Bellingham + Stanley RFM300-T, RFM340-T, RFM330-T User Manual

USER GUIDE

19-461’02 REV D

RFM300-T Series

Refractometer

RFM300-T User Guide (EN)

Bellingham + Stanley Bellingham + Stanley

Code 19-461

Issue 02

Revision D

Date September 2017

Bellingham + Stanley, a Xylem brand, has been manufacturing high quality optical

instruments in the UK for over 100 years and is a leading manufacturer of

refractometers and polarimeters.

Our current range of products includes optical and digital hand refractometers as well

as a full range of laboratory refractometers and polarimeters available through a

network of trained distributors throughout the world. Process refractometers are also

available through specialist outlets.

Visit our website, www.bellinghamandstanley.com

Stanley, our products and foreign language brochures.

Contact our Sales team to discuss a particular application or to receive details of your

local distributor.

Xylem Inc. recognise all trademarks

2016 Xylem Inc.

Every effort has been made to ensure the accuracy of the contents of the manual.

However, Bellingham + Stanley Ltd. and Xylem Inc. can assume no responsibility for

errors contained in the manual or their consequences.

Printed in UK

, for full details of Bellingham +

Longfield Road 90 Horizon Drive

Tunbridge Wells, Kent TN2 3EY Suwanee, GA 90024

United Kingdom United States of America

Main: +44 (0) 1892 500400 Main: (678) 804 5730

Fax: +44 (0) 1892 543115 Fax: (678) 804 5729

sales.bs.uk@xyleminc.com sales.bs.us@xyleminc.com

Contents

Section 1: Installation ............................................................................. 3

Instrument overview ..................................................................... 4

Menu flow chart ............................................................................ 5

Unpacking .................................................................................... 7

Positioning the system ................................................................. 8

Mains connection ......................................................................... 8

Section 2: Instrument operation ............................................................ 9

Basic operation ........................................................................... 11

Setup Wizard .............................................................................. 13

Measurement Display ................................................................. 14

Measurement settings ................................................................ 20

Calibration and Reading ............................................................. 27

Saving results ............................................................................. 30

Data Menu .................................................................................. 35

Section 3: Instrument Setup ................................................................ 38

Methods ...................................................................................... 39

User accessibility ........................................................................ 42

Reading setup ............................................................................ 51

Communications ......................................................................... 58

System settings .......................................................................... 60

Section 4: System maintenance .......................................................... 63

Maintenance Menu ..................................................................... 64

Information and Help .................................................................. 67

Setting default values ................................................................. 67

Section 5: Specification ........................................................................ 70

Specification ............................................................................... 71

Section 6: Accessories and Contact ................................................... 73

Accessories ................................................................................ 74

Contact ....................................................................................... 77

RFM300-T 19-461’02 Rev. D September 2017 Page 1

This symbol is an internationally agreed indicator that the

and facilities are in place.

Declaration of conformity

According to ISO/IEC 17050-1 & 2: 2004

Manufacturer's Name Bellingham + Stanley

Manufacturer's Address Longfield Road,

Tunbridge Wells,

Kent TN2 3EY

United Kingdom

declares that the product

Product Name RFM300-T Series Refractometer

Model Number All

Is designed to conform to the following Product Specifications:

Safety:

BS EN 60950-1:2002

Applied and met EMC test standards:

Emissions

EN 61326-1:2013

• Radiated emissions CISPR 11:2009 inc.

A1:2010, Class A

• Conducted emissions, ac port CISPR 11:2009 inc.

A1:2010, Class A

• Conducted emissions, ethernet port CISPR 11:2009 inc.

A1:2010, Class A

EN 61000-3-2:2014

• Mains harmonics Class A

EN 61000-3-3:2013

• Mains voltage flicker (dmax=4%)

Immunity:

EN 61326-1:2013 - Basic immunity requirement (Table 1)

• Electrostatic discharge EN 61000-4-2:2009

• Radiated RF interference EN 61000-4-3:2006 inc.

A1:2008 & A2:2010

• Fast transient bursts EN 61000-4-4:2012

• Surge EN 61000-4-5:2014

• Conducted immunity EN 61000-4-6:2014

• Voltage dips and interruptions EN 61000-4-11:2004

Supplementary:

The product herewith is designed to comply with the requirements of the EMC

Directive 2014/30/EU and the Low Voltage Directive 2014/35/EU.

The symbols below are used throughout this user guide.

Caution or warning.

Hint or tip.

Page 2 19-461’02 Rev. D September 2017 RFM300-T

product bearing it should not be disposed of as general

waste or garbage which might end up in landfill sites, but

should instead be sent for special processing and/or

recycling in those countries where appropriate legislation

Electrical hazard.

Section 1: Installation

Instrument overview ............................................................................... 4

Menu flow chart ....................................................................................... 5

Unpacking ................................................................................................ 7

Contents list .................................................................................. 7

Positioning the system ........................................................................... 8

Mains connection .................................................................................... 8

Power requirements ..................................................................... 8

Warning ........................................................................................ 8

RFM300-T 19-461’02 Rev. D September 2017 Page 3

Instrument overview

The RFM300-T Series Refractometer is a self-contained easy to use

instrument suitable for measuring the refractive index of samples in

demanding factory environments as well as for use as a primary quality

control tool.

The instrument is housed in a case which is light in weight whilst being

extremely rugged. The ergonomic design ensures spills are dealt with by

the sloping of the case and the PEEK spill barrier and stainless steel

prism dish gasket ensure high resistance to chemical attack from the

majority of commonly used samples. The large sampling area on the

prism surface allows measurements of not only homogenous fluids like

juices, sodas and edible oils but also difficult to read samples like fruit

pulps and industrial resins.

Sample temperature is controlled by the Peltier Temperature control

system and intelligent temperature management which enables rapid

stabilisation and little noise. The low profile sample dish and non-contact

presser makes sample application and cleaning easy.

A high definition, capacitive touchscreen display facilitates operation in

factory environments, even when operated whilst wearing gloves, and the

GUI helps the operator quickly manoeuvre through the user and

configuration menus. On-screen graphical prompts support simple

operation such as method loading, calibration and routine maintenance.

The instruments conform to a number of industry measurement

standards and offer operational features that allow use in an environment

controlled by FDA regulation 21 CFR Part 11. Built in RFID technology

helps provide clearance and a log of operator and configuration functions.

Readings can be printed via USB, serial or network ports. Alternatively

they can be stored in a database or as secure PDFs to later download via

either a USB removable storage device or across a local area network.

A wide range of accessories including printers, barcode readers and USB

keyboards is available.

