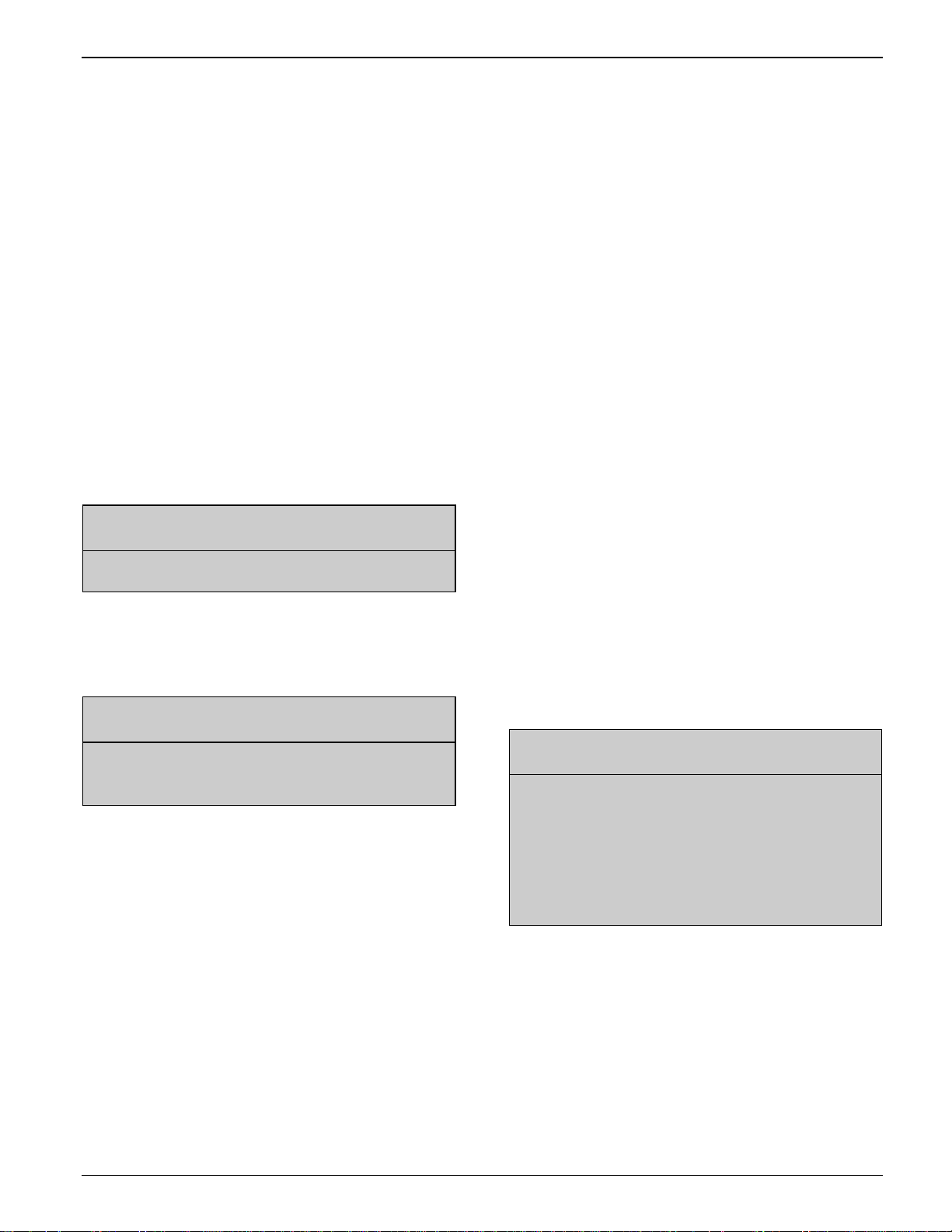

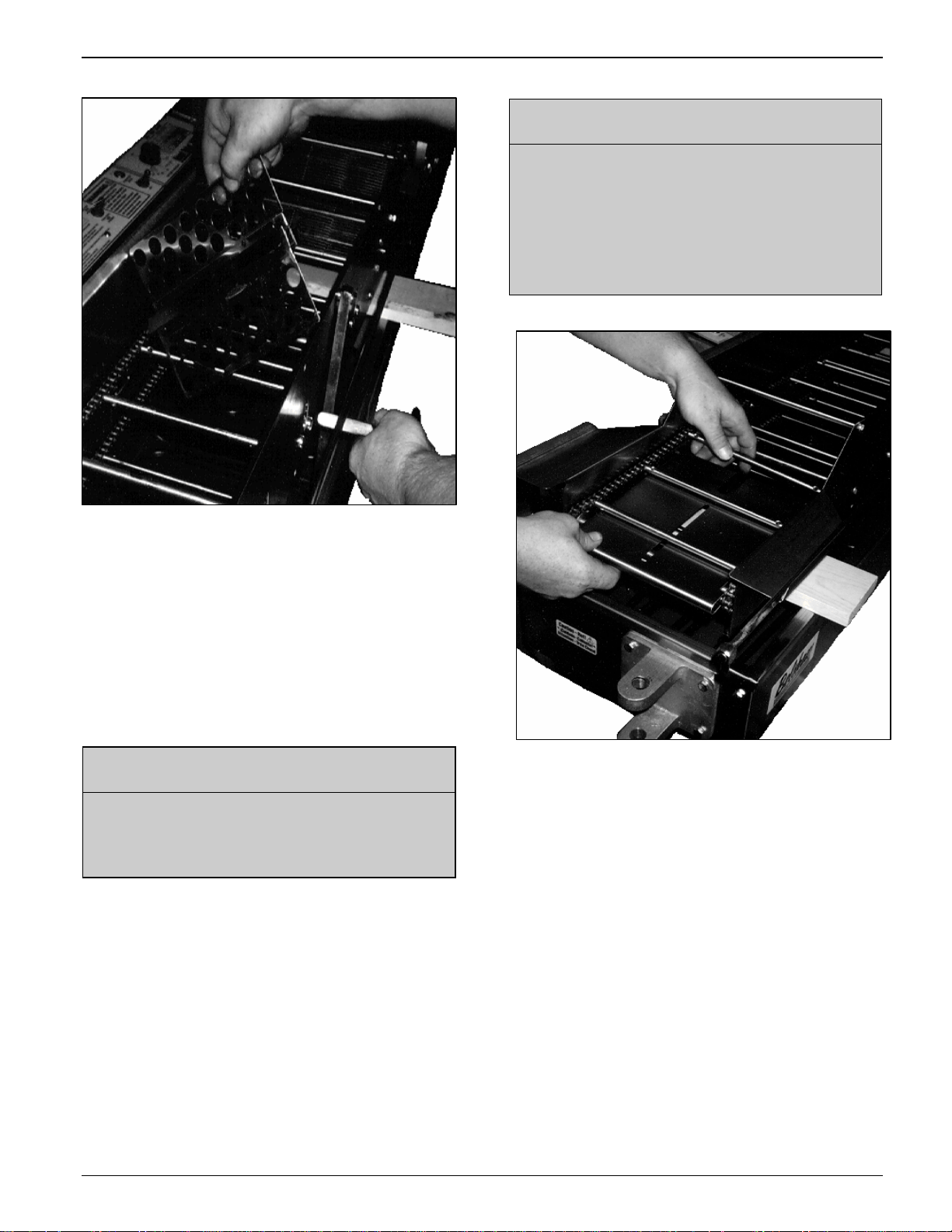

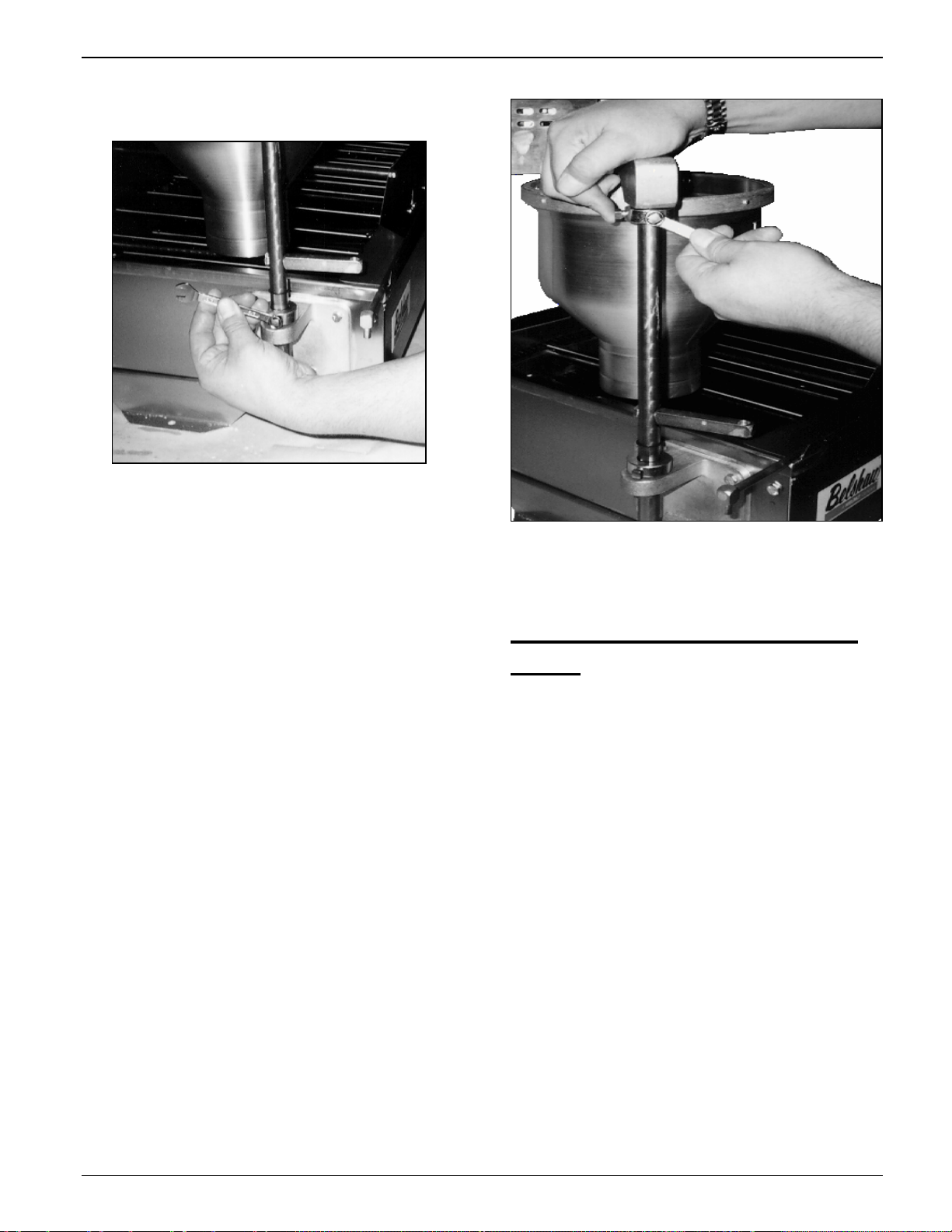

Figure 2-1. Draining the Shortening off of

the Conveyor.

6. If you want to clean the turner assembly,

remove and clean it as follows:

To avoid being burned, electrocuted, or

otherwise injured, unplug the machine

before cleaning the fryer.

1. Disconnect the machine from the power

source.

2. Let the shortening cool to 100F/38C.

3. Unplug the cutter head power cord.

4. Lift the cutter head off the swing column.

5. Remove the conveyor assembly as follows:

a. Obtain two pieces of wood, at least 1” x

1” x 15” (2.5 cm x 2.5 cm x 38 cm).

b. Lift off the swing connecting rod.

c. Lift the conveyor assembly from the

conveyor locating pin and pull it away

from the heater head to disengage the

main drive shaft coupling from the

conveyor drive coupling.

