Page 1

User manual

EPC LX

EPC LX nautic

CiS-Nr.: 360.610.0370

Reg 10530/0408

Version 1.1/06.10

© Elektronik-Systeme LAUER GmbH & Co. KG

Page 2

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-2

Elektronik Systeme LAUER GmbH & Co. KG

P.O Box 1465

D-72604 Nürtingen

Operating instructions: EPC LX & EPC LX nautic

Issue: 06.2010

Editor: Mutter

Operating instructions, manuals and software are copyrighted. All rights

are reserved. Copying, duplicating, translating, transcribing en bloc or

partially is prohibited. An exception is the making of a software back up

copy for private use.

• We reserve the right to make amendments to the manual without

prior notice.

• We can not guarantee the accuracy and correctness of the programmes and data stored on the CD-ROM.

• Helpful suggestions, improvements as well as references to errors

are welcome at any time.

• The stipulations are also valid for any special annexes to this

manual.

Microsoft, Windows CE, Windows XP and the Windows Logo are either

registered trademarks or trademarks of the Microsoft Corporation in the

USA and/or other countries.

The above terms in this documentation can be brands, whose use by

third parties can breach the rights of the proprietor.

Page 3

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-3

User tips

Please read the manual prior to using for the first time and keep it in a

safe place for future use.

Target group The documented information in this manual refers to the appliance, place

of use, transport, storage, assembly, use and maintenance.

This manual is directed to the following target groups:

• User

• Service technicians/maintenance technicians

Especially observe the chapter „safety instructions and general

instructions“.

Knowledge of PC and Microsoft-operating systems are assumed. General

knowledge in the area of automation technology is recommended.

Diagram convention [Key] Key entries by the user are shown in squared brackets,

for example [CTRL] or [DEL]

italic Names of push buttons to be used, menus or other

screen elements as well as brand names are shown in

italic letters.

Necessary basic knowledge A solid Knowledge of the personal computer and Microsoft-operating

systems is assumed and a general knowledge in the area of automation

technology is recommended.

Approbation’s & standards You will nd information in the annex, chapter „certicate and guide

lines“.

Safety instructions Anywhere in the automation equipment, where dangerous errors may

occur, i.e. that an occurring error may cause major material or personal

damage, additional external precautions or facilities have to be made (for

example by means of independent limit switches, mechanical interlocks

etc.), which in case of an error guarantee or enforce a secure operating

condition.

The test and aptitude of the intended usage by the user res. the usage

under operational conditions is the responsibility of the user. Therefore

Elektronik-Systeme LAUER does not assume liability.

Page 4

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-4

User tips

Icons The following icons are used in the manual to mark certain para-

graphs:

Danger

Means that death or severe injury will occur when the relevant precautionary measures are not taken

Caution

Means that death or severe injury may occur when the relevant precautionary measures are not taken.

Warning

With warning triangle means that a light injury may occur when the rel-

evant precautionary measures are not taken

Precaution

Without warning triangle means that material damage may occur when

the relevant precautionary measures are not taken

Attention

Means that an undesirable effect or situation may occur if the respective

advise is ignored.

The warning advise for the highest level is used if various danger levels

occur. When a warning advise with a warning triangle warns about

personal damage then an additional warning for material damage can

be added.

Qualied personnel The described appliance may only be installed and operated in accor-

dance with this documentation. Only qualified personnel may put it into

operation and operate this appliance. Qualified personnel are persons,

who in accordance with the safety regulations contained in this documentation, are authorised to put into operation, earth and stamp appliances,

systems and circuits.

Intended use

The appliance can only be used for the designated purposes as described

in the catalogue and the technical write up and only in conjunction

with external devises i.e. components recommended and authorised

by Elektronik-Systeme LAUER GmbH & Co. KG. The efcient and

safe operation of the appliance presupposes appropriate transport,

storage, assembly and installation as well as accurate handling and

maintenance.

