Page 1

Users Manual

ENGLISH

PRO MDX1400

Version 1.4 June 2001

D

®

AUTOCOM

www.behringer.com

Page 2

AUTOCOM PRO MDX1400

SAFETY INSTRUCTIONS

CAUTION: To reduce the risk of electric shock, do not remove

the cover (or back). No user serviceable parts inside;

refer servicing to qualified personnel.

WARNING: To reduce the risk of fire or electric shock, do not

expose this appliance to rain or moisture.

This symbol, wherever it appears,

alerts you to the presence of

uninsulated dangerous voltage inside

the enclosurevoltage that may be

sufficient to constitute a risk of shock.

DETAILED SAFETY INSTRUCTIONS:

All the safety and operation instructions should be read before the appliance is operated.

Retain Instructions:

The safety and operating instructions should be retained for future reference.

Heed Warnings:

All warnings on the appliance and in the operating instructions should be adhered to.

Follow instructions:

All operation and user instructions should be followed.

Water and Moisture:

The appliance should not be used near water (e.g. near a bathtub, washbowl, kitchen sink, laundry tub, in a wet

basement, or near a swimming pool etc.).

Ventilation:

The appliance should be situated so that its location or position does not interfere with its proper ventilation.

For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may block the

ventilation openings, or placed in a built-in installation, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

Heat:

The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

Power Source:

The appliance should be connected to a power supply only of the type described in the operating instructions

or as marked on the appliance.

Grounding or Polarization:

Precautions should be taken so that the grounding or polarization means of an appliance is not defeated.

Power-Cord Protection:

Power supply cords should be routed so that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to cords and plugs, convenience receptacles and the point

where they exit from the appliance.

Cleaning:

The appliance should be cleaned only as recommended by the manufacturer.

Non-use Periods:

The power cord of the appliance should be unplugged from the outlet when left unused for a long period of time.

Debris and Liquid Entry:

Care should be taken that debris and/or liquids do not enter the enclosure through openings.

Damage Requiring Service:

The appliance should be serviced by qualified service personnel when:

- The power supply cord or the plug has been damaged; or

- Debris or liquid has entered the appliance; or

- The appliance has been exposed to rain; or

- The appliance does not appear to operate normally or exhibits a marked change in performance; or

- The appliance has been dropped, or the enclosure damaged.

Servicing:

The user should not attempt to service the appliance beyond that which is described in the operating instructions. All other servicing should be referred to qualified service personnel.

This symbol, wherever it appears, alerts

you to important operating and maintenance instructions in the accompanying

literature. Read the manual.

2

Page 3

AUTOCOM PRO MDX1400

FOREWORD

Dear Customer,

Welcome to the team of AUTOCOM PRO users and thank you very much for expressing your confidence in

Behringer products by purchasing this unit.

It is one of my most pleasant tasks to write this letter to you, because it is the culmination of many months of

hard work delivered by our engineering team to reach a very ambitious goal: making an outstanding device

better still. The AUTOCOM has for quite a long time been a standard tool used by numerous studios and

PA rental companies. The task to improve one of our best-selling products certainly meant a great deal of

responsibility, which we assumed by focusing on you, the discerning user and musician. It also meant a lot of

work and night shifts to accomplish this goal. But it was fun, too. Developing a product usually brings a lot of

people together, and what a great feeling it is when everybody who participated in such a project can be proud

of what weve achieved.

It is our philosophy to share our joy with you, because you are the most important member of the BEHRINGER

family. With your highly competent suggestions for new products youve greatly contributed to shaping our

company and making it successful. In return, we guarantee you uncompromising quality (manufactured under

ISO9000 certified management system) as well as excellent technical and audio properties at an extremely

favorable price. All of this will enable you to fully unfold your creativity without being hampered by budget

constraints.

We are often asked how we can make it to produce such high-grade devices at such unbelievably low prices.

The answer is quite simple: its you, our customers! Many satisfied customers means large sales volumes

enabling us to get better conditions of purchase for components, etc. Isnt it only fair to pass this benefit back

to you? Because we know that your success is our success, too!

I would like to thank all people whose help on Project AUTOCOM PRO has made it all possible. Everybody

has made very personal contributions, starting from the designers of the unit via the many staff members our

our company to you, the user of BEHRINGER products.

My friends, its been worth the trouble!

Thank you very much,

Uli Behringer

3

Page 4

AUTOCOM PRO MDX1400

®

AUTOCOM

Interactive 2-channel expander/gate/compressor/enhancer of the reference class

PRO

s

IKA (Interactive Knee Adaptation) compressor concept combines the advantages of hard knee and soft

knee characteristics

s

Attack and Release times controllable automatically or manually

s

Switchable highpass filter in control signal path avoids low-frequency signals from dominating compressor

action

s

Compression characteristics switchable between IKA and hard knee characteristics

s

IRC circuit in expander/gate allows for inaudible elimination of disturbing noise signals

s

Dynamic Enhancer for compression dependent equalization

s

Extremely low-noise operational amplifiers and high-grade VCAs

MDX1400

s

High-quality detented potentiometers and backlit switches

s

Stereo Couple function selectable with real totaling of RMS output

s

Accurate 12-digit LED meters for input level, output level and gain reduction

s

Switchable sidechain input with sidechain monitor function

s

Operating level switchable from +4 dBu to -10 dBV

s

Servo-balanced gold-plated XLR and 1/4" TRS connectors

s

High-grade output transformer BEHRINGER OT-1 can be retrofitted

s

Manufactured under ISO9000 certified management system

4

Page 5

AUTOCOM PRO MDX1400

TABLE OF CONTENT

1. INTRODUCTION..................................................................................................................... 6

1.1 The Design Concept ........................................................................................................................ 6

1.2 Before you begin ............................................................................................................................. 7

2. CONTROLS ............................................................................................................................8

2.1 Expander/Gate Section ................................................................................................................... 8

2.2 Compressor Section ....................................................................................................................... 9

2.3 Dynamic Enhancer Section ........................................................................................................... 10

2.4 Rear Panel Control Elements Of The AUTOCOM PRO .................................................................. 10

3. APPLICATIONS ..................................................................................................................... 11

3.1 Compression/Levelling/Limiting/Clipping ......................................................................................... 11

3.2 Expander/Gate Section ................................................................................................................. 12

3.2.1 Controlling Leakage In The Studio ....................................................................................... 12

3.2.2 Initial Settings For The Expander/Gate Section ................................................................... 13

3.2.3 Reducing Leakage In Stage Mics ........................................................................................ 13

3.2.4 Reducing Feedback In Stage Mics ...................................................................................... 14

3.2.5 Noise Reduction On Effects Paths ...................................................................................... 14

3.2.6 Creative Use Of The Expander/Gate Section ....................................................................... 14

3.3 Compressor Section ..................................................................................................................... 14

3.3.1 Initial Settings For The Compressor Section ....................................................................... 15

3.3.2 The AUTOCOM PRO As A Sound Effects Unit .................................................................... 16

3.3.3 The Muffling Effect Of A Compressor ................................................................................. 16

3.4 Dynamic Enhancer Section ........................................................................................................... 16

3.4.1 Initial Settings For The Dynamic Enhancer Section ............................................................. 17

4. SPECIAL APPLICATIONS ..................................................................................................... 17

4.1 Using The AUTOCOM PRO For Recording And Cassette Duplication ............................................ 17

4.1.1 The AUTOCOM PRO In Digital Recording And Sampling ..................................................... 18

4.1.2 The AUTOCOM PRO In Mastering ...................................................................................... 18

4.2 The AUTOCOM PRO As A Protective Device ................................................................................. 18

4.2.1 Protection Of A System With A Passive Crossover .............................................................. 18

4.2.2 Protection Of A System With An Active Crossover ............................................................... 19

4.2.3 Improving The Sound Of A Processor System ..................................................................... 19

4.3 The AUTOCOM PRO In Broadcast ................................................................................................ 19

5. EXTERNAL SIDECHAIN APPLICATIONS............................................................................ 20

5.1 The Sidechain Function ................................................................................................................. 20

5.2 Using An Equalizer In The Sidechain Path .................................................................................... 20

5.2.1 The AUTOCOM PRO As A De-Esser ................................................................................. 20

5.2.2 Frequency Selective Filtering Of Unwanted Signals ............................................................. 21

5.2.3 Suppressing Instruments During Recording ......................................................................... 21

5.2.4 Emphasizing Musical Instruments During Recording ........................................................... 21

5.3 Anticipated Compression .............................................................................................................. 22

5.4 Voice-Over Compression (Ducking) ........................................................................................... 22

5.5 Triggering Additional Sounds From A Rhythm Track ...................................................................... 22

6. TECHNICAL BACKGROUND .............................................................................................. 22

6.1 Noise As A Physical Phenomenon ................................................................................................ 22

6.2 What Are Audio Dynamics? .......................................................................................................... 22

6.3 Compressors/Limiters .........................................................................................................24

6.4 Expanders/Noise Gates ...................................................................................................... 24

7. AUDIO CONNECTIONS ....................................................................................................... 25

7.1 Inputs And Outputs ....................................................................................................................... 25

7.1.1 Balanced Inputs And Outputs .............................................................................................. 25

7.1.2 Transformer Balanced Outputs (Optional) ............................................................................ 25

8. TECHNICAL DATA ................................................................................................................ 27

9. WARRANTY ........................................................................................................................... 29

5

Page 6

AUTOCOM PRO MDX1400

1. INTRODUCTION

In purchasing the new AUTOCOM PRO Model MDX1400, you have acquired an extremely efficient and

universal dynamics processor, which combines the most commonly used dynamic functions within a compact

stereo unit: every channel has its own independent Compressor/Limiter, an Expander/Gate and a Dynamic

Enhancer. The precision and flexibility of the functions are the main outstanding features of this high end unit.