Page 4 19-461’02 Rev. D September 2017 RFM300-T

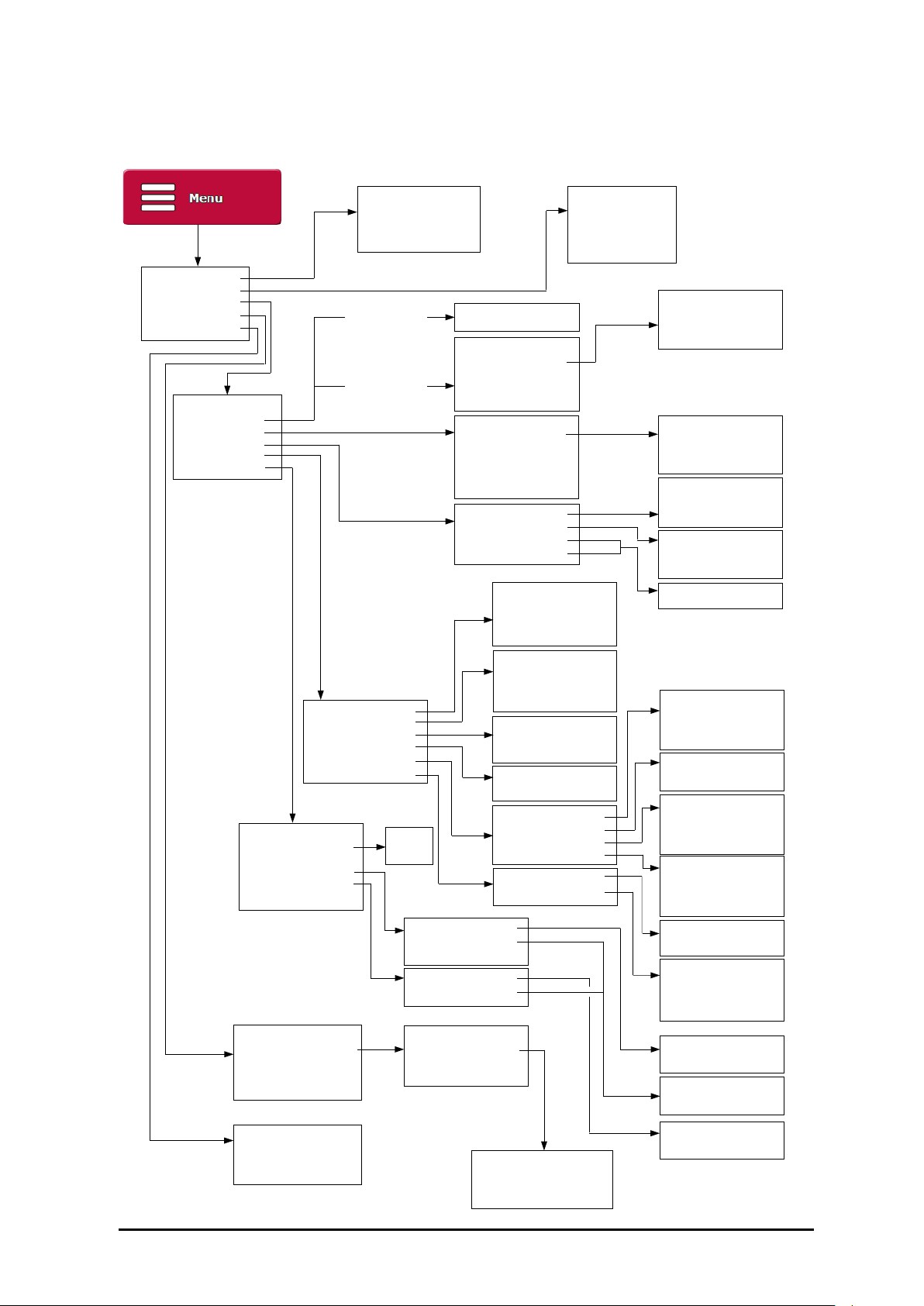

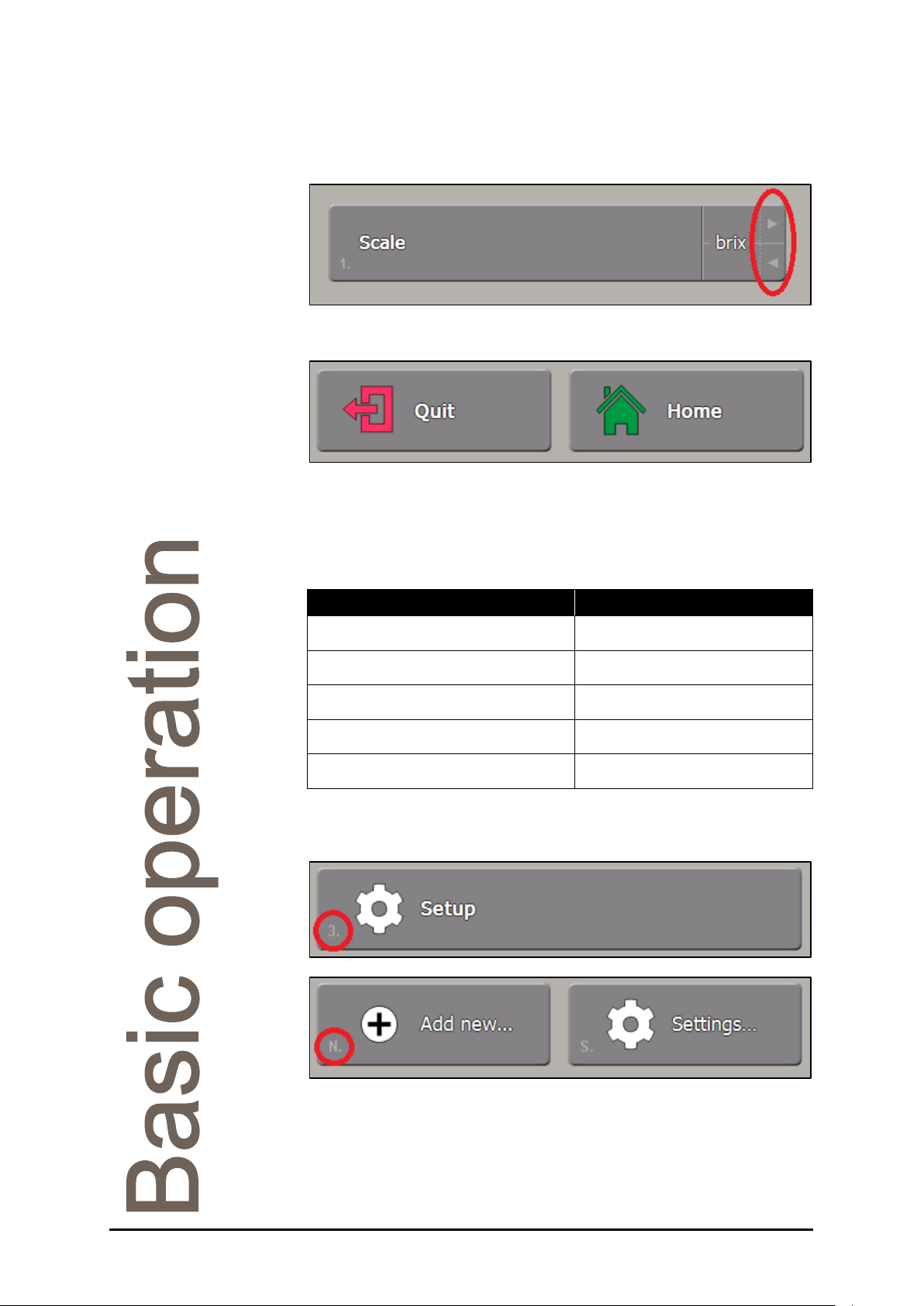

Menu flow chart

1. Calibration

2. Data

3. Setup

4. Maintenance

5. Help

1. Setup Wizard…

2. Methods

3. Users

4. Reading

5. Recording

6. System

1. Zero

2. Span (Top Calibration)

3. Undo

4. Report

If Methods are

not enabled

If Methods are

enabled

1. Use Methods

N. Add new…

S. Settings…

1. normal

2. zero

3. span

N. Add new…

P. Protection

1. administrator – 000

2. calibrator – 355

3. operator – 123

(default PINS shown)

