Beko DEC 4-80, DEC 1-30, DEC 2-40, DEC 3-60, DEC 5-115 Installation And Operating Manual

...

DRYPOINT® M eco control

DEC 1-30

DEC 2-40

DEC 3-60

DEC 4-80

DEC 5-115

DEC 6-135

DEC 7-165

DEC 8-250

DEC 9-330

Drying system

Installation and operating manual

EN - English

07-068

Installation and operating manual EN

2 DRYPOINT® M eco control

Contents

1. Safety information .......................................................................................................................................... 4

1.1. Pictograms and symbols .......................................................................................................................... 4

1.1.1. In this documentation ........................................................................................................................................................4

1.1.2. On the device .......................................................................................................................................................................4

1.2. Signal words according to ISO 3864 and ANSI Z.535 ................................................................................ 5

1.3. Safety instructions .................................................................................................................................. 5

1.4. Transport and storage ............................................................................................................................. 6

1.5. Intended use ........................................................................................................................................... 7

1.6. Legal and material defect liabilities ......................................................................................................... 7

2. Product information ....................................................................................................................................... 8

2.1. Scope of delivery .................................................................................................................................... 8

2.2. Rating plate ............................................................................................................................................ 8

2.2.1. Rating plate for drying system .........................................................................................................................................8

2.2.2. Rating plate for control unit .............................................................................................................................................9

2.3. Product overview and description ......................................................................................................... 10

2.3.1. Principle function methods ............................................................................................................................................ 11

2.3.2. Operating mode ...............................................................................................................................................................12

2.4. Control and display elements ................................................................................................................ 13

2.5. 4 ... 20 mA interface .............................................................................................................................. 14

2.6. Alarm relay ........................................................................................................................................... 14

2.7. Dimensions ........................................................................................................................................... 15

2.8. Technical data ....................................................................................................................................... 16

3. Assembly ...................................................................................................................................................... 20

3.1. Prerequisites ........................................................................................................................................ 20

3.2. Assembly steps ..................................................................................................................................... 21

4. Electrical installation .................................................................................................................................... 22

4.1. Warning note ........................................................................................................................................ 22

4.2. Terminal positions................................................................................................................................. 22

4.3. Opening the control unit ....................................................................................................................... 23

4.4. Connection of voltage power cable to power supply board ..................................................................... 24

4.5. Connection of 4 ... 20 mA interfaces on the control unit PCB .................................................................. 24

4.6. Connection of equipotential contact on the control unit PCB ................................................................. 24

5. Commissioning ............................................................................................................................................. 24

6. Operation ..................................................................................................................................................... 25

6.1. Indicators in operation .......................................................................................................................... 25

6.2. Solenoid valve test function .................................................................................................................. 26

6.3. Acquiring settings (setup mode) ............................................................................................................ 26

6.3.1. Altering the operating mode ......................................................................................................................................... 26

6.3.2. Altering the values ........................................................................................................................................................... 26

6.3.3. Service mode ..................................................................................................................................................................... 27

EN Installation and operating manual

DRYPOINT® M eco control 3

7. Maintenance and servicing............................................................................................................................ 27

7.1. Maintenance schedule .......................................................................................................................... 27

7.1.1. Function and visual inspections .................................................................................................................................... 27

7.1.2. Maintaining the lter element ...................................................................................................................................... 28

7.1.3. Exchanging the control unit ........................................................................................................................................... 29

7.1.4. Replacing the oat drain-o conduit ........................................................................................................................... 29

7.1.5. Measuring the permeation rate .................................................................................................................................... 30

7.1.6. Cleaning .............................................................................................................................................................................. 31

8. Spare parts and accessories ........................................................................................................................... 31

9. Remedying errors, faults and troubleshooting ............................................................................................... 32

9.1. Behaviour in the event of malfunctions/errors, faults ............................................................................ 32

9.1.1. Failure of the voltage power supply ............................................................................................................................. 32

9.1.2. Device fault ........................................................................................................................................................................ 32

9.1.3. Deviating degree of drying ............................................................................................................................................ 33

9.2. FAQ ...................................................................................................................................................... 34

10. Decommissioning ....................................................................................................................................... 36

11. Dismantling and disposal ............................................................................................................................ 36

12. Declaration of Conformity .......................................................................................................................... 37

Installation and operating manual EN

4 DRYPOINT® M eco control

1. Safety information

1.1. Pictograms and symbols

1.1.1. In this documentation

General instructions

Observe installation and operating instructions

General hazard symbol (danger, warning, caution)

General hazard symbol (danger, warning, caution) for mains voltage

and mains voltage energised plant and system parts

1.1.2. On the device

eco label

Symbol for particularly energy-ecient devices

!

20.. 20.. 20..

Maintenance information for nanolter:

Details relating to next required lter exchange

Maintenance information for nanolter:

Never open the housing lid when exchanging the lter

General instructions

General hazard symbol (danger, warning, caution)

