Bell BHT-206L3-FM-1 LongRanger-III Flight Manual

MODEL

206L3

ROTORCRAFT

FLIGHT MANUAL

BHT-206L3-FM-1

BHT 51001 THROUGH 51612

THIS MANUAL SHALL BE IN THE HELICOPTER DURING ALL OPERATIONS

COPYRIGHT NOTICE

COPYRIGHT

®

HELICOPTER TEXTRON INC.

BELL

AND BELL HELICOPTER TEXTRON

CANADA LTD.

ALL RIGHTS RESERVED

2005

28 OCTOBER 1992

REVISION 6 — 26 APRIL 2005

BHT-206L3-FM-1

NOTICE PAGE

Additional copies of this publication may be obtained by contacting:

Commercial Publication Distribution Center

PN

Bell Helicopter Textron Inc.

P. O. Box 482

Fort Worth, Texas 76101-0482

TC APPROVED BHT-206L3-FM-1

LOG OF REVISIONS

Original ....................0 ....................... 09 DEC 81

Revision...................1 .......................29 NOV 82

Revision...................2 ....................... 12 DEC 83

Revision...................3 ....................... 26 OCT 84

Revision...................4 ...................... 14 MAR 85

Revision...................5 ....................... 21 OCT 86

Revision...................6 ........................24 JUL 87

Revision...................7 .......................09 MAY 88

Revision...................8 ....................... 14 OCT 88

Revision ...................9 ....................... 12 SEP 89

LOG OF PAGES

REVISION REVISION

PAGE

Cover......................................................... 0

Title............................................................ 6

NP .............................................................. 0

A/B............................................................. 6

C/D............................................................. 6

E/F ............................................................. 6

i — ii .......................................................... 2

iii/iv............................................................ 0

1-1 — 1-2................................................... 0

1-3.............................................................. 5

1-4.............................................................. 4

1-5.............................................................. 0

1-6.............................................................. 5

1-6A/1-6B .................................................. 5

1-7 — 1-8................................................... 6

1-9.............................................................. 4

1-10............................................................ 0

1-11 —1-12................................................ 4

1-13............................................................ 0

1-14............................................................ 4

2-1/2-2 ....................................................... 0

2-3.............................................................. 1

NO.

Revision ................ 10 ....................... 04 DEC 89

Revision ................ 11 ....................... 25 MAY 90

Reissued ................. 0 ....................... 28 OCT 92

Revision .................. 1 ....................... 09 AUG 93

Revision .................. 2 ........................ 14 SEP 95

Revision .................. 3 ........................ 04 JUN 97

Revision .................. 4 ....................... 03 MAR 99

Revision .................. 5 ....................... 18 DEC 01

Revision .................. 6 ....................... 26 APR 05

PAGE

2-4 ............................................................. 0

2-5 — 2-6 .................................................. 3

2-7 ............................................................. 0

2-8 —2-10 ................................................. 4

2-11 — 2-14 .............................................. 1

3-1/3-2 ....................................................... 3

3-3 ............................................................. 4

3-4 —3-5 ................................................... 3

3-6 —3-7 ................................................... 4

3-8 ............................................................. 3

3-9 ............................................................. 5

3-10 — 3-12 .............................................. 3

4-1/4-2 ....................................................... 0

4-3 — 4-4 .................................................. 4

4-5 — 4-6 .................................................. 0

4-7 — 4-8 .................................................. 4

4-9 — 4-18 ................................................ 0

4-19/4-20 ................................................... 0

A-1............................................................. 5

A-2............................................................. 3

A-3/A-4...................................................... 3

NO.

Revised text is indicated by a black vertical line. Insert latest revision pages; dispose of

NOTE

superseded pages.

26 APR 2005 Rev. 6 A/B

LOG OF TC APPROVED REVISIONS

BHT-206L3-FM-1

Original ....................0 ....................... 09 DEC 81

Revision...................1 .......................29 NOV 82

Revision...................2 ....................... 12 DEC 83

Revision...................3 ....................... 26 OCT 84

Revision...................4 ...................... 14 MAR 85

Revision...................5 ....................... 21 OCT 86

Revision...................6 ........................24 JUL 87

Revision...................7 .......................09 MAY 88

Revision...................8 ....................... 14 OCT 88

Revision ...................9 ....................... 12 SEP 89

Revision ................ 10 ....................... 04 DEC 89

Revision ................ 11 ....................... 25 MAY 90

Reissue.................... 0 ....................... 28 OCT 92

Revision .................. 1 ....................... 09 AUG 93

Revision .................. 2 ........................ 14 SEP 95

Revision .................. 3 ........................ 04 JUN 97

Revision .................. 4 ....................... 03 MAR 99

Revision .................. 5 ....................... 18 DEC 01

Revision .................. 6 ....................... 26 APR 05

APPROVED: DATE:

CHIEF, FLIGHT TEST

FOR

DIRECTOR — AIRCRAFT CERTIFICATION

TRANSPORT CANADA

26 APR 2005 Rev. 6 C/D

LOG OF FAA APPROVED REVISIONS

BHT-206L3-FM-1

Original ....................0 ....................... 09 DEC 81

Revision...................1 .......................29 NOV 82

Revision...................2 ....................... 12 DEC 83

Revision...................3 ....................... 26 OCT 84

Revision...................4 ...................... 14 MAR 85

Revision...................5 ....................... 21 OCT 86

Revision...................6 ........................24 JUL 87

Revision...................7 .......................09 MAY 88

Revision...................8 ....................... 14 OCT 88

Revision ...................9 ....................... 12 SEP 89

Revision ................ 10 ....................... 04 DEC 89

Revision ................ 11 ....................... 25 MAY 90

Reissue.................... 0 ....................... 28 OCT 92

Revision .................. 1 ....................... 09 AUG 93

Revision .................. 2 ........................ 14 SEP 95

Revision .................. 3 ........................ 04 JUN 97

Revision .................. 4 ....................... 15 MAR 99

Revision .................. 5 ........................ 15 JAN 02

Revision .................. 6 ....................... 04 MAY 05

APPROVED: DATE:

CHIEF, FLIGHT TEST

FOR

DIRECTOR — AIRCRAFT CERTIFICATION

TRANSPORT CANADA

26 APR 2005 Rev. 6 E/F

DOT APPROVED

BHT-206L3-FM-1

GENERALINFORMATION

ORGANIZATION

This Rotorcraft Flight Manual is divided

into four sections and an appendix as

follows:

Section 1 - LIMITATIONS

Section 2 - NORMAL PROCEDURES

Section 3 - EMERGENCY AND

MALFUNCTION

PROCEDURES

Section 4 - PERFORMANCE

Appendix - OPTIONAL EQUIPMENT

A

SUPPLEMENTS

Sections 1 through 4 contain the DOT

approved data necessary to operate the

basic helicopter in a safe and efficient

manner.

Appendix A contains the approved

supplements for optional equipment,

which shall be used in conjunction with

the basic Flight Manual when the

respective optional equipment kits are

installed.

The Manufacturer’s Data (BHT-206L3-MD-1)

manual, contains information to be used in

conjunction with the Flight Manual. The

manual is divided into four sections:

Section 1 - WEIGHT AND BALANCE

Section 2 - SYSTEMS DESCRIPTION

Section 3

- OPERATIONAL

INFORMATION

Section 4 - HANDLING/SERVICING/

MAINTENANCE

TERMINOLOGY

WARNINGS, CAUTIONS, AND

NOTES

Warnings, cautions, and notes are used

throughout this manual to emphasize

important and critical instructions as

follows:

AN OPERATING PROCEDURE,

PRACTICE, ETC., WHICH, IF NOT

CORRECTLY FOLLOWED, COULD

RESULT IN PERSONAL INJURY

OR LOSS OF LIFE.

AN OPERATING PROCEDURE,

PRACTICE, ETC., WHICH IF NOT

STRICTLY OBSERVED, COULD

RESULT IN DAMAGE TO OR

DESTRUCTION OF EQUIPMENT.

NOTE

An operating procedure,

condition, etc., which is essential

to highlight.

USE OF PROCEDURAL WORDS

The concept of procedural word usage and

intended meaning which has been adhered

to in preparing this manual is as follows:

“Shall” has been used only when

application of a procedure is mandatory.

Rev. 2 i

BHT-206L3-FM-1

“Should” has been used only when

application of a procedure is

recommended.

“May” and “need not” have been used only

when application of a procedure is

optional.

“Will” has been used only to indicate

futurity, never to indicate a mandatory

procedure.