Advanced BEHRINGER Technology

Compared to its predecessors, the AUTOCOM PRO offers several advanced features such as the extended

LED meters, balanced inputs and outputs, a couple function for the two channels and the sidechain filter.

Additionally, we have succeeded in refining the audio properties as well as the circuit topology.

For the first time, the AUTOCOM PRO MDX1400 uses SMD technology (Surface Mounted Device). These

sub-miniature components known from aerospace technology allow for an extreme packing density, plus

improve the units reliability. Additionally, the unit is manufactured under ISO9000 certified management

system.

1.1 The Design Concept

The philosophy behind BEHRINGER products guarantees a no-compromise circuit design and employs the

best choice of components. The operational amplifiers NJM4580 which are used in the AUTOCOM PRO, are

exceptional. They boast extreme linearity and very low distortion characteristics. The most important aspect

of the AUTOCOM PRO design is a radical VCA implementation which results in outstanding technical

specification and excellent performance. To complement this design the choice of components includes high

precision resistors and capacitors, detent potentiometers and several other stringently selected elements.

Despite the extremely complex internal circuitry, the unit has a control surface which is clearly laid out and

easy to understand. The internal design of the unit, together with its external sidechain path, gives the user all

the creative flexibility when processing sound.

IKA (Interactive Knee Adaptation) Compressor

Our proven IKA (Interactive Knee Adaptation) circuit successfully combines the concept of a hard knee

compressor with the characteristics of a soft knee approach. This program-dependent regulation scheme

forms the prerequisite both for inaudible and musical program compression and for creative and highly

effective dynamics processing.

The chosen value for the compression-ratio is being reached after the signals level is higher then 10 dB above

the treshold point. This stands for an extremely smooth impact of the compression. Thereby a convincingly

dense audiomaterial can be achieved: Even at extreme levels of compression or while processing critical

audiodata (e. g. classical music), your material stays musical, transparent and free from breathing or pumplike effects in a wide range. With its IKA circuit the AUTOCOM PRO is capable of delivering outstanding

musical results both in studio and live PA applications.

Additionally, the AUTOCOM PROs sidechain filter allows for limiting the influence low-frequency signal

portions usually have on the control logic, so that the compression ratio is mainly determined by those

frequencies that are essential to the loudness perceived by the listener the midrange frequencies.

IRC (Interactive Ratio Control) Expander

A basic problem in the use of a compressor is the fact that the noise floor is highly amplified during quiet

sections or when there are music pauses. This effect is exaggerated when the compression ratio is

inappropriate. In order to eliminate this problem, one would normally use an additional expander or gate. The

noise is then simply faded out in the quiet sections. However, simple expanders, even when they are used

correctly, drastically cut signals below the preset threshold. This effect becomes more noticeable during the

transition from signal to noise floor. This can mean, that the start or end of words can be cut on a vocal track.

A newly developed IRC (Interactive Ratio Control) Expander has been integrated into the AUTOCOM PRO the

ratio of which, is automatically adjusted, depending on the program material. The result is an expander which

is less critical of adjustment and which is more tolerant in the presence of those signals which appear slightly

above the noise floor. Because of its new IRC circuit design, the BEHRINGER AUTOCOM PROs Expander/

6

1. INTRODUCTION

Page 7

AUTOCOM PRO MDX1400

Gate section can be used as an independent unit to eradicate noise offering almost limitless possibilities

within this application.

The BEHRINGER Dynamic Enhancer

One of the most common negative effects of broadband compressors is the dulled or squashed sound that

is produced when it is applied to composite music, since high-energy low frequency instruments cause a

compressor to reduce the overall gain. Any high frequency instrument which occurs at the same time will also

be reduced in level. This spectral intermodulation causes the squashed sound effect.

The solution to this problem is the new AUTOCOM PROs Dynamic Enhancer which allows for selective

replacement of high-end loss accrued through use of compression. Since the Enhancer tracks the amount of

compression, enhancement will not be added when no compression throughout the mix without any additional

outboard enhancer etc.

+ The following instructions should familiarize you with the special terms used first, so that you

can get to know all the functions of the unit. After you have read the instructions carefully,

please put them away safely, so that you can refer to them again if necessary.

1.2 Before you begin

Your BEHRINGER AUTOCOM PRO was carefully packed in the factory and the packaging is designed to

protect the unit from rough handling. Nevertheless, we recommend that you carefully examine the packaging

and its contents for any signs of physical damage, which may have occurred during transit.

+ If the unit is damaged, please do not return it to BEHRINGER, but notify your dealer and the

shipping company immediately, otherwise claims for damage or replacement may not be

granted. Shipping claims must be made by the consignee.

The BEHRINGER AUTOCOM PRO fits into one standard 19" rack unit of space. Please allow at least an

additional 4" depth for the connectors on the back panel.

Be sure that there is enough space around the unit for cooling and please do not place the ULTRA-GRAPHPRO

on high temperature devices such as power amplifiers etc. to avoid overheating.

+ Before you connect your AUTOCOM PRO to the mains, please make sure that your local volt-

age matches the voltage required by the unit!

The fuse holder on the female mains connector has 3 triangular markers, with two of these triangles opposing

each other. Your AUTOCOM PRO is set to the operating voltage printed next to these markers, and can be set

to another voltage by turning the fuse holder by 180°. CAUTION: this instruction does not apply to export

models exclusively designed, e.g., for 115 V operation!

The mains connection of the AUTOCOM PRO is made by using the enclosed mains cable and a standard IEC

receptacle. It meets all of the international safety certification requirements.

+ Please make sure that all units have a proper ground connection. For your own safety, never

remove or disable the ground conductor of the unit or of the AC power cable.