General hazard symbol (danger, warning, caution) for mains voltage

and mains voltage energised plant and system parts

EN Installation and operating manual

DRYPOINT® M eco control 5

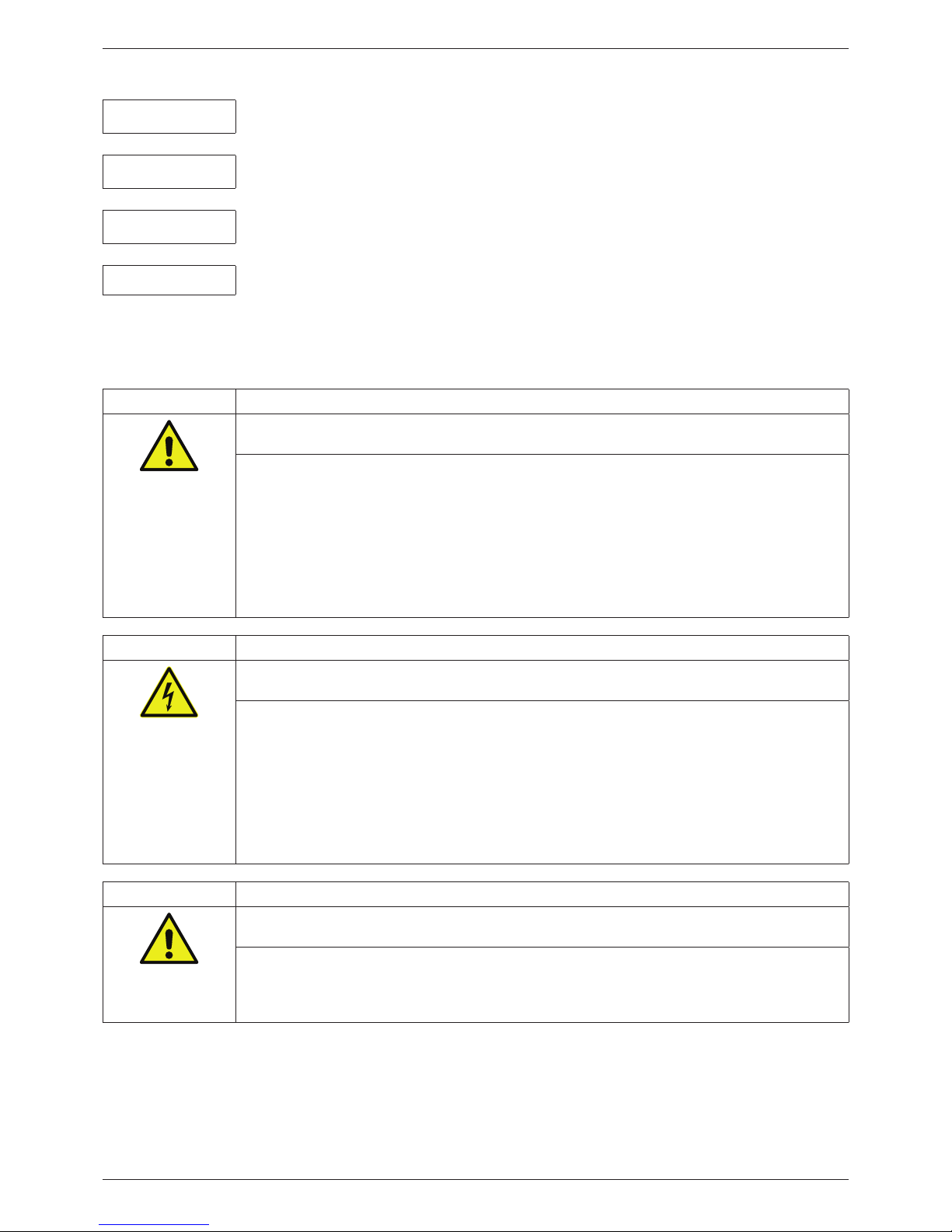

1.2. Signal words according to ISO 3864 and ANSI Z.535

DANGER!

Imminent danger

Consequences of non-compliance: serious personal injury or death

WARNING!

Potential danger

Consequences of non-compliance: possible serious personal injury or death

CAUTION!

Imminent danger

Consequences of non-compliance: possible personal injury or damage to property

NOTICE

Additional notes, tips and hints

Consequences of non-compliance: Disadvantages in operation and maintenance.

No hazards for people.

1.3. Safety instructions

DANGER! Escaping compressed gas

Risk of serious personal injury or death caused by suddenly released compressed gas, condensate on

unsecured device components.

• Only execute assembly, installation or maintenance works when the system is depressurised.

These works may only be executed by authorised specialist technical personnel1.

• Always utilise pressure-resistant installation materials and suitable tools that are in proper

working order.

• Always inspect all plant and system parts and, if applicable, repair them before pressurising the

system. Open valves slowly to prevent pressure blow outs during operation.

• Always prevent that people or objects can be aected condensate or escaping compressed gas.

• Protect the device parts against vibrations, oscillations and impact.

• Perform a leakage test.

DANGER!

Mains voltage

Risk of injury or death from electric shock when coming into contact with non-insulated, energised

parts.

• Comply with all applicable regulations (e.g. VDE 0100 / IEC 60364) for electrical installation

works.

• Only execute installation and maintenance works when the system has been deenergised.

• Electrical works may only be executed by authorised specialist technical personnel1.

• The permissible operating voltage is printed on the rating plate and must be strictly adhered to.

• Only utilise components for the electrical installation which have a current approval

and are labelled with a CE-Identication Marking.

• A safely accessible circuit breaker (e.g. power plug or switch) must be provided close to the unit

for disconnecting all current and/or power lines for the voltage supply.

WARNING! Operation of device outside limiting value range

If the specied limiting values are undershot and/or exceeded, then there is a risk of device or

operating malfunctions.

• The device must only be operated for the intended purpose and within the permissible limiting

values specied on the rating plate as well as those listed in the technical data.

• Strictly adhere to the prescribed operating times and maintenance intervals.

• Strictly adhere to the prescribed storage and transport conditions.

