Beko DRYPOINT RA 80, DRYPOINT RA 160, DRYPOINT RA 12, DRYPOINT RA 120, DRYPOINT RA 100 Installation And Operation Instructions Manual

...

PNEUMATIG

www.pneumatig.eu

Instructions for installation

and operation

COMPRESSED-AIR REFRIGERATION DRYER

®

DRYPOINT

RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Dear customer,

Thank you for deciding in favour of the DRYPOINT® RA 3-160 compressed-air refrigeration dryer. Please

read these installation and operating instructions carefully before mounting and starting up the DRYPOINT®

RA 3-160, and follow our directions. Perfect functioning of the DRYPOINT® RA 3-160 a nd thus reliable

compressed-air drying can only be guaranteed when the provisions and not es stipulated here are strictly

adhered to.

PNEUMATIG

ul. Wielkopolska 158

81-534 Gdynia, POLAND

Phones

+48 58 622 49 22

+48 58 622 49 25

Fax

+48 58 739 12 45

E-mail

pneumatig@pneumatig.com.pl

Our company is one of the most known pneumatic distributors in Poland.

More then 16 years of experience on the market is a solid package of experience, which we successfully use as our advantage.

We keep an eye on the market, and we can notice and urgently react on customers demands, and introduce new products they need.

Our company offers whole range of pneumatic equipment - everything our customers might ever need - compressors, tubes, air regulators,

filters, dryers, valves, air cylinder, air tools and more.

Please visit our on-line store www.pneumatig.eu where you can find more information, details, photos, user guides, and place an order.

2 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

1 Contents

PNEUMATIG

1 Contents ................................................................................................................................................ 3

2 Type plate .............................................................................................................................................. 5

3 Safety instructions ................................................................................................................................. 5

3.1 Safety pictograms in accordance with DIN 4844................................................................................... 6

3.2 Signal words in accordance with ANSI.................................................................................................. 7

3.3 Overview of the safety instructions........................................................................................................ 7

4 Proper use ........................................................................................................................................... 10

5 Exclusion from a field of application .................................................................................................... 10

6 Special advice for plants under pressure in accordance with the

97/23/EC Pressure Equipment Directive ............................................................................................. 10

7 Transport ............................................................................................................................................. 11

8 Storage ................................................................................................................................................ 11

9 Installation............................................................................................................................................ 12

9.1 Place of installation.............................................................................................................................. 12

9.2 Installation plan.................................................................................................................................... 13

9.3 Correction factors ................................................................................................................................ 14

9.4 Connection to the compressed-air system .......................................................................................... 15

9.5 Connection to the cooling-water network (water-cooled) .................................................................... 15

9.6 Electrical connections .......................................................................................................................... 16

9.7 Condensate drain ................................................................................................................................ 16

Contents

10 Start-up ................................................................................................................................................ 17

10.1 Preliminary stages ............................................................................................................................... 17

10.2 Initial start-up ....................................................................................................................................... 18

10.3 Removal from service and restart........................................................................................................ 19

11 Technical data ..................................................................................................................................... 20

11.1 Technical data DRYPOINT RA 3-60 /AC ............................................................................................ 20

11.2 Technical data DRYPOINT RA 80-160 /AC ........................................................................................ 21

11.3 Technical data DRYPOINT RA 55-160 /WC ....................................................................................... 22

12 Technical description ........................................................................................................................... 23

12.1 Control panel ....................................................................................................................................... 23

12.2 Functional description.......................................................................................................................... 23

12.3 Flow diagram (air-cooled).................................................................................................................... 24

12.4 Flow diagram (water-cooled) ............................................................................................................... 24

12.5 Refrigerating compressor .................................................................................................................... 25

12.6 Condenser (air-cooled)........................................................................................................................ 25

12.7 Condenser (water-cooled) ................................................................................................................... 25

12.8 Cooling-water controller....................................................................................................................... 25

12.9 Filter dryer............................................................................................................................................ 26

12.10 Capillary tube....................................................................................................................................... 26

12.11 Aluminium heat exchanger .................................................................................................................. 26

12.12 Hot gas bypass valve .......................................................................................................................... 26

12.13 Refrigerant pressure switches PA-PB-PV.............................................................................................. 27

12.14 Safety temperature switch Ts .............................................................................................................. 27

12.15 DMC 14 electronics (control unit compressed-air dryer)..................................................................... 28

12.16 Electronically level-controlled BEKOMAT condensate drain............................................................... 29

13 Maintenance, troubleshooting, spare parts and dismantling............................................................... 30

13.1 Checks and maintenance .................................................................................................................... 30

13.2 Troubleshooting................................................................................................................................... 31

13.3 Recommended spare parts ................................................................................................................. 34

13.4 Maintenance works at the refrigeration cycle ...................................................................................... 35

13.5 Dismantling of the dryer....................................................................................................................... 35

14 Appendices .......................................................................................................................................... 36

14.1 Dryer dimensions................................................................................................................................. 36

14.1.1 Dryer dimensions DRYPOINT RA 3-12 /AC........................................................................................ 36

14.1.2 Dryer dimensions DRYPOINT RA 18-23 /AC...................................................................................... 36

14.1.3 Dryer dimensions DRYPOINT RA 30-40 /AC...................................................................................... 37

14.1.4 Dryer dimensions DRYPOINT RA 55-60/AC....................................................................................... 37

14.1.5 Dryer dimensions DRYPOINT RA 80-100 /AC.................................................................................... 38

14.1.7 Dryer dimensions DRYPOINT RA 55-60 /WC..................................................................................... 39

DRYPOINT® RA 3-160 3

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Contents

PNEUMATIG

14.1.8 Dryer dimensions DRYPOINT RA 80-100 /WC................................................................................... 39

14.1.9 Dryer dimensions DRYPOINT RA 120-160 /WC................................................................................. 39

14.2 Exploded diagram................................................................................................................................ 40

14.2.1 Exploded diagram – diagram of the functional elements .................................................................... 40

14.2.2 Exploded diagram DRYPOINT RA 3-12............................................................................................. 41

14.2.3 Exploded diagram DRYPOINT RA 18-23........................................................................................... 42

14.2.4 Exploded diagram DRYPOINT RA 30-40............................................................................................ 43

