Page 1

Page 2

Forward

Forward

Introduction

Thank you for choosing Behringer, the world’s leading manufacturer of

Pipe and Tube supports. Behringer has been manufacturing pipe

clamps and support systems for over 30 years and has developed a

reputation in the industrial and sanitary markets that is second to none.

We have made developments and product improvements over the years

both strengthening and broadening our product offering. This is evident

in the breadth of our line and ability to accommodate new applications

and designs. Behringer can be counted on for all clamping

requirements.

Product

Behringer Industrial Pipe and Tube Supports have natural vibrationdampening characteristics. This is important in pressure piping in order

to reduce vibration, noise, and shock. This will effectively protect the

system and its sensitive components from the damaging effects of these

adverse system byproducts typically found in pressure piping systems.

Behringer offers many different series and within each series there are

many different configurations available. We offer options for mounting

such as welding, bolting, rail and strut mounting, double and group

mounting, etc. Behringer always welcomes a challenge and would be

happy to work with you to design a product that is custom-tailored to

any application. This is where many of our developments are first

generated and helps to further progress the complexity of our product.

Challenge us with your requirements.

Applications

Behringer clamps are used in may different types of applications

ranging from low pressure lubrication and water systems to high

pressure hydraulic and process systems. Anywhere that there are

pipes, tubes, or hoses is a viable application for Behringer clamps.

Behringer clamps are most frequently used in the following markets

and applications:

Mobile Equipment Power Generation

Mining Equipment Pulp and Paper

Offshore and Marine Applications Industrial Hydraulics

Shipbuilding Power Units

Instrumentation Agricultural Equipment

Nuclear OEM Machinery

General Construction

Electrical / Mechanical Contracting

Process Piping

Pharmaceutical / Biotechnology

Food and Dairy

Beverage

Assistance

Behringer Corporation has a competent and highly skilled staff of

inside sales and customer service personnel available to assist you

with any of your needs. Behringer can be reached in the following

ways:

Guarantee

Behringer Corporation, hereinafter called the “MANUFACTURER”,

guarantees that the product shall be free from defects in workmanship

and materials. THIS GUARANTEE IS IN LIEU OF ALL OTHER

GUARANTEES EITHER EXPRESSED OR IMPLIED, INCLUDING

GUARANTEES FOR FITNESS FOR PURPOSE INTENDED. The

MANUFACTURER'S liability is limited to the replacement of any

materials which, after inspection by the MANUFACTURER at its sole

option are found to be defective. The MANUFACTURER will honor

only those claims that are presented to it within one hundred eighty

(180) days of the delivery of the materials to the purchaser. The

MANUFACTURER SPECIFICALLY DISCLAIMS ANY AND ALL

LIABILITY FOR CONSEQUENTIAL DAMAGES. The

MANUFACTURER shall not be liable for any damages which arise

out of the misuse or abuse of the products.

Post Mail: Behringer Corporation

17 Ridge Road

Branchville, NJ 07826

Telephone: +1 (973) 948-0226

Fax: +1 (973) 948-2562

Email: cserv@behringersystems.com

Our regular business hours are Monday through Friday, 8AM - 5 PM

Eastern Time. For after hours service, please contact your regional

sales manager.

Please Read

The information contained in this document is provided as an aid in

properly selecting products and/or options. It is intended to be used by

technically experienced users for general reference only. The supplier

assumes no responsibility or liability for the accuracy or completeness

of this document, as well as results obtained by the use of this

information. Due to the variety of possible operating conditions, it is

highly recommended that the user make their own tests to determine

the safety and suitability of all products and combinations thereof.

The user is solely responsible for final determination of such

conditions.

Page 3

Table of Contents

Table of Contents

Pipe Clamp Selection 2 - 3

Pipe Clamp Series Specifications 4 - 5

Standard Series Pipe Clamps

Clamp Pair Selection and Part Numbers 6

Clamp Pair Dimensional Information 7

Securing Plate Selection and Dimensions 8

Rail and Strut Mounting Options 9

Cover and Stacking Component Selection and Dimensions 10

Complete Assembly Ordering Code 11

Ordering Examples 12

Heavy Series Pipe Clamps

Clamp Pair Selection and Part Numbers 13

Clamp Pair Dimensional Information 14

Securing Plate Selection and Dimensions 15

Fastening Hardware Selection and Dimensions 16

Rail and Strut Mounting Options 17

Complete Assembly Ordering Code 18

Ordering Examples 19

Twin Series Pipe Clamps

Clamp Pair Selection, Part Numbers and Dimensions 20

Hardware Selection and Dimensions 21

Rail and Strut Mounting Options 22

Complete Assembly Ordering Code 23

Ordering Examples 24

Heavy-4 Series Pipe Clamps

Clamp Pair Selection, Part Numbers and Dimensions 25

Hardware Selection and Dimensions 26

Complete Assembly Ordering Code & Ordering Examples 27

Saddle Series Pipe Clamps

Long Saddle U-Bolt Clamp 28

Short Saddle U-Bolt Clamp 29

Cushioned Clamping System

Cushioned Clamping System 30

Technical Appendix

Material Properties Technical Data 31

Tightening Torques and Maximum Loads 32

Recommended Spacing 33

Page

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

1

Page 4

Pipe Clamp Selection

Pipe Clamp Selection

Behringer’s pipe clamps are available with many different mounting

configurations and arrangements. In choosing a pipe clamp, there are

five required pieces of information: series, size, clamp pair material,

hardware material and mounting/hardware configuration.

Series Selection

In order to select the proper clamp, the first thing that must be

determined is the series of clamp to be used. Refer to pages 4-5 on

Series Specifications to see what clamp series are available, as well as

the technical characteristics of those series. The most important

factors to be considered are the operating pressure of the line to be

secured, the weight being supported, and the dynamic load. Other

considerations include size, environment, and application. For

example, a 1 in. pipe for a hydraulic system operating at 2,000 psi

would typically require the use of the standard series, but the heavy

series may be selected if it will be required to support the weight of a

large filter or other system component. Maximum weight loads and

shearing forces can be found in the Technical Appendix (pg 32). Also,

the heavy series might be selected rather than the standard series if the

line is on a piece of mining or mobile equipment that may see a very

high amount of impact with other equipment or materials such as

stones and metals. In Fig. 1 below, you can see the suggested operating

pressures by series. These suggested values take into consideration the

shock and vibration that a typical hydraulic system operating at these

pressures can deliver.

Fig. 1: General Pressure Guidelines by Series

Series Suggested Operating Pressure

Standard up to 2000 psi

Heavy 5000 psi for single heavy/10,000 psi for double

Twin up to 1500 psi

Heavy 4 5000 psi for single heavy/10,000 psi for double

Size

The next important factor in the selection of the pipe clamp is the size

of the line to be secured. Behringer clamps use a modular group size

that consists of multiple OD sizes being available within the same

group. Clamps are listed as pipe or tube sizes. The difference is in the

standard measurements used to rate pipe and tubing sizes. Pipe is

rated by the inside diameter, and will have a larger outside diameter

because of the wall thickness. For example, a 1 in. pipe has an OD of

1.315. This is a standard pipe OD size and is consistent of all

hydraulic pipe, regardless of schedule. Tubing, on the other hand, is

rated by the outside diameter. Therefore, a 1 in. tube will have an OD

of 1.00 in. This is important in determining the size of the pipe clamp

that will be selected. Also, the size may determine the series of clamp

selected. For example, in a 6 in. pipe size with a low pressure line

operating at 1,500 psi the Heavy Series must be used as it’s not

available in the Standard Series.

Clamp Pair Material

The clamp pair material is the next thing that should be selected.

Behringer’s clamp pairs are offered in different materials: Polypropylene

(PP), Santoprene (SP), Aluminum (AL), HDPE (NN) and High

Temperature Cast Nylon (HT). The single most important determining

factor of clamp pair material is operating temperature. The temperature

ratings and other important specifications can be found in the Technical

Appendix (pg 31). Some materials are not available in all sizes or all

series. Refer to the specific clamp pair selection charts from each series

to see what is available in the required size. Other considerations for

materials are compatibility with the environment and for aesthetic

reasons.

Hardware Material

Once you have determined the series of pipe clamp and the size that is

required, the next step is to determine the hardware materials that you

will require. In the series specification pages (pg 4 - 5), you will see that

each series has a standard hardware material type. See Fig. 2 for

standard hardware choices. The standard hardware is either plain carbon

steel or zinc plated steel. All Behringer clamps that are zinc plated use a

trivalent blue zinc plating, which is more environmentally friendly than

typical hexavalent zinc plating, and is RoHS compliant. In addition to

the standard hardware choices, Behringer offers stainless steel in 2

grades from stock. AISI 304 Stainless Steel (A2 - 1.4301/1.4305) is used

in applications where stainless steel is required. This may be in an

outside environment, because of chemical compatibility reasons, or

because of requirements from the FDA or other regulatory committee.

AISI 316 Ti Stainless Steel (A4 - 1.4401/1.4571) is a high grade

stainless steel. The 316 Stainless is used in applications where it will

come in contact with salt water or air with a high salt concentration such

as offshore or marine applications.

Fig. 2: Standard Hardware Material by Series

Series Code Material

Standard Z Zinc Plated Steel

Heavy C Plain Carbon Steel

Twin Z Zinc Plated Steel

Heavy 4 C Plain Carbon Steel

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

2

Page 5

Pipe Clamp Selection

Pipe Clamp Selection

Mounting / Hardware Configuration

Behringer offers a multitude of mounting configurations and

arrangement styles. Clamps can be mounted to the support structure by

either welding, bolting, rail-mounting, strut mounting, or stanchion and

special securing plates. In addition, clamps can be stacked on top of each

other, suspended from threaded rods, or any number of double and group

positions can be made on multiple clamp weld plates, called Group Weld

Plates (GRW). These options are not available for every series. Please

check the ordering code for available mounting and hardware

configurations. Here are some examples of these mounting types.

