Beko TELEVISION COLOUR SERVICE MANUAL

CONTENTS PAGE

Safety Instructions 3

Technical Specifications 4

Pin Voltages of IC’s 5

Pin Voltages of Some Transistors 8

Oscillograms 9

Electrical and Service Adjustments 12

Trouble Shooting Guide 16

Parts List 23

Circuit Diagram PIP Module 30

Circuit Diagrams Attached

27/05/2002, Version 2

SAFETY INSTRUCTIONS

GENERAL GUIDELI NES

1. It is advised to insert an isolation transformer

in the AC supply before servicing a hot

chassis.

2. Potentials as high as 33KV are present when

this receiver is in operation. Operation of the

receiver without the rear cover involves the

danger of a shock hazard from t he receiver

power supply. Servicing should not be

attempted by any one who is not

competent with the precautions necessary

when working on the high voltage

equipment. Always discharge the anode of

the tube.

3. When servicing observe the original lead

dress in the high voltage circuits. If a short

circuit is found, replace all the parts which

have been overheated or damaged by the

short circuit.

4. Always use the manufacturer’s replacement

safety components. The critical safety

components marked with

on the

schematics diagrams should not be

replaced by other substitutes. Other

substitute may create the electrical shock,

fire or other hazards. Take attention to

replace the spacers with the originals.

Furthermore where a short circuit has

occurred, replace those components that

indicate evidence of overheating.

5. After servicing, see that all the protective

devices such as insulation barriers, insulation

papers, shields and isolation R-C

combinations are correctly installed.

6. When the receiver is not being used for a

long time of period of time, unplug the

power cord from the AC outlet.

7. After servicing make the following leakage

current checks to prevent the customer

from being exposed to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper

between the two prongs of the plug.

2. Turn the receiver’s power switch on.

3. Measure the resistance value with an

ohmmeter, between the jumpered AC plug

and each exposed metallic cabinet part on

the receiver, such as screw heads, aerials,

connectors, control shafts etc. When the

exposed metallic part a return path to the

chassis the reading should be between

4Mohm and the 20Mohm. When the

exposed metal does not have a return path

to the chassis, the reading must be infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly in to the AC

outlet. Do not use an isolation transformer

for this check.

2. Connect a 2Kohm 10W resistor in series with

an exposed metallic part on the receiver

and an earth, such as a water pipe.

3. Use an AC voltmeter with high impedance

to measure the potential across the resistor.

4. Check each exposed metallic part and

check the voltage at the each point.

5. Reverse th e AC plug at the outlet and

repeat each of the above measurements.

6. The potential at the any point should not

exceed 1.4 Vrms. In case a measurement is

outside the limits specified, there is the

possibility of a shock hazard, and the

receiver should be repaired and rechecked

before it is returned to the customer.

HOT CHECK CIRCUIT

TO INSTRUMENTS

EXPOSED

METALLIC PARTS

AC-Voltmeter

Water pipe

(earth)

2 K Ohm

Figure 1

X-RAY RADIATION WARNING

The primary source of X-ray radiation in this receiver

is the picture tube. The chassis is specially

constructed to limit X-ray radiation. For continued

X-ray radiation protection, replace the tube with

the same type of the original one.

CAUTION

AFTER REMOVAL OF THE ANODE CAP, DISCHARGE

THE ANODE OF THE PICTURE TUBE AND THE ANODE

CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT WITH A HIGH

VOLTAGE PROBE AND MULTIMETER (SELECT VDC)

AND THEN SHORT CIRCUIT DIRECTLY TO DISCHARGE

COMPLETELY.

TECHNICAL SPECIFICATIONS

Power source: 220-240 VAC, 50-60Hz

Power consumption (max.)