1

Specialist technical personnel

Specialist technical personnel are considered to be people who, due to their professional qualication and knowledge in

the technical elds for measuring, controlling, regulating and compressed air as well as having experience and knowledge

with regard to country-related applicable statutory provisions, regulations, standards and guidelines and are independently

capable of executing the described works and foreseeing potential hazards. Special assignment and/or operating conditions

demand additional knowledge e.g. With regard to aggressive media.

Installation and operating manual EN

6 DRYPOINT® M eco control

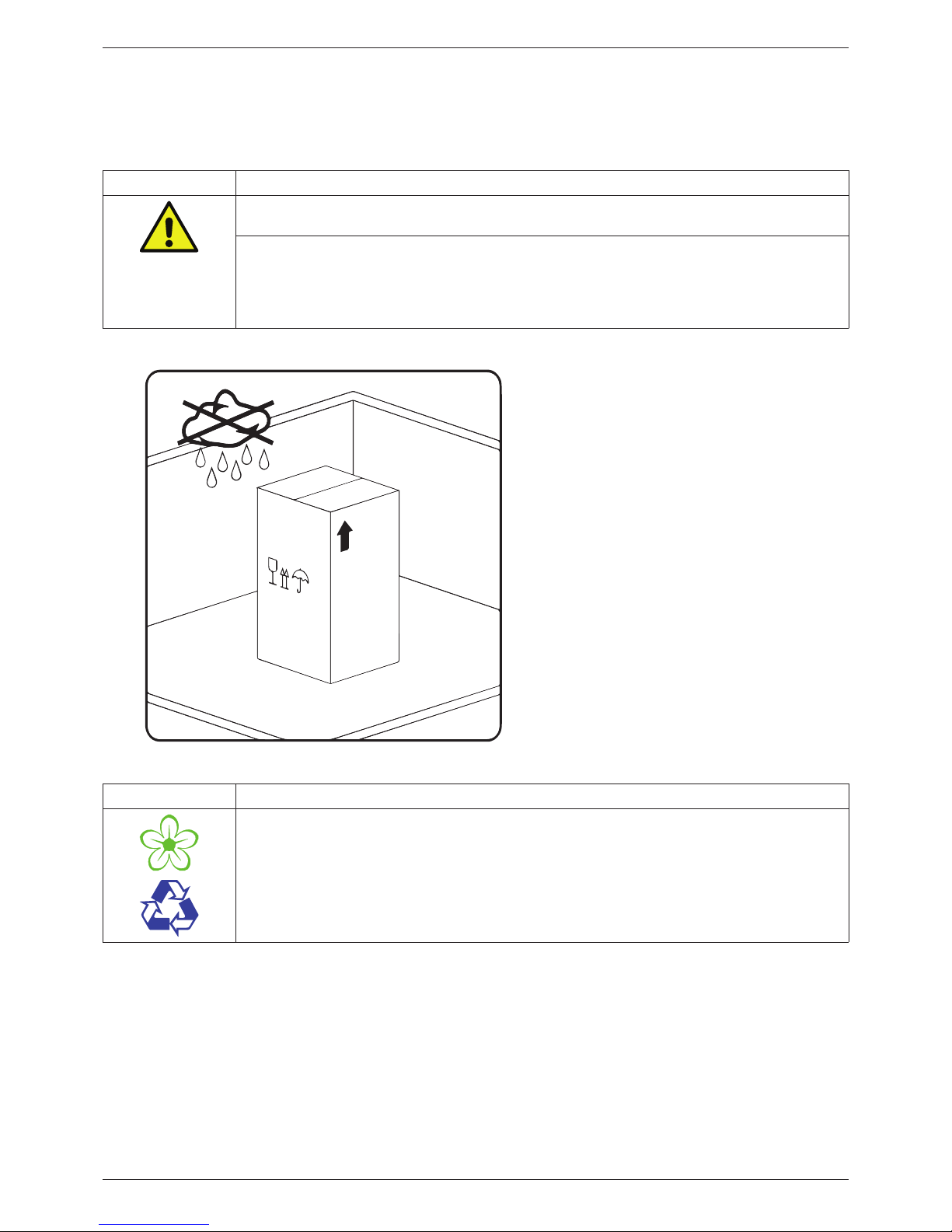

1.4. Transport and storage

Despite our utmost care and attention it is not possible to rule out transport damage. Please therefore remove all packaging

material immediately after receipt and inspect the product for any possible transport damage. Any damages must be

immediately notied to the transport company and BEKO TECHNOLOGIES GMBH or one of their agents.

CAUTION! Damage caused during transport or storage

Incorrect transport, storage or the use of unsuitable lifting equipment can cause damage to the

device.

• The device may only be transported and stored by authorised and trained personnel.

• The device must not be operated with any damages.

• Always comply with the permissible storage and transport temperatures (refer to technical

data).

• Protect the device against continuous direct sunlight and heat radiation.

The device must be stored in the original

packaging in a closed, dry and frost-free room.

Ensure that the ambient temperature and

storage conditions do not undershoot/exceed

the details stated on the rating plate.

The device must be protected against the

eects of external weather even when it is in a

packaged condition.

While in storage, secure the device so that it

cannot topple over or fall, and protect it against

vibration.

NOTICE Recycling of packaging material

• The packaging material is recyclable. Dispose of the packaging material according to the

applicable statutory guidelines, provisions and regulations of the country concerned.

EN Installation and operating manual

DRYPOINT® M eco control 7

1.5. Intended use

The DRYPOINT® M eco control drying system with integrated nanolter and pressure dew point control is designed for the

removal of aerosols and particles from compressed air and subsequent targeted drying of the air according to the individual

settings from the utiliser.

