Page 1

IMMUNITY TEST REPORT

REPORT NO.: RM920221R04A

MODEL NO.:

F5D7000

RECEIVED: Feb. 21, 2003

TESTED: Feb. 27 ~ Mar. 7, 2003

APPLICANT: Belkin Corporation

501 WEST WALNUT STREET COMPTON,

ADDRESS:

CA 90220

ISSUED BY: Advance Data Technology Corporation

LAB LOCATION: No.47 14th Ling, Chia Pau Tsuen, Linkou

Hsiang, Taipei, Taiwan, R.O.C.

This test report consists of 29 pages in total. It may be duplicated completely for legal use with the

approval of the applicant. It should not be reproduced except in full, without the written approval of

our laboratory. The client should not use it to claim product endorsement by NVLAP or any U.S.

government agencies. The test results in the report only apply to the tested sample.

ILAC MRA

Report No.: RM920221R04A

Reference No.: RM920221R04

0528

1

Issued: Mar. 14, 2003

Page 2

Table of Contents

1 CERTIFICATION ..................................................................................................................... 3

2 SUMMARY OF TEST RESULTS ............................................................................................ 4

3 GENERAL INFORMATION ..................................................................................................... 5

3.1 GENERAL DESCRIPTION OF EUT ........................................................................................5

3.2 DESCRIPTION OF TEST MODE.............................................................................................6

3.3 GENERAL DESCRIPTION OF APPLIED STANDARD ...........................................................6

3.4 DESCRIPTION OF SUPPORT UNIT.......................................................................................7

4 EMISSION TEST..................................................................................................................... 8

4.1 CONDUCTED EMISSION MEASUREMENT ..........................................................................8

4.1.1 LIMITS OF CONDUCTED EMISSION MEASUREMENT ........................................................8

4.1.2 TEST INSTRUMENTS .............................................................................................................8

4.1.3 TEST PROCEDURES..............................................................................................................9

4.1.4 DEVIATION FROM TEST STANDARD....................................................................................9

4.1.5 TEST SETUP .........................................................................................................................10

4.1.6 EUT OPERATING CONDITIONS ..........................................................................................10

4.1.7 TEST RESULTS..................................................................................................................... 11

5 IMMUNITY TEST ..................................................................................................................13

5.1 GENERAL DESCRIPTION ....................................................................................................13

5.2 GENERAL PERFORMANCE CRITERIA DESCRIPTION .....................................................13

5.3 EUT OPERATING CONDITION.............................................................................................15

5.4 ELECTROSTATIC DISCHARGE IMMUNITY TEST (ESD) ...................................................16

5.4.1 TEST SPECIFICATION..........................................................................................................16

5.4.2 TEST INSTRUMENT .............................................................................................................16

5.4.3 TEST PROCEDURE ..............................................................................................................17

5.4.4 DEVIATION FROM TEST STANDARD..................................................................................17

5.4.5 TEST SETUP .........................................................................................................................18

5.4.6 TEST RESULT .......................................................................................................................19

5.5 RADIATED, RADIO-FREQUENCY, ELECTROMAGNETIC FIELD IMMUNITY TEST (RS) .21

5.5.1 TEST SPECIFICATION .........................................................................................................21

5.5.2 TEST INSTRUMENT .............................................................................................................21

5.5.3 TEST PROCEDURE ..............................................................................................................22

5.5.4 DEVIATION FROM TEST STANDARD..................................................................................22

5.5.5 TEST SETUP .........................................................................................................................23

5.5.6 TEST RESULT .......................................................................................................................24

6 PHOTOGRAPHS OF THE TEST CONFIGURATION........................................................... 26

7 APPENDIX - INFORMATION ON THE TESTING LABORATORIES.................................... 29

Report No.: RM920221R04A

Reference No.: RM920221R04

2

Issued: Mar. 14, 2003

Page 3

1 CERTIFICATION

PRODUCT:

MODEL NO:

BRAND NAME:

2.4GHz wireless PCI

F5D7000

Belkin

APPLICANT: Belkin Corporation

STANDARDS: EN 301 489-1 (09-2001), EN 301 489-17 (09-2000)

EN 55022:1998, Class B

EN 61000-4-2:1995

EN 61000-4-3:1995

We, Advance Data Technology Corporation, hereby certify that one sample of the

designation has been tested in our facility from Feb. 27 ~ Mar. 7, 2003. The test

record, data evaluation and Equipment Under Test (EUT) configurations represented

herein are true and accurate accounts of the measurements of the sample's immunity

characteristics under the conditions herein specified.

