Belling 864 Installation And User Instructions Manual

2

CONTENTS

INTRODUCTION page 3

INSTRUCTIONS FOR THE INSTALLER pages 4-10

FOR YOUR OWN SAFETY page 11

KNOW YOUR COOKER pages 12-13

OVEN TIMER OPERATION pages 14-15

USING THE GAS HOB page 16

USING THE GAS HOB - GENERAL NOTES pages 17

GRILLING page 18

TOP OVEN COOKERY NOTES page 19

TOP OVEN COOKERY CHARTS page 20

MAIN OVEN COOKERY NOTES pages 21-22

MAIN OVEN COOKERY CHARTS page 23

CLEANING AND MAINTENANCE page 24

IS THERE SOMETHING WRONG WITH YOUR COOKER? pages 25-26

SERVICE page 27

The appliance was designed and made in accordance with the European standards listed below:

• EN 30-1-1, EN 30-2-1 and EN 437 plus subsequent amendments (gas)

• EN 60 335-1 and EN 60 335-2-6 (electrical) plus relative amendments

The appliance complies with the prescriptions of the European Directives as below:

• 73/23 + 93/68 EC concerning electrical safety (BT).

• 89/336 + 92/31 + 93/68 EC concerning electromagnetic compatibility (EMC)

• 90/396 + 93/68 EC concerning gas safety.

Oven accessories that could come into contact with foodstuffs are made with materials that comply

with the provisions of the 89/109 EC directive dated 21/12/88.

G83

Your Belling Cooker

Thank you for purchasing a new Belling Dual Fuel Cooker . Its stylish and practical design will enhance

your kitchen and make cooking a pleasure. Dependant on model, it features a large electric main fan

oven with a light, separate top oven and a grill. The hob features four gas burners with push button

ignition. Some models also feature a clock/timer with minute minder and an automatic main oven

switch on and off function as well as a toughened glass lid with safety shut off valve.

Even if you have used a gas or electric cooker before, it is important that you read these instructions

thoroughly before starting to cook, as there may be many new features not featured on your previous

cooker. Pay particular attention to the installation and safety instructions.

Getting Help

If you have any problems with installation, operating or cooking with your Belling cooker please

check through these instructions thoroughly to make sure that you have not missed anything. If you

still need help, then please contact (including a daytime telephone number if possible):

INTRODUCTION

3

Consumer Relations Department

Belling Appliances Ltd.,

Talbot Road,

Mexborough

South Y orkshire.

S64 8AJ.

G83

BELLING HELP LINE Tel: 01709 579902

Please quote the cooker model and serial number with your enquiries. This can be found on the rating

label, positioned on the rear panel of the cooker

WARNING! For your own safety, make sure that these instructions on installation, use and

maintenance are followed.

We advise you to keep these instructions in a safe place for future reference.

If you sell or transfer ownership of this product, please pass on these instructions to the new owner.

Note: the pictures shown in the figures in this handbook are purely indicative.

4

INSTRUCTIONS FOR THE INSTALLER

TECHNICAL INFORMATION

• All installation and maintenance must only be

carried out by qualified personnel. The manufacturer

cannot be held responsible for any damage to

persons or property resulting from an incorrect

installation of the appliance.

• The appliance must only be used for its original

purpose, that is, cooking for domestic use.

• The manufacturer cannot be held responsible for

any damage to persons or property resulting from

an incorrect installation, maintenance or use of the

appliance.

• The electrical safety of this appliance is only

guaranteed if it is correctly connected to a suitable

earth system, as prescribed by the electrical safety

standards. The manufacturer disclaims all

responsibility if these instructions are not followed.

Should you have any doubts, seek the assistance

of a qualified person.

• Before connecting the appliance ensure that the

rating plate data corresponds to that of the gas and

electricity supply.

• The safety and automatic adjustment devices of

the appliance may, during its life, only be modified

by the manufacturer or duly authorised supplier.

UNPACKING YOUR COOKER

• Remove all packaging before use and check to

make sure that the appliance is in perfect condition.