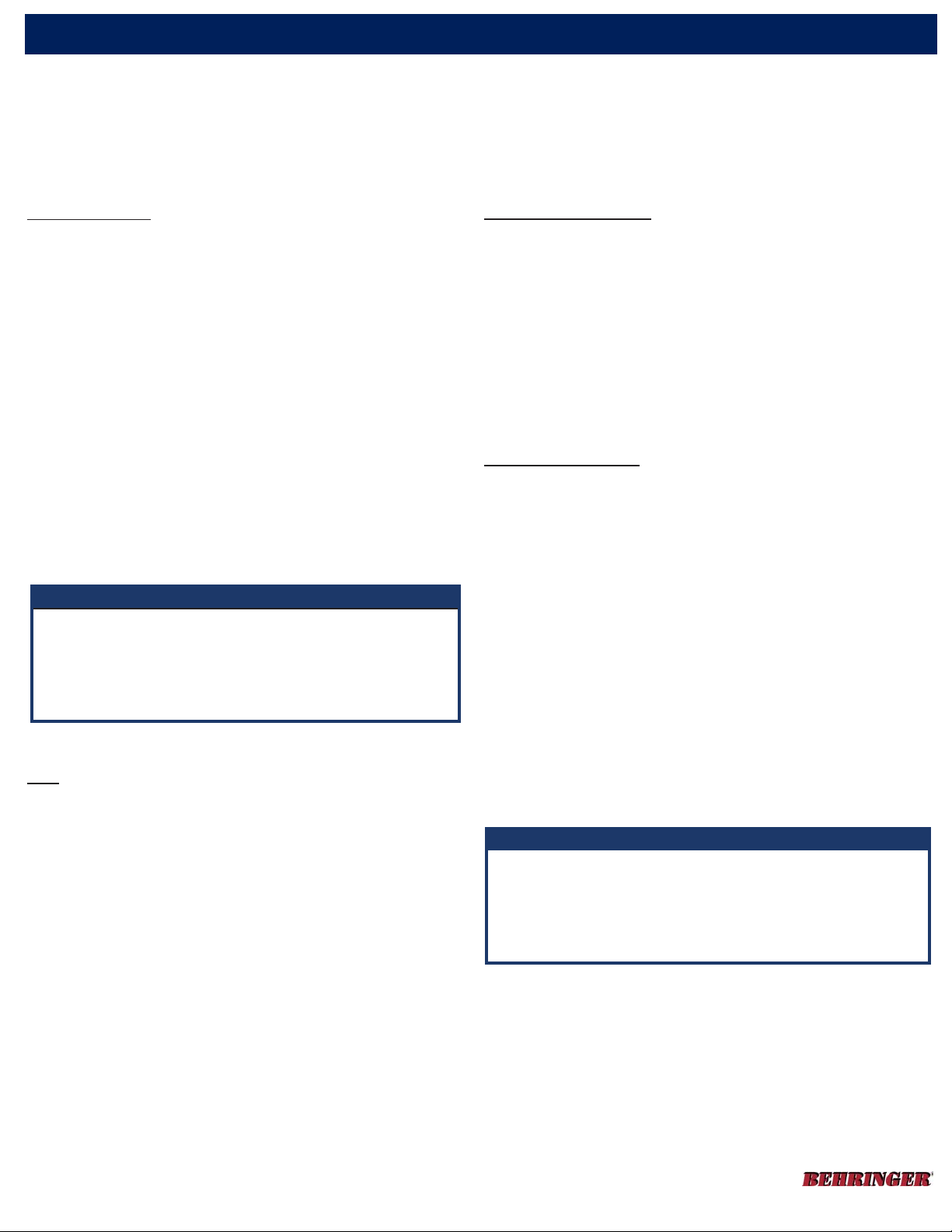

Weld Mounting [STW, SWP, TWP]

Clamps are supplied with a weld plate for welding

directly to the support structure. This is the most common

form of clamp mounting and it is available in all series of

pipe clamps. It is typically used with a cover plate and

bolts and it is a commonly stocked item.

Standard Series: STW

Heavy Series: SWP / DWP

Twin Series: TWP

Heavy 4 Series: SWP / DWP

Bolt Mounting with Base Plates [BAP]

Clamps are supplied with a base plate for applications

where the clamp cannot be welded into position. This is

commonly used to mount the clamps to non-metallic

surfaces such as wood or drywall. However, base plates

can be welded into position if required. Base plates are

only available in the standard series and are available

from stock.

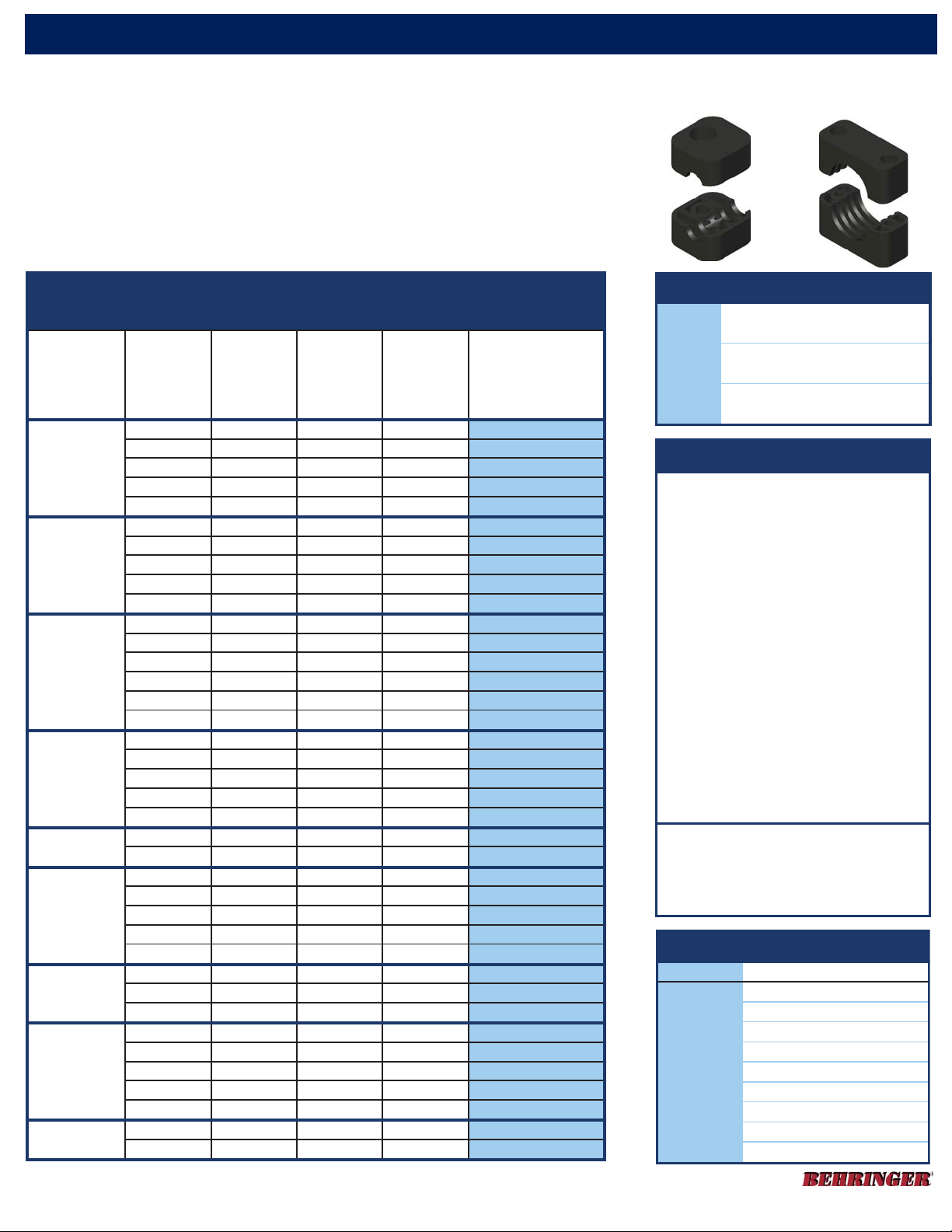

Rail Mounting [RCN, RAL]

Rail mounting makes installation of multiple lines of

different group sizes an easy task. All clamps within

one series can be mounted directly to a single

channel using rail nuts that are designed for that rail.

Behringer also makes proprietary rails that can

accept the weld plates rather than the rail nuts

[RCN]. The rail uses are as follows.

RAL-0 Standard and Twin Series Clamps with

RCN-0 (standard) / RCN-T0 (twin)

RAL-1 Standard and Twin Series with STW or

RCN-1 (standard) / RCN-4 (twin)

RAL-2 Heavy Series Clamps with SWP (H3-H5)

RAL-3 Heavy Series Clamps with SWP (H6)

RAL-4 Heavy Series Clamps with RCN

Strut Mounting [UCN]

Behringer clamps can also be supplied with strut

nuts [UCN] for mounting to standard strut channel.

The new spring-loaded nuts are adaptable to any

strut channel that is 1-5/8” wide. The depth of the

channel is not important as the UCN clips attach with

spring loaded tension on the top of the channel. Strut

adaptation is available for all series of pipe clamps.

