Beko Samsung V3 Service Manual

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

DATE: July 15, 2004

Beko

SERVICE MANUAL

107cm (42 Inch) Wide Plasma Display Module

MODEL : 42” S3.1 PDP

1 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

CONTENTS

1.Overview

1-1 Model Name of plasma Display

1-2 External View

1-3 Specifications

2. Precaution

2-1 Handling Precaution for Plasna Display,

2-2 Safety Precautions for Service (Handling, prevention of a electrical shock, measure against

power outage, etc)

3. Name & Function

3-1 Layout of Assemblies

3-2 Block Diagram:

3-3 Main function of Each Assembly

3-4 Product/Serial Label Location

4. Operation checking after rectification

4-1 Flow chart

4-2 Defects , Symptoms and Detective Parts

5. Disassembling / Assembling

5-1 Tools and measurement equipment

5-2 Exploded View

5-3 Disassembling & Re-assembling

6. Operation Check after Repair Service

6-1 Check Item

6-2 Check Procedure

7. Operation Check

7-1 Adjustment Specification, Checking Position etc.

7-2 Adjusting procedure

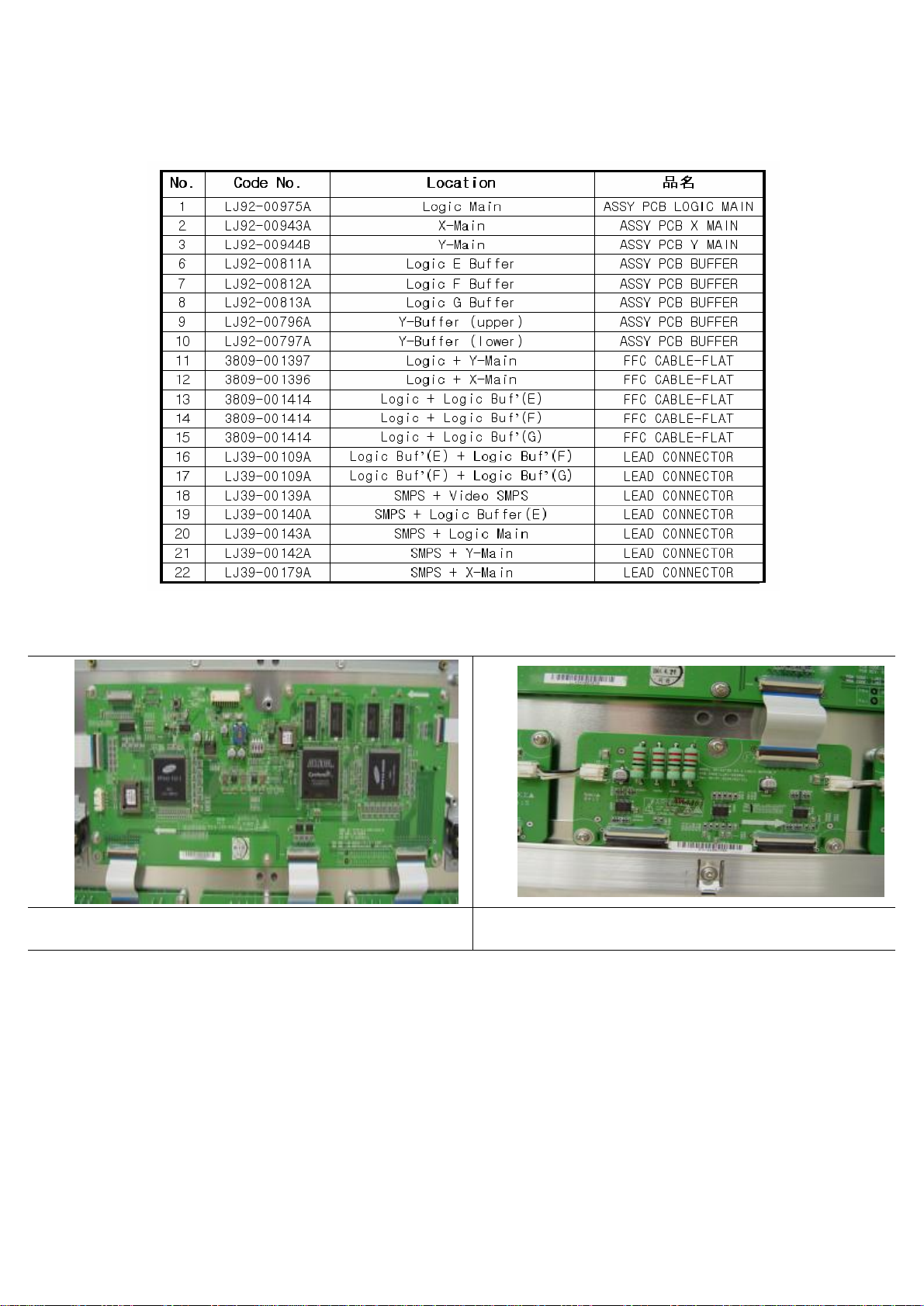

8. Spare part list for the panel

2 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

1. Overview

1-1 Model Name of Plasma Display

MODEL : 42” S3.1 PDP (S42SD-YD05)