If you have any doubts do not use the appliance

and call your supplier for advice.

• Do not move the appliance using the handles.

Some parts on the appliance may be protected by a

plastic film. This protective film must be removed before

the appliance is used. W e recommend carefully slitting

the plastic film along the edges with a sharp knife or

pin.

The packaging materials should carefully

discarded and not left within easy reach of

children, as they are a potential safety hazard.

Prior to installation, ensure that the local distribution

conditions (nature of the gas and gas pressure) and the

adjustment conditions are compatible. The factory set

adjustment conditions for this appliance are stated on

the rating label, which is fitted to the back panel of the

appliance.

This appliance is not designed to be connected to a

combustion products evacuation device. It must be

installed and connected in accordance with current

installation regulations. Particular attention should be

given to the relevant requirements regarding ventilation.

This appliance is factory set to burn NATURAL GAS (G20)

at 20mbar but can be converted by a suitably qualified

engineer to burn BUTANE (G30) at 28-30 mbar and

PROPANE (G31) at 37 mbar, using the kit supplied.

GAS SAFETY (INSTALLATION & USE)

REGULATIONS

It is the law that all gas appliances are installed by

competent persons in accordance with the current

edition of the above regulations. It is in your interest

and that of safety to ensure compliance with the law.

In the UK, CORGI registered installers work to safe

standards of practice.

The cooker must also be installed in accordance with

BS 6172: 1990.

Failure to install the cooker correctly could invalidate

the warranty liability claims and could lead to

prosecution.

LOCATION

The cooker may be located in a kitchen, kitchen/diner

or a bed-sitting room, but not in a room containing a

bath or shower. The cooker must not be installed in a

bed-sitting room of less than 20m3.

LPG models shall not be installed in a room or internal

space below ground level, e.g. in a basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air

supply in accordance with BS 5440:Part 2.

The room must have an opening window or equivalent;

some rooms may also require a permanent vent. If the

room has a volume between 5 and 10m3, it will require

an air vent of 50 cm2 effective area unless it has a door

which opens directly to outside. If the room has a volume

of less than 5m3, it will require an air vent of 100 cm2

effective area. If there are other fuel burning appliances

in the same room, BS 5440: P art 2 should be consulted

to determine air vent requirements.