1. Recurrence

2. Appl. Correction

3. Scales

4. Temp. Comps

1. none 5. statistics

2. single 6. multi

3. save

4. single + save

1. Saved Results

2. System Log

3. Copy PDFs to USB

4. Move PDFs to USB

5. Export logs to CSV

1. Use Methods

2. Hide Preset

3. Selection Type

4. Print List…

1. low

2. medium

3. high

4. custom

1. single

2. continuous

3. auto single

1. none

2. offset

3. citric acid

N. Add new…

1. Mode

2. Printer

3. CSV (Lims)

4. Record After Read

5. Traceability

6. Ports

1. Language

2. Remote Display

3. Display Brightness

4. Time / Date

5. Temp. Control

6. Clone From Backup

1. Maintenance Report

2. Filter Change Reminder

3. Backup to USB

4. Clean Screen

5. Update Software

1. off

2. on

1. Date Format

2. Summer Time

3. Set Clock

1. Mode

2. Disable Presser

1. New Filters Fitted

2. Frequency

3. Last Changed

4. Replacement Status

1. none 5. network

2. serial

3. usb

4. pdf

1. none 4. usb

2. serial

3. network

1. no

2. yes

1. Batch Codes

2. Auto Increment

3. Log Users

4. Remember Text

1. Serial Port

2. Network

1. off

2. number

3. text

4. dateinc

1. off

2. on

1. off

2. number

3. text

4. login

1. off

2. batch

3. user

4. batch and user

1. Baud Rate

2. Word Length

1. DHCP

2. IP Address

3. Subnet Mask

4. Default Gateway

1. dd/mm/yy

2. mm/dd/yy

1. no

2. yes

1. Information

2. Contact

3. User Guide

4. PC Software

1. off 5. 2 months

2. 1 week 6. 3 months

3. 2 weeks 7. 6 months

4. 1 month

1. off

2. on

RFM300-T 19-461’02 Rev. D September 2017 Page 5

Page 6 19-461’02 Rev. D September 2017 RFM300-T

Refractometer module

only

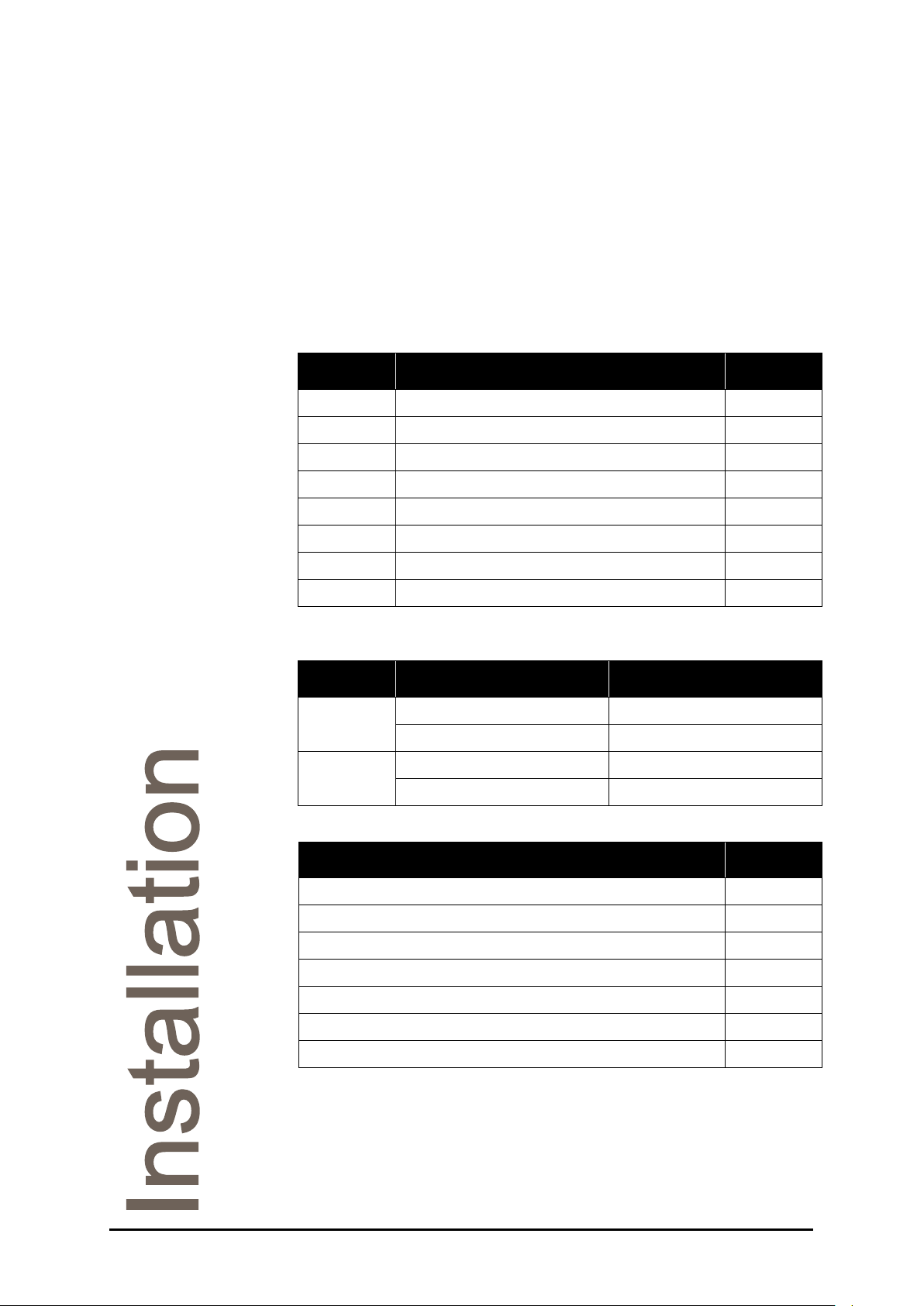

Unpacking

Carefully remove all of the packing material. It is recommended that the

box and other packing materials are retained so that, should the need

arise, the refractometer can be safely returned to the supplier for service.

Check that all parts listed below are present and that no transit damage

has occurred. If any are damaged or missing, contact the supplier

immediately.

