Page 1

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

1

BFI Applications Support Library

Application Note

AN-BEI-P2-050

Title

Open Loop Permanent Magnet Motor Control

Related Products

Beijer Frequency Inverter P2

Level

4

1 – Fundamental - No previous experience necessary

2 – Basic – Some Basic drives knowledge recommended

3 – Advanced – Some Basic drives knowledge required

4 – Expert – Good experience in topic of subject matter recommended

Overview:

This document provides an overview of the operation of the Beijer Frequency Inverter P2 when used for open-loop

permanent magnet (PM) motor control. Beijer Frequency Inverter P2 continues the design philosophy of ‘easy to set-

up’ and ‘high levels of performance’ into PM motor applications through simplification of the parameter set and

intelligent and accurate auto-tuning functions.

Applications:

PM motor control is provided as standard on the Beijer Frequency Inverter P2. In order to simplify the user manual

PM motor parameters have been excluded and this application note is provided as the addendum for this function.

The objective of using a PM motor in combination with Beijer Frequency Inverter P2 is to realize the high efficiency

and savings, in combination with smooth and responsive performance, and smaller motor frame sizes, which can be

achieved.

Beijer Frequency Inverter P2 provides open loop PM motor control, there is no facility for operation of PM motors in

closed loop or for any internal positioning functionality.

The Beijer Frequency Inverter P2 PM Control algorithm is suitable for both Surface mounted (SPM) and rotor inbuilt

(IPM) permanent magnet motors. Brushless DC motor control is realizable but it is important to first consult

technical support for additional data and advice.