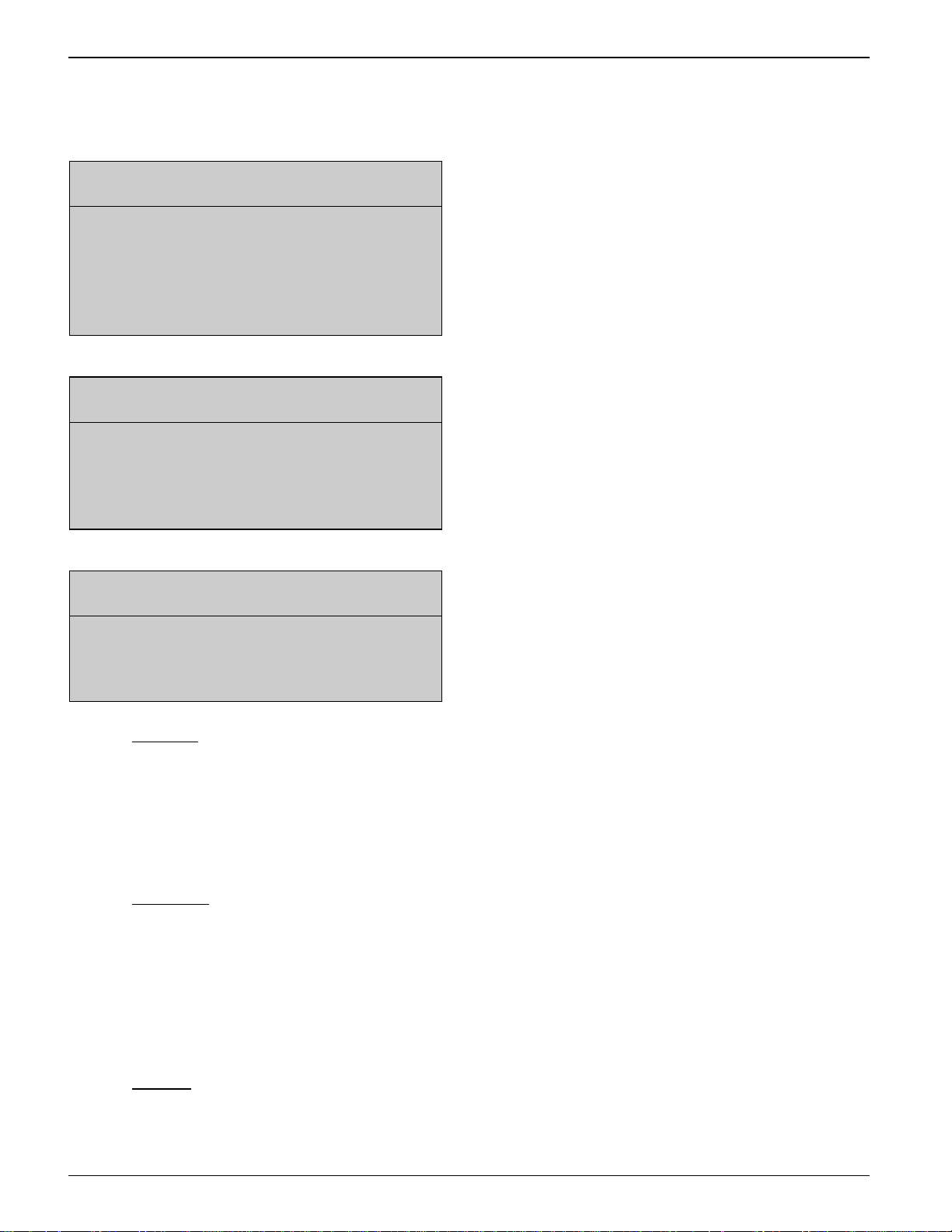

a. Move the flight bars of the conveyor

until the turner is in the middle of a

flight pocket.

b. Swing the turner cam weight up out of

position.

c. Lift up and pull out on the turner cam

assembly. See Figure 2-2.

d. Lift the outfeed end of the conveyor.

Slide one piece of wood under the

conveyor and lay it across the top of the

kettle. Lift the other end of the conveyor

and do the same thing with the other

piece of wood. The conveyor will now

be resting on the two pieces of wood.

Let the shortening drain off of the

conveyor and into the kettle. See Figure

2-1.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

6 MN-1022EN Donut Robot Mark V OM

Figure 2-2. Removing the Turner Cam

Assembly.

d. Lift out the turner assembly. See Figure

2-3.

Page 14

CAUTION

If the drop plate is scratched, donuts will

stick to it. To prevent this from happening,

always wipe the drop plate in the direction

of the grain in the metal, which runs

parallel to the length of the conveyor, and

never use abrasive cleaners.

Figure 2-3. Removing the Turner Assembly.

e. Wash the turner cam assembly and the

turner assembly using mild detergent and

warm water.

f. Rinse the turner cam assembly and

turner assembly in clear water.

g. Dry these parts thoroughly.

WARNING

All parts must be dried thoroughly.

Moisture causes hot shortening to spatter,

which may cause serious injury.

7. If you want to clean the drop plate, remove

it by lifting its forward end and sliding it

toward the rear of the conveyor. (See Figure

2-4.) Wipe the drop plate with a damp cloth.

Figure 2-4. Removing the Drop Plate.

8. After the shortening has drained off of the

conveyor assembly, set the conveyor

assembly aside.

9. Check again to see that the shortening in the

kettle has cooled to 100F/38C.

10. Remove the shortening from the kettle. You

may drain it out (if your kettle has the

optional drain), siphon it out, or pour it out.

You may transfer the shortening to a

Belshaw EZ Melt or to one or more large

metal buckets. If you use buckets, and you

want to re-use the shortening, either place a

filter over each bucket, or be careful not to

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 7

Page 15

disturb the sediment that has accumulated on

the bottom of the kettle.

WARNING

Do not use plastic buckets. If the

shortening is not cool enough, the buckets

will melt; possibly causing you to be

burned, and causing shortening to get on

the floor.

WARNING

Do not allow the shortening to overflow the

buckets. Shortening will get on the floor,

and if the shortening is not cool enough,

you may be burned.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Shortening on the

floor can cause serious injury or loss of life.

raising the heating element out of the

kettle. Use a small saucepan or a metal

to pitcher to scoop as much shortening as

you can into an EZ Melt or one or more

metal buckets. Then lift the kettle out of

the fryer case and carefully pour the

remaining shortening into an EZ Melt or

a large metal bucket.

11. Return the kettle to the fryer case, if you

have removed it, and tilt the heater head

assembly down.

12. Brush off any carbon that has accumulated

on the heating element. Accumulated

carbon can cause corrosion and ineffective

heating.

13. Tilt the heater head assembly back, raising

the heating element out of the kettle.

14. Dispose of the carbon and other sediment

using one of these methods:

If your kettle has the optional drain, put a

bucket under the drain, and scrape the

carbon and other sediment through the drain,

using a non-abrasive, non-metallic spatula.

If your kettle does not have the optional

drain, do the following:

Draining

Put an EZ Melt or a metal bucket under

the drain. Slowly open the drain valve.

If you are using a bucket and the bucket

becomes full, close the drain valve, put

another bucket under the drain, and

resume draining.

Siphoning

Put an EZ Melt or a metal bucket under a

Belshaw Filter Flo Siphon. (Refer to the

Filter Flo Siphon instructions in

Appendix A.) If you are using a bucket

and the bucket becomes full, stop the

siphon, put another bucket under the

siphon, and resume siphoning.

Pouring

Tilt the heater head assembly back,

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

8 MN-1022EN Donut Robot Mark V OM

a. Lift the kettle out of the fryer case.

b. Use a non-abrasive, non-metallic spatula

to scrape the carbon and other sediment

out of the kettle.

c. Dry the outside of the kettle.

d. Put the kettle back in the fryer case.

15. Tilt the heater head assembly down.

16. Put the drop plate, turner cam assembly, and

turner assembly back on the conveyor

assembly.

17. Install the conveyor assembly.

18. If your kettle has the optional drain, close

the drain valve.

Page 16

Washing

1. Pour hot water into the kettle, up to the

normal level of the shortening. Add about

2 oz/59 ml of trisodium phosphate or other

appropriate cleaner.

2. Connect the machine to the power source.

Heat the solution to 200F/93C. Turn on

the conveyor. Keep the solution at this

temperature for 15-20 minutes.

3. Turn off the conveyor and scrub the soiled

parts while the solution is under heat. Do

not use any abrasive cleaners or scrapers.

4. Turn off the heater and disconnect the

machine from the power source. Allow the

cleaning solution to cool to 100F/38C.

5. Remove the conveyor and tilt the heater

head back as you did before.

6. Remove the cleaning solution from the

kettle, transfering it to one or more large

metal buckets. You may drain it out (if your

kettle has the optional drain), siphon it out,

or pour it out.

WARNING

Do not use plastic buckets. If the cleaning

solution is not cool enough, the buckets will

melt; possibly causing you to be burned,

and causing cleaning solution to get on the

floor.

WARNING

Thoroughly clean and dry the floor if

cleaning solution is spilled. Liquid on the

floor can cause serious injury or loss of life.

Draining

Put a large metal bucket under the drain.

Slowly open the drain valve. If the

bucket becomes full, close the drain

valve, put another bucket under the

drain, and resume draining.

Siphoning

Put a large metal bucket under a

Belshaw Filter Flo Siphon. Remove the

filter from the siphon. (Refer to the

Filter Flo Siphon instructions in

Appendix A.) If the bucket becomes

full, stop the siphon, put another bucket

under the siphon, and resume siphoning.

Pouring

Tilt the heater head assembly back,

raising the heating element out of the

kettle. Use a small saucepan or a metal

to pitcher to scoop as much cleaning

solution as you can into one or more

metal buckets. Then lift the kettle out of

the fryer case and carefully pour the

remaining solution into a large metal

bucket.

Carefully carry the buckets to the sink and

WARNING

Do not allow the cleaning solution to

overflow the buckets. Cleaning solution

will get on the floor, and if the solution is

not cool enough, you may be burned.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 9

slowly pour the solution into the sink.

7. Lift the kettle out of the fryer case, if you

have not done so already.

8. Rinse the kettle thoroughly and dry it on the

outside.

9. Install the kettle, tilt the heater head

assembly down, and install the conveyor

assembly as before.

10. If your kettle has the optional drain, close

the drain valve.

Page 17

Rinsing

1. Pour clean water into the kettle, up to the

normal level of the shortening.

2. Connect the machine to the power source.

Heat the water to 200F/93C.

3. Run the conveyor for 5-10 minutes.

4. Turn off the heater and disconnect the

machine from the power source. Allow the

water to cool to 100F/38C.

5. Lift the conveyor assembly out of the fryer

case. Tilt the heater head assembly back.

6. Remove the water from the kettle,

transfering it to one or more large metal

buckets. You may drain it out (if your kettle

has the optional drain), siphon it out, or pour

it out.

WARNING

Slowly open the drain valve. If the

bucket becomes full, close the drain

valve, put another bucket under the

drain, and resume draining.

Siphoning

Put a large metal bucket under a

Belshaw Filter Flo Siphon. Remove the

filter from the siphon. (Refer to the

Filter Flo Siphon instructions in

Appendix A.) If the bucket becomes

full, stop the siphon, put another bucket

under the siphon, and resume siphoning.

Pouring

Tilt the heater head assembly back,

raising the heating element out of the

kettle. Use a small saucepan or a metal

to pitcher to scoop as much water as you

can into one or more metal buckets.

Then lift the kettle out of the fryer case

and carefully pour the remaining water

into a large metal bucket.

Do not use plastic buckets. If the water is

not cool enough, the buckets will melt;

possibly causing you to be burned, and

causing water to get on the floor.

WARNING

Do not allow the water to overflow the

buckets. Water will get on the floor, and if

the water is not cool enough, you may be

burned.

WARNING

Thoroughly clean and dry the floor if water

is spilled. Liquid on the floor can cause

serious injury or loss of life.

Carefully carry the buckets to the sink and

slowly pour the water into the sink.

Drying

1. Thoroughly dry all parts, including the

conveyor, the heating element(s), and the

inside of the kettle.

WARNING

All parts must be dried thoroughly.

Moisture causes hot shortening to spatter,

which may cause serious injury.

2. Assemble the Donut Robot as before.

3. If your kettle has the optional drain, close

the drain valve.

Draining

Put a large metal bucket under the drain.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

10 MN-1022EN Donut Robot Mark V OM

Page 18

3 Maintenance

WARNING

To avoid being burned, electrocuted, or

otherwise injured, always unplug the

machine and allow it to cool before

performing any maintenance.