ABBREVIATIONS AND ACRONYMS

Abbreviations and acronyms used

throughout this manual are defined as

follows:

AC

- Alternating Current

A/F

- Airframe

ANTI

COLL LT -

Anticollision Light

APU

BAT

C

CG

DC

DECR

ECS

ELT

ENG

F

ft

GEN

GOV

- Alternate Power Unit

- Battery

- Celsius

-

Center of Gravity

- Direct Current

- Decrease

- Environmental Control

System

- Emergency Locater

Transmitter

- Engine

- Fahrenheit

- Foot, Feet

- Generator

- Governor

Hd

-

Hg -

HP -

HYDR IDLE REL IFR IGE -

IN

-

INCR INST LT KCAS -

kg -

LBS KIAS KTAS LDG LTS LT MCP -

mm

-

MPH

OAT OGE POS LT -

PSI QTY RLY RPM

DOT APPROVED

Density Altitude

Mercury

Pressure Altitude

Hydraulic

Idle Release

Instrument Flight Rules

In Ground Effect

Inch(es)

Increase

Instrument Light

Knots Calibrated Airspeed

Kilograms

Pounds

Knots Indicated Airspeed

Knots True Airspeed

Landing Lights

Light

Maximum Continuous

Power

millimeter

Miles Per Hour (Statute)

Outside Air Temperature

Out of Ground Effect

Position Light

Pounds per Square Inch

Quantity

Relay

Revolutions Per Minute

ii

Rev. 2

FAA APPROVED

BHT-206L3-FM-1

SL - Sea Level

TOT or

- Turbine Outlet Temperature

TURB OUT

TEMP

T/R - Tail Rotor

TRANS - Transmission

VFR

- Visual Flight Rules

Vne - Never Exceed Velocity

WRN

- Warning

XMSN

- Transmission

FAA APPROVED

BHT-206L3-FM-1

Paragraph

TABLE OF CONTENTS

1-1

1-2

-

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

1-18

1-19

1-20

1-21

1-22

1-23

1-24

1-25

1-26

1-27

1-28

1-29

1-30

1-31

1-32

1-33

1-34

1-35

1-36

1-37

GENERAL

................................................................

BASIS OF CERTIFICATION

..............................................

TYPE OF OPERATION

...................................................

OPTIONAL EQUIPMENT..

...............................................

FLIGHT CREW

...........................................................

WElGHT/CG

..............................................................

WEIGHT

.............................................................

CENTER OF GRAVITY - LONGITUDINAL

.........................

CENTER OF GRAVITY - LATERAL

................................

DOOR(S) OFF

.......................................................

AIRSPEED

...............................................................

ALTITUDE

................................................................

AMBIENT AIR TEMPERATURE.. ........................................

MANEUVERING

..........................................................

ELECTRICAL

.............................................................

GENERATOR

........................................................

POWERPLANT

...........................................................

GAS PRODUCER RPM..

............................................

POWER TURBINE RPM ...............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T OT) . . . . . . . . . . . . . . . . . . . . . . . . .

TURBINE OUTLET TEMPERATURE (

ENGINE TORQUE ....................

FUEL PRESSURE ....................

ENGINE OIL PRESSURE.. ...........

ENGINE OIL TEMPERATURE.. ......

..............................

..............................

..............................

..............................

..............................

ANTIICE ...............................

STARTER

............................................................

TRANSMISSION

..........................................................

TRANSMISSION OIL PRESSURE..

.................................

TRANSMISSION OIL TEMPERATURE

..............................

ROTOR

...................................................................

ROTOR RPM - POWER ON..

......................................

ROTOR RPM - POWER OFF

.......................................

FUEL AND OIL.. .........................................................

FUEL

................................................................

ENGINE OIL.. .......................................................

TRANSMISSION AND TAIL ROTOR GEARBOX OIL

...............

HYDRAULIC

..............................................................

Page

Number

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-8

1-8

1-8

1-8

1-8

1-8

1-9

1-9

1-9

1-9

1-10

1-10

1-10

1-10

1-10

1-10

1-10

1-10

1-10

1-10

1-11

1-11

1-11

l-1

BHT-206L3-FM-1 FAA APPROVED

Figure

Number

LIST OF FIGURES

Title

Page

Number

1-1

Gross weight center of gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5

1-2

Placards and decals....................................................... 1-6

1-3

Instrument markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12

1-2

TC

APPROVED

BHT-206L3-FM-1

Section

1

.

1-1.

GENERAL

Flight

with

any

combination

of

doors

off

is

approved.

Refer

to

AIRSPEED

limitations.

Compliance

with

limitations

section

is

required

by

appropriate

operating

rules.

1-4.

OPTIONAL

EQUIPMENT

Anytime

an

operating

limitation

is

exceeded,

an

appropriate

entry

shall

be

made

in

The

following

equipment

shall

be

installed

helicopter

logbook.

Entry

shall

state

which

when

conducting

flight

operations

in

falling

limit

was

exceeded,

the

duration

of

time,

the

and/or

blowing

snow

to

reduce

possibility

of

extreme

value

attained,

and

any

additional

engine

flameout:

information

essential

in

determining

maintenance

action

required.

The

Snow

Deflector

Kit

or

the

Particle

Separator

Engine

Air

Induction

System

Intentional

use

of

transient

limits

is

Kit

and

the

Snow

Deflector

Kit.

(See

BHT-

prohibited.

206L3-FMS-3

and

BHT-206L3-FMS-7.)

Torque

events

shall

be

recorded.

A

torque

Refer

to

appropriate

Flight

Manual

event is

defined

as

a

takeoff

or a load

lift

Supplement(s)

for

additional

limitations,

(internal

or

external),

procedures,

and

performance

data.

1-2.

BASIS

OF

1-5.

FLIGHT

CREW

CERTIFICATION

The

minimum

flight

crew

consists of

one

pilot

This

helicopter

is

certified

under

Civil Air

who

shall

operate

the

helicopter

from

the

Regulation,

Parts

6,

Rotorcraft

Airworthiness,

right

crew

seat

Normal

Category.

The

left

crew

seat

may

be

used

for

an

1-3.

TYPE

OF

OPERATION

additional

pilot

when

the approved

dual

controls

are

installed.

seven-place

seating

and

is

certified

for

land

*

H

operation

under

day

or

night

VFR

nonicing

conditions.

1-7. WEIGHT

Flight

operations

are

approved

with

the

..

....

landing

gear

crosstube

fairings

installed

or

CAUTION

removed.

LOADS

THAT

RESULT

IN

GROSS

NOTE

WEIGHTS

ABOVE

4,150

POUNDS

(1882.4

KG)

SHALL

BE

CARRIED

ON

All

unsecured

items

shall

be

removed

AN

APPROVED

EXTERNAL

LOAD

KIT

from

cabin

when

any

door

is

removed.

AND

SHALL

NOT

BE

IMPOSED

ON

LANDING

GEAR.

18

DEC

2001

Rev.