Page 2

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

2

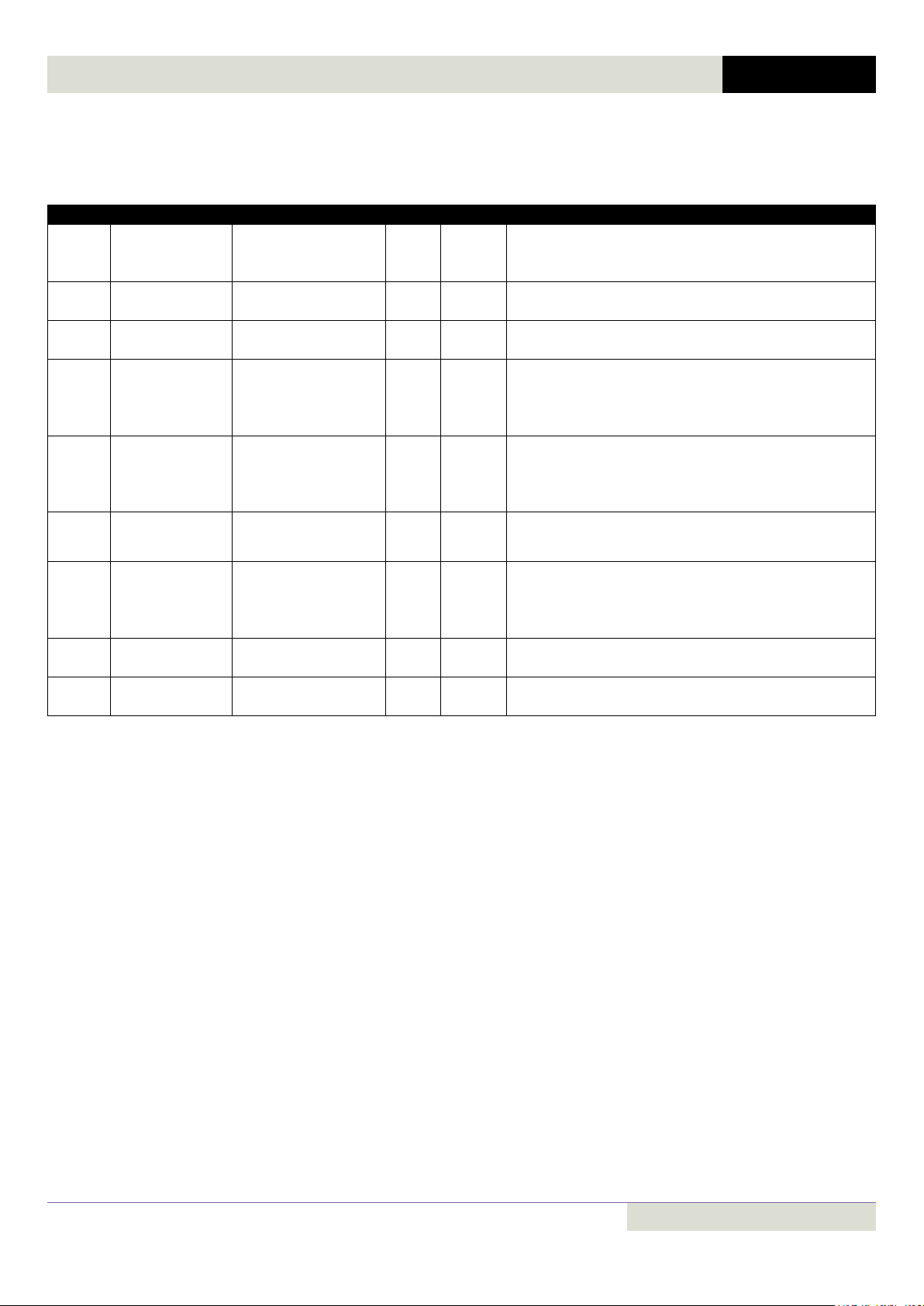

Par.

Description

Range

Units

Default

Explanation

P1-14

Extended menu

access

Code 0 to 30000

--- 0 Set to ‘201’ for access to PM motor control parameters.

PM motor selection setting (in P4-01) and menu 7 are

not visible when other value (than 201) is set.

P4-01

Control Mode

0, 1, 2: See Std Guide

3: PM Motor Control

--- 2 Selects the motor control method.

Set to ‘3’ for Sensor-less PM motor control

P7-01

Stator

Resistance

0.000 – 50.000

ohm

2.8

Motor Stator Resistance (phase –phase).

Measure with ‘auto-tune’ or enter manually.

P7-03

Lsd Phase

Inductance

0.0000 – 1.0000

Henry

0.13

Inductance Per Phase.

‘d’ component of armature winding inductance from

the d-q linear model.

Measure with ‘auto-tune’ or enter manually.

P7-06

Lsq Phase

Inductance

0.0000 – 1.0000

Henry

0.13

Inductance Per Phase.

‘q’ component of armature winding inductance from

the d-q linear model.

Measure with ‘auto-tune’ or enter manually.

P7-10

Inertia Ratio

0 - 100

%

10

System Load Inertia to Motor Inertia Ratio. Entered into

P7-10 as:

P7-10 = (J

Tot

/ J

Mot

) . 10

P7-12

Current

magnetising

time

0 - 2000

mS

45

Motor magnetising time at start.

Time following drive enable to establish magnetising

flux in motor windings in order to accurately phase

motor shaft.

P7-14

Boost Current

Level

0 - 100 % 0

Boost current applied at start-up, as % of motor rated

current (P1-08)

P7-15

Boost

Frequency

0 – 50 % 0

Frequency range for applied boost current (P7-14) as %

of motor rated speed (P1-10)

Firmware Overview – Additional Parameters and Settings:

Additional Parameter information to that provided in the standard Beijer Frequency Inverter P2 manual is as