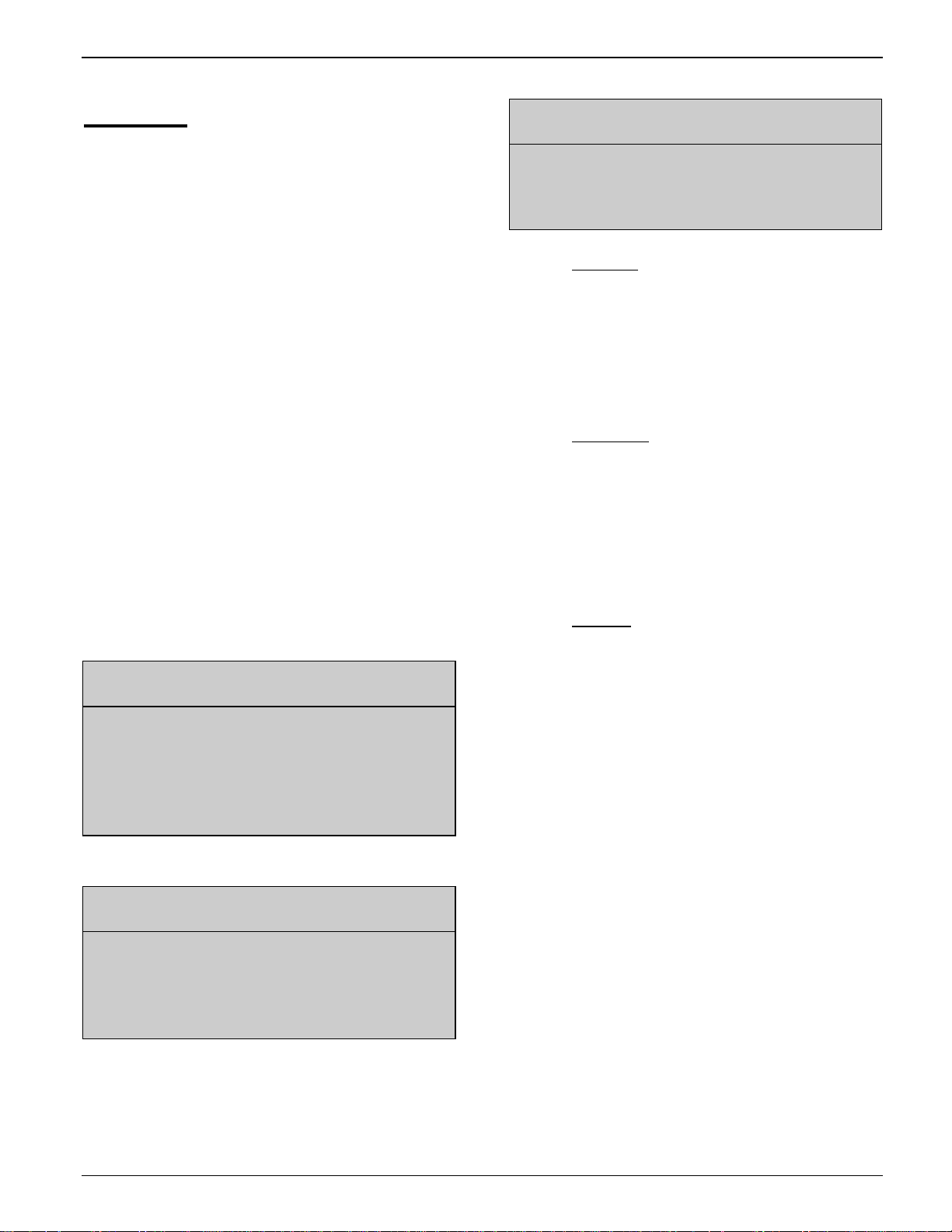

Lubricating

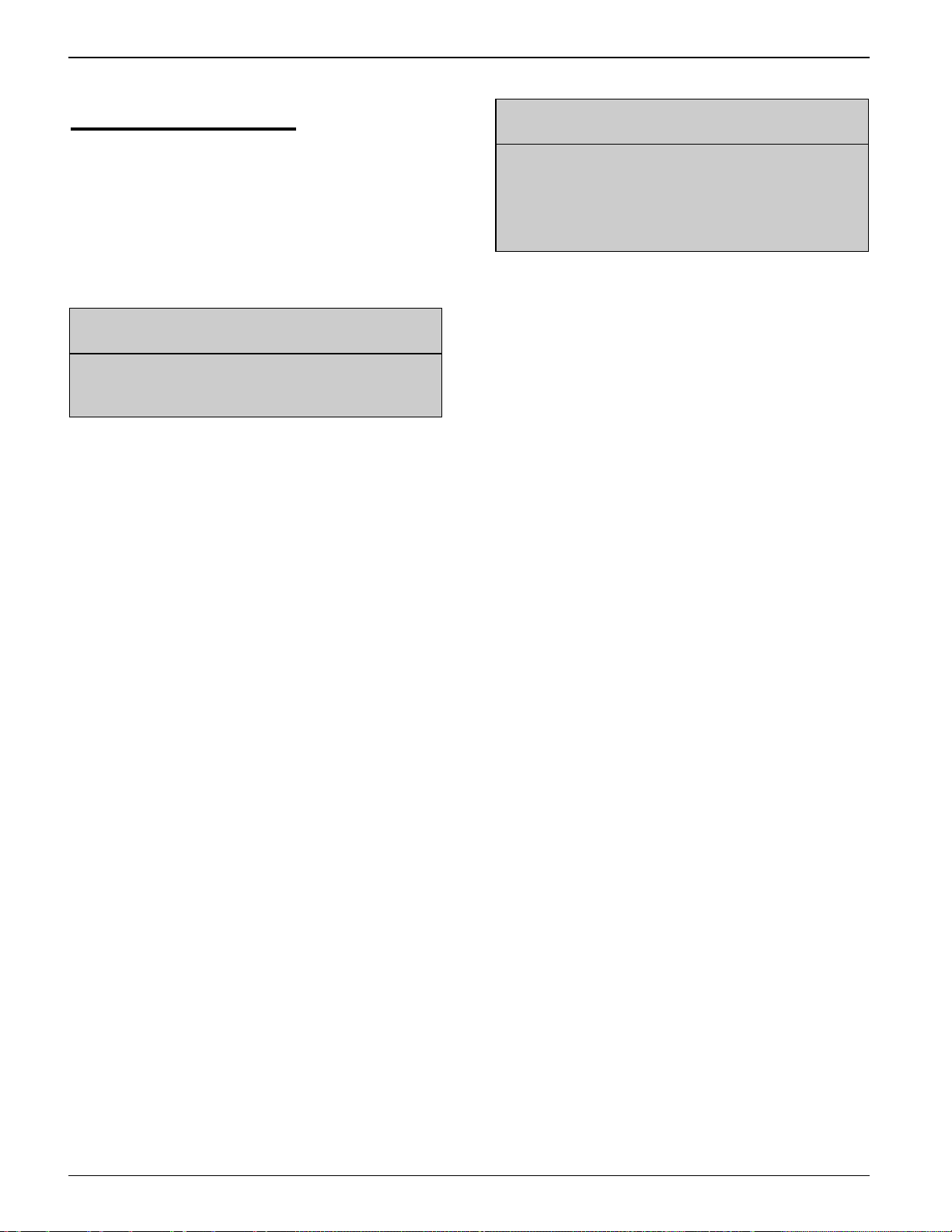

Daily

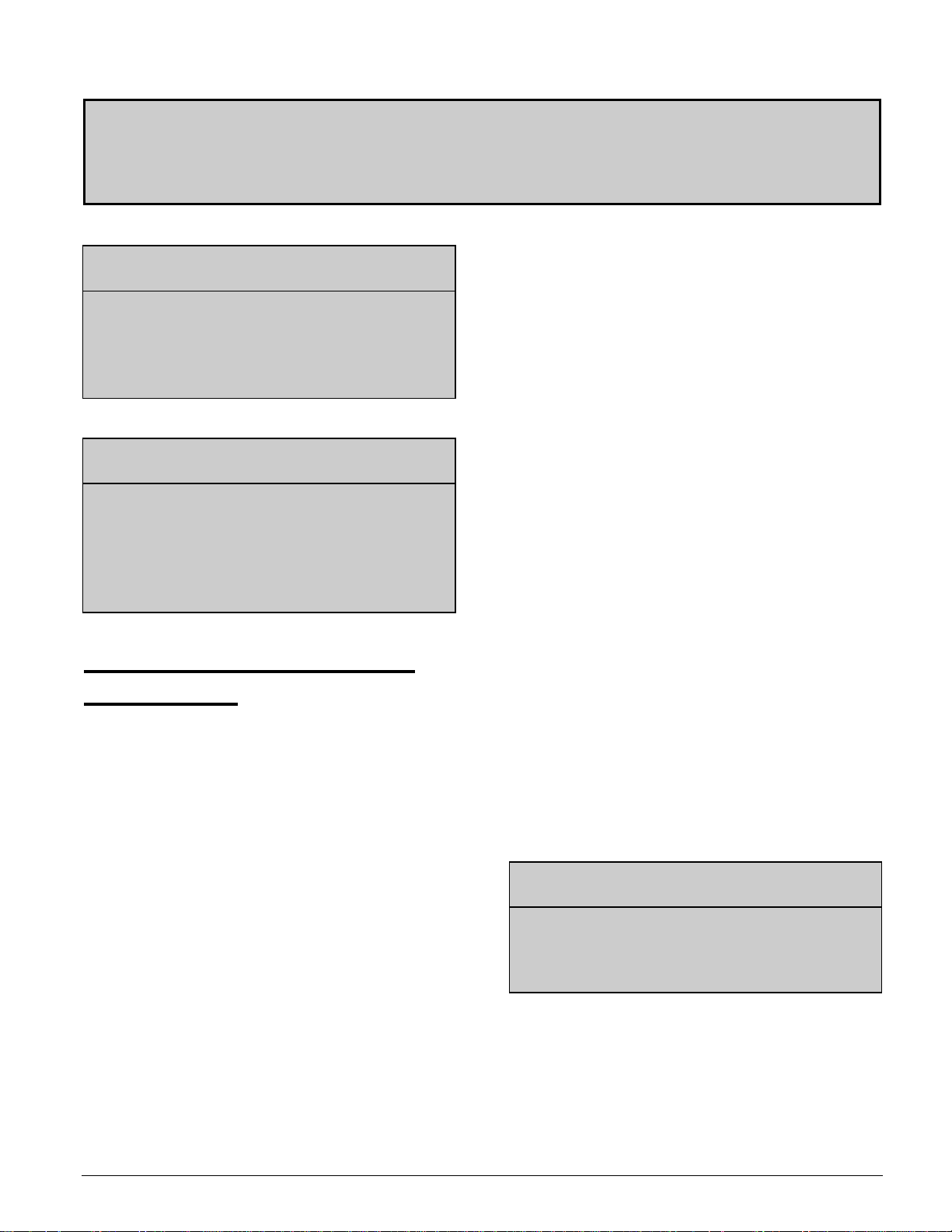

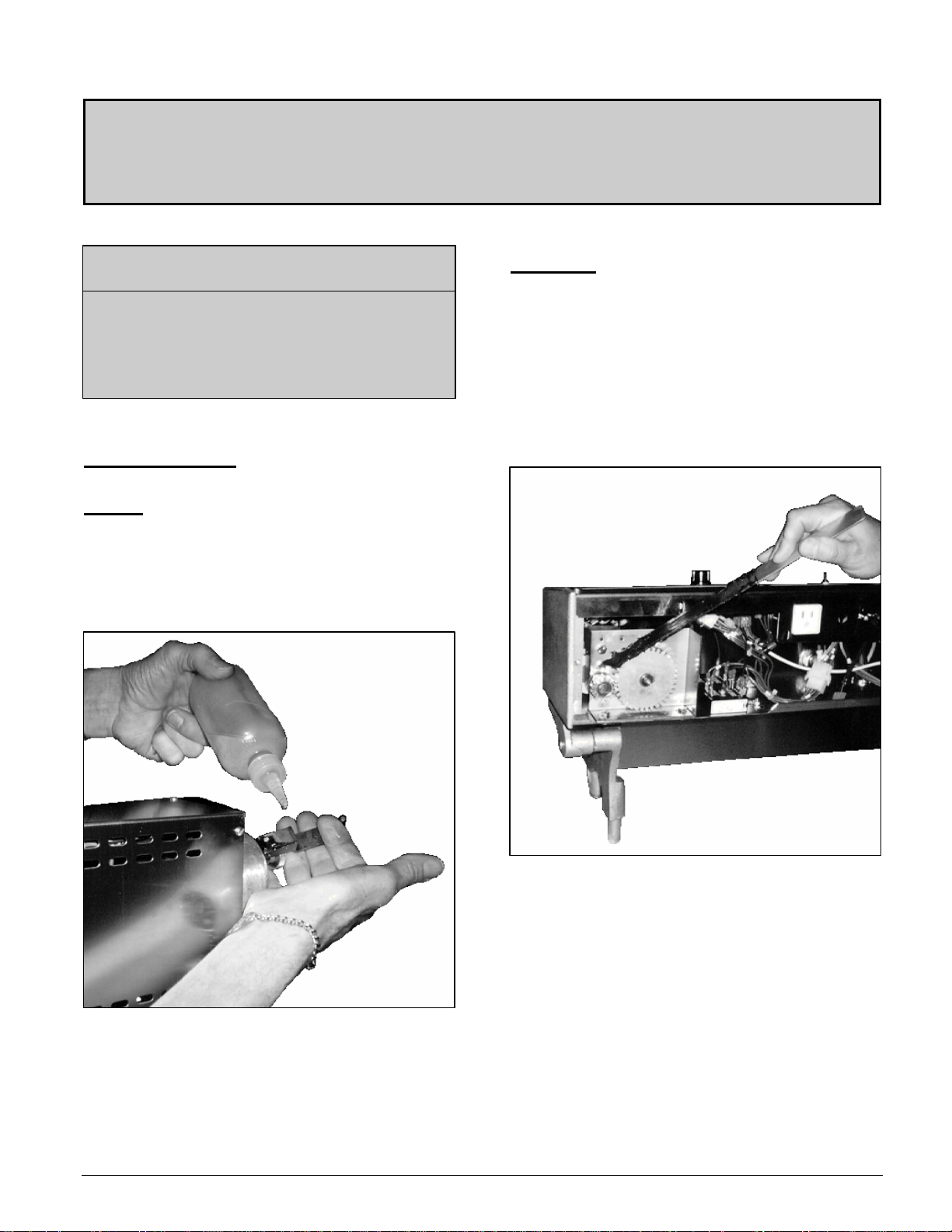

Before using the machine each day, apply ediblegrade mineral oil to the plunger connecting rod.

The oil should penetrate the ball lock and the

spring socket. See Figure 3-1.