5

1-3

BHT-206L3-FM-1

DOTAPPROVED

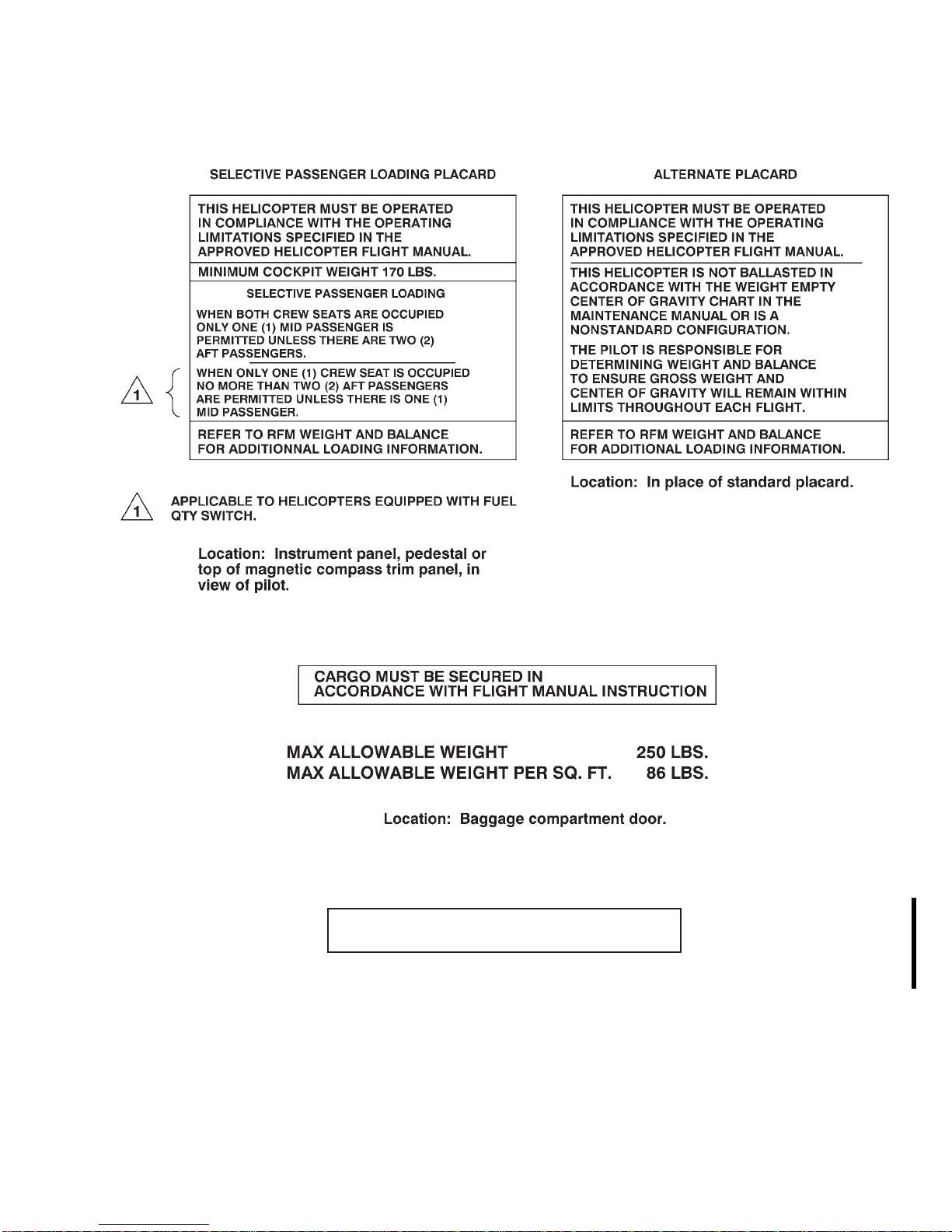

Maximum internal approved gross weight

for takeoff and landing is 4,150 pounds

(1882.4 kilograms).

Minimum combined crew weight at

fuselage station 65.0 is 170 pounds (77.1

kilograms) when operating in accordance

with the SELECTIVE PASSENGER

LOADING placard.

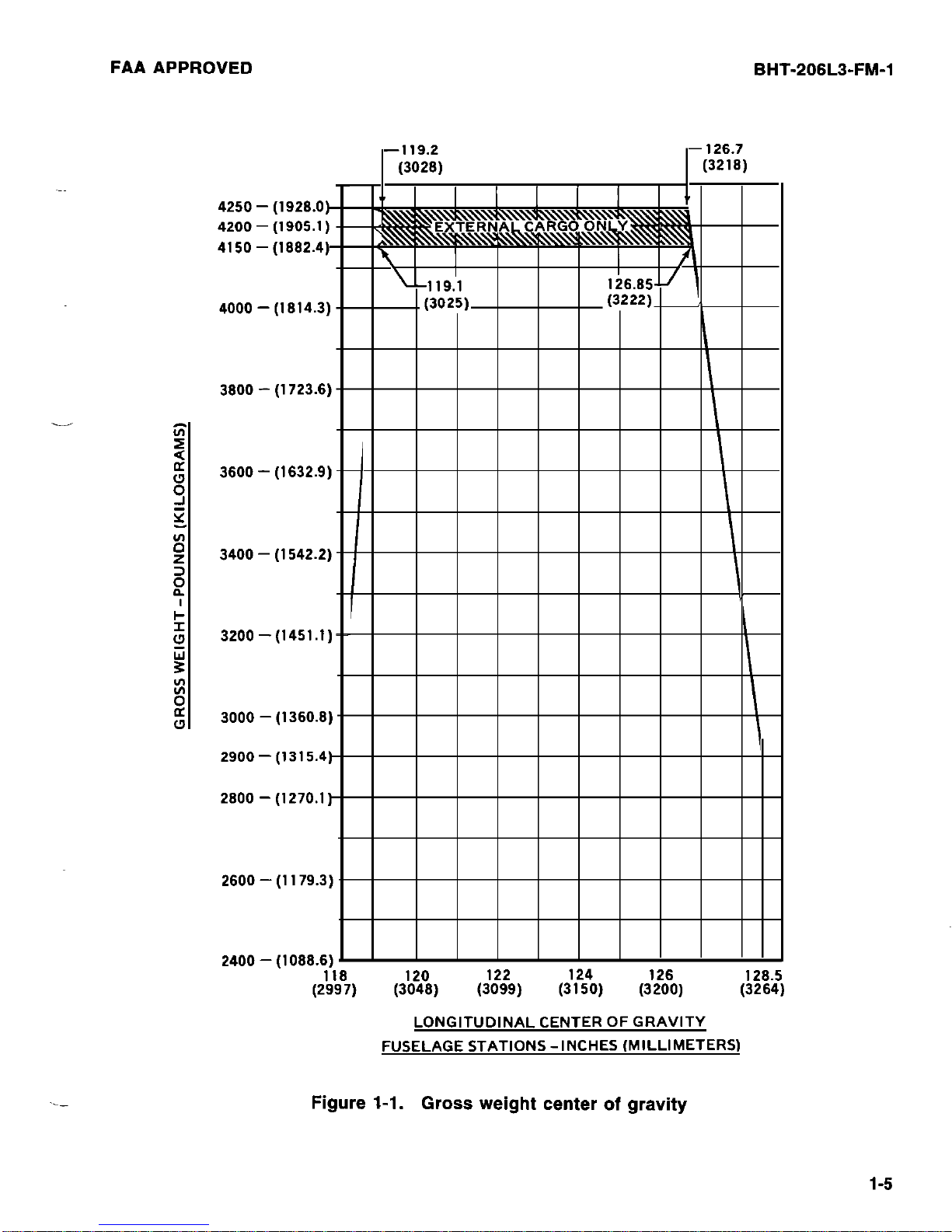

1-8. CENTER OF GRAVITY LONGITUDINAL

For gross weight longitudinal center of

gravity limits, refer to figure l-l.

The standard helicopter [standard seating

and fuel system) is ballasted in

accordance with the Weight Empty Center

of Gravity chart in the maintenance

manual. The SELECTIVE PASSENGER

LOADING placard shall be installed and

may be used for loading passengers only

within appropriate weight limitations

without computing center of gravity. When

passengers are seated other than in

accordance with the selective loading

placard or the baggage compartment is

utilized, the pilot is responsible for

determining weight and balance to ensure

gross weight and center of gravity will

remain within limits throughout each flight.

The helicopter with nonstandard fuel

system or seating arrangement is not

ballasted in accordance with the Weight

Empty Center of Gravity chart in the

maintenance manual. Selective passenger

loading does not apply and the

ALTERNATE placard shall be installed. The

pilot is responsible for determining weight

and balance to ensure gross weight and

center of gravity will remain within limits

throughout each flight.

Refer to BHT-206L3-MD-1 for loading

tables and instructions.

1-9. CENTER OF GRAVITY -

LATERAL

Lateral center of gravity limits are 4.0

inches (102 mm) left of and 3.5 inches (89

mm) right of fuselage centerline.

1-4 Rev. 4

1-10. DOOR(S) OFF

Determine weight change after doors have

been removed and adjust ballast if

necessary. Refer to BHT-206L3-MD-1.