1. INTRODUCTION

7

Page 8

AUTOCOM PRO MDX1400

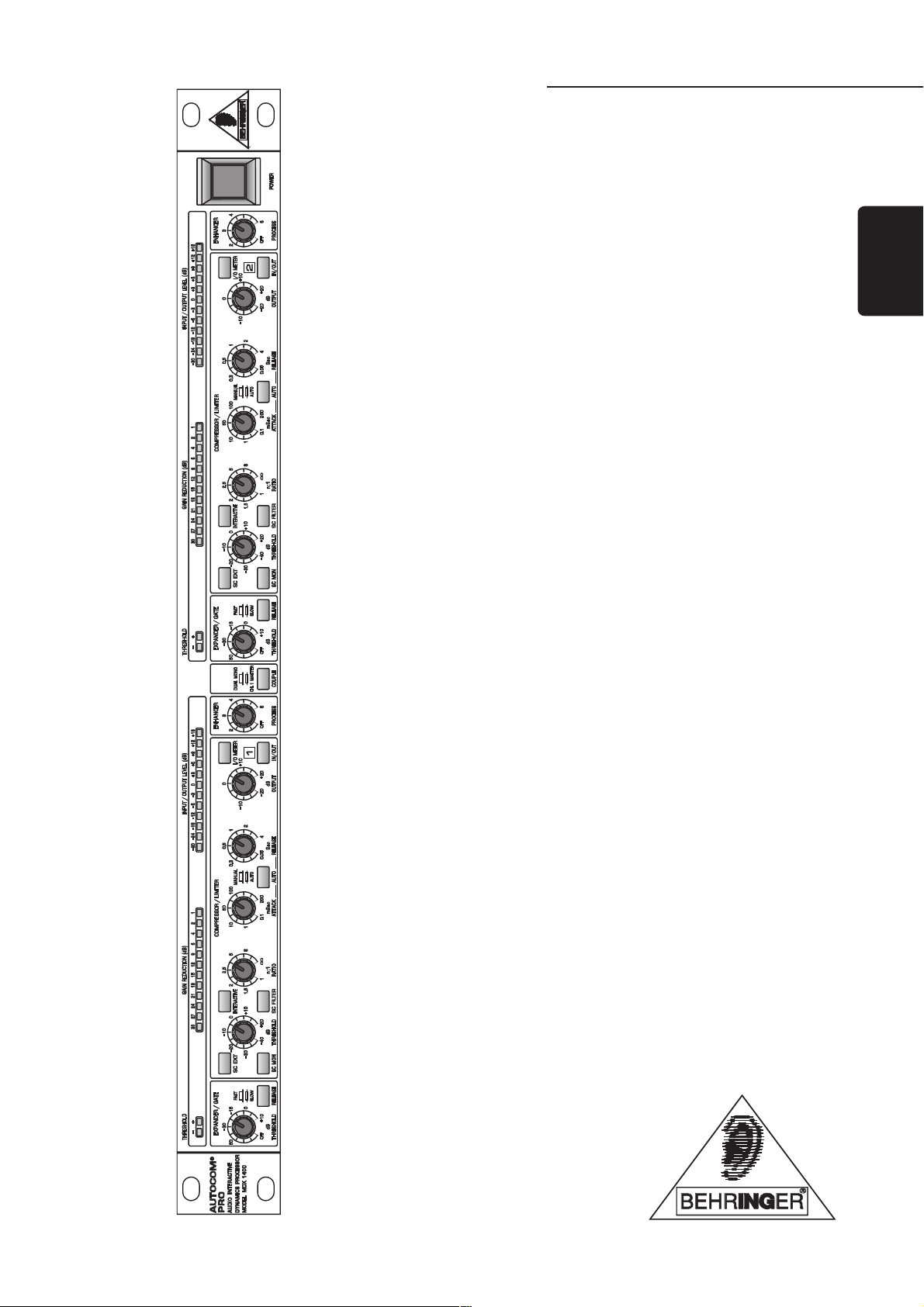

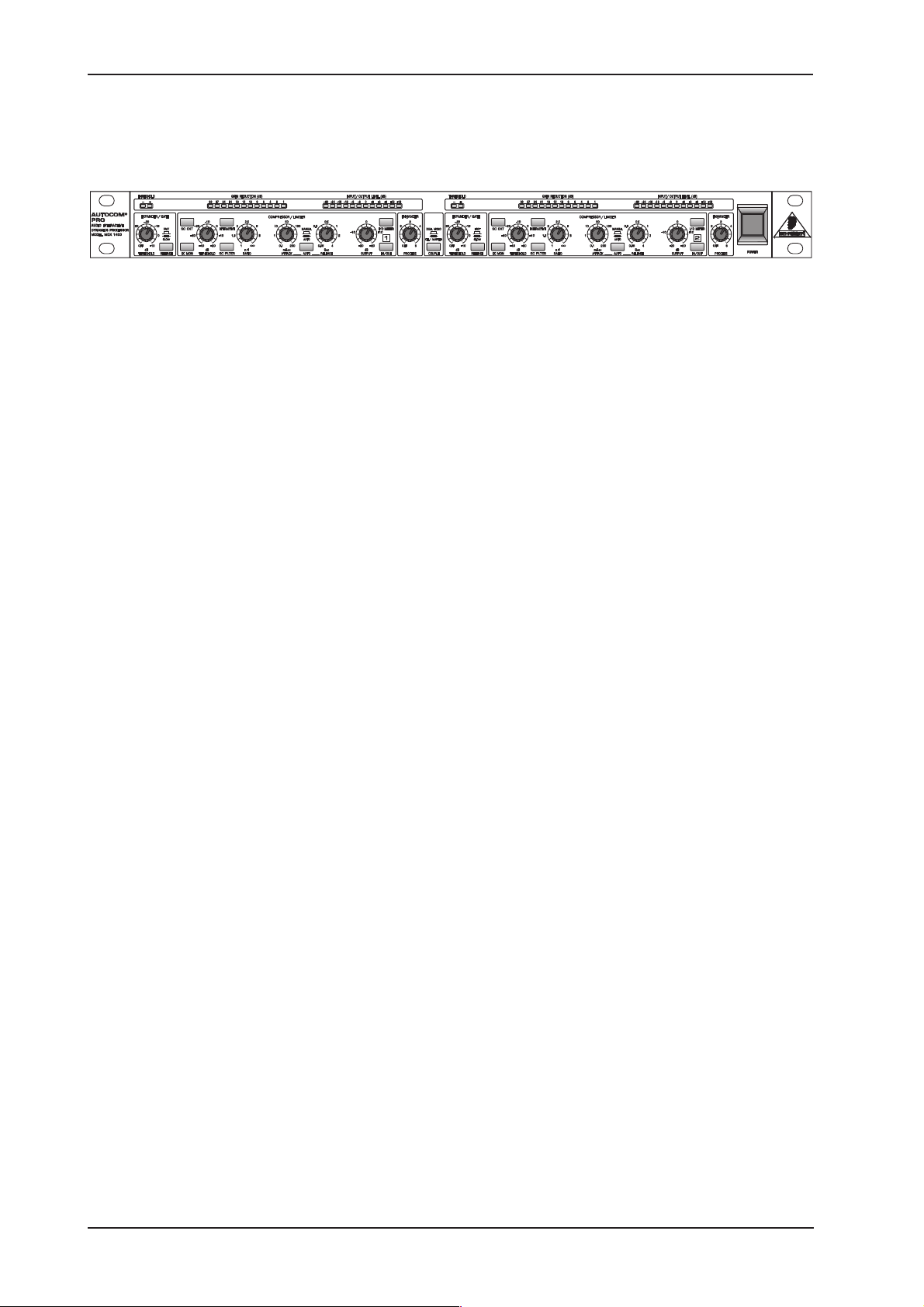

2. CONTROLS

1

Fig. 2.1: AUTOCOM PRO front panel

The BEHRINGER AUTOCOM PRO has two identical channels. Each channel is equipped with 8 backlit

push-buttons, 7 rotary controls and 26 LEDs. The COUPLE switch is for stereo operation:

1

By engaging the COUPLE switch the AUTOCOM PRO is converted to stereo mode, where the controls of

the left channel take over the control of both audio channels. The control signal for the control

characteristic consists of either the sum of the left and right audio signal or the sum of the external audio

signals, which are being fed into both SC RETURN connectors. By pressing the COUPLE switch, you

override all the controls and switches of channel 2 with the exception of the IN/OUT, SC EXT, SC MON,

SC FILTER and I/O METER switches as well as the OUTPUT and PROCESS controls. As a result, the

controls of channel 1 take over the functions of channel 2.

+ Should you wish to use the SC EXT function in stereo mode, then be sure that both SC RETURN

jacks are connected to the external control signal, and that the SC EXT switches on both

channels are engaged.

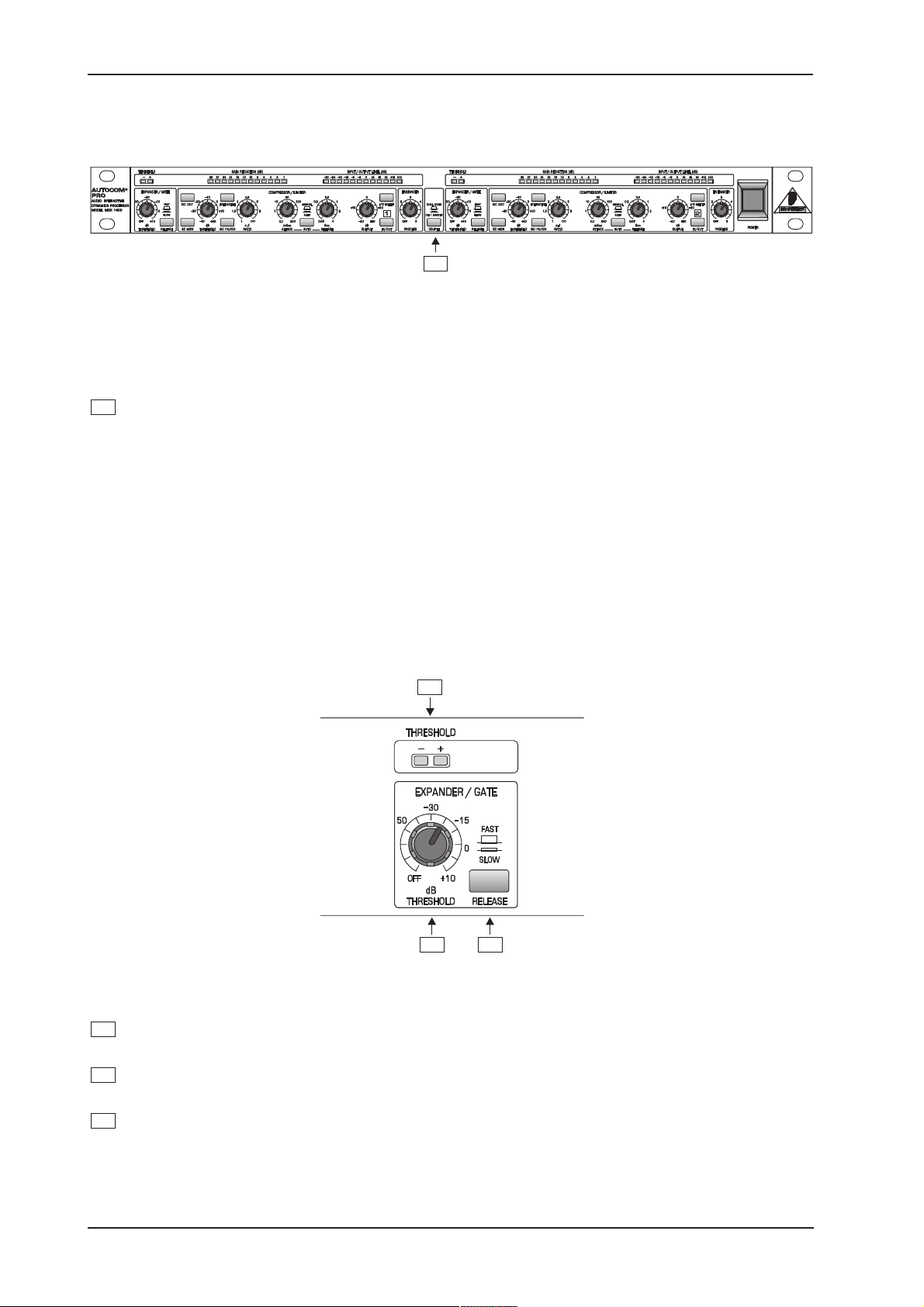

2.1 Expander/Gate Section

3

24

Fig. 2.2: Control elements of expander/gate section

2

Use the THRESHOLD control to determine the threshold point below which expansion occurs. The

range of this control is from OFF to +10 dB.