125 W 25”, 28” Mono

145 W 25”, 28” 4/3, 29” Pure Flat

140 W 29” Super Flat

150 W 28” 16/9 Super Flat

155 W 28” 16/9 Pure Flat, 32” Super Flat

165 W 32” Pure Flat

160 W 33”

Standby power consumption : 3 W

Aerial impedance : 75Ohm, coaxial type

2

Receiving system

: PAL BG

PAL SECAM BG

PAL SECAM BG DK

PAL SECAM BG LL’

PAL I

Receiving channels: VHF BAND I , CH2-4

VHF BAND III , CH5-12

CABLE TV S1-41

UHF BAND CH21-69

NTSC Playback Frequencies: 3.58&4.43 MHz

Audio outputs : Stereo : 2 x 10W RMS at %10 THD (Except 21” Pure Flat)

2 x 7W RMS at %10 THD (21” Pure Flat)

+ 20W RMS at %10 THD (if subwoofer available)

Mono : 2 x 7W RMS at %10 THD

High Voltage : 28.5 ± 0.5 KV 25”, 28”4/3

29.0 ± 0.5 KV 28”16/9, 29”, 32” Super Flat

29.5 ± 0.5 KV 32” Pure Flat, 33”

Focus voltage : %25.6 ± %38 of EHT

Grid 2 voltage : 0-1400 V

Heater voltage : 6.2 ± 0.2 Vrms

Video/Audio Terminals : AV1/2 IN Video : 1 Vpp,75 Ohm

Audio : 0.5 Vrms, >10 Kohm

AV1 IN RGB

AV1/2 OUT Video : 1 Vpp, 75 Ohm

Audio : 0.5 Vrms, <1 Kohm

AV2 IN (RCA) Video : 1 Vpp, 75 Ohm

Audio : 0.5 Vrms, >10 Kohm

Operating temperature : 0-45 Degrees

Safety : IEC 65 /BS P2N

X-Ray radiation : ACC. IEC 65/BS P2N

1

: 20W should be added to find the max. power consumption of the models with subwoofer.

2

: TV set is produced to receive “one” of these colour and sound systems.