Report No.: RM920221R04A

Reference No.: RM920221R04

3

Issued: Mar. 14, 2003

Page 4

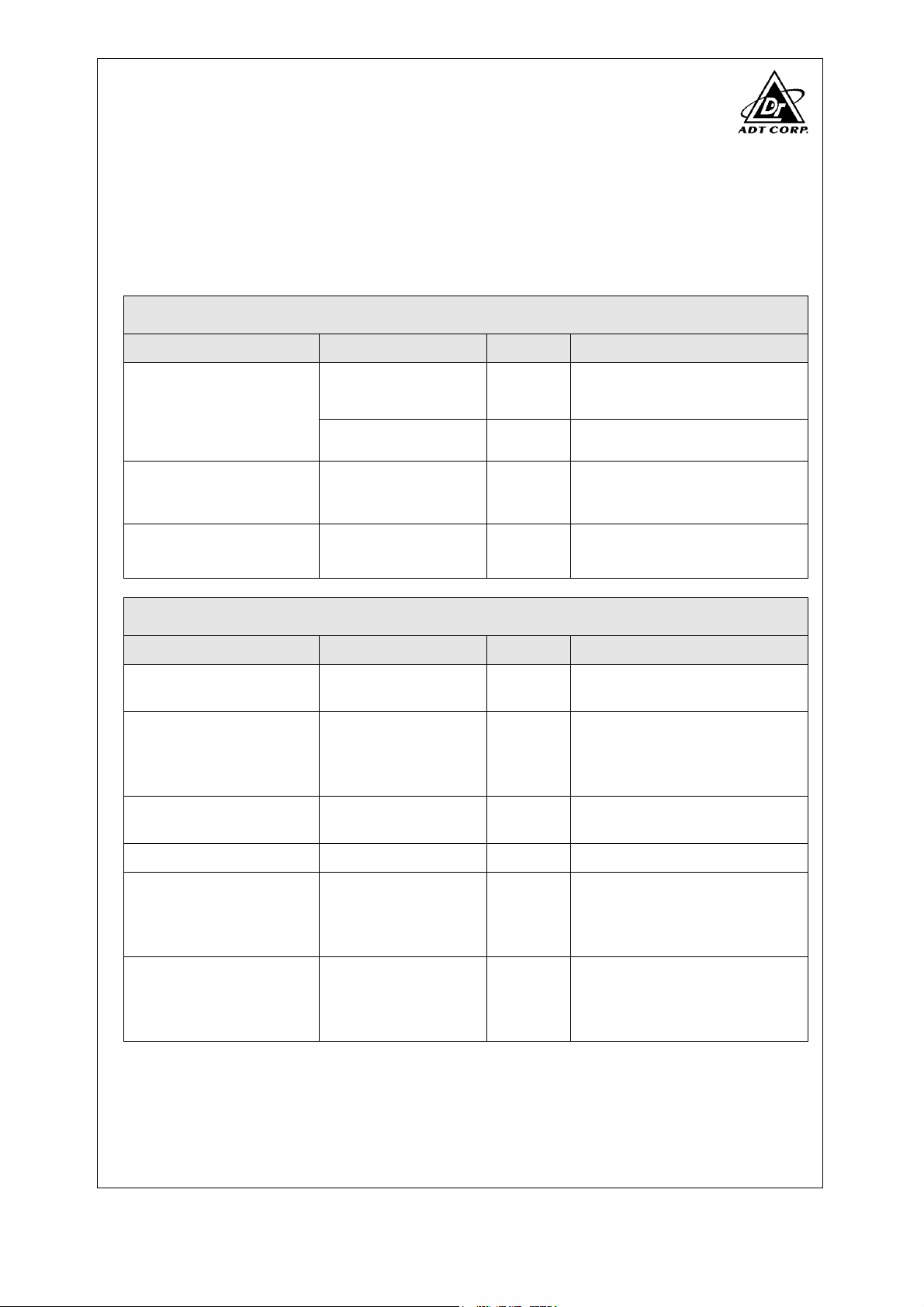

2 SUMMARY OF TEST RESULTS

The EUT has been tested according to the following specifications:

EMISSION

Standard Test Type Result Remarks

Meet the requirement of limit

EN 55022:1998,

Class B (Conducted

Emission)

Conducted Test PASS

Radiated Test

NA NOT APPLICABLE

Minimum passing margin is

–23.49dBuV/m at 0.255MHz

EN 61000-3-2:1995

+A1:1998+A2:1998, Class

A

EN 61000-3-3:1995

Harmonic current

emissions

Voltage fluctuations &

flicker

NA NOT APPLICABLE

NA NOT APPLICABLE

IMMUNITY

Standard Test Type Result Remarks

EN 61000-4-2:1995

EN 61000-4-3:1995

EN 61000-4-4:1995

EN 61000-4-5:1995 Surge immunity test NA NOT APPLICABLE

EN 61000-4-6:1996

Electrostatic discharge

immunity test

Radiated, radiofrequency,

electromagnetic field

immunity test

Electrical fast transient

/ burst immunity test.

Immunity to conducted

disturbances, induced

by radio-frequency

fields

PASS

PASS

NA NOT APPLICABLE

NA NOT APPLICABLE

Meets the requirements of

Performance Criterion A

Meets the requirements of

Performance Criterion A

Voltage dips, short

EN 61000-4-11:1994

NOTE: Please refer to Item 3.3 for more detailed description.

Report No.: RM920221R04A

Reference No.: RM920221R04

interruptions and

voltage variations

immunity tests

NA NOT APPLICABLE

4

Issued: Mar. 14, 2003

Page 5

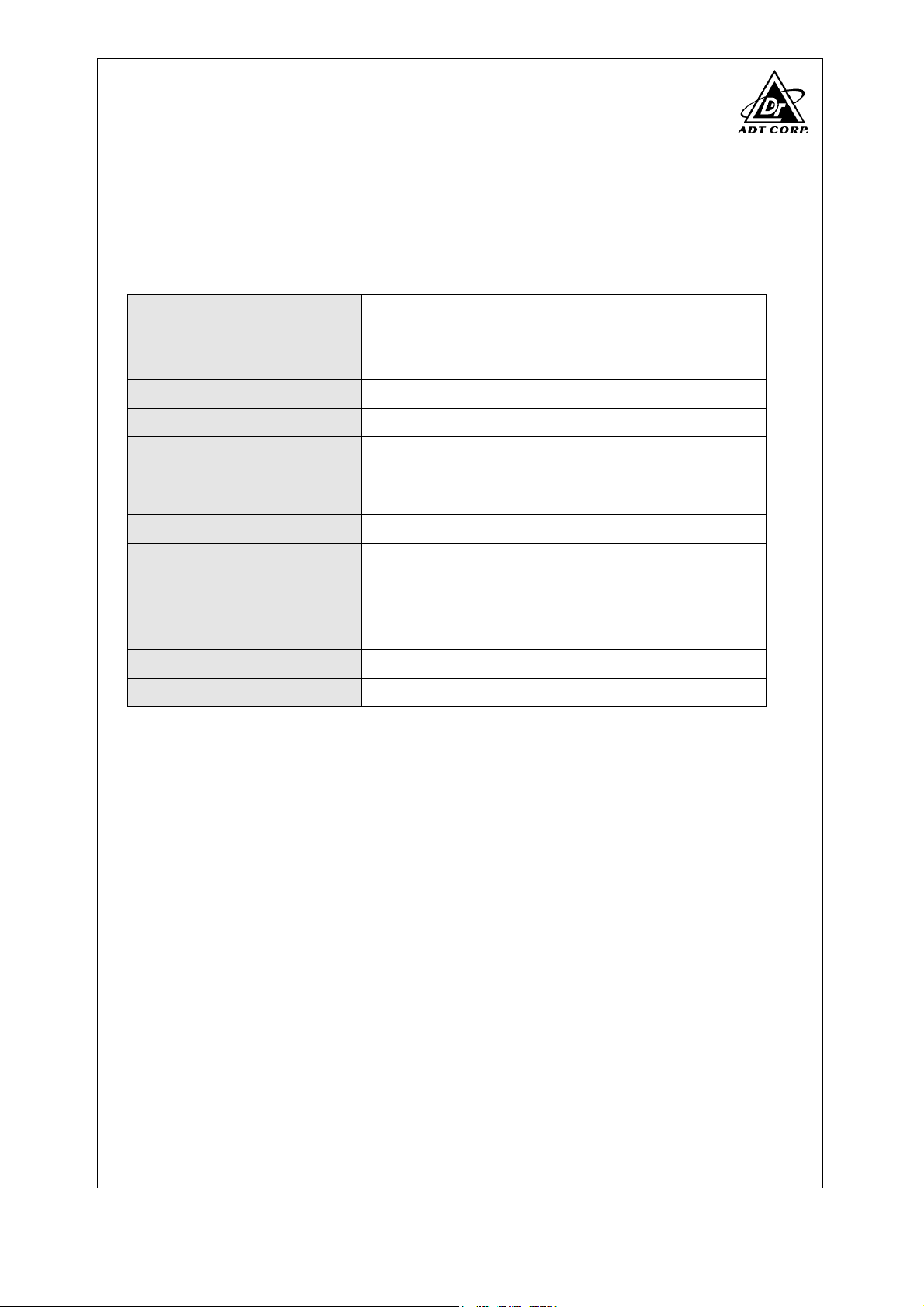

3 GENERAL INFORMATION

3.1 GENERAL DESCRIPTION OF EUT

PRODUCT 2.4GHz wireless PCI

MODEL NO. F5D7000

POWER SUPPLY 3.3VDC from host equipment

MODULATION TYPE DSSS, OFDM

TRANSFER RATE Up to 54Mbps

OPERATING

FREQUENCY

2.412GHz ~ 2.472GHz

NUMBER OF CHANNEL 13

CHANNEL SPACING 5 MHz

RATED RF OUTPUT

POWER LEVEL

18.69dBm (Measured Max. Average)

22.87dBm (Measured Max. Peak))

ANTENNA TYPE Dipole Antenna

DATA CABLE NA

I/O PORTS NA

ASSOCIATED DEVICES NA

NOTE: For a more detailed features description, please refer to the manufacturer's specifications

or User's Manual.