3

When a signal above the threshold value is applied, the - LED lights up, while the + LED lights up

when expansion occurs.

4

To optimally adapt the expander/gate to the program material, the RELEASE switch allows for selecting

a SLOW or FAST release time. When you engage this switch, the expander responds with a slow

release. As a general rule, percussive material with little or no ambience is processed using the FAST

release mode, whereas signals with long decay or with heavy ambience require the SLOW release

mode.

8

2. CONTROLS

Page 9

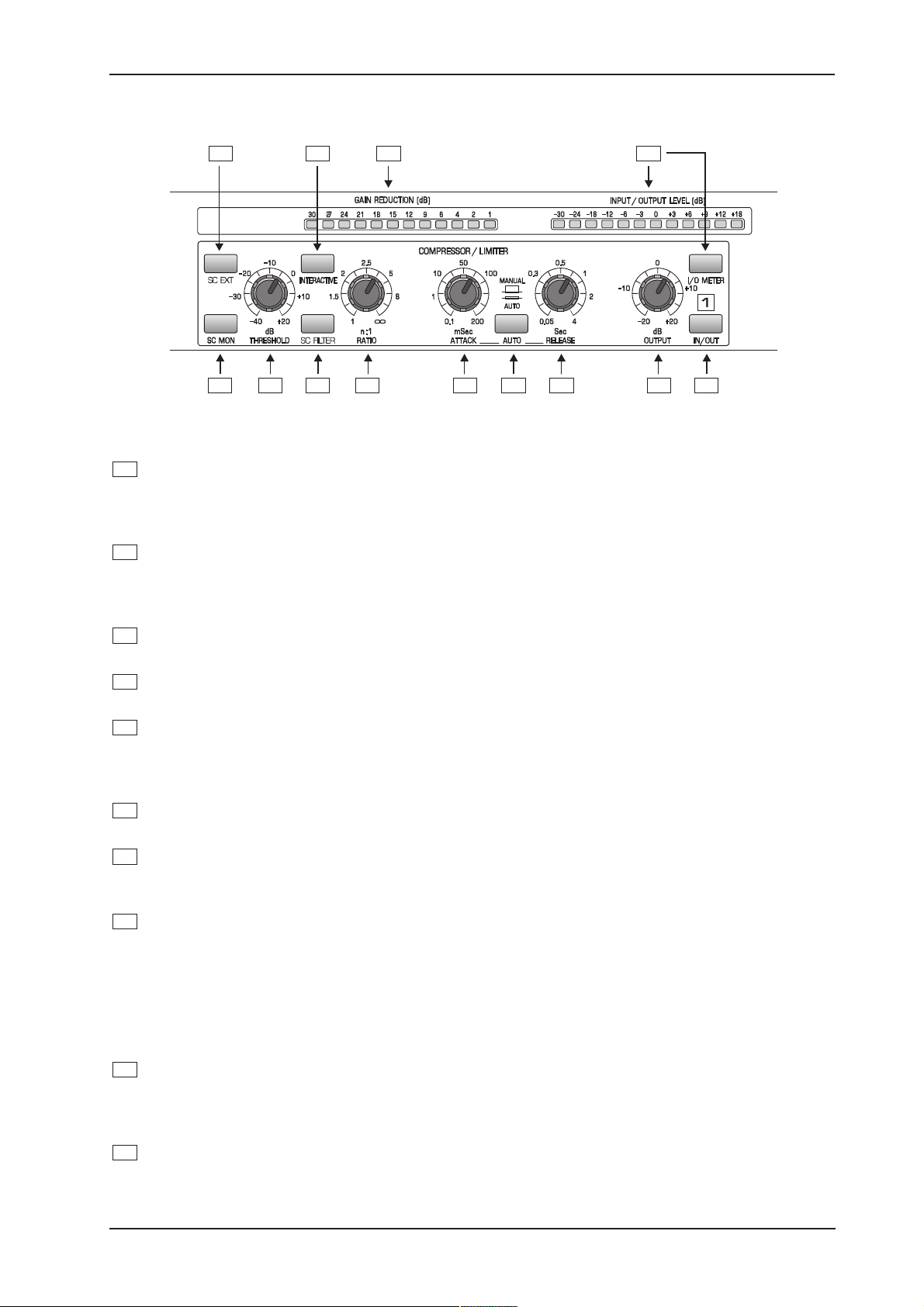

2.2 Compressor Section

AUTOCOM PRO MDX1400

11

12

5

The THRESHOLD control sets the threshold point for the compressor section. It has a range of -40 to

+20 dB. If the channel is switched to INTERACTIVE mode (Interactive Knee Adaptation), a Soft Knee

characteristic is applied to the signal exceeding the threshold point by a maximum of 10 dB. Above

10 dB, the signal would experience Hard Knee compression.

6

The RATIO control determines the ratio between the input and output level for all signals exceeding the

threshold point. If the INTERACTIVE mode is used, this control determines the ratio between input and

output levels for signals exceeding the threshold point by more than 10 dB. The control range can be

adjusted from 1:1 to oo:1.

7

The ATTACK control determines the rate by which the compressor responds to the signal which

exceeds the threshold. This control can be adjusted from 0.1 to 200 milliseconds.

8

The RELEASE control determines the rate that the compressor returns to unity gain after falling below

the threshold level. This control can be adjusted from 0.05 to 4 seconds.

9

By activating the AUTO switch, the ATTACK and RELEASE controls are disabled and the attack and

release rates are automatically derived from the program material. This function allows for unobtrusive

musical compression of signals or mixes with widely varying dynamics. Only if set to MANUAL the

settings of the attack and release controls will function.

10

The OUTPUT control allows for the increase or decrease of the output signal by a maximum of 20 dB.

Thus, a level loss due to the compression or limiting process can be compensated for.

11

When activated, the SC EXT switch severs the connection between the audio input and the sidechain

path, whilst at the same time allowing an external signal to be sourced at the SC RETURN jack on the

rear panel.

12

Using the SC MON switch will enable you to connect the sidechain control signal to the audio output,

whilst at the same time muting the audio input. This function provides you with the ability to monitor the

sidechain signal that is returned via inserted equalizers or other external processors. The SC MONITOR

function will assist you with tuning equalizer parameters for example.

14 16

Fig. 2.3: Control elements of the compressor section

17

13108976155

+ Please note when the SC MON switch is engaged, the audio processing facility of the respec-

tive channel is disabled. When this function is active, a visual indication will be provided by

the switches LED, which will blink.

13

The IN/OUT switch activates the corresponding channel. This switch acts as a so-called hard-bypass,

which means that when the switch is OUT, the input jack is directly linked to the output jack. Normally,

this switch is used to perform a direct A/B comparison between the unprocessed and the compressed

or limited signals.

14

Press the INTERACTIVE switch to change from hard knee to IKA characteristics. IKA provides a very

subtle and musical compression of the program material and should therefore be used whenever

compression is expected to be more or less inaudible.

2. CONTROLS

9

Page 10

AUTOCOM PRO MDX1400

15

The SC FILTER switch activates a highpass filter in the sidechain path and thus limits the influence of

low frequencies on the AUTOCOM PROs control processes.

16

The 12-digit GAIN REDUCTION meter indicates how effectively the gain is reduced by the compressor,

within a range from 1 to 30 dB.

17

The 12-digit INPUT/OUTPUT LEVEL meter informs you depending on the setting of the I/O METER

switch about the current input or output level, within a range from -30 to +18 dB. When the switch is

set to IN (engaged), the meter reads the input level, when it is OUT (not engaged), the output level is

displayed. The meter is referenced to the operating level (-10 dBV or +4 dBu) adjusted with the

OPERATING LEVEL switch.

2.3 Dynamic Enhancer Section

18

Fig. 2.4: Control elements of the dynamic enhancer section

18

The PROCESS control sets the available amount of enhancement between Off and 6. Dynamic

enhancement allows you to replenish any high frequencies lost through the compression process for

absolutely natural sounding dynamics control. Enhancement is only added when compression is taking

place.

2.4 Rear Panel Control Elements Of The AUTOCOM PRO

20 19 23

2421

Fig. 2.5: Control elements of the rear panel

22

2625

19

SERIAL NUMBER. Please take the time to fill out and return the warranty card within 14 days from the

date of purchase, so as to be entitled to benefit from our extended warranty. Or use our online

registration option available on the Internet at www.behringer.com.

20

FUSE HOLDER / VOLTAGE SELECTOR. Please make sure that your local voltage matches the

voltage indicated on the unit, before you attempt to connect and operate the AUTOCOM PRO. Blown

fuses may only be replaced by fuses of the same type and rating.

21

MAINS CONNECTION. Use the enclosed power cord to connect the unit to the mains. Please also note

the instructions given in the INSTALLATION chapter.

10

2. CONTROLS

Page 11

AUTOCOM PRO MDX1400

22

AUDIO IN. These are the audio inputs of your AUTOCOM PRO, available both as balanced 1/4" TRS

and XLR connectors.

23

AUDIO OUT. These are the audio outputs of your AUTOCOM PRO. Matching phone jack and XLR

connectors are wired in parallel. These outputs can be transformer-balanced by retrofitting the optional

output transformer OT-1.

24

With the OPERATING LEVEL switch you can adapt the AUTOCOM PRO to various operating levels,

i.e. you can select both the -10 dBV home recording level and the professional studio level of +4 dBu.