follows:-

Page 3

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

3

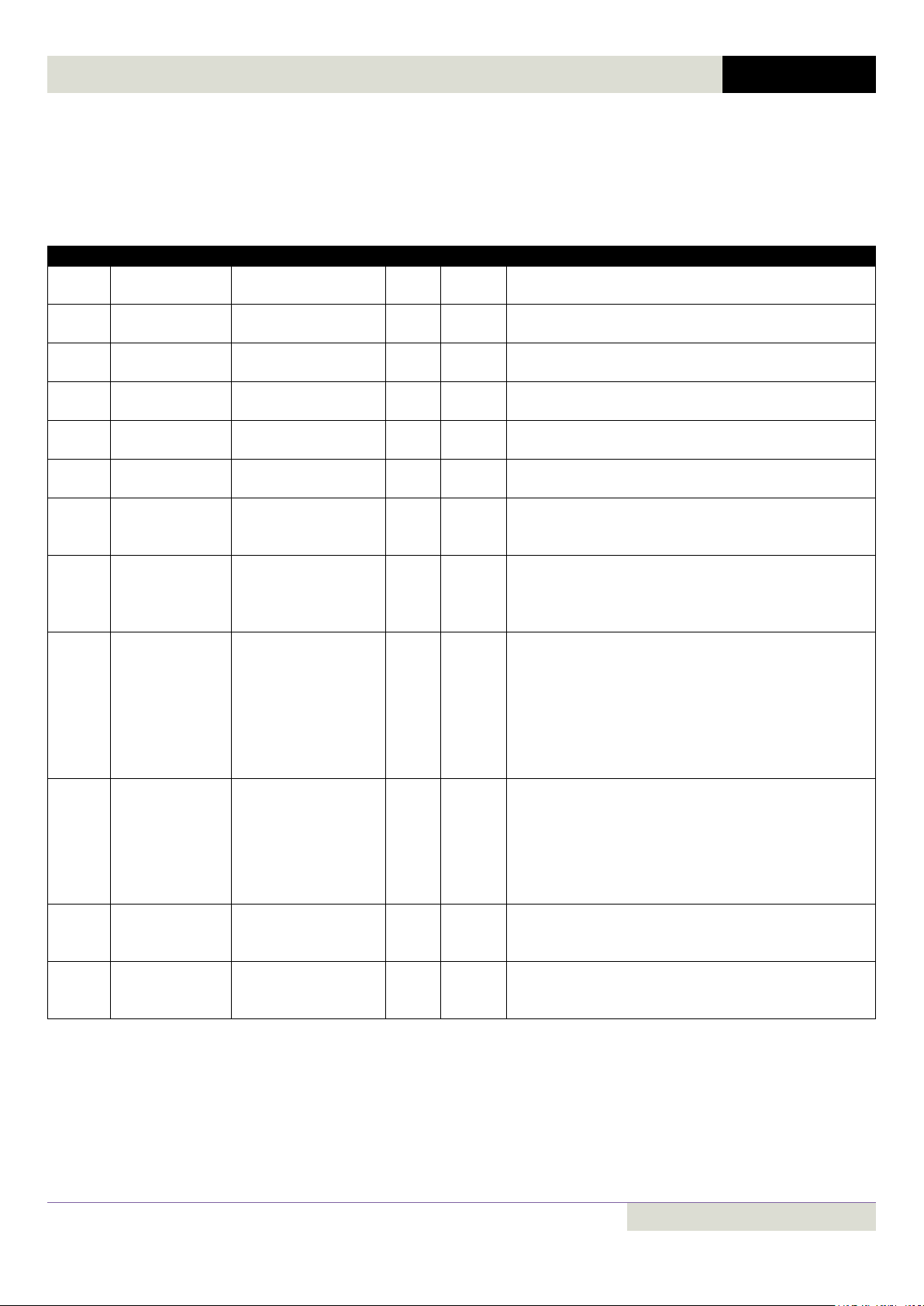

Par.

Description

Range

Units

Default

Explanation

P1-03

Acceleration

ramp time

0 – 3000.0

Sec

5.0

Acceleration ramp time from 0 to base speed (P1-09) in

seconds

P1-04

Deceleration

ramp time

0 – 3000.0

Sec

5.0

Deceleration ramp time from base speed (P1-09) to

standstill in seconds

P1-07

Nominal back

emf

0 – 250 / 500

Volts

(rms)

8

Phase – Phase voltage imposed by magnets while

motor rotating at motor rated speed (P1-10)

P1-08

Motor rated

current

25 – 100% of drive

rated current

Amps

(rms)

0.13

Rated (nominal) phase current of the motor (used for

over-current protection)

P1-09

Motor rated

frequency

25 – 500

Hz

0.13

Rated (nominal) frequency of the motor.

P1-10

Motor rated

speed

0 – 60,000

Rpm

0

Rated (nominal) speed of the motor.

P2-24

Switching

frequency

4 - 32

kHz

Model

Based

Value

Effective Power Stage switching frequency. Higher

frequencies give smoother operation but care must be

taken to apply necessary de-rate factors.

