Beijer Electronics EPC T170/170 C2D Nautic, EPC T150/150 C2D Nautic, EPC T190/190 C2D Nautic, EPC Box C2D Nautic Installation Manual

Page 1

EPC C2D Naut ic

Installation M anual

MAEN979B, 2010-08

English

Page 2

Foreword

© Beijer Electronics AB, MAEN979B, 2010-08

Please read the entire installation manual prior to installing and using this equipment. Only qualified

personnel may install, operate or repair this equipment. Beijer Electronics AB, including all its group

companies, is not responsible for modified, altered or renovated equipment. Because the equipment has a

wide range of applications, users must acquire the appropriate knowledge to use the equipment properly

in their specific applications.

Persons responsible for the application and the equipment must themselves ensure that each application

is in compliance with all relevant requirements, standards and legislation in respect to configuration and

safety. Only parts and accessories manufactured according to specifications set by Beijer Electronics AB

may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP COMPANIES, SHALL NOT BE

LIABLE TO ANYONE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE INSTALLATION, USE OR REPAIR OF THIS

EQUIPMENT, WHETHER ARISING IN TORT, CONTRACT, OR OTHERWISE. BUYER'S

SOLE REMEDY SHALL BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB.

EPC C2D Nautic Installation Manual

Foreword

The EPC C2D Nautic series consists of enhanced Panel IPCs, compatible with

the toughest of maritime environments. Shock and vibration resistant and functional throughout comprehensive temperature changes, the series features a

robust hard-disk drive, fanless CPU and Windows XP as the standard operating

system.

The series also offers the option of modifying a number of its features, affording

a customized version with a flash-memory, fanless chassis and Windows XP

embedded.

The rugged EPC C2D Nautic series provides an open platform solution that can

be utilized with the customer’s choice of software to meet the demands of any

marine environment with high performance reliability that’s built to last.

This manual describes each model and gives instructions on installation, operation and service.

Beijer Electronics, MAEN979B

Page 3

Contents

Contents

1 Safety Precautions................................................................................... 5

1.1 Nautic Approvals and Certificates .......................................................5

1.2 General ...............................................................................................6

1.3 During Installation..............................................................................7

1.4 During Use .........................................................................................7

1.5 Service and Maintenance.....................................................................8

1.6 Dismantling and Scrapping.................................................................8

2 Product Naming ..................................................................................... 9

3 Supplied Equipment ............................................................................. 10

4 Compass Safety Distance ...................................................................... 11

5 Description of Parts.............................................................................. 12

5.1 EPC C2D Nautic..............................................................................12

5.2 Display..............................................................................................13

5.3 Communication Ports .....................................................................14

5.4 Motherboard.....................................................................................15

5.5 Assembly...........................................................................................15

5.6 Power Supply ....................................................................................16

5.7 Earthing System ................................................................................17

5.8 ATX Power Switch............................................................................17

5.9 ATX Remote Connector ...................................................................18

5.10 Compact Flash Memory Card...........................................................18

6 Operation ............................................................................................. 19

6.1 Operating System..............................................................................19

6.2 Default BIOS Settings.......................................................................20

6.3 Important Items Regarding Software Installation ..............................23

6.4 Graphic Board Installation ................................................................24

6.5 Touch Screen Installation..................................................................25

6.6 Installation of LAN-/Network Card ..................................................29

Beijer Electronics, MAEN979B

Page 4

Contents

7 Service .................................................................................................. 31

7.1 Introduction......................................................................................31

7.1.1 Tools .................................................................................................31

7.1.2 Preparation........................................................................................31

7.1.3 Opening the EPC..............................................................................31

7.2 Changing the Fan Filter.....................................................................32

7.3 PCI-board Installation.......................................................................32

7.4 Cable Fixing Points ...........................................................................36

8 Technical Data ..................................................................................... 37

9 Drawings .............................................................................................. 39

9.1 EPC T150/150 C2D Nautic Front View .........................................39

9.2 EPC T150/150 C2D Nautic Cut Out Drawing................................40

9.3 EPC T150/150 C2D Nautic Outline Drawings................................41

9.4 EPC T170/170 C2D Nautic Front View .........................................42

9.5 EPC T170/170 C2D Nautic Cut Out Drawing................................43

9.6 EPC T170/170 C2D Nautic Outline Drawings................................44

9.7 EPC T190/190 C2D Nautic Front View .........................................45

9.8 EPC T190/190 C2D Nautic Cut Out Drawing................................46

9.9 EPC T190/190 C2D Nautic Outline Drawings................................47

9.10 EPC Box C2D Nautic Outline Drawings..........................................48

Beijer Electronics, MAEN979B

Page 5

Safety Precautions

1Safety Precautions

Both the installer and the owner and/or operator of the EPC must read and understand this installation manual.