1-2 External View

【 M1 = X Board + Y Board + Logic Board 】

3 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

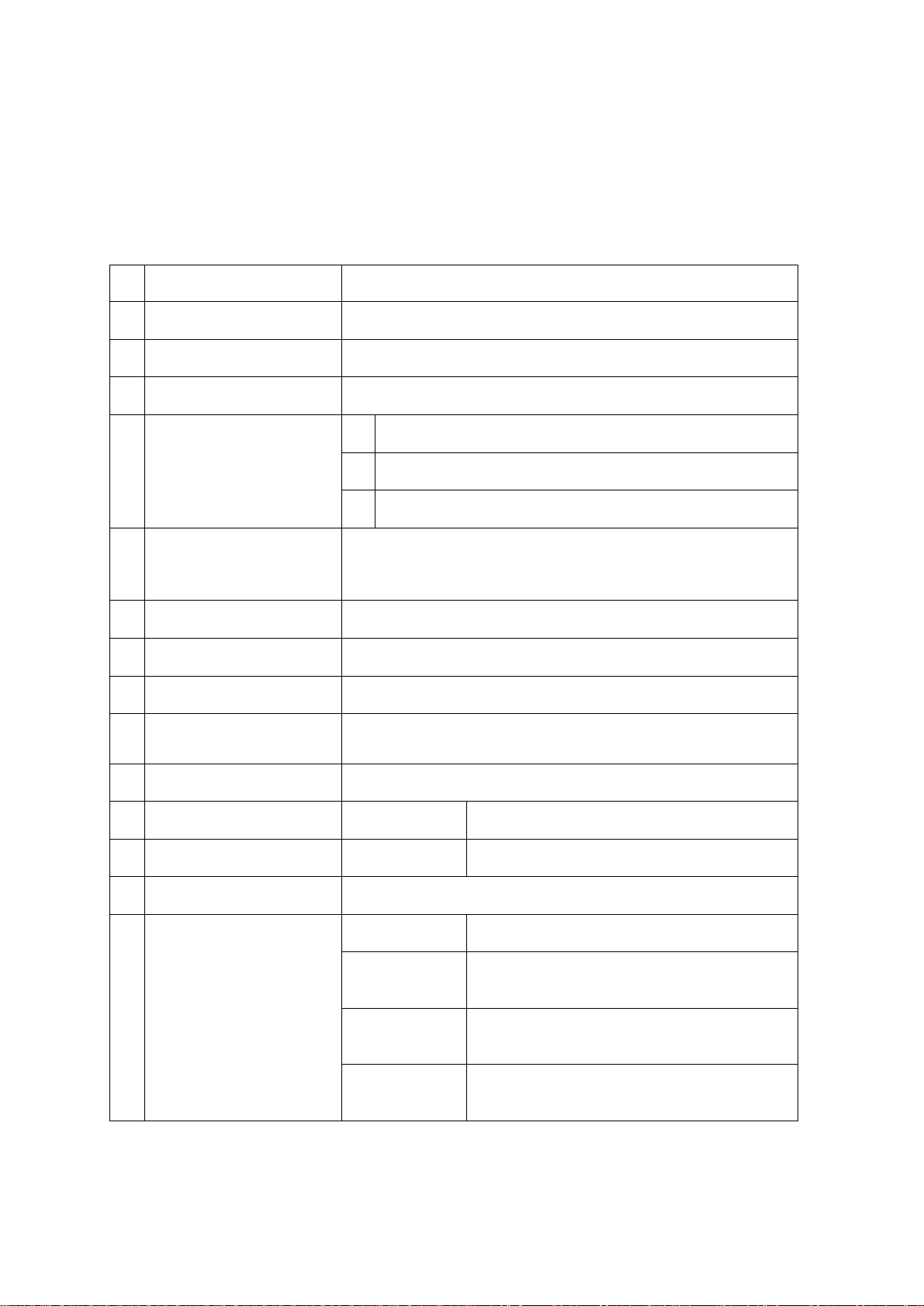

1-3 Specifications

No

Item Specification

1 Pixel 852 (H) × 480 (V) pixels (1 pixel = 1 R,G,B cells)

2 Number of Cells 2556 (H) × 480 (V)

3 Pixel Pitch 1.095 (H) ㎜ × 1.110 (V) ㎜

R 0.365 (H) ㎜ × 1.110 (V) ㎜

4

Cell Pitch

G 0.365 (H) ㎜ × 1.110 (V) ㎜

B 0.365 (H) ㎜ × 1.110 (V) ㎜

5 Display size

932.940 (H) ㎜ × 532.800(V) ㎜

[ 36.73 inch × 20.98 inch ]

6 Screen size Diagonal 42" Color Plasma Display Module

7 Screen aspect 16 : 9

8 Display color 16.77 million colors

Over 160°

9 Viewing angle

(Angle with 50% and greater brightness perpendicular to PDP

module)

10

11

12

13

14

Dimensions 982 (W) × 582 (H) × 52.9 (D) ㎜

Weight Module 1 About 16.6 kg

Packing weight Module 1

Packing size L 1175 * W 1140 * H 970 (mm) / 10pcs/BOX

Broadcasting reception

PL42SD003C 60Hz/ 50Hz, LVDS

Vertical frequency

and

Video/Logic Interface

4 / 44

240kg ± 5kg (including modules) /

10pcs/BOX

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

2. PRECAUTIONS

** To prevent the risks of unit damage, electrical shock and radiation, take the

following safety, service, and ESD precautions.

2-1 Handling Precautions for Plasma Display

n PDP module use high voltage that is

dangerous to human. Before operating

PDP, always check the dust to prevent

circuit short. Be careful touching the

circuit device when power is on.

n PDP module is sensitive to dust and

humidity. Therefore, assembling and

disassembling must be done in no dust

place.

n PDP module has a lot of electric

devices. Service engineer must wear

equipment(for example , earth ring) to

prevent electric shock and working

n PDP module use a fine pitch connector

which is only working by exactly

connecting with flat cable. Operator

must pay attention to a complete

connection when connector is

reconnected after repairing.