G83

INSTRUCTIONS FOR THE INSTALLER

5

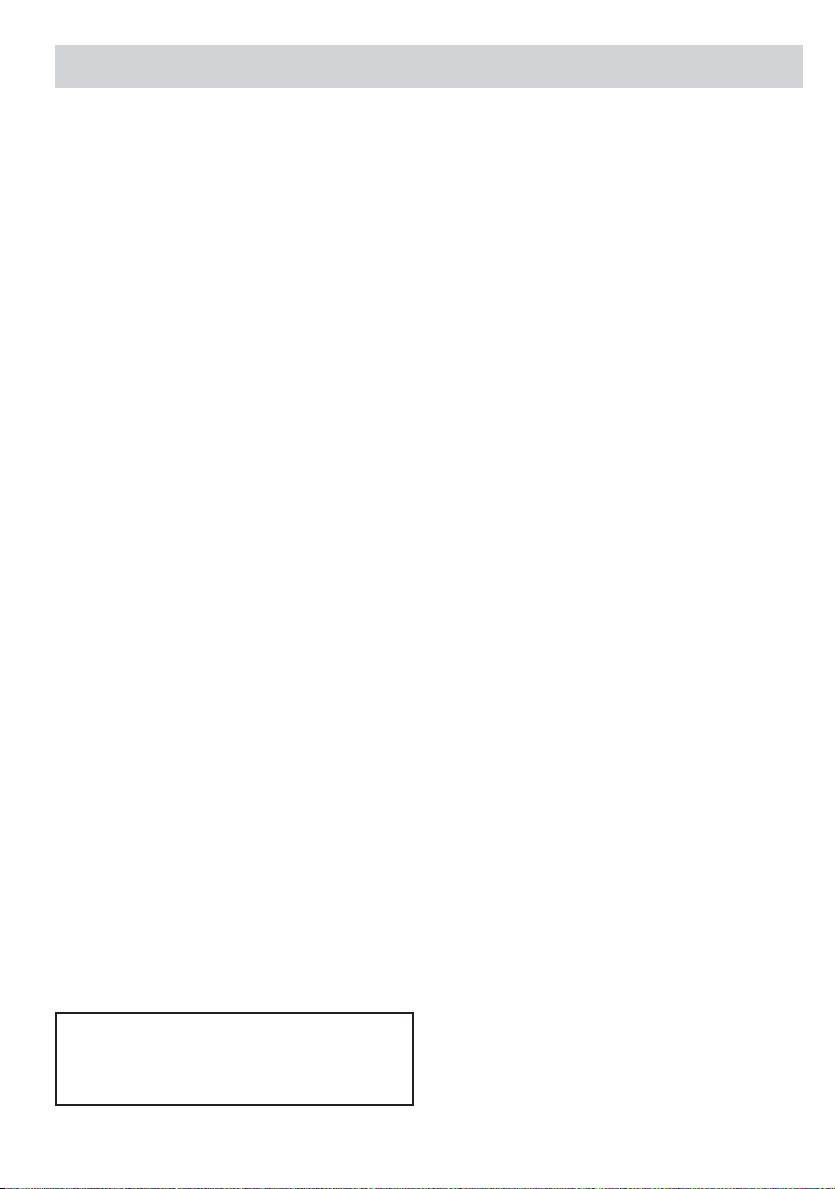

POSITION

The appliance should be positioned in good light and

free from draughts. Any shelf or cupboard of combustible

material should be at least 750mm above the hob top,

a greater clearance is desirable if discoloration is to be

avoided, otherwise the shelf etc. should be protected.

In accordance with the gas standards, the gas

appliances can be installed as “class 1” (free standing)

or “class 2 subclass 1” (recessed) and, as such, must

comply with the clearances specified in figures 1 and 2

respectively.

The rear wall and surfaces adjacent to or surrounding

the appliance must be able to resist a temperature rise

of 65(C. We recommend fitting ceramic tiles to protect

the surrounding surfaces.

NOTE: When installing the appliance adequate space

must be provided to allow the glass lid (where fitted) to

be opened to its fullest extent.

LEVELLING THE COOKER

• It is important that the cooker is placed on a firm

level surface and that the feet, are adjusted to

ensure that the cooker is perfectly level. An

unlevelled cooker can affect the cooking results.

To level the cooker simply adjust the feet (P) (See

diagram below) screwing up or down as required.

By turning these feet you can align the cooker height

with the adjacent work surfaces.

• The cooker is fitted with two spacers placed at the

rear part of the hob top, which ensures a minimum

distance between the appliance and the rear wall.

They must not be removed.