14.2.5 Exploded diagram DRYPOINT RA 55-60............................................................................................ 44

14.2.6 Exploded diagram DRYPOINT RA 80-100........................................................................................ 45

14.2.7 Exploded diagram DRYPOINT RA 120-160........................................................................................ 46

14.3 Circuit diagrams................................................................................................................................... 47

14.3.1 Circuit diagram – diagram of the functional elements ......................................................................... 47

14.3.2 Circuit diagram DRYPOINT RA 3-40................................................................................................... 47

14.3.3 Circuit diagram DRYPOINT RA 55-60................................................................................................. 48

14.3.4 Circuit diagram DRYPOINT RA 80-160 .............................................................................................. 48

4 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Pos:1/Beko Technische Dokum entation/Überschrift en/1/Sicherh eitshinweise @ 0\ mod_118363 7609261_6.doc @ 5365

PNEUMATIG

Type plate

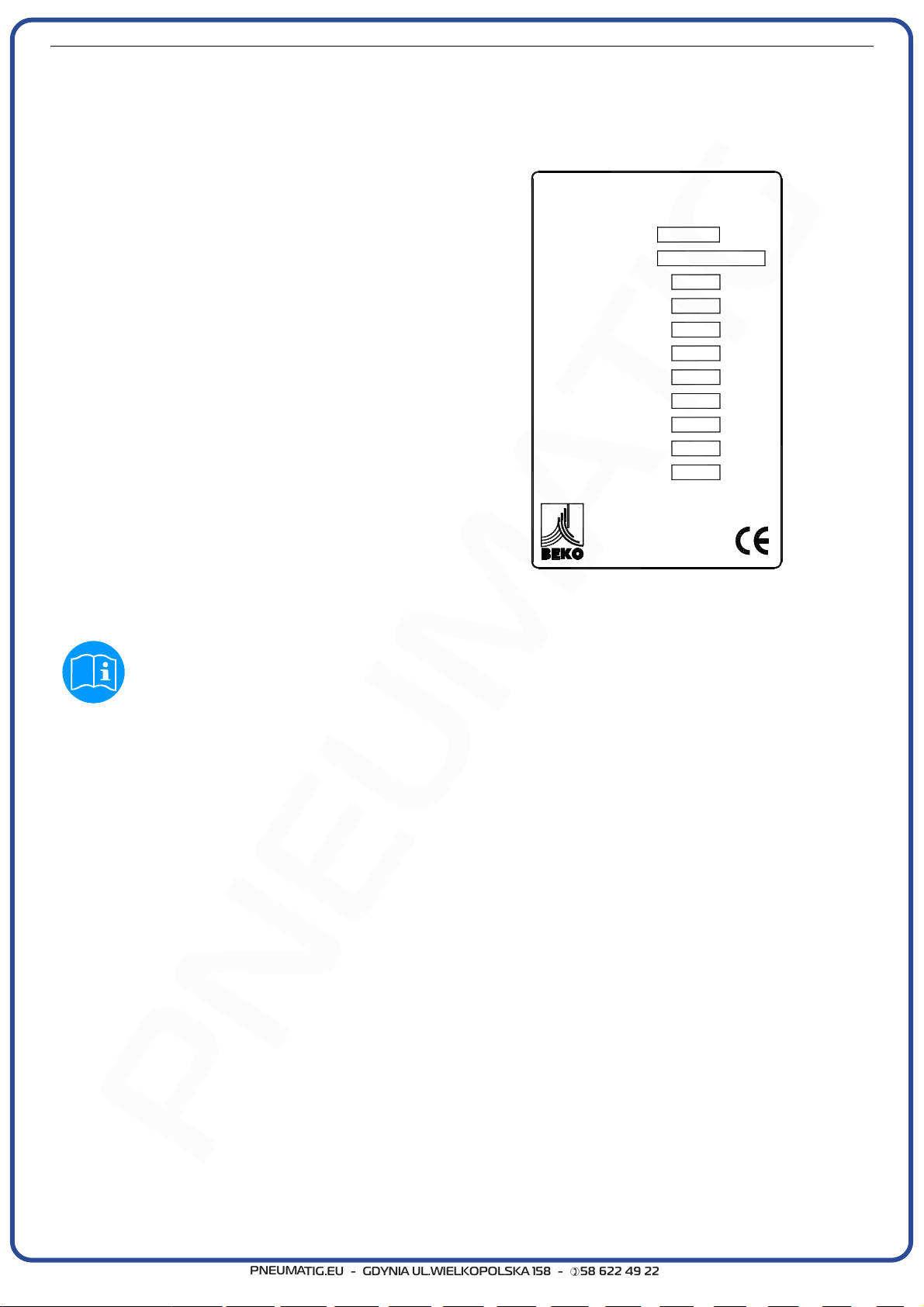

2 Type plate

The type plate is on the back of the dryer and comprises all primary data of the device. Please complete the table on

this page during the installation with all data from the type plate and always refer to these when contacting the manufacturer or the sales department.

All guarantee claims will expire in the event that the type plate is modified or removed.

Model

Product key

Serial number

Nominal flow rate

Operating overpressure PS min/max

Inlet temperature TS max

Ambient temperature

Refrigerant

Refrig. Design pressure HP/LP

Electrical connection

Electric power

Fuse protection max.

3 Safety instructions

Pos:2/Beko Technische Dokum entation/Global eT exte/Allge meinerHi nweis BM @ 0\mod_11836157373 13_6.doc @ 40 04

Pos:3/Beko Technische Dokum entation/Sicherh eit/Hinweis Anlei tung BEKO @ 0\mod_1184147787557 _6.doc @ 5758

Please check whether or not these instructions correspond to the device type.

Please adhere to all advice given in these operating instructions. They include essential information

which must be observed during installation, operation and maintenance. Therefore, it must be ensured

that these operating instructions are read by the fitter and the responsible operator / certified skilled personnel prior to installation, start-up and maintenance.

The operating instructions must be accessible at all times at the place of application of the DRYPOINT®

RA 3-160 compressed-air refrigeration dryer.

In addition to these operating instructions, local and national regulations need to be observed, where

required.