Report No.: RM920221R04A

Reference No.: RM920221R04

5

Issued: Mar. 14, 2003

Page 6

.

3.2 DESCRIPTION OF TEST MODE

The EUT was tested under following conditions:

CONDITION CONFIGURATION REMARKS

1 Transmission

2 Standby

3.3 GENERAL DESCRIPTION OF APPLIED STANDARD

The EUT is a kind of computer peripheral with wireless data transmission function.

According to the specifications of the manufacturer, it must comply with the

requirements of the following standards:

EN 301 489-1 (09-2001), EN 301 489-17 (09-2001)

EN 55022:1998, Class B (Conducted Emission)

EN 61000-4-2:1995

EN 61000-4-3:1995

According to clause 7.1 (table 2) and clause 7.2 (table 3) of EN 301 489-1 (09-2001),

all tests have been performed and recorded as per the above standards.

Report No.: RM920221R04A

Reference No.: RM920221R04

6

Issued: Mar. 14, 2003

Page 7

3.4 DESCRIPTION OF SUPPORT UNIT

The EUT has been tested as an independent unit together with other necessary

accessories or support units. The following support units or accessories were used to

form a representative test configuration during the tests.

For Conducted Emission

NO. PRODUCT BRAND MODEL NO. SERIAL NO. FCC ID

1 PERSONAL

COMPUTER

2 MONITOR ADI CM100 020058T10200182FCC DOC APPROVED

3 PS/2 KEYBOARD BTC 5121W A00800777 E5XKB5121WTH0110

4 PS/2 MOUSE LOGITECH M-S61 HCA12605710 JNZ211403

5 MODEM ACEEX 1414 980020539 IFAXDM1414

6 PRINTER EPSON LQ-300+ DCGY017059 FCC DOC APPROVED

NO. SIGNAL CABLE DESCRIPTION OF THE ABOVE SUPPORT UNITS

1NA

2 1.8 m braid shielded wire, terminated with VGA connector via metallic frame, w/o core

3 1.6 m foil shielded wire, terminated with PS/2 connector via metallic frame, w/o core.

4 1.8 mNon shielded wire, terminated with PS/2 connector via drain wire, w/o core.

5 1.2 m braid shielded wire, terminated with DB25 and DB9 connector via metallic frame, w/o

core.

6 1.2m braid shielded wire, terminated with DB25 and Centronics connector via metallic