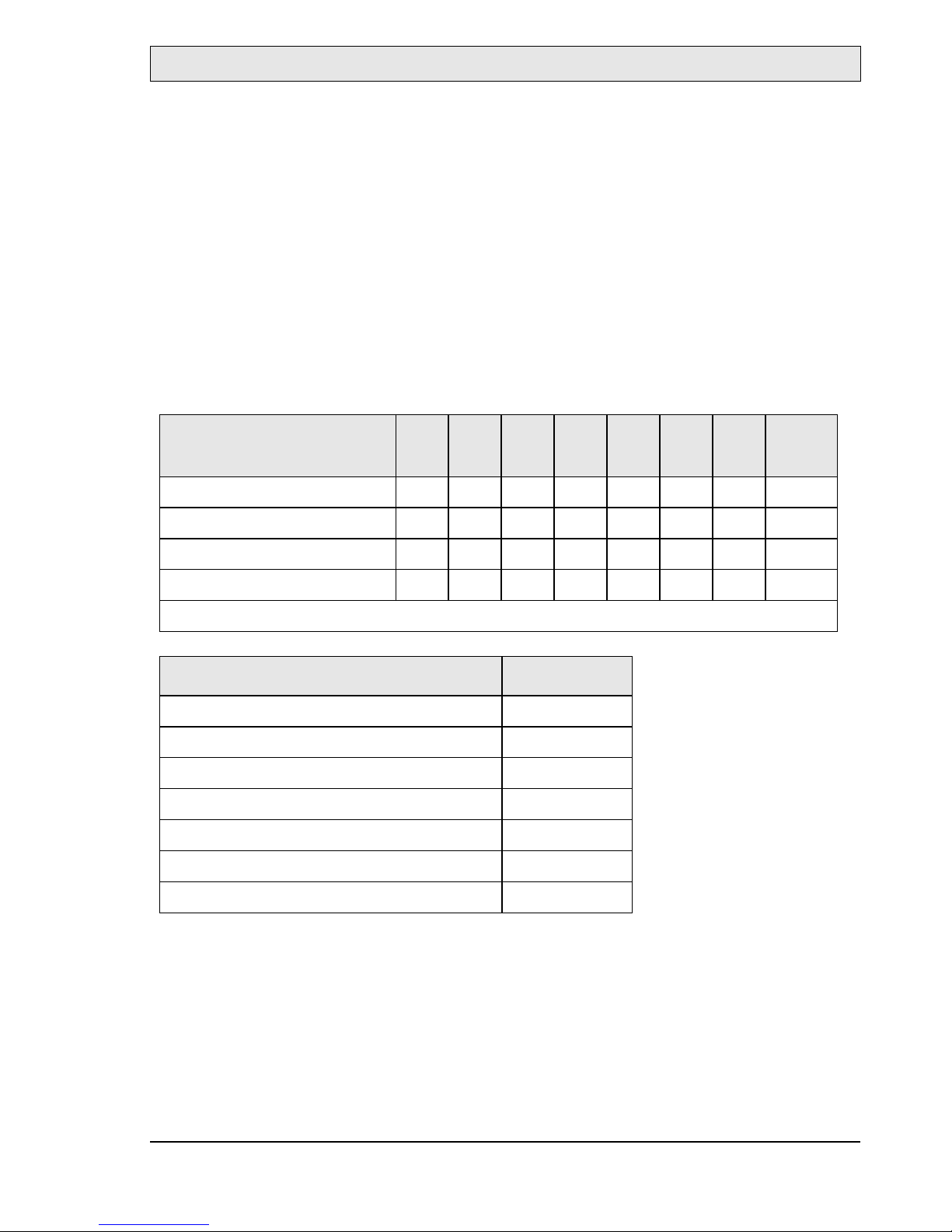

1.1 Nautic Approvals and Certificates

The EPC C2D Nautic series are certified according to the following list. Some

approvals are in progress. Please visit our web site for the latest information.

Model CE LR BV GL DNV ABS RS

EPC T150/150 C2D Nautic XXXXXXX X*

EPC T170/170 C2D Nautic XXXXXXX X*

EPC T190/190 C2D Nautic XXXXXXX X*

EPC Box C2D Nautic XXXXXXX X*

* Also for bridge applications

Approval/Certificate Abbreviation

Conformité Européenne CE

Lloyd’s Registe r LR

Bureau Veritas BV

Germanischer Lloyd GL

Det Norske Veritas DNV

American Bureau of Shipping ABS

EN

60945

Russian Maritime Register of Shippin g RS

Beijer Electronics, MAEN979B 5

Page 6

Safety Precautions

1.2 General

– The EPC is intended for industrial use only.

– The EPC is constructed for naval applications and for indoor use according

to IEC 60945.

– Read the safety precautions carefully.

– Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

– Do not use the EPC in an environment with high explosive hazards.

– The supplier is not responsible for modified, altered or reconstructed equip-

ment.

– Use only parts and accessories manufactured according to specifications of the

supplier.

– Read the installation and operating instructions carefully before installing, us-

ing or repairing the EPC.

– Never allow fluids, metal filings or wiring debris to enter any openings in the

EPC. This may cause fire or electrical shock.

– Only qualified personnel may operate the EPC.

– Storing the EPC where the temperature is lower/higher than recommended

in this manual can cause the LCD display liquid to congeal/become isotopic.

– The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open, flush with plenty of water and get medical attention.

– The figures in this manual serves an illustrative purpose. Because of the many

variables associated with any particular installation, the supplier cannot assume responsibility for actual use based on the figures.

– The supplier neither guarantees that the EPC is suitable for your particular

application, nor assumes responsibility for your product design, installation

or operation.

6 Beijer Electronics, MAEN979B

Page 7

Safety Precautions

1.3 During Installation

– The EPC is designed for stationary installation on a plane surface, where the

following conditions are fulfilled:

• no high explosive risks

• no strong magnetic fields

•no direct sunlight

• no large, sudden temperature changes

– Install the EPC according to the accompanying installation instructions.

– Ground the EPC according to the accompanying installation instructions.

– Only qualified personnel may install the EPC.

– Separate the high voltage, signal and supply cables.

– Make sure that the voltage and polarity of the power source is correct before

connecting the EPC to the power outlet.

– Peripheral equipment must be appropriate for the application and location.

– The controlling transformer has to comply with EN60742.

1.4 During Use

– Keep the EPC clean.

– Emergency stop and other safety functions may not be controlled from the

EPC.

– Do not use too much force or sharp objects when touching the keys, touch

screen etc.

Beijer Electronics, MAEN979B 7

Page 8

Safety Precautions

1.5 Service and Maintenance

– Only qualified personnel should carry out repairs.

– The agreed warranty applies.

– Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

– Clean the display and surrounding front cover with a soft cloth and mild de-

tergent.

– Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier.

1.6 Dismantling and Scrapping

– The EPC or parts thereof shall be recycled according to local regulations.

– The following components contain substances that might be hazardous to

health and the environment: lithium battery, electrolytic capacitor and display.