Multiple Clamp Weld Plates [DOW, GRW]

For multiple lines, Behringer offers double weld plates

or group weld plates. The double weld plates create a

double clamp that allows the convenience of welding

only one plate, but the strength and durability of using

standard series hardware with individual clamp halves

and four hex bolts. Group weld plates can accommodate

between 3-10 positions, depending on the application.

This is beneficial for keeping a tightly regimented center

distance on the piping or tubing where multiple lines are

run along the same plane. For both the double and group

weld plates, all clamps to be fitted to the same plate must

be within the same hardware group size.

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

3

Stacking Kits

Stacking kits consist of a set of clamp halves,

stacking bolts, and a safety plate. A stacking kit is

everything that is needed to take an existing clamp

and make it one level taller. You use the hardware

from the existing clamp; remove the cover plate,

clamp halves, and hex bolts from the existing clamp,

insert the stacking kit onto the bottom fixture (weld

plate, rail nuts, etc...), and then replace the existing

clamp hardware on top. Multiple stacking kits can be

added to increase the number of clamps stacked on

top of each other. Stacking kits are available in all

series.

Page 6

Pipe Clamp Series Specifications

Pipe Clamp Series Specifications

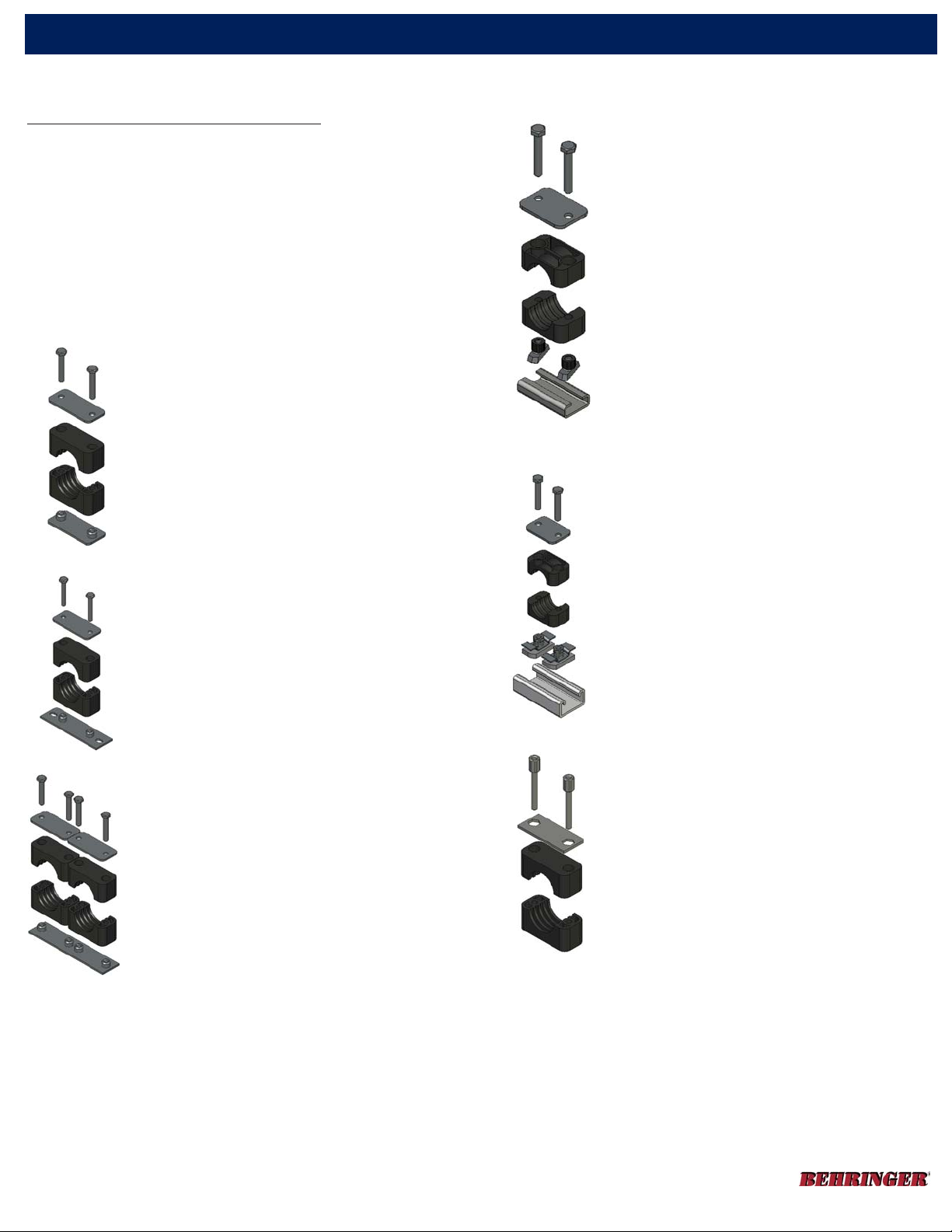

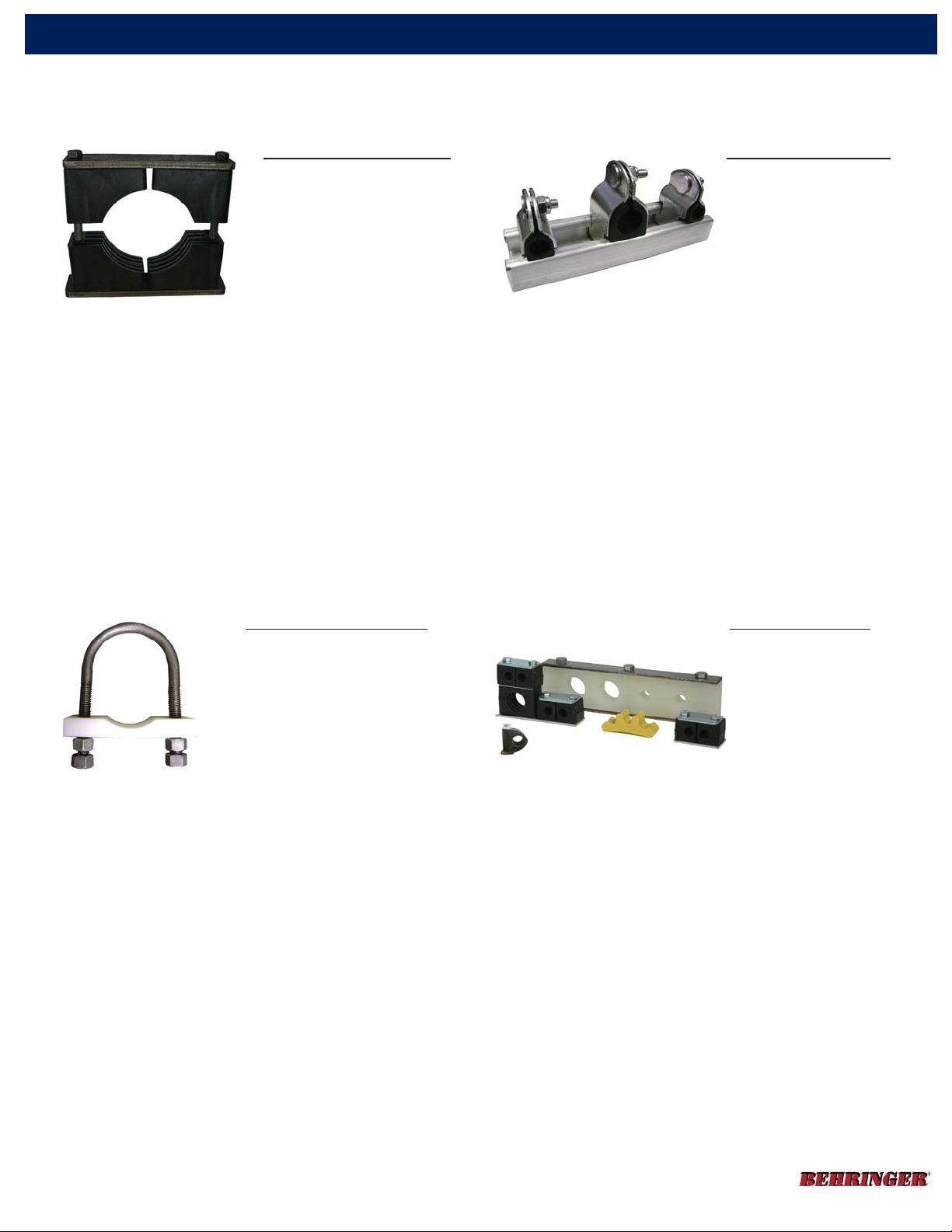

Vibration-Dampening Pipe Clamps

Behringer’s vibration-dampening pipe clamps are manufactured in

different series for use in many different applications. The core range

of pipe clamps encompasses Standard Series, Heavy Series, and Twin

Series. They meet ASTM, Shipbuilding, Nuclear, Coast Guard, and

other specifications.

In addition to these main types of pipe clamps, Behringer also

manufactures other clamping components and hardware. For large

diameter pipes, Behringer’s patented Heavy Four Series offers

unparalleled performance in securing and vibration dampening, as well

as electrical isolation of piping from support structure. We offer plastic

saddle clamps and U-bolts as well. Behringer has its roots in the metal

fabrication business and we can easily manufacture customer-specific

fabricated metal or injection molded products. We currently

manufacture many other items for OEMs that are specially designed for

that specific customer. We work closely with key personnel in the

research and design stages and can make prototypes in a very short

time. Let us know what we can do for you.