frame, w/o core

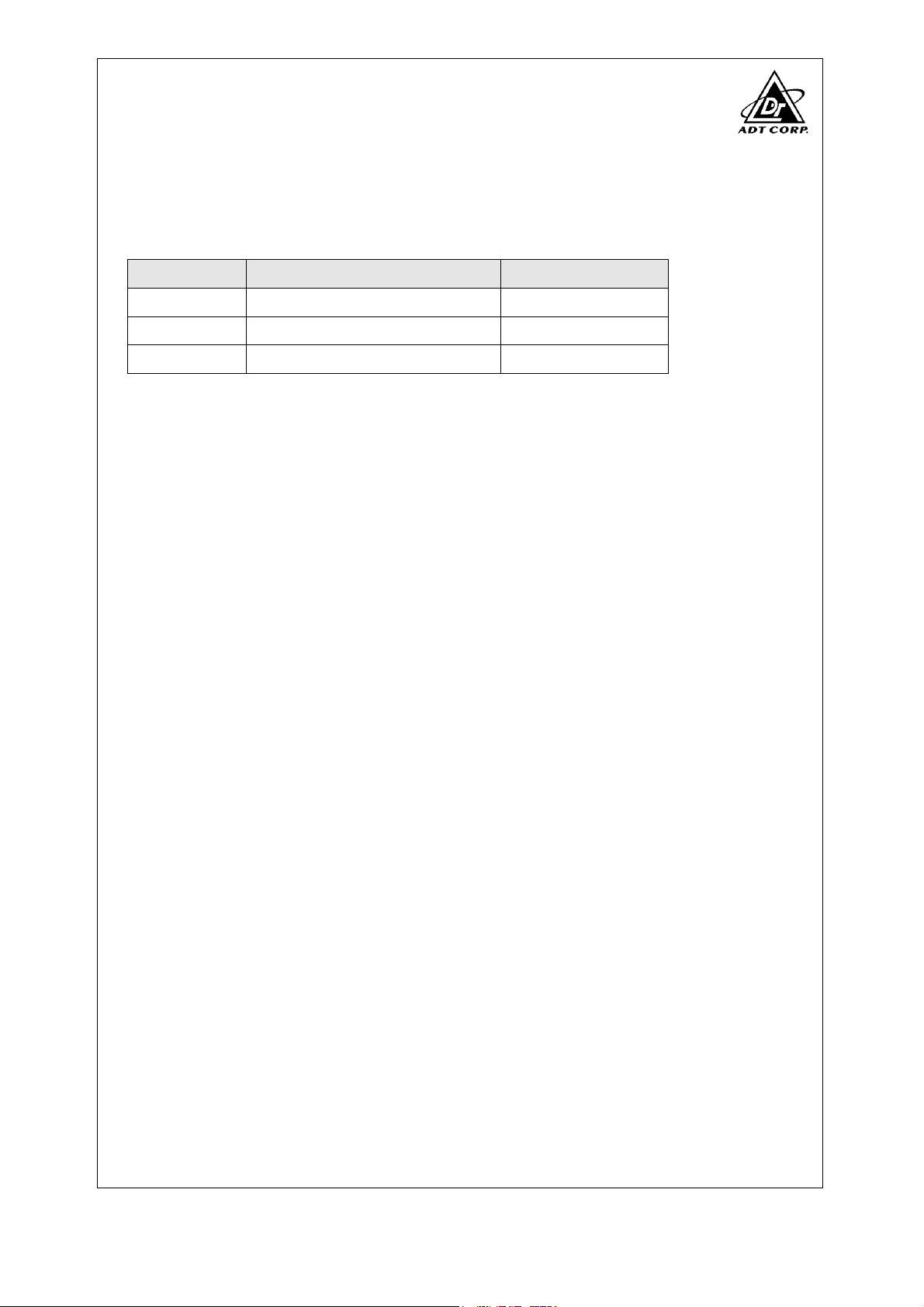

For EMS

NO. PRODUCT BRAND MODEL NO. SERIAL NO. FCC ID

1 PERSONAL

COMPUTER

2 MONITOR DELL E772f NA NA

3 PS/2 KEYBOARD HP 6511-PK 99P468101CY1

4 PS/2 MOUSE HP M-S48a LZE11308376AW JNZ201213

5 MODEM GVC F-1128V1R6 96-191-113003 DK4F1128VR6

6 PRINTER HP 2225C 2931S53817 DSI6XU2225

7 ACCESS POINT D-Link DWL-2000AP NA NA

HP DTPC-16 NA FCC DOC APPROVED

HP DTPC-16 NA FCC DOC APPROVED

FCC DOC APPROVED

W06S012293

NO. SIGNAL CABLE DESCRIPTION OF THE ABOVE SUPPORT UNITS

1NA

2 1.8 m braid shielded wire, terminated with VGA connector via metallic frame, with core

3 1.8 m foil shielded wire, terminated with PS/2 connector via metallic frame, w/o core

4 1.8 m Non shielded wire, terminated with PS/2 connector via drain wire, w/o core.

5 1.2 m braid shielded wire, terminated with DB25 and DB9 connector via metallic frame,

w/o core.

6 1.2m braid shielded wire, terminated with DB25 and Centronics connector via metallic

frame, w/o core.

7NA

NOTE: All power cords of the above support units are non shielded (1.8m).

Report No.: RM920221R04A

Reference No.: RM920221R04

7

Issued: Mar. 14, 2003

Page 8

4 EMISSION TEST

)

4.1 CONDUCTED EMISSION MEASUREMENT

4.1.1 LIMITS OF CONDUCTED EMISSION MEASUREMENT

FREQUENCY (MHz

Class A (dBuV) Class B (dBuV)

Quasi-peak Average Quasi-peak Average

0.15 - 0.5 79 66 66 - 56 56 - 46

0.50 - 5.0 73 60 56 46

5.0 - 30.0 73 60 60 50

NOTE: (1) The lower limit shall apply at the transition frequencies.

(2) The limit decreases in line with the logarithm of the frequency in the range of 0.15

to 0.50 MHz.

(3) All emanations from a class A/B digital device or system, including any network of

conductors and apparatus connected thereto, shall not exceed the level of field

strengths specified above.

4.1.2 TEST INSTRUMENTS

DESCRIPTION & MANUFACTURER MODEL NO. SERIAL NO. CALIBRATED UNTIL

ROHDE & SCHWARZ Test Receiver ESHS30 828109/007 July 03, 2003

ROHDE & SCHWARZ Artificial

Mains Network (for EUT)

* ROHDE & SCHWARZ

4-wire ISN

* ROHDE & SCHWARZ

2-wire ISN

EMCO-L.I.S.N. (for peripheral) 3825/2 9204-1964 July 02, 2003

Software Cond-V2M1 NA NA

RF cable (JYEBAO) 5D-FB Cable-C02.01 July 5, 2003

HP Terminator (For EMCO LISN) 11593A E1-01-298 Feb. 23, 2004

HP Terminator (For EMCO LISN) 11593A E1-01-299 Feb. 23, 2004

ESH3-Z5 839135/006 July 02. 2003

ENY41 838119/028 Nov. 29, 2003

ENY22 837497/016 Nov. 29, 2003

NOTE: 1. The calibration interval of the above test instruments is 12 months and the

calibrations are traceable to NML/ROC and NIST/USA.

2. “*”: These equipment are used for conducted telecom port test only (if tested).

3. The test was performed in ADT Shielded Room No. 2.

4. The VCCI Site Registration No. is C-240.

Report No.: RM920221R04A

Reference No.: RM920221R04

8

Issued: Mar. 14, 2003

Page 9

4.1.3 TEST PROCEDURES

a. The EUT was placed 0.4 meters from the conducting wall of the shielded room

with EUT being connected to the power mains through a line impedance

stabilization network (LISN). Other support units were connected to the power

mains through another LISN. The two LISNs provide 50 ohm/ 50uH of coupling

impedance for the measuring instrument.

b. Both lines of the power mains connected to the EUT were checked for maximum

conducted interference.

c. The frequency range from 150 kHz to 30 MHz was searched. Emission levels

over 10dB under the prescribed limits could not be reported

4.1.4 DEVIATION FROM TEST STANDARD

No deviation

Report No.: RM920221R04A

Reference No.: RM920221R04

9

Issued: Mar. 14, 2003

Page 10

4.1.5 TEST SETUP

For the actual test configuration, please refer to the related item – Photographs of the

Test Configuration.

4.1.6 EUT OPERATING CONDITIONS

a. Connected the EUT to a computer system placed on a testing table.

b. The computer system ran a test program to enable EUT under

transmission/receiving condition continuously at specific channel

frequency.

c. The computer system sent "H" messages to its screen.

d. The computer system sent “H” messages to modem.

e. The computer system sent "H" messages to printer and the printer prints

them on paper.