Contents list

Quantity Item Code

1 RFM300-T Series Refractometer See below

1 Mains lead See below

1 Power supply 55-105

1 Quick Start Guides 19-406

2 Card type ID tag 37-530

2 Spare air vent filter 22-482

2 Touchscreen stylus 19-203

1 Touchscreen protector 19-204

RFM300-T refractometer code numbers:

Model Complete refractometer

RFM330-T

RFM340-T

Mains lead code numbers:

Moulded plug type for Code

Switzerland 61-181

Denmark 61-182

India / South Africa 61-188

Australia 61-189

19-30 19-330

19-31 19-331

19-40 19-340

19-41 19-341

RFM300-T 19-461’02 Rev. D September 2017 Page 7

UK 13 Amp square pin to BS1363/A 61-191

United States (3 pin) 61-192

Europe (Schuko) 61-193

Positioning the system

Place the instrument on a flat and stable bench that is:

• Dry and indoors.

• Capable of holding the instrument’s weight.

• Away from draughty or hot equipment like fans or heaters.

• Out of direct sunlight or strong ambient light.

• Away from potential sources of interference, such as RFI

generating equipment.

• Within reach of a power point.

• Not using a power circuit that also has large motors or noise

generating equipment connected to it.

Do not block the air vents.

Mains connection

The power supply adapter is supplied with a moulded mains cord and

plug to suit one of several socket types. For UK leads, replace the fuse

only with the type indicated on the plug.

Power requirements

Voltage 110 to 230 V ~ ±10%

Frequency 50 to 60 Hz

Maximum current 2 A

Warning

RISK OF ELECTRIC SHOCK:

• For indoor use only.

• Must be kept dry.

• Disconnect the equipment from the mains supply before

unplugging the mains lead from the instrument.

WARNING:

• Do not cover, designed to operate with free air convection.

• No cleaning required

A waterproof power supply adaptor, code no. 55-250, which can be used

in damp environments, is available as an optional extra.

Page 8 19-461’02 Rev. D September 2017 RFM300-T

Section 2: Instrument

operation

Basic operation ..................................................................................... 11

Switching on and off ................................................................... 11

Manoeuvring through menus ..................................................... 11

Setup Wizard .......................................................................................... 13

Measurement Display ........................................................................... 14

Title Bar ...................................................................................... 15

Reading display and data ........................................................... 17

Reading configuration ................................................................ 18

Action Buttons ............................................................................ 18

Menu Buttons ............................................................................. 19

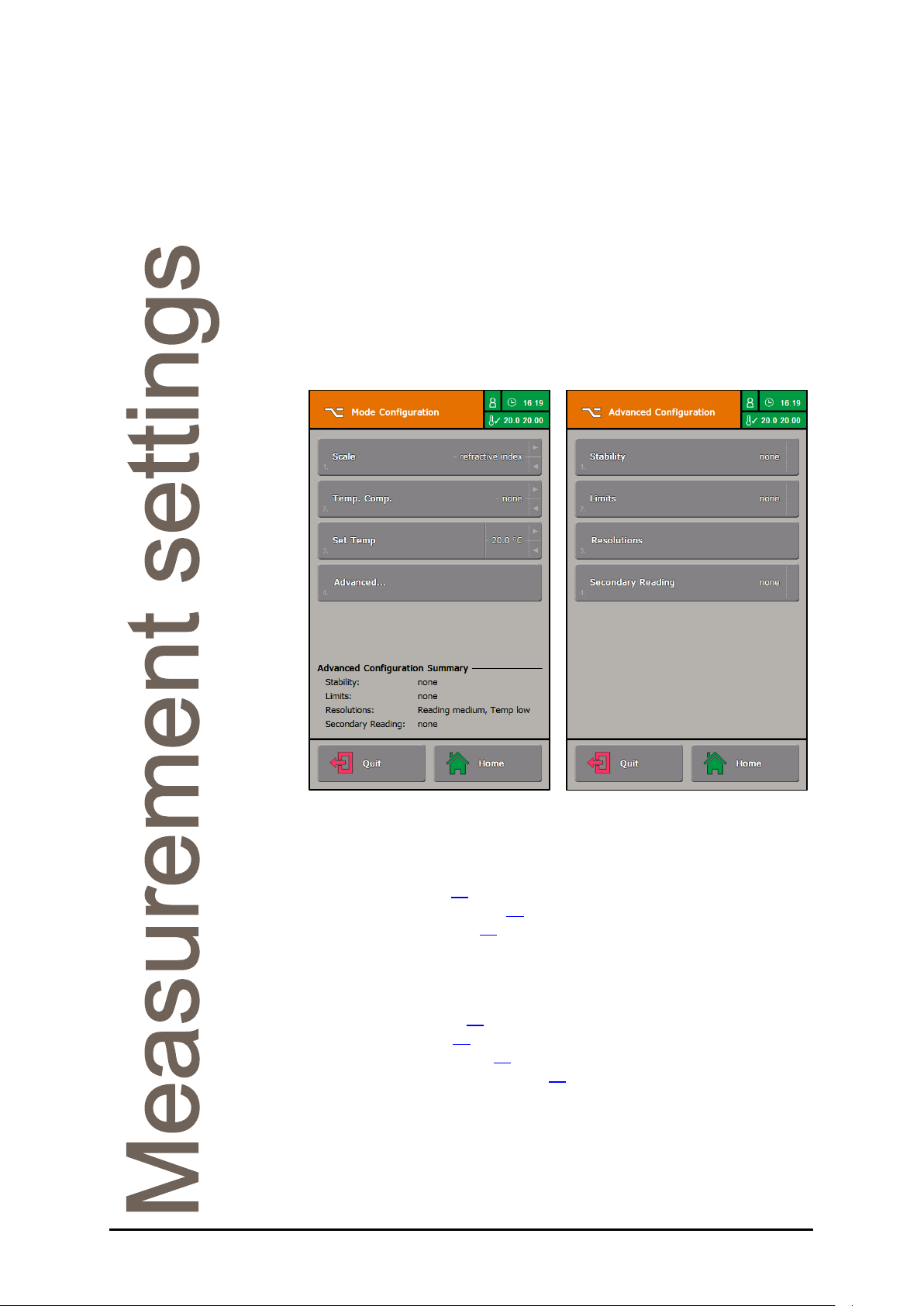

Measurement settings .......................................................................... 20

Changing settings ....................................................................... 20