n The capacitor’s remaining voltage in

the PDP module’s circuit board

temporarily remains after power is off.

Operator must wait for discharging of

remaining voltage during at least 1

minute.

clothes to prevent electrostatic.

2-2 Safety Precautions for Service (Handling, prevention of a electrical shock, measure

against power outage, etc)

5 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

( Safety Precautions )

n Before replacing a board, discharge forcibly

The remaining electricity from board.

n When connecting FFC and TCPs to the

module, recheck that they are perfectly

connected.

n To prevent electrical shock, be careful not

to touch leads during circuit operations.

n To prevent the Logic circuit from being

damaged due to wrong working, do not

connect/disconnect signal cables during

circuit operations.

n Do thoroughly adjustment of a voltage label

and voltage-insulation.

n Before reinstalling the chassis and the

n If any parts of wire is overheats of damaged,

replace it with a new specified one

immediately, and identify the cause of the

problem and remove the possible

dangerous factors.

n Examine carefully the cable status if it is

twisted or damaged or displaced. Do not

change the space between parts and circuit

board. Check the cord of AC power

preparing damage.

n Product Safety Mark : Some of electric or

implement material have special

characteristics invisible that was related on

safety. In case of the parts are changed

with new one, even though the Voltage and

chassis assembly, be sure to use all

protective stuffs including a nonmetal

controlling handle and the covering of

partitioning type.

n Caution for design change : Do not install

any additional devices to the module, and

do not change the electrical circuit design.

n For example: Do not insert a subsidiary

audio or video connector. If you insert It, It

cause danger on safety. And, If you change

the design or insert, Manufactor guarantee

will be not effect. .