Report No.: RM920221R04A

Reference No.: RM920221R04

10

Issued: Mar. 14, 2003

Page 11

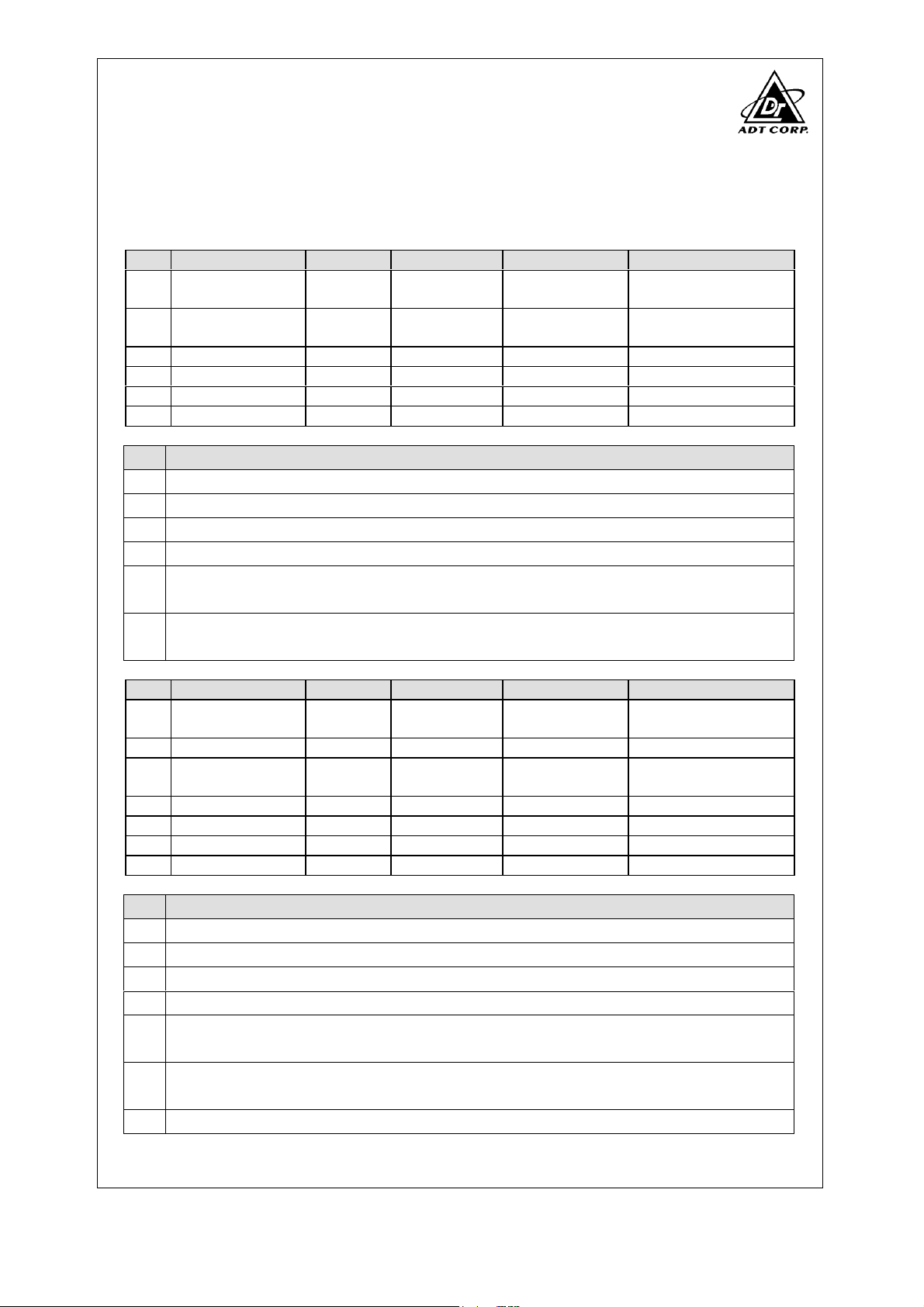

4.1.7 TEST RESULTS

EUT 2.4GHz wireless PCI Model F5D7000

INPUT POWER

230Vac, 50 Hz

PHASE

6dB BANDWIDTH

ENVIRONMENTAL

CONDITIONS

Freq. Corr. Reading Value

No Factor [dB (uV)] [dB (uV)] [dB (uV)] (dB)

[MHz] (dB) Q.P. AV. Q.P. AV. Q.P. AV. Q.P. AV.

1 0.255 0.10 33.16 - 33.26 - 61.59 51.59 -28.33 2 0.385 0.10 29.89 - 29.99 - 58.17 48.17 -28.18 3 0.767 0.10 26.86 - 26.96 - 56.00 46.00 -29.04 4 0.894 0.10 27.21 - 27.31 - 56.00 46.00 -28.69 5 1.402 0.10 29.45 - 29.55 - 56.00 46.00 -26.45 6 7.103 0.46 26.08 - 26.54 - 60.00 50.00 -33.46 -

REMARKS:

1. Q.P. and AV. are abbreviations of quasi-peak and average individually.

2. "-": The Quasi-peak reading value also meets average limit and measurement with

the average detector is unnecessary.

3. The emission levels of other frequencies were very low against the limit.

4. Margin value = Emission level - Limit value

5. Correction factor = Insertion loss + Cable loss

6. Emission Level = Correction Factor + Reading Value.

22 deg. C, 68 % RH,

1005 hPa

TESTED BY: Cody Chang

Emission

Level

Limit Margin

10 kHz

Line (L)

Report No.: RM920221R04A

Reference No.: RM920221R04

11

Issued: Mar. 14, 2003

Page 12

EUT

2.4GHz wireless PCI

Model

F5D7000

INPUT POWER

230Vac, 50 Hz

PHASE

6dB BANDWIDTH

ENVIRONMENTAL

CONDITIONS

Freq. Corr. Reading Value

No Factor [dB (uV)] [dB (uV)] [dB (uV)] (dB)

[MHz] (dB) Q.P. AV. Q.P. AV. Q.P. AV. Q.P. AV.

1 0.255 0.10 38.00 - 38.10 - 61.59 51.59 -23.49 2 0.384 0.10 33.92 - 34.02 - 58.19 48.19 -24.17 3 0.768 0.10 26.09 - 26.19 - 56.00 46.00 -29.81 4 0.894 0.10 28.17 - 28.27 - 56.00 46.00 -27.73 5 1.404 0.10 29.69 - 29.79 - 56.00 46.00 -26.21 6 7.427 0.36 28.20 - 28.56 - 60.00 50.00 -31.44 -

REMARKS:

1. Q.P. and AV. are abbreviations of quasi-peak and average individually.

2. "-": The Quasi-peak reading value also meets average limit and measurement with the

average detector is unnecessary.

3. The emission levels of other frequencies were very low against the limit.

4. Margin value = Emission level - Limit value

5. Correction factor = Insertion loss + Cable loss

6. Emission Level = Correction Factor + Reading Value.

22 deg. C, 68 % RH,

1005 hPa

TESTED BY: Cody Chang

Emission

Level

Limit Margin

10 kHz

Neutral (N)

Report No.: RM920221R04A

Reference No.: RM920221R04

12

Issued: Mar. 14, 2003

Page 13

5 IMMUNITY TEST

5.1 GENERAL DESCRIPTION

Product

EN 301 489-1 (09-2001), EN 301 489-17 (09-2000)

Standard

EN 61000-4-2

Electrostatic Discharge – ESD:

8kV air discharge, 4kV Contact discharge,

Basic Standard,

Specification, and

Performance

Criterion required

EN 61000-4-3

Performance Criterion B

Radio-Frequency Electromagnetic Field

Susceptibility Test – RS:

80-1000 / 1400-2000 MHz, 3V/m, 80% AM (1kHz),

Performance Criterion A

5.2 GENERAL PERFORMANCE CRITERIA DESCRIPTION

The Requirement of Performance Criteria

Performance criteria for

1

continuous phenomena applied

Criterion A of the applicable class shall apply

to transmitters (CT)

Performance criteria for

2

transient phenomena applied to

Criterion B of the applicable class shall apply

transmitters (TT)

Performance criteria for

3

continuous phenomena applied

to receivers (CR)

Performance criteria for

4

transient phenomena applied to

receivers (TR)

Criterion A of the applicable class shall apply

Criterion B of the applicable class shall apply

Report No.: RM920221R04A

Reference No.: RM920221R04

13

Issued: Mar. 14, 2003

Page 14

The phenomena allowed during and after test in each criterion are clearly stated in

the following table

Performance criteria

Criteria During test After test

Shall operate as intended.

May show degradation of

performance (see note1).

A

Shall be no loss of function.

Shall be no unintentional

transmissions.

May show loss of function (one or

more).