Page 5

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-5

Contents

User tips 3

Contents 5

Preamble 6

1 Product description 7

1.1 Operating panel 8

1.2 Slot panel 8

1.3 Ports 9

1.3.1 Compact FLASH Slot 9

1.3.2 VGA-/COM1-/PS/2 port 9

1.3.3 Ethernet, USB 10

1.4 Back side 10

2 Start-up 11

2.1 Power supply 11

2.2 Grounding diagram 12

2.3 Installation 12

2.4 Switch on the PC 12

3 Service 13

3.1 Replacing the external CFC 14

3.2 Replacing the internal CFC 15

3.3 Replacing the fuse 16

3.4 Changing the battery 17

T Technical data 19

T1 Mechanical dimensions 19

T1.1 EPC LX 640 Exterior/installation dimensions 19

T1.2 EPC LX 640 Unit dimensions 20

T1.3 EPC LX 840 Exterior/installation dimensions 21

T1.4.1 EPC LX 840 Unit dimensions 22

T1.4.2EPC LX 840 nautic Unit dimensions with Dual CAN IXKAT 23

T1.4.3EPC LX 840 nautic Unit dimensions with inttegrated Buzzer 24

T1.5 EPC LX 1000 Exterior/installation dimensions 25

T1.6.1 EPC LX 1000 Unit dimensions 26

T1.6.2 EPC LX 1000 nautic Unit dimensions 27

T1.7 EPC LX 1200 Exterior/installation dimensions 28

T1.8 EPC LX 1200 Unit dimensions 29

T1.9 EPC LX 1500 Exterior/installation dimensions 30

T1.10 EPC LX 1500 Unit dimensions 31

T2 Electrical data 32

T3 Environmental conditions 33

Page 6

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-6

Preamble

Elektronik-Systeme LAUER GmbH & Co. KG

Kelterstraße 59

D-72669 Unterensingen

Tel. +49 (0) 7022 / 9660-0

Fax +49 (0) 7022 / 9660-103

www.lauer-hmi.de

Our philosophy Elektronik-Systeme Lauer is one of the leading suppliers in the area

of industrial automation. For more than 30 years, Lauer has developed

and marketed innovative HMI solutions for operating and monitoring

machinery and equipment. The portfolio stretches from text displays

through modern operating terminals all the way to powerful panel PCs.

These innovative products nd thousands of applications in many various

industry sectors such as Packaging, Automotive, Pharma & Food and

Marine.

Since May 2007 Lauer belongs to the Beijer Electronics Group which

is listed on the Stockholm stock exchange, and has its headquarter in

Malmoe, Sweden. Beijer Electronics has other subsidiaries in Europe,

Asia and North America. Beijer Electronics enjoys close relationships

with OEMs, brand-label-partners and distribution partners worldwide.

Support contact Telephone: +49 (0) 7022 / 9660 -209

eMail: Support@lauer-hmi.de

For support inquiries always have the serial number of your

appliance at hand!

Up to date driver units, software, driver units, manuals ...and innovations

can be found in our download-area:

www.lauer-hmi.de

Sales contact Telephone: +49 (0) 7022 / 9660 -0

eMail: sales@lauer-hmi.de

Additionally on offer ... ... courses and technical training in our modern equipped training cen-

tre or alternatively at your place of business. Please ask your distribution

agent for the latest training course schedule.

... not only demo-appliances but also specialists who will personally assist you when you first take your appliance into operation.

Page 7

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-7

1 Product description

The EPC LX line is a compact, mechanically robust, fanless industrial

panel PC. This embedded PC system comes in two variants, either as just

a CPU box or together with a high-contrast industrial color TFT display.

It is available in the following display sizes: 6.4" 8.4", 10.4", 12" and 15".

The analog resistive touch screen is the basis of communication between

human and machine. The combination of a standardized CPU unit and

the different front units allows customers to best meet their requirements.