Ensure that operation of the DRYPOINT® RA 3-160 compressed-air refrigeration dryer only takes place

within the permissible limit values indicated on the type plate. Any deviation from these limit values involves a risk for persons and for the material, and may result in malfunction or a breakdown.

After installing the device correctly and in accordance with the instructions in this manual, the dryer is

ready to operate, further settings are not required. Operation is fully automatic and maintenance is limited to several examinations and cleaning measures which are described in the following chapters.

This manual must be available at all times for future reference and is a constituent part of the dryer.

DRYPOINT

Produktschlüssel:

Product key:

Serienr. / Baujahr:

Serial n° / year of building:

Nemmvolumenstrom (ISO1217):

Nominal flow rate (ISO1217):

Betriebsüberdruck PS min/max:

Working pressure PS min/max:

Eintrittstemperatur TS max:

Inlet temperature TS max:

Umgebungstemperatur:

Ambient Temperature:

Kältemittel:

Refrigerant:

Kältem. Auslegungsdruck HD/ND:

Refrig. Design Pres. HP/LP:

Elektrischer Anschluß:

Power supply:

Elektrische Leistung:

Electric Nominal Power:

Absicherung max:

Fuse protection max:

BEKO TECHNOLOGIES GMBH

Im Taubental 7, 41468 Neuss

Germany

TAD0003

http:// www.beko.de

3

m /h

bar(g)

°C

°C

kg

bar

ph/V/Hz

W/A

A

If you have any queries regarding these installation and operating instructions, please contact BEKO

TECHNOLOGIES GMBH.

DRYPOINT® RA 3-160 5

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Safety instructions

PNEUMATIG

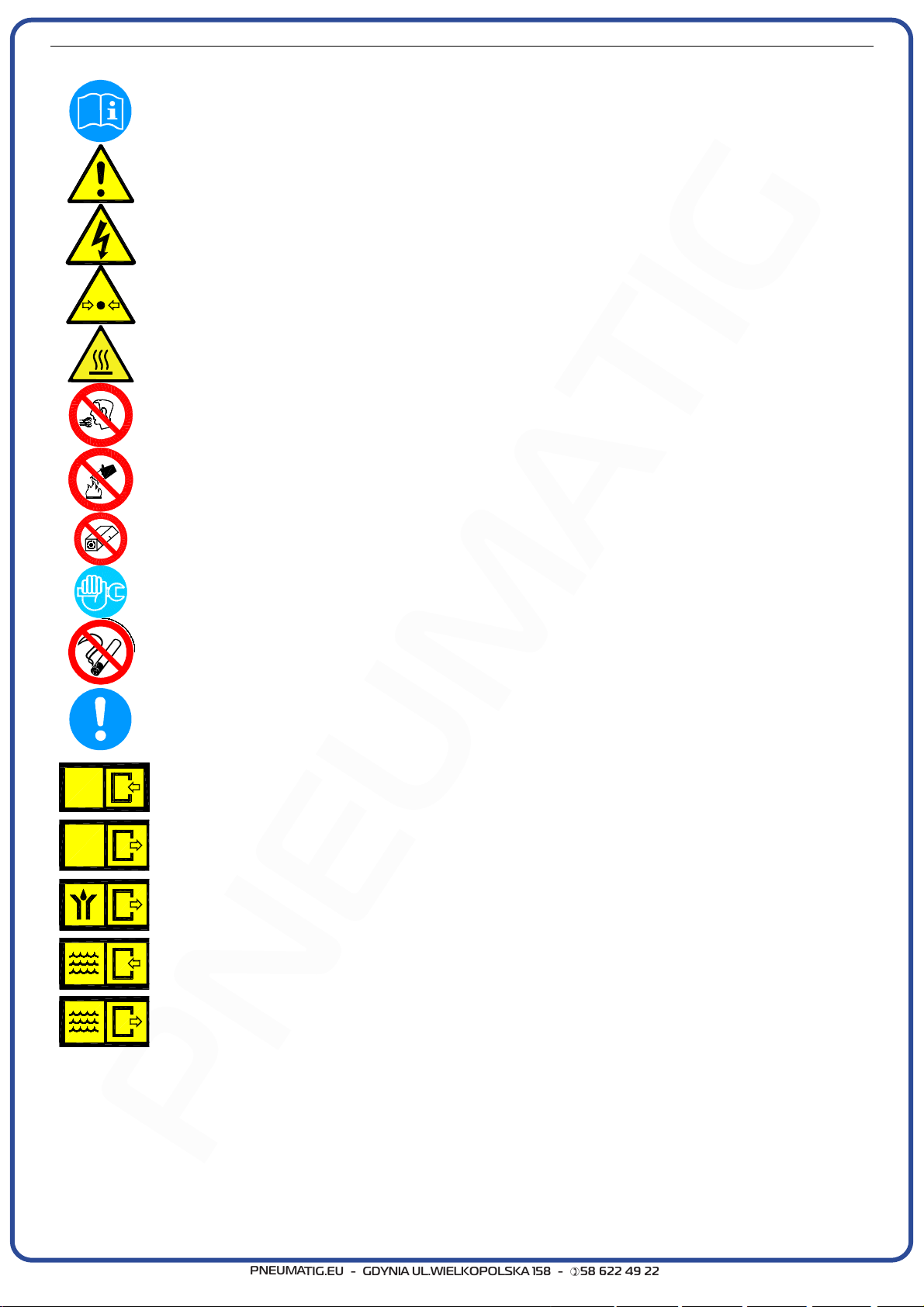

3.1 Safety pictograms in accordance with DIN 4844

Observe operating instructions

General danger symbol

Supply voltage

Danger: component or system under pressure

Hot surfaces

Non-breathable air

Do not use water to extinguish the fire

Pos:4/Beko Technische Dokum entation/Sicherh eit/Gefahr Druc kluft @ 0\mod_11 84148143854 _6.doc @ 577

6

ARIA

AIR

LUFT

AIR

ARIA

AIR

LUFT

AIR

Do not operate with open cover (housing)

Maintenance works or controlling measures must only be carried out by qualified personnel1.