P4-02

Motor

parameter

auto-tune

0: Disable

1: Enable

--- 0 When set to 1 the drive will perform an auto-tune

immediately of exiting the parameter. Values will be

written automatically to parameters P7-01, P7-03, &

P7-06.

P4-03

Speed

Controller

proportional

Gain

0.0 – 400.0

%

25.0

Sets the proportional gain value for the speed

controller. Higher values provide better output

frequency regulation and response. Too high a

value can cause instability or even over current

trips. For applications requiring best possible

performance, the value should be adjusted to suit

the connected load.

P4-04

Speed

Controller

integral time

constant

0.000 – 1.000

s

0.500

Sets the integral time for the speed controller.

Smaller values provide a faster response in

reaction to motor load changes, at the risk of

introducing instability. For best dynamic

performance, the value should be adjusted to suit

the connected load.

P4-07

Maximum

motoring

Torque limit

P4-08 – 200

%

200

When P4-01 is set to 3, sets the maximum torque limit.

P4-09

Maximum

generating

Torque limit

0.0 - 200

%

200

Sets the maximum regenerating torque limit permitted

by the drive.

Firmware Overview – Standard Parameters for PM motor set-up:

The following parameters are taken from the main Beijer Frequency Inverter P2 user manual but are required for

set-up / configuration of a PM motor. Parameters highlighted in ‘Blue’ are essential for successful PM motor control

with the Beijer Frequency Inverter P2. They are not configured during the auto-tune function and must be entered

manually:-

Page 4

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

4

Set-up Procedure – Permanent magnet motors:

The following procedure should be followed to ensure correct parameterisation of the Beijer Frequency Inverter P2

P-2 and optimum performance from the permanent magnet motor.

Step 1: Entering basic motor parameters.

Note: Accurate entry of data for parameters P1-07 thru P1-10 is very important for optimum performance.

P1-07: Nominal back emf

Voltage imposed by the magnets when the motor is spun at rated speed and often referred to as motor nominal

voltage (UN). Its value can be found from the motor manufacturer, from the motor technical data sheet, or taken

from the motor data plate. Value entered must be phase to phase voltage. Phase voltages (phase – neutral) must be

multiplied by √3 (1.732) and the resultant value entered into P1-07

P1-08: Motor rated current

Rated phase current of the motor often referred to as the motor nominal current (IN). Its value can be found from

the motor manufacturer, from the motor technical data sheet, or taken from the motor data plate. Values given in

motor data are generally provided as current per phase and thus can be entered directly into P1-08.

P1-09: Motor rated frequency

Rated operating frequency of the motor often referred to as the motor nominal frequency (fN). Its value can be

found from the motor manufacturer, from the motor technical data sheet, or taken from the motor data plate.

P1-10: Motor rated speed

Rated output speed of the motor shaft often referred to as the motor nominal speed (nN). Its value can be found

from the motor manufacturer, from the motor technical data sheet, or taken from the motor data plate.

Step 2: Entering security code for Permanent Magnet parameter access.

In order to select PM motor control method and enter associated parameters a dedicated access code must be

entered into parameter P1-14. The dedicated code for PM motor set up is ‘201’. Once this value is set parameter

P4-01 will allow selection of PM motor control method and parameter group 7 will be available (visible). Security

Code ‘201’ also provides access to any menus accessible through the standard security password (default 101).

Step 3: Setting Beijer Frequency Inverter P2 effective output switching frequency.

Note: For smooth operation and consistent performance the minimum recommended switching frequency for PM

motor control is 16 kHz.

Setting of the drive output switching frequency is a compromise between smoothest possible operation and

minimisation of drive losses (and the potential need to de-rate the drive). Some testing may be required to

establish the lowest switching frequency (minimum 16kHz) that can be selected whilst maintaining the required

level of performance. When increasing switching frequency setting always consult the appropriate de-rating data

and configure parameter P1-08, Motor rated current, appropriately.

Step 4: Selecting PM motor control.