8 Beijer Electronics, MAEN979B

Page 9

Product Naming

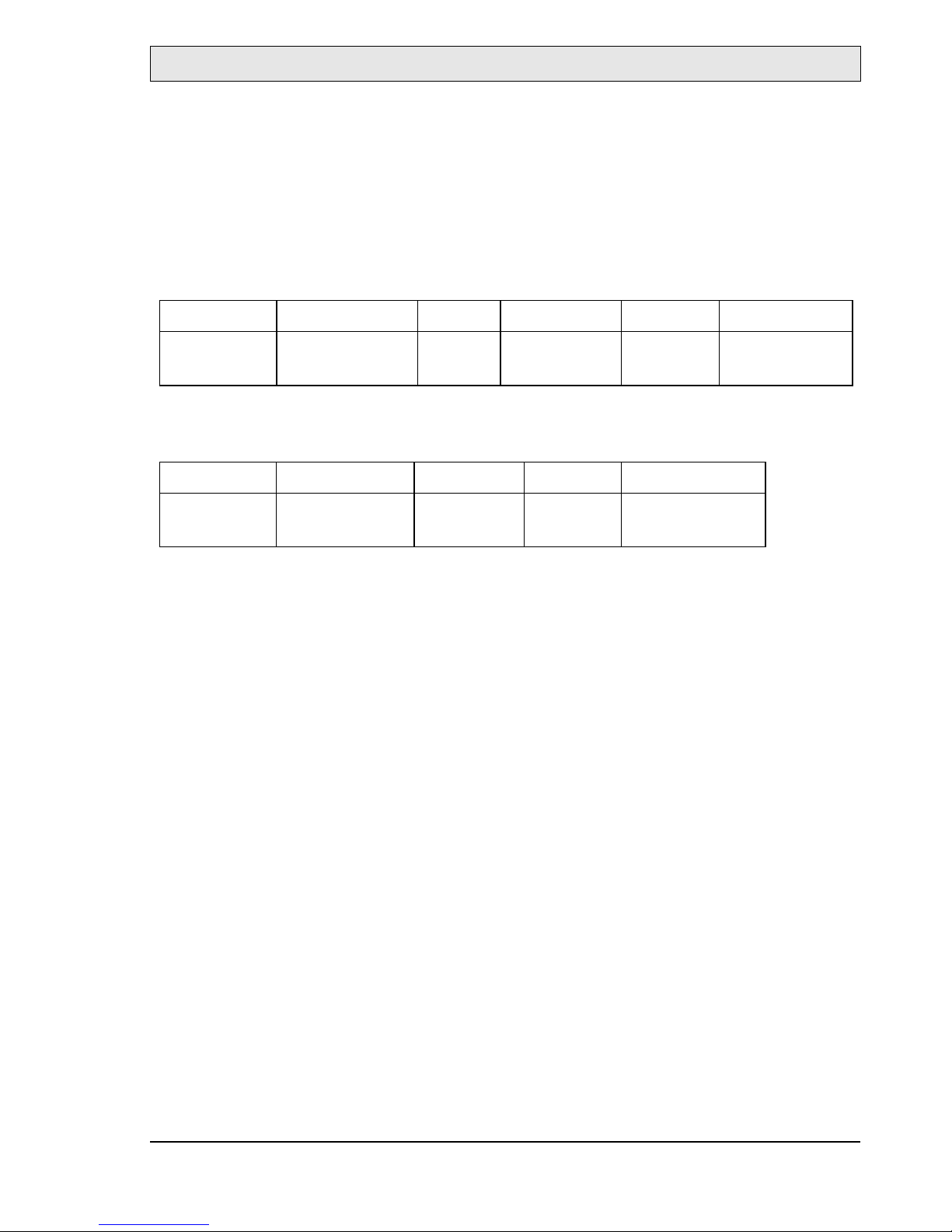

2Product Naming

The naming of the computers is constructed with a number of parameters that

indicate the characteristics of each model, for example EPC T170 C2D Nautic

AC according to below:

EPC T 170 C2D Nautic AC

Computer

series

Optional touch

screen

Screen

size

Processor

type

Main

usage

There is a variant without display; EPC C2D Box Nautic AC:

EPC C2D Box Nautic AC

Computer

series

Processor type No display Main

usage

Type of

power supply

Type of

power supply

Beijer Electronics, MAEN979B 9

Page 10

Supplied Equipment

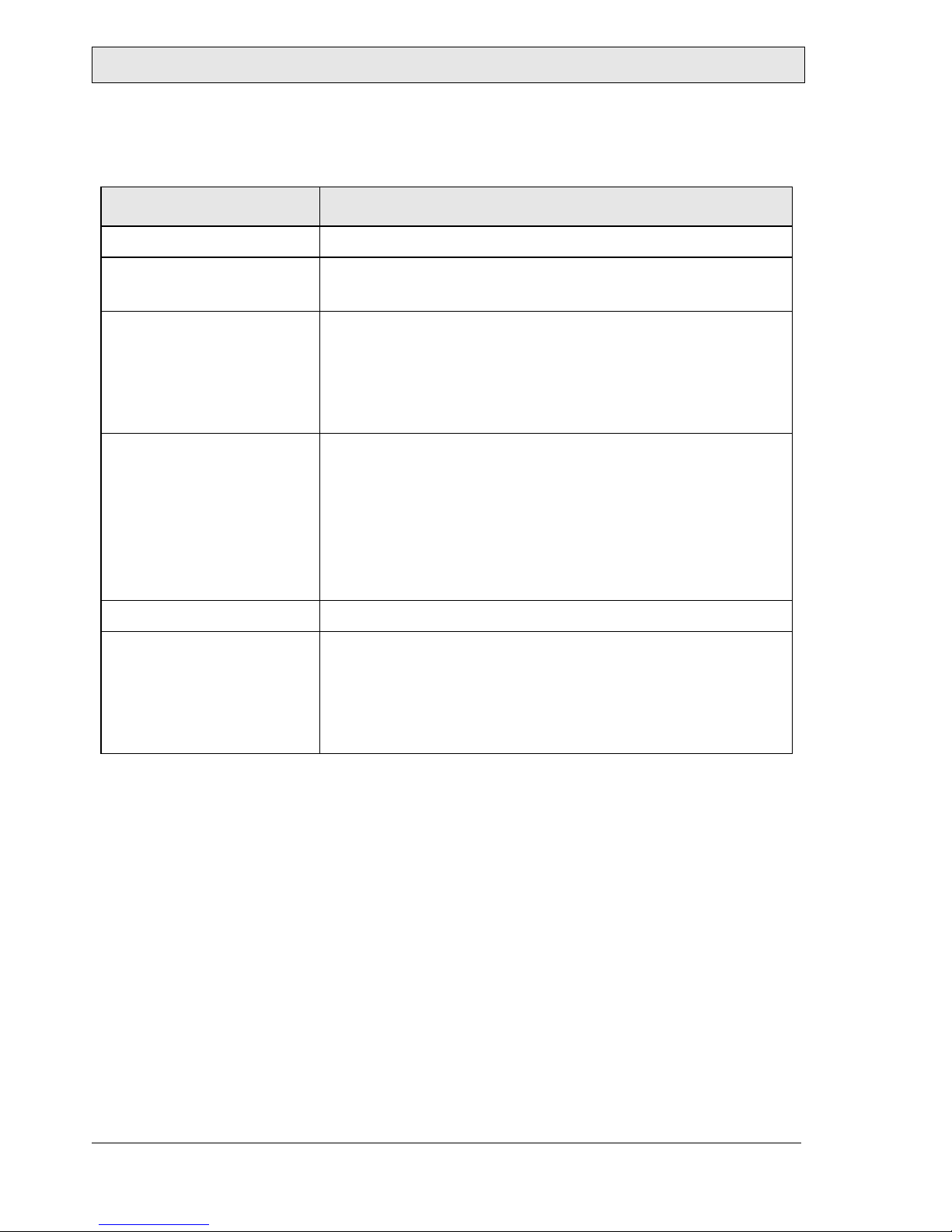

3 Supplied Equipment

Part Description

CD; operating syste m CD with operating system.

CD; driver software Driver softwar e C D for al l pr e-i nstalled component s

such as mother board, touch screen, keyboard etc.