1

: 120 W 21” Pure Flat

12

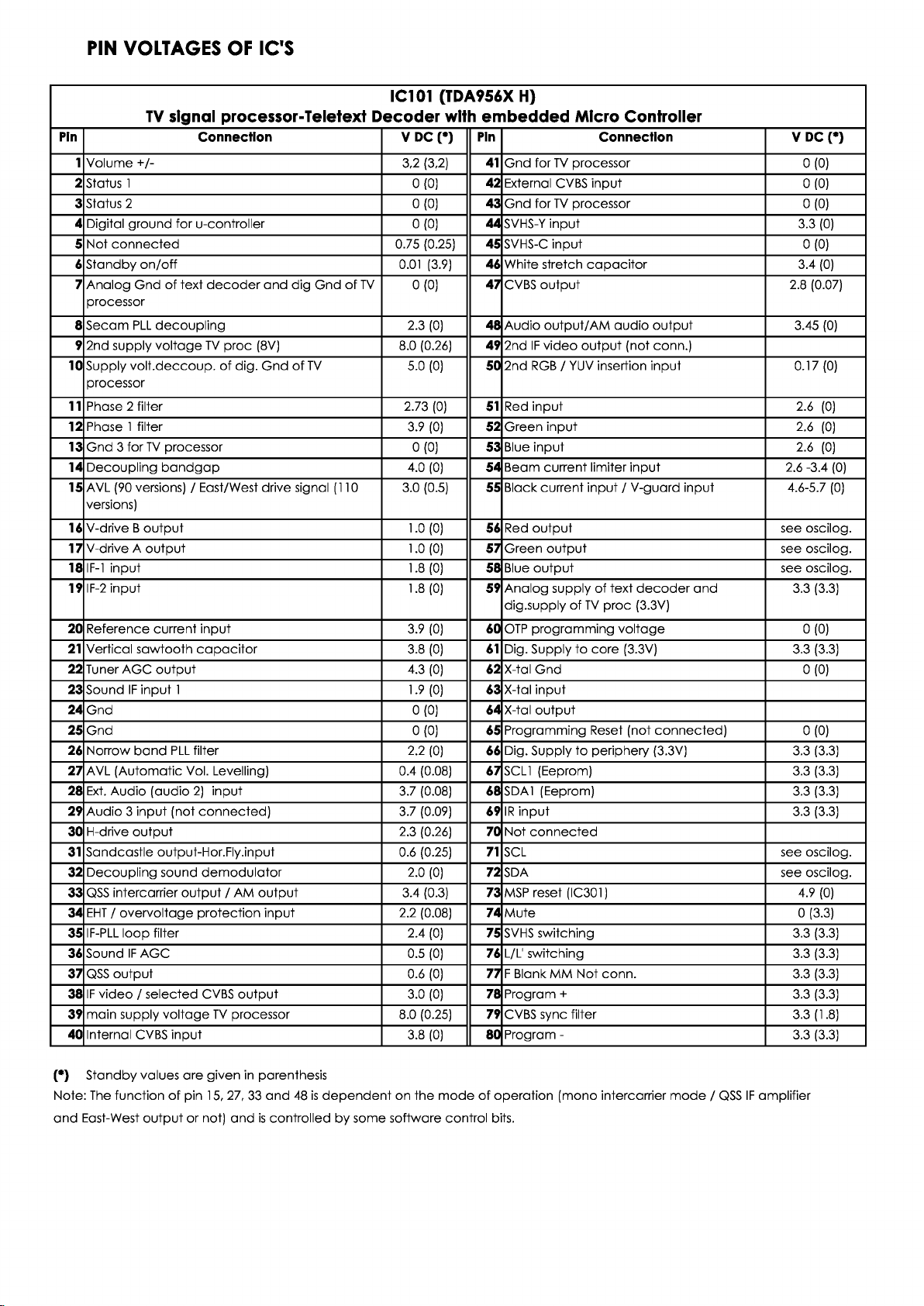

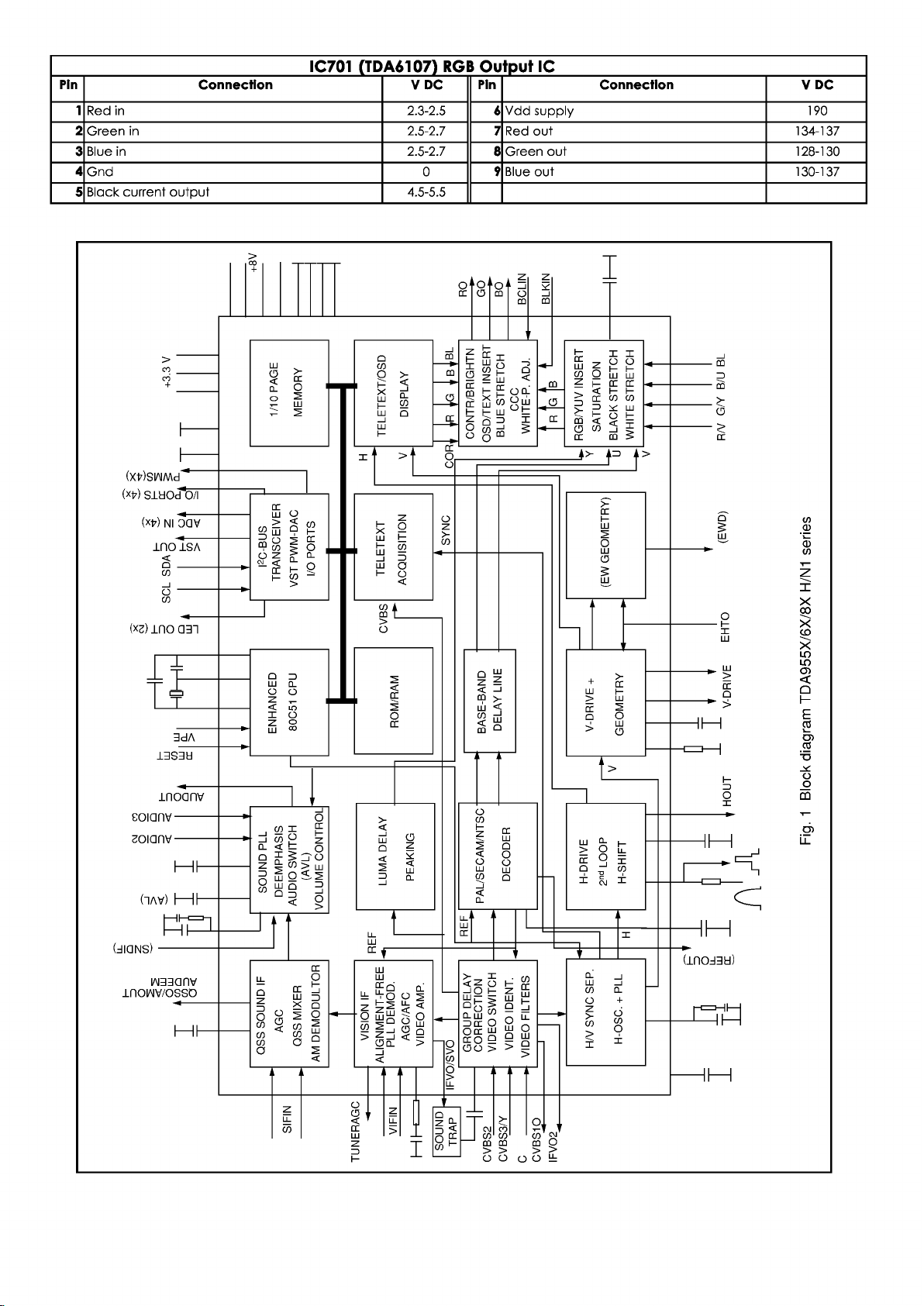

IC 301 (MSP 3400G) MULTI STANDARD SOUND PROCESSOR

Pin Connection V DC Pin Connection V DC

1

Not connected

2

Gnd 0

3

Gnd 0

4

Digital control input/output 0

5

Digital control input/output 0

6

Gnd 0

7

Standby (in normal operation it must be high) 4.9

8

Not connected 4.9

9

SCL 2.4-2.6

10

SDA 1.8-2.1

11

Not connected 2.4

12

Not connected 2.4

13

Not connected 2.4

14

Not connected 4.9

15

Not connected 0.7

16

Not connected 0.7

17

ADR Bus Clock Output 0.7

18

Digital Circuitry Supply Voltage 4.9

19

Digital Circuitry Supply Ground 0

20

Not connected 0.7

21

Not connected (Ground) 0

22

Not connected (Ground) 0

23

Not connected (Ground) 0

24

MSP RESET input 4.9

25

Headphone sound output (R) 2.1

26

Headphone sound output (L) 2.1

27

Reference analog ground 0

28