May show degradation of

performance (see note 1).

B

No unintentional transmissions.

Shall operate as intended.

Shall be no degradation of

performance (see note 2).

Shall be no loss of function.

Shall be no loss of stored data or

user programmable functions.

Functions shall be selfrecoverable.

Shall operate as intended after

recovering.

Shall be no degradation of

performance (see note 2).

Shall be no loss of stored data or

user programmable functions.

May be loss of function (one or more). Functions shall be recoverable

by the operator.

C

Shall operate as intended after

recovering.

Shall be no degradation of

performance (see note 2).

NOTE 1:Degradation of performance during the test is understood as a degradation to a level

not below a minimum performance level specified by the manufacturer for the use of

the apparatus as intended. In some cases the specified minimum performance level

may be replaced by a permissible degradation of performance.

If the minimum performance level or the permissible performance degradation is not

specified by the manufacturer then either of these may be derived from the product

description and documentation (including leaflets and advertising) and what the user

may reasonably expect from the apparatus if used as intended.

NOTE 2: No degradation of performance after the test is understood as no degradation below a

minimum performance level specified by the manufacturer for the use of the

apparatus as intended. In some cases the specified minimum performance level may

be replaced by a permissible degradation of performance. After the test no change of

actual operating data or user retrievable data is allowed.

If the minimum performance level or the permissible performance degradation is not

specified by the manufacturer then either of these may be derived from the product

description and documentation (including leaflets and advertising) and what the user

may reasonably expect form the apparatus if used as intended.

Report No.: RM920221R04A

Reference No.: RM920221R04

14

Issued: Mar. 14, 2003

Page 15

5.3 EUT OPERATING CONDITION

1. Connected the EUT to a computer system placed on a testing table.

2. The computer system ran a test program to enable all functions of EUT.

3. Prepared the access point and placed it outside of testing area to act as

communication partner for EUT.

4. Sent data to EUT by command "PIN" from the communication partner.

Note: For standby mode test, connected a coupling antenna to a spectrum analyzer and placed the

antenna near the EUT to monitor any unintentional response occurring from the EUT during the test.

Report No.: RM920221R04A

Reference No.: RM920221R04

15

Issued: Mar. 14, 2003

Page 16

5.4 ELECTROSTATIC DISCHARGE IMMUNITY TEST (ESD)

5.4.1 TEST SPECIFICATION

Basic Standard: EN 61000-4-2

Discharge Impedance: 330 ohm / 150 pF

Discharge Voltage:

Air Discharge - 8 kV (Direct)

Contact Discharge – 4kV (Direct/Indirect)

Polarity: Positive & Negative

Number of Discharge: Minimum 20 times at each test point

Discharge Mode: Single Discharge

Discharge Period: 1 second minimum

5.4.2 TEST INSTRUMENT

DESCRIPTION &

MANUFACTURER

KeyTek, ESD Simulator MZ-15/EC 9902287 Feb. 26, 2003

EM Test ESD Simulator ESD 30C 0201-28 Jul. 15, 2003

EM Test ESD Discharge Unit P30C 0201-28 Jul. 15, 2003

EM Test ESD Discharge Unit P30C-RFCI 0601-07 Jul. 15, 2003

FCC Coupling Decoupling

Network

FCC Coupling Decoupling

Network

MODEL NO. SERIAL NO.

FCC-801-T2 020022 Jun.12, 2003

FCC-801-T4 020033 Jun.12, 2003

CALIBRATED

UNTIL

NOTE: 1. The test was performed in ESD Room No. 1.

2. The calibration interval of the above test instruments is 12 months and the

calibrations are traceable to NML/ROC and NIST/USA.

Report No.: RM920221R04A

Reference No.: RM920221R04

16

Issued: Mar. 14, 2003

Page 17

5.4.3 TEST PROCEDURE

a. Electrostatic discharges were applied only to those points and surfaces of the

EUT that are accessible to users during normal operation.

b. The test was performed with at least ten single discharges on the pre-selected

points in the most sensitive polarity.

c. The time interval between two successive single discharges was at least 1

second.

d. The ESD generator was held perpendicularly to the surface to which the

discharge was applied and the return cable was at least 0.2 meters from the

EUT.

e. Contact discharges were applied to the non-insulating coating, with the pointed

tip of the generator penetrating the coating and contacting the conducting

substrate.

f. Air discharges were applied with the round discharge tip of the discharge

electrode approaching the EUT as fast as possible (without causing

mechanical damage) to touch the EUT. After each discharge, the ESD

generator was removed from the EUT and re-triggered for a new single

discharge. The test was repeated until all discharges were complete.

g. At least ten single discharges (in the most sensitive polarity) were applied to

the Horizontal Coupling Plane at points on each side of the EUT. The ESD

generator was positioned vertically at a distance of 0.1 meters from the EUT

with the discharge electrode touching the HCP.

h. At least ten single discharges (in the most sensitive polarity) were applied to

the center of one vertical edge of the Vertical Coupling Plane in sufficiently

different positions that the four faces of the EUT were completely illuminated.

The VCP (dimensions 0.5m x 0.5m) was placed vertically to and 0.1 meters

from the EUT.

5.4.4 DEVIATION FROM TEST STANDARD

No deviation

Report No.: RM920221R04A

Reference No.: RM920221R04

17

Issued: Mar. 14, 2003

Page 18

5.4.5 TEST SETUP

eference Ground

e

1m

0.1m

Vertical

coupling plane

0.5mm Isolation Support

ESD

EUT

Generator

470k

X4

Nearest

Wall

Horizontal

80cm

coupling plane

PS

PS

PSPS

R

Plan

For the actual test configuration, please refer to the related item – Photographs of the

Test Configuration.

NOTE:

TABLE-TOP EQUIPMENT

The configuration consisted of a wooden table 0.8 meters high standing on the Ground Reference

Plane. The GRP consisted of a sheet of aluminum at least 0.25mm thick, and 2.5 meters square

connected to the protective grounding system. A Horizontal Coupling Plane (1.6m x 0.8m) was placed

on the table and attached to the GRP by means of a cable with 940kΩ total impedance. The equipment

under test, was installed in a representative system as described in section 7 of EN 61000-4-2:1995,

and its cables were placed on the HCP and isolated by an insulating support of 0.5mm thickness. A

distance of 1-meter minimum was provided between the EUT and the walls of the laboratory and any

other metallic structure.