Power cable Standard power cable (European or US standard) for

units with 230 V AC power supply.

Length: approximately 3.0 m.

24 V DC units are delivered without cable.

A variety of cables are available separately.

Installation manual This manual describes specific information about

Beijer Electronics products only – not about third

party components.

Note:

Separate documentation of third party components is

included on the enclosed driver software CD + as

printed documentation.

Mounting kit Screws, nuts etc.

Sticker Device sticker with device name and part number

Note:

Place the sticker on the front of the device when

mounting, to identify device while installing and at

startup.

10 Beijer Electronics, MAEN979B

Page 11

Compass Safety Distance

4Compass Safety Distance

The EPC C2D Nautics are certified according to EN 60945 for bridge applications. The tests include a compass safety distance test.

Electrical devices, such as the EPC C2D Nautic, must be kept in a safe distance

to a compass in operation according to the following table:

Compass type Minimum distanc e to the EPC C 2D Nautic

Steering compass 1 meter in all directions

Emergency compass

Standard compass 1.45 meter in all directions

Beijer Electronics, MAEN979B 11

Page 12

Description of Parts

Front unit

PC unit

5Description of Parts

5.1 EPC C2D Nautic

The EPC C2D Nautic consists of a Front unit and a PC unit. These are installed

in the same way independent of the display size.

The EPC Box C2D Nautic consists of the PC unit only.

12 Beijer Electronics, MAEN979B

Page 13

Description of Parts

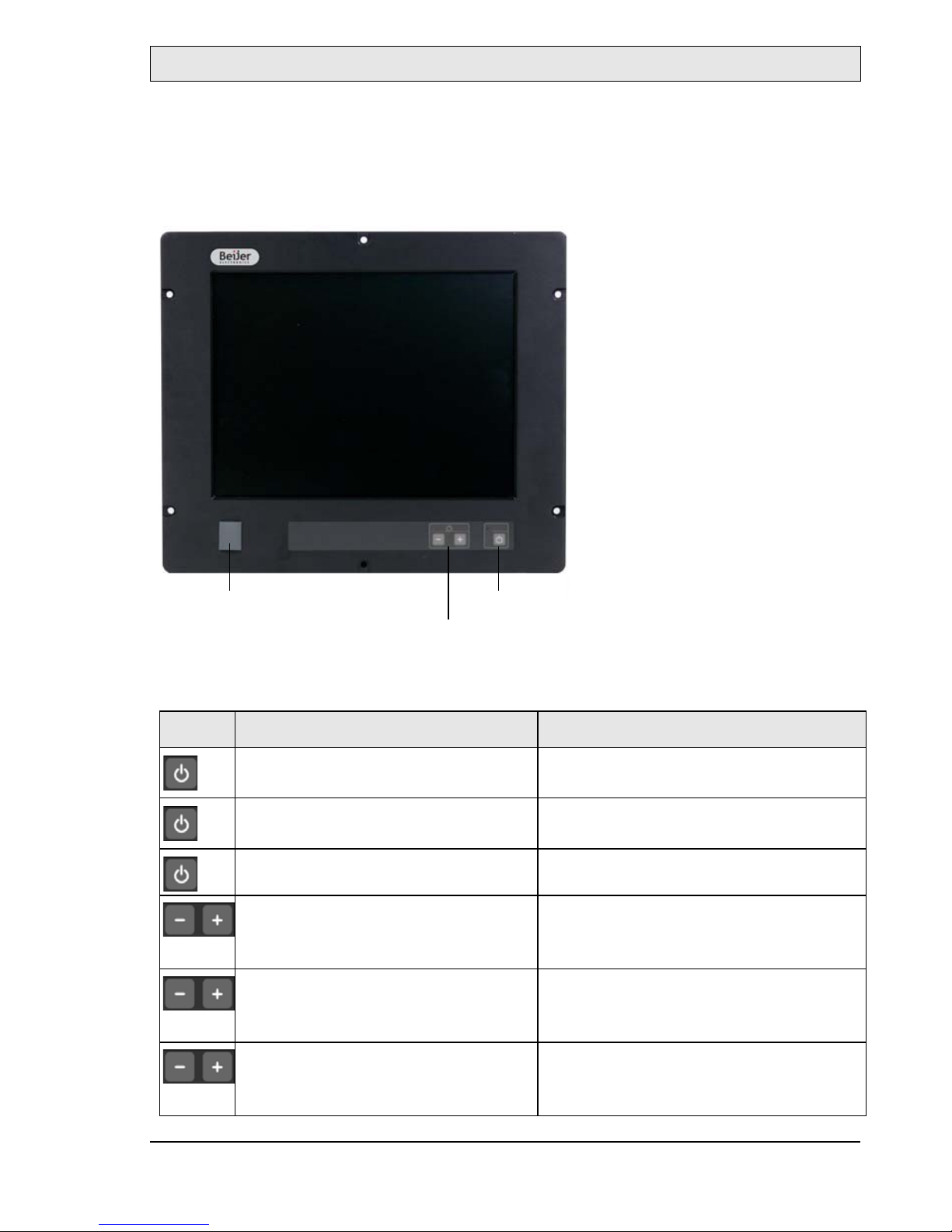

USB port

Po wer button

Dimmer buttons

5.2 Display

Display sizes 15", 17" and 19" are available, as well as the EPC Box C2D Nautic

without display.

The front includes a USB-port under hatch, a power button with a LED, and a

set of dimmer buttons. The buttons are explained below:

Button Instruction Description

Press the power button quickly Turns th e E PC off in a co n trolled way

(as from the Windows Start menu)

Press the power button for longer

than 4 seconds

Press the power button again Turn s the EPC o n

Press - (brightness down) on the

dimmer button (single step or automatic repeating after one second)

Press + (brightness up) on the

dimmer button (single step or automatic repeating after one second)

Press + and - simultaneously for

more than one se cond

Forces the EPC to be turned off

Makes th e d isplay d arker

Makes th e d isplay b r ighter

Turns on fu ll bright n e ss quickl y

(default - may be configured according

to RBC software manual MAEN986)

Beijer Electronics, MAEN979B 13

Page 14

Description of Parts

Power

ATX switch

PS/2 mouse

PS/2 keyboard

COM1

COM2

DVI-1

VGA

Compact Flash slot

Mic in

supply

PCI slot 1

USB 1-2

LAN 1

Earth

USB 3-4

LAN 2

Line in

Line out

PCI slot 2

Fan

ATX remote

The power LED can assume the following statuses:

LED Description

Green Normal operation

Red No input signal avail ab le or the screen is in energy saving mode

- The EPC is turned off or the screen is dimmed to 0 (lowest value,

darkest possible)

5.3 Communication Ports

14 Beijer Electronics, MAEN979B

Page 15

Description of Parts

5.4 Motherboard

The EPC C2D Nautic has 2 SODIMM slots for main storage and 2 PCI-slots.