Heavy Series Pipe Clamps

Range: 0.25 in. (6.4 mm) through

8.625 in. (219 mm)

Pressure: 5,000 to 10,000 psi

Material: Plain Carbon Steel,

304SS, 316SS, Zinc Plated

Clamp Halves: Polypropylene,

Santoprene, Aluminum

Heavy series pipe clamps can withstand the shock and vibration that a

hydraulic system operating at up to 5,000 psi can deliver. With the use

of our Double Heavy design, lines with operating pressure of up to

10,000 psi can be accommodated. Standard hardware material is plain

carbon steel. Also available from stock are 304SS and 316SS hardware.

The heavy series can be mounted using a weld plate, rails, and stacking

kits. Many other options are possible with existing hardware and custom

arrangements are always a possibility.

Standard Series Pipe Clamps

Range: 0.25 in. (6.4 mm) through

4 in. (102 mm) OD

Pressure: 2,000 psi maximum

Material: Zinc Plated, 304SS,

316SS, Plain Carbon Steel

Clamp Halves: Polypropylene,

Santoprene, Aluminum

Standard series pipe clamps can withstand the shock and vibration that

a hydraulic system operating at up to 2,000 psi can deliver. Standard

hardware material is zinc plated steel, unless otherwise noted. Also

available from stock are 304SS and 316SS hardware. The standard

series is offered in a multitude of configurations, such as weldmounting, bolt-mounting, rail mounting, stacking, double weldmounting, and group weld-mounting. Many other options are possible

with existing hardware and custom arrangements are always a

possibility.

Twin Series Pipe Clamps

Range: 0.25 in. (6.4 mm) through

1.66 in. (42 mm)

Pressure: 1,500 psi maximum

Material: Zinc Plated, 304SS,

316SS, Plain Carbon Steel

Clamp Halves: Polypropylene,

Santoprene

The twin series is an excellent choice where multiple lines are required,

while keeping a close center distance between the lines. Twin series

pipe clamps can withstand the shock and vibration that a hydraulic

system operating at up to 1,500 psi can deliver. Twin series hardware

material is zinc plated steel. Also available from stock are 304SS and

316SS hardware. The twin series can be mounted using a weld plate,

rails and stacking kits. Many other options are possible with existing

hardware and custom arrangements are always a possibility.

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

4

Page 7

Pipe Clamp Series Specifications

Pipe Clamp Series Specifications

Pipe Clamps

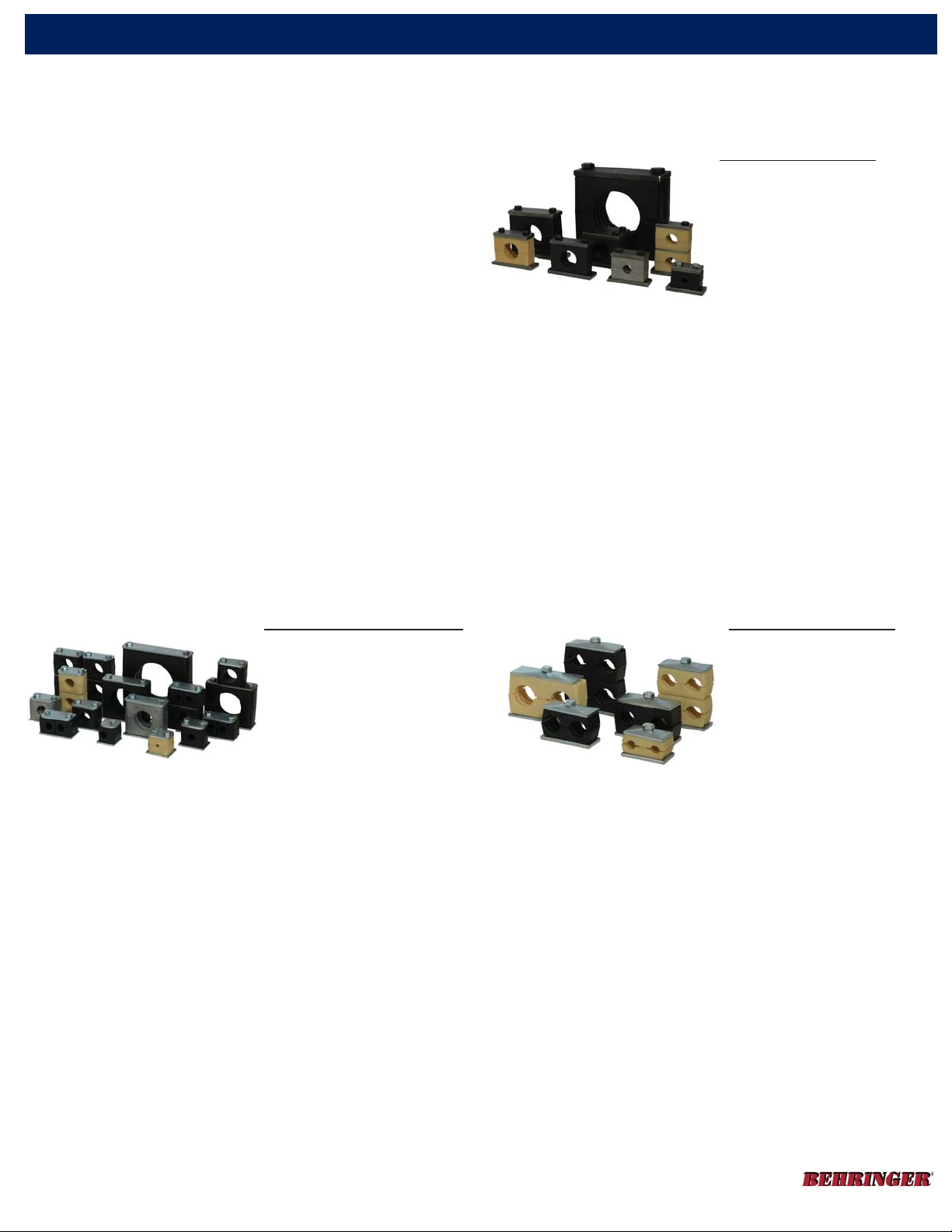

Heavy 4 Series Pipe Clamps

Range: 8.625 in. (219 mm)

through 30 in. (762 mm) OD

Pressure: 5,000 psi to 10,000 psi

Material: Plain Carbon Steel,

304SS, 316SS, Zinc Plated

Clamp Halves: Polypropylene

Others on request

Behringer’s patented Heavy 4 Series pipe clamps are unrivaled in design

and performance. Our clamps feature a unique 4-segmented plastic

design which retains dimensional accuracy, resists stress and impact,

absorbs vibration, and accomplishes a strong plastic-to-metal contact

interface. This segmented plastic design is complemented by substantial

steel support hardware.

Heavy 4 Series pipe clamps can withstand the shock and vibration that a

hydraulic system operating at up to 5,000 psi can deliver and with the

use of our double heavy design they can accommodate lines with

pressures up to 10,000 psi. Standard hardware material is a low carbon

steel. Also available are 304SS and 316SS as well as zinc plated

hardware. The Heavy 4 Series is only offered as a weld mounted clamp.

Cushioned Pipe Clamps

Range: 0.25 in. (6.4 mm) through

6.625 in. (168 mm) OD

Pressure: Low pressure

Material: Zinc Plated, 304SS,

316SS

Clamp Insert: Thermoplastic

Elastomer

Behringer’s new line of cushioned clamps are designed for low

pressure applications such as conduit, water, waste and other non or

low pressure lines. They easily mount to standard strut channels that

are available in many industrial and mobile applications. The standard

hardware material is zinc plated steel. Also available are 304SS and

316SS. The cushion is manufactured from a thermoplastic elastomer

material that is designed to reduce vibration and noise, while

providing constant reliability in operating temperatures to 275º F.

Saddle Series Pipe Clamps

Range: 0.84 in. (21 mm) through 30

in. (762 mm)

U-Bolt Material: Zinc Plated,

304SS, 316SS, Plain Carbon Steel

Saddle Material: Polypropylene,

UHMW

The Saddle Series pipe clamps consist of a heavy duty plastic saddle,

and a U-bolt with 4 hex nuts. The saddle series allows for movement due

to vibrations and thermal expansion and contraction. The plastic saddle

eliminates the metal-to-metal contact of the piping from the support

structure, preventing costly damage to pipe installations. Behringer’s

Saddle Series clamps are typically used in shipbuilding, offshore and

marine vessels, chemical plants, or where ever large diameter, low

pressure piping is installed. Behringer’s saddle clamps are available in 2

different designs; Long Saddle and Short Saddle. The Long Saddle

(shown above) extends past the u-bolt legs and has holes for the legs to

be inserted into. The Short Saddle does not extend to the u-bolts and sits

on the support structure or is held in place with location nipples.

Custom Pipe Clamps

Range: Any

Pressure: Any

Material: Any

Clamp Insert: Any

Customization is an easy task for Behringer’s vast experience in

custom metal fabrication and injection molding. If you have ideas

about a custom-made product, we can easily and quickly take concepts

and turn them into prototypes and ultimately production items.

Behringer currently manufactures custom products for major OEM

manufacturers in the mobile, offshore, industrial and construction

markets. Some custom items are a variation of a standard item and

others are completely different from our cataloged items. Let

Behringer work for you to help resolve any of your fastening or

clamping requirements.

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

5

Page 8

Standard Series Pipe Clamps

Clamp Pair Selection

Industrial Pipe Clamps

Behringer’s clamp pairs are available in different materials and incorporate a modular insert

by group size. Standard series pipe clamps are available in sizes from ¼ in. (6.35mm)

Group 0

Group 1-7A

through 4-1/4 in. (114.3mm) OD Sizes.