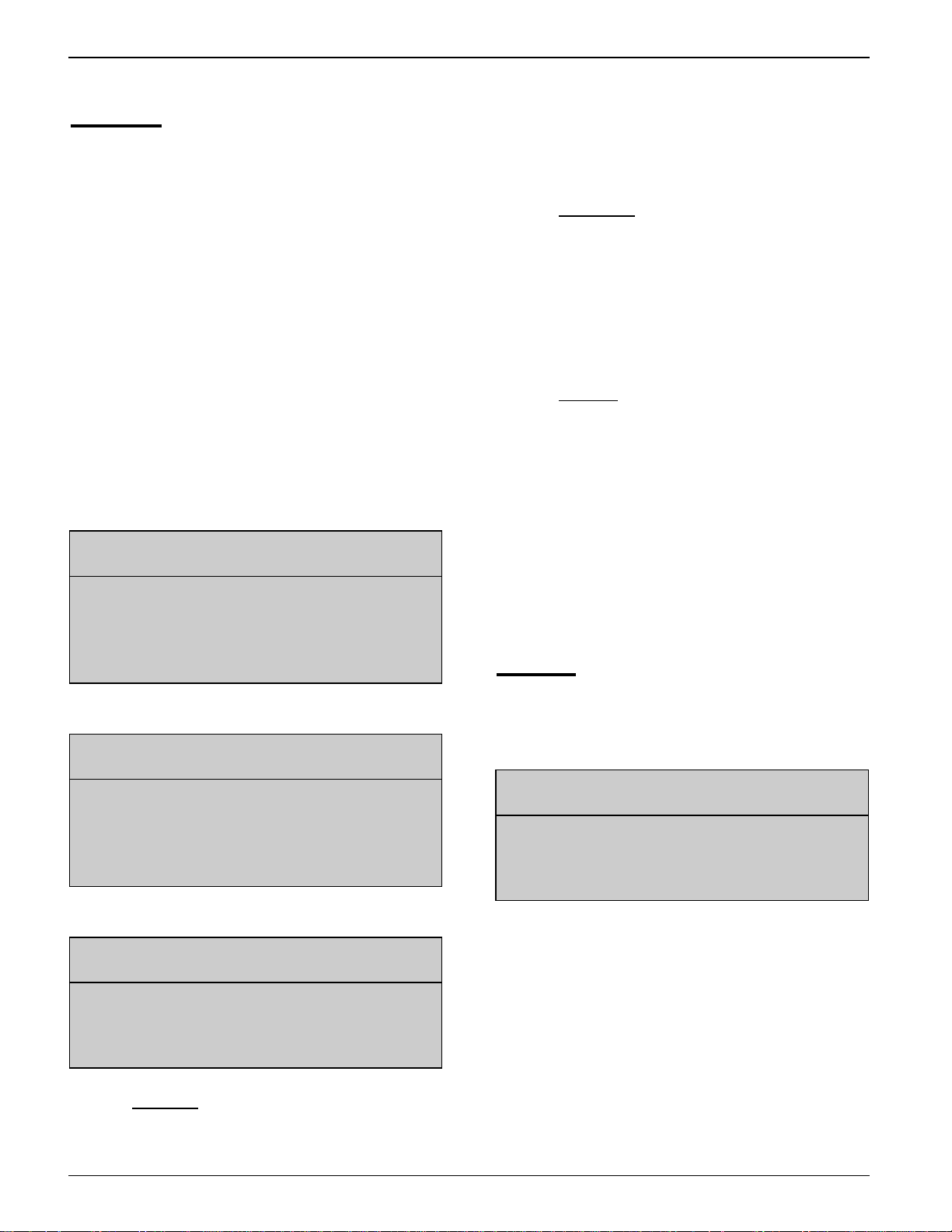

Weekly

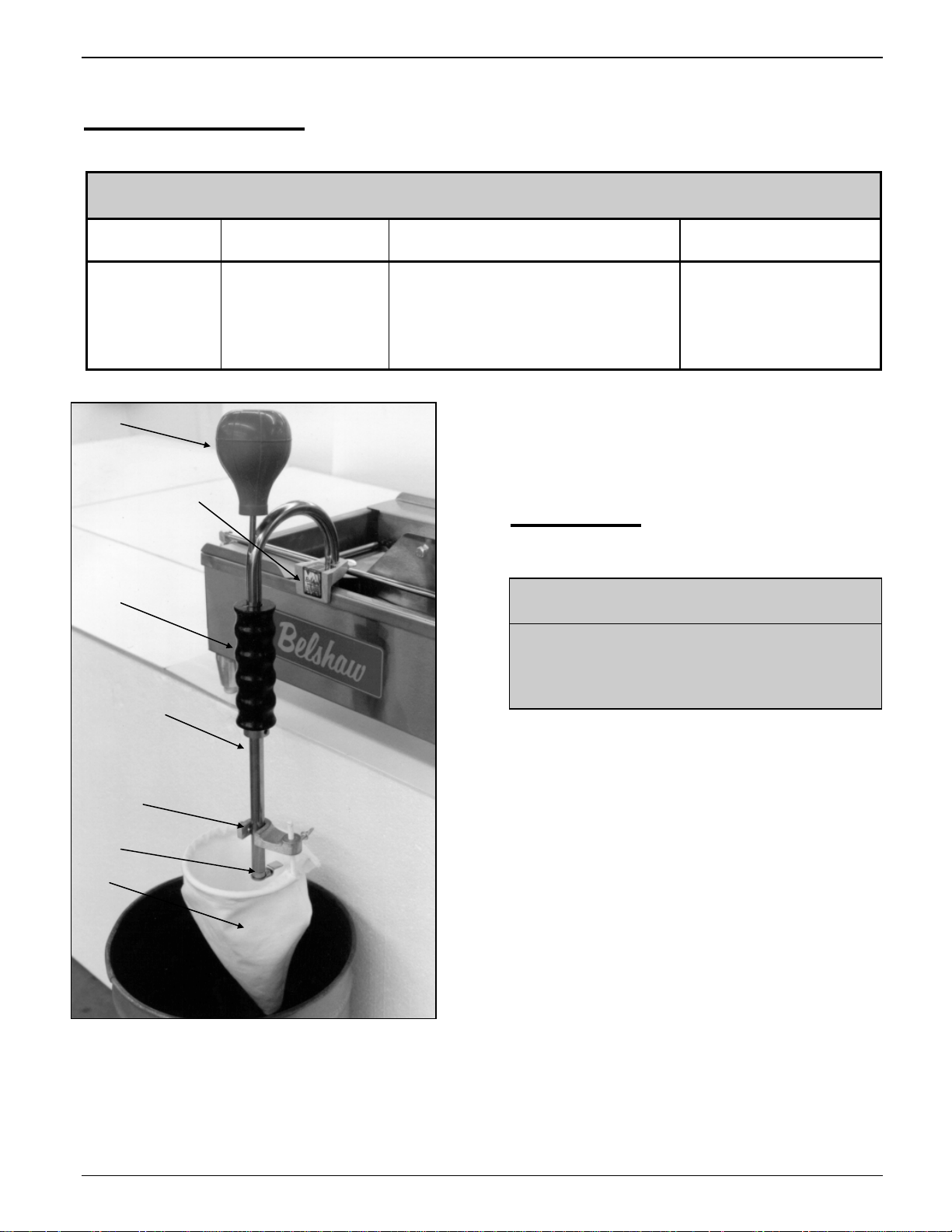

Apply a few drops of SAE 30 machine

oil to the swing column where it contacts

the swing column bracket.

Remove the heater head cover and

lightly coat the gear teeth with

multipurpose grease. Replace the cover.

See Figure 3-2.

Figure 3-2. Lubricating the Drive Gears.

Figure 3-1. Lubricating the Connecting Rod

Assembly.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 11

Page 19

Yearly

Lubricate the conveyor drive motor as explained

below. To help you better understand where to

lubricate, refer to Figure D-3 in Appendix D,

“Parts Lists.”

1. Disconnect the machine from the power

source.

2. Remove the back cover of the heater head.

3. Unscrew the two bolts that connect the

conveyor drive assembly to the bottom of

the heater head.

CAUTION

Be gentle with all parts of the conveyor

drive assembly, especially when pulling the

assembly out of the heater head and

putting it back in the heater head..

Damaging the parts could stop production.

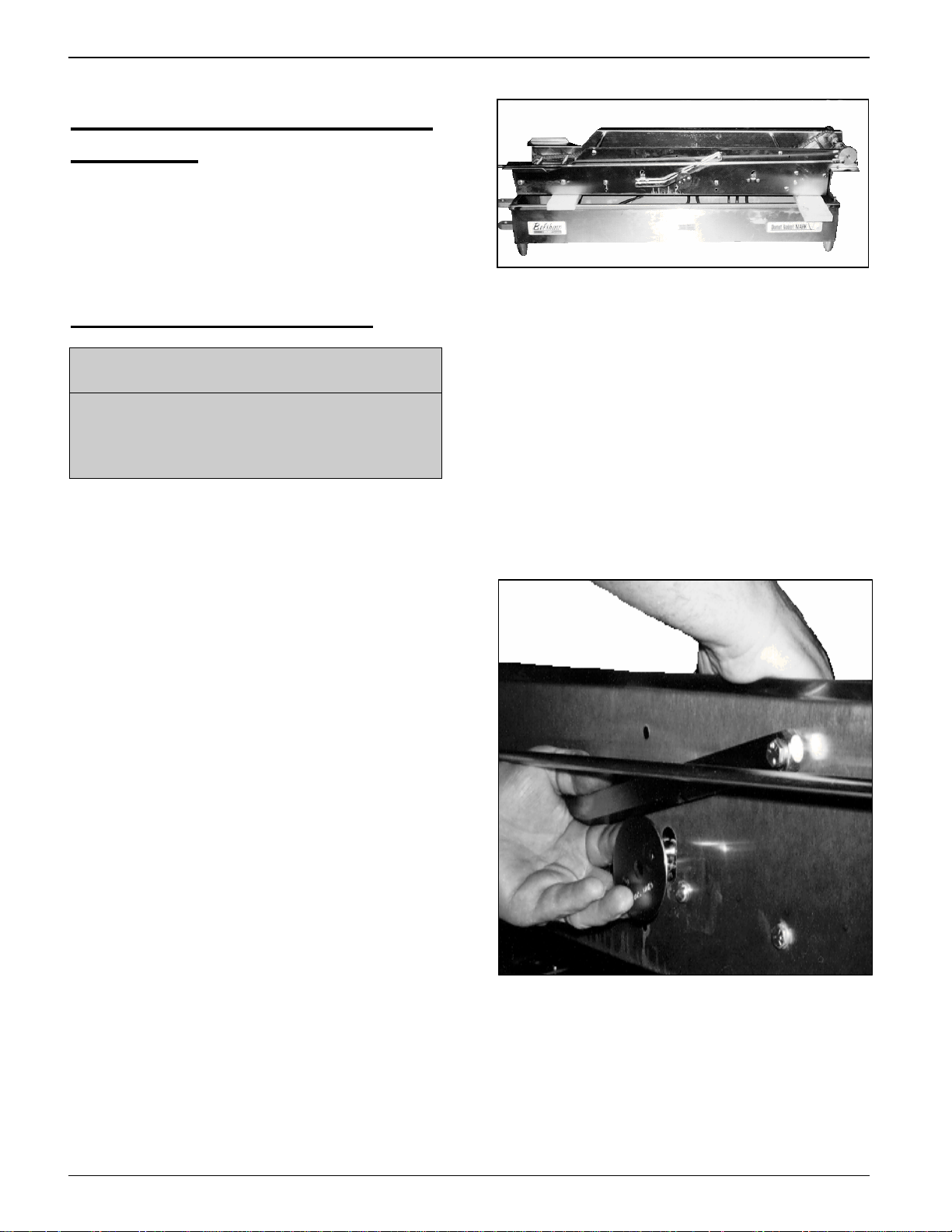

5. Apply 4 to 6 drops of SAE 30 machine oil

through the lubricating hole in the bearing

cap until the felt pad is saturated. See

Figure 3-4.

Figure 3-4. Lubricating the Conveyor Drive

Motor.

6. Carefully put the motor back in the heater

head, bolt the motor to the bottom of the

heater head, and replace the back cover of

the heater head.

4. Carefully pull the motor out of the heater

head. See Figure 3-3.

Figure 3-3. Removing the Conveyor Drive

Motor.

Taking Care of the Plunger,

Hopper, and Cylinder

The plunger, hopper, and cylinder of your Donut

Robot are precision instruments. If you take

good care of them, they will perform well for

years. Follow these guidelines:

Clean these parts only in the manner

explained in this manual.

Handle these parts with care. Avoid

dropping them on hard surfaces.

Do not force the machine if it becomes

jammed. To avoid damaging the

plunger, disassemble the machine and

remove any obstructions.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

12 MN-1022EN Donut Robot Mark V OM

Page 20

4 Related Products

This section contains information about the

following products which you might use with

your Donut Robot:

Feed Table

Roto Cooler

Icing Finishing Tree and Roto Cooler

Sugaring Tray and Roto Cooler

Filter Flo Siphon

Shortening Reserve Tank

FT-42 Feed Table

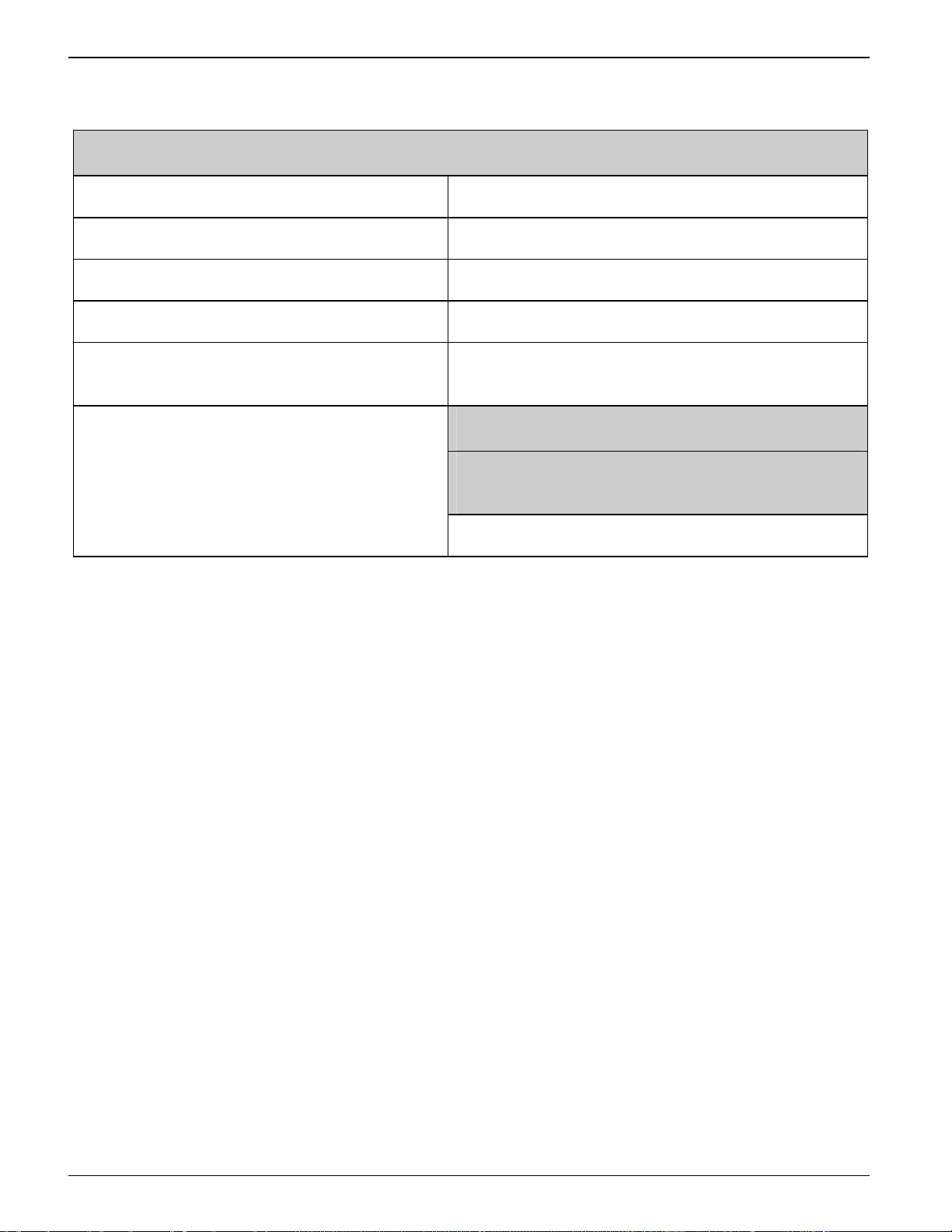

SPECIFICATIONS

Dimensions Shipping

Weight

L = 52”/132 cm

W = 19”/48 cm

H = 11 3/4”/30

cm

The FT-42 Feed Table is designed to supply

proofed yeast-raised donuts to the Donut Robot.