Operate the DRYPOINT® M eco control only for the intended purpose and within the limit range specied in the technical

data. Do not operate the unit with any media (uids, gas/vapour mixtures) other than those listed above. Any other use

of the device, which exceeds the intended use, is hereby deemed to be improper and can cause a hazard for the safety of

people and the environment.

• Operating the unit may only be executed within the permissible operating parameter limits (refer to technical data).

• Operating pressure will be required for the proper functional operation.

• The device is not suitable for operation in explosion hazard areas as well as in areas with aggressive atmospheres.

• Do not operate the device with corrosive gases.

• Strictly observe the prescribed storage and transport conditions.

• The device is not suitable for use in conjunction with CO² systems.

If utilised in plants and systems with increased requirements for compressed air quality (such as e.g. food industry, medical

technology, laboratory equipment, special processes, etc.), then the device owner and/or operator must decide about

measures for the monitoring the compressed air quality. These inuence the safety for subsequent processes and can

prevent injuries to people and damage to plants and systems. It is the duty of the owner and/or operator to always comply

with the stated conditions during the entire operating time.

1.6. Legal and material defect liabilities

All liability claims will be deemed to be invalid when the DRYPOINT-M® eco control is not utilised in accordance with its

intended use or is operated outside the specifications stated in the technical data, this particularly includes:

• Technically incorrect installation, incorrect commissioning, incorrect maintenance or incorrect operation

• Utilising defective components

• Non-compliance with the work steps included in these instructions or the safety-related technical instructions

• Execution of constructive interventions or modications on the device

• Non-compliance with the prescribed maintenance intervals

• Utilising non-original or unapproved spare parts for repair and maintenance works

Installation and operating manual EN

8 DRYPOINT® M eco control

2. Product information

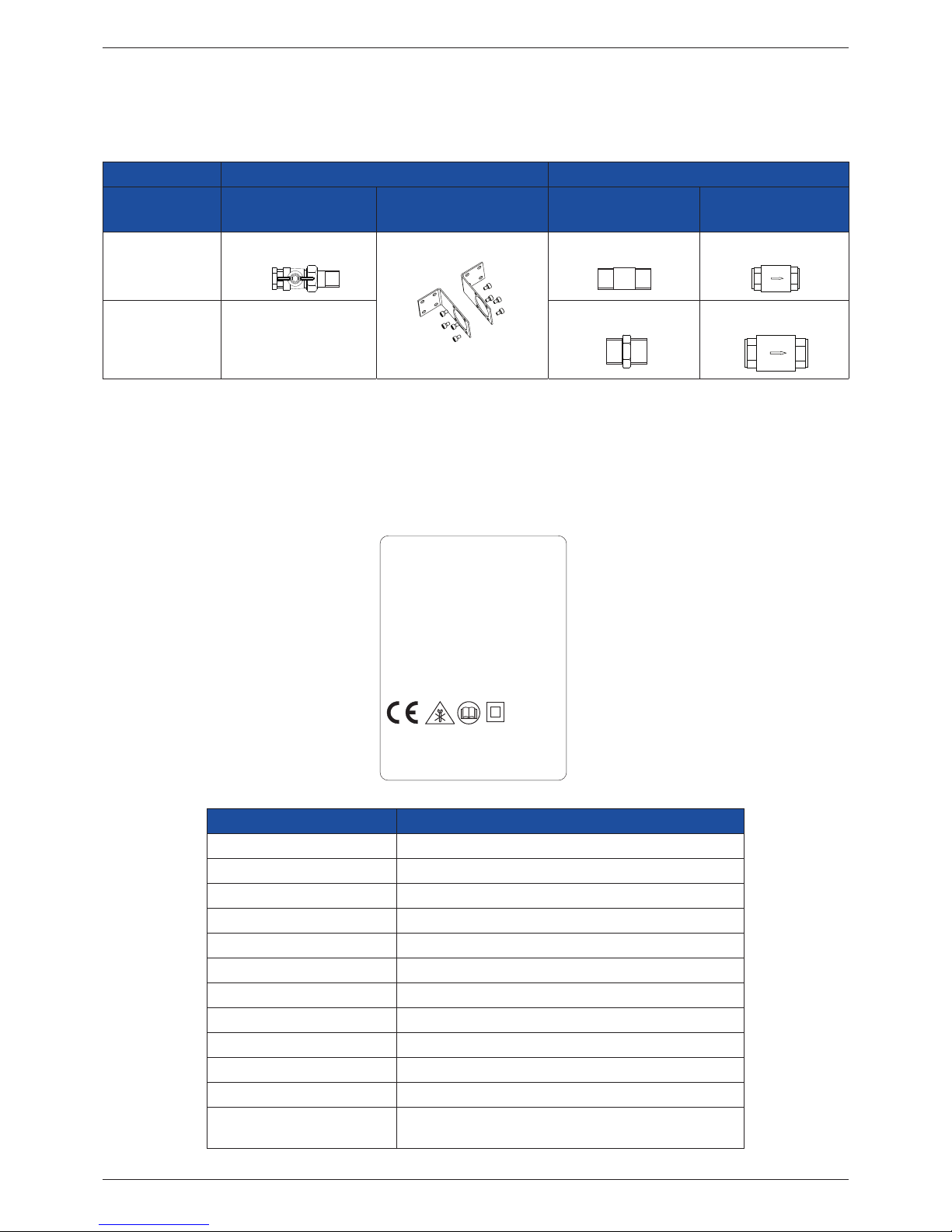

2.1. Scope of delivery

The following table indicates the scope of delivery for the DRYPOINT® M eco control.