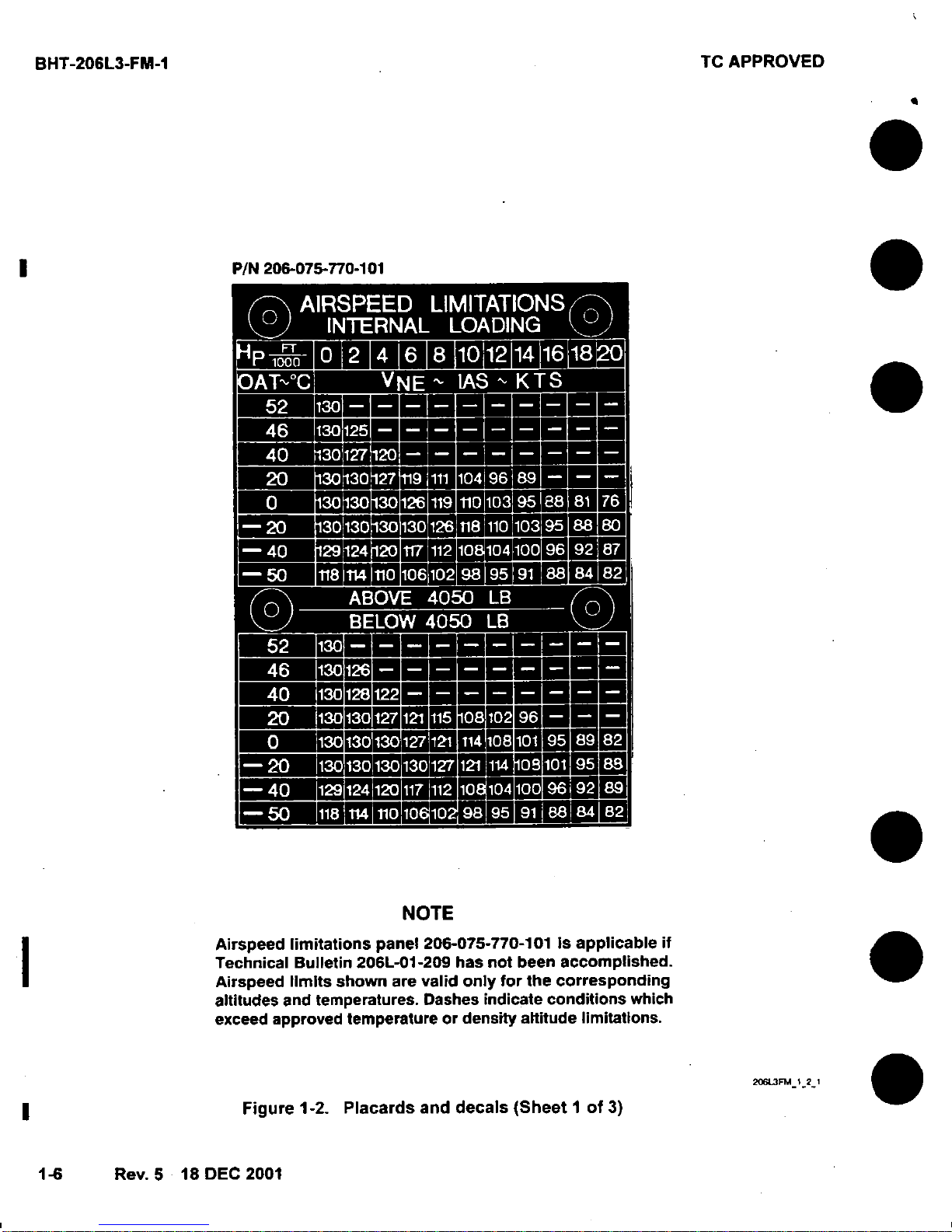

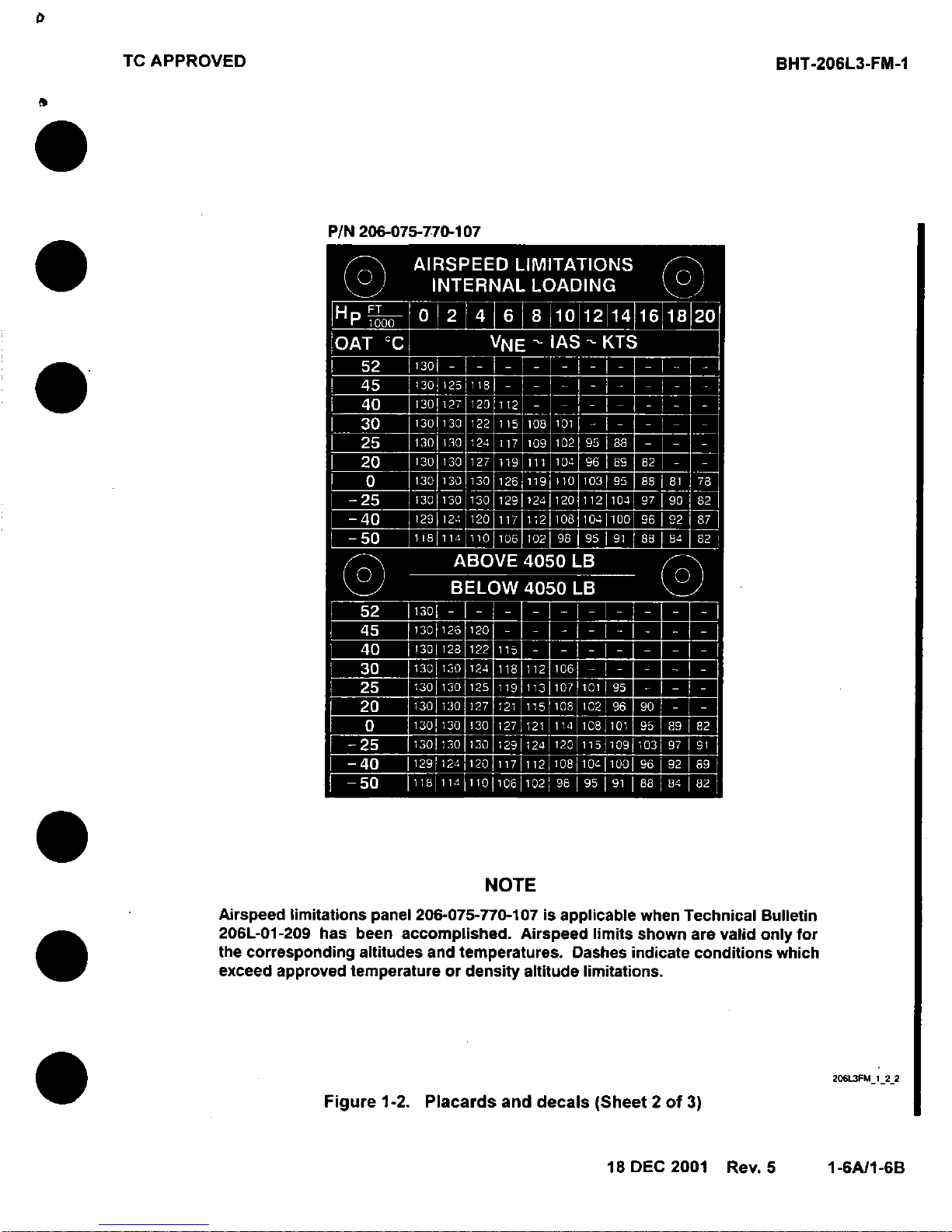

1-11. AIRSPEED

Basic V,, is 130 KIAS (150 MPH) sea level

to 3,000 feet density altitude. Decrease V,,

for ambient conditions in accordance with

AIRSPEED LIMITATIONS placard (figure 1-

2).

V ne is 84 KIAS (96 MPH) at 85 to 100%

TORQUE takeoff power.

Vne, is 90 KIAS (104 MPH) with any door(s)

off, not to exceed placarded Vne.

1-12. ALTITUDE

Maximum operating pressure altitude is

20,000 feet.

NOTE

For high altitude pressure

operation, refer to appropriate

rules for oxygen requirements.

1-13.

AMBIENT AIR

TEMPERATURE

The maximum sea level ambient air

temperature for operation is +51.7°C

(+125°F) and decreases with pressure

altitude at the standard lapse rate of 2°C

(3.6°F)/1000 feet to 20,000 feet.

1-14. MANEUVERING

Aerobatic maneuvers are prohibited.

FAA APPROVED

BHT-206L3-FM-1

-119.2

(3026)

Figure 1-1. Gross weight center of gravity

1-5

BHT-206L3-FM-1

TC

APPROVED

|IU~~~

P/N

206-075-770-101

i" e

*0

S

a

Z

s

NOTE

Airspeed

limitations

panel

206-075-770-101

Is

applicable

if

Technical

Bulletin

206L-01-209

has

not

been

accomplished.

Airspeed

limits

shown

are

valid only

for

the

corresponding

altitudes

and

temperatures.

Dashes

indicate

conditions

which

exceed

approved

temperature

or

density

altitude

limitations.

206L3FM_121

Figure

1-2.

Placards

and

decals

(Sheet I of

3)

4

1-6

Rev. 5 18

DEC

2001

TC

APPROVED

BHT-206L3-FM-1

P/N

206-075-770-107

NOTE

Airspeed

limitations

panel

206-075-770-107

is

applicable

when

Technical

Bulletin

206L-01-209

has

been

accomplished.

Airspeed

limits

shown

are

valid

only for

the

corresponding

altitudes

and

temperatures.

Dashes

indicate

conditions

which

exceed approved temperature

or

density

altitude

limitations.

Figure

1-2.

Placards

and

decals

(Sheet 2 of

3)

TC APPROVED BHT-206L3-FM-1

Figure 1-2. Placards and Decals (Sheet 3 of 3)

AVOID CONT OPS 71.8% TO 91.5% N2

Location: Instrument panel.

206L3FM_1_0001

26 APR 2005 Rev. 6 1-7

BHT-206L3-FM-1 TC APPROVED

1-15. ELECTRICAL

1-16. GENERATOR

Continuous

operation

Maximum 90% DC LOAD

0 to 90% DC

LOAD

1-17. POWERPLANT

Allison model 250-C30P.

1-18. GAS PRODUCER RPM

Continuous

operation

Maximum 105%

Maximum transient

(Do not exceed 10

seconds above

105%)

63 to 105%

106%

Maximum continuous 100%

Transient overspeed

range

NOTE

Refer to Allison Operation and

Maintenance Manual for transient

overspeed limits.

100 to 103%

1-20. TURBINE OUTLET

TEMPERATURE (TOT)

WARNING

EXCEEDING 768°C TURB OUT TEMP

OR 100% TORQUE CAN CAUSE GAS

PRODUCER TOPPING WITH

RESULTANT ROTOR RPM DROOP.

Continuous

operation

100 to 716°C

1-19. POWER TURBINE RPM

WARNING

USE OF THE THROTTLE TO CONTROL

RPM IS NOT AUTHORIZED.