It is designed to be used on a flat, stationary table

or countertop, positioned end-to-end with the

Donut Robot. The operator is expected to read

and follow these instructions and warnings.

73 lb/33.1 kg 115 V

Electrical Data Construction Standard

1 Phase

50 or 60 Hz

Stainless steel,

nickel-plated mild

steel, and aluminum

alloys.

Equipment

Complete conveyor

assembly, including

drive system and

controls. Does not

include proofing

cloths or proofing

boards.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 13

Page 21

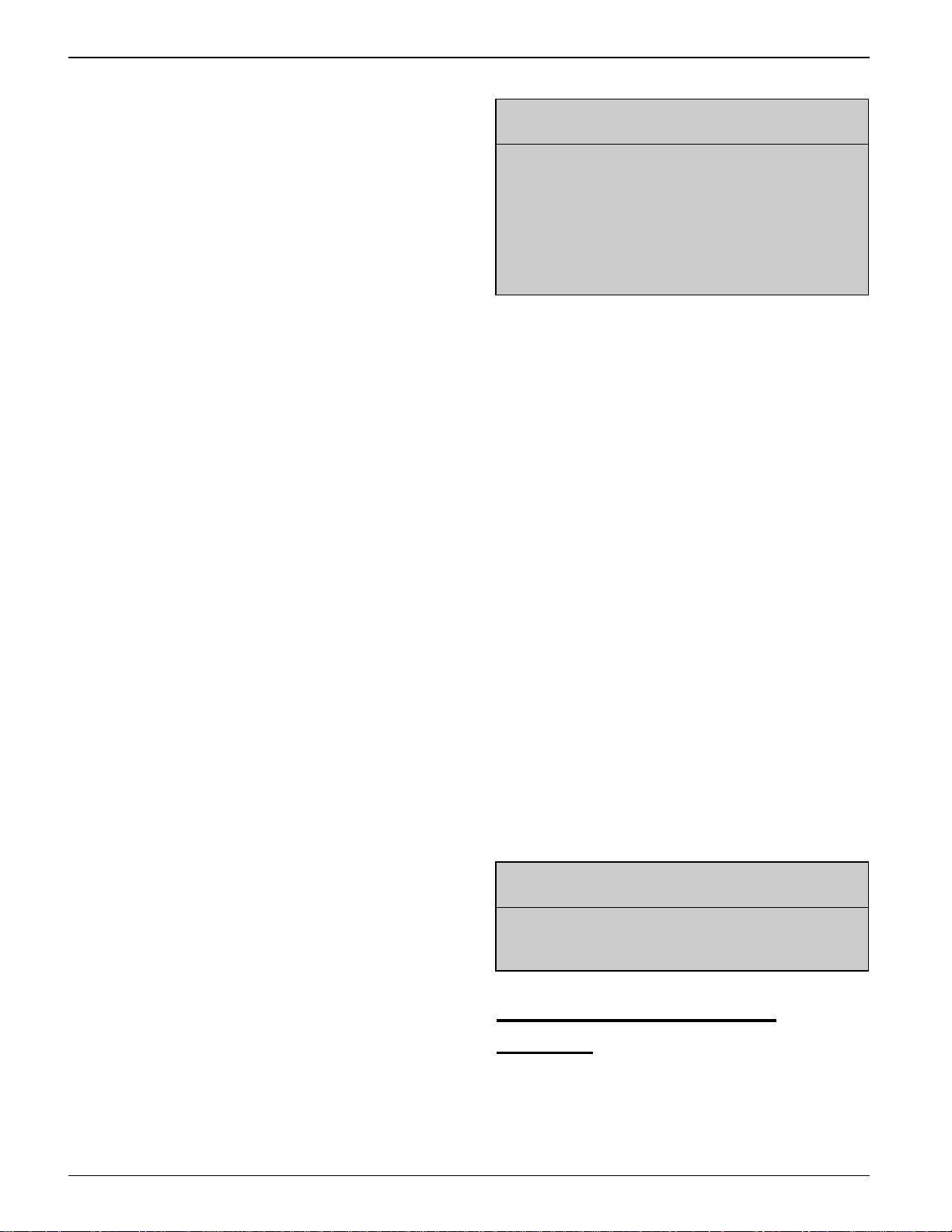

Figure 4-1. FT-42 Feed Table.

Installation

1. Unplug the cutter head power cord of your

Donut Robot.

2. Release the plunger from the cutter head.

3. Unscrew and lift off the hopper assembly.

4. Lift off the cutter head and swing column

assemblies.

5. Lift the outfeed end of the Feed Table and

set the brace under the trip shelf over the

edge of the kettle.

WARNING

To avoid injury, make sure that the Feed

Table is turned off before proceeding.

6. Plug the Feed Table power cord into the

outlet on the end of the heater head.

7. Set the Donut Robot to cut one cut per

pocket.

Operation

1. Test to make sure that the automatic timing

for the Feed Table is working. To do this:

a. Turn on the Donut Robot’s conveyor

drive.

b. Turn on the Feed Table’s conveyor

drive.

The Feed Table should receive a signal

from the Donut Robot, move forward the

distance needed to supply one pocket of

donuts, and then stop until it receives the

next signal.

2. Proof your donuts on the proofing cloths

from the Feed Table.

3. Put a proofing board, with a proofing cloth

on it, on the Feed Table.

4. Press the prime switch on the power head

assembly. The hooks on the Feed Table will

grab the proofing cloth off of the proofing

board. Allow the cloth to advance to the

front of the Feed Table.

5. Release the prime switch and turn on the

main power. Remove the proofing board.

When the Feed Table is on, the Feed Table

automatically advances donuts when the

Donut Robot is ready to accept them. After

the donuts go into the fryer, the proofing

cloths are carried underneath the Feed Table

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

14 MN-1022EN Donut Robot Mark V OM

Page 22

and fall onto the work surface. If you desire,

you may place a pan underneath the Feed

Table to receive the used proofing cloths.

6. Continue putting proofing cloths on the Feed

Table.

CAUTION

To avoid damaging the Feed Table, never

use force to assemble or operate it.

Maintenance and Cleaning

After Each Use

Use a soft, damp cloth for cleaning.

CAUTION

To avoid electrocuting yourself or

damaging the machine, never allow any

liquid to enter the power head.

As Needed

If you ever need to adjust the tension of the

conveyor chains, follow these steps:

1. Loosen the hex head bolts that hold the

roller shaft at the outfeed end of the

conveyor.

2. Pull the shaft until the chains reach the

correct tension. The tension is correct when

you can lift the chains about 1”/2,5 cm

above the surface of the Feed Table. Each

chain should have the same tension.

3. Tighten the hex head bolts that hold the

roller shaft.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 15

Page 23

Roto Cooler

SPECIFICATIONS

Dimensions Shipping

Weight

Dia.=24”/61 cm

H=6-5/8”/17 cm

16 lb/7.3 kg 120 V

Electrical Data Construction Standard

Equipment

1 Phase

50 or 60 Hz

Basket: High-density

polyethylene. Base:

Spun, polished,

heavy-gauge

aluminum.

To use the Roto Cooler:

1. Place the Roto Cooler near the outfeed end

of the Donut Robot so donuts will fall into

it.

2. Connect the Roto Cooler power cord to the

120 V outlet on back of the Donut Robot’s

heater head.

3. Turn on the Roto Cooler. It will rotate and

receive donuts. Remove cooled donuts from

the Roto Cooler as needed.

Basket and turntable

base with power cord

and motor.

4. When you are finished using the Roto

Cooler, turn it off and unplug it.

WARNING

Figure 4-2. Roto Cooler.

The Roto Cooler is designed to catch and cool

donuts as they drop from the outfeed end of the

Donut Robot. It is meant to be used on a flat,

stationary table or countertop. The operator is

expected to read and follow these instructions.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

16 MN-1022EN Donut Robot Mark V OM

5. Clean the Roto Cooler using soap and water

On the following pages are a wiring diagram and

a parts list for the Roto Cooler.

To avoid electrocuting yourself or

damaging the machine, never immerse the

base of the Roto Cooler.

and a non-abrasive cloth or scrubber.

Page 24

Icing Finishing Tree and Roto Cooler

SPECIFICATIONS

Dimensions Shipping

Weight

Dia.=24”/61 cm

H=32”/81 cm

28 lb/12.7 kg 120 V

Electrical Data Construction Standard

Equipment

1 Phase

50 or 60 Hz

Trays: Heavy-gauge

aluminum. Basket:

High-density

polyethylene. Base:

Spun, polished,

heavy-gauge

aluminum.

which donuts can be dipped. The operator is

expected to read and follow these instructions.

To use the Roto Cooler and the Icing Finishing

Tree:

1. Attach the Icing Finishing Tree to the Roto

Cooler. Fill the trays with toppings.

2. Install and operate the Roto Cooler as

explained in the previous section.

Power turntable and

four trays, three of

which have dividers.

3. Decorate the donuts with the toppings in the

trays.

4. When you are finished using the Roto

Cooler and the Icing Finishing Tree, turn off

the Roto Cooler and unplug it.

WARNING

To avoid electrocuting yourself or

Figure 4-3. Icing Finishing Tree with Roto

Cooler.

The Roto Cooler is designed to catch and cool

donuts as they drop from the outfeed end of the

Donut Robot. It is meant to be used on a flat,

stationary table or countertop.

The Icing Finishing Tree, which mounts on the

Roto Cooler, is designed to hold toppings in

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 17

damaging the machine, never immerse the

base of the Roto Cooler.

5. Clean the trays of the Roto Cooler and the

Icing Finishing Tree using soap and water

and a non-abrasive cloth or scrubber.

On the following page is a parts list for the Icing

Finishing Tree.

Page 25

Sugaring Tray and Roto Cooler

SPECIFICATIONS

Dimensions Shipping

Weight

Dia.=17-1/4”/

44 cm

H=6-5/8”/17 cm

16 lb/7.3 kg

Electrical Data Construction Standard

Equipment

120 V

1 Phase

50 or 60 Hz

Spun, polished,

heavy-gauge

aluminum.

To use the Sugaring Tray and Roto Cooler base:

1. Put sugar, powdered sugar, or cinnamonsugar in the tray.

2. Place the Sugaring Tray and Roto Cooler

base near the outfeed end of the Donut

Robot so donuts will fall into the tray.

3. Connect the Roto Cooler power cord to the

120 V outlet on back of the Donut Robot’s

heater head.

4. Turn on the Roto Cooler base. The Sugaring

Tray will rotate and receive donuts.

Power turntable with

sugar tray.

5. Coat the donuts with the topping in the tray.

Figure 4-4. Sugaring Tray and Roto Cooler.

The Roto Cooler base makes the Sugaring Tray

rotate. It is meant to be used on a flat, stationary

table or countertop.

The Sugaring Tray, which mounts on the Roto

Cooler base, is designed to catch donuts as they

drop from the outfeed end of the Donut Robot,

and to hold toppings in which donuts can be

dipped. The operator is expected to read and

follow these instructions.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

18 MN-1022EN Donut Robot Mark V OM

6. When you are finished using the Sugaring

Tray, turn off and unplug the Roto Cooler

base.

WARNING

To avoid electrocuting yourself or

damaging the machine, never immerse the

base of the Roto Cooler.

7. Clean the Sugaring Tray using soap and

water and a non-abrasive cloth or scrubber.

Page 26

Filter Flo Siphon

SPECIFICATIONS

Dimensions Shipping Weight Construction Standard Equipment

H=16”/41 cm

Dia.=6-1/4”/

16 cm

3 lb/1 kg Siphon tube and valve: nickel-plated

steel. Handle: wood. Filter ring:

powder-coated. Filters: flannel.

Clamp: aluminum alloy.

Siphon assembly

including valve, filter,

filter ring, and clamp.