FIG.3

G83

FIG.2FIG.1

6

INSTRUCTIONS FOR THE INSTALLER

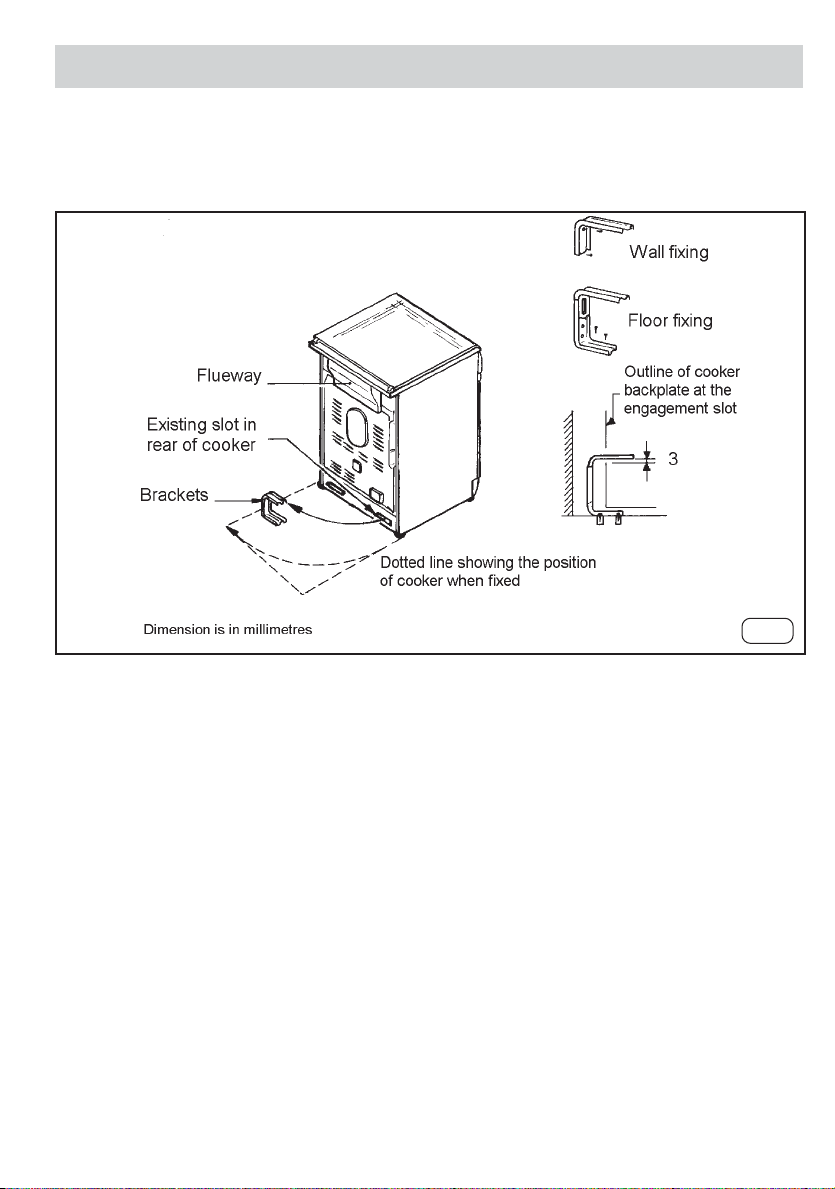

STABILITY BRACKET

We recommend a stability bracket is fitted to the cooker. The type shown in the diagram below can be purchased

from most plumbers merchants and DIY shops.

FIG.4

Note: The power supply cable must be positioned so that no part of the cable can come into contact with any

surface which could reach temperatures in excess of 75°C.