Speaker output (R) 0.1-2.1

29

Speaker output (L) 0.1-2.1

30

Not connected 0.1-2.1

31

Not connected 0.1-2.1

32

Not connected 0

33

Scart 2 sound output (R) 3.7

34

Scart 2 sound output (L) 3.7

35

Reference analog ground 0

36

Scart 1 sound output (R) 3.7

37

Scart 1 sound output (L) 3.7

38

Volume capacitor Headphone

39

Analog Supply High Voltage (8V) 8

40

Volume capacitor Speaker

41

Ground for Analog Power Supply High

42

Internal Analog Reference Voltage 3.7

43

Scart 4 input (L) 3.7

44

Scart 4 input (R) 3.7

45

Analog Shield Ground 0

46

CINCH - sound input (L) 3.7

47

CINCH - sound input (R) 3.7

48

Analog Shield Ground 0

49

Scart 2 sound input (L) 3.7

50

Scart 2 sound input (R) 3.7

51

Analog Shield Ground 0

52

Scart sound 1 input (R) 3.7

53

Scart 1 sound input (L) 3.7

54

A/D converter ref. Voltage 2.5

55

Mono sound input 3.7

56

Ground for Analog Power Supply Voltage 0

57

Analog Power Supply Voltage (5V) 4.9

58

IF input 1 1.5

59

IF Common reference for IF IN1/IN2 1.5

60

IF input 2 0

61

Factory test mode enable (ground) 0

62

Crystal oss. input 2.3

63

Crystal oss. output 2.3

64

Not connected (Ground) 0

0

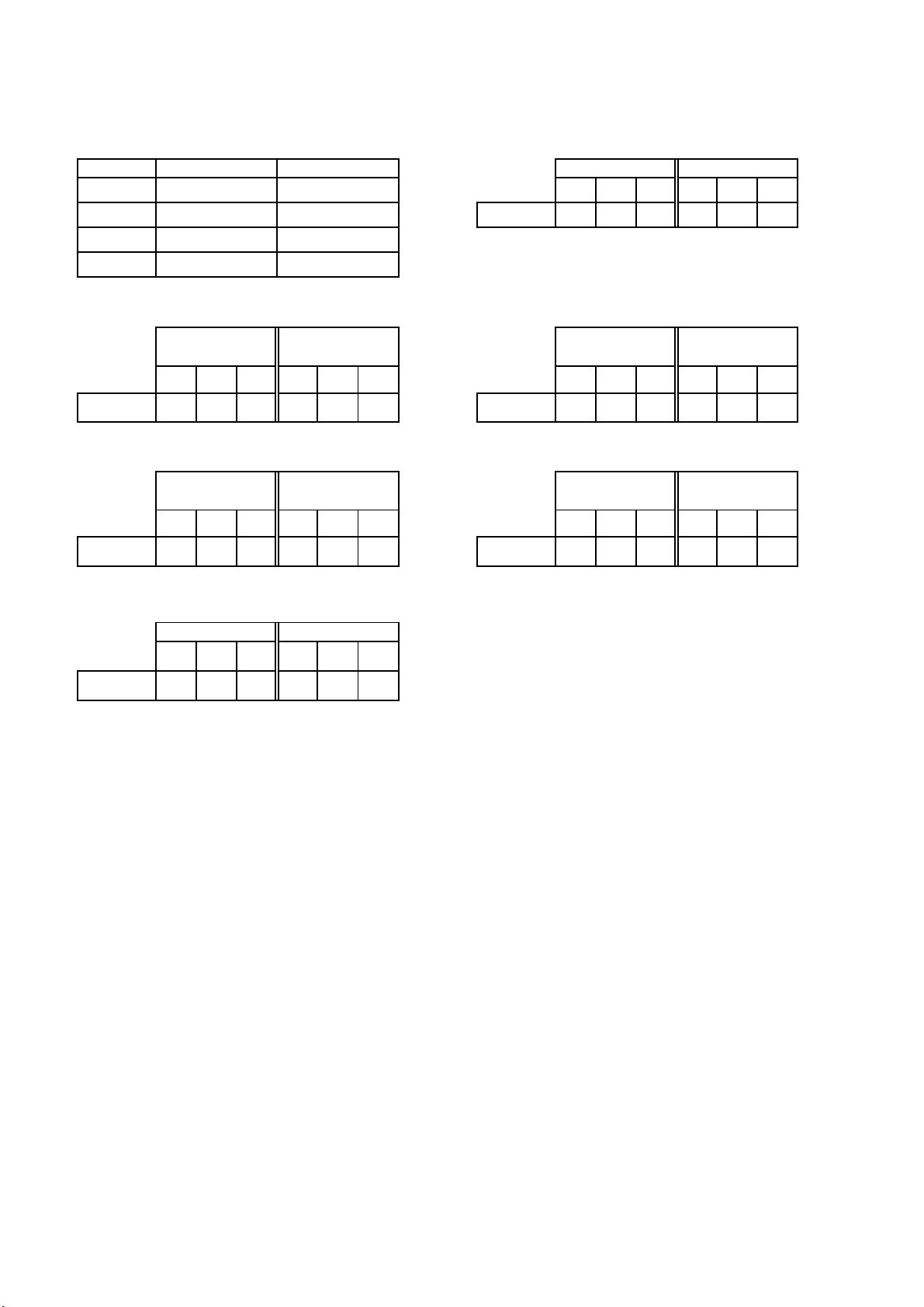

IC303, IC304 (TDA7263) Audio Output IC

Pin Connection V DC Pin Connection V DC

1

Left In 1.6

2

Left In V 1.6

3

Mute 15.3

4

Right In V 1.6

5

Right In 1.6

6

Gnd 0

7

8

Right out 14.2

9

VS 28

10

Left out 13.9

11

12

Left In 0.6

0,5-0,9

0,5-0,9

IC501 (TDA835X) Vertical Deflection Output IC

Pin Connection V DC Pin Connection V DC

1

Input A 0,98 (0)

2

Input B 0.94 (0)

3

Supply voltage 14,7 (1.0)

4

Output B 7,55 (0,4)

5

Gnd 0 (0)

6

Vertical Flyback Supply Voltage 45,6 (10,9)

7

Output A 7,64 (0,1)

8

Guard Output 0,3 (0)

9

Feedback Input 7,9 (0)

IC601 (MC44608 AP) Power Supply IC

Pin Connection V DC Pin Connection V DC