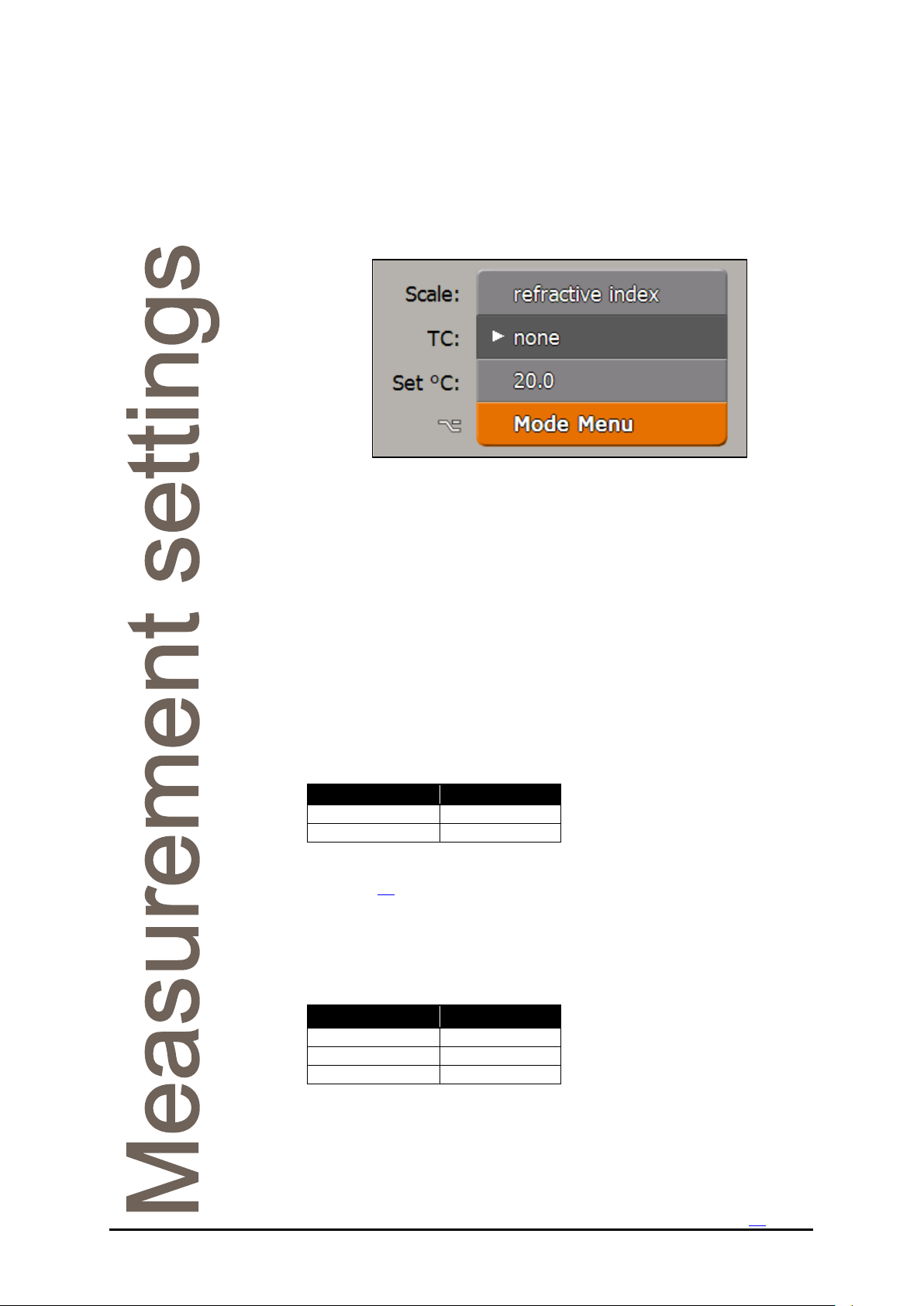

Using the Reading Configuration Panel ..................................... 21

Basic settings ............................................................................. 21

Scale........................................................................................... 21

Temp. Comp. (temperature compensation) ............................... 21

Set Temp (temperature control set-point) .................................. 22

Advanced settings ...................................................................... 22

Stability ....................................................................................... 22

Limits .......................................................................................... 24

Resolution .................................................................................. 25

Secondary reading ..................................................................... 25

Using Methods ........................................................................... 26

Calibration and Reading ....................................................................... 27

Zeroing the instrument ............................................................... 27

Auto Zero .................................................................................... 28

Taking a reading ......................................................................... 28

Span calibration .......................................................................... 29

Undo calibration ......................................................................... 29

Calibration report ........................................................................ 29

Saving results ........................................................................................ 30

Set the print mode ...................................................................... 30

Print formats ............................................................................... 31

Traceability ................................................................................. 31

Batch codes ................................................................................ 32

User codes ................................................................................. 32

RFM300-T 19-461’02 Rev. D September 2017 Page 9

Remember text ........................................................................... 32

Statistics print mode ................................................................... 33

Data Menu .............................................................................................. 35

The Reading Log ........................................................................ 35

The System Log ......................................................................... 36

Downloading Logs ...................................................................... 36

Downloading PDFs ..................................................................... 36

PDF and FTP ............................................................................. 37

Page 10 19-461’02 Rev. D September 2017 RFM300-T

Basic operation

Switching on and off

Plug in the power supply and switch on the mains supply, after startup

the instrument will show a loading screen indicating the software version.

Once loaded, the instrument will be in standby mode. To switch on, swipe

a finger or stylus across the display. After a few moments the instrument

will show the Measurement Display (or the Setup Wizard if switching on

for the first time). An Auto Zero will be requested once the instrument

temperature has stabilised, see Page 27

To switch to standby mode press and hold the Menu Button for several

seconds and select Yes on the confirmation screen. It is then safe to turn

off the mains supply and disconnect the power lead.

Manoeuvring through menus

The RFM300-T Series Refractometer features a capacitive, highresolution touchscreen display. On-screen buttons can be easily used by

simply touching the display. A compatible stylus can also be used, as

supplied with the instrument.

Use the supplied stylus and screen protector to keep the touchscreen

clean and avoid damage from improper use. The touchscreen should

only be used with a finger or stylus designed for use with a capacitive

touchscreen.

Alternatively, a USB keyboard, available from Bellingham + Stanley, can

be used to select items and navigate menus. The USB keyboard can

perform the following actions from the Measurement Display.

.

USB keyboard key Function

F1 / Space Start a reading

F2 / Enter Print / Save the current reading

F3 / z Zero

F4 / m Open Mode / Methods

F5 / Esc Open Main Menu

F6 / d Data

Left / Right Logout

Whilst in a Menu, options that are currently unavailable will appear faded.