Clamp Pair Material Codes (*)

Behringer

Group

Clamp Pair Selection and Part Numbers

Pipe Size Tube Size

Metric

ØD (mm)

Imperial

ØD (Inch)

Clamp Pair P/N

(See material

code for *)

P [PP] Polypropylene

Black Color

S [SP] Santoprene

Beige Color

A [AL] Aluminum

Aluminum Color

1/4 6.4 0.250 ST-CLH-00-*-025

3/8 9.5 0.375 ST-CLH-00-*-038

0

1

2

3

4

5

6

7

7A

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

1/8 10.0 0.405 ST-CLH-00-*-041

1/2 12.7 0.500 ST-CLH-00-*-050

5/8 16.0 0.620 ST-CLH-00-*-062

1/4 6.4 0.250 ST-CLH-01-*-025

8.0 0.315 ST-CLH-01-*-032

/8 9.5 0.375 ST-CLH-01-*-038

3

1/8 10.0 0.405 ST-CLH-01-*-041

12.0 0.472 ST-CLH-01-*-047

3/8 9.5 0.375 ST-CLH-02-*-038

1/2 12.7 0.500 ST-CLH-02-*-050

1/4 14.0 0.540 ST-CLH-02-*-054

15.0 0.591 ST-CLH-02-*-

059

5/8 16.0 0.620 ST-CLH-02-*-062

3/8 17.1 0.675 ST-CLH-02-*-068

18.0 0.709 ST-CLH-03-*-070

3/4 19.0 0.750 ST-CLH-03-*-075

1/2 21.3 0.840 ST-CLH-03-*-084

7/8 22.2 0.870 ST-CLH-03-*-087

1 25.4 1.000

ST-CLH-03-*-100

3/4 26.7 1.050 ST-CLH-04-*-105

1 1/8 28.6 1.125 ST-CLH-04-*-112

1 1/8 28.6 1.125 ST-CLH-05-*-113

1 1/4 32.0 1.250 ST-CLH-05-*-125

1 33.4 1.315 ST-CLH-05-*-132

1 1/2 38.1 1.500 ST-CLH-05-*-150

1 1/4 42.2 1.660 ST-CLH-05-*

-166

1 3/4 44.5 1.750 ST-CLH-06-*-175

1 1/2 48.3 1.900 ST-CLH-06-*-190

2 50.8 2.000 ST-CLH-06-*-200

2 1/4 57.2 2.250 ST-CLH-07-*-225

2 60.3 2.375 ST-CLH-07-*-238

2 1/2 73.0 2.875 ST-CLH-07-*-288

376.2 3.000 ST-CLH-07-*-300

33 1/2

88.9 3.500 ST-CLH-07-*-350

4 102.0 4.000 ST-CLH-7A-*-400

4 4 1/2 114.3 4.500 ST-CLH-7A-*-450

6

Custom sizescanbemade by specially

boring the clamppair to any desiredsize.

To order a special size, first find the

group that this will fall under. All groups

areavailable starting with 1/4 in.ODand

canbe useduptothe maximumODsize

in the chart below. This is expressedin

th

e part number as a two-digit number

(G#). Once thegroup size hasbeen

determined, simply add the desired OD

of theline to be securedinthe3digit end

numberofthe clamppair (XXX) by

rounding the number to two decimals and

dropping

numberwill looklike this:

ST-CLH-G#-*-XXX

Example: For aline wih OD of 1.08 in.,

this wouldfall within thegroup 4. The

Part numberwill beasfollows:

ST-CLH-04-*-108

Special Bore Range by Group

Group (G#) Range

00

01

02

03

04

05

06

07

7A

Custom Sizes

the decimal point. The part

0.25 in through 0.620 in.

0.25 in through 0.405 in.

0.25 in through 0.675 in.

0.25 in through 1.000 in.

0.25 in through 1.125 in.

0.25 in through 1.660 in.

0.25 in through 2.000 in.

0.25 in through 3.240 in.

0.25 in through 4.500 in.

Page 9

Standard Series Pipe Clamps

Clamp Pair Dimensions

Dimensions for the clamp pairs can be found at the right and in the chart below.

As a general rule of thumb, the outside diameter of the line to be secured

should not vary over or under the ØD dimension in the chart by more than ½

of the tension clearance dimension, or no more than 0.015 in. If an acceptable

size is not available, custom sizes can be made to order.

Clamp Pair Dimensional Information

Group 0

Industrial Pipe Clamps

Group 1-7A

Behringer

Group

0

1

2

3

4

5

6

7

7A

Metric

ØD (mm)

6.40 0.250 ST-CLH-00-*-025

9.50 0.375ST-CLH-00-*-038

10.00 0.405 ST-CLH-00-*-041

12.70 0.500 ST-CLH-00-*-050

16.00 0.620 ST-CLH-00-*-062

6.40 0.250 ST-CLH-01-*-025

8.00 0.315 ST-CLH-01-*-032

9.50 0.375ST-CLH-01-*-038

10.00 0.405 ST-CLH-01-*-041

12.00 0.472ST-CLH-01

9.50 0.375ST-CLH-02-*-038

12.70 0.500 ST-CLH-02-*-050

14.00 0.540 ST-CLH-02-*-054

15.00 0.591 ST-CLH-02-*-059

16.00 0.620 ST-CLH-02-*-062

17.10 0.675ST-CLH-02-*-068

18.00 0.709 ST-CLH-03-*-070

19.00 0.750 ST-CLH-03-*-075

21.300.8

22.20 0.870ST-CLH-03-*-087

25.40 1.000 ST-CLH-03-*-100

26.70 1.050 ST-CLH-04-*-105

28.60 1.125 ST-CLH-04-*-112

28.60 1.125 ST-CLH-05-*-113

32.00 1.250 ST-CLH-05-*-125

33.4 1.315 ST-CLH-05-*-132

38.1 1.500 ST-CLH-05-*-150

42.2 1.660 ST

44.5 1.750 ST-CLH-06-*-175

48.3 1.900 ST-CLH-06-*-190

50.8 2.000 ST-CLH-06-*-200

57.2 2.250 ST-CLH-07-*-225

60.3 2.375ST-CLH-07-*-238

73 2.875ST-CLH-07-*-288

76.2 3.000 ST-CLH-07-*-300

88.9 3.500 ST-CLH

102 4.000 ST-CLH-7A-*-400

114.3

Imperial

ØD (Inch)

40 ST-CLH-03-*-084

4.500 ST-CLH-7A-*-450

Clamp Pair P/N

(See page 6 for complete

order numbers)

-*-047

-CLH-05-*-166

-07-*-350

L W H O C Weight Ea.

1.125 in.

(28.6 mm)

1.375 in.

(35 mm)

1.625 in.

(42 mm)

1.875 in.

(48 mm)

2.250 in.

(57 mm)

2.750 in.

(70 mm)

3.375 in.

(86 mm)

5.000 in.

(127 mm)

5.750 in.

(146 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31mm)

1.125 in.

(28.6 mm)

1.375 in.

(35 mm)

1.375 in.

(35 mm)

1.375 in.

(35 mm)

1.625 in.

(42 mm)

2.375 in.

(60 mm)

2.625 in.

(67 mm)

4.375 in.

(111 mm)

4.82

8 in.

(123 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.031 in.

(0.8 mm)

0.375 in.

(9.5 mm)

0.790 in.

(20 mm)

1.020 in

(26 mm)

1.300 in.

(33 mm)

1.580 in.

(40 mm)

2.050 in.

(52 mm)

2.600 in.

(66 mm)

4.250 in.

(108 mm)

4.948 in.

(126 mm)