Watt is higher than before, the Safety and

Protection function will be lost.

n The AC power always should be turned off,

before next repair..

n Check assembly condition of screw, parts

and wire arrangement after repairing.

Check whether the material around the

parts get damaged.

6 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

( Precaution when repairing ESD )

n There is ESD which is easily damaged by

electrostatics.(for example Integrated circuit,

FET ) Electrostatic damage rate of product

will be reduced by the following technics

n Before handling semiconductor

parts/assembly, must remove positive

electric by ground connection, or must wear

the antistatic wrist-belt and ring. ( It must be

operated after removing dust on it – It

comes under precaution of electric shock.)

n After removing ESD assembly, put on it with

aluminum stuff on the conductive surface to

prevent charging.

n Do not use chemical stuff using Freon. It

n Must use anti-static solder removal device.

Most removal device do not have antistatic

which can charge a enough positive electric

enough damaging ESD.

n Before removeing the protective material

from the lead of a new ESD, bring the

protective material into contact with the

chassis or assembly that the ESD is to be

installed on.

n When handing an unpacked ESD for

replacement, do not move around too much.

Moving (legs on the carpet, for example)

generates enough electrostatic to damage

the ESD.

generates positive electric that can damage

ESD.

n Must use a soldering device for ground-tip

when soldering or de-soldering ESD.

n Do not take a new ESD from the protective

case until the ESD is ready to be installed.

Most ESD have a lead, which is easily

short-circuited by conductive materials

(such as conductive foam and aluminum)

7 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

3.NAME & FUNCTION

3-1 Layout of Assemblies

8 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

1. L-Main 7. F-Buffer

9 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

2. X-Main 3. Y-Main

4, Y-Buffer (upper) 5. Y-Buffer (lower)