The level meters are referenced automatically to the selected level, i.e. an optimum operating range of

the meters will always be ensured.

25

SC SEND. This is the unbalanced sidechain output which allows for routing the audio signal to external

processing devices.

26

SC RETURN. This is the unbalanced sidechain input used to return any external or processed control

signal.

3. APPLICATIONS

In this section, several typical applications of the BEHRINGER AUTOCOM PRO are discussed. The following

basic settings can resolve most dynamic problems. They are the ideal starting point. Please take the time

to study the application examples carefully, in order to be able to make full use of the AUTOCOM PROs

capabilities in the future.

Main Applications And Initial Settings

The main applications of the BEHRINGER AUTOCOM PRO can be divided into three categories:

1. The EXPANDER/GATE section is used to eliminate interference and to suppress background noise and

leakage on individual tracks in multitrack recording.

2. The COMPRESSOR section is used to compress the program material and to create special effects and

unusual sounds, which are used for recording and musical performance.

3. The subsequent DYNAMIC ENHANCER section is designed to freshen the signal after compression.

3.1 Compression/Levelling/Limiting/Clipping

Now that the functions of the individual sections have been clearly explained, we would like to acquaint you

with more terms and relationships of the dynamics process.

Compression

A compressor converts a large dynamic level into a restricted range. The extent of the resulting dynamic level

is dependent on the threshold, attack, release and ratio settings. As it is the desired effect of a compressor to

increase a low level signal, generally the threshold is set low. The inaudible compression mode requires fast

attack and release times and low ratios. The faster the chosen control times and the higher the compression

ratio, the greater the effect on the short term dynamics. This fact is often used to achieve audible and creative

sound effects.

Levelling

The levelling mode is used to keep output level constant, i.e. to compensate for long term gain changes,

without affecting the short term dynamics. Normally, the threshold is set quite low in order to be able to

increase low level signals. Levelling requires slow attack and release times, combined with a high ratio.

Because of the very slow response time, levelling has no effect on signal peaks or short term changes in

average level.

Limiting

The limiting function requires a fast attack time and a high ratio and release time setting, which is dependent

on the specific use and the desired sound effect. As it is usually the task of a limiter to limit only high signal

peaks, the threshold is usually set at a high level. The dynamics are reduced dependent on the ratio setting

and the degree by which the threshold point was exceeded. If the attack time is adjusted to control only the

average level without affecting signal peaks above the threshold, this is referred to as the program limiter. For

this purpose the attack time will be set above 20 ms. If the attack time is further reduced in order to also control

signal peaks, this is defined as the peak limiter.

3. APPLICATIONS

11

Page 12

AUTOCOM PRO MDX1400

Clipping

In contrast to the two previously mentioned limiters, the clipping mode features infinitely fast control times, an

infinite compression ratio and creates an unsurpassable barrier (brickwall) for all signals above a certain level.

To be able to control the signal peaks, the clipping function radically cuts signals above the threshold, without

affecting the amplitude of the original signal. If used in normal applications, this function remains inaudible and

under certain circumstances it can even lead to an improved sound, because cutting the transients creates

artificial harmonics. If misused, clipping can cause very obvious and distasteful distortion, which in an extreme

manner, will convert the signals waveform into a square wave signal. This effect is often produced in guitar

distortion devices (fuzz boxes).

3.2 Expander/Gate Section

The main task of the Expander/Gate is to inaudibly eliminate undesirable background noise from the usable

signal. As additionally described in chapter 6.4, a downward expander automatically reduces the overall level

for all signals below an adjustable threshold. The expander therefore operates in opposite way to that of a

compressor/limiter. Expanders generally function with a flat ratio curve, so that the signal continually fades.

Noise gates however, can be seen as high ratio expanders. If the signal falls below the threshold, it is

radically attenuated.

The BEHRINGER AUTOCOM PRO is equipped with a newly developed IRC (Interactive Ratio Control)

Expander, the ratio of which is automatically adjusted dependent on the program material. The response

characteristics of conventional expanders tend to cut into the signal abruptly and the result of this is

unacceptable most of the time. Gain changes become audible.

The IRC Expander is therefore equipped with a soft, interactive non-linear ratio curve, which is best suited to

human hearing. Critical signals in the vicinity of the threshold level are processed with a minute expansion

ratio, whereas signals that reduce in level will be subjected to an increasingly higher ratio, which will result in

greater attenuation.

Output

Gain 0 dB

Threshold

IRC-Curve

Expander, 1:8

Noise Gate,

1:oo

Input

Fig. 3.1: IRC curve characteristic of the Expander

The result is expansion, which is less critical to adjust and which is more tolerant of useable signals, whose

level is slightly above that of the noise floor. Expansion therefore occurs extremely soft with low ratio settings,

while the known negative effects of expansion are inaudible. The Attack time of the IRC expander is set

automatically and program-dependent, i.e. extremely short for quickly changing signals and slower for a more

balanced program material. Since the expander/gate adapts itself automatically to the program material,

you will note that the new IRC (Interactive Ratio Control) circuit produces considerably better results than

conventional expanders.

3.2.1 Controlling Leakage In The Studio

Expander/gates are most commonly used to suppress undesirable leakage of sound from one track to another

during recording or playback. They are usually used when recording drum kits, where the mics are very close

to each other. High volume levels of individual instruments often cause considerable leakage onto all the

12

3. APPLICATIONS

Page 13

AUTOCOM PRO MDX1400

adjacent mics and results in conflicting frequency and phase coherence problems, as well as unspecified

sounds (comb filter effects). It is vitally important that every instrument is recorded into a separate mic and

that each mic is individually gated.

Patch the BEHRINGER AUTOCOM PRO into a snare drum channel for example and adjust it so that triggering

only occurs on snare hits. Each mic should be set to its maximum operating level, monitored (see SC MON

switch) and the THRESHOLD level set so that each snare hit sounds acoustically clean and seperate, as

though it was played on its own.

The optimum use of the Expander/Gate depends principally on microphone technique. Be particularly careful,

when high frequency instruments are located to the side or rear of a cardioid microphone. Most cardioids

exhibit a sharply rising off-axis response characteristic at higher frequencies. If there is only a 2 or 3 dB

difference between the on-axis and off-axis response in the 5 to 10 kHz region, cymbals may leak excessively

into the tom mics and you may have hi-hat spilling all over the snare mic.

Please make full use of the directional characteristic of the mics, to acoustically exclude all other instruments

as much as possible. Make sure that you do everything possible to achieve source separation with good

microphone technique. Otherwise the Expander/Gate is not able to undertake clear acoustic separation.

Sometimes, it is necessary to prevent the Expander/Gate from responding to low frequencies (rumbles etc.),

especially if a singer is moving the microphone around on a mic-stand. More information about this topic in

chapter 5.2.

3.2.2 Initial Settings For The Expander/Gate Section

Control Se tting

THRESHOLD control OFF

RELEASE switch SLOW

Tab. 3.1: Initial settings for the expander/gate section

Begin with very low threshold levels, so that the signal can pass through the unit unaffected. Now turn the

control clockwise until all unwanted noise is removed and only the sound of the desired instrument can be

heard.

To adapt the unit to the program material properly, you can additionally choose between a SLOW or FAST

release time. In the depressed position, the unit works at a slow release time. Percussive material with little or

no reverb, is processed in fast mode, whereas the slow mode is advantageously used for signals with long

durations or signals with heavy ambience. You will find that a fast release time (FAST mode) is preferable for

acoustic separation of most percussive sounds, whilst cymbals and tom toms, normally benefit from the

SLOW mode.

If the controls are set correctly, the drum sounds will be dry, sharp and clearly defined. If you do not have

enough mics (or AUTOCOM PRO channels!) to record each instrument separately, try to create sub-groups:

put the snare and mid-toms together, and group the side-toms, bass drum and cymbals together with the help

of a mixing console.

The aim is to set up the Expander/Gate and to position the group mics so that each strike on an instrument

opens a specific mic and so only that instrument is recorded, whilst the other mics remain muted.

3.2.3 Reducing Leakage In Stage Mics

The AUTOCOM PRO has many uses in live-work, on stage and in multi-miking situations: a well set up

Expander/Gate can effectively suppress background noise, compressor type pumping noise and microphone

leakage etc. without producing any undesirable side effects. Expander/gates are commonly used for

processing vocals. When specifically used with a compressor, the distance and position of the mic in relation

to the singer is very critical: the further the distance, the more sensitive the mic is to background noise. Use

the Expander/Gate section in the slow release mode to inaudibly eliminate background noise, that occurs in

pauses between singing. When used in live situations, leakage of miked instrumentation is substantially

reduced, as well as other acoustic contaminants in various recording situations.

3. APPLICATIONS

13

Page 14

AUTOCOM PRO MDX1400

3.2.4 Reducing Feedback In Stage Mics

When a singer is using a vocal mic, their voice effectively stops other sounds from entering the mic. But in

pauses between the singing, the mic will pick up noise from the house PA and monitors, which can lead to

unpleasant feedback problems. If the AUTOCOM PRO is inserted into the mic channel, it will shut off the

channel when it is not being used, reducing the possibility of feedback. Principally all mics should be included

in this application.

3.2.5 Noise Reduction On Effects Paths

The effects rack is one of the main overlooked sources of noise in a PA system or recording facility. The price

of reverb and delay units and harmonizers has fallen drastically over the last number of years, which have made

these units a common feature in small studios and home recording installations. However, multiple effects

units considerably increase the overall noise level, so that the pleasure in acquiring a new sound effect is short

lived.