Set parameter P4-01, Beijer Frequency Inverter P2 control method, to a value of 3 to enable PM motor control. If

P1-14 has not been set with the correct security code then P4-01 will be locked at a maximum value ‘2’ (refer to

set-up Step 2).

Step 5: Beijer Frequency Inverter P2 Auto-tune for PM motor control.

Motor inductance and resistance values, programmed into Beijer Frequency Inverter P2 menu 7, can be configured

manually or derived by the Beijer Frequency Inverter P2 software using the auto-tune function.

If motor values for parameter menu 7 are know then step 5 can be omitted and the values entered manually,

however it is generally recommended for optimum performance and ease of set-up that the auto-tune procedure

is completed.

To activate auto-tune function set parameter P4-02 to value ‘1’ and exit the parameter. Auto-tune begins

immediately on exiting the parameter. During autoreturning to its normal condition once auto-tune is complete.

Page 5

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

5

Auto-tune is a non-rotational function although some minor rotation of the motor shaft may occur. It is not

necessary to disconnect the motor from the driven load for this function to be completed successfully but the rotor

should not be locked such that motion is prevented.

Step 6: Setting baseline values for speed loop gains.

The Default gains values for the speed controller are generally suited to standard induction motor control. PM

motors generally permit high gains values and faster response / improved performance. The recommended

starting values for PM motor control are: P4-03: Speed Controller proportional Gain, Set to Value 50 (%).

P4-04: Speed Controller Integral Time Constant, Set to Value 100 (ms).

These values may need to be adjusted at the end of the process when system performance can be monitored for

effective tuning and improvement.

Step 7: Enter or check of menu 7 motor values.

If auto-tune function (P4-02) was completed then the following values will be measured and entered automatically

by the Beijer Frequency Inverter P2. The measured values can be viewed in the listed parameters for reference.

The motor values can be entered manually direct to the parameters listed below (taken from the manufacturer

data) if required: P7-01: Stator Resistance, Phase to Phase – measured between motor terminals.

P7-03: Lsd Phase Inductance, ‘d’ component of armature winding inductance.

P7-04: Lsq Phase Inductance, ‘q’ component of armature winding inductance.

It is generally recommended for optimum performance and ease of set-up that the auto-tune procedure is used to

complete these values.

Step 8: Setting Motor magnetising time.

Parameter P7-12, motor magnetising time, is used to set a time delay between drive output enable and the drive

output being ramped to the set-point speed. This delay is used by the drive to establish magnetising current in the

motor windings and to align orientation of the rotor to a known position. Magnetising current applied is 50% of the

value contained in parameter P1-08.

This function creates a start-up delay, however if insufficient time is provided to magnetise and orientate the rotor

position then start up and operational performance could be affected. Set to minimum value where the rotor can

be seen to successfully align prior to start up: P7-12: Motor Magnetising Time.

Step 9: Low Speed Boost Phase.

Low speed operation of a PM motor, below the speed range of approximately 20:1, should generally be avoided.

Low output voltage from the drive at low speeds (caused by V/f ratio and proportional to designed nominal motor

voltage) can create instabilities in the motor control model as the known phase angle of the rotor becomes

gradually more difficult to predict.

Beijer Frequency Inverter P2 provides a boost function that can inject some current into the motor at low speed to

help ensure the rotor alignment is maintained and to allow effective operation of the motor at lower speeds.

To implement some low speed boost run the drive at the effective lowest frequency required by the application

and increase boost levels to provide both required torque and smooth operation.

Boost current is set as a percentage of motor nominal current setting (P1-08). Boost frequency (P7-15) sets the

frequency cut off point above which boost current is no longer applied to the motor. Boost frequency is set as a

percentage of nominal motor frequency (P1-09).

Care should be taken not to cause motor over-heating issues through sustained low speed / high current boost

operation.

Below are some recommended settings: Default Boost Setting: P7-14: Boost Current = 0%. P7-15: Boost Frequency = 0%

Low Boost Setting: P7-14: Boost Current = 25%. P7-15: Boost Frequency = 10%

High Boost Setting: P7-14: Boost Current = 50%. P7-15: Boost Frequency = 20%

Beijer Frequency Inverter P2 PM motor configuration is now complete.