Do not smoke

Note

Connection point compressed-air inlet

Connection point compressed-air outlet

Connection point condensate drain

Connection point cooling-water inlet (water-cooled)

Connection point cooling-water outlet (water-cooled)

6 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

3.2 Signal words in accordance with ANSI

PNEUMATIG

Safety instructions

Danger!

Warning!

Caution!

Notice!

Important!

3.3 Overview of the safety instructions

Imminent hazard

Consequences of non-observance: serious injury or death

Potential hazard

Consequences of non-observance: possible serious injury or death

Imminent hazard

Consequences of non-observance: possible injury or property damage

Potential hazard

Consequences of non-observance: possible injury or property damage

Additional advice, info, hints

Consequences of non-observance: disadvantages during operation and maintenance, no danger

Certified skilled personnel

Installation works must exclusively be carried out by authorised and qualified skilled personnel. Prior to

undertaking any measures on the DRYPOINT® RA 3-160 compressed-air refrigeration dryer, the certified skilled personnel shall read up on the device by carefully studying the operating instructions. The

operator is responsible for the adherence to these provisions. The respective directives in force apply to

the qualification and expertise of the certified skilled personnel.

For safe operation, the device must only be installed and operated in accordance with the indications in

the operating instructions. In addition, the national and operational statutory provisions and safety regulations, as well as the accident prevention regulations required for the respective case of application,

need to be observed during employment. This applies accordingly when accessories are used.

Pos:5/Beko Technische Dokum entation/Sicherh eit/Maßnahmen Dr uckluft BM @ 0\mod_11841482842 91_6.doc @ 5812

Pos:6/Beko Technische Dokum entation/Sicherh eit/Gefahr Netzsp annung @ 0\mod_1184148186948_6.d oc @ 5794

Pos:7/Beko Technische Dokum entation/Sicherh eit/Maßnahmen N etzspannung BM 31/32/33@ 0\mod_1216898 430699_6.doc @ 11319

Danger!

Compressed air!

Risk of serious injury or death through contact with quickly or suddenly escaping compressed

air or through bursting and/or unsecured plant components.

Compressed air is a highly dangerous energy source.

Never work on the dryer when the system is under pressure.

Never direct the compressed-air outlet or condensate drain hoses at persons.

The user is responsible for the proper installation of the dryer. Non-observance of the instructions in the

"Installation" chapter leads to the expiration of the guarantee. Improper installation may result in dangerous situations for the personnel and/or the device.

Danger!

Supply voltage!

Contact with non-insulated parts carrying supply voltage involves the risk of an electric shock

resulting in injuries and death.

Only qualified and skilled personnel are authorised to run electrically-operated devices. Prior to undertaking maintenance measures at the device, the following requirements must be met:

Make sure that the power supply is switched off and that the device is off and marked for maintenance

measures. Please also ensure that the power supply cannot be re-established during the works.

Caution!

Refrigerant!

The compressed-air refrigeration dryer uses HFC-containing refrigerants as a coolant.

Please observe the corresponding paragraph entitled "Maintenance works at the refrigeration cycle".

Warning!

Refrigerant leak!

A refrigerant leak involves the danger of serious injury and damage to the environment.

DRYPOINT® RA 3-160 7

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Safety instructions

PNEUMATIG

The DRYPOINT® RA 3-160 compressed-air refrigeration dryer contains fluorinated greenhouse

gas/refrigerant.

Installation, repair and maintenance works at the refrigeration system must only be carried out by certified

skilled personnel (specialists). A certification in accordance with EC regulation 303/2008 must be available.

The requirements of the EC 842/2006 directive must be met under all circumstances.

Please refer to the indications on the type plate as regards the type and amount of refrigerant.

Comply with the following protective measures and rules of conduct:

In addition, the safety data sheet for the refrigerant needs to be observed!

Storage: Keep the container tightly closed. Keep it in a cool and dry place. Protect it against

heat and direct sunlight. Keep it away from ignition sources.

Handling: Take measures against electrostatic charging. Ensure good ventilation/suction at

the workplace. Check fittings, connections and ducts for tightness. Do not inhale the gas.

Avoid contact with the eyes or the skin.

Prior to carrying out works on refrigerant-carrying parts, remove the refrigerant to such an ex-

tent that safe working is possible.

Do not eat, drink or smoke during work. Keep out of the reach of children.

Breathing protection: ambient-air-independent respirator (at high concentrations).

Eye protection: sealing goggles.

Hand protection: protective gloves (e.g. made of leather).

Personal protection: protective clothing.

Skin protection: use protective cream.

Caution!

Hot surfaces!

During operation, several components can reach surface temperatures of more than +60°C. There

is the risk of burns.

All components concerned are installed inside of the closed housing. The housing must only be opened

by certified skilled personnel.

Caution!

Improper use!

The device is intended for the separation of water in compressed air. The dried compressed air cannot be

used for breathing-air purposes and is not suitable for the direct contact with food.

This dryer is not suitable for the treatment of contaminated air or of air containing solids.

Note!

Contaminated intake air!

In the event that the intake air is strongly contaminated (ISO 8573.1 class 3.-3 or poorer quality), we recommend the additional installation of a prefilter (e.g. CLEARPOINT F040), to avoid clogging of the heat

exchanger.

Caution!

Heating-up through fire!

In the event of a heating-up through fire, the containers and pipes of the refrigerant system can

burst.

8 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

In this case, please proceed as follows:

PNEUMATIG

Switch off the refrigeration plant.

Switch off the mechanical ventilation of the machinery compartment.

Use ambient-air-independent respirators.

Containers and plants which are filled with refrigerant can burst violently in the event of fire.

The refrigerants themselves are incombustible, but they are degraded to very toxic products at high temperatures.

Remove the container/plant from the fire zone, as there is the risk of bursting!

Cool down containers and bottles via a directed water jet from a safe position.

In the event of fire, please use an approved fire extinguisher. Water is not a suitable agent to extinguish

an electrical fire.

This must only be carried out by persons who are trained and informed about the hazards emanating

from the product.

Caution!

Unauthorised intervention!

Unauthorised interventions may endanger persons and plants and lead to malfunction.

Unauthorised interventions, modification and abuse of the pressure devices are prohibited.

The removal of sealings and leadings at safety devices is prohibited.

Operators of the devices must observe the local and national pressure equipment regulations in the

country of installation.