(REFER TO SECTION 3, EMERGENCY

PROCEDURES — ENGINE

OVERSPEED FOR EXCEPTION.)

Avoid continuous

operations

Minimum 97%

Continuous

operation

71.8 to 91.5%

97 to 100%

Maximum continuous 716°C

5 minute takeoff

range

Maximum for takeoff 768°C

Maximum transient

(Do not exceed 10

seconds above

768°C).

Maximum for starting

and shutdown (Do

not exceed 10

seconds above

768°C.)

716 to 768°C

871°C

927°C

1-8 Rev. 6 26 APR 2005

--

-

DOTAPPROVED

NOTE

Intentional use of power transient

area (768 to 871°C) is prohibited.

The TURB OUT TEMP gage is

equipped with a red warning light

that will illuminate when either of

the following conditions occur:

770 to 927°C more than 10

seconds or above 927°C.

1-21. ENGINE TORQUE

Continuous

operation

0 to 85%

Maximum continuous

85%

5 minute takeoff

range

85 to 100%

Maximum for takeoff

Maximum transient

(Do not exceed 5

seconds above

100%. Intentional use

prohibited.)

100%

105%

1-22. FUEL PRESSURE

Minimum

Continuous

operation

4 PSI

4 to 25 PSI

Maximum

25 PSI

BHT-206L3-FM-1

Minimum

Continuous

operation

4 PSI

4 to 25 PSI

Maximum

Minimum for use of

type A, A-l, or JP-5

fuel, or any mixture

of these, at ambient

temperature below 18°C (0°F)

25 PSI

8 PSI

1-23. ENGINE OIL PRESSURE

Minimum below 79%

50 PSI

GAS PRODUCER (N,)

RPM

Minimum from 79 to

90 PSI

94% GAS

PRODUCER (N,) RPM

Minimum above 94%

115 PSI

GAS PRODUCER

RPM (N1) RPM

Maximum

130 PSI

1-24. ENGINE OIL TEMPERATURE

Continuous

operation

0 to 107°C

Maximum

107°C

I

l

Gage with red triangle at 8 psi.

Rev. 4

1-9

BHT-206L3-FM-1

DOT APPROVED

1-25. ANTI-ICE

The maximum ambient temperature for use

I

of engine anti-ice is

4.4°C (40°F).

ENGINE ANTI-ICING shall be ON for flight

I

in visible moisture in temperature below

4.4°C (40°F).

1-26. STARTER

Limit starter energize time to the following:

External Power Start Battery Start

40 Seconds ON

60

Seconds ON

30 Seconds OFF

60

Seconds OFF

40 Seconds ON

60

Seconds ON

30 Seconds OFF

60

Seconds OFF

40 Seconds ON

60

Seconds ON

30 Minutes OFF

30

Minutes OFF

1-27. TRANSMISSION

1-26.

TRANSMISSION OIL

PRESSURE

Minimum

Continuous

operation

Maximum

30 PSI

40 to 70 PSI

70 PSI

1-29. TRANSMISSION OIL

TEMPERATURE

Continuous

operation

15 to 110°C

Maximum

110°C

1-30. ROTOR

1-31. ROTOR RPM - POWER ON

Minimum transient

(Do not exceed 5

seconds)

-

95%

Minimum

Continuous

operation

Maximum continuous

Maximum transient

during low power

descent. (Do not

exceed 6 minutes

above 100%.)

97%

97 to 100%

100%

103%

1-32. ROTOR RPM - POWER

OFF

Minimum

90%

Maximum

107%

1-33. FUEL AND OIL

1-34. FUEL

Turbine fuel ASTM-D-1655, Type B, or MIL-

T-5624, Grade JP-4, may be used at all

ambient temperatures.

1-10

DOT APPROVED BHT-206L3-FM-1

Turbine fuel ASTM-D-1655, Type A or A-l,

or MIL-T-5624, Grade JP-5, (NATO F-44), or

MIL-T-83133, Grade JP-8, (NATO F-34),

limited to ambient temperatures above .

- -17.8% (0°F).

Turbine fuel ASTM-D-1655, Type A or A-l,

or MIL-T-5624, Grade JP-5, (NATO F-44), or

MIL-T-83133, Grade JP-8, (NATO F-34),

limited to ambient temperatures -32°C

(-25°F) and above when equipped with fuel

pressure gage with red triangle at 6 psi.

NOTE

Anti-icing fuel additives are not

required for any ambient

temperature.

fer to Allison Operation and

intenance Manual for cold weather fuel

and blending instructions.

Re

Ma

1-35. ENGINE OIL

Turbine oil MIL-L-7808 may be used at all

ambient temperatures.

DOD-L-85734(AS) or MIL-L-23699 limited to

ambient temperatures above -40°C (-40°F).

NOTE

Refer to Allison Operation and

Maintenance Manual and BHT206L3-MD-1 manual for approved

oils and mixing of oils of different

brands, types, and manufacturers.

1-36. TRANSMISSION AND TAIL

ROTOR GEARBOX OIL

Turbine oil MIL-L-7808 may be used at all

ambient temperatures.

DOD-L-85734(AS) or MIL-L-23699 limited to

ambient temperatures above -40°C (-40°F).

1-37. HYDRAULIC

Hydraulic fluid MIL-H-5606 may be used at

all ambient temperatures.

Rev. 4

1-11

BHT-206L3-FM-1

DOT APPROVED

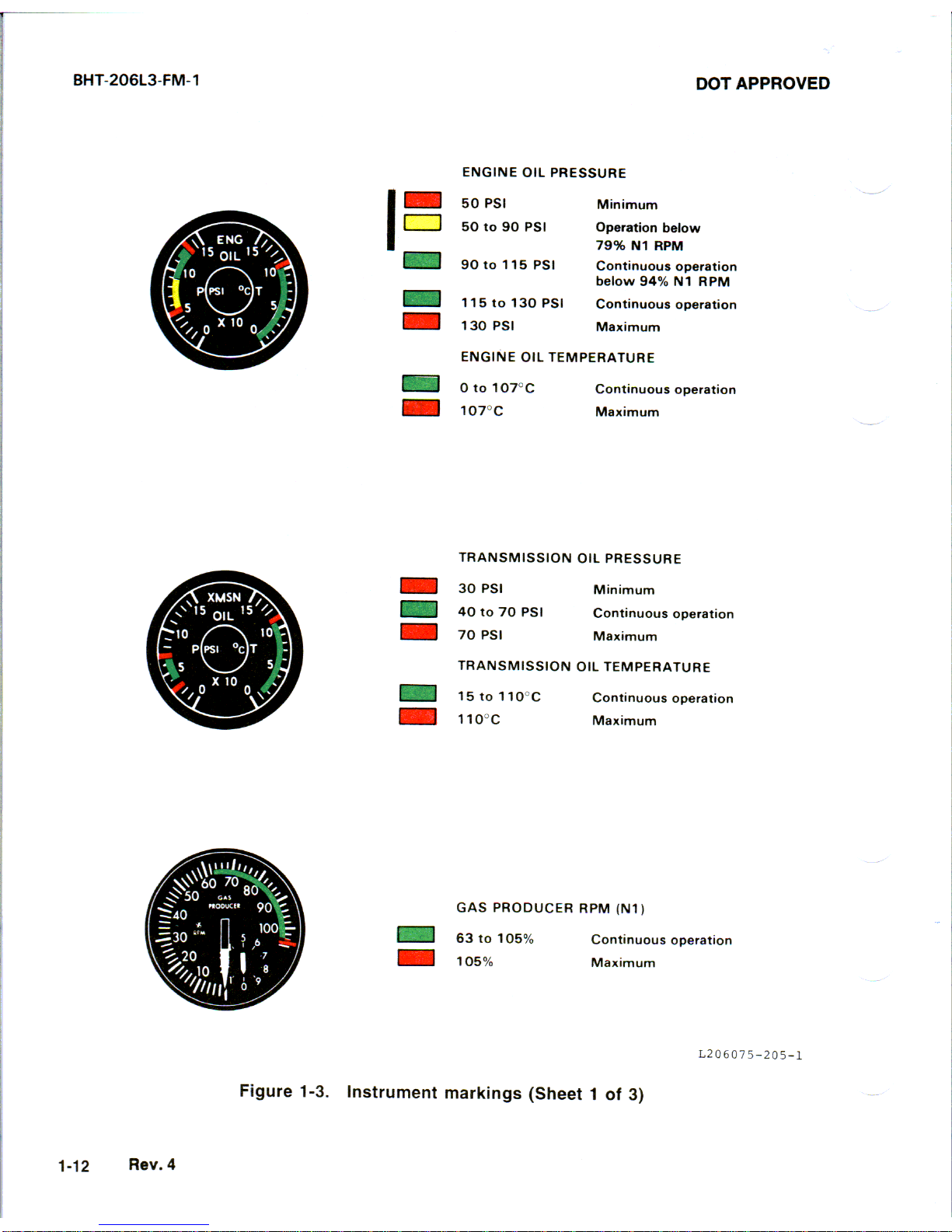

ENGINE OIL PRESSURE

50 PSI

Mhmum

50 to so PSI

Operation below

79% Nl RPM

so to 115 PSI

Continuous operatmn

below 94% Nl RPM

115 to 130 PSI

Contmuous operation

130 PSI

Maximum

ENGINE OIL TEMPERATURE

m 0 to 107oc

Continuous operation

Maximum

TRANSMISSION OIL PRESSURE

30 PSI

Mmlmum

40 to 70 PSI

Continuous operatlo”

70 PSI

Maximum

TRANSMISSION OIL TEMPERATURE

15 to 110°C

Continuous operatmn

110°C

Maxmum

GAS PRODUCER RPM (Nl,

Continuous operation

Maximum

L206075-205-l

Figure 1-3. instrument markings (Sheet 1 of 3)

1-12

Rev. 4

.