1

Demag 0.85 (0.0)

2

I sense 0.1 (0.32)

3

Control input 5 (5.5)

4

Gnd 0

(*)

Standby values are given in parenthesis

5

Driver 2.1 (0.14)

6

VCC 12.3 (8.8)

7

Not connected -

8

VI 116 (117)

14

Pin

Standby VDC

TV ON VDC

Standby VDC

TV ON VDC

PIN VOLTAGES OF SOME TRANSISTORS

1. PH601 (PC127FY) PHOTOCOUPLER 2. T603 (BC848) NPN

Standby VDC

1 B C E B C E

2

3

4

3. T604 (BC848) NPN 4. T605 (BC848) NPN

12.5

11.5

5.5

8.8

Standby VDC TV ON VDC Standby VDC TV ON VDC

B C E B C E B C E B C E

ON VDC

11

10

5

12.3

T603

0.6 0.02 0 0.1 0.3 0

T604

5. T606 (BC848) NPN 6. T607 (BC848) NPN

T606

7. T307 (BC848) NPN

T307

0.02 12.7 0 0.7 0.05 0

Standby VDC TV ON VDC Standby VDC TV ON VDC

B C E B C E B C E B C E

0.6 0 0 1 6.8 0

B C E B C E

0.6 0 0 0.1 15 0

T605

T607

0.6 0.02 0 0.1 0.7 0

0.6 0 0 0.1 2.5 0

Note:

TV is connected to a patern generator (Colour bar, sound 1 kHz).