Page 6

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

6

Optimisation for Permanent magnet motors:

Once the basic set-up procedure is complete for the Beijer Frequency Inverter P2 with PM motor the following

parameters can be adjusted to improve or optimise performance.

Changing Speed Controller Ramp Rates

Acceleration Ramp Rate:

Parameter P1-03 sets acceleration ramp rate. If adjusting speed controller gains (P4-03 & P4-04) always set

required ramps rates prior to tuning these values. Ensure ramp rate setting and acceleration / deceleration cycle

does not result in the drive operating excessively in the over-current (>100%) region such that nuisance tripping

might occur.

Deceleration Ramp Rate:

Parameter P1-04 sets deceleration ramp rate. If adjusting speed controller gains (P4-03 & P4-04) always set

required ramps rates prior to tuning these values. Ensure deceleration ramp rate setting does not result in

excessively braking energy being returned to the drive such that an over-voltage nuisance trip occurs.

Changing Beijer Frequency Inverter P2 Output Switching Frequency

Parameter P2-24 sets the drive effective output switching frequency. If adjusting speed controller gains (P4-03 &

P4-04) always set required switching frequency prior to tuning these values.

Higher values result in smoother motor operation but are less efficient and may require some de-rating of the

drive. Set for optimised performance, or optimised efficiency or combination thereof.

Note: For smooth operation and consistent performance the minimum recommended switching frequency for

PM motor control is 16 kHz.

Entering Motor / Load Inertia Ratio

Parameter P7-10 allows the inertia ratio between the motor and connected load to be entered into the Beijer

Frequency Inverter P2. This value can normally be left at the default value (10); however it is used by the Beijer

Frequency Inverter P2 control algorithm as a feed forward term in order to provide optimum torque / current to

accelerate the load. Hence accurate setting of the inertia ratio will produce better system response and dynamics.

If value is unknown then leave value set to default (10).

The value entered into P7-10 is given as; P7-10 = (J

Where; J

J

is Total Inertia (including motor, load, and any coupling)

Tot

is Motor Inertia

Mot

Motor inertia will be given by the motor manufacturer as part of their standard motor data.

Total inertia must either be known from the system design or measured.

Tuning Speed Controller Responses

Changes to the speed controller tuning parameters should be made very gradually with close observation of the

resulting effect on system response.

P4-03: Speed Controller proportional Gain

The proportional gain is used to change the output to the motor as a proportional of the error in the speed loop

controller (difference between commanded and actual speed). The proportional response of the drive is adjusted

by multiplying the error by a constant called the proportional gain that is set in parameter P4-03. Increasing the

value in parameter 4.03 decreases drive response times / improves system dynamics.

If proportional gain is set too low the system response will be poor (slow) however if set too high the system could

oscillate and could grow unstable.

P4-04: Speed Controller integral time constant

The integral gain is an ‘accumulated’ gain based on both the magnitude of the error in the speed controller and the

time the error has existed, essentially working to eliminate prolonged and steady state error in the system.

Tot

/ J

Mot

) . 10

Page 7

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

7

Symptom

Solution / Advice

Cannot set P4-01 for PM motor Control

PM motor access code not entered in P1-14. Value ‘201’ required.

Delay seen after drive enable

There is an in-built delay after enable to magnetise and orientate the motor

shaft immediately after enable. Delay time is controlled by parameter P7-12.

See drive optimisation setting for optimal set-up.

Auto-tune failure

See standard Beijer Frequency Inverter P2 P-2 user guide

Poor Torque Performance at low speed

Some low speed current boost required. See Low speed boost phase in set

up section.

Too much current causing motor to heat up

Check parameter P1-07, motor nominal voltage is set correctly

Check parameter P1-08, motor nominal current is set correctly

If operating for sustained time period at low speed check levels of boost

current applied (P7-14, and P7-15)

Motor Stalled

Check motor connection

Check values entered into motor parameters (P1-07 to P1-10)

Check Auto-tune performed

Reduce the load

Increase acceleration / deceleration time

Increase drive / motor rating

Unstable motor speed

Check switching frequency hasn’t been adjusted below recommended

minimum (16 kHz)

Check values entered into motor parameters (P1-07 to P1-10)

Check Auto-tune performed

Check appropriate tuning of speed loop controller, reduce gains as required

Poor motor dynamics, slow response times

Check values entered into motor parameters (P1-07 to P1-10)

Check Auto-tune performed

Check appropriate tuning of speed loop controller, increase gains as

required

Parameter P4-04 is set as a time (in ms). The smaller the time (integration time) the more responsive the drive

output, at the possible expensive of instability.