Pos:8/Beko Technische Dokum entation/Sicherh eit/Sicherheitshi nweise, weitere BM (nicht Ex) @ 0\mod _1183616103 770_6.doc @ 400 9os: 9 /Beko Tec hnische Doku mentation/Sich erheit/Zusatz Sic herheitshin weise BM33 @ 0\m od_12319268 87620_6.doc @ 1 2829s: 10 /B eko Technische D okumentation/Sic herheit/Vorsic ht Fehlfunktion @0\mod _1214378096 290_6.doc @ 935 9

Note!

Ambient conditions!

In the event that the dryer is not installed under suitable ambient conditions, the ability of the device to

condense refrigerant gas is impaired. This can result in a higher load of the refrigerating compressor, and

in a loss of efficiency and performance of the dryer.

This in turn leads to overheated condenser fan motors, to malfunction of electric components and to a

breakdown of the dryer.

Do not install the dryer in an environment in which chemicals with a corrosive effect, explosive gases,

toxic gases, evaporation heat, high ambient temperatures or extreme dust and dirt can be found.

Safety instructions

Pos:12/Be koT echnisch eD okumentati on/Überschriften/ 1/Bestimmungsg emäße Ver wendung @ 0\mo d_118363770 6293_6.doc @ 53 83

DRYPOINT® RA 3-160 9

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Proper use

PNEUMATIG

4 Proper use

This dryer was designed, manufactured and tested to separate the moisture which normally exists in compressed air.

Any other use is considered improper.

The manufacturer shall not be liable for problems occurring as a consequence of improper use. The user alone is responsible for any damage resulting from that.

Furthermore, the correct use includes the compliance with the installation instructions, in particular in respect of:

The voltage and frequency of the main voltage supply.

The pressure, temperature and flow rate of the inlet air.

The pressure, temperature and cooling-water throughput (water-cooled).

The ambient temperature.

When delivered, the dryer is tested and fully assembled. The customer only needs to connect the device to the system

in accordance with the instructions in the following chapters.

Pos:15/Be koT echnisch eD okumentati on/Überschriften/ 1/Ausschluss vomAnw endungsbereich @ 0\mod_123600343 9359_6.doc @ 13 709

5 Exclusion from a field of application

Pos:16/Be koT echnisch eD okumentati on/Bestimmungsge mäße Ver wendung/BEKOM AT/Ausschluß An wendung BM 3 1/32/33 @ 0\ mod_1236003837 511_6.doc @ 13736

Note!

Improper use!

The device is intended for the separation of water in compressed air. The dried compressed air cannot

be used for breathing-air purposes and is not suitable for the direct contact with food.

This dryer is not suitable for the treatment of contaminated air or of air containing solids.

6 Special advice for plants under pressure in accordance with the 97/23/EC Pressure

Equipment Directive

The DRYPOINT® RA 3-160 compressed-air refrigeration dryer contains pressure equipment in the sense of the

97/23/EC Pressure Equipment Directive. Therefore, the entire plant needs to be registered with the supervisory authority in accordance with the local regulations, and requires the approval of the latter.

The category of the respective pressure device is indicated in the declaration of conformity.

For the examination prior to the start-up and for periodic inspections, the national regulations need to be observed,

such as the industrial safety regulation in the Federal Republic of Germany. In countries outside the EU, the respective

regulations in force there need to be adhered to.

The proper use of pressure devices is the basic requirement for safe operation. As regards pressure devices, the following points need to be observed:

The DRYPOINT® RA 3-160 compressed-air refrigeration dryer must only be employed within the pressure and

temperature range limits indicated by the manufacturer on the type plate.

No welding must be carried out on the housing and bottom of the devices.

The DRYPOINT® RA 3-160 compressed-air refrigeration dryer must neither be installed in insufficiently venti-

lated rooms nor near heat sources or inflammable substances.

To avoid fractures resulting from material fatigue, the refrigeration dryer should not be exposed to vibrations

during operation.

The maximum operating pressure indicated by the manufacturer on the type plate must not be exceeded. It is

the operator's responsibility to install the appropriate safety and control devices. Prior to the start-up of the

DRYPOINT® RA 3-160 compressed-air refrigeration dryer, the connected pressure generator (compressor

etc.) must be fused to the max. permissible operating pressure. The integrated safeguard needs to be checked

by an approved inspection agency.

The documents related to the DRYPOINT® RA 3-160 compressed-air refrigeration dryer (manual, operating

instructions, manufacturer's declaration etc.) must be kept safe for future reference.

No objects whatsoever must be installed at or placed on the DRYPOINT® RA 3-160 compressed-air refrigera-

tion dryer and the connecting lines.

Installation of the plant in frost-free places only.

Operation of the plant is only permissible with fully closed and intact housing and cover panels. Operation of

the plant with damaged housing/cover panels is prohibited.

10 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Transport

PNEUMATIG

7 Transport

Check the packaging for visible loss or damage. If no visible damage can be ascertained, place the unit in close proximity to the place of installation and unpack the device.

During this procedure, the dryer must always remain in an upright position. The components may be damaged when

the unit is tilted or turned upside down.

Store the device in a dry environment and do not expose it to extreme weather conditions.

Handle with care. Strong shocks can cause irreparable damage.

8 Storage

Keep the device away from extreme weather conditions

even when packaged.

Keep the dryer in an upright position, also while it is

stored. Tilting the device or turning it upside down can

cause irreparable damage to some components.

When the dryer is not in use, it can be stored in its packaging in a dust-free and protected place at a temperature

of up to max. 50°C and at a specific humidity of max.

90%. If the storage period exceeds 12 months, you

should contact the manufacturer.

The packaging material is recyclable. Dispose of the material in accordance with the directives and provisions in

force in the country of destination.

SCC0001

DRYPOINT® RA 3-160 11

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Installation

PNEUMATIG

9 Installation

9.1 Place of installation

Note!

Ambient conditions!

In the event that the dryer is not installed under suitable ambient conditions, the ability of the device to condense refrigerant gas is impaired. This can result in a higher load of the refrigerating compressor, and in a

loss of efficiency and performance of the dryer.

This in turn leads to overheated condenser fan motors, to malfunction of electric components and to a

breakdown of the dryer.