Inlet side Outlet side

Model Ball valve Wall bracket Long nipple/double

nipple

Non-return valve

DEC 1 ... DEC 6

G 1/2 G 1/2 G 1/2

DEC 7 ... DEC 9

-

G 1 G 1

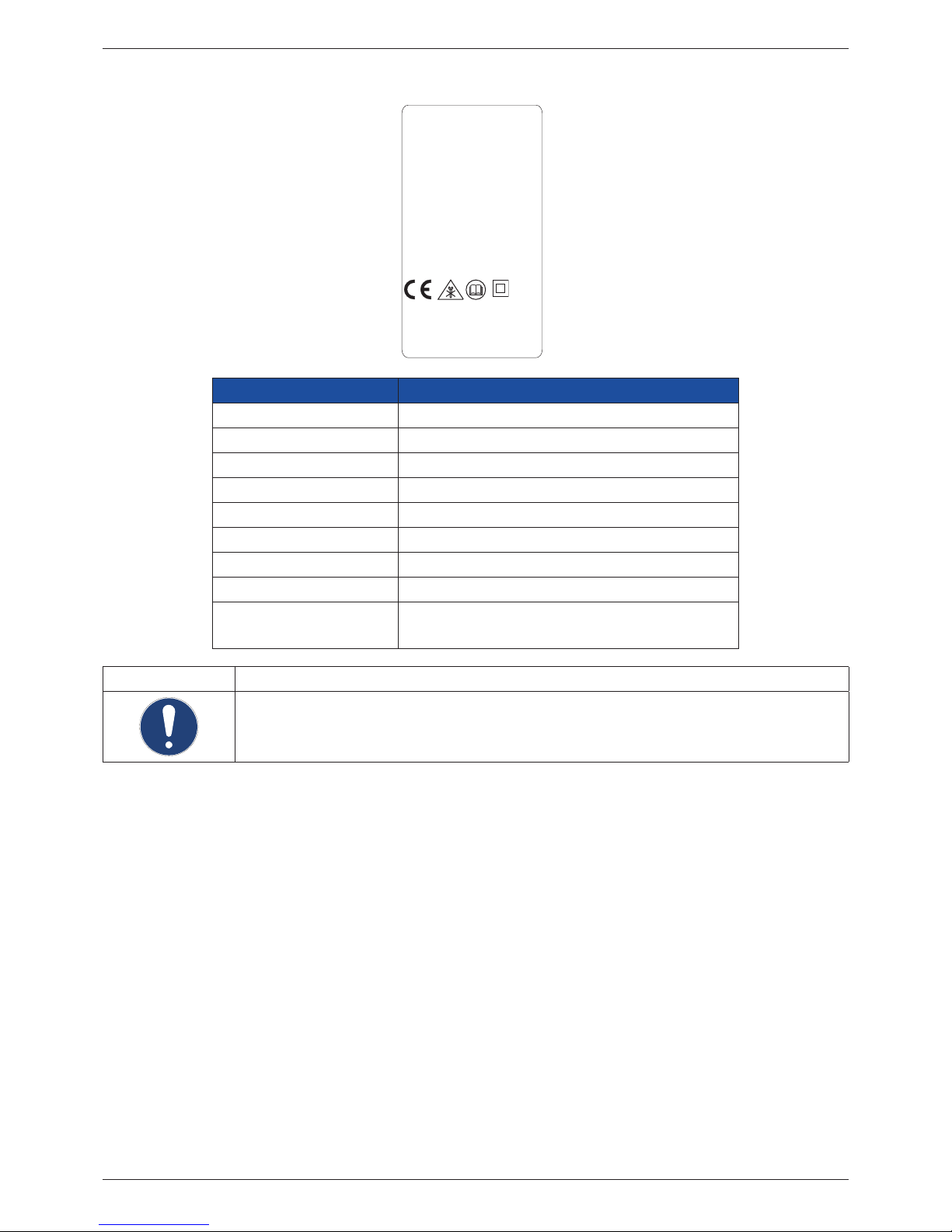

2.2. Rating plate

The drying system is equipped with two rating plates. One for the whole system and one for the control unit.

2.2.1. Rating plate for drying system

DRYPOINT® M eco control

BEKO TECHNOLOGIES

Made in Germany

www.beko-technologies.com

Type: DEC6-135S

Material-no.: 4039476

Serial-no.: 13434090

Lot: 201621

Element: 06N-V02

Element mat.-no.: 4010849

Work. temp. TS:

+2 ... 50 °C / +35 ... 122 °F

Max. work. pr. PS: 4 ... 10 bar / 45 ... 145 psi

Connection: pipe G

¾

Power supply: 95 ... 240 VAC ± 10 %

50-60 Hz, max. 20 VA(W)

100 ... 125 VDC ± 10 %

Protection-Class: IP 54

PED2014/68/EU/Category - Fluidgroup 2

DRYPOINT

Designation Description

Model: Model designation

Material No.: Material number

Serial No.: Serial number

Batch: Date of manufacture

Element: Designation for integrated lter element

Element mat.-no.: Material number for integrated lter element

Work. temp. TS: Permissible min./max. operating temperature

Max. work. pr. PS: Permissible min./max. operating pressure

Connection: Pipework connection

Power supply: Data for voltage supply

Protection-Class: IP protection class

PED2014/68/EU/Category Permissible uid group according to pressure device

guidelines

EN Installation and operating manual

DRYPOINT® M eco control 9

2.2.2. Rating plate for control unit

DEC Control Unit

BEKO TECHNOLOGIES

Made in Germany

www.beko-technologies.com

Type: DEC-CU135S

Material-no.: 4039455

Serial-no.: 13434090

Lot: 201621

Work. temp. TS:

+2 ... 50 °C / +35 ... 122 °F

Max. work. pr. PS:

4 ... 10 bar / 45 ... 145 psi

Power supply:

95 ... 240 VAC ± 10 %, 50-60 Hz

100 ... 125 VDC ± 10 % / max. 20 VA(W)

Protection-Class: IP 54

PED2014/68/EU/

Cat. - /Fluidgroup 2

DRYPOINT

Designation Description

Model: Model designation

Material No.: Material number

Serial No.: Serial number

Batch: Date of manufacture

Work. temp. TS: Permissible min./max. operating temperature

Max. work. pr. PS: Permissible min./max. operating pressure

Power supply: Data for voltage supply

Protection-Class: IP class

PED2014/68/EU/Category Permissible uid group according to European

Pressure Equipment Directive

NOTICE Handling the rating plate

Never damage or remove the rating plate or make it illegible.

For additional information about the symbols utilised, please refer to “Pictograms and symbols” on

Page 4.

Installation and operating manual EN

10 DRYPOINT® M eco control

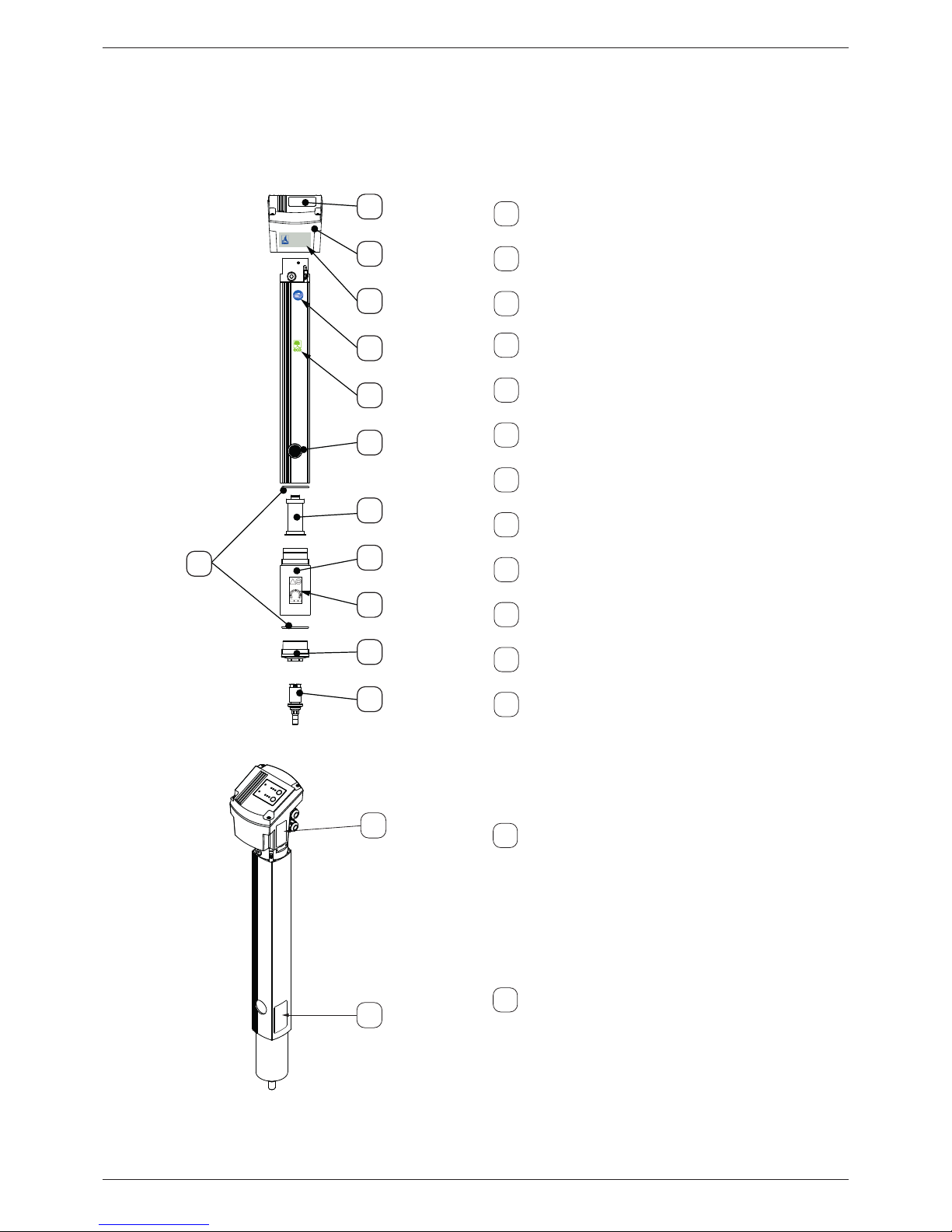

2.3. Product overview and description

The DRYPOINT® M eco control is a drying system that guarantees a constant degree of drying even under uctuating

operating conditions. The sensor system integrated into the control unit (2) reacts to uctuating operating pressure, inlet

pressure dew point as well as dierential requirements for compressed air quantities. The display and control elements

are integrated into the control panel (1). The operating modes as well as specied degree of drying are displayed here. An

adjustment to the operating mode or degree of drying is possible at all times with ongoing operation.

1

2

3

4

8

5

7

9

6

11

12

10

!

20.. 20.. 20..