Further details on the motherboard can be found in a separate manual, included

in the delivery.

Note:

The quality of the memory module may influence the system stability . When updating

the memory module, or adding a second one, please only use memory modules approved by Beijer Electronics. Memory modules are electrostatic sensitive components. Re levant protecti ve measures (earth) have to be considered during as sembly/

disassembly. ESD-protective measu res ar e t o be considered when opening a nd working on the EPC.

5.5 Assembly

A free space of 100 mm, for air circulation, has to be provided around the EPC,

to dissipate the heat generated during operation.

The EPC C2D Nautic is assembled with items included in the supplied mounting kit.

Note:

Possible ris k of damage to the EPC!

Prote ction class IP65 for the front panel is only guaranteed with a perfect fi tting seal.

Pay attention to the torque when fixing the front panel.

Beijer Electronics, MAEN979B 15

Page 16

Description of Parts

Earth screw

Fuse 1 A

Earth screw

Fuse 6.3 A

5.6 Power Supply

The EPC C2D Nautic is available with 230 V AC or 24 V DC power system.

230 V AC Power Supply Connection with Integrated Fuse

24 V DC Power Supply Connection

The power supply for 24 V DC is carried out via a double-pole connector

(Phoenix MST BT 2,5/2).

The EPC C2D Nautic is certified for the connection to protective grounded

power supply according to EN60950. The EPC Box C2D Nautic can also be

operated with extra low voltage in accordance with EN60950. The controlling

transformer has to comply with EN60742.

Note:

Check the power supply system with the relevant data on the type plate.

16 Beijer Electronics, MAEN979B

Page 17

Description of Parts

5.7 Earthing System

The following items have to be observed to guarantee a safe dissipation of electronic interference:

– The EPC and switch board have to be connected to the nearest possible cen-

tral earthing point.

– Make sure of a possibly low inductive connection between EPC and switch

board.

– All data cables connected to the EPC have to be of the shielded type.

– The screens have to be earthed on both sides. A low ohm connection between

the connected systems is essential. Avoid high equalizing currents through the

cable screen due to voltage fluctuations.

– The earthing connection is to be carried out with min. 4 mm² cross section.

5.8 ATX Power Switch

Power packs, main boards and operation systems are used in the EPC C2D Nautic, using up to date PC-technologies such as ATX and ACPI. Switching on the

EPC is done in accordance with ATX specification via the ATX power switch

(the red button next to the power supply).

Should a correct automatic booting not function then this can have the following reason:

In the BIOS settings, the option PWRON After PWR-Fail in the Integrated

Peripherals/Super IO Device menu must be enabled, i.e. On. See also section

6.2 Default BIOS Settings.

The operating system must be ended correctly using the Shut down command

from the operating system menu (Windows start menu), so that the operating

system of the EPC is shut down. The EPC must not be switched off while the

operating system is still running.

The power pack now has to be separated from the power supply for a minimum

of 15 seconds prior to a re-start. During the booting process the main voltage

may not fall (not even for a short time) below the permitted value.

A manual actuation of the ATX power switch, i.e. to start the BIOS menu automatically to check and confirm correct settings, can be necessary if the system

registers an error during shut-down or booting. This is not a malfunction but a

safety feature.

Beijer Electronics, MAEN979B 17

Page 18

Description of Parts

5.9 ATX Remote Connector

The ATX remote terminal is a double-pole connector close to the red ATX power switch button. It is parallel connected to the button. An external push-button

switch or a relay contact can be connected to the ATX remote connector.

5.10 Compact Flash Memory Card

An external Compact Flash memory card can be used for data storage. Some

EPC models also allow mounting an internal Compact Flash memory card as a

boot-up device, or for data storage.

Note:

Only Compact Flash cards distributed by Beijer Electronics may be used. Third party products may cause system malfunction or performance loss.

If a Compact Flash memory card is mounted in/removed from a running EPC,

the EPC must be restarted in order to detect the system change.

Booting from a Compact Flash Card

Follow the instructions below, in order to boot the EPC from an internal Compact Flash card:

– Make sure that the Compact Flash card is used as local drive. Standard Com-

pact Flash cards are available only as removeable drives for data storage.

– Confirm that the Compact Flash card is set as first boot device in the BIOS

in order to boot the operation system from it.

– Removing the Compact Flash card while the EPC is running may damage the

operating system.

18 Beijer Electronics, MAEN979B

Page 19

Operation

6Operation

6.1 Operating System

The EPC C2D Nautic is delivered with Windows XP operating system.

The operating system and other programs are installed on drive “C:”.

Drive “D:” contains all data required for a new installation (drivers and operation system) and may also be used for user data (beneficial for example for data

backup).

Beijer Electronics, MAEN979B 19

Page 20

Operation

6.2 Default BIOS Settings

The BIOS settings may need to be checked or altered if the system becomes instable.

To start the setup: Switch on the EPC and press the [DEL] button, according to

the first screen image.

Selecting Load Optimized Defaults loads the following settings.

Menu Menu item Setting

Standard CMOS Features Date Current date

Time Current time

Check that all IDE-Devices (HD, CD and CF) are

correctly recognized

Advanced BIOS Features

CPU Features

Advanced BIOS Features Hard Disk Boot Priority Default

Execute Disable Bit Enabled

Virtualization Technology Enabled

Core Multi-Processing Enabled

Virus Warning Disabled

Quick Power On Self Test Enabled

First Boot Device Harddisk

Second Boot Device Harddisk

Third Boot Device Disabled

Boot Other Device Disabled

Boot Up NumLock Status On

Gate A20 Option Fast

Security Option Setup

20 Beijer Electronics, MAEN979B

MPS Version Control For OS 1.4

Report No FDD For Win95 No

Small Logo (EPA) Show Disabled

Page 21

Menu Menu item Setting

Advanced Chipset Features Syste m Bio s Cacheabl e Enabled

On Chip Frame Buffer Size 8 MB

DVMT Mode DVMT

DVMT / Fixed Memory Size 128 MB

Boot Display Auto

Panel Nu mber

15"

17"

19"