It will prove useful to use the BEHRINGER AUTOCOM PRO as the last component in the chain of effects units

and use the noise reduction function of the Expander/Gate section. We recommend that you use a slow

release time in order to maintain the natural reverb.

3.2.6 Creative Use Of The Expander/Gate Section

In addition to the previously explained applications, the Expander/Gate can be used to change the sound

characteristics. For example, the quality of ambience or reverberation created by an instrument within a room

can be modified: when an instrument stops decaying, the reverberation of the instrument falls below the

user-defined threshold. The reverberation can be controlled by using the THRESHOLD control and the

RELEASE switch. The decay characteristics of the instrument can be controlled using the release switch, so

that the natural characteristics of the instrument remains. Experiment with the effect, this control has on the

decay of the instrument. In SLOW mode, the signal is gently faded out in FAST mode, the duration of the

reverberation can be removed completely.

3.3 Compressor Section

The task of a compressor is to reduce the dynamic range of program material and to control the overall level.

The extensive controls of the Compressor section, provide a great range of dynamic effects: from musical and

soft compression to limiting signal peaks, right up to extreme and effective compression of the overall

dynamics. For example, a low ratio and very low threshold setting can be used to achieve soft and musical

processing of the general dynamics of the program material.

Higher ratios, together with low threshold settings, create relatively constant volume (levelling) for instruments

and vocals. High threshold levels generally limit the overall level of a program. Ratios greater than 6:1 effectively

prevent the output level from significantly exceeding the threshold point (provided that the OUTPUT control is in

the 0 dB position).

Please note that the compression of the entire program material (achieved by low threshold settings) sounds

less natural with higher ratio settings. Ratio settings in the range of 4:1 and lower, effect the dynamics of the

program material less and are often used to compress the sound of a bass guitar, a snare drum or a vocal.

Sensitive and moderate settings are generally used in mixing and for levelling of program material in broadcast.

14

3. APPLICATIONS

Page 15

AUTOCOM PRO MDX1400

Output

Threshold

Hard Knee

IKA Curve

Gain 0 dB

Ratio 2:1

Ratio 4:1

Limiter

oo:1

Input

Fig. 3.2: IKA characteristic of the compressor section

The new IKA (Interactive Knee Adaptation) circuit prevents aggressive compression, created by high ratios,

from sounding too unnatural. This is achieved with an interactive control function, which begins above the

threshold level and introduces a Soft Knee curve characteristic in the range up to 10 dB above the threshold

point. Beyond this range, the signal is subjected to linear (Hard Knee) compression.

+ With the threshold control completely turned to the right, the threshold value is +20 dB. Since

such a value will not be reached in practice, you can use it to disable the compressor section

and work exclusively with the expander/gate and dynamic enhancer circuits.

3.3.1 Initial Settings For The Compressor Section

Control Setting

IN/OUT switch IN

SC EXT switch OUT

SC MON switch OUT

INTERACTIVE switch IN

SC FILTER switch OUT

THRESHOLD control +20 dB

RATIO control 3:1

AUTO switch IN

OUTPUT control 0 dB

Tab. 3.2: Initial settings for the compressor section

Rotate the THRESHOLD control counterclockwise until an appropriate amount of gain reduction is indicated on

the GAIN REDUCTION meter. This operation will be accompanied by an audible drop in output level. The

OUTPUT control should now be turned clockwise to reinstate the output level. The level of the unprocessed and

the processed signal can be compared by pressing the I/O METER switch and observing the INPUT/OUTPUT

LEVEL meter.

Final adjustments of the controls can then be made to suit your particular requirements, including the RATIO,

ATTACK and RELEASE controls. The AUTO function of the attack and release times, provides program

dependent dynamic processing which suits most standard uses. If a condensed or wider sound processing

technique is required, the attack and release times can also be manually adjusted.

3. APPLICATIONS

15

Page 16

AUTOCOM PRO MDX1400

The experienced user will be in a position to specify parameters while in bypass mode and thus realize the

effect before the unit is actually switched into operation. This is important in live situations, where a signal

needs to be managed efficiently by the engineer, without the convenience of continual A/B comparison.

For using the AUTOCOM PRO as a Limiter, you should set RATIO to oo:1, INTERACTIVE to off and use short

Attack and max. Release Times. Use the THRESHOLD control to set the threshold level for limiting.

3.3.2 The AUTOCOM PRO As A Sound Effects Unit

In the early 1960s, musicians began looking at the recording process as a way to create new sounds. The

pumping effect which had been avoided by earlier engineers suddenly became fashionable and was utilized as

a creative tool, laying the groundwork for many of the sounds which are now considered indispensable in

contemporary music. The compressor is used in this role because you can hear it working, and control of the

dynamic range is of secondary importance.

The BEHRINGER AUTOCOM PRO, with its extensive range of functions, is well suited to this application.

Sound effects of this kind can be achieved using extreme settings. To achieve this, set the THRESHOLD

control to a fairly low level, the RATIO control to almost maximum and use the ATTACK and RELEASE

controls to obtain the desired effect. Experiment with all the controls in order to get a feel of their function!

3.3.3 The Muffling Effect Of A Compressor

Quite often, compressors are sometimes accused of muffling the sound, whilst at the same time reducing the

dynamics. This fact should be investigated further. Bass frequencies contain most of the energy within music

and therefore cause the compressor to reduce the overall dynamics. If the music also contains high

frequencies along with the bass frequencies, these are also reduced in level. This is the reason why: in an

extremely compressed recording of drums, the cymbals and high-hats are acoustically swamped by the sound

of the snare or the bass drum. The same effect is experienced when processing reverberated or ambient

sounds. The solution commonly used to this basic problem is either to reduce the compression ratio or to slow

down the attack time, so that the increasing high frequency transients pass through the compressor

unhindered before the compressor takes effect.

The AUTOCOM PRO MDX1400 offers a solution to this problem that is by much more elegant. The SC Filter

switch allows you to activate a highpass filter in the control signal path of the compressor. This filter makes

sure that midrange and treble range frequencies are taken into account to a greater extent, and that a

low-frequency signal triggers less compression than a midrange/treble signal of comparable level. A major

advantage of this design can be seen in the fact that the frequency response of the overall signal is not modified

below the threshold adjusted with the Threshold control.

In pop music the dynamics of both kick drum and bass guitar are usually processed individually. The sidechain

filter is therefore ideally suited to apply overall compression in the mixdown, to compress the music while

increasing its loudness, but without having to accept the drawbacks described above.

3.4 Dynamic Enhancer Section

In addition to the above mentioned method with the sidechain filter the AUTOCOM PRO offers another

alternative solution: the Dynamic Enhancer. It eliminates the problems without creating any additional negative

side effects. As the signal level rises towards the threshold point where compression will occur, high frequency

enhancement is added at the same degree to which the input signal is compressed. The AUTOCOM PRO

accurately tracks the amount of compression in order to compensate with the same amount of dynamic

enhancement, even if there are heavy signal variations. When there is no compression taking place, the

Dynamic Enhancer is inoperative and therefore, no additional noise or signal equalization is added to the

signal. For more versatility, a PROCESS control allows you to control the available amount of dynamic

enhancement. The range lies between Off and 6.

The typical dynamic enhancement function is shown in the following figure:

16

3. APPLICATIONS

Page 17

Output

AUTOCOM PRO MDX1400

0 dB

-20 dB

No Gain Reduction

With Enhancer

20 dB Gain Reduction Without Enhancer

Frequency

Fig. 3.3: The frequency response with and without dynamic enhancer

3.4.1 Initial Settings For The Dynamic Enhancer Section

Turn the PROCESS control beginning from Off to a value, where you have the impression of a correct

frequency response at compression. Also check out the combination with the sidechain filter.

Control Se tting

PROCESS control OFF

Tab. 3.3: Initial settings for the dynamic enhancer section

4. SPECIAL APPLICATIONS

4.1 Using The AUTOCOM PRO For Recording And Cassette Duplication

In the recording and duplication field the goal should always be to achieve an optimum recording level onto the

recording media. Too low or too high recording levels lead to side effects such as noise, distortion etc. In

mastering and multitrack recording, as well as in duplication, one should always take care to utilize the full

dynamic range of the tape recorder, DAT recorder etc. Principally, it is possible to control the recording level by

riding faders, which means with low level signals, the gain is increased, whereas the amplitude of high level

signal is reduced. It is obvious that this method is insufficient because, especially in live recordings, the

expected signal levels cannot be anticipated correctly. Especially with multitrack recordings, which are run

under hectic circumstances, the signal level of all channels cannot be monitored and controlled at the same

time. Generally, with manual control, it is not possible to achieve satisfying recording results.

An automatic gain control system achieves better and more constant results. Use the AUTOCOM PRO by

starting with the initial settings, and use its dynamic control functions in order to be able to drive an analog, as

well as a digital recording, up to the limit of its maximum dynamic range while remaining noise- and distortionfree.

4. SPECIAL APPLICATIONS

17

Page 18

AUTOCOM PRO MDX1400

4.1.1 The AUTOCOM PRO In Digital Recording And Sampling

In an analog recording, too low recording levels lead to an increased noise level, whereas too high levels will

cause a compressed and squashed sound. In extreme cases, it will cause distortion due to tape saturation.