DOT APPROVED

BHT-206L3-FM-1

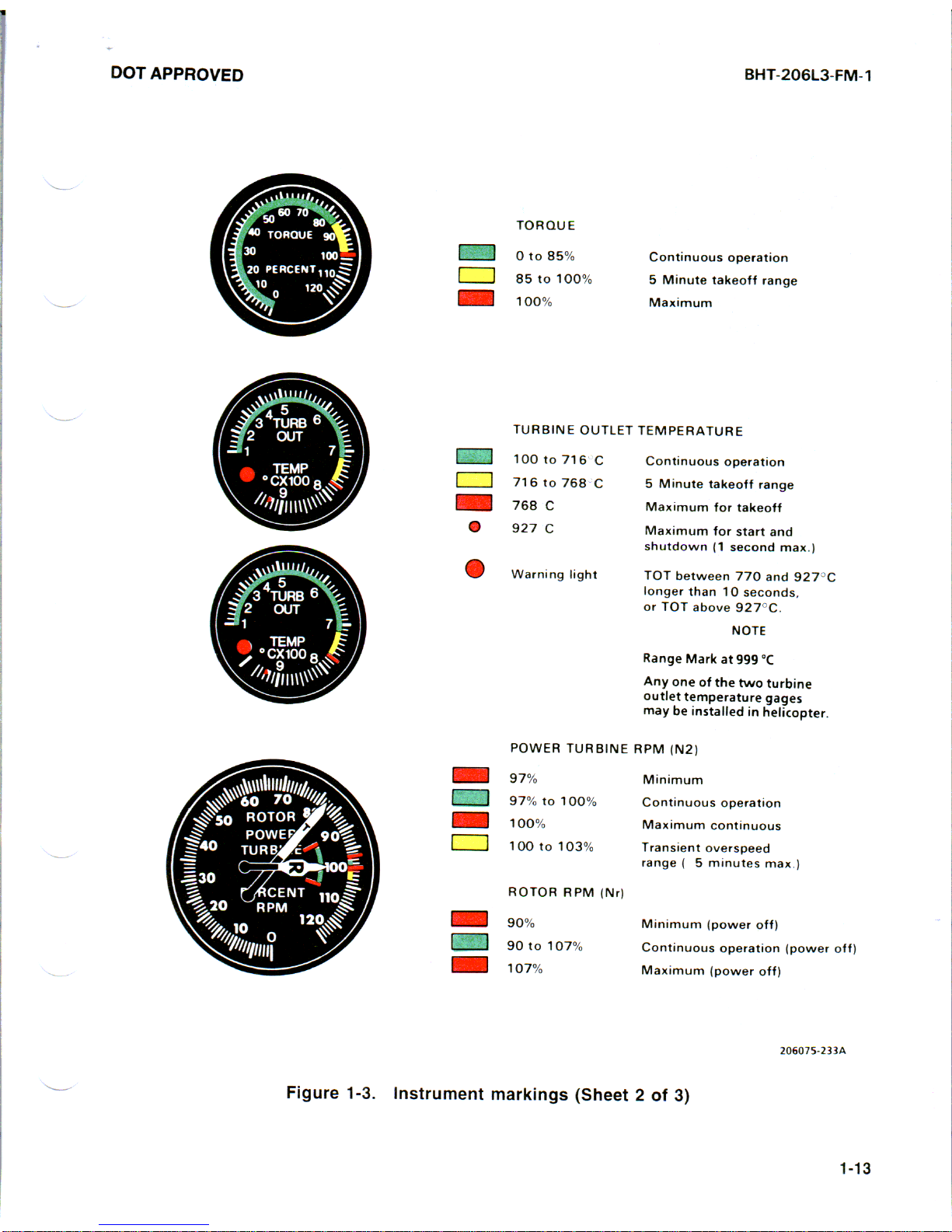

TORQUE

0 to 85%

85 to 100%

100%

TURBINE OUTLET

m

100 to716 C

r”

716fo768 C

768 C

@

927 C

a

Warn1nq lqht

Continuous operatmn

5 Mmute takeoff range

Maximum

TEMPERATURE

Continuous operatmn

5 Minute takeoff range

Manmum for takeoff

MaxImum for start and

shutdown (1 second max )

TOT between 770 and 927 C

longer than 10 seconds.

or TOT above 927 C

NOTE

Range Mark at 999 “C

Any one of the two turbme

outlet temperature gages

may be mstalled I” hellcopter

POWER TURBINE RPM (N2)

97%

97% to 100%

100%

100 to 103%

Minimum

Continuous operation

Maximum continuous

Transient overspeed

range f 5 minutes rmx.)

Mnmum (power off)

Continuous operat,on (power off)

Mawmum (power off)

Fiaure 1-3.

Instrument markings (Sheet 2 of 3)

BHT-206L3-FM-1

DOT APPROVED

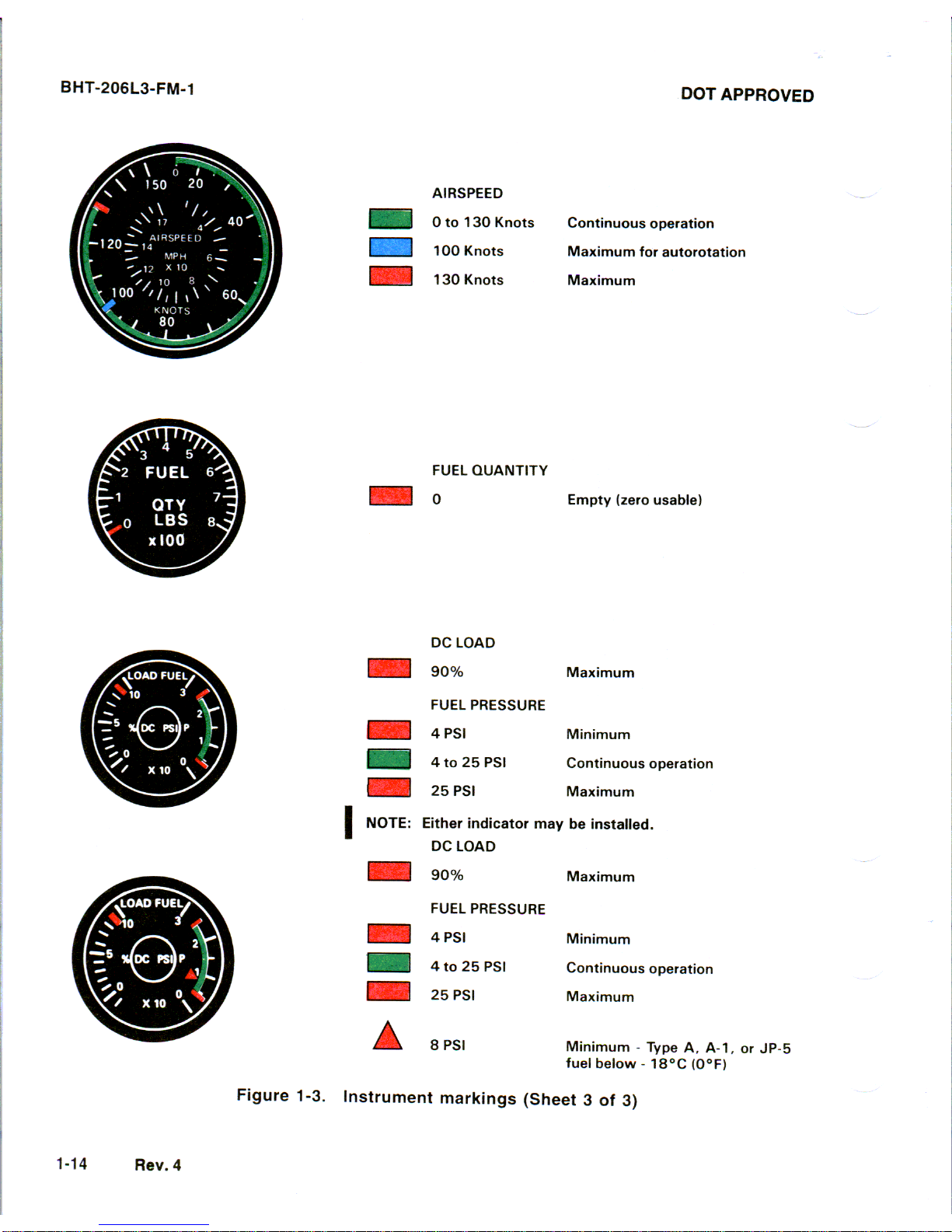

AIRSPEED

:o 130 Knots

IO Knots

130 Knots

Continuous operation

Maximum for autorotation

Maximum

FUEL QUANTITY

0

Empty (zero usable)

“L LUAU

I 90%

Maximum

FUEL PRESSURE

4 PSI

Minimum

4 to 25 PSI

Continuous operatio

I 25 PSI

Maximum

I

NOTE: Either indicator may

be

installed.

m

DC LOAD

n

Maximum

FUEL PRESSURE

m 4PSI

Minimum

0 25 PSI

Continuous operation

PSI Maximum

A

8 PSI Minimum Type A, A-l, or JP-5

fuel below 18°C (O°Fj

Figure 1-3.