12: 1024x768 24 bit

13: 1280x1024 48 bit

13: 1280x1024 48 bit

Operation

Integrated Peripherals

On Chip IDE Device

Integrated Peripherals

Onboard Device

Integrated Peripherals

Super IO

Integrated Peripherals

USB Device Se tting

IDE HDD Block Mode Enabled

IDE DMA transfer access Enabled

SATA Mode IDE

OnChipSerial ATA Enhanced Mode

Onboard LAN1 control Auto

Onboard LAN2 control Auto

Onboard LAN ROM control Disabled

Po wer ON Fu ncti on Button only

Onboard Serial Port1 3F8/IRQ4

Onboard Serial Port2 2F8/IRQ3

PWRON After PWR-Fail On

Watch Dog Timer Select Disabled

USB 1.0 Controller Enabled

USB 2.0 Controller Enabled

USB Storage Function Enabled

USB Mass Storage Device

Auto mode

Boot setting

Power Manage ment Se tup PCI Express PME Dis ab led

Beijer Electronics, MAEN979B 21

ACPI Sus pend Type S1

Soft-Off by PWR-BTTN Instant-Off

Wake-Up by PCI Card Disabled

Po wer On by Ring Disabled

Resume b y Alarm Disabled

Page 22

Operation

Menu Menu item Setting

PNP / PCI Configuration Init Display First Onboard

Reset Configurati on Data Disabled

PCI/VGA Palett e Snoop Disabl ed

INT Pin 1 Assignment Auto

INT Pin 2 Assignment Auto

INT Pin 3 Assignment Auto

INT Pin 4 Assignment Auto

INT Pin 5 Assignment Auto

INT Pin 6 Assignment Auto

INT Pin 7 Assignment Auto

INT Pin 8 Assignment Auto

Frequency Vo ltag e Control Auto Detect PCI / clk Enabled

Spread Spectrum Disabled

22 Beijer Electronics, MAEN979B

Page 23

Operation

6.3 Important Items Regarding

Software Installation

The included driver CD includes all drivers needed for a successful reinstallation

of the EPC. Since the EPC is not equipped with a CD/DVD player, an external

USB CD/DVD player has to be used.

The drivers are also available on the “D:” drive.

When the CD is loaded, a menu is displayed for selection of driver installation,

displaying manuals etc. Follow the steps below in the specified order, when reinstalling the system:

1. Install the chipset driver.

2. Install the graphic drivers.

3. Install the touch screen drivers.

4. Install the network drivers.

Note:

To avoid always having to re-s tart the installa ti o n proc edure of the operating system, we recommend making an image of the new hard disk (using e.g. Norton Ghost,

Drive Image etc.). Then you can always fall back on the operational image, if needed.

Note:

After operating the system for the first time we recommend that you make start

discs (emergency discs). These mi ght be required t o restore an operational sy stem.

Additionally, we recommend making backup copies of your own data and applications.

Beijer Electronics, MAEN979B 23

Page 24

Operation

6.4 Graphic Board Installation

After finalizing the Windows installation (chipset driver) and re-starting the system, terminate the automatic driver search for the graphic board driver and use

the installation CD instead.

Note:

The graphic driver will be installed twice.

5. After finishing the installation and re-starting the EPC, the following

entries are available under the Display icon in the Control Panel, or in the

display properties.

24 Beijer Electronics, MAEN979B

Page 25

Operation

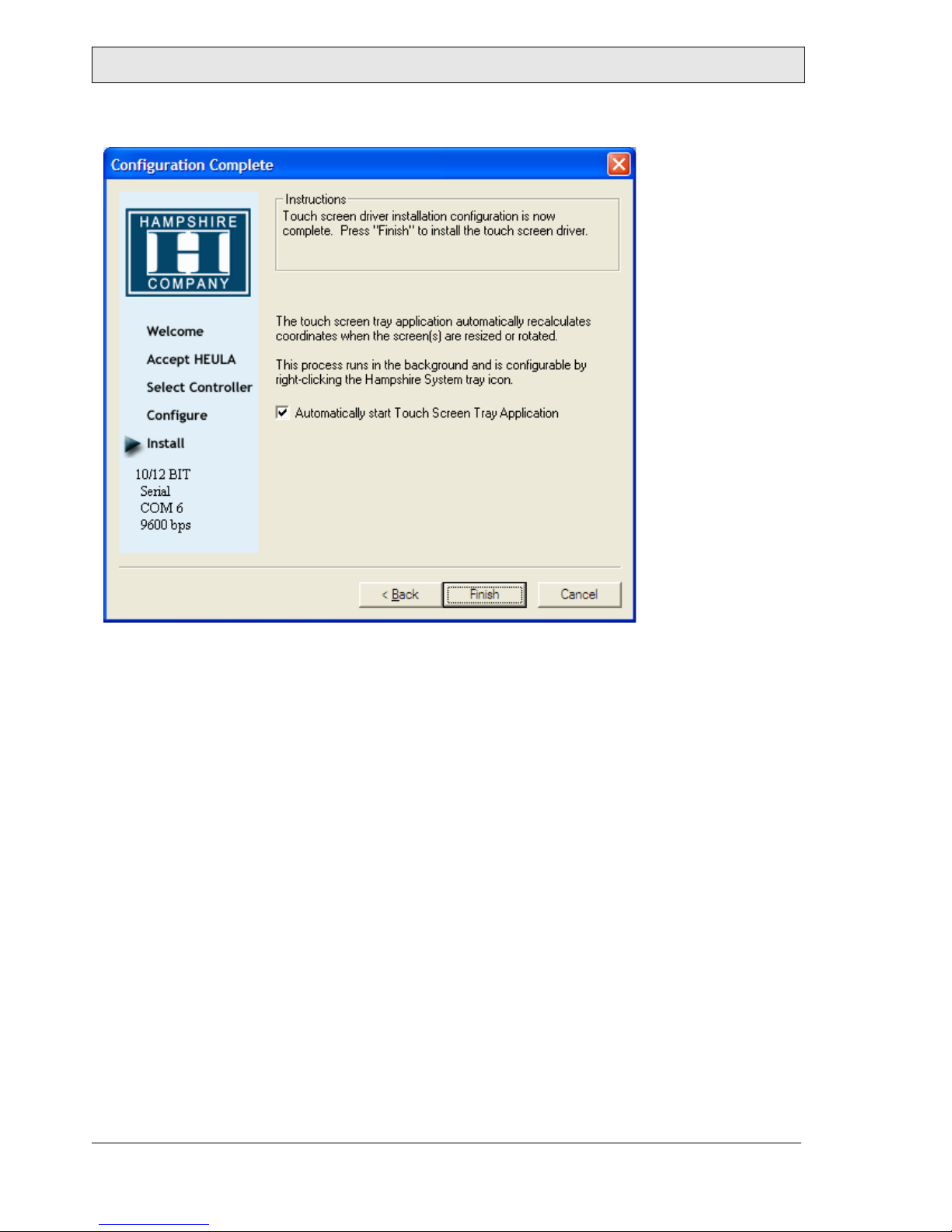

6.5 Touch Screen Installation

Note:

Make sure to use a touch driver of version 6.31.a or higher.