RFM300-T 19-461’02 Rev. D September 2017 Page 11

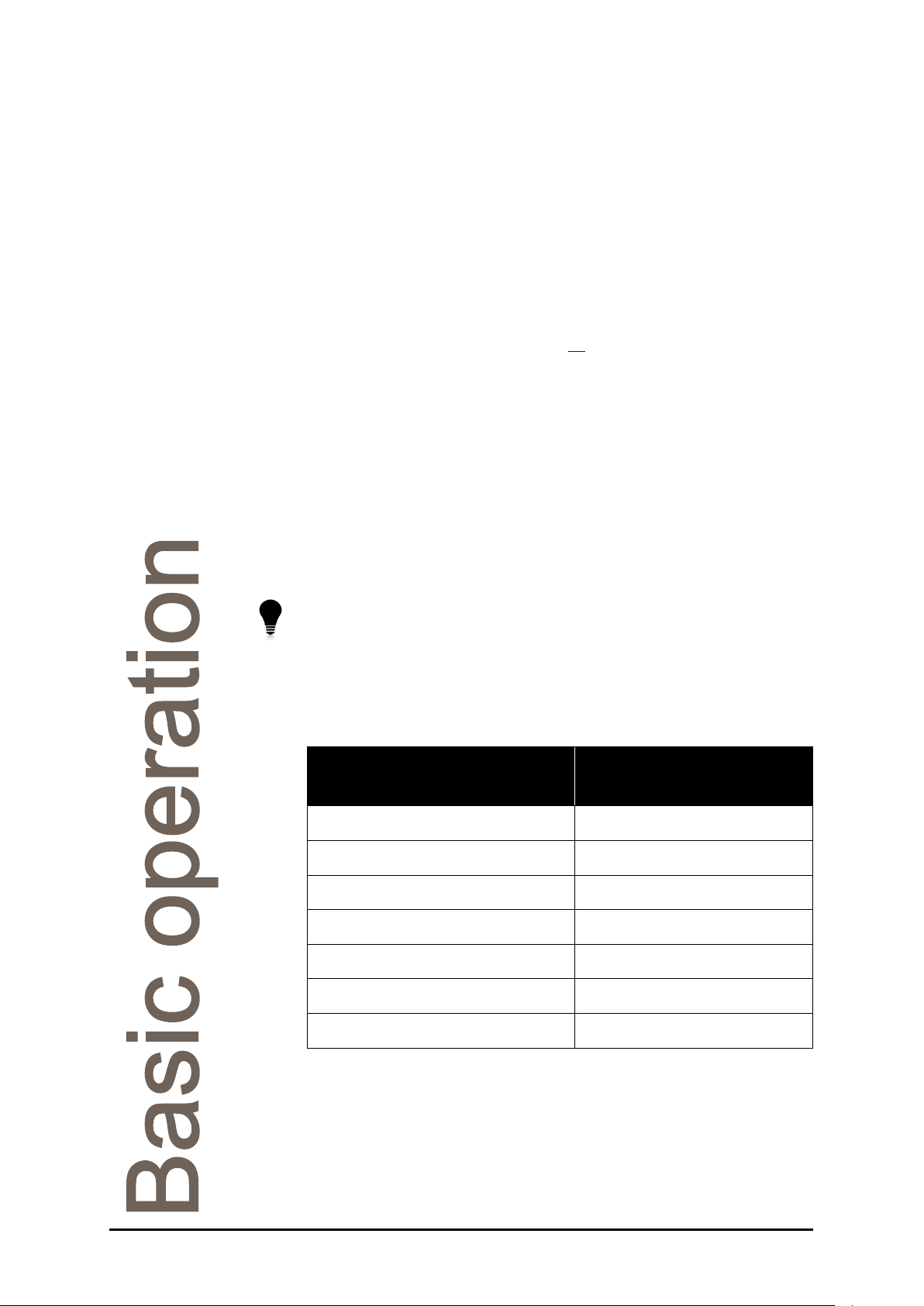

Many buttons feature a quick select option, indicated by the two arrows

on the right of the button. Simply touch either arrow to cycle through the

possible settings.

When in a menu, the Quit and Home buttons become available.

Press the Quit Button to return to the previous menu. Any changes made

will be saved. The Home Button will exit to the Measurement Display,

again any changes made will be saved.

The USB keyboard can be used for Menu navigation.

USB keyboard key Function

Up / Down Change highlighted button

Enter Push highlighted button

Left / Right Cycle quick select options

Esc Quit

Shift + Esc Home

The USB keyboard also allows menu items to be selected by pressing

the related number or letter shown on the left of the on-screen buttons.

Text or number entry boxes can be completed with either the on-screen

keypads or a USB keyboard.

Page 12 19-461’02 Rev. D September 2017 RFM300-T

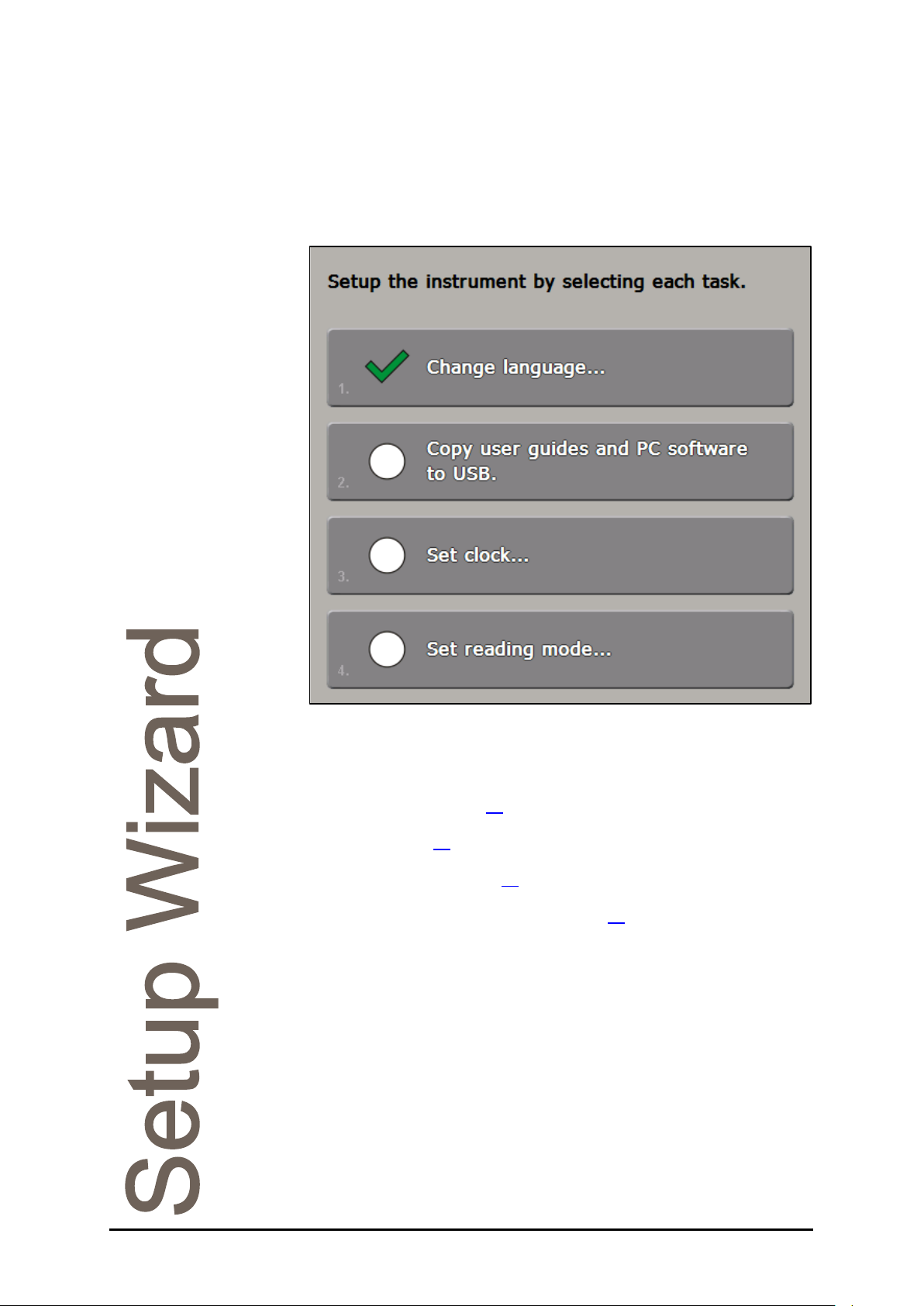

Setup Wizard

When switching on for the first time, after the instrument has completed

its startup procedures, the Setup Wizard will appear. First select the

desired language. A list of different options will then appear.