Do not install the dryer in an environment in which chemicals with a corrosive effect, explosive gases, toxic

gases, evaporation heat, high ambient temperatures or extreme dust and dirt can be found.

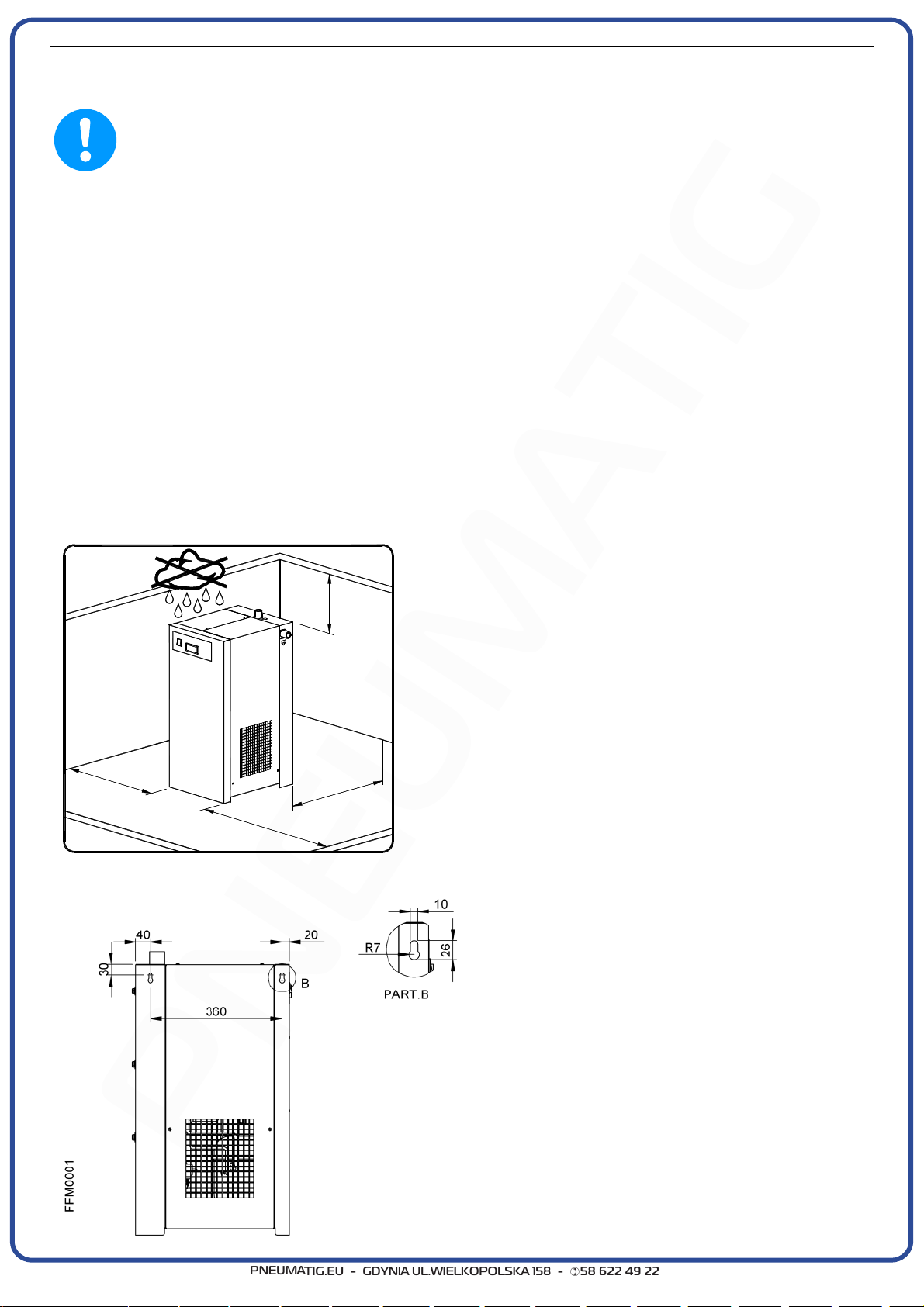

Minimum installation requirements

Choose an area which is clean and dry, free from dust and protected against atmospheric disturbances.

The load-bearing zone must be even, horizontal and able to bear the weight of the dryer.

Minimum ambient temperature +1°C.

Maximum ambient temperature 50°C.

Leave a free area of at least one metre in all directions of the dryer. This space is necessary to facilitate maintenance

works.

The dryer does not need bottom attachment. However, in installations in which the device is suspended, an attaching

part will be required for the suspended device.

1

m

1

LGT0001

Dryer DRYPOINT RA 3-23, suspended:

m

1 m

m

1

Part. B = Teil B

12 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

9.2 Installation plan

PNEUMATIG

Installation

- A -

1

IN

7

OUT

3 4

2

9 9

9

8

9

6

5

1 Air compressor

2 Aftercooler

3 Condensate separator

4 Prefilter

5 Bypass group

6 Dryer

7 Compressed-air tank

- B -

1

IN

4

3

2

9

9

6

OUT

5

7

8

9

9

8 Final filter

9 Bekomat condensate drain

Installation type A is recommended when the compressor functions with reduced step switching and when the total

consumption corresponds to the throughput rate of the compressor.

Installation type B is recommended when the air consumption constantly varies, with peak values which considerably

exceed the throughput rate of the compressor. The storage capacity of the tank must be dimensioned in such a way

that a possible short-term high air demand (peak air consumption) can be compensated.

Note!

Contaminated intake air!

In the event that the intake air is strongly contaminated (ISO 8573.1 class 3.-3 or poorer quality), we

recommend the additional installation of a prefilter (e.g. CLEARPOINT F040), to avoid clogging of the

heat exchanger.