1. Start the touch screen installation from the driver CD, follow the instruc-

tions on the screen and press Next:

Beijer Electronics, MAEN979B 25

Page 26

Operation

2. Accept the license agreement.

26 Beijer Electronics, MAEN979B

Page 27

3. Select Autodetect or manually select the technical connection data.

Operation

Beijer Electronics, MAEN979B 27

Page 28

Operation

4. Press Finish and follow the instructions for a re-start.

5. After a re-start of the operating system you will find Hampshire Control

Panel among the programs.

6. Calibrate the touch screen with your finger or with a rounded pointed

touch pen.

28 Beijer Electronics, MAEN979B

Page 29

Operation

6.6 Installation of LAN-/Network Card

After installing the operating system and the chipset driver, the system automatically creates a link to a network connection. You will find a network icon on the

lower right-hand side of the task bar.

1. To install the second network card, follow the instructions on the driver

CD.

2. Confirm each installation step and re-start the EPC at the end of the installation.

3. After the re-start two new network icons appear in the right hand side lower

task bar.

4. You can now configure both network cards to your own requirements (IPaddress etc.) via the system control.

5. Via the MS-DOS window, under Start/All Programs/Accessories/

Command prompt, you can set a “connection PING” to test your connections to the server and other PC’s.

(for example: C:\ping 192.168.5.100).

Beijer Electronics, MAEN979B 29

Page 30

Operation

30 Beijer Electronics, MAEN979B

Page 31

7Service

7.1 Introduction

Only spare parts recommended by Beijer Electronics may be used.

7.1.1 Tools

Service

You can carry out the disassembly and assembly with an 2.5 mm Allen key and

a Phillips head screwdriver, size 3.

7.1.2 Preparation

Disconnect the EPC from the power supply.

Attention! Deadly Peril!

Make sure that yo ur electrosta tic pad does not damage the fron t panel

of the EPC.

7.1.3 Opening the EPC

All operations to the opened EPC may only be carried out by authorized personnel. Only the expansion of hardware with memory and plug-in-cards is permissible within the defects liability period.

Note:

Inside the EPC there are electronic components which can be destr oyed by el ectrostatic charges. Therefore cautionary measures have to be taken from the moment the EPC is opened. These can be found in the guidelines for electrostatic

endangered components (EGB-guidelines).

Beijer Electronics, MAEN979B 31

Page 32

Service

7.2 Changing the Fan Filter

The fan filter will have to be replaced regularly, especially in dusty environments.

Gently remove the fan cover, remove the filter and insert a new filter in its place.

7.3 PCI-board Installation

To install a PCI-board the right hand side part of the rear enclosure has to be

removed.

1. To open the enclosure remove the marked seven screws with an Allen key.

After removing the screws the enclosure can be easily removed.

32 Beijer Electronics, MAEN979B

Page 33

Service

The picture of the opened EPC below shows the board holder (1) and the 2 PCIslots (2).

1

2

2. Remove the cover of the desired slot to insert your PCI-board, by removing

the screw and pulling out the cover.

Beijer Electronics, MAEN979B 33

Page 34

Service

3

4

3. Remove the board holder by unscrewing the two marked screws.

4. Insert the PCI-board, if necessary bend the slot bracket a little bit. Please

ensure a correct fit at the rear edge (3) of the slot and make sure the metal

bracket goes into the groove (4).

34 Beijer Electronics, MAEN979B

Page 35

5. Mount your PCI-board and make sure to properly tighten the screw.

Service

6. Re-assemble the board holder and tighten the two screws properly.

Beijer Electronics, MAEN979B 35

Page 36

Service

5

7. To ensure an optimal use of the board holder, we recommend that you put

wide boards in the lower slot and narrow boards in the upper. This way the

support can be used in the correct way.

Note:

If two wide boards are used, the short support (5) can be removed.

7.4 Cable Fixing Points

When connecting interface cables such as RS232, USB, LAN or VGA, the cables must be fixed at the cable fixing points, to avoid that the cables loosen be-

cause of vibrations.

36 Beijer Electronics, MAEN979B

Page 37

Te c h n i c a l D a t a

8 Technical Data

The EPC T150/T170/T190 C2D Nautic models have touch screens; the EPC

150/170/190 C2D Nautic models have an antireflective glass.

Parameter

Size, W x H x D,

complete with front

plate

Mounting depth 145 mm (245 mm including clearance) 114 mm (214

Front panel seal IP65 Rear panel seal IP20 according to DIN EN 60529 IP20 according

Weight 9 kg 10 kg 13 kg 5.5 kg

Processor Intel Core 2 Duo

Cache / Bus Speed 4 MB / 800 MHz

System chipset Intel GME965 / ICH8-M

BIOS Award 4 MBit Flash memory, supports ACPI

EPC T150/150

C2D Nautic

412 x 351 x 142.5 mm430 x 390 x

EPC T170/170

C2D Nautic

142.5 mm

EPC T190/190

C2D Nautic

483.2 x 444 x

142.5 mm

EPC C2D Box

Nautic

389 x 276 x 114

mm

mm including

clearance)

to DIN EN

60529 on all

sides

RAM 2 GB DDR2-SDRAM (SODIMM), max. 4 GB

Graphics chip Intel GMA X3100

IDE controller 1 x IDE port, supports Ult ra ATA 100/66/33

Serial ports 2 x RS23 2

Ethernet 2 x 10/100/1000 Mbps

USB ports 4 x USB 2.0 (rear side)

1 x USB 2.0 (front side) under hatch

Extens io n slots 2 x PCI up to 22 0 m m le ngth

Compact Flash ports 1 x internal (optional) boot ab le

1 x external not bootable

Keyboard/mouse 2 x PS/2

VGA For external monitor, supports QXGA 2048 x 1536

DVI For external monitor, supports DVI 1.0

Audio ports Line in/out, microphone in

4 x USB 2.0

Beijer Electronics, MAEN979B 37

Page 38

Technical Data

Parameter

Power consumption

EPC T150/150

C2D Nautic

85 VA

EPC T170/170

C2D Nautic

EPC T190/190

C2D Nautic

at rated voltage

Fuse 1 AT (230 V AC) or 6.3 AT (24 V DC)

Power supply options 115-230 V AC ± 15%. 1 A max (switch on peak 30 A).