Report No.: RM920221R04A

Reference No.: RM920221R04

18

Issued: Mar. 14, 2003

Page 19

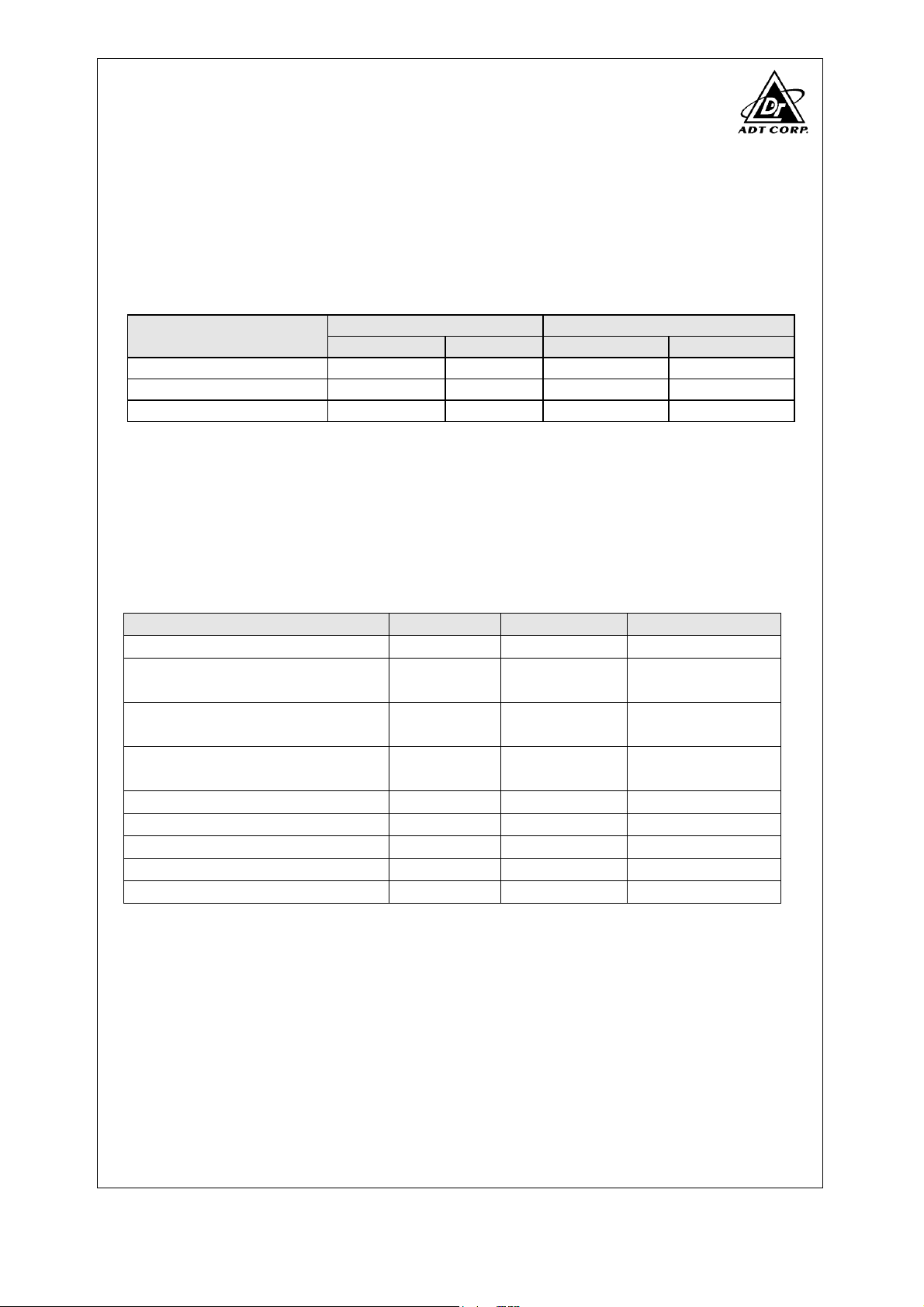

5.4.6 TEST RESULT

EUT

MODE

ENVIRONMENTAL

CONDITIONS

2.4GHz wireless PCI

Transmission

23 deg.C, 47 % RH

1005 hPa

MODEL NO.

INPUT POWER

(SYSTEM)

TESTED BY: Cody Chang

TEST RESULTS OF DIRECT APPLICATION

Discharge

Level (kV)

2, 4 +/- 1, 2 NOTE NA A

2, 4, 8 +/- 3 NA NOTE A

Description of test point:

1.breaket 2. Metal of Antenna connector 3.Antenna

Polarity

(+/-)

Test P oi n t

Contact

Discharge

Air Discharge

TEST RESULTS OF INDIRECT APPLICATION

Discharge

Level (kV)

2, 4 +/- 1 ~ 4 NOTE NOTE A

Polarity

(+/-)

Test P oi n t

Horizontal

Coupling Plane

Ver t i c al

Coupling

Plane

F5D7000

230Vac, 50 Hz

Performance

Criterion

Performance

Criterion

Description of test point:

1. Front side 2. Rear side 3. Right side 4. Left side

NOTE:

There was no change compared with the initial operation during and after the test. No unintentional

response was found during the test.

Report No.: RM920221R04A

Reference No.: RM920221R04

19

Issued: Mar. 14, 2003

Page 20

EUT

2.4GHz wireless PCI

MODEL NO.

F5D7000

MODE

ENVIRONMENTAL

CONDITIONS

Standby

23 deg.C, 47 % RH

1005 hPa

INPUT POWER

(SYSTEM)

TESTED BY: Cody Chang

TEST RESULTS OF DIRECT APPLICATION

Discharge

Level (kV)

2, 4 +/- 1, 2 NOTE NA A

2, 4, 8 +/- 3 NA NOTE A

Description of test point:

1.breaket 2. Metal of Antenna connector 3.Antenna

Polarity

(+/-)

Test P oi n t

Contact

Discharge

Air Discharge

TEST RESULTS OF INDIRECT APPLICATION

Discharge

Level (kV)

2, 4 +/- 1 ~ 4 NOTE NOTE A

Description of test point:

1. Front side 2. Rear side 3. Right side 4. Left side

Polarity

(+/-)

Test P oi n t

Horizontal

Coupling Plane

Ver t i c al

Coupling

Plane

230Vac, 50 Hz

Performance

Criterion

Performance

Criterion

NOTE:

There was no change compared with the initial operation during and after the test. No unintentional

response was found during the test.

Report No.: RM920221R04A

Reference No.: RM920221R04

20

Issued: Mar. 14, 2003

Page 21

5.5 RADIATED, RADIO-FREQUENCY, ELECTROMAGNETIC FIELD IMMUNITY

TEST (RS)

5.5.1 TEST SPECIFICATION

Basic Standard: EN 61000-4-3

Frequency Range: 80 MHz - 1000 / 1400 - 2000 MHz

Field Strength: 3 Vrms

Modulation: 1kHz Sine Wave, 80%, AM Modulation

Frequency Step: 1 % of momentary frequency

Polarity of Antenna: Horizontal and Vertical

Test Distance: 3 m

Antenna Height: 1.5m

Dwell Time: at least 3 seconds

5.5.2 TEST INSTRUMENT

DESCRIPTION & MANUFACTURER MODEL NO. SERIAL NO.