6. E-Buffer 8. G-Buffer

10 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

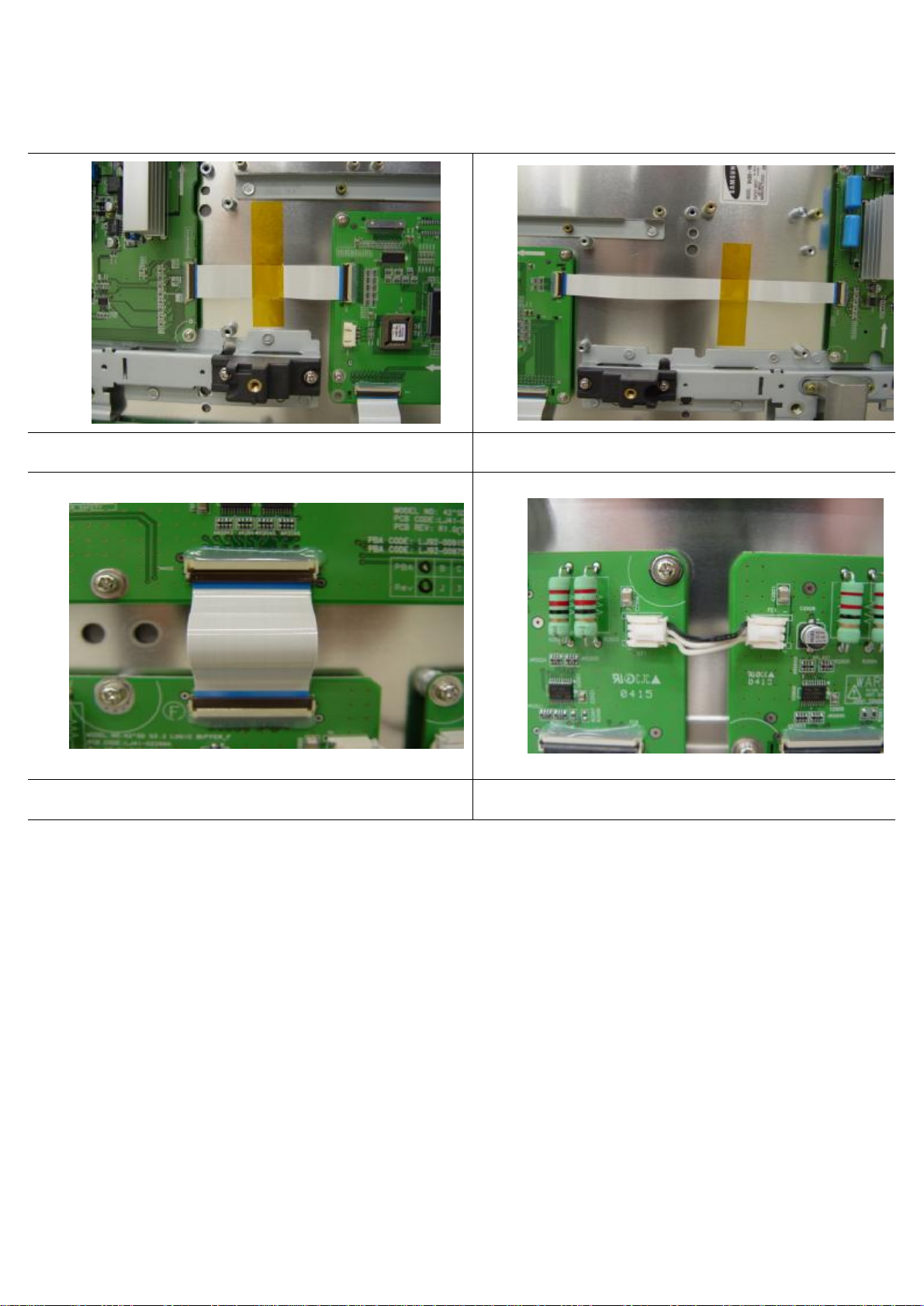

9. Logic + Y-Main 10. Logic + X-Main

11. 12. 13. Logic + Logic Buf’(E,F,G) 14. 15. Logic Buffer 間

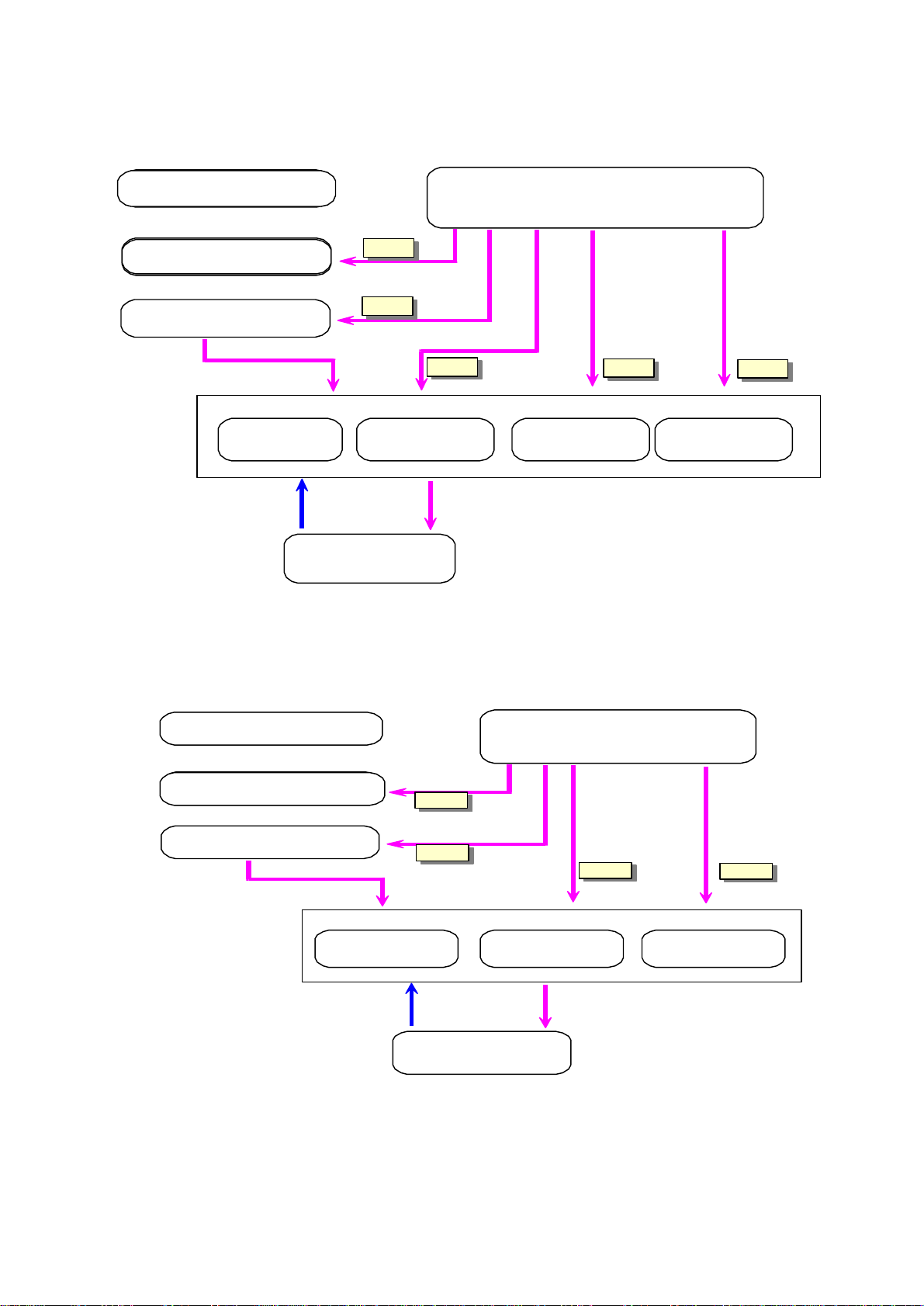

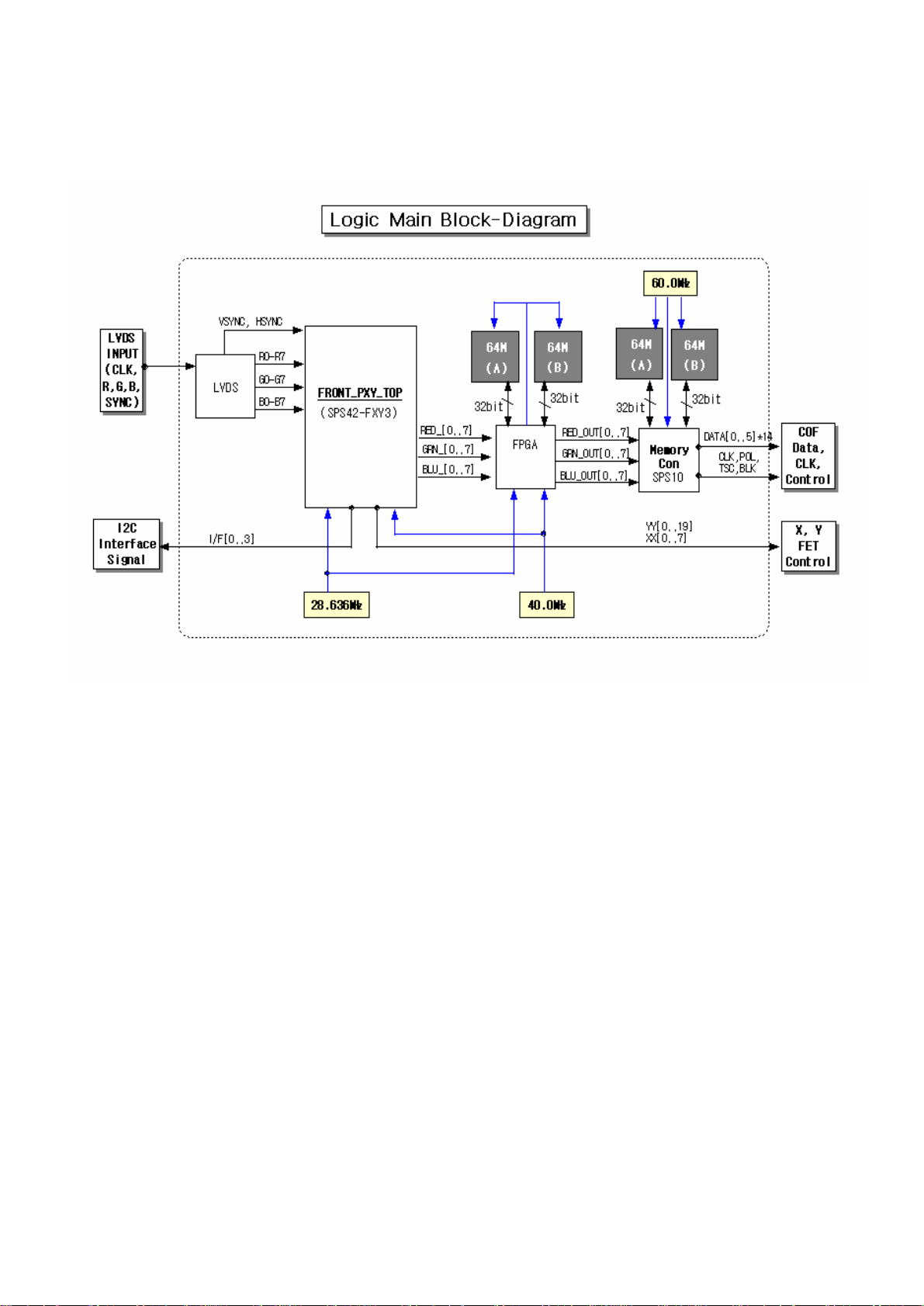

3-2 BLOCK DIAGRAM

3-2-1 BLOCK DIAGRAM FOR DRIVE CIRCUIT OPERATION

11 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

Logic 신호입력부

SignalinputSection

Ysc,SIA,SIB,CLK,LESTB

(

(Ysc,SIA,SIB,CLK,LE,STB)

(5Vd,17Vcc,75Vsc,165Vs,220Vset)

PowerSupplyInput

Logic 신호 Buffer)

Logicsignalbuffer

FetGateDriver)

Recovery

Switching

5V

17V

165V

Main

Switching

Recoverycircuit

(RecoveryCap)

< DRIVE Y Board >

220V

Vset

Switching

Vscan

Switching

75V

Logic 신호입력부

Signalinputsection

(Xr,Xf,Xs,Xg)

(Xr,Xf,Xs,Xg)

Logic 신호 Buffer)

Logicsignalbuffer

FetGateDriver)

Recovery

Switching

5V

17V

Recoverycircuit

(RecoveryCap)

< DRIVE X Board >

Powersupplyinput

(5Vd,17Vcc,195Ve,165Vs)