Year

Month

NEXT ELEMENT

CHANGE

DRYPOINT® M

eco control

1

User interface

2

Control unit/housing head

3

Label: DRYPOINT® M eco control

4

Label: BEKO quality

5

Labels: eco label

6

Purge air outlet

7

Nanolter element

8

O-rings (housing)

9

Housing extension

10

Label: Next element change

11

Housing base

12

Float drain o conduit

13

14

13

Rating plate for the control unit

14

Rating plate for the drying system

EN Installation and operating manual

DRYPOINT® M eco control 11

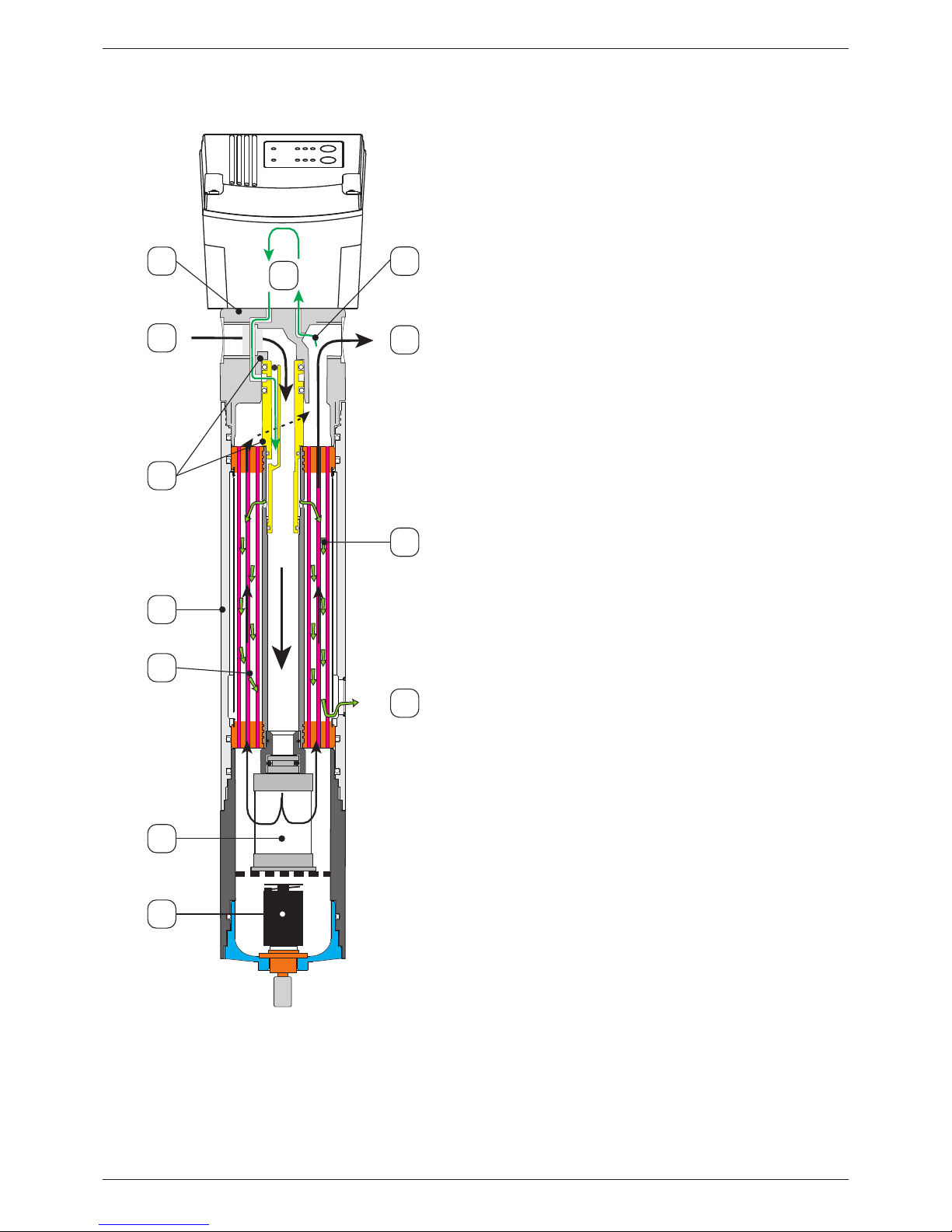

2.3.1. Principle function methods

1

2

4

3

5

6

7

9

8

11

10

12

Damp compressed air (2) enters the unit through the housing

head (1) and ows downwards through the core pipe of the

membrane element (5). A nanolter (6) is tted in the core

pipe outlet

which then frees the compressed air of residual aerosols and

particles. Separated condensate ows out of the base and

is routed through the oat drain-o conduit (7). The ow

direction is reversed in the nanolter element area and the

damp compressed air ows through the membranes of the

internal membrane element.

A part of the compressed air ow

(9) is diverted downstream of the membrane element and

passed by the sensor continuously in the purge air control.

The sensor measuring results will be evaluated in the purge

air control and the purge air feed to the membrane dryer will

be opened as required. As a result, the purge air decreases to

atmospheric pressure and is considerably dryer as the damp

contained in the compressed air is distributed to a multiple of

the original volume.

The very dry purge air (10) will be routed via the purge air jets

(3)

to the external side of the membranes (11) and then evenly

distributed via the arranged position of the membranes.

This means that two air ows move through the membrane

element in an opposite direction with dierential damp

content(5):

Damp compressed air on the inside and dry purge air on the

outside.

Due to the damp dierence, water diuses from the

compressed air into the purge air. The damp purge air (12) is

then released to the ambient air. The compressed air (8) exits

as dry from the membrane dryer.