G83

INSTRUCTIONS FOR THE INSTALLER

7

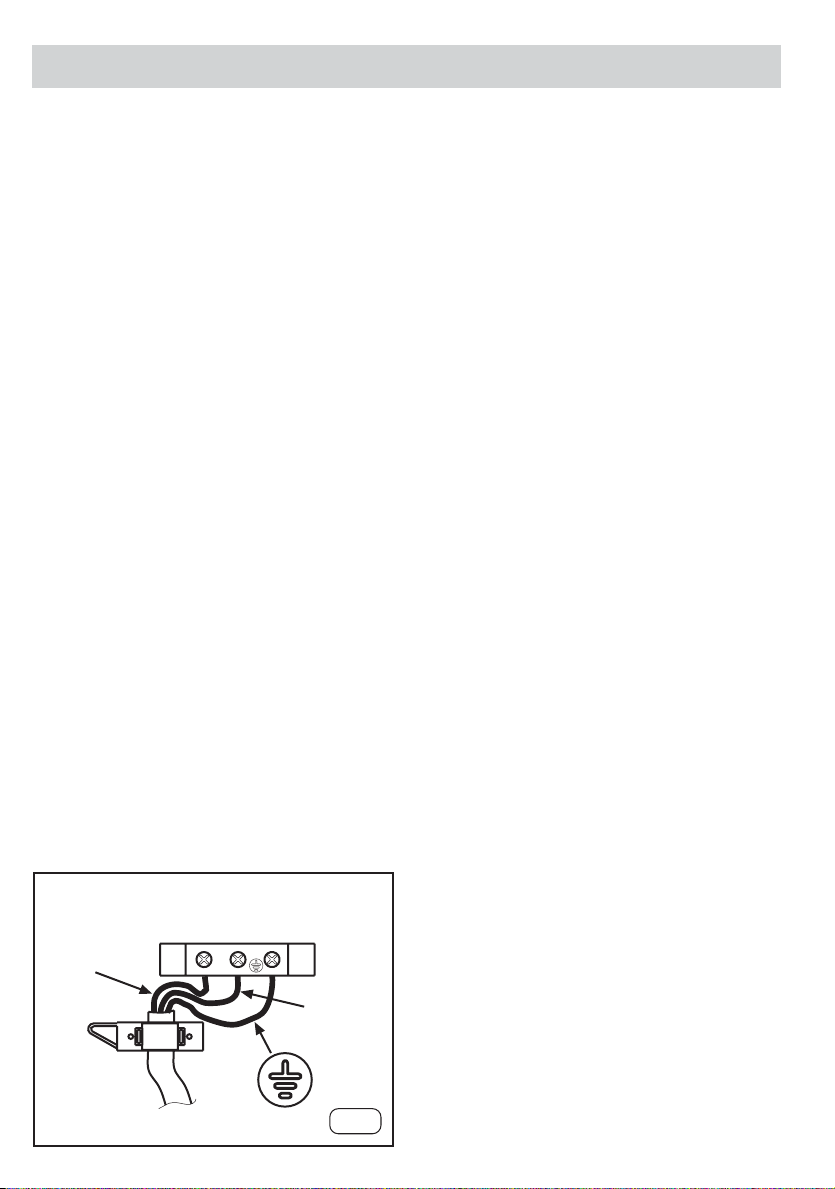

ELECTRICAL CONNECTION

WARNING! THIS APPLIANCE MUST BE EARTHED!

Your cooker should have been checked to ensure that

the voltage corresponds with the supply voltage, this is

stated on the rating plate, which is situated on the rear

of the cooker. The cooker must be connected by a

qualified electrician to a suitable double-pole control unit

with a minimum of 32A and a minimum contact

clearance of 3mm, which should be fitted adjacent to

(but not above) the cooker, in accordance with IEE

regulations. The power supply cable should conform to

BS6004. W e recommend P.V.C. insulated twin and earth

cable with a conductor size of 6mm2 .. The control unit

should be easily accessible in the event of an emergency .

This appliance conforms to EN55014 regarding

suppression of radio and television interference.

Allow sufficient cable length for the cooker to be pulled

out for cleaning, but do not let it hang c loser than 50mm

(2") to the floor. The cable can be looped if necessary,

but make sure that it is not kinked or trapped when the

cooker is in position.

Before you cook for the first time, we recommend that

you switch on each element in turn to burn off any odours

remaining from

manufacture. Simply operate the grill on maximum for

a few minutes, and the oven for approximately 30

minutes. Ensure that the room is well ventilated (eg.

open a window or use an extractor fan) and that persons

who may be sensitive to the odour avoid any fumes. It

is suggested that any pets be removed from the room

until the smell has ceased.

Connection to the mains terminal block as shown below.

It is accessed by removing the cooker back panel.

G83

L

LN

N

FIG.5

8

INSTRUCTIONS FOR THE INSTALLER

GAS CONNECTION

WARNING! This appliance is adjusted for NATURAL GAS

at 20 mbar ONLY.

The hob is suitable for conversion to Liquid Petroleum

Gas (BUTANE (G30) at 28-30 mbar and PROP ANE (G31)

at 37 mbar) by the follo wing procedure using the kit

supplied.