Instrument markings (Sheet 3 of 3)

1-14 Rev.

4

FAA APPROVED

BHT-206L3-FM-1

Paragraph

TABLE OF CONTENTS

2-1

2-2

2-3

2-4

2-6

2-6

2-7

2-6

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-l 6

2-19

2-20

2-21

2-22

2-23

2-24

2-25

2-26

INTRODUCTION ..........................................................

OPERATING LIMITATIONS ..............................................

FLIGHT PLANNING ......................................................

TAKEOFF AND LANDING DATA

....................................

WEIGHT AND BALANCE

............................................

PREFLIGHT CHECK .....................................................

BEFORE EXTERIOR CHECK

............................................

EXTERIOR CHECK..

.....................................................

FUSELAGE - CABIN RIGHT SIDE..

...............................

FUSELAGE - CENTER RIGHT SIDE..

.............................

FUSELAGE - AFT RIGHT SIDE

....................................

FUSELAGE - FULL AFT..

.........................................

FUSELAGE - AFT LEFT SIDE

.....................................

FUSELAGE - CABIN LEFT SIDE

..................................

FUSELAGE - FRONT ..............................................

INTERIOR AND PRESTART CHECK.. ...................................

ENGINE STARTING.. ....................................................

PRELIMINARY HYDRAULIC SYSTEMS CHECK..

.......................

ENGINE RUNUP .........................................................

HYDRAULIC SYSTEMS CHECK

....................................

BEFORE TAKEOFF ......................................................

TAKEOFF ................................................................

INFLIGHT OPERATIONS.. ...............................................

DESCENT AND LANDING ...............................................

ENGINE SHUTDOWN ....................................................

AFTER EXITING HELICOPTER

..........................................

LIST OF FIGURES

Figure

Number Title

Page

Number

2-3

2-3

2-3

2-3

2-3

2-3

2-5

2-5

2-5

2-5

2-6

2-6

2-7

2-8

2-8

2-9

2-10

2-11

2-11

2-l 1

2-11

2-12

2-12

2-12

2-13

2-13

Page

Number

2-l

Preflight check sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-112-2

FAA APPROVED

BHT-206L3-FM-1

2-1. INTRODUCTION

This section contains instructions and

procedures for operating the helicopter

from the planning stage, through actual

flight conditions, to securing the

helicopter after landing.

Normal and standard conditions are

assumed in these procedures. Pertinent

data in other sections is referenced when

applicable.

The instructions and procedures contained

herein are written for the purpose of

standardization and are not applicable to

all situations.

2-2. OPERATING

LIMITATIONS

The minimum and maximum limits, and the

normal and cautionary operating ranges

for the helicopter and its subsystems are

indicated by instrument markings and

placards. The instrument markings and

placards represent careful aerodynamic

calculations that are substantiated by

flight test data. Refer to Section 1,

--

LIMITATIONS, for a detailed explanation of

each operating limitation.

2-3. FLIGHT PLANNING

Each flight should be planned adequately

to ensure safe operations and to provide

the pilot with the data to be used during

flight.

Check type of mission to be performed

and destination.

Select appropriate performance charts to

be used from Section 4, PERFORMANCE.

2-4. TAKEOFF AND LANDING

DATA

Refer to Section 1 for takeoff and landing

weight limits and to Section 4 for

performance information.

2-5. WEIGHT AND BALANCE

Determine proper weight and balance of

the helicopter as follows:

1.

Consult BHT-206L3-MD-1 for

instructions.

2. Compute takeoff and anticipated

landing gross weight, check

helicopter center of gravity (CG)

locations, and determine weight of

fuel, oil, payload, etc.

3. Ensure weight/CG limits listed in

Section 1 have not been exceeded.

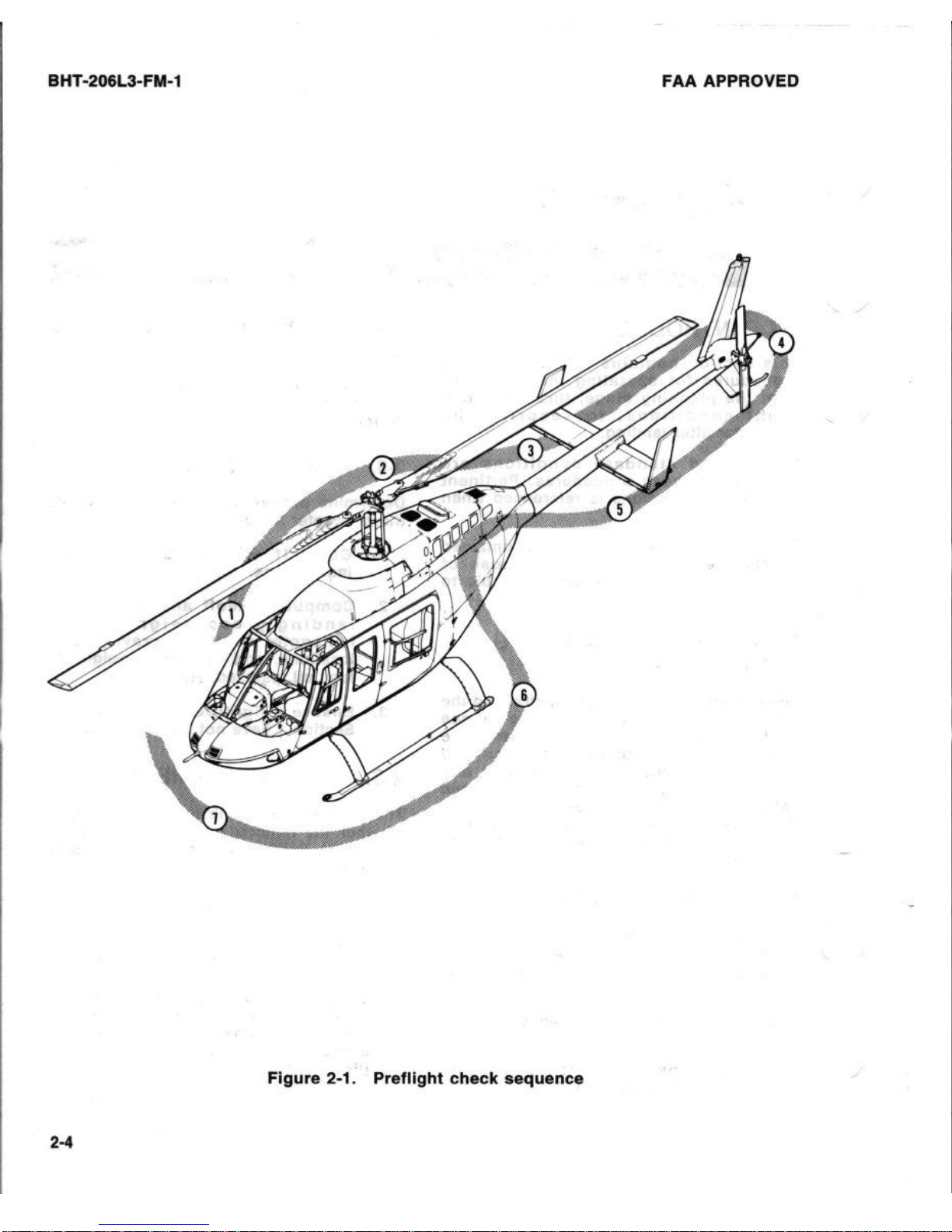

2-6. PREFLIGHT CHECK

The pilot is responsible for determining

whether the helicopter is in condition for

safe flight. Refer to figure 2-l for preflight

check sequence.