DRYPOINT® RA 3-160 13

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Installation

PNEUMATIG

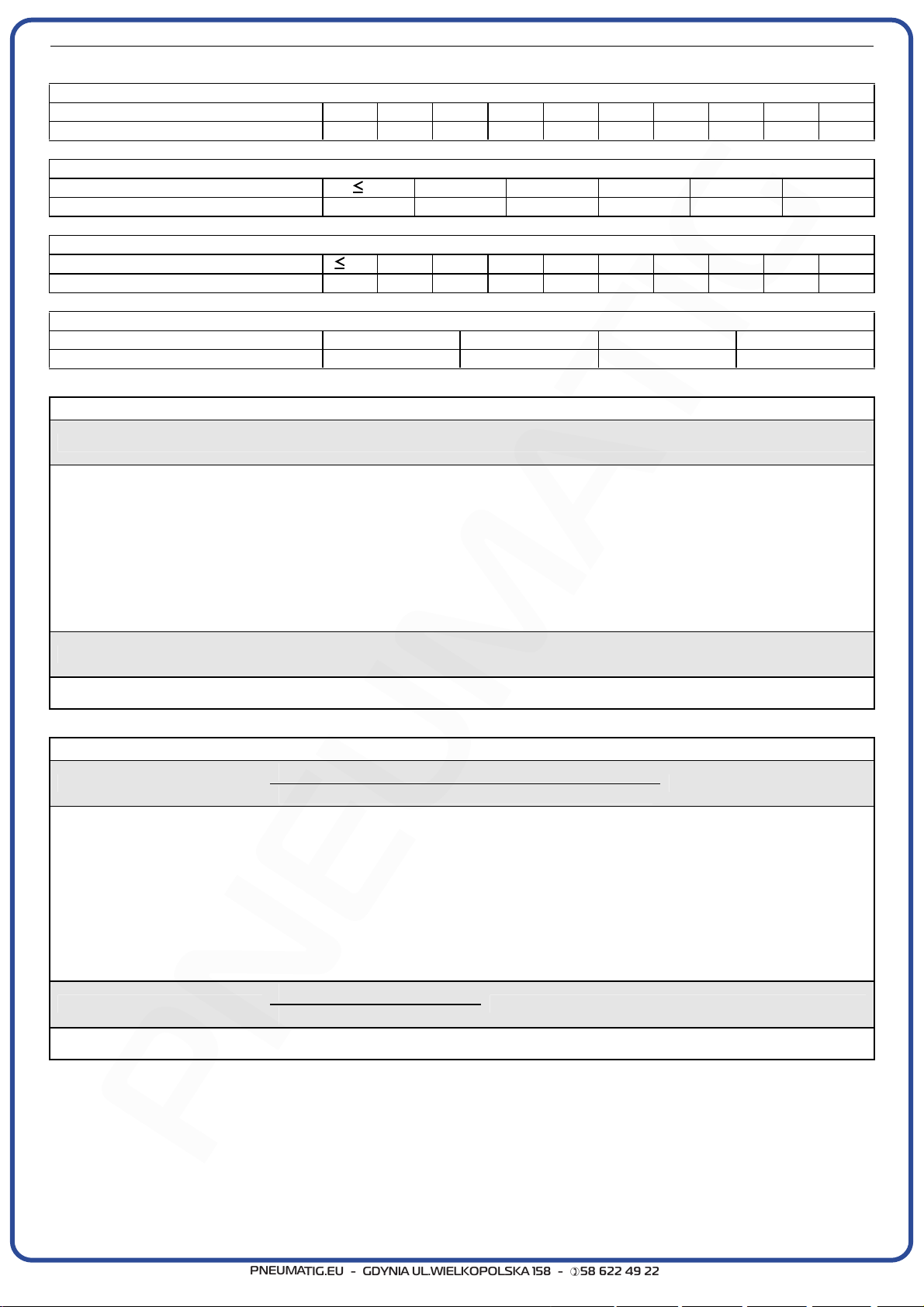

9.3 Correction factors

Correction factor for operating pressure modifications:

Air inlet pressure bar(g) 4 5 6 7 8 10 12 14 15 16

Factor (F1) 0,77 0,86 0,93 1,00 1,05 1,14 1,21 1,27 1,30 1,30

Correction factor for ambient temperature modifications (air-cooled):

Ambient temperature ºC 25 30 35 40 45 50

Factor (F2) 1,00 0,99 0,97 0,93 0,88 0,81

Correction factor for inlet air temperature modifications:

Air temperature ºC 25 30 35 40 45 50 55 60 65 70

Factor (F3) 1,27 1,12 1,00 0,88 0,78 0,70 0,62 0,55 0,49 0,43

Correction factor for dew point modifications:

Dew point ºC 3 5 7 10

Factor (F4) 1,00 1,09 1,19 1,37

Calculation of the air throughput:

Air throughput = nominal capacity x factor (F1) x factor (F2) x factor (F3) x factor (F4)

Example:

The R A 40 has a nom inal capac ity of 24 0 m³ / h . Which is the max. permissible flow through the dryer under

the following operating conditions?

Air inlet pressure = 8 bar(g)

Ambient temperature = 45°C

Air inlet temperature = 50°C

Pressure dew point = 10°C

Every data element has a corresponding numerical factor, which, multiplied with the nominal capacity, is as follows:

Factor (F1) = 1.05

Factor (F2) = 0.88

Factor (F3) = 0.70

Factor (F4) = 1.37

Air throughput = 240 x 1.05 x 0.88 x 0.70 x 1.37 = 212 m³/h

212 m³/h This is the maximum throughput rate for a dryer under these operating conditions.

Selection of a suitable dryer for a given task:

Min. air throughput =

Example:

With the following operating parameters:

Required nominal capacity = 180 m3/h

Air inlet pressure = 8 bar(g)

Ambient temperature = 45°C

Air inlet temperature = 50°C

Pressure dew point = 10°C

For the selection of the suitable dryer type, the required air flow must be divided by the correction factors of the parameters indicated above:

Min. air throughput =

The suitable model is, therefore, DRYPOINT RA 40 (240 m³/h – nominal capacity).

factor (F1) x factor (F2) x factor (F3) x factor (F4)