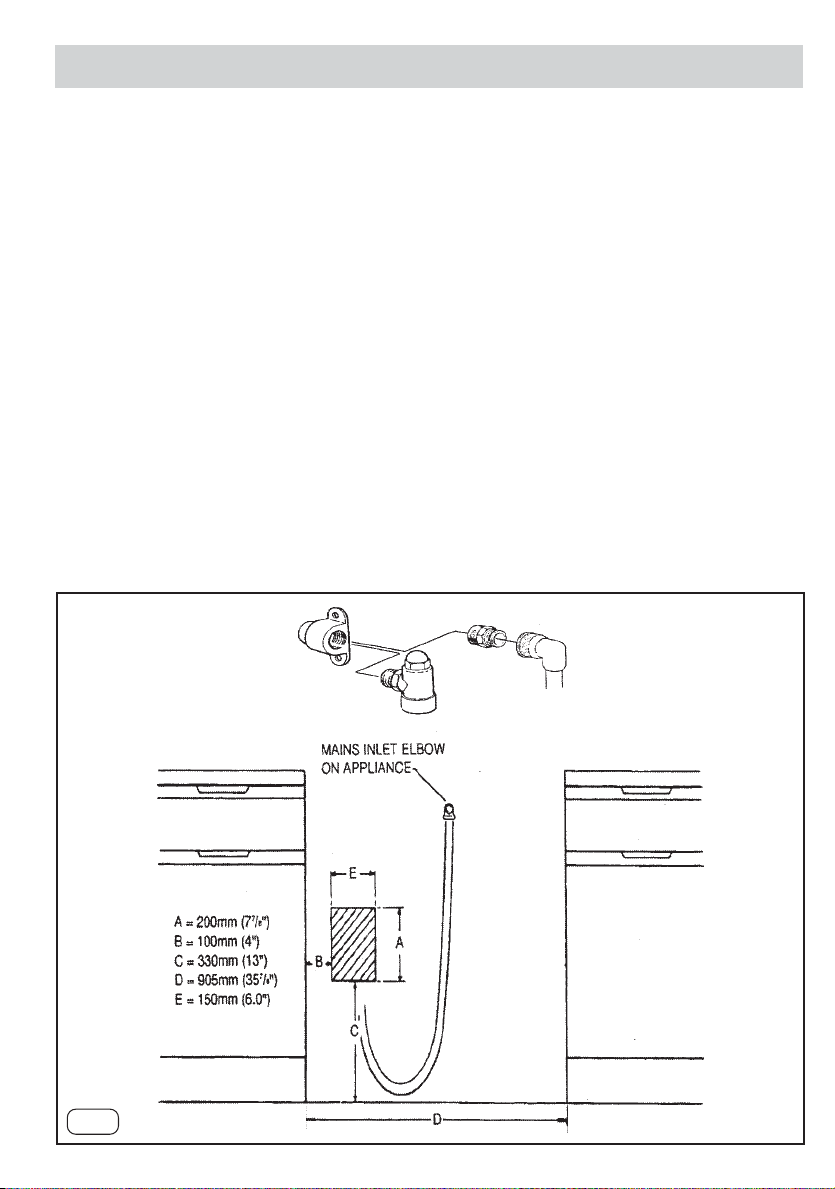

CONNECTING TO GAS SUPPLY

The cooker is designed to match the depth of standard

600mm worktops. An adaptor backplate should,

therefore, be fitted within the shaded area shown to

allow the cooker to be pushed fully to the wall.

Connection to the cooker should be made with an

approved appliance flexible connection to BS 669. A

length of 0.9 to 1.25m is recommended. The length of

hose chosen should be such that when the cooker is in

situ, the hose does not touch the floor.

LPG models should be connected with a hose suitable

for LPG and capable of withstanding a pressure of 50

mbar.