NOTE

The preflight check is not

intended to be a detailed

mechanical inspection, but simply

a guide to help the pilot check the

condition of the helicopter. It may

be as comprehensive as

conditions warrant at the

discretion of the pilot.

Rev. 1

2-31

BHT-206L3-FM-1

FAAAPPROVED

Figure 2-1. Preflight check sequence

2-4

DOT APPROVED

BHT-206L3-FM-1

All areas checked shall include a

visual check for evidence of

corrosion, particularly when

helicopter is flown near or over

salt water or in areas of high

industrial emissions.

3.

Hydraulic system filters Bypass indicator retracted.

4.

Hydraulic actuators and lines Condition, security, interference,

leakage.

2-7. BEFORE EXTERIOR

CHECK

5.

6.

Forward fairing - Secured.

--

1. Flight planning - Completed.

2. Publications - Checked.

3.

Gross weight and CG Computed.

4.

Helicopter servicing -

Completed.

5. Battery - Connected.

Transmission

- Check oil level.

Verify actual presence of oil in

sight gage.

7. Transmission oil cooler lines Condition and security.

6.

Nodal beam - Check condition

and security of elastomeric

bearings, elastomeric straps, and

fore and aft restraint damper.

9.

2-8. EXTERIOR CHECK

2-9. FUSELAGE

- CABIN RIGHT

Main driveshaft forward coupling

- Condition, security, and grease

leakage. Check Temp-Plates (four

places) for evidence of elevated

temperature indicated by dot

changing color to black.

SIDE

1.

2.

3.

4.

5.

2-10.

Right static port - Condition.

Cabin doors - Condition and

security.

Windows

- Condition and

security.

Landing gear - Condition and

ground handling wheel removed.

Forward and aft crosstube

fairings - Secured, condition,

and aligned.

FUSELAGE

- CENTER

RIGHT SIDE

1. Engine inlet - Condition; remove

inlet covers.

2. Cabin roof, transmission cowling,

and engine air inlet area Cleaned of all debris and

accumulated snow and ice;

cowling secured.

IF ANY TEMP-PLATE IS MISSING

OR HAS BLACK DOTS

MAINTENANCE PERSONNEL

SHALL ASSIST IN DETERMINING

AIRWORTHINESS.

10. Access door - Secured.

11. Rotor head - Condition.

12. Fuel filler cap - Visually check

fuel level and cap secured.

13. Fuel sump - Drain fuel sample

as follows:

a. FUEL BOOST circuit breakers

- out.

b. BAT switch - On.

c. FUEL VALVE switch - OFF.

d. PUSH FOR FUEL SUMP DRAIN

button -

Press, drain sample,

then release.

Rev. 3 2-5

BHT-206L3-FM-1

DOTAPPROVED

NOTE

Forward fuel cells can be drained

manually as desired.

14. A/F fuel filter - Drain and check

before first flight of the day as

follows:

a. FUEL VALVE switch - ON.

b. FUEL BOOST circuit breakers

- In.

c. Fuel filter drain valve - Open,

drain sample, then close.

NOTE

Filter test button is located on top

of fuel filter.

15. Fuel filter test button - Press

and check FUEL FILTER caution

light illuminated. Release switch

and check light extinguished.

16. FUEL VALVE switch - OFF.

17. BAT switch - OFF.

16. Powerplant Area

a. Main driveshaft aft coupling -

Condition, security, and grease

leakage. Check Temp-Plates

(four places) for evidence of

elevated temperature indicated

by dot changing color to black.

IF ANY TEMP-PLATE IS MISSING

OR HAS BLACK DOTS,

MAINTENANCE PERSONNEL

SHALL ASSIST IN DETERMINING

AIRWORTHINESS.

b. Engine - Condition; security

of attachments. Evidence of oil

leakage.

c. Engine mounts - Condition

and security.

d. Throttle linkage - Condition,

security,

and freedom of

operation.

e. Fuel control and mechanical

fuel pump - Security and

condition; evidence of leakage,

governor air lines.

f. Hoses and tubing - Chafing,

security, and condition.

19. Engine cowl - Secured.

20. Generator cooling scoop Clear of debris.

21.

Oil tank - Oil level, leaks,

security, and cap secured.

22. Access door - Secured.

23. Aft fairing - Secured.

2-11. FUSELAGE - AFT RIGHT

SIDE

1. Fuselage - Condition.

2. Tail. rotor driveshaft cover -

Condition and security.

3. Tailboom - Condition.

4. Horizontal stabilizer and position

light - Condition and security.

5. Sync elevator - Check lateral

freedom, bearing play, and clear

of obstructions.

6. Main rotor blade - Condition.

2-12. FUSELAGE - FULL AFT

1. Vertical fin - Condition.

2. Tail rotor guard - Condition and

security.

3. Anticollision light - Condition

and security of lens.

4. Aft position light - Condition.

5. Tail rotor gearbox - Oil level,

leaks and security.

2-6

Rev. 3

DOT APPROVED

6. Tail rotor - Tiedown removed,

condition and free movement.

7. Tail rotor controls - Condition and

security.

6. Tail rotor blades - Condition; tip

block security, evidence of

corrosion, and seal condition.

2-13. FUSELAGE - AFT LEFT

SIDE

FAILURE TO REMOVE ROTOR

TIEDOWNS BEFORE ENGINE

STARTING MAY RESULT IN

SEVERE DAMAGE AND POSSIBLE

INJURY.

1.

Main rotor blade - Tiedown

removed; condition.

2. Tailboom - Condition.

3. Tail rotor driveshaft cover Condition and security.

4. Horizontal stabilizer and position

light - Condition and security.

6. Sync elevator - Check lateral

freedom, bearing play, and clear of

obstructions.

6. Fuselage - Condition.

7.

Forward tail rotor driveshaft

coupling - Condition of splined

adapter.

6. Oil cooler blower shaft hanger

bearings - Evidence of grease

leakage and overheating.

9. Oil cooler blower - Clear of

obstruction and condition.

10. Oil cooler - Condition and leaks.

BHT-206L3-FM-1

11. Oil cooler access door - Secured.

12. Aft fairing - Secured.

13. Baggage compartment - Cargo

tied down, door secured.

14. Exhaust cover - Removed.

15. Powerplant Area

a. Engine - Condition; security of

attachments.

b. Engine mounts - Condition and

security.

c. Exhaust stack - Condition and

security.

d. Evidence of fuel and oil leaks.

e. Hoses and tubing for chafing

and condition.

f. Pneumatic lines - Condition and

security.

g.

Linear actuator and governor

control linkage - Condition and

security.

h.

Tail rotor driveshaft - Condition

of splines, couplings, and

freedom of movement.

i. Air induction diffuser hose -

Condition and security.

j. Engine cowling - Secured.

k. Air Induction cowling -

Secured.

I.

Cabin roof, transmission

cowling, engine air inlet area,

and plenum - Clear of all debris

and accumulated snow and ice;

cowling secured.

16. Transmission Area

2-7

BHT-206L3-FM-1

DOT APPROVED

a. Nodal beam - Condition and

security of elastomeric

bearings, elastomeric strap,

and fore and aft restraint

damper.

I

b. Transmission oil filter bypass

button - Ensure not extended.

c. Main driveshaft forward

coupling - Condition and

evidence of grease leakage.

Check paint strip for evidence

of overheat indicated by brown

color.

d. Cockpit indicator pressure

lines - Condition and security.

e. Access door - Secured.

2-14. FUSELAGE - CABIN LEFT

SIDE

1. Main rotor hub and yoke Condition.

2. Main rotor blade doublers and

skin - Condition.

3. Pitch horn trunnion bearing -

Wear and security.

4.

Main rotor pitch links Condition and security of

attachment bolts and locking

hardware.

6. Swashplate assembly Condition, security of attached

controls, and boot condition.

6. Control linkages to swashplate -

Condition, security of attachment

bolts and locking hardware.

7. Forward fairing and access door

- Secured.

6. Cabin doors and hinge pins Condition and security.

9. Windows - Condition and

security.

2-8 Rev. 4

10. Hydraulic reservoir - Check

fluid level.

11. Landing gear - Condition and

ground handling wheel

removed.

12.

Forward and aft crosstube

fairings - Secured, condition

and aligned.

13. Left static port - Condition.

2-15. FUSELAGE - FRONT

1. Exterior surfaces - Condition.

2. Windshield - Condition and

cleanliness.

3.

Battery and vent lines Condition and security.

4. HOUR METER circuit breaker In.

5.

FUEL BOOST LEFT circuit

breaker - In.

6. Battery access door - Secured.

7. Pitot tube - Cover removed,

clear of obstruction.

6. External power door - Condition

and security.

NOTE

APU should be 500 amperes or

less to reduce risk of starter

damage from overheating.

9. Landing light glass - Condition.

10. Antennas - Condition and

security.

11. Main rotor blade - Condition.

12. External power - Check BAT

switch OFF and APU connected

as desired.

Loading...

Loading...