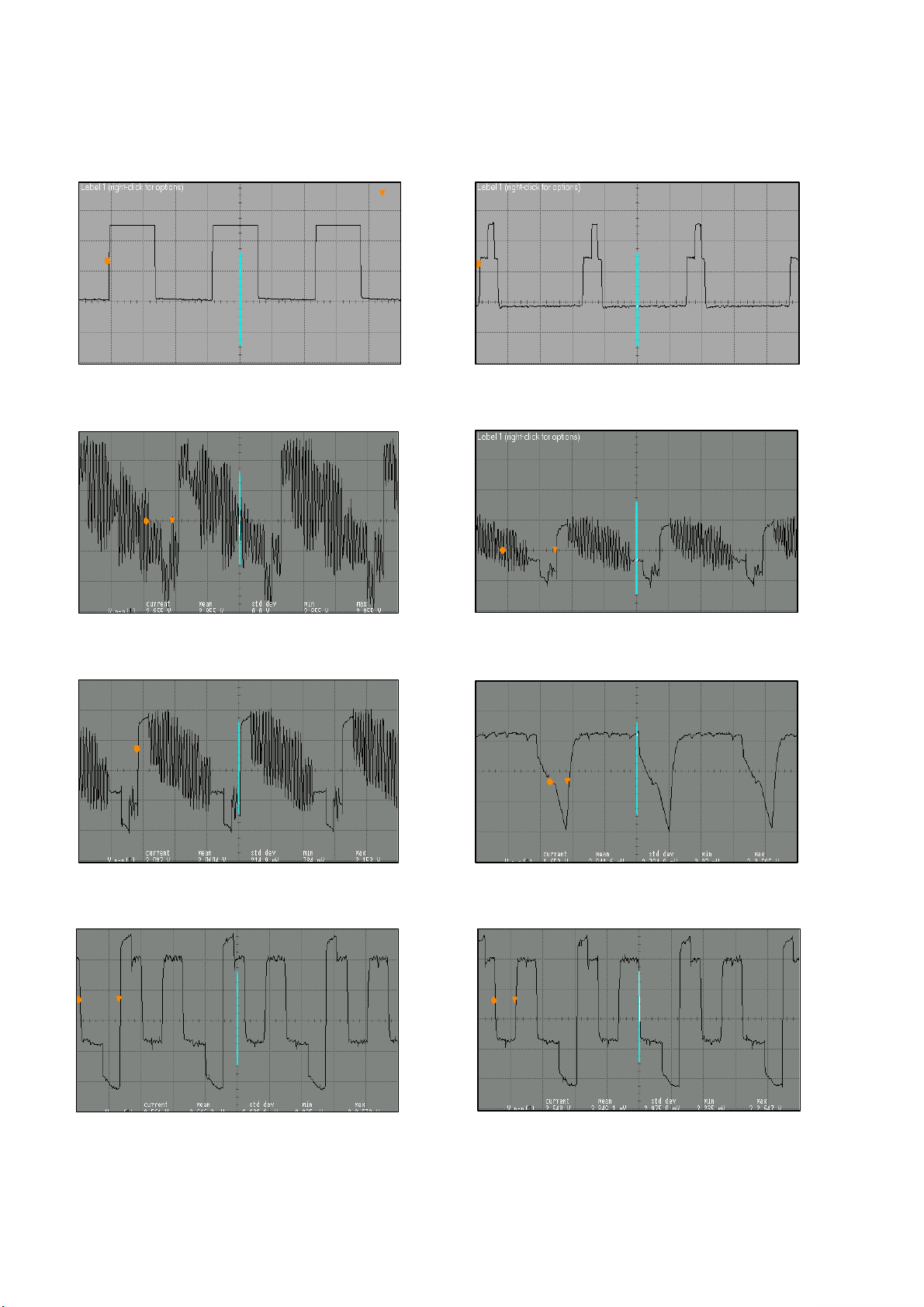

OSCILLOSGRAPHS OF SOME IC PINS

500 mV/div, 20 usn/div, Vpp=1.2 V, 15625 kHz

500 mV/div, 20 usn/div, Vpp=2.1 V, 15625 kHz

500 mV/div, 20 usn/div, Vpp=2.7 V, 15625 kHz

500 mV/div, 20 usn/div, Vpp=2.6 V, 15625 kHz

1. IC101 (TDA956X)

Pin 30

2V/div, 20 usn/div, Vpp=4.9 V, 15625 kHz

Pin 38

2V/div, 20 usn/div, Vpp=2.9 V, 15625 kHz

Pin 31

2V/div, 20 usn/div, Vpp=5.6 V, 15625 kHz

Pin 40

Pin 47