Another advantage is its compact installation dimensions.

By using special processors and cooling elements, tempermental fan

systems are no longer necessary.

Also, compact ash cards have replaced hard drives. This means that the

failure quota is very low despite the often harsh industrial environment.

The LAUER EPC series comes with the Windows®XP operating system

embedded, Windows® CE and VxWorks. This allows you to visualize and

control your systems reliably in a harsh environment.

CPU Unit CPU: On Board AMD Geode LX 800/700

(533MHz) CPU

System Memory: 200-pin DDR SDRAM 1GB for DDR333 and

512MB for DDR400

Chipset: AMD LX series + CS5536

I/O chipset: IT8712/FKX + IT8888G

BIOS: Award 512KB FLASH ROM

Battery: CR 2032 lithium battery

SSD: internal Type II Compact Flash™

Display chipset: AMD LX series + TI SN75LVDS83

Ports Serial: 1x RS232

Ethernet: 2x Realtek RTL8139DL,

10/100Base-TX RJ45 connector

USB 2x USB2.0

External memory card: Type II Compact Flash

Mouse and keyboard: via Mini DIN PS/2 Y cable

Page 8

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-8

1.1 Operating panel

1

Color TFT resistive touch display

6.4", 8.4", 10.4",12" or 15"

1.2 Slot panel

1

Page 9

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-9

1.3 Ports

1.3.1 Compact FLASH Slot

Position of the Compact FLASH slot

1 Captive screw

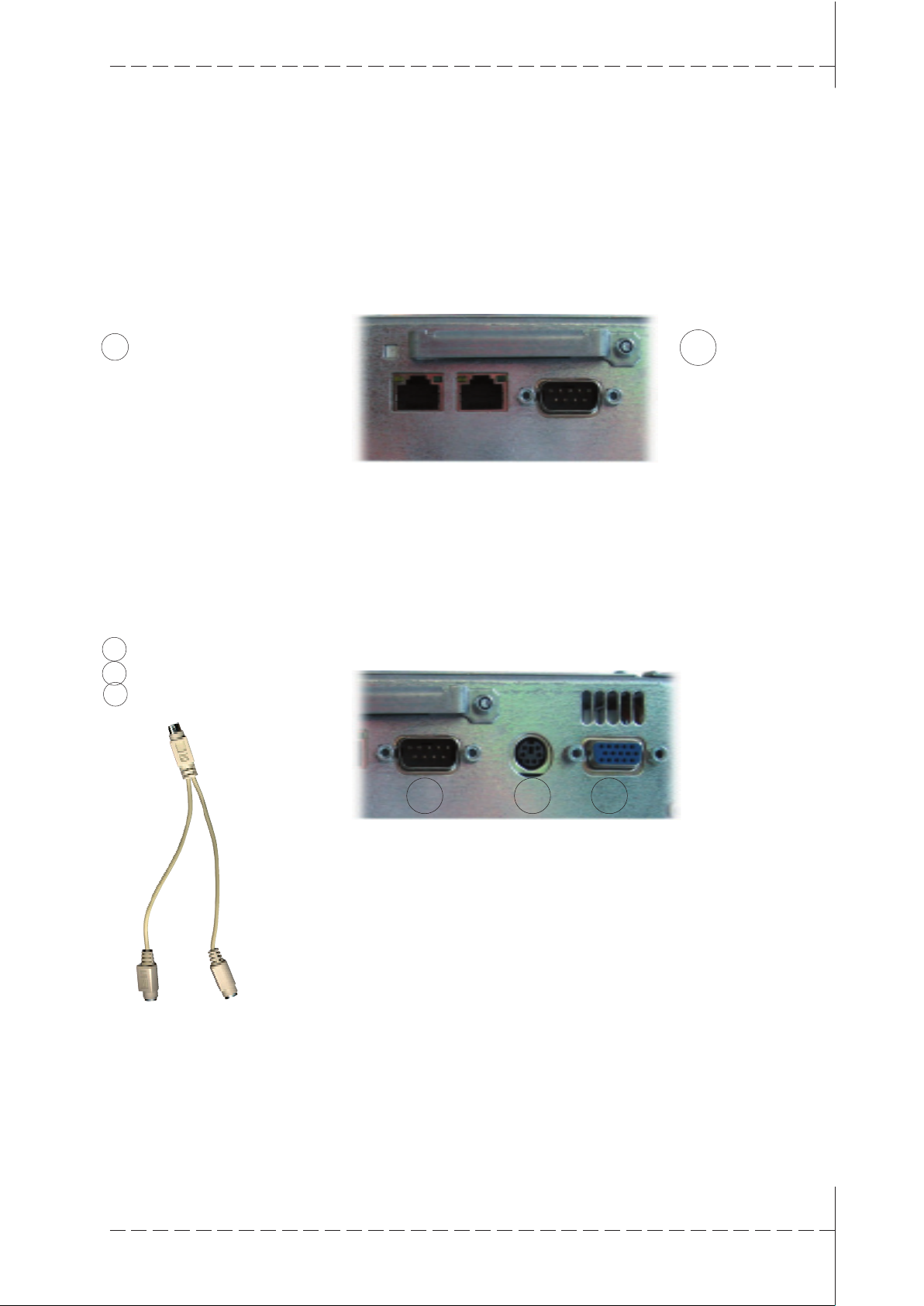

1.3.2 VGA-/COM1-/PS/2 port

The EPC industrial PC is standardly equipped with a Compact FLASH

slot according to CFA standards (Type 1).

1

Warning!

In connection with the EPC, only Compact FLASH cards from the

company SANDISK may be used.

Do not replace the Compact FLASH card unless the PC is switched

off!

1

VGA port

2 COM 1

3 PS/2 mouse/keyboard

PS2 adapter cable for mouse and keyboard

2

The debug port is designed as a serial port for all standard embedded

PCs.

This port can be configured as a debug port to support program

development.

Warning!

The COM 1 port is only available if it is activated by software.

The serial port is standardly assigned according to the PC XT/AT!

Warning!

Do not remove the PS/2 mouse and PS/2 keyboard unless the PC is

switched off.

Otherwise, the operating system will not detect these input devices!