165V

Main

Switching

Switching

195V

Ve

12 / 44

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

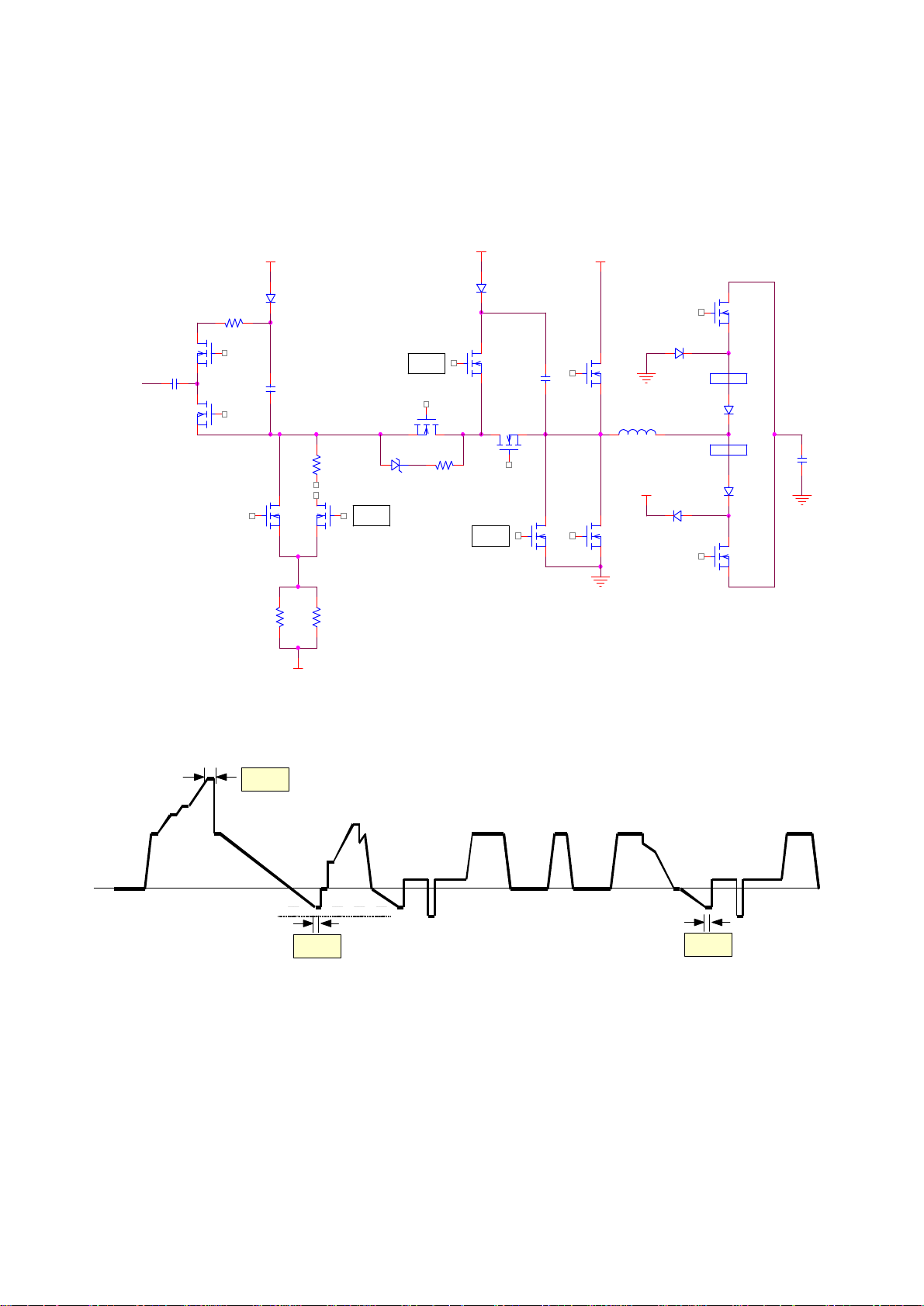

Vs

12

Vsc_h

Vset

12

Vs

Yr

Panel

Vset

Ysc_h

Ysc_l

Ysc

10us

Vsc

R5124

1k

Yfr

R5117R5118

RAMP

Ypn

RAMP

Yset

Ypp

RAMP

YDCL

Ys

YgYer

GND

1 2

GND

Vs

YDCH

bead

bead

12

12

YDr

12

YDf

Yf

GND

GND

Vsc_h

Vfr=Vsc_l+12V

30us

< Drive waveforms >

3-2-2 Block Diagram for Logic circuit

13 / 44

Vsc_l

Vs

30us

Beko Elektronik A.S Service Manual Plasma Display Module-Samsung V3

3-3 Main function of Each Assembly

■ X-main board : The X-main board generate a drive signal by switching the FET in synchronization with logic

main board timing and supplies the X electrode of the panel with the drive signal through the

connector.

1) Maintain voltage waveforms (including ERC)

2) Generate X rising ramp signal

3) Maintain Ve bias between Scan intervals

■.Y-main board : The Y-main board generate a drive signal by switching the FET in synchronization with the logic

Main Board timing and sequentially supplies the Y electrode of the panel with the drive signal

through the scan driver IC on the Y-buffer board. This board connected to the panel’s

Y terminal has the following main functions.

1) Maintain voltage waveforms (including ERC)

2) Generate Y-rising Falling Ramp

3) Maintain V scan bias

■ Logic main board : The logic main board generates and outputs the address drive output signal and the X ,Y

drive signal by processing the video signals. This Board buffers the address dirve output

14 / 44

Loading...

Loading...