Installation and operating manual EN

12 DRYPOINT® M eco control

The control software decides in dened cycles on the basis of the measurement results whether, and for how long, the

complete purge air volume must be supplied in order to achieve and stabilise the required degree of drying. This process

will be implemented via a targeted cycling of a solenoid valve. The duration for both subsequent described process steps

therefore varies in every cycle to retain the degree of drying within the specied tolerance range.

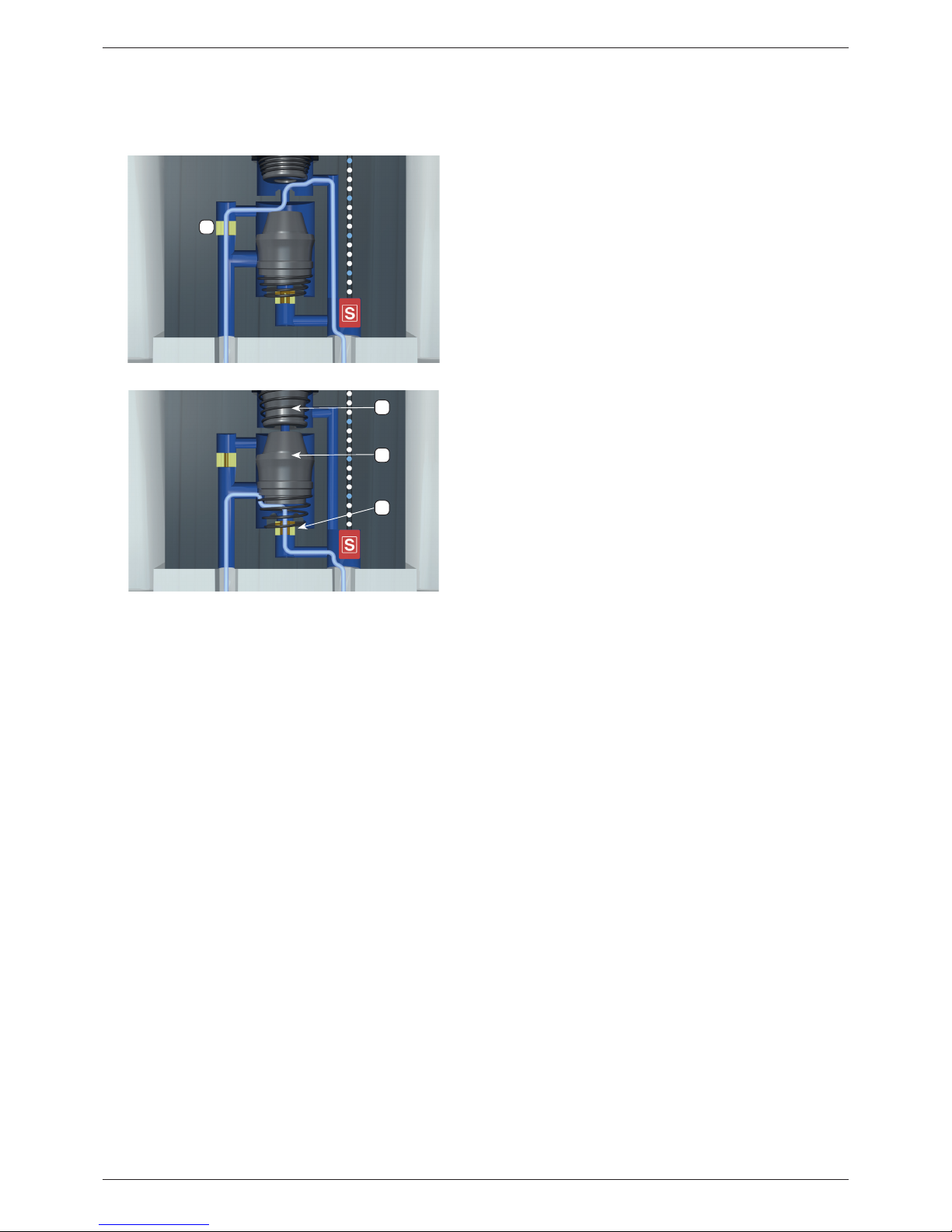

Function: Measuring gas ows

A very small partial ow of the dried compressed air

(measuring gas) ows continuously through the internal

duct guide past a temperature and damp sensor (S) to the

measuring gas jet (1). This sensor continuously species the

degree of drying for the compressed air in the measuring gas

and noties the result to the control system.

Function: Purge air ows

The control system continuously compares the measured

degree of drying of the measuring gas with the individual

specied set point value on the DRYPOINT® M eco control.

The valve unit will be actuated with deviations: The solenoid

core (2) and piston (3) close the valve seat so that the

compressed air ows through the purge air nozzle (4)

to the membrane dryer. The drying process commences

immediately.

2.3.2. Operating mode

Constant mode (-10 °C; factory-set as default) - Setting for a constant outlet pressure dew point:

The DRYPOINT® M eco control constantly retains the pressure dew point at the outlet between +10 and –26 °C in this

operating mode. If the set pressure dew point is <5K below the compressed air temperature, then the set point pressure dew

point is reduced by one step (max. -26 °C). As soon as the minimum dierence of 5K is retained, then the system returns to

normal mode.

Dynamic Mode - constant dierence between compressed-air temperature and outlet pressure dew point:

In this operating mode, the pressure dew point is reduced relative to the compressed air temperature by a specied

dierence between 10 and 55 Kelvin. If the compressed air temperature alters, then the pressure dew point will

automatically follow suit. For programme-technical reasons, an increase in the compressed air temperature is limited to 2

°C/h in order to reduce short-term alterations in the ambient conditions at the installation and/or assembly location.

1

3

2

4

Loading...

Loading...