3

1

Page 10

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-10

1.3.3 Ethernet, USB

1 Ethernet 1 (RJ45)

2 Ethernet 2 (RJ45)

3 USB 1/2

1.4 Back side

3

2

1

Page 11

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-11

2 Start-up

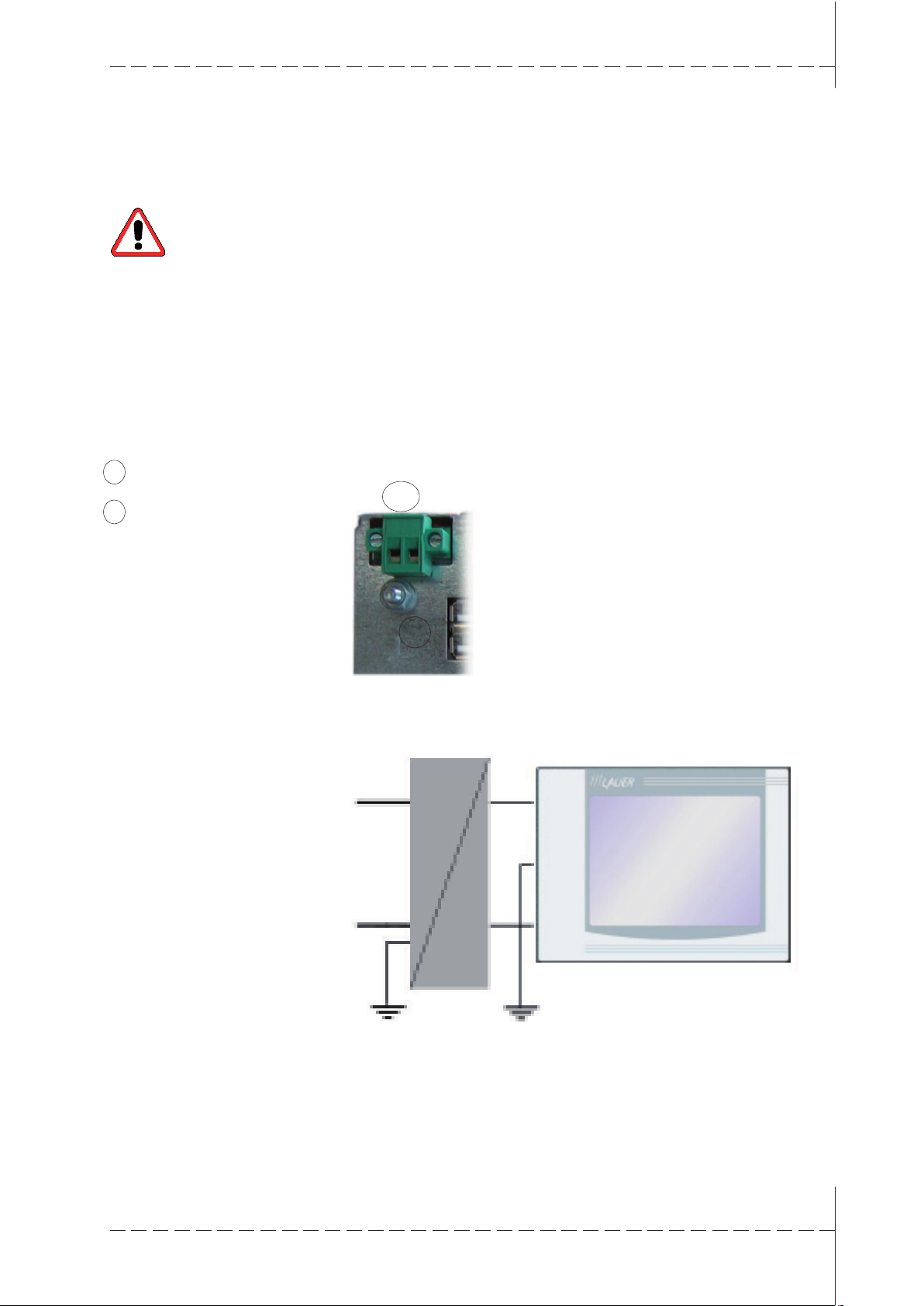

2.1 Power supply

1 24V voltage supply

Warning!

Only operate the embedded PC using protective extra-low voltage

according to EN60950!

The transformer must meet the EN60742 standard!

Check the power supply to ensure it corresponds to the type plate.

Prior to system start-up, check all cable connections.

Make sure that all voltages and signals meet the relevant

specifications.

The 0V supply voltage connection to the housing (earth) is a low-

impedance connection.

2 Earth screw

Power supply arrangement

1

2

The power supply is provided by means of a two-pronged plug-in

connector (Phoenix MST BT 2,5/2).

230 VAC

+ 24 V

230 VAC

0 V

24 V DC

Page 12

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-12

2.2 Grounding diagram

In order to reliably prevent electrical disruptions,

please note the following points:

• Connect the PC and control cabinet as close to a central grounding

point as possible.

• Make sure inductive connection between the computer and the

control cabinet is as low as possible.

• All data cables connected to the computer have to be shielded

cables.

• The shields have to be grounded on both ends. There must be a

low-impedance connection between the connected systems. Rule

out high equalizing currents through the shielding resulting from

potential differences.

• The grounding connection with a green-yellow cable must be designed with at least a 4 mm² cross-section.

2.3 Installation

Installation The industrial PC has to be installed in an HF- impermeable housing or

metal control cabinet.