In contrast to analog, side effects in the digital field always become extremely audible: with decreasing level,

a tape previously recorded with insufficient level loses resolution: the recording sounds hard and loses

atmosphere. With excessive level, the recording sounds harsh and heavily distorted. In order to avoid these

effects, the AUTOCOM PRO as a limiter should be placed before for example a sampler. As a result of this

process, a digital recording or a sampling event can be optimally set in level without any problem.

4.1.2 The AUTOCOM PRO In Mastering

The mastering process is one of the most critical processing steps in recording. In this production step, it is

the goal to achieve a maximum level copy of the recording, without any noise or distortion. In many

applications it is further required to produce a high average volume. In the field of commercial media for

example, this is apparent especially with records and cassettes which are processed with high average

volumes. Quite often in these cases, dynamics suffer drastically, because the program material has been

compressed and limited too heavily. Using the Compressor section of the AUTOCOM PRO as a limiter allows

you to drastically increase the overall volume, without audibly affecting the dynamics.

Proceed as follows:

Limit the dynamics of the program material by 6 dB using the AUTOCOM PRO as a Peak Limiter (Ratio

1:oo). By softly clipping just the transients, the real audio signal will not be limited, resulting in a higher

headroom. The overall gain can now be increased by 6 dB, which leads to a higher volume. More than 6 dB

should not be limited, otherwise side effects could become audible.

This effect is particularly noticeable with DAT recorders, whose level indicators achieve a response time of less

than 1 ms. Set the DAT recorder at unity and now reduce the LEVEL control of the peak limiter until a gain

reduction of 6 dB is indicated. The cut signal peaks cause a reduced recording level of about 6 dB, which is

visible on the level indicators of the DAT recorder. Now increase the recording level of the recorder back to

unity. The result is a clearly louder recording without any loss of sound.

4.2 The AUTOCOM PRO As A Protective Device

Sound system distortion is usually a result of amplifiers and loudspeakers being driven beyond their limitations

by signals clipping. The signal limitations that occur lead to unpleasant distortion that is dangerous to the

speakers.

A speaker diaphragm is required to accelerate, slow down, smoothly change direction and accelerate again in

normal operation. Distorted operation (clipping) leads to instant acceleration, instant stop, change of direction

and instant acceleration again. Since speaker diaphragms are subject to the laws of physics, they will not take

this kind of punishment for long: the diaphragm will either break up or its voice coil may overheat.

In addition to the damage caused by sustained overload, the speaker may also be damaged by an occasional

high level overload, e.g. the sound of a microphone falling onto a hard floor. Even if this type of transient does

not destroy a speaker outright, it may damage the speaker surround in such a way, as to cause mechanical

abrasion and future failure. It is recommended that you use the Behringer AUTOCOM PRO in order to protect

the speaker. Brick Wall peak limiters are not normally necessary for PA systems, as amplifiers and

loudspeakers are tolerant of short signal peaks.

Nevertheless, conventional limiters have to be generally driven far beyond the headroom limit of an amplifier, in

order to limit the level and length of the transients responsible for overloading the system. The disadvantage of

this principle is that the units full range cannot be completely used. If an increase in the average level of up to

3 dB is attained with the AUTOCOM PRO as a Limiter, this means that you effectively double the power

amplification. The AUTOCOM PRO can act in this way to convert a PA system of 5,000 Watts into a distortion

free 10,000 Watts system. The following instructions will help you to integrate the unit into your system.

4.2.1 Protection Of A System With A Passive Crossover

If your sound system incorporates a passive crossover network (included in the loudspeaker case), insert the

BEHRINGER AUTOCOM PRO between your mixing console output and the power amplifier input. It is used as

the last link in the chain preceding the power amp. Thus, you can effectively avoid the technical knockout of

18

4. SPECIAL APPLICATIONS

Page 19

AUTOCOM PRO MDX1400

the midrange/tweeter range caused by high-energy bass signals! This statement, as paradox as it may seem

at first, can be explained with the fact that especially low-frequency signals with high amplitudes can overload

the power supplies in the amplifier(s). The resulting clipping (cutting off of signal peaks) produces high-energy

distortion (upper harmonics), which is abruptly added to the midrange/tweeter signals. For this reason, weak

power amps, in particular, must be protected by a limiter in their input dynamics.

4.2.2 Protection Of A System With An Active Crossover

For systems using active crossovers, there are two ways to use the BEHRINGER AUTOCOM PRO. The unit

may be inserted between the console output and the crossover input. In this application, the BEHRINGER

AUTOCOM PRO will process the entire audio frequency spectrum.

Alternately, the BEHRINGER AUTOCOM PRO can be inserted between the output of an active crossover and

the input of a power amplifier. In this application it will only affect a specific range of frequencies. This

application is particularly suited to protect the most fragile components of a multi-way speaker system against

harmful signal peaks. For example, when your tweeters keep on going up in smoke all the time, the entire

system should be operated at lower sound pressure levels or the tweeters should be replaced by other models.

Using the AUTOCOM PRO in the corresponding tweeter band avoids overloading and thus damage to the

speakers.

4.2.3 Improving The Sound Of A Processor System

A processor system is understood as a PA system which contains a special active crossover whose outputs

are linked via separated power amplifiers to the loudspeakers. Each band has its own limiter whose task it is

to limit dangerous signal peaks to a certain level. This process avoids overloading the subsequent power

amplifier or destruction of the loudspeaker.

In some units, the crossover frequencies in the crossover unit are further changed during high signal levels to

achieve a loudness contour suited to the human hearing. But in many cases, this function leads more to a

disturbance than to an improvement of the sound quality.

If the AUTOCOM PRO is preceding this system, the signal peaks can be eliminated before they reach the

limiters of the processing system. The sound quality therefore remains natural and free of side effects caused

by the changing frequencies of the crossover.

4.3 The AUTOCOM PRO In Broadcast

The main aim of processing sound recordings for commercial radio and television is to achieve a maximum

transmission volume at all costs. Owners of these radio and television stations strive to get bigger audience

ratings, because principally, radio programs whose reception is louder than the average are preferred by the

listener. By achieving a bigger audience, the broadcast station gains more money from the increasing number

of promotion companies placing adverts.

What Is Volume?

Volume is defined as the relationship between the average level of program material to peak-to-peak level, in

response to amplitude and duration. The higher the average level and the time it remains at a high level, the

louder the program material will be perceived by the listener.

If you want to run your broadcast station at maximum average volume, proceed as mentioned in chapter 6.1.2

The AUTOCOM PRO In Mastering. Please make sure that the maximum peak level is below the threshold of

the transmitters limiter, otherwise this could lead to very hard and audible use of the transmisson limiters.

Keep in mind that a heavy increase in average volume by means of compression always leads to a loss in

dynamics and an increased perception of side effects. The intense use of all functions of the AUTOCOM PRO,

including sidechain filtering, IKA, Attack and Release time constants, results in higher average volumes, free

of distortion and side effects.

4. SPECIAL APPLICATIONS

19

Page 20

AUTOCOM PRO MDX1400

5. EXTERNAL SIDECHAIN APPLICATIONS

5.1 The Sidechain Function

With the AUTOCOM PROs sidechain function you have a very useful external control option. By activating the

SC EXT switch, the AUTOCOM PROs control path is disconnected from the audio input and therefore

interrupted. The audio input is routed to the SC SEND output and the SC RETURN input now receives the new

control signal which is derived from an inserted effects processor.

Please note the correct wiring for mains powered units in order to avoid ground loops, as the sidechain inputs

and outputs are unbalanced. The working level of external units must be at line level (-20 to +10 dBu) and must

be at unity gain.

5.2 Using An Equalizer In The Sidechain Path

It is very common to make the response threshold of a compressor frequency-dependent, where a

graphic or parametric equalizer is connected to the sidechain path. To retain the threshold setting of the

AUTOCOM PRO, unwanted frequencies should be reduced by an equalizer and the desired frequencies should

be kept at the same level. Should for example, the compressor be controlled by a narrow mid-frequency band,

it is advisable to lower the bass and treble controls. The middle frequency control remains at unity gain.

5.2.1 The AUTOCOM PRO As A De-Esser

De-essing is a special application of frequency selective compression. A problem often encountered in

recording, is the sibilant (Ssss) sound of the human voice. High frequency, sibilant sounds and pops can

produce very high energy levels which can sometimes cause an otherwise normal and undistorted voice to

sound very harsh, shrill and sometimes unintelligible. The solution is frequency conscious compression or

limiting. The unit responds only to selected frequencies and reduces the level temporarily, as soon as sibilant

sounds or pops are detected.

If the detector circuit registers an excessive amount of high frequency information within the program material,

as in a normal compressor, the VCA is activated and the overall level is reduced. As this type of compression

affects the whole frequency range, this process is called broadband de-essing.

Please note that this type of frequency selective compression is very different from simple, fixed equalization

using notch filters, since de-essing has no effect on the signal except at the instant the sibilant occurs. The

general frequency response is principally not affected during this process.

When de-essing, simply insert an equalizer not into the audio path but into the sidechain path of the BEHRINGER

AUTOCOM PRO. The equalizer is inserted between the SC SEND output and the SC RETURN input of the

BEHRINGER AUTOCOM PRO. While the SC EXT switch is pressed, the equalizer is inserted into the sidechain

loop and controls the unit. With the help of the sidechain monitor function, the center frequencies of the

equalizer are then adjusted exactly to match the frequencies of the sibilant sounds. All other frequencies are

filtered out, so that with maximum attenuation of these frequency bands, along with a correctly adjusted

threshold point, the unit responds solely to the selected signal being produced by the equalizer. The level of the

sibilant sounds can therefore be effectively limited.