Small amounts of integral gain can have a significant effect on reaction times and stability of the speed controller.

General practice with tuning a PI system is to set the integral value (P4-04) to its highest possible setting (1.0 sec)

and tune the proportional value (P4-03) for optimum performance. When proportional gain has been set /

optimized then the integral gain (P4-04) can then be adjusted to eliminate steady state speed errors.

Changing Beijer Frequency Inverter P2 Torque Limits

Drive torque limits (proportionally related to current limits) are adjusted by parameters P4-07 (for drive motoring

torque), and P4-09 (for drive generating torque) respectively.

Generally PM motors have a significantly higher peak torque rating in relation to nominal torque (>200% of

nominal torque), such that these values do not normally need to be adjusted. Peak torque values are available

from the motor technical data sheet and if less that 200% of nominal torque these parameters can be adjusted to

provide peak torque to the motor.

PM Motor Troubleshooting:

Trip codes and fault diagnostic information is provided in the standard Beijer Frequency Inverter P2 manual. Below

is further troubleshooting information specific to PM motor control.

Page 8

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

8

1

2

3

4

5

6

7

P1-12 = 0

P1-13 = 1

Input 1:

O: Stop (Disable)

C: Run (Enable)

Input 3:

Enable

Imput 2:

+24V Output

+10V Output

0V

Analog Speed Ref

12

13

Safe Torque Off Input

Safe Torque Off 0V

Permanent magnet motors quick set-up:

The quick start is intended as a basic first step to successfully running the motor. For Optimum performance the

full programming and optimisation procedure should be followed.

Quick Step 1: Setting of the required parameters

Set the following parameters in the sequence they are listed.

P1-07: Nominal back emf (rms Phase-Phase) - = Motor Dependant

P1-08: Motor rated current (rms Phase) - - = Motor Dependant

P1-09: Motor rated frequency (Hz) - - = Motor Dependant

P1-10: Motor rated speed (rpm) - - - = Motor Dependant

P1-14: Parameter access code - - - = 201

P2-24: Switching frequency (kHz) - - = 16

P4-01: Control Mode - - - - = 3

P4-03: Speed Controller proportional Gain (%) - = 50

P4-04: Speed Controller integral time constant (ms) = 100

Quick Step 2: Complete Auto-tune function

Note: Safe Torque Off input (terminal 12 and 13) needs to be connected in order to enable the safe torque off

function and allow auto-tune and motor control. See connection diagram below.

Set the following parameter. Drive will perform auto-tune on exit of parameter entry.

P4-02: Auto-tune Function - - = 1

Wait for completion of auto-tune.

Quick Step 3: Check motor operation

Apply enable and speed set-point inputs to the Beijer

Frequency Inverter P2 P-2 Default configuration is shown right.

Vary speed set-point and check smooth operation of the motor.

Optional:

To set Beijer Frequency Inverter P2 in keypad mode set

parameter P12 = 1 Beijer Frequency Inverter P2 can now be

controlled direct from the keypad.

Quick Step 4: Set Current magnetising time

Set the following parameter to adjust Current magnetising time.

P7-12: Current magnetising time

Adjust upward if the rotor cannot be seen to orientate on start

up.

Adjust downward if a significant delay follows the orientation

of the rotor on start up.

Quick Step 5: Set Low speed boost parameters

Check low speed operation of the motor. If torque performance

at low speed needs adjustment set the following values.

P7-14: Boost Current Level - - = 25%

P7-14: Boost Frequency - - = 10%

Values should be optimised following on from the quick start procedure.

Page 9

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

9

Revision History

Version

Comments

Author

Date

1.00

New Application Note Created

JP

15/02/12

Appendix:

Loading...

Loading...