• Copy user guides and PC software to USB: Makes copies of

all user guides and PC software compatible with the instrument

to a removable USB storage device.

• Set clock: Set the instrument to local time and set the date

format, see Page 60

• Set reading mode: Make changes to the measurement settings,

see Page 20

• Set record settings: Specify how reading results will be printed

or saved, see Page 30

• Set user settings: Alter the security settings to a level suitable

for the area of operation, see Page 42

Select each in turn and alter the settings as desired, then press Quit to

return to the Setup Wizard Menu. Each menu will be marked by a tick

after the settings are altered.

Once all required settings are changed press Quit on the Setup Wizard

Menu to show the Measurement Display.

.

.

.

.

RFM300-T 19-461’02 Rev. D September 2017 Page 13

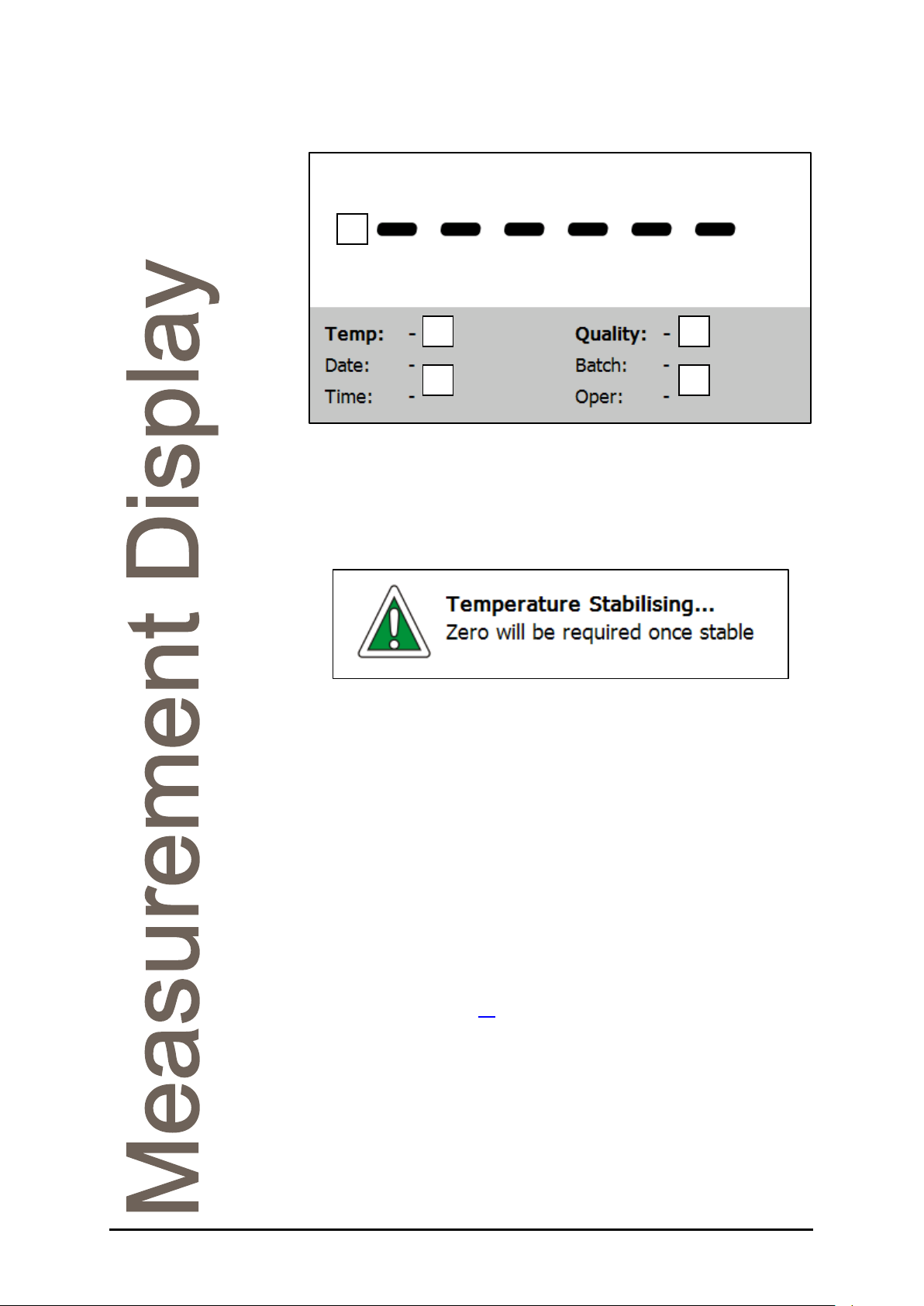

Measurement Display

From the Measurement Display readings can be taken, viewed and

saved. Quick access to all the frequently used features of the instrument

is also available.

Title bar

Reading

display and

data

Reading

configuration

Action

buttons

Menu

buttons

Page 14 19-461’02 Rev. D September 2017 RFM300-T

Title Bar

The title bar contains several elements that will be displayed on every

screen.

1

1. Title: Current location within the instrument’s menu structure.

The colour of the title bar will change depending on the current operation.

Red: In the Main Menu structure. This indicates that changes will be

made to the instrument’s settings.

Orange: In Modes/Methods. Changes made will affect the measurement

settings.

Green: Associated with taking and initiating readings.

Blue: Within a process that affects how the current reading will be printed

or saved.

Purple: For calibration requests.

Brown: Whilst exporting or viewing saved readings, logs or PDFs.

These colours are replicated on the associated Action and Menu buttons.

If security settings are in use, the username of a logged-in user will also

appear here whilst in the Measurement Display and in the Main Menu.

3 2

4

Pressing the title bar will also log out the current user. User accessibility

is discussed in detail from Page 42

2. Security status: A further indicator for whether a User is logged in,

displayed in all menus within the instrument.

Users logged out, symbol orange

User logged in, symbol green

3. System clock: Shows the current system time in a 24 hour format. To

alter the time, see Page 60

RFM300-T 19-461’02 Rev. D September 2017 Page 15

.

.

4. Temperature control status: Displays the stability status, prism set

temperature and current prism temperature. The colour and status

symbol will change depending on the set-point temperature and the

measured temperature.

• Temperature stable

The tick indicates that the measured prism temperature (second value) is

stable to within ±0.05°C of the set-point temperature (first value).

• Temperature stabilising

This will often occur when applying a fresh sample which has a

significantly different temperature to the prism.

The stability symbol oscillates to show that the prism temperature is not

yet stable.

• Temperature changing

This will occur when the temperature set-point is changed or after the

instrument is switched on.