Turn the THRESHOLD control counterclockwise until the GAIN REDUCTION meter shows an appropriate drop

in level. Now press the SC MON switch and adjust the equalizer corner frequencies (generally 6 - 10 kHz) by

monitoring, until it is within the range of the sibilance. Release the SC MON switch and recalibrate the

THRESHOLD control, so that the unit reacts only when the sibilant sound occurs.

Level compensation using the OUTPUT control is not necessary. Although the recommended attack and

release times for this function are proven, the time parameters can be adjusted if necessary to achieve

maximum results. The AUTO function should not be used.

20

5. EXTERNAL SIDECHAIN APPLICATIONS

Page 21

AUTOCOM PRO MDX1400

Control Setting

SC EXT switch IN

SC MON switch OUT

INTERACTIVE switch OFF

SC FILTER switch OUT

THRESHOLD control +20 dB

RATIO control 1:4

AUTO switch OUT

ATTACK co ntrol 0,5 ms

RELEASE co n trol 200 ms

OUTPUT control 0 dB

Tab. 5.1: Initial settings for the De-Esser functions

5.2.2 Frequency Selective Filtering Of Unwanted Signals

Based on the set-up described in the de-esser section, the unit may also be used to eliminate rumble, hum

and equipment noise (air-conditioning systems, camera noise etc.). Using the SC MON switch, adjust the

frequencies of the equalizer to match the unwanted frequencies and use a peak filter with a high slope. Take

care to decrease the amplitudes of the unrequired frequencies. Proceed now as described in the

previous chapter 5.2.1. This will result in compression of the selected frequencies and thus a decrease in the

gain of the program material.

5.2.3 Suppressing Instruments During Recording

Another function of the BEHRINGER AUTOCOM PRO allows helpful correction of previously recorded material.

If, for example, an excessively loud bass drum needs to be suppressed, reduce all the equalizers frequency

bands above 150 Hz. This setting causes frequency specific compression, which reacts as soon as increased

energy is detected in this band. By increasing the threshold level, the compression can be made to react only

to loud pedal or stick actions. Generally, it can be said that relatively high threshold settings prevent the overall

sound from being impaired and lead to the compression of solo instruments or very loud sounds.

5.2.4 Emphasizing Musical Instruments During Recording

On the other hand, you can use the BEHRINGER AUTOCOM PRO to bring out an instrument solo or a lead

vocal in a cluttered mix. Using the SC MON switch, match the frequencies of the equalizer to the frequencies

of the instruments to be emphasized and for this it is best to use a notch filter with a high slope.

Please make sure that in this application, you only reduce the amplitude of the selected frequencies. The

compression results in a subjective decrease in the volume of the overall program material. Only the selected

frequencies coming from the equalizer remain uncompressed and are therefore perceived as being louder. This

inverse type of compression also helps to emphasize instruments during low level passages, so that they

become more pronounced.

5.3 Anticipated Compression

If you feed the audio signal directly into the SC RETURN input and send the audio signal through a delay

before the audio input, the BEHRINGER AUTOCOM PRO can anticipate the need for gain change. With

experimentation, the effect can create a zero attack time at a given frequency. Additional delay beyond this

zero attack time will produce a special sound effect, similar to the dynamic envelope inversion you may

already be familiar with from reverse tape playback.

5. EXTERNAL SIDECHAIN APPLICATIONS

21

Page 22

AUTOCOM PRO MDX1400

5.4 Voice-Over Compression (Ducking)

The BEHRINGER AUTOCOM PRO can be used to automatically reduce music to a background level, when an

announcer is speaking through a microphone. For this purpose, the BEHRINGER AUTOCOM PRO is used as

an automatic fader and is controlled by the announcers microphone, which is connected to the SC RETURN

input via a preamplifier. The music output and the announcers voice, are then mixed. This application is known

as voice-over compression or ducking and is commonly used in discos, radio stations etc.

5.5 Triggering Additional Sounds From A Rhythm Track

This technique is used to give a rhythm track more punch. For this purpose, only the Expander/Gate section

is required and the Compressor and Dynamic Enhancer sections are switched off. The bass guitar track is

connected to the audio chain of the BEHRINGER AUTOCOM PRO, while the bass drum is connected to the

SC RETURN input. By activating the SC EXT switch, the bass guitar is now triggered by the bass drum.

Another application allows the sound of the bass drum to be supported or extended by other instruments

(synthesizers etc.), where the bass drum is used to trigger a new sound, which is then mixed into the track.

6. TECHNICAL BACKGROUND

By employing current modern analog technology it is possible to manufacture audio equipment with a dynamic

range of up to 125 dB. In contrast to analog techniques, the dynamic range of digital equipment is

approximately 25 dB less. With conventional record and tape recorder technology, as well as broadcasting,

this value is further reduced. Generally, dynamic restrictions are due to noisy storage and transmission media

and also the maximum headroom of these systems.

6.1 Noise As A Physical Phenomenon

All electrical components produce a certain level of inherent noise. Current flowing through a conductor leads

to uncontrolled random electron movements. For statistical reasons, this produces frequencies within the

whole audio spectrum. If these currents are highly amplified, the result will be perceived as noise. Since all

frequencies are equally affected, we term this white noise. It is fairly obvious that electronics cannot function

without components. Even if special low-noise components are used, a certain degree of basic noise cannot

be avoided.

This effect is similar when replaying a tape. The non-directional magnetic particles passing the replay head can

also cause uncontrolled currents and voltages. The resulting sound of the various frequencies is heard as

noise. Even the best possible tape biasing can only provide signal-to-noise ratios of about 70 dB, which is not

acceptable today since the demands of listeners have increased. Due to the laws of physics, improving the

design of the magnetic carrier is impossible using conventional means.

6.2 What Are Audio Dynamics?

A remarkable feature of the human ear is that it can detect the most wide ranging amplitude changes from the

slightest whisper to the deafening roar of a jet-plane. If one tried to record or reproduce this wide spectrum of

sound with the help of amplifiers, cassette recorders, records or even digital recorders (CD, DAT etc.), one

would immediately be restricted by the physical limitations of electronic and acoustic sound reproduction

technology (see fig. 6.1).

The usable dynamic range of electro-acoustic equipment is limited as much at the low end as at the high end.

The thermal noise of the electrons in the components results in an audible basic noise floor and thus

represents the bottom limit of the transmission range. The upper limit is determined by the levels of the internal

operating voltages; if they are exceeded, audible signal distortion is the result. Although in theory, the usable

dynamic range sits between these two limits, it is considerably smaller in practice, since a certain reserve

must be maintained to avoid distortion of the audio signal if sudden level peaks occur. Technically speaking,

we refer to this reserve as headroom usually this is about 10 - 20 dB (see fig.1.2). A reduction of the

operating level would allow for greater headroom, i.e. the risk of signal distortion due to level peaks would be

reduced. However, at the same time, the basic noise floor of the program material would be increased considerably.

22

6. TECHNICAL BACKGROUND

Page 23

140

120

100

80

60

40

AUTOCOM PRO MDX1400

P/dB

Ear

Microphone Amplifier

Power Amplifier

Tape Recorder

Radio

Cassette

Recorder

Fig. 6.1: The dynamic range capabilities of various devices

It is therefore useful to keep the operating level as high as possible without risking signal distortion in order to

achieve optimum transmission quality.

It is possible to further improve the transmission quality by constantly monitoring the program material with the

aid of a volume fader, which manually levels the material. During low passages the gain is increased, during

loud passages the gain is reduced. Of course it is fairly obvious that this kind of manual control is rather

restrictive; it is difficult to detect signal peaks and it is almost impossible to level them out. Manual control is

simply not fast enough to be satisfactory.

P/dB

+20

-20

0

Headroom

Clipping

Operating level

-40

Effective SNR

-60

-80

Noise floor

t

Fig. 6.2: The interactive relationship between the operating level and the headroom

The need therefore arises for a fast acting automatic gain control system which will constantly monitor the

signals and which will always adjust the gain to maximize the signal-to-noise ratio without incurring signal

distortion. This device is called a compressor or limiter. This system is a part of the BEHRINGER AUTOCOM PRO.

6.3 Compressors/Limiters

By measuring the dynamic range of musical instruments in live recording situations, you will find that extreme

amplitudes occur which often lead to overload in subsequent signal processing equipment. Especially in

broadcasting and record cutting techniques, these signal peaks can lead to heavy distortion. To avoid this kind

6. TECHNICAL BACKGROUND

23

Page 24

AUTOCOM PRO MDX1400

of distortion or, for example, to avoid loudspeakers being damaged by overload, Compressors or Limiters are

used.

The principal function used in these devices is dependent on an automatic gain control as mentioned in the

previous section, which reduces the amplitude of loud passages and therefore restricts the original dynamics

to a desired range. This application is particularly useful in microphone recording techniques, to compensate

for level changes which are caused by varying microphone distances. Although compressors and limiters

perform similar tasks, one essential point makes them different: Limiters abruptly limit the signal above a

certain level, while compressors control the signal gently over a wider range. A limiter continuously monitors

the signal and intervenes as soon as the level exceeds an user-adjustable threshold. Any signal exceeding this