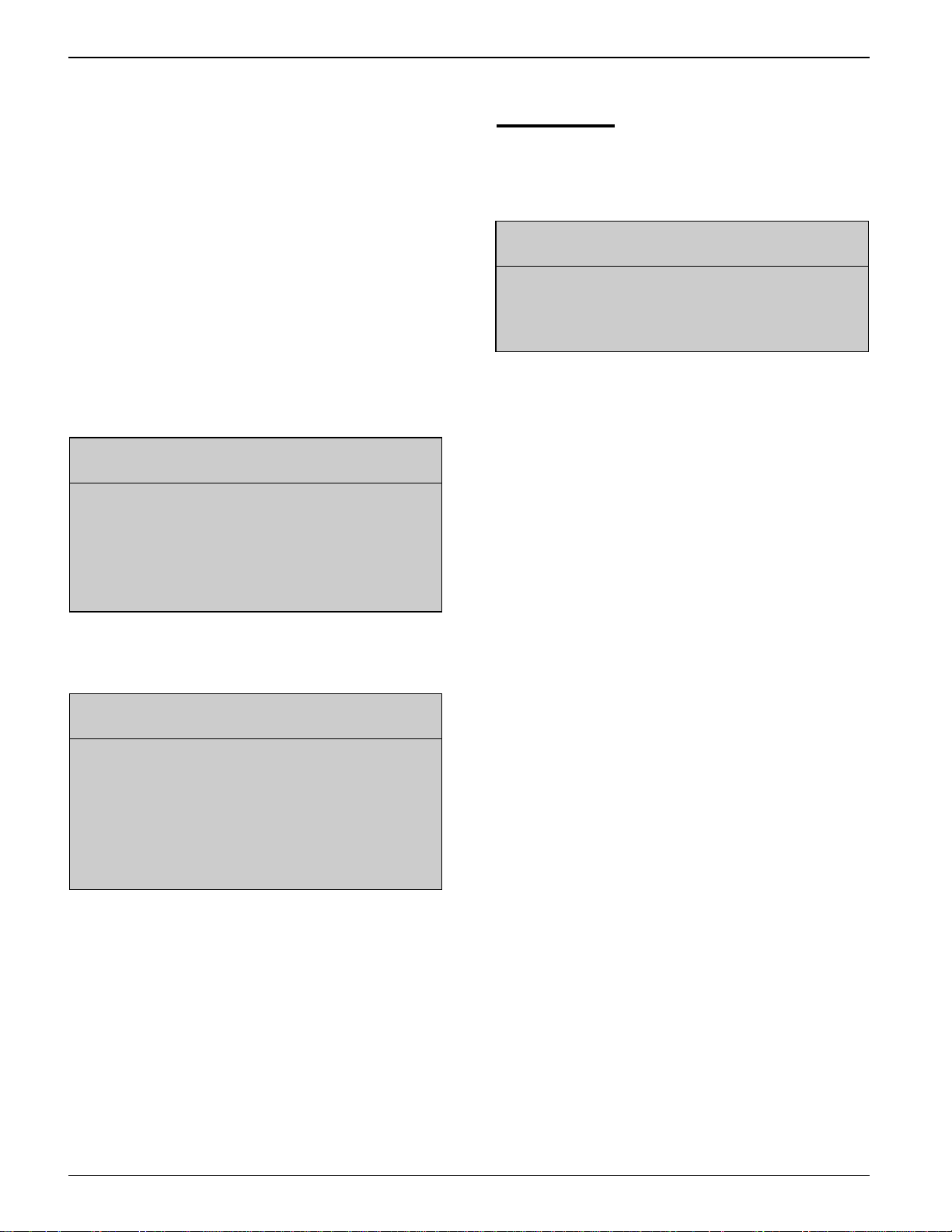

bulb

The Filter Flo Siphon is designed to drain and

filter shortening from the kettle of the Donut

Robot. The operator is expected to read and

follow these instructions.

mounting bracket

Installation

1. Let the shortening cool to 100F/38C.

handle

siphon tube

filter mounting

bracket

valve

filter

Figure 4-5. Filter Flo Siphon.

WARNING

Hot shortening can cause serious burns.

Never touch hot shortening. Never wear

shorts while using the Filter Flo Siphon.

2. Place the mounting bracket, with the siphon

tube in it, on the lip of the kettle. You may

place it on the infeed end of the kettle, or on

the front side of the kettle. If you place it on

the front side, you must disconnect the

swing connecting rod from the throw arm

and move it out of the way.

3. Position the opening of the siphon tube near

the bottom of the kettle.

4. Tighten the thumb screw in the mounting

bracket.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 19

Page 27

5. Attach the filter assembly to the lower part

of the siphon tube, as shown in Figure 4-7.

To do this:

a. Slide the opening in the filter mounting

bracket around the siphon tube.

b. Adjust the filter mounting bracket

vertically to ensure that the filter does

not touch the valve assembly.

c. Tighten the screw that holds the filter

mounting bracket to the siphon tube.

d. Tighten the screw that holds the filter

retaining ring to the filter mounting

bracket.

WARNING

Make sure that both screw in the filter

assembly are tight. If they are not, the

filter assembly might slide off of the siphon

tube during operation, causing shortening

to splatter.

6. Place a five-gallon metal container under the

filter.

Operation

1. Compress the bulb quickly and release it

quickly. Do this only once. Shortening

should flow into the container.

CAUTION

Do not compress the bulb more than once.

Doing so could allow hot shortening to get

into the bulb, damaging your equipment.

2. Watch the container as the shortening flows

into it. If the shortening rises to within 2”/

5 cm of the top of the container, do the

following:

a. With one hand, hold the siphon by the

handle. With the other hand, loosen the

thumb screw that holds the siphon

assembly to the mounting bracket on the

lip of the kettle.

b. Slowly lift the siphon assembly so its

opening is above the shortening. Do not

remove it from the mounting bracket.

c. Tighten the thumb screw.

WARNING

Do not use a plastic container. Hot

shortening could melt the container,

possibly burning you and getting

shortening on the floor. Shortening on the

floor could cause you to slip or fall,

resulting in injury or even death.

d. When the shortening stops flowing and

the valve closes, move the container out

from under the filter.

e. Place another five-gallon metal container

under the filter.

f. With one hand, hold the siphon by the

handle. With the other hand, loosen the

thumb screw that holds the siphon

assembly to the mounting bracket on the

lip of the kettle.

g. Slowly lower the siphon assembly so its

opening is near the bottom of the kettle.

h. Tighten the thumb screw.

i. Restart the siphon, as explained in step

1.

j. Continue watching the container and

repeat the above procedure as needed.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

20 MN-1022EN Donut Robot Mark V OM

Page 28

WARNING

If you allow shortening to overflow the

container, the shortening could burn you,

and it will get on the floor, possibly causing

slips, falls, injury, or even death. If

shortening does get on the floor, thoroughly

clean and dry the floor right away.

3. When the shortening stops flowing, tilt up

the side of the kettle opposite the siphon.

Place a wedge under the side of the kettle to

hold it up. The remaining shortening will

now flow toward the siphon.

4. Set aside the container of shortening.

5. Remove the filter assembly.

6. Place a different container under the valve

assembly and start the siphon again. Drain

the remaining shortening and discard it; it

will be full of sediment.

Cleaning

1. Remove the siphon from the Donut Robot.

2. Squeeze the bulb several times to expel

shortening from the siphon.

3. Wipe the siphon clean and hang it with the

bulb side up so any remaining shortening

will drain. Place a pan under the siphon to

collect the shortening.

4. Rinse the filter bag and hang it to dry. You

may launder it as needed.

WARNING

After washing, be sure the Filter Flo

Siphon is completely dry before using it

again. Moisture will cause hot shortening

to spatter, which may cause serious injury.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 21

Page 29

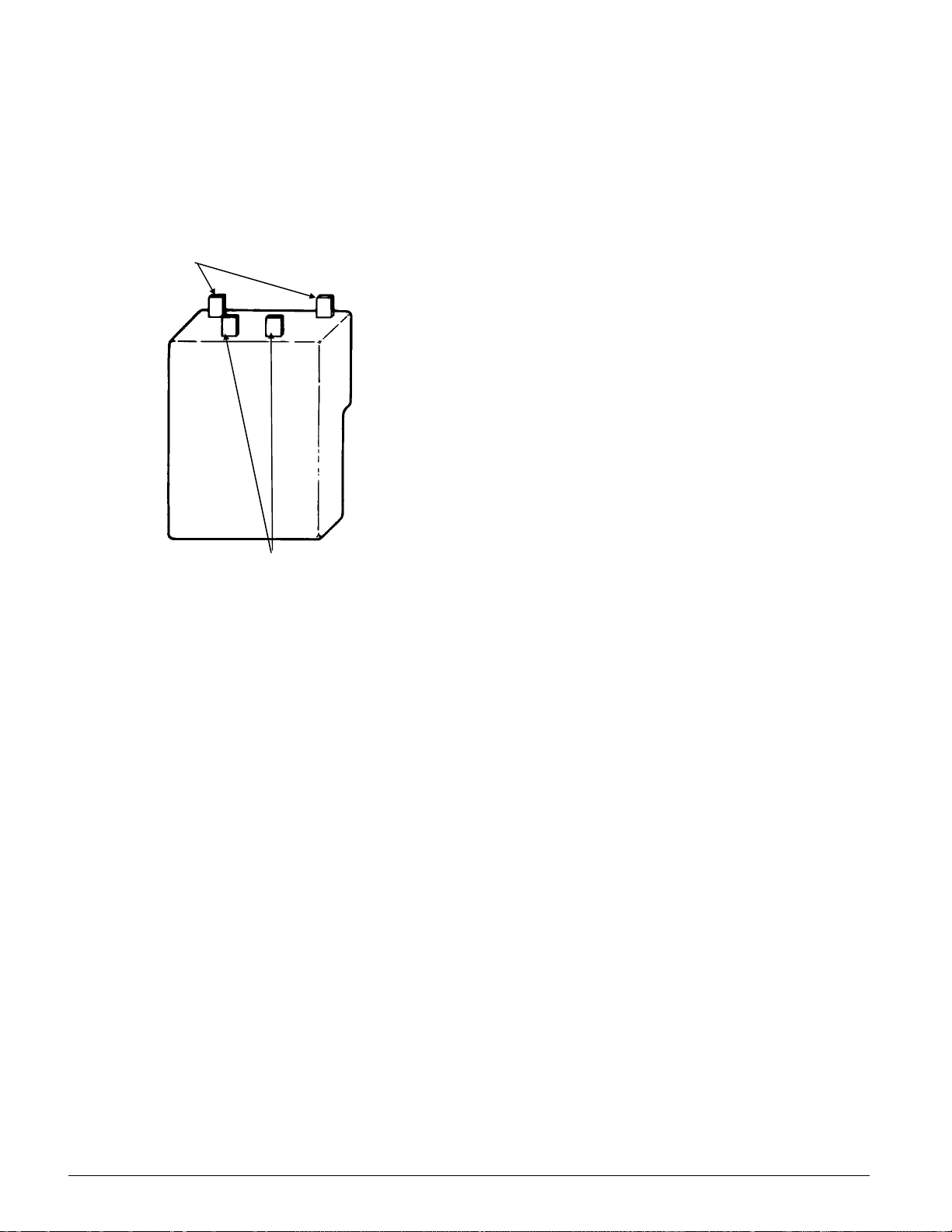

Shortening Reserve Tank

SPECIFICATIONS

Dimensions Shipping

Weight

L=11”/28 cm

W=5-1/2”/14 cm

D=4”/10 cm

The Shortening Reserve Tank is designed to

supply melted shortening to the kettle of the

Donut Robot. The operator is expected to read

and follow these instructions.

To use the Shortening Reserve Tank:

1. Position the Shortening Reserve Tank on the

conveyor side panels. Make sure that you

do not position it above the donut turner.

4 lb/2 kg 4 lb/2 kg

Capacity Construction Standard

shortening

WARNING

Be careful if you put hot shortening into

the tank. Hot shortening can cause serious

burns.

Equipment

Nickel-plated steel

tank and noncorrosive self-closing

valve.

2. Place shortening in the tank.

3. Turn on the Donut Robot. The heat of the

fryer will melt the shortening in the tank.

4. To supply shortening to the fryer, open the

valve by pushing down on the valve

assembly.

5. When you are done making donuts, drain the

remaining shortening into the fryer.

6. When the shortening and equipment have

cooled completely, remove the Shortening

Reserve Tank and wash it.

Shortening reserve

tank and valve

assembly.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

22 MN-1022EN Donut Robot Mark V OM

Page 30

5 Donut-Making Helps

Tips on Making Quality

Cake Donuts

Use the correct batter temperature.

In general, the correct batter temperature is

75-80F/24-27C. Check the mix

manufacturer’s instructions, as the

recommended temperature range may vary.

If the batter is too warm, the donuts will lack

volume and may “ring out” or be misshapen.

If the batter is too cold, the donuts will stay

under the shortening too long, fry too

slowly, and crack open or ball up. They

may also absorb excess shortening and lose

volume.

Use the correct floor time.

A floor time of 10 minutes between mixing

and cutting allows the baking powder to

react with the water. This helps the donuts

attain the proper volume and absorb the

proper amount of shortening.

If the floor time exceeds 30 minutes, the mix

will gas off, the donuts will lose volume and

shape and will absorb too much shortening.

If the shortening is too cold, the donuts will

spread too rapidly, will form large rings, will

tend to crack open, will be too light in

appearance, and will absorb too much

shortening.

Maintain the proper shortening level. We

recommend a distance of 1 1/4” between the

cutter and the shortening.

If the shortening is too deep, the donuts may

not turn over when they reach the turner,

causing them to cook unevenly.