ROHDE & SCHWARZ Signal Generator SMY01 840490/009 July 31, 2003

KALMUS Power Amplifier LA1000V 091995-1 NA

KALMUS Power Amplifier 757LC 091995-2 NA

HOLADAY Field Probe HI-4422 89915 Mar. 05, 2003

EMCO BiconiLog Antenna 3141 1001 NA

COMTEST Compact Full Anechoic

Chamber (7x3x3 m)

HP Signal Generator E4422A US37040138 Jun. 10,2003

AR RF Amplifier 80S1G3 304334 NA

W&G E-Field Sensor 3GHz TYP-8 AD-0034 Dec. 22, 2003

W&G EM Radiation Monitor EMR-20 AB-0039 Dec. 22, 2003

R&S Power Sensor NRV-Z5 837878/038 Nov. 20, 2003

R&S Power Sensor NRV-Z5 837878/039 Nov. 20, 2003

R&S Power Meter NRVD 837794/040 Nov. 20, 2003

NOTE: 1. The test was performed in RS Room.

2. The calibration interval of the above test instruments is 12 months and the

calibrations are traceable to NML/ROC and NIST/USA.

CFAC ADT-S01 Aug. 10, 2003

CALIBRATED

UNTIL

Report No.: RM920221R04A

Reference No.: RM920221R04

21

Issued: Mar. 14, 2003

Page 22

5.5.3 TEST PROCEDURE

The test procedure was in accordance with EN 61000-4-3

a. The testing was performed in a fully-anechoic chamber. The transmit antenna

was located at a distance of 3 meters from the EUT.

b. The frequency range is swept from 80 MHz to 1000 MHz / 1400 MHz to

2000 MHz, with the signal 80% amplitude modulated with a 1kHz sinewave. The

rate of sweep did not exceed 1.5 x 10

-3

decade/s. Where the frequency range is

swept incrementally, the step size was 1% of momentary frequency.

c. The dwell time at each frequency shall be not less than the time necessary for the

EUT to be able to respond.

d. The field strength level was 3Vrms.

e. The test was performed with the EUT exposed to both vertically and horizontally

polarized fields on each of the four sides.

5.5.4 DEVIATION FROM TEST STANDARD

No deviation

Report No.: RM920221R04A

Reference No.: RM920221R04

22

Issued: Mar. 14, 2003

Page 23

5.5.5 TEST SETUP

3m measurement distance in a Full Anechoic Chamber

EUT

RF Amplifier

RF Generator

and

control system

Monitoring

system

For the actual test configuration, please refer to the related item – Photographs of the

Test Configuration.

NOTE:

TABLETOP EQUIPMENT

The EUT installed in a representative system as described in section 7 of EN 610004-3:1996 was placed on a non-conductive table 0.8 meters in height. The system

under test was connected to the power and signal wire according to relevant

installation instructions.

Report No.: RM920221R04A

Reference No.: RM920221R04

23

Issued: Mar. 14, 2003

Page 24

5.5.6 TEST RESULT

EUT

MODE

ENVIRONMENTAL

CONDITIONS

Frequency

(MHz)

80 -1000 PASS V&H 0 3

80 -1000 PASS V&H 90 3

80 -1000 PASS V&H 180 3

80 -1000 PASS V&H 270 3

Frequency

(MHz)

1400 - 2000 PASS V&H 0 3

1400 - 2000 PASS V&H 90 3

1400 - 2000 PASS V&H 180 3

1400 - 2000 PASS V&H 270 3

2.4GHz wireless PCI

Transmission

22 deg.C, 56 % RH

1005 hPa

Result Polarity Azimuth

Result Polarity Azimuth

MODEL NO.

INPUT POWER

F5D7000

230Vac, 50 Hz

(SYSTEM)

TESTED BY: Cody Chang

Field

Strength

(V/m)

Field

Strength

(V/m)

Obser-

vation

NOTE A

Obser-

vation

NOTE A

Performance

Criterion

Performance

Criterion

NOTE: There was no change compared with the initial operation during and after the test. No

unintentional response was found during the test.

Report No.: RM920221R04A

Reference No.: RM920221R04

24

Issued: Mar. 14, 2003

Page 25

EUT

2.4GHz wireless PCI

MODEL NO.

F5D7000

MODE

ENVIRONMENTAL

CONDITIONS

Frequency

(MHz)

80 –1000 PASS V&H 0 3

80 –1000 PASS V&H 90 3

80 –1000 PASS V&H 180 3

80 –1000 PASS V&H 270 3

Frequency

(MHz)

1400 - 2000 PASS V&H 0 3

1400 - 2000 PASS V&H 90 3

1400 - 2000 PASS V&H 180 3

1400 - 2000 PASS V&H 270 3

Standby

22 deg.C, 56 % RH

1005 hPa

Result Polarity Azimuth

Result Polarity Azimuth

INPUT POWER

230Vac, 50 Hz

(SYSTEM)

TESTED BY: Cody Chang

Field

Strength

(V/m)

Field

Strength

(V/m)

Obser-

vation

NOTE A

Obser-

vation

NOTE A

Performance

Criterion

Performance

Criterion

NOTE: There was no change compared with the initial operation during and after the test. No

unintentional response was found during the test.

Report No.: RM920221R04A

Reference No.: RM920221R04

25

Issued: Mar. 14, 2003

Page 26

6 PHOTOGRAPHS OF THE TEST CONFIGURATION

CONDUCTED EMISSION TEST

Report No.: RM920221R04A

Reference No.: RM920221R04

26

Issued: Mar. 14, 2003

Page 27

ESD TEST

Report No.: RM920221R04A

Reference No.: RM920221R04

27

Issued: Mar. 14, 2003

Page 28

RS TEST

Report No.: RM920221R04A

Reference No.: RM920221R04

28

Issued: Mar. 14, 2003

Page 29

7 APPENDIX - INFORMATION ON THE TESTING LABORATORIES

We, ADT Corp., were founded in 1988 to provide our best service in EMC and Safety

consultation. Our laboratories are accredited and approved by the following

approval agencies according to ISO/IEC 17025, Guide 25 or EN 45001:

USA FCC, NVLAP, UL

Germany TUV Rheinland

Japan VCCI

New Zealand MoC

Norway NEMKO

Canada INDUSTRY CANADA

R.O.C. CNLA, BSMI, DGT

Copies of accreditation certificates of our laboratories obtained from approval

agencies can be downloaded from our web site: www.adt.com.tw/index.5/phtml.

If you have any comments, please feel free to contact us at the following:

Lin Kou EMC Lab:

Tel: 886-2-26052180

Fax: 886-2-26052943

Lin Kou Safety Lab:

Tel: 886-2-26093195

Fax: 886-2-26093184

Hsin Chu EMC Lab:

Tel: 886-35-935343

Fax: 886-35-935342

Lin Kou RF & Telecom Lab.

Tel: 886-3-3270910

Fax: 886-3-3270892

Email: service@mail.adt.com.tw

Web Site: www.adt.com.tw

The address and road map of all our labs can be found in our web site also.

Report No.: RM920221R04A

Reference No.: RM920221R04

29

Issued: Mar. 14, 2003

Loading...

Loading...