1.05 x 0.88 x 0.70 x 1.37

required nominal capacity

Factor (F1) = 1.05

Factor (F2) = 0.88

Factor (F3) = 0.70

Factor (F4) = 1.37

180

= 203 m³/h

14 DRYPOINT® RA 3-160

PNEUM

A

TIG.EU - GDYNI

A

UL.WIELKOPOLSK

A

158 -

58 622 49 22

Installation

PNEUMATIG

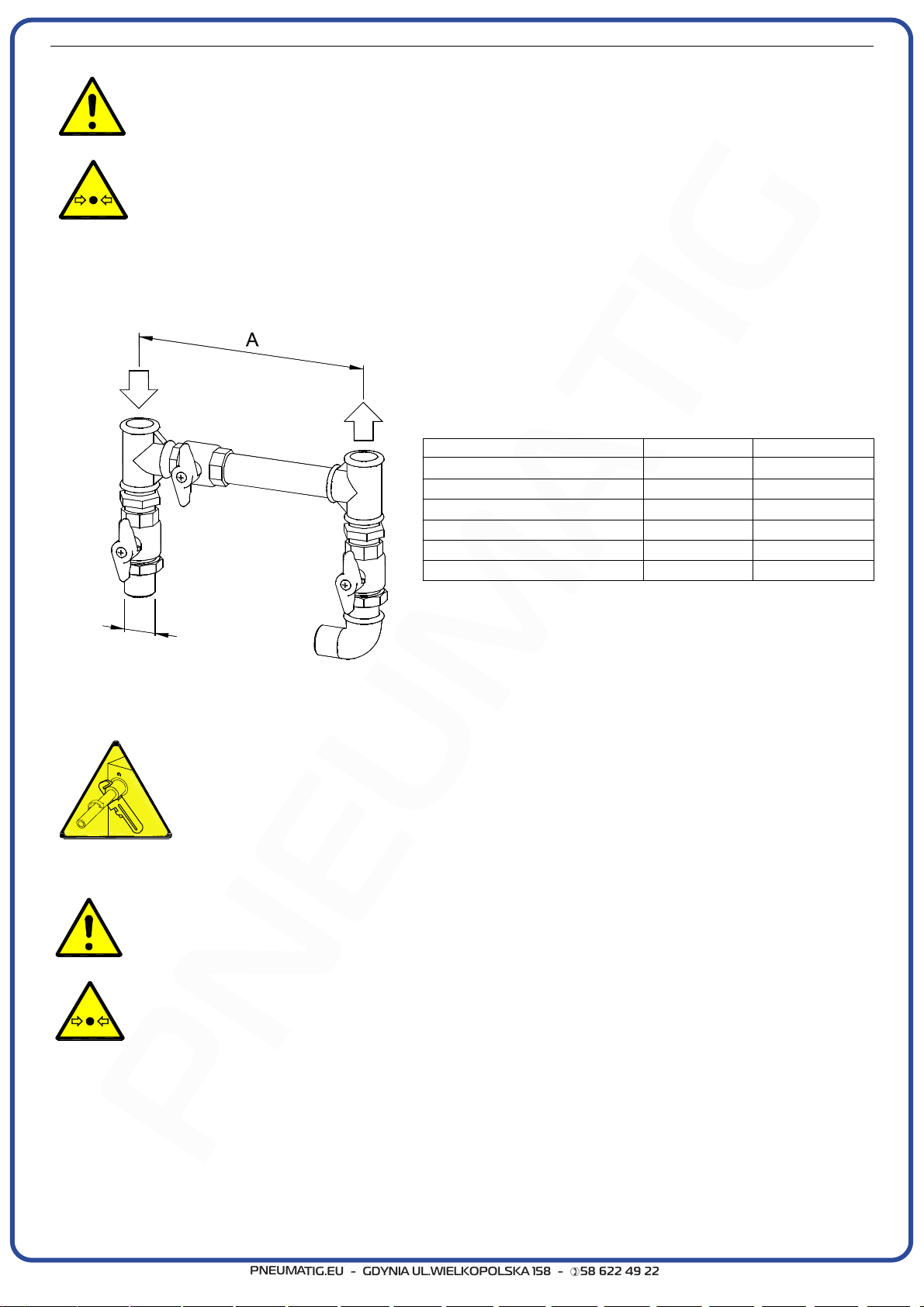

9.4 Connection to the compressed-air system

Danger!

Compressed air!

All works must only be carried out by qualified skilled personnel.

Never work on compressed-air systems which are under pressure.

The operator or the user must ensure that the dryer is never operated with a pressure exceeding the

maximum pressure value indicated on the type plate.

Exceeding the maximum operating pressure can be dangerous for the operator but also for the device.

The air temperature and the air flow at the inlet of the dryer must lie within the limit values indicated on the type plate.

The connecting lines must be free from dust, iron rust, shards and other contaminations and correspond to the flow

rate of the dryer. Should air with a very high temperature be treated, the installation of an aftercooler may be necessary. For the implementation of maintenance works, the installation of a bypass system is recommended, as is shown

in the following illustration.

Dryer Ø [BSP-F] A [mm]

DRYPOINT RA 3-12 1/2” 210

DRYPOINT RA 18-23 1” 205

DRYPOINT RA 30-40 1.1/4” 205

DRYPOINT RA 55-60 1.1/2” 235

DRYPOINT RA 80-100 2" 345

DRYPOINT RA 120-160 2.1/2" 410

Ø

BPY0001

The dryer was designed in such a manner that vibrations that may occur during operation are limited. Therefore, it is

advisable to employ connecting lines (flexible hoses, vibration-inhibiting fittings etc.) which protect the dryer against

possible vibrations in the pipework.

Note:

During the piping of the dryer, the inlet and outlet connections need to be fixed in position, as is

shown in the illustration.

Non-observance will cause damage.

=====Ende der Stückliste = ====

9.5 Connection to the cooling-water network (water-cooled)

Danger!

Compressed air and unqualified personnel!

All works must only be carried out by qualified skilled personnel.

Never work on compressed-air systems which are under pressure.

The user must ensure that the dryer is never operated with a pressure exceeding the nominal values.

Possible overpressure can be dangerous for the operator but also for the device.

The temperature and the amount of cooling water need to correspond to the limit values indicated on the type plate.

The cross-section of the connecting lines which should preferably be flexible, must be free from dust, iron rust, shards

and other contaminations. We recommend employing connecting lines (flexible hoses, vibration-inhibiting fittings etc.)

which protect the dryer against possible vibrations in the pipework.

DRYPOINT® RA 3-160 15

Loading...

Loading...