In order to dissipate the heat emanating from the PC, 100 mm on three

sides of the PC must be kept clear so air can freely circulate.

The PC is assembled by screwing in eight hexagon nuts.

Caution!

Damage to the PC possible!

Front-end IP65 degree of protection is only guaranteed if the sealing sits

correctly on the front plate.

Once installed, 100 mm on three sides of the PC must be kept clear so

air can freely circulate

Caution!

The use of Compact Flash Card’s from different manufacturers can lead

to errors.

When using an internal and external Compact Flash card, only use cards

from the same manufacturer (same type and same size)

2.4 Switch on the PC

Start-up procedure The EPC boots up and loads the operating system.

Page 13

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-13

3 Service

Tools All you need to assemble the PC is a 2.0 hexagon socket as well as a

5.5 socket wrench. A small screwdriver and pliers are also helpful (see

illustrations).

Preparation Disconnect the PC from the power supply!

Danger!

Make sure that your electro-static underlay is not able to damage the

front of the EPC.

Open PC Only authorized personnel may perform work on the open PC. Within the

warranty period, the hardware may only be updated with memory and

plug-in cards.

Caution!

The PC contains electronic components that can be disrupted by electro-

static charges.

Therefore, you have to take precautionary measures when opening the

PC. You can find these in the guidelines for electro-statically discharge

sensitive devices (EDSD guidelines).

Page 14

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-14

3.1 Replacing the external CFC

To replace the external CFC, loosen the locking system using a socket

wrench.

Then turn the locking bracket upward to replace the CFC.

Page 15

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-15

3.2 Replacing the internal CFC

To replace the internal CFC, remove the cover.

Loosen the screws indicated in the illustration and remove the cover

plate.

The internal CFC slot is then visible.

Press on the release levers (see arrows) and replace the CFC.

Afterwards, simply screw the cover plate back on.

Page 16

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-16

3.3 Replacing the fuse

If the fuse has to be replaced, it can easily be removed using a pair of

pliers.

Replacing a new fuse T2,5A (item no.: 200.140.0110).

Page 17

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-17

3.4 Changing the battery

If the battery needs to be replaced, you have to remove the back cover

plate. To do so, loosen the screws as shown.

Remove the back cover plate.

The battery can be conveniently removed by hand.

Please note that the BIOS settings may disappear when changing the

battery.

Page 18

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-18

Insert the new lithium 3V battery (item no.: 200.300.0070) with lettering

facing up and screw the back plate back on firmly.

Page 19

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-19

T Technical data

T1 Mechanical dimensions

Air circulation To dissipate the heat emanating from the PC, 100 mm on three sides of

the PC must be kept clear so air can freely circulate.

T1.1 EPC LX 640 exterior/installation dimensions

Front plate Width 211 mm

Height 156 mm

Cut out dimensions Width 197 mm

Height 142 mm

Installation depth 70 mm

Weight approx. 1 kg

Front panel cut-out for installation

W x H cut-out

197.0 mm x 142.0 mm

1. Type of attachment: with 6 pieces.

Holding blocks made of aluminum or

plastic with threaded pins

M5x30, DIN 914, with nib and

hexagon socket, galvanized

Page 20

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-20

T1.2 EPC LX 640 Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 21

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-21

T1.3 EPC LX 840 Exterior/installation dimensions

Front plate Width 252 mm

Height 190 mm

Cut out dimensions Width 232 mm

Height 170 mm

Installation depth 61 mm

Weight approx. 1.9 kg

Page 22

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-22

T1.4.1 EPC LX 840 Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 23

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-23

with Dual CAN IXXAT (optional)

T1.4.2 EPC LX 840 nautic Unit dimensions with Dual CAN IXKAT

lateral view unit rear view lateral view

view of the unit underneath

view of the equipment top side

Page 24

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-24

Data sheet EPC-GX 840tc nautic

with integrated buzzer (optional)