0.02 lbs

0.03 lbs

0.04 lbs

0.05 lbs

0.06 lbs

0.11 lbs

0.12 lbs

0.41 lbs

0.39 lbs

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

7

Page 10

Standard Series Pipe Clamps

s

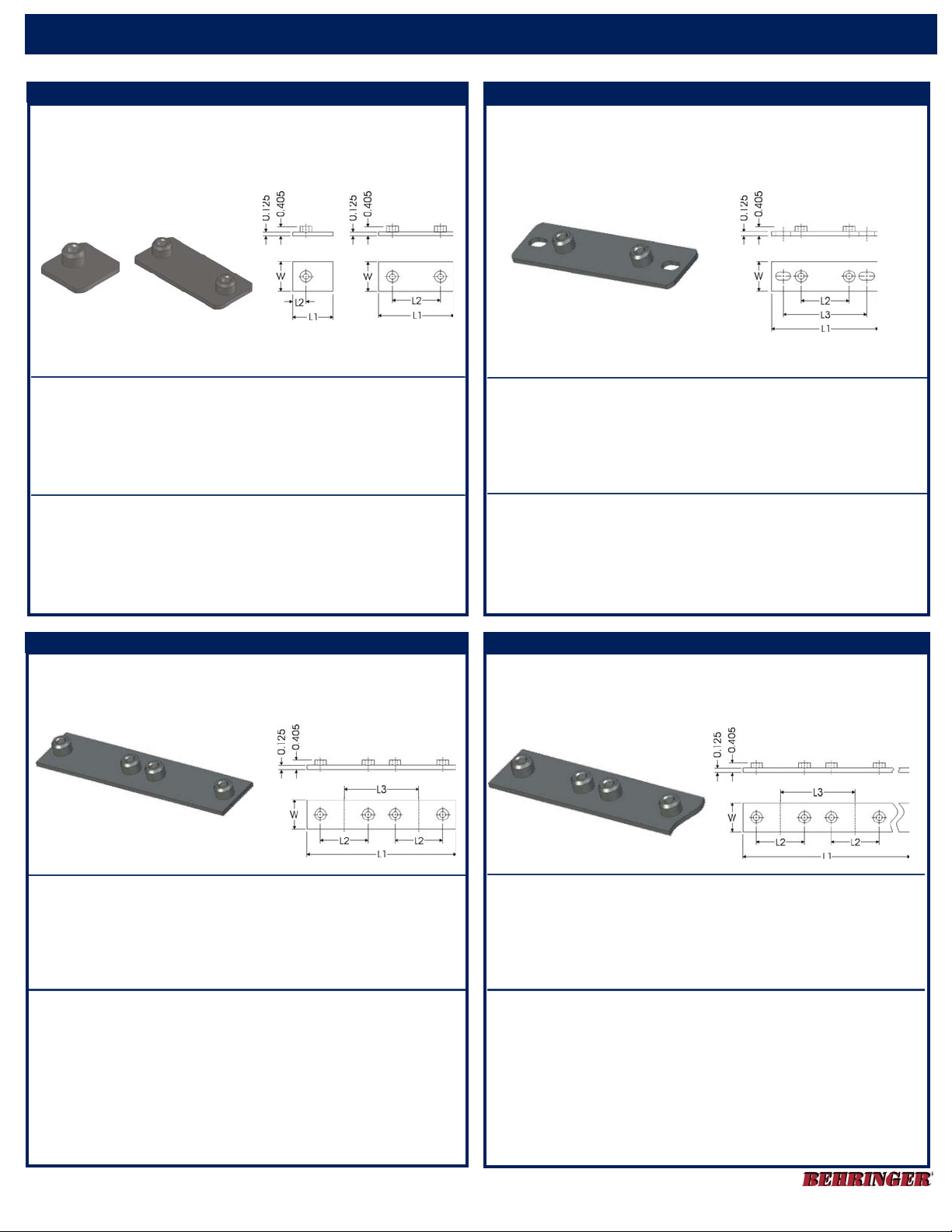

Securing Plate Selection and Dimensions

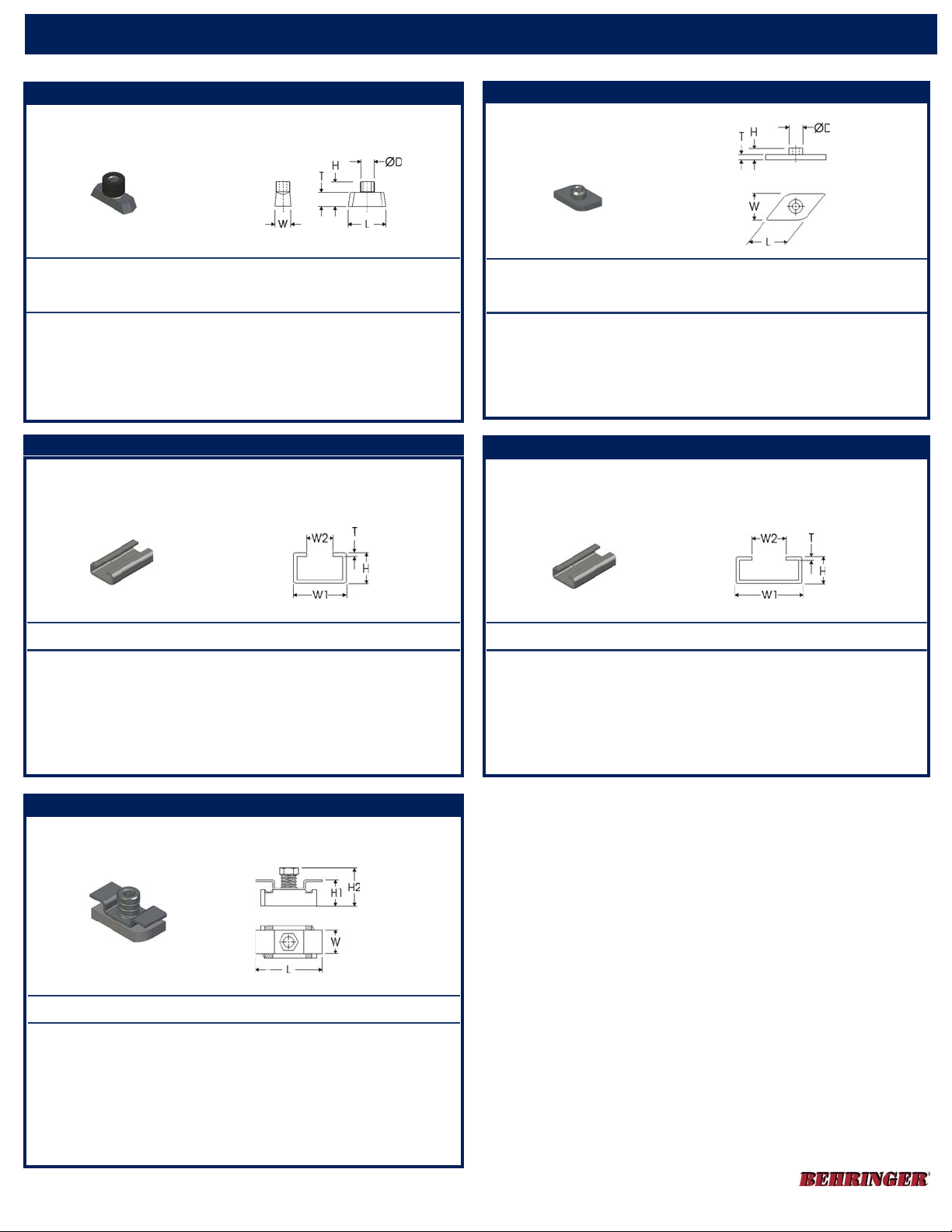

Weld Plate [STW]

The typical mounting configuration is one where the clamp is welded

to the support structure. Weld plates can also be used in the RAL-1

mounting rail as an alternative to using the RCN-1 rail nuts.

Group 0

Group 1-7A

Industrial Pipe Clamps

Base Plate [BAP]

The versatile base plate can be either welded or bolted to the

structure. This is typically used where welding is not an option such

as on drywall or wood support structures.

Group Order Number L1 L2 W Weight

0

ST-STW-00-*

1

ST-STW-01-*

2

ST-STW-02-*

3

ST-STW-03-*

4

ST-STW-04-*

5

ST-STW-05-*

6

ST-STW-06-*

7

ST-STW-07-*

7A

ST-STW-7A-*

*Materials: Z Zinc Plated Steel (Standard Material)

Threads: omit A

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C Plain Carbon Steel (Special Order)

-MET

1.188 in. (30 mm) 0.420 in. (11 mm) 0.06 lbs.

1.510 in. (38 mm) 0.790 in. (20 mm) 0.07 lbs.

1.740in. (44 mm) 1.020 in. (26 mm) 0.08 lbs.

2.020 in. (51 mm) 1.300 in. (33 mm) 0.10 lbs.

2.

300 in. (58 mm) 1.580 in. (40 mm) 0.11 lbs.

2.770 in. (70 mm) 2.050 in. (52 mm) 0.13 lbs.

3.320 in. (84 mm) 2.600 in. (66 mm) 0.15 lbs.

4.970 in. (126 mm) 4.250 in (108 mm) 0.21 lbs.

5.776 in. (147 mm) 4.948 in (126 mm) 0.2

s ordered above, the weld plates have standard 1/4 - 20 UNC thread

By adding the "-MET" designation after the material designation above, the

threads are M6 metric thread

1.223 in

(31 mm)

7 lbs.

Double Weld Plate [DOW]

Double weld plates allow for runs of two lines side by side, while

keeping center distances aligned and reducing installation time

required.

Group Order Number L1 L2 L3 W Weight

0 N/A -- -

1

ST-BAP-01-*

2

ST-BAP-02-*

3

ST-BAP-03-*

4

ST-BAP-04-*

5

ST-BAP-05-*

6

ST-BAP-06-*

7

ST-BAP-07-*

7A

ST-BAP-7A-* 7.188 in. (183

*Materials: Z Zinc Plated Steel (Standard Material)

Threads: omit As ordered above, the weld plates have standard 1/4 - 20 UNC thread

-MET

3.000 in. (76 mm) 0.790 in. (20 mm) 1.750 in. (44 mm)

3.250 in. (83 mm) 1.020 in. (26 mm) 2.000 in. (51 mm)

3.500 in. ( 89 mm) 1.300 in. (33 mm) 2.250 in. (57 mm)

(97 mm) 1.580 in. (40 mm) 2.563 in. (65 mm)

3.813 in.

4.250 in. (108 mm) 2.050 in. (52 mm) 3.000 in. (76 mm)

4.875 in. (124 mm) 2.600 in. (66 mm) 3.625 in. (92 mm)

6.500 in. (165 mm) 4.250 in. (108 mm) 5.250 in. (133 mm)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C Plain Carbon Steel

By adding the "-MET" designation after the material designation above, the thread

are M6 metric thread

mm) 4.948 in. (126 mm) 5.938 in. (171 mm)

(Special Order)

--

0.13 lbs.

0.14 lbs.

0.16 lbs.

0.16 lbs.

1.223 in.

(31 mm)

0.19 lbs.

0.20 lbs.

0.27 lbs.

0.35 lbs.

Group Weld Plate [GRW]

Group weld plates allow for runs of multiple lines side by side, while

keeping regimented center distances and reducing installation time

required. GRWs can run from 3 to 27 positions, depending on the

group size and are typically unplated.