24 V DC ± 15%. 3 A max (switch on peak 15 A).

Active area of display

304.1 x 228.1

mm

337.9 x 270.3

mm

376.3 x 301.1 mm-

Pixels 1024 x 768 1280 x 1024 Pixel pitch (RGB) 0.297 x 0.2 97

mm

Max. number of col-

16.7 million -

0.264 x 0.264

mm

0.294 x 0.294 mm-

ors

View angle

50/60/75/75 ° 89/89/89/89 ° (up/down/left/

right) (typical)

Light intensity (typi-

250 cd/m

2

cal)

EPC C2D Box

Nautic

-

Contrast ratio 450:1 1500:1 1000:1 R e sponse ti m e ( r ise/

6 ms/19 ms 15 ms/10 ms 13 ms/7 ms fall)

Display technology TN PVA SPV A Touch screen tech-

Resistive* nology

Touch screen resolu-

4096 x 4096 points* tion

Ambient tempera-

-15 ° to +55 °C

ture

Relative ambi ent

30% to 90% non-condensed

humidity

Storage temperature -20 ° to +70 °C

Relative stor age

10% to 90% non-condensed

humidity

Basic RBC software

version

V0003 May 28, 2009

Please contact Beijer Electronics/Elektronik-Systeme Lauer for

information about current version.

* Only applies to EPC T150 C2D Nautic/ EPC T170 C2D Nautic/ EPC T190 C2D Nautic

38 Beijer Electronics, MAEN979B

Page 39

Drawings

9 Drawings

9.1 EPC T150/150 C2D Nautic Front

View

412

394

206

351

333

64.5 222

206

6 x hole Ø 6.5 mm

R10

Beijer Electronics, MAEN979B 39

Page 40

Drawings

9.2 EPC T150/150 C2D Nautic Cut Out

Drawing

Cut out dimensions: 369.0 x 324.0 mm, tolerance +1 mm. Space for mounting

screws on all sides: 15 mm = needed space 399.0 x 354.0 mm.

222

333

55.5

+1

0

324

197

369

+1

0

6 x bore holes Ø 6.5 mm

197

394

Front plate 412.0 x 351.0 mm, tolerance: ±0.2 mm.

Mounting method: 6 x M6x25 steel screws DIN 6912. Screws and o-ring seals

are included.

Max. 8 mm thick mounting frame.

40 Beijer Electronics, MAEN979B

Page 41

Drawings

9.3 EPC T150/150 C2D Nautic Outline

Drawings

Bottom view

387.5

375.5

36.5

80.3

24.5

205.7

R3

Rear view Side view

R10

333

238.2

112.8

67.5

18

Beijer Electronics, MAEN979B 41

Page 42

Drawings

9.4 EPC T170/170 C2D Nautic Front

View

430

414

115

390

374

180

200

105

115 200

8 x bore holes Ø 6.5 mm

R10

42 Beijer Electronics, MAEN979B

Page 43

Drawings

9.5 EPC T170/170 C2D Nautic Cut Out

Drawing

Cut out dimensions: 396.0 x 364.0 mm, tolerance +1 mm. Space for mounting

screws on all sides: 15 mm = needed space 426.0 x 394.0 mm.

374

180

0

+1

364

8 x bore holes Ø 6.5 mm

92

200

396

+1

0

414

Front plate 430.0 x 390.0 mm, tolerance: ±0.2 mm.

Mounting method: 8 x M6x25 steel screws DIN 6912. Screws and o-ring seals

are included.

Max. 8 mm thick mounting frame.

Beijer Electronics, MAEN979B 43

Page 44

Drawings

9.6 EPC T170/170 C2D Nautic Outline

Drawings

Bottom view

412

384.5

45.5

89.3

18

214.7

R3

Rear view Side view

R10

361.5

280.2

154.8

109.5

15

44 Beijer Electronics, MAEN979B

Page 45

Drawings

9.7 EPC T190/190 C2D Nautic Front

View

444

426

235

104.4 104.6

126.6

230

8 x bore holes Ø 6.5 mm

126.6

230

483.2

126.6

R10

Beijer Electronics, MAEN979B 45

Page 46

Drawings

9.8 EPC T190/190 C2D Nautic Cut Out

Drawing

Cut out dimensions: 438.0 x 416.0 mm, tolerance +1 mm. Space for mounting

screws on all sides = 15 mm - needed space 468.0 x 446.0 mm.

235

0

+1

416

426

8 x bore holes Ø 6.5 mm

90.4

230

438

+1

0

465.2

Front plate 483.2 x 444.0 mm, tolerance: ±0.2 mm.

Mounting method: 8 x M6x25 screws DIN 6912. Screws and o-ring seals are

included.

Max. 8 mm thick mounting frame.

46 Beijer Electronics, MAEN979B

Page 47

Drawings

9.9 EPC T190/190 C2D Nautic Outline

Drawings

Bottom view

458.1

115.9

241.3

72.1

25.1

12

411.1

R3

Rear view Side view

R10

398.5

317.2

191.8

146.5

16.5

Beijer Electronics, MAEN979B 47

Page 48

Drawings

9.10 EPC Box C2D Nautic Outline

Drawings

Bottom view

339

169.2

43.8

114

104

10

Rear view Side view

382

276

134

44

20.5

255.5

220.5

144

120

55.5

0

119

0

14.5

131.5

Ø7

Ø4.6

374.5

389

234

144

Ø8.5

34

244244

182.7

57.3

44

12

Mounting method: 6 x M4x12 steel screws DIN 912 or 4 x M6x12 steel screws

DIN 912. Screws are included.

264

276

48 Beijer Electronics, MAEN979B

Page 49

Head Office

Sweden

Beijer Electronics Products AB

Box 426

201 24 Malmö, SWEDEN

Tel: +46 40 35 86 00

Fax: +46 40 93 23 01

info@beijerelectronics.com

Subsidiaries

Germany

Elektronik-Systeme Lauer GmbH & Co. KG

Kelterstraße 59

72669 Unterensingen, GERMANY

Tel.: +49 70 22/96 60 0

Fax: +49 70 22/96 60-103

info@lauer-hmi.com

USA

Beijer Electronics Inc.

939 N. Plum Grove Road, Suite F

Schaumburg, IL 601 73, USA

Tel: +1 847 619 6068

Fax: +1 847 619 6674

info.usa@beijerelectronics.com

China

Beijer Electronics Co. Ltd

Room 201, Buildning B, No. 1618,

Yishan Road, Shanghai 201103, CHINA

Tel: +86 21 6145 0400

Fax: +86 21 6145 0499

info@beijerelectronics.cn

Taiwan

Beijer Electronics Corp.

7 & 8 F, No. 108 Minquan Rd.

Xindian City, Taipei County, TAIWAN

23141

Tel: +886-2-2218-3600

Fax: +886-2-2218-9547

info.tw@beijerelectronics.com

Loading...

Loading...