The temperature rise of areas at the rear of the cooker

that are likely to come in contact with the flexible hose

do not exceed 70ºC

FIG.6

G83

INSTRUCTIONS FOR THE INSTALLER

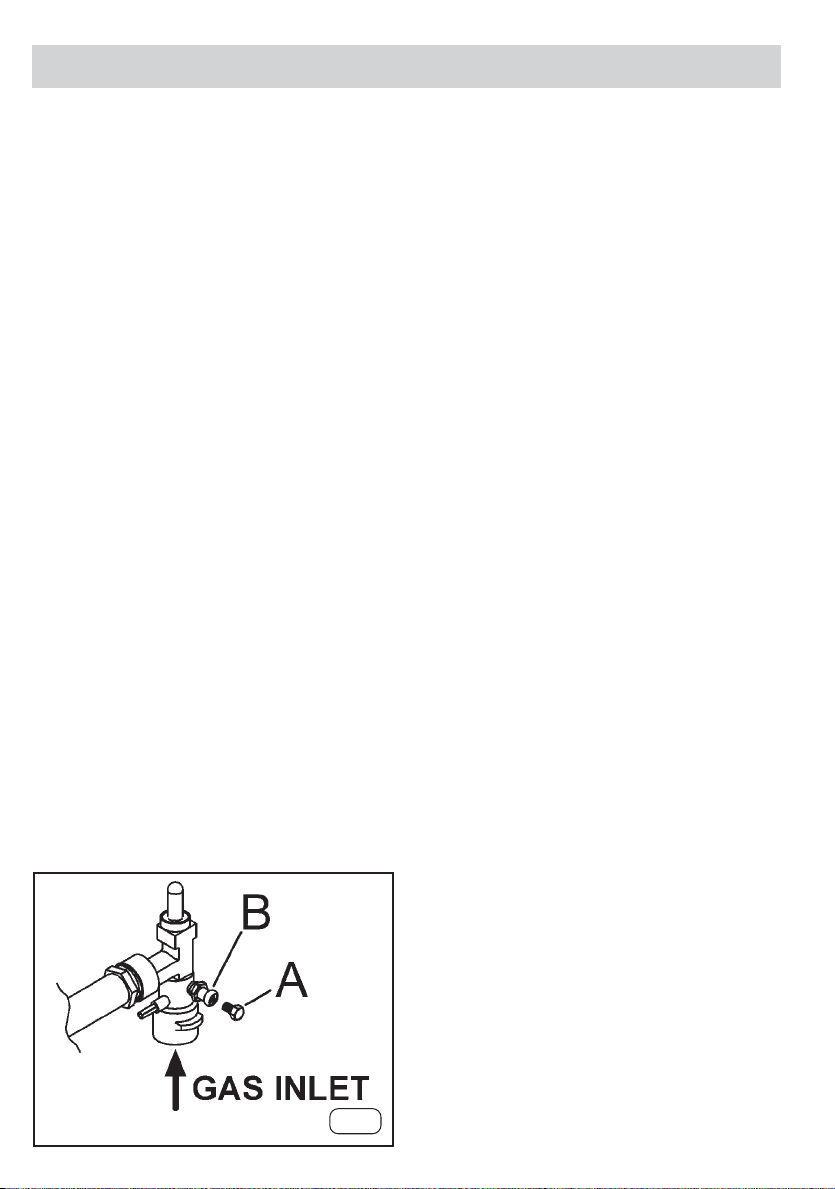

TESTING FOR CORRECT PRESSURE OF GAS

Before attempting to light burners, it is necessary to

ascertain that the correct and desired pressure of gas

is arriving at the appliance.

The test is carried out by removing screw (A) from the

test point (B) and attaching a water gauge tester by

rubber tube to the test point. Turn on the gas and

ascertain the pressure being received (NATURAL GAS,

20 mbar, BUTANE, 28-30 mbar or PROPANE, 37 mbar).

Should the pressure be lower or in excess of the desired

pressure then the installer should consult the gas

supplier . With LP Gas, the installer must ensure that the

correct regulator is fitted and particular attention should

be made when one or more appliances are operating at

the same time so as to obtain correct reading at the

test point on the cooker . Once the correct pressure has

been ascertained, replace screw (A).

After ensuring that the correct gas pressure is being

supplied to the appliance and if the appliance is to be

operated with natural gas, you can now proceed to light

the burners to ascertain that they are burning correctly.

If the appliance is to be converted for use with L.P. gas,

please follow the conversion instructions prior to testing

the hotplate burners.

9

G83

FIG.7

Loading...

Loading...