The stability symbol becomes a cross and there can be a significant

difference between the measured temperature and the set-point

temperature.

An Auto Zero will be required after changing the temperature set-point,

see Page 28

.

• Temperature control off

If the instrument temperature control is turned off (see Page 61

) the

control status will turn red.

Page 16 19-461’02 Rev. D September 2017 RFM300-T

Reading display and data

1

2 3

4 5

1. Reading result: After taking a reading, the final result will be displayed

here. The result will be displayed in the units set in the Mode/Method,

shown in the reading configuration section of the Measurement Display.

Warning and alert messages will also appear here. For example, after the

temperature set-point is changed, a Zero calibration will be requested.

2. Temperature: The temperature that the prism was at when the

reading was recorded will be displayed here.

3. Quality: The Quality figure is derived from the optical pattern that falls

upon the instrument detection system. A high Quality value indicates that

the optical pattern is well-defined, making the reading signal easy to

resolve. A low Quality value, caused for instance by an opaque sample or

poor sample application, means a less well defined optical pattern so the

reading will be less reliable.

The Quality value for the sample used to set Zero is automatically set to

100, which can then be used as a reference with which to compare other

measured samples.

4. Date/Time: When the displayed result was obtained.

5. Traceability data: Displays batch and operator codes associated with

each reading. See Page 31

for details on traceability settings.

RFM300-T 19-461’02 Rev. D September 2017 Page 17

Reading configuration

1

2

1. Reading Configuration Panel: Displays the measurement settings for

the currently displayed reading or, if a result is not currently displayed,

the settings to be used for the next reading. It also allows for quick

changes to the Basic reading settings, see Using the Reading

Configuration Panel, Page 21

2. Mode button: Gives access to edit all Basic and Advanced reading

settings (Page 20

When working with Methods the Reading Configuration Panel is disabled,

see Page 39

).

.

.

Action Buttons

2

1

3

1. Read button: Initiates a reading. Readings will be taken in the manner

described in Mode or the current Method, the Basic settings can be seen

in the Reading Configuration screen section.

If using continuous read mode (Page 51

the Read button.

Holding down the Read button for several seconds will display the

Reading setup menu.

Page 18 19-461’02 Rev. D September 2017 RFM300-T

) a progress bar will appear on

1

2

2. Record button: If a result has yet to be printed or saved and a printer

is set, the record icon will appear grey. Pushing the button will record the

result to the Reading Log (Page 35

settings, see Page 30. The record icon will then turn red.

) or printer depending on the print

If the print mode is set to record after read (Page 30

be red permanently.

Holding down the Record button for several seconds will display the

Recording Menu for quick change of printer settings.

3. Zero button: Initiates a Zero calibration routine. A Zero can be

performed with any sample but distilled water is typically used. See Page

for Zero calibration procedure and recommendations.

27

Holding down the Zero button for several seconds will open the

Calibration Menu.

) the record icon will

Menu Buttons

1. Menu button: Opens the instrument’s Main Menu from where all

instrument settings can be changed. Hold for several seconds to switch

the instrument to standby.

2. Data button: Opens the Data Menu, this includes viewers for saved

results and the System Log (see Page 35

download the results and any saved PDFs.

Holding down the Data button for several seconds will open the Saved

Results viewer.

RFM300-T 19-461’02 Rev. D September 2017 Page 19

) as well as the ability to

Measurement settings

The measurement settings affect how a reading is collected and

presented. If different sets of measurement settings are required then

Methods can be enabled. For simplicity, the instrument is supplied in

Mode operation.

Changing settings

To change measurement settings press the orange Mode button. The

Mode Configuration is divided into two screens with Basic and Advanced

settings.

The Basic settings change the way a result is calculated, for example the

scale units and temperature compensation applied, and also allows

changes to temperature. The Basic settings are:

• Scale, Page 21

• Temp. Comp., Page 21

• Set Temp, Page 22

The Advanced settings allow the use of additional criteria to affect how a

measurement is taken and displayed. The Advanced settings are:

• Stability, Page 22

• Limits, Page 22

• Resolutions, Page 25

• Secondary Reading, Page 25

Once set, press the Quit button or Home button to return to the

Measurement Display. Changes to the Basic settings will be displayed on

the Reading Configuration section of the screen, ready for the next

reading.

Page 20 19-461’02 Rev. D September 2017 RFM300-T

Scale name

Scale ID

Refractive Index

ri

Brix

bx

TC name

TC ID

none

no

sugar

su

ag fluid

ag

Using the Reading Configuration Panel

Basic settings can be changed with the Reading Configuration Panel.

To change a setting, touch and hold the panel and an arrow will appear

next to the selected item. If the wrong item is selected, the user can slide

their finger up or down until the required item is highlighted.

When the arrow is next to the desired item, release the screen. The

options for the selected item will then be displayed.

Changing settings in this manner overwrites the settings in the Mode

Menu, a login may therefore be required if PINs are active.

Basic settings

The following settings can be changed in the Mode Menu, in each

Method or with the Reading Configuration Panel.

Scale

By default the available scales are:

Many other pre-installed scales, as well as custom scales, can be added,

see Page 53

.

RFM300-T 19-461’02 Rev. D September 2017 Page 21

Temp. Comp. (temperature compensation)

By default the available temperature compensation modes are:

Sugar compensation operates in accordance to ICUMSA in the range 10

to 40°C and has been extended to cover the range 5 to 70°C.

Ag fluid compensation can be used with Bellingham + Stanley’s range of

AG Fluid calibration materials, see the Accessories section.

Additional temperature compensations can be added, see Page 56

.

Set Temp (temperature control set-point)

The temperature control system in the instrument can be set over a wide

range of temperatures. In many situations, it is likely that all samples will

be measured at the same temperature, e.g. 20°C for a bottling plant or

70°C for a preserves factory.

Some manufacturers, who produce a range of different products for

different markets at one facility, may need to measure samples at more

than one temperature. However, temperature changes must be used with

care. Due to the time required for stabilisation it is not practical to

continually adjust the temperature set-point for every sample.

After changing the Set Temp, the instrument will inhibit measurement

until the system has stabilised and a Zero calibration has been carried

out (see Page 28

will be more practical if, say, all samples to be measured at 20°C were

carried out in a morning session and then those at 70°C in the afternoon.

The temperature of the stainless steel prism plate will be similar to

the temperature control set-point and so could become extremely

hot. Direct contact with skin should be avoided when applying

sample or cleaning the prism plate at temperatures above 50°C.

for information on Auto Zero). Changing the set-point

Advanced settings

Advanced settings can be changed in the Mode Menu or in the individual

Methods. They cannot be changed via the Reading Configuration Panel.

Stability

Stability sets conditions that must be met before a reading will be taken.

Stability can be set to:

• none

• delay

• repeatability

• SMART

Delay causes a wait period before measurements are initiated after

pressing the Read button. This delay provides a fixed time for the sample

to stabilise on the prism and to achieve thermal equilibrium throughout

the sample mass.

Page 22 19-461’02 Rev. D September 2017 RFM300-T

Loading...

Loading...