If the shortening is too shallow (too far

below the cutter), the donuts may not drop

flat, may turn over while submerging and

surfacing, and may become irregular,

cracked, or rough-crusted.

Ensure that the donuts absorb the right

amount of shortening.

Donuts should absorb 1-1/2 to 3 oz/42 to 85

g of shortening per dozen, depending on

their weight. You can achieve proper

absorption by following tips 1-3.

If the donuts do not absorb enough

shortening, they will not keep well.

Use the correct frying temperature.

The correct shortening temperature for

frying is 370-380F/188-193C.

If the shortening is too hot, the donuts will

fry too quickly on the outside and will lose

volume. The donuts may also become dense

inside.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V OM MN-1022EN 23

If they absorb too much shortening, they

will lose volume and may become

misshapen. If this happens, follow tips 1-3,

mix the batter a little longer than usual, turn

the donuts as soon as they become golden

brown, and turn the donuts only once.

Page 31

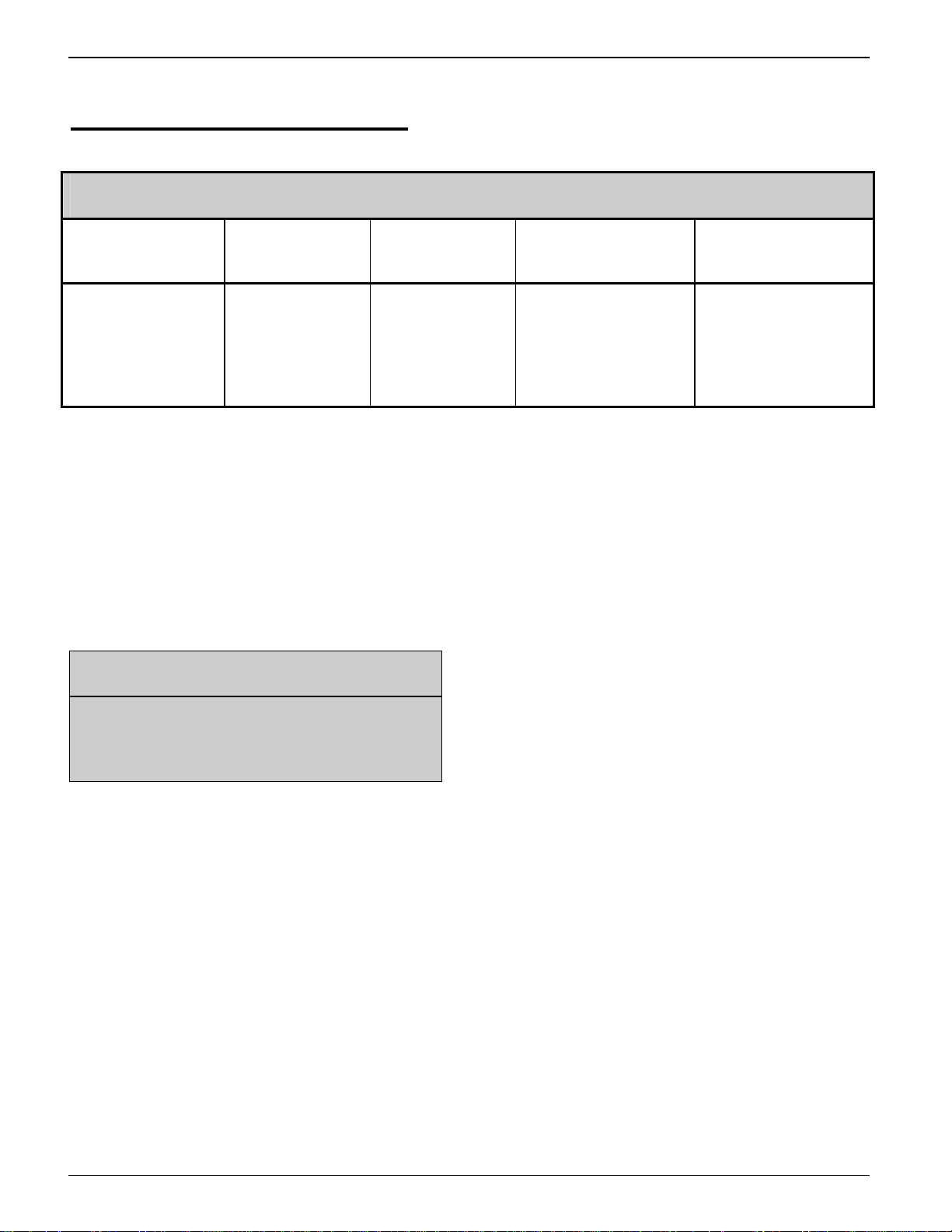

Calculating Correct Water

Temperature

The following is an example of how to calculate

the correct water temperature to use. You must

Cake Donuts Yeast-Raised Donuts

Room temperature 72 22.2 72 22.2

Dry mix temperature +70 +21.1 +70 +21.1

Total A

Desired batter temperature 75 23.9 80 26.7

x3

Total B

Total B

-Total A

Desired water temp. for cake donuts

Temperature increase during mixing (average: 30F/17C)

Desired water temperature for yeast-raised donuts

F

142 43.3 142 43.3

225 71.7 240 80.1

225 71.7 240 80.1

-142

83F

use your own room temperature, dry mix

temperature, desired batter temperature, and, if

you are making yeast-raised donuts, estimated

temperature increase during mixing.

x3 x3 x3

-43.3 -142 -43.3

Figure from above 98 36.8

C

28.4C

98 36.8

F

-30 -17

68F

C

19.8C

Ratios of Plunger Sizes to

Donut Weights

The weights given are for donuts without icings

or other toppings. They are provided for

reference only, as weights vary according to the

density of the batter.

Plunger Size Donut Weight per

Dozen

1” 5-8 oz/142-227 g

1 7/16” 10-17 oz/283-482 g

1 9/16” 14-21 oz/397-595 g

1 13/16” 19-23 oz/539-652 g

Temperature Conversion

To convert temperatures from Fahrenheit to

Celsius, subtract 32 from F and divide the result

by 1.8. For example, 212F-32/1.8 = 100C.

To convert temperatures from Celsius to

Fahrenheit, multiply C by 1.8 and add 32 to the

result. For example, (100C x 1.8) + 32 = 212F.

F C F C

55 12.8 340 171.1

60 15.6 345 173.9

65 18.3 350 176.7

70 21.2 355 179.4

75 23.9 360 182.2

80 26.7 365 185.0

325 162.8 370 187.8

330 165.6 375 190.6

335 168.3 380 193.3

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

24 MN-1022EN Donut Robot Mark V OM

Page 32

Donut Robot

Mark V

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 Fax: (206) 322-5425

E-mail: service@belshaw.com http://www.belshaw.com

Page 33

Page 34

If you accept the machine from the shipping

company, you are, in effect, saying that the

machine is in good condition, and you must

pay for the machine. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, inspect the machine to see

that no parts are bent, scratched, or otherwise

damaged. If any damage has occurred in

shipping, file a freight claim with the shipping

company immediately.

IMPORTANT

Keep this manual for reference purposes.

To unpack the Donut Robot Mark V and

transport it to the work station:

1. Remove the foam and other packing

materials from the two boxes.

2. Carry the hopper, plunger, and column to the

work station.

3. Coil the cutter head power cord and carry

the cutter head to the work station.

4. Carry the conveyor assembly to the work

station.

5. Remove the clevis pins that hold the heater

head in place, and lift the heater head out of

the fryer.

6. Coil the power cord and carry the heater

head to the work station.

7. Move the fryer case and kettle to the work

station.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

011708

MN-1023EN

Belshaw Bros., Inc.

814 44

Phone: (206) 322-5474 Fax: (206) 322-5425

th

Street NW, Suite 103

Auburn, WA 98001 USA

E-mail: service@belshaw.com http://www.belshaw.com

Page 35

Page 36

Contents

1 Installation 1

Unpacking the Fryer 1

Initial Cleaning 2

Assembling the Fryer 2

Assembling the Cutter 3

Adjusting the Hopper 4

Leveling and Securing the Fryer 5

Moving the Fryer 6

2 Maintenance 7

Checking the Thermostat 7

3 Troubleshooting 8

Mark V 9

FT-42 20

4 Electrical Components 22

Continuity Testing 22

5 Appendix 25

Parts List Drawing Insert Page Insert

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN iii

Page 37

Preface

The Donut Robot Mark V is designed to

automatically cut and fry cake donut products,

and to fry yeast-raised donut products. It is not

designed to cut or fry any other products. The

Mark V uses electrical elements to heat

shortening in its kettle.

The Mark V is designed to be used on a flat,

stationary table or countertop, with the operator

standing opposite the heater head of the machine.

The operator must work safely at all times and

read this manual and follow its instructions and

warnings.

Study the instructions and warnings in this

manual carefully. A thorough understanding of

how to install, maintain, and safely operate the

Donut Robot Mark V will prevent production

delays and injuries.

To use the Mark V safely, heed the following

warnings and all other warnings that appear in

this manual:

Make sure the machine is secured to the

work surface. Doing so will prevent the

machine from moving or falling, which

could cause serious injury.

Never let water and hot shortening come

in contact with each other. Moisture

causes hot shortening to spatter, which

may cause serious burns.

Do not overfill the kettle with

shortening. If shortening overflows the

kettle, it could cause serious burns or

could cause someone to slip on the floor

and be seriously injured.

Hot shortening can cause serious burns.

Make sure that the system and the

shortening are cool before attempting

any adjustment, repair, disassembly, or

cleaning.

To avoid electrocution or other injury,

unplug the machine before attempting

any adjustment, repair, disassembly, or

cleaning.

To avoid damaging the machine, never

use force to assemble, disassemble,

operate, clean, or maintain it.

Be careful never to get shortening,

water, or other materials on the floor. If

anything does get spilled on the floor,

mop it up immediately. Materials on the

floor can cause people to slip or fall,

resulting in serious injury or loss of life.

To prevent unintentional startup and

possible fire, unplug the machine if there

is a local power outage. When the

power is restored, it is safe to plug the

machine in again.

To avoid electrocution, make sure that

all electrical cords are not frayed or

cracked and that they do not pass

through any water or shortening.

Make sure that all electrical cords are

routed so that no one will trip over them.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

iv MN-1023EN Donut Robot Mark V TS

Page 38

1 Installation

To help familiarize you with the major parts of

your Donut Robot Mark V, please study the

photograph below.

bearing

strut

cutter head

plunger

hopper

heater head conveyor

swing column

Figure 1-1. Donut Robot Mark V, Front View.

Unpacking the Fryer

To unpack the Donut Robot Mark V and

transport it to the work station:

1. Remove the foam and other packing

materials from the two boxes.

2. Carry the hopper, plunger, and swing

column to the work station.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 1

swing connecting rod fryer

3. Coil the cutter head power cord and carry

the cutter head to the work station.

4. Carry the conveyor assembly to the work

station.

5. Remove the clevis pins that hold the heater

head in place, and lift the heater head out of

the fryer.

6. Coil the power cord and carry the heater

head to the work station.

Page 39

7. Move the fryer case and kettle to the work

station.

Initial Cleaning

Thoroughly clean your Donut Robot Mark V

before using it. Remove all packing materials.

Refer to Section 3, “Cleaning.”

WARNING

To avoid electrocuting yourself or

damaging the machine, never allow water,

steam, cleaning solution, or other liquid to

enter the cutter head or heater head

assemblies.

WARNING

Never let water and hot shortening come in

contact with each other. Moisture causes

hot shortening to spatter, which may cause

serious injury. Prior to use, make sure the

kettle and any other parts you have washed

are dry.

4. Install the heater head assembly as follows:

a. Align the holes in the heater head end

caps with the holes in the heater head

mounting brackets.

b. Slide the clevis pins through the holes so

that the pin heads are on the outsides.

c. Insert the hairpin clips into the holes in

the clevis pins.

5. Lower the heater head assembly into

position so the thermostat bulb bracket rests

on or very near the bottom of the kettle.

6. Install the conveyor assembly as follows:

a. Hold the conveyor at the angle shown in

Figure 1-2 and slide the conveyor drive

coupling over the main drive shaft

coupling. The conveyor coupling has a

notch in it. Turn the conveyor coupling

until the head of the socket head screw

in the drive coupling can slide into this

notch. (See Figure 1-2.)

b. Lower the front side of the conveyor

assembly so the hole in the conveyor

flange fits over the locating pin on the

lip of the kettle.

After cleaning, assemble the fryer and cutter as

explained below.

Assembling the Fryer

1. Place the fryer case on a flat, stationary

surface.

2. Screw the fryer’s legs in as far as they will

go.

3. Set the kettle into the fryer case. The end of

the kettle that has the locating pin must be

placed at the outfeed end of the fryer case.

The lip of the kettle should fit securely over

the edge of the case

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

2 MN-1023EN Donut Robot Mark V TS

Figure 1-2. Joining the Couplings.

If you are preparing to make yeast-raised donuts,

skip steps 7 and 8 and proceed to step 9.

Page 40

7. Insert the swing column into the swing

column mounting bracket. Make sure the

plastic spacer washer is on the swing column

between the set collar and the swing column

mounting bracket. See Figure 1-3.

9. Be sure your power source matches the

specifications on the data plate. Connect the

machine to the power source.

10. Turn on the conveyor only and check to see

that it operates smoothly. The power switch

for the conveyor drive is on the heater head.

Assembling the Cutter

Read this section only if you are preparing to

make cake donuts.

1. Set the cutter head assembly onto the swing

column. See Figure 1-5.

Figure 1-3. Inserting the Swing Column.

8. Connect the swing connecting rod to the

throw arm of the swing column. A locating

pin on the swing connecting rod rests in a

hole in the throw arm. See Figure 1-4.