Group Order Number L1 L2 L3 W Weight

0 N/A

1 ST-DOW-01-* 3.00 in. (76 mm) 0.790 in. (20 mm) 1.51 in. (38 mm)

2 ST-DOW-02-* 3.50 in. (89 mm) 1.020 in. (26 mm) 1.74 in. (44 mm)

3 ST-DOW-03-* 4.00 in. (102 mm) 1.300 in. (33 mm) 2.02 in. (51 mm)

4 ST-DOW-04-* 4.69 in. (119 mm) 1.580 in. (40 mm) 2.30 in.

5 ST-DOW-05-* 5.63 in. (143 mm) 2.050 in. (52 mm) 2.77 in. (70 mm)

6 ST-DOW-06-* 6.88 in. (175 mm) 2.600 in. (66 mm) 3.32 in. (84 mm)

7 ST-DOW-07-* 10.22 in. (260 mm) 4.250 in. (108 mm) 5.24 in. (133 mm)

7A ST-DOW-7A-* 11.69 in. (297 mm) 4.948 in. (126 mm)

*Materials: Z Zinc Plated Steel (Standard Material)

Threads: omit As ordered above, the weld plates have standard 1/4 - 20 UNC thread

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C Plain Carbon Steel (Special Order)

By adding the "-MET" designation after the material designation above, the

-MET

threads are M6 metric thread

6.02 in. (153 mm)

(58 mm)

1.223 in.

(31 mm)

0.16 lbs

0.17 lbs

0.19 lbs

0.24 lbs

0.26 lbs

0.30 lbs

0.45 lbs

0.56 lbs

Group Order Number L1 L2 L3W

0 N/A -- --

1 ST-GRW-01-*-XXX C/F 0.790 in. (20 mm) 1.51 in. (38 mm)

2 ST-GRW-02-*-XXX C/F 1.020 in. (26 mm) 1.74 in. (44 mm)

3 ST-GRW-03-*-XXX C/F 1.300 in. (33 mm) 2.02 in. (51 mm)

4 ST-GRW-04-*-XXX C/F 1.580 in. (40 mm) 2.30 in. (58 mm)

5

ST-GRW-05-*-XXX C/F 2.050 in. (52 mm) 2.77 in. (70 mm)

6 ST-GRW-06-*-XXX C/F 2.600 in. (66 mm) 3.32 in. (84 mm)

7 ST-GRW-07-*-XXX C/F 4.250 in (108 mm) 5.24 in. (133 mm)

7A ST-GRW-7A-*-XXX C/F 4.948 in (126 mm) 6.02 in. (153 mm)

*Materials: Z Zinc Plated Steel (Specia

XXX:Number of positions expressed as a 3-digit number

Threads: omit Weld plates have standard 1/4 - 20 UNC thread

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C Plain Carbon Steel (Standard Material)

Example #1: ST-GRW-03-C-005 = G

Example #2: ST-GRW-04-Z-010 = Group 4, 10 Positions, Zinc Plated Steel

-MET

By adding the "-MET" designation after the material designation

the threads are M6 metric thread

l Order)

roup 3, 5 Positions, Carbon Steel

1.223

(31 mm)

above,

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

8

Page 11

Standard Series Pipe Clamps

r

W

X

r

*

X

X

r

W

X

r

W

X

r

X

q

Rail and Strut Mounting Options

Rail Nut [RCN-0 / MRN-0]

The RCN-0 is for use when mounting Behringer’s RAL-0, and

competitor’s DIN standard rails. The MRN is the same rail nut but

with metric thread.

Industrial Pipe Clamps

Rail Nut [RCN-1 / MRN-1]

The RCN-1 is used only when mounting to Behringer’s proprietary

RAL-1.

Group Order Numbe

0-7A

ST-RCN-99-*-RN0

0-7A

ST-MRN-99-*-RN0

*Materials: C

Weight Ea.: Approx. 0.02 lbs ea.

T

Z

L

0.950 in.

(24 mm)

0.950 in.

(24 mm)

Plain Carbon Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Zinc Plated Steel (Special Material)

0.405 in

(10.2 mm)

0.405 in

(10.2 mm)

T H Thread

0.210 in.

(5.3 mm)

0.210 in.

(5.3 mm)

0.570 in.

(14.5 mm)

0.570 in.

(14.5 mm)

1/4 - 20

UNC

M6

Mounting Rail [RAL-0]

Behringer’s RAL-0 can be used to mount clamps with RCN-0 rail

nuts only. This rail is a DIN standard rail. (DIN 3015-1)

Group Order Numbe

0-7A

ST-RA0-99-*-XXX

Materials: C Plain Carbon Steel (Standard Material)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

Z Zinc Plated Steel (Special Order)

W1 W2 Length T H

1.125 in.

(28 mm)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

0.438 in

(11 mm)

See Below 14 gauge

0.438 in

(11 mm)

Group Order Numbe

0-7A

ST-RCN-99-*-RN1

0-7A

ST-MRN-99-*-RN1

*Materials: Z

Weight Ea.:

T

C

L

1.075 in.

(27.3 mm)

1.075 in.

(27.3 mm)

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Plain Carbon Steel (Special Order)

Approx. 0.04 lbs ea.

0.783 in

(19.9 mm)

0.783 in

(19.9 mm)

T H Thread

0.175 in.

(4.4 mm)

0.175 in.

(4.4 mm)

0.405 in.

(10 mm)

0.405 in.

(10 mm)

1/4 - 20

UNC

M6

Mounting Rail [RAL-1]

Behringer’s Proprietary RAL-1 can be used to mount both clamps

with RCN-1 rail nuts or STW weld plates. This allows more

flexibility of inventories and simplifies installation and field

modifications.

Group Order Numbe

0-7A

ST-RA1-99-*-XXX

*Materials: Z

T

C

W1 W2 Length T H

1.438 in.

(28 mm)

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Plain Carbon Steel (Special Order)

0.625 in

(11 mm)

See Below 14 gauge

0.438 in

(11 mm)

XX Length: 6FT 3.30 lbs ea.

3FT 1.65 lbs ea.

72 in. (1829 mm) Length (Standard Length)

36 in. (914 mm ) Length (Special Length)

Custom sizes available on request

XXX Length: 6FT 4.06 lbs ea.

3FT 2.03 lbs ea.

72 in. (1829 mm) Length (Standard Length)

36 in. (914 mm ) Length (Special Length)

Custom sizes available on re

uest

Strut Clip Nut [UCN]

The UCN nut is used to adapt Behringer’s pipe clamps to standard

strut channels. This allows for even greater flexibility and mounting

possibilities.

Group Order Numbe

0-7A

ST-UCN-99-*N

*Materials: Z

Weight Ea.: Approx. 0.10 lbs. ea.

T

C

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

L

1.660 in.

(42 mm)

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Plain Carbon Steel (Special Order)

0.635 in

(16 mm)

H1 H2 Thread

0.525 in.

(13 mm)

0.813 in.

(20.5 mm)

1/4 - 20

UNC

9

Page 12

Standard Series Pipe Clamps

X

X

r

X

X

X

Cover and Stacking Component Selection and Dimensions

Cover Plate [COP]

The Cover plate is the standard top fixture for securing the clamp

with hexagon head bolts.

Group 0

Group 1-7A

The safety plate is used in conjunction with the STB stacking bolts

below. This ensures that the stacking bolts will remain locked in

place when tightening the clamp module stacked above.

Industrial Pipe Clamps

Safety Plate [SAF]

Group Order Number L1 L2 W ØD Weight

0 ST-COP-00-* 1.044 in. (27 mm) 0.370 in. (9 mm) 0.04 lbs.

1 ST-COP-01-* 1.362 in. (36 mm) 0.790 in. (20 mm) 0.05 lbs.

2 ST-COP-02-* 1.592 in. (40 mm) 1.020 in. (26 mm) 0.06 lbs.

3 ST-COP-03-* 1.872 in. (48 mm) 1.300 in. (33 mm) 0.07 lbs.

4 ST-COP-04-* 2.152 in. (55 mm) 1.580 in.

5 ST-COP-05-* 2.790 in. (71 mm) 2.050 in. (52 mm) 0.10 lbs.

6 ST-COP-06-* 3.340 in. (85 mm) 2.600 in. (66 mm) 0.14 lbs.

7 ST-COP-07-* 5.020 in. (128 mm) 4.250 in (108 mm) 0.18 lbs

7A ST-COP-7A-* 5.782 in. (147 mm) 4.948 in (126 mm) 0.27 lbs

*Materials: Z

Zinc Plated Steel (Standard Material)

T

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571

C Plain Carbon Steel (Special Order)

1.223 in.

(31 mm)

0.275 in.

(7 mm)

)

(40 mm) 0.08 lbs.

Hexagon Head Bolt [HEX]

The Hexagon head bolt is used when using clamps with cover

plates or cover washers.

Group Order Number LThread Weight

ST-HEX-01-*

0

ST-HEX-01-*

1

ST-HEX-02-*

2

ST-HEX-02-*

3

4 ST-HEX-04-

5 ST-HEX-05-* 2.50 in. (64 mm) 1/4 - 20 UNC (M6 metric)

6 ST-HEX-06-* 2.75 in. (70 mm) 1/4 - 20 UNC (M6 metric)

7 ST-HEX-07-* 4.50 in. (114 mm) 1/4 - 20 UNC (M6 metric)

7A ST-HEX-7A-* 5.00 in. (127 mm) 1/4 -

*Materials: Z

Threads: omit

T

C

-MET

1.25 in. (32 mm) 1/4 - 20 UNC (M6 metric) 0.02 lbs.

1.25 in. (32 mm) 1/4 - 20 UNC (M6 metric) 0.02 lbs.

1.50 in. (38 mm) 1/4 - 20 UNC (M6 metric) 0.02 lbs.

1.50 in. (38 mm) 1/4 - 20 UNC (M6 metric) 0.02 lbs.

* 1.75 in. (44 mm) 1/4 - 20 UNC (M6 metric)

20 UNC (M6 metric)

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Plain Carbon Steel (Specia

As ordered above, the weld plates have standard 1/4 - 20 UNC thread

By adding the "-MET" designation after the material designation above,

the threads are M6 metric thread

l Order)

0.03 lbs.