T1.4.3 EPC LX 840 nautic Unit dimensions with integrated Buzzer

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 25

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-25

T1.5 EPC LX 1000 Exterior/installation dimensions

Front plate Width 318 mm

Height 244 mm

Cut out dimensions Width 303 mm

Height 228 mm

Installation depth 77 mm

Weight approx. 2.8 kg

Page 26

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-26

T1.6.1 EPC LX 1000 Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 27

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-27

T1.6.2 EPC LX 1000 nautic Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 28

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-28

T1.7 EPC LX 1200 Exterior/installation dimensions

Front plate Width 364 mm

Height 296 mm

Cut out dimensions Width 345 mm

Height 277 mm

Installation depth 77 mm

Weight approx. 2.8 kg

Page 29

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-29

T1.8 EPC LX 1200 Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 30

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-30

T1.9 EPC LX 1500 Exterior/installation dimensions

Front plate Width 452 mm

Height 357 mm

Cut out dimensions Width 429 mm

Height 334 mm

Installation depth 77 mm

Weight approx. 5.0 kg

Front view

Front dimensions W x H

452.0 x 357.0 mm

Tolerance 0,2 mm

Front panel cut-out

for installation

W x H cut-out

429.0 mm x 334.0 mm

Space for holding blocks

around 15 mm

Space total W x H

459.0 mm x 364.0 mm

Page 31

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-31

T1.10 EPC LX 1500 Unit dimensions

view of the unit underneath

lateral view unit rear view lateral view

view of the equipment top side

Page 32

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-32

T2 Electrical data

Power supply DC Operating voltage 24 V ± 20%, reverse polarity protected

Fuse 2,5 A delay

Power failure buffering time 1 ms bei 19,2 V (Ub-20%)

Display Display 640 840 1000 1200 1500

Resolution 640x480 640x480 800x600 800x600 1024x768

Charging rate EPC LX Box 0,55 A

EPC LX 640 0,75 A

EPC LX 840 / nautic 0,85 A

EPC LX 1000 / nautic 0,90 A

EPC LX 1200 1,10 A

EPC LX 1500 1,20 A

Touch resistive

CPU unit CPU: On Board AMD Geode LX 800/700(533MHz) CPU

System Memory: 200-pin DDR SDRAM

1GB for DDR333 and 512MB for DDR400

Chipset: AMD LX series + CS5536

I/O Chipset: IT8712/FKX + IT8888G

BIOS: Award 512KB FLASH ROM

Battery: Lithium battery CR 2032

SSD: internal Type II Compact Flash™

Display Chipset: AMD LX series + TI SN75LVDS83

Interfaces Serial: 1x RS232

Ethernet: 2x Realtek RTL8139DL,

10/100Base-TX RJ45 connector

USB: 2x USB2.0

Memory card

external: Type II Compact Flash

Mouse and

keyboard: over Mini DIN PS/2 Y- cabel

Hardware options on PC104 base RS232/TTY RS485/422 MPI

Profibus DP and Profibus-Master

Can Open and Can Open-Master

PC104 Codesys PLC / Can Open-Master

Page 33

© Elektronik-Systeme Lauer GmbH & Co KG • Kelterstr.59 • 72669 Unterensingen • Tel. (07022) 9660-0 • Fax (07022) 9660-103

0-33

T3 Environmental conditions

Surrounding temperature Operating 0 ... 50° C

Operating 0 ... 55° C for nautic Versions

storage -20 ... 60° C

Humidity Operating 10 ... 75%, non-condensing

storage 10 ... 95%, non-condensing

Resistance to

vibration and shock Sinus 2g, 10-500 Hz

Shock 15g, 11 ms

Continuous shock 10g, 16 ms

free fall from 1m height (in packaging), 1 x each axle

Protection front IP 65

back IP 20

EMV/CE Interference

resistance EN 61000-6-2

Interference

radiation EN 61000-6-4

Loading...

Loading...