Figure 1-5. Mounting the Cutter Head

Assembly.

2. Mount the hopper by sliding the two

mounting studs on the hopper arch into the

notches on the bearing strut. Secure the

hopper with the thumb nuts. See Figure 1-6.

Figure 1-4. Connecting the Swing

Connecting Rod.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 3

Page 41

Figure 1-6. Mounting the Hopper.

3. Install the plunger as follows:

a. Lift the plunger connecting rod assembly

up and out of the way.

b. Put the narrow part of the plunger’s

center rod through the slot in the center

of the hopper arch.

c. Lower the plunger until the wider part at

the top of the center rod enters the round

opening in the hopper arch and the

plunger’s piston just enters the hopper

cylinder.

d. Lower the connecting rod assembly and

insert the pin on the rod into the hole

near the top of the center rod. See

Figure 1-7.

Figure 1-7. Installing the Plunger.

4. Plug the power cord from the cutter head

assembly into the outlet on the back of the

heater head.

5. Test the cutter head to ensure that it is

operating properly. Turn it on using the

prime switch on the cutter head. The cutter

should run continuously. Turn off the cutter.

Adjusting the Hopper

Read this section only if you are preparing to

make cake donuts.

WARNING

To avoid injury, always unplug the

machine before making adjustments.

1. The bottom of the hopper should be 1”/ 2.5

cm above the flight bars. To set the height

of the hopper:

a. Hold the cutter and the hopper from

below.

b. Loosen the set screw in the lower set

collar on the swing column.

c. Raise or lower the swing column as

needed.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

4 MN-1023EN Donut Robot Mark V TS

Page 42

d. Tighten the set screw. See Figure 1-8.

Figure 1-8. Adjusting the Height of the

Hopper.

2. As the hopper swings back and forth over

the kettle, the hopper cylinder should stop

the same distance away from either side of

the kettle at each end of the swing.

To check the swing of the hopper, turn on

the conveyor. If you need to center the

swing of the hopper, follow these steps:

a. Turn off the conveyor.

b. Loosen the set screws in the upper set

collar.

c. Swivel the bearing strut as needed.

d. Tighten the set screws. (See Figure 1-9.)

e. Double-check the swing of the hopper

by turning on the conveyor. Then turn

off the conveyor.

Figure 1-9. Adjusting the Swing of the

Hopper.

Leveling and Securing the

Fryer

Check to see if the fryer is level. If it is not,

adjust the heights of the legs. Be sure that all six

legs rest on the work surface when the fryer is

level.

Bolt the fryer to the work surface as follows:

1. There are brackets on the ends of the fryer

case. Each has a hole in it. Mark the

locations of the holes on the work surface.

2. Drill holes through the work surface.

3. Insert bolts through the holes.

4. Tighten nuts onto the bolts to ensure that the

Donut Robot will not move.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 5

Page 43

Moving the Fryer

If you ever need to move the fryer to a different

work station, follow this procedure:

1. Turn off the machine and disconnect it from

the power source.

2. Allow the machine and the shortening to

cool.

WARNING

Do not touch hot shortening. It can cause

serious burns.

3. Remove and set aside the plunger, the

hopper, and the cutter head, in that order.

4. Disconnect the swing connecting rod.

Remove and set aside the swing column.

5. Remove the shortening from the fryer as

explained in “Removing the Shortening” in

Section 2 of the Operator's Manual.

6. To avoid dropping the machine or getting

shortening on the floor, wipe excess

shortening off of the fryer and conveyor.

WARNING

Thoroughly clean and dry the floor if

shortening is spilled. Materials on the floor

can cause people to slip or fall, resulting in

serious injury or loss of life.

7. Set aside the conveyor.

8. Remove the clevis pins that hold the heater

head in place. Remove the heater head from

the fryer.

9. To avoid tripping, coil the power cord.

Move the heater head to the new work

station.

10. Move the fryer to its new location.

11. Install the heater head.

12. Move and install the conveyor.

13. Move and install the swing column.

Connect the swing connecting rod.

14. Move and install the cutter head, the hopper,

and the plunger.

15. Level and secure the fryer.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

6 MN-1023EN Donut Robot Mark V TS

Page 44

2 Maintenance

WARNING

To avoid being burned, electrocuted, or

otherwise injured, always unplug the

machine and allow it to cool before

performing any maintenance.

Checking the Thermostat

If the quality of your product decreases, check

the accuracy of the thermostat. Heat some

shortening in the fryer, measure the temperature

of the shortening using a thermometer you know

to be accurate, and compare this reading to the

thermostat setting. It is important that you put

the thermometer in the top 1” or so of shortening,

because this is where the donuts are fried, and

this is where the temperature should be

consistent. If you need to calibrate the

thermostat, consult Section 4, “Electrical

Components.”

If you ever want to test the continuity of the

thermostat or any of the switches on your Donut

Robot, refer to Section 4, “Electrical

Components.”

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 7

Page 45

3 Troubleshooting

This section is designed as an aid in

troubleshooting, not as a substitute for a

qualified technician. You may encounter a

problem with your Donut Robot that is not

covered in this section, or you may try the

remedies suggested here and find that they do not

correct the problem. In either case, feel free to

call Belshaw Bros. at (206)322-5474. One of our

customer support representatives will be happy

to help you.

CAUTION

If you perform repairs yourself or have

them performed by anyone other than

Belshaw Bros. or a service technician

authorized by Belshaw Bros., you do so at

your own risk.

If your Donut Robot becomes badly worn or

seriously out of adjustment, send it to our factory

for complete rebuild and repair service. Return

your machine, freight prepaid, with your

instructions for service, your phone number, and

the name of the person for us to contact when we

have made a cost estimate. In most cases, the

machine can be shipped back, freight collect,

within five days.

To avoid down time, call us to see whether we

have a machine we can loan to you while your

machine is being serviced.

Ship machines in need of servicing to:

Belshaw Bros., Inc.

814 44th Street NW, Suite 103.

Auburn, WA 98001 USA

If you need a replacement part, use the parts lists

and assembly drawings in Section 5 to determine

the part number and description. When you

order the part, please specify the following:

The model name of the machine.

The serial number of the machine.

The voltage, phase, and hertz of the

machine.

The part number.

The part description, including the size,

if applicable.

The quantity desired.

Following is a troubleshooting chart to help you

identify and solve some basic problems. For

additional information regarding baking mixes,

temperature, and fry time, refer to “DonutMaking Helps” in the Operator's Manual.

WARNING

To avoid being burned, electrocuted, or

otherwise injured, unplug the machine and

allow it to cool before disassembling,

repairing, or wiring.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

8 MN-1023EN Donut Robot Mark V TS

Page 46

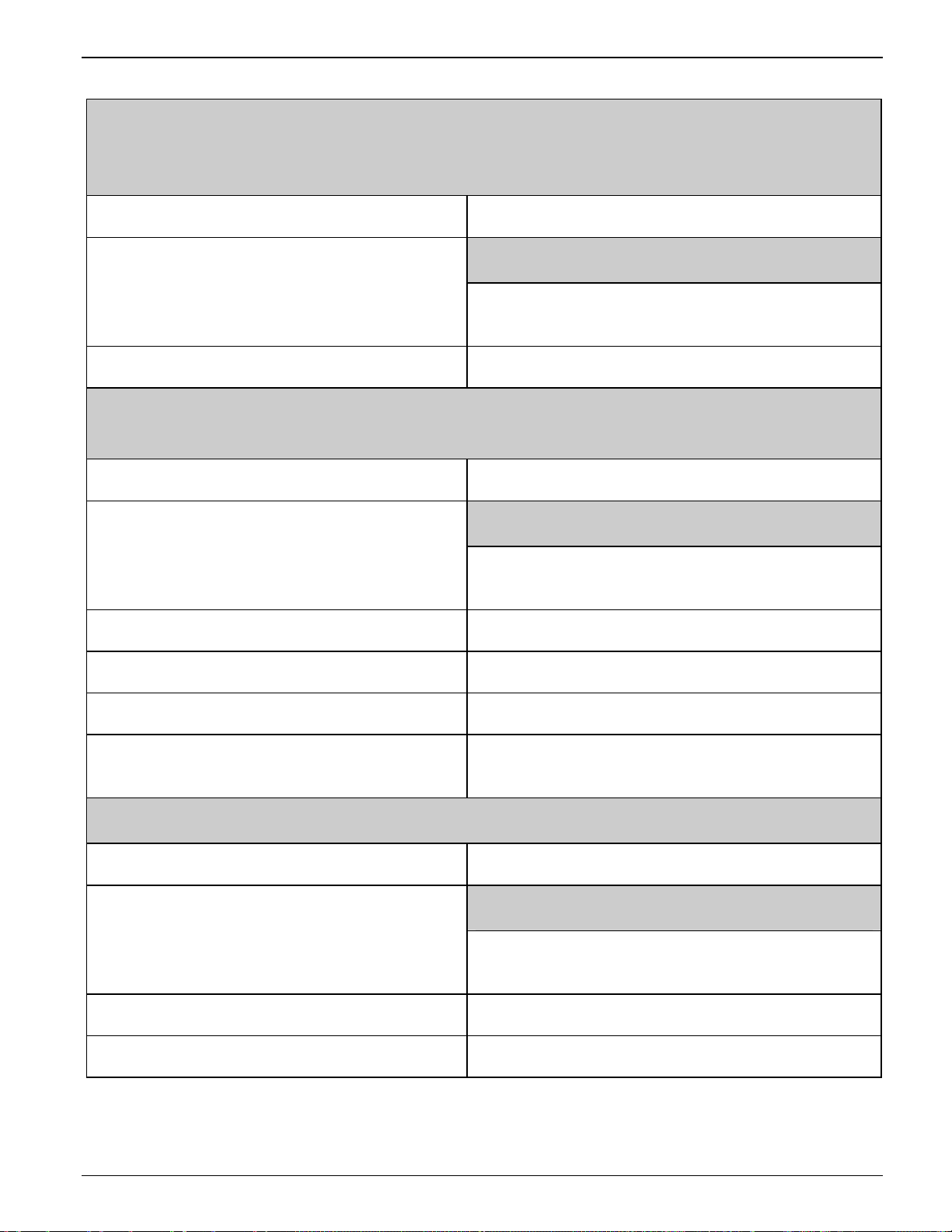

Mark V Donut Robot

THE DONUTS ARE UNDERCOOKED.

Possible Causes What To Do

The shortening is not hot enough. Increase the temperature setting.

The conveyor is moving too quickly. Decrease the speed of the conveyor, using the knob

labeled “Fry Time in Seconds.”

The dough is too cold. See “Donut-Making Helps” in the Operator's Manual.

The dough has not had enough floor time. See “Donut-Making Helps” in the Operator's Manual.

The thermostat reads inaccurately. Calibrate the thermostat.

THE DONUTS ARE OVERCOOKED.

Possible Causes What To Do

The shortening is too hot. Decrease the temperature setting. The temperature

setting should never exceed 375F/191C.

The conveyor is moving too slowly. Increase the speed of the conveyor, using the knob

labeled “Fry Time in Seconds.”

The thermostat reads inaccurately. Calibrate the thermostat.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 9

Page 47

THE DONUTS BALL OR BLISTER.

Possible Causes What To Do

The dough is too cold. See “Donut-Making Helps” in the Operator's Manual.

The shortening is too hot. Decrease the temperature setting.

The dough is overmixed. Review the mixing procedure.

The donuts are too large. Adjust the dial on the cutter head to produce smaller

donuts.

The shortening is old or contaminated.

Replace the bad shortening with fresh shortening.

To avoid being burned, turn off the machine and

allow the shortening to cool.

WARNING

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

10 MN-1023EN Donut Robot Mark V TS

Page 48

THE DONUTS ARE SHAPED IMPERFECTLY.

Possible Causes What To Do

The shortening level is too low. Add shortening to reach the proper level.

The hopper is too far above the shortening. Lower the hopper to 1”/2.5 cm above the shortening.

The drop plate is out of position. Reposition the drop plate.

The tip of the cylinder is dirty.

Clean the cylinder.

The tip of the cylinder is nicked. Replace the hopper.

The size-selection dial is not tightened. Tighten the thumb nut.

The dough is overmixed. Review the mixing procedure.

To avoid being burned, turn off the machine and

allow the shortening to cool.

To avoid injury, turn off the machine. Remove

the hopper.

WARNING

WARNING

THE DONUTS DROP AT THE WRONG TIME.

Possible Cause What To Do

The hopper swing is adjusted incorrectly.

Adjust the hopper swing. See “Adjusting the

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

Donut Robot Mark V TS MN-1023EN 11

To avoid injury, turn off the machine.

Hopper” in Section 1, “Installation.”

WARNING

Page 49

THE CONVEYOR BITES THE DONUTS.

Possible Causes What To Do

The donuts are not cooking enough. See “The donuts are undercooked” below.

The shortening level is too low. Add shortening to reach the proper level.

The turner is bent or packed with cooked food

particles.

The cam weight is sticking due to the

accumulation of varnish.

The fryer is not level. Level the fryer.

To avoid being burned or otherwise injured,

before doing any of the following, turn off the

machine and allow the shortening to cool.

Straighten and/or clean the turner.

Clean to remove the cooked-on varnish.

THE MOTOR OVERHEATS.

Possible Causes What To Do

The power requirements of the machine do not

match the power source.

Supply the correct power as specified on the data

plate.

WARNING

WARNING

The motor is binding. Repair or replace the motor.

The motor is defective. Repair or replace the motor.

Belshaw Bros., Inc. www.belshaw.com Phone 206-322-5474 Fax 206-322-5425

12 MN-1023EN Donut Robot Mark V TS