Pin 56 Pin 57

Pin 55

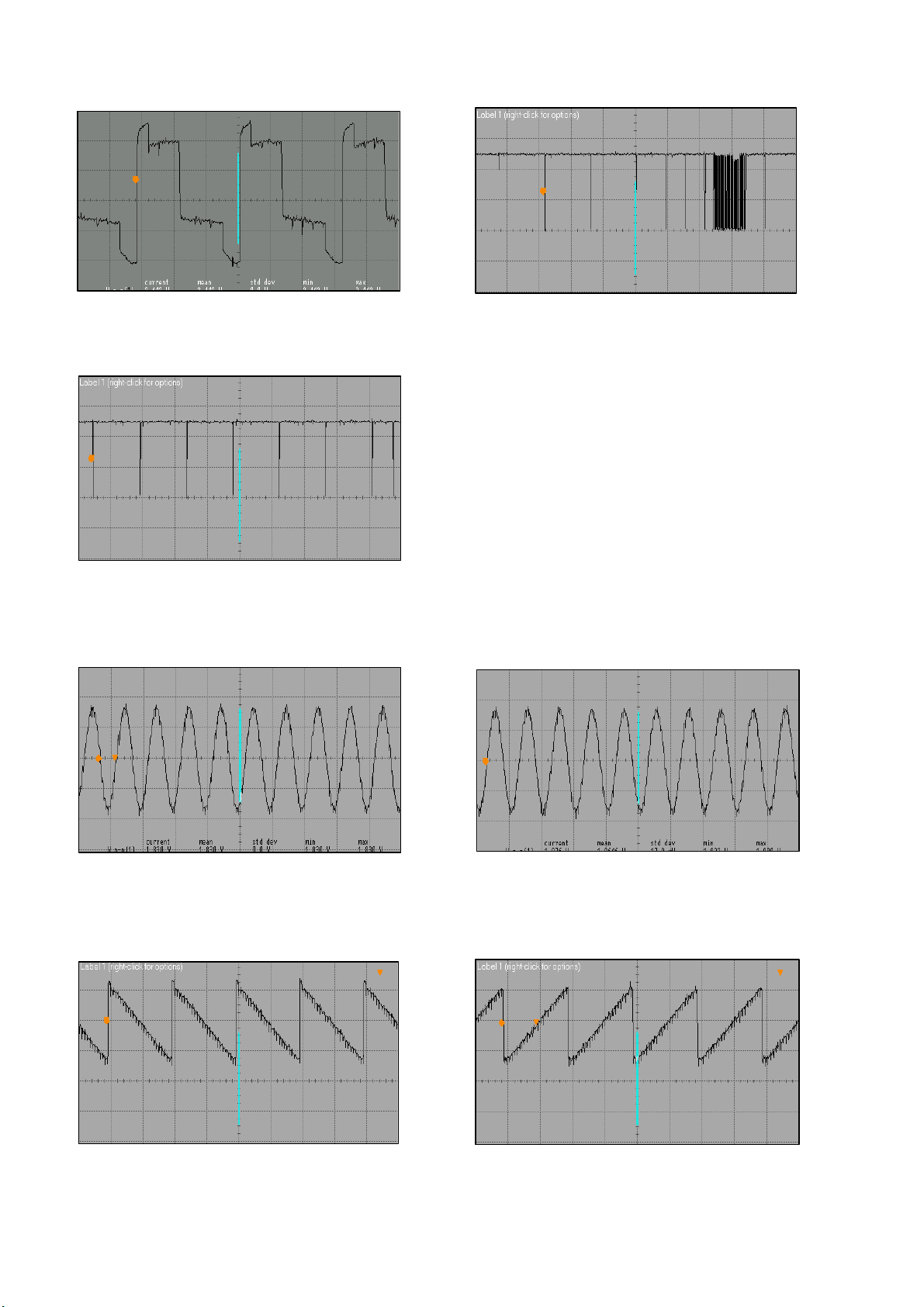

Pin 58 Pin 71

500 mV/div, 20 usn/div, Vpp=2.4 V, 15625 kHz

Pin 72

2 V/div, 1 msn/div, Vpp=5.2 V

2. IC301 (MSP34XX)

2 V/div, 1 msn/div, Vpp=5.2 V

Pin 28

500 mV/div, 1 msn/div, Vpp=1.8 V

3. IC501 (TDA835X)

Pin 1

500 mV/div, 10 msn/div, Vpp=1.4 V, 50Hz

Pin 29

500 mV/div, 1 msn/div, Vpp=1.8 V

Pin 2

500 mV/div, 10 msn/div, Vpp=1.4 V, 50Hz

Loading...

Loading...