0.04 lbs.

0.04 lbs.

0.06 lbs.

0.06 lbs.

Group 1-4

Group Order Number L W1 W2 T Weight

0 N/A -

1 ST-SAF-01-* 1.330 in. (34 mm)

2 ST-SAF-02-* 1.560 in. (40 mm)

3 ST-SAF-03-* 1.872 in. (48 mm)

4 ST-SAF-04-* 2.120 in. (54 mm)

ST-SAF-05-* 2.760 in. (70 mm)

5

6 ST-SAF-06-* 3.340 in. (85 mm)

7 ST-SAF-07-* 5.020 in. (128 mm)

7A ST-SAF-7A-* 5.782 in. (147 mm)

*Materials: Z

Group 5-7A

1.125 in. (29 mm) 0.440 in. (11.2 mm) 0.01 lbs.

1.125 in. (29 mm) 0.440 in. (11.2 mm) 0.02 lbs.

1.125 in. (29 mm) 0.440 in. (11.2 mm) 0.02 lbs.

1.125 in. (29 mm) 0.440 in. (11.2 mm) 0.03 lbs.

1.125 in. (29 mm) 0.460 in. (11.7 mm) 0.04 lbs.

1.125 in. (29 mm) 0.460 in. (11.7 mm) 0.04 lbs.

1.125 in. (29 mm) 0.460 in. (11.7 mm) 0.07 lbs.

1.125 in. (29 mm) 0.460 in. (11.7 mm) C/F

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

T

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C

Plain Carbon Steel (Special Order)

--

--

0.046 in.

(1 mm)

Stacking Bolt [STB]

The stacking bolt is used when another clamp module will be

stacked on top of the bottom or existing module. The head of the

stacking bolt has a female thread for the next bolt to engage.

Group Order Number L1 L2 L3 Weight

ST-STB-00-*

0

ST-STB-00-*

1

ST-STB-02-*

2

ST-STB-02-*

3

4 ST-STB-04-* 1.938 in. (49 mm) 1.313 in. (33 mm)

5 ST-STB-05-* 2.688 in. (68 mm) 2.063 in. (52 mm)

6 ST-ST

7 ST-STB-07-* 4.688 in. (119 mm) 4.063 in. (103 mm)

7A C/F -

*Materials: Z

Threads: omit

B-06-* 2.938 in. (75 mm) 2.313 in. (59 mm)

-MET

1.438 in. (36.5 mm) 0.813 in. (21 mm) 0.75 in. (19 mm) 0.03 lbs.

1.438 in. (36.5 mm) 0.813 in. (21 mm) 0.75 in. (19 mm) 0.03 lbs.

1.688 in. (43 mm) 1.063 in. (27 mm) 0.75 in.

1.688 in. (43 mm) 1.063 in. (27 mm) 0.75 in. (19 mm) 0.04 lbs.

---

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.43

T

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

C

Plain Carbon Steel (Special Order)

As ordered above, the weld plates have standard 1/4 - 20 UNC thread

By adding the "-MET" designation after the material designation above,

the threads are M6 metric thread

0.75 in. (19 mm) 0.04 lbs.

0.75 in. (19 mm) 0.05 lbs.

0.75 in. (19 mm) 0.05 lbs.

0.75 in. (19 mm) 0.08 lbs.

01/1.4305)

(19 mm) 0.04 lbs.

Cover Washer [COW]

Cover washers can be used as an alternative to cover plates in

some applications where there is little vibration, and low operating

pressure.

Group Order Numbe

0-7A

ST-COW-99-*

*Materials: Z

T

C

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

ØD1 ØD2 T Weight

0.630 in. (16 mm) 0.265 in (6.7 mm) 0.117 in. (3 mm) 0.01 lbs

Zinc Plated Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Plain Carbon Steel (Special Material)

10

Page 13

Standard Series Pipe Clamps

Complete Assembly Ordering Code

Industrial Pipe Clamps

S

BS

DS

R0S

R1S

US

G*S

SSK

Omit

T

X

C

PP

SP

AL

Omit

MET

Chart 1

Chart 2

Chart 3

S T 5150 -PP-MET

Clamp Configuration

Complete Clamp for Weld Mounting [STW]

Complete Clamp for Bolt Mounting [BAP]

Complete Double Clamp for Weld Mounting [DOW]

Complete Clamp for mounting to RAL-0 [RCN-0]

Complete Clamp for mounting to RAL-1 [RCN-1]

Complete Clamp for mounting to Strut Channel [UCN]

Complete Clamp for Group Weld Plate Mounting [GRW]

* number of positions

Stacking Kit [SAF + STB]

Hardware Materials

Electro-Zinc Dichromate Plating

RCN-0 rail nuts and group weld plates (GRW) are still supplied as

untreated carbon steel. Zinc plating available for these parts on

request.

AISI 304 Stainless Steel (A2 - 1.4301/1.4305)

AISI 316/316Ti Stainless Steel (A4 - 1.4401/1.4571)

Untreated Carbon Steel

Clamp Pair Material

Polypropylene

Santoprene

Aluminum

Groups 1-6 only

Threads

UNC Thread (Standard)

Metric Thread (Special)

Chart 4Chart 5

Group

Behringer

0

1

2

3

4

5

6

7

7A

Pipe Size

1/8 10.0 0.405 00405

1/8 10.0 0.405 10405

1/4 14.0 0.540 20540

3/8 17.1 0.675 20675

1/2 21.3 0.840 30840

3/4 26.7 1.050 41050

1

1 1/4 42.2 1.660 51660

1 1/2 48.3 1.900 61900

2 60.3 2.375 72375

2 1/2 73.0 2.875 72875

33 1/2 88.9 3.500 7350

4 4 1/2 114.3 4.500 7A450

Clamp Group and Size

Clamp Halves

(Set of 2)

Tube Size

Metric ØD (mm)

1/4 6.4 0.250 0025

3/8 9.5 0.3750038

1/4 6.4 0.250 1025

3/8 9.5 0.3801038

12.0 0.472 10472

1/2 12.7 0.500 2050

15.0 0.591 2059

5/8 16.0 0.620 2062

18.0 0.709 3070

3/4 19.0 0.750 3075

7/8 22.2 0.870 3087

1 25.4 1.000 3100

1 1/8 28.6 1.125 41125

1 1/4 32.0 1.250 5125

33.4 1.315 51315

1 1/2 38.1 1.500 5150

1 3/4 44.5 1.750 6175

2 50.8 2.000 6200

2 1/4 57.2 2.250 7225

376.2 3.000 7300

4 102.0 4.000 7A400

(Inch)

Imperial ØD

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

11

Page 14

Standard Series Pipe Clamps

Ordering Examples

Single Clamp for Weld Mounting

Industrial Pipe Clamps

Double Clamp for Weld Mounting

S

BS

Consists of:

2 HEX Bolts

1 COP Cover Plate

1 CLH Clamp Set (2 halves)

1 STW Weld Plate

Clamp for Bolt Mounting

Consists of:

2 HEX Bolts

1 COP Cover Plate

1 CLH Clamp Set (2 halves)

1 BAP Weld Plate

DS

SSK

Consists of:

4 HEX Bolts

2 COP Cover Plate

2 CLH Clamp Sets (4 h alves)

1 DOW Weld Plate

Stacking Kit

Consists of:

2 STB Stacking Bolts

1 SAF Safety Plates

1 CLH Clamp Sets (2 halves)

R0S

US

Clamp for Rail-0 Mounting

Consists of:

2 HEX Bolts

1 COP Cover Plate

1 CLH Clamp Set (2 halves)

2 RCN-0 Rail Nuts

Standard material for the RCN-0 rail

nuts is un-plated steel.

Clamp for Strut Mounting

Consists of:

2 HEX Bolts

1 COP Cover Plate

1 CLH Clamp Set (2 halves)

2 UCN Strut Clips

R1S

G*S

Clamp for Rail-1 Mounting

Consists of:

2 HEX Bolts

1 COP Cover Plate

1 CLH Clamp Set (2 halves)

2 RCN-1 Rail Nuts

Clamp for Group Weld Mounting

Consists of:

2 HEX Bolts Per Position

1 COP Cover Plate Per Position

1 CLH Clamp Set Per Position

1 GRW Group Weld Plate

Standard Material for GRW is un-plated steel.

*is the number of positions

Example: Group 2, 5 positions of 1/2” Tube,

PP Clamps, 304SS = G5ST2050-PP

(continuous)

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

12

Page 15

Heavy Series Pipe Clamps

)

Clamp Pair Selection and Part Numbers

Behringer’s clamp pairs are available in different materials and incorporate a modular

insert by group size. Heavy Series pipe clamps are available in sizes from ¼ in.

(6.35mm) through 8.625 in. (219mm) OD Sizes.

Industrial Pipe Clamps

Behringer

Group

H3

H4

H5

H6

H7

H8

H9

H10

Clamp Pair Selection and Part Numbers

Pipe Size Tube Size

1/4 6.4 0.250 HS-CLH-03-*-025

3/8 9.5 0.375 HS-CLH-03-*-038

1/8 10.0 0.405 HS-CLH-03-*-041

1/2 12.7 0.500 HS-CLH-03-*-050

1/4 13.7 0.540 HS-CLH-03-*-054

5/8 16.0 0.620 HS-CLH-03-*-062

3/8 17.1 0.675 HS-CLH-03-*-068

3/4 19.0 0.750 HS-C

1/2 21.3 0.840 HS-CLH-04-*-084

7/8 22.2 0.870 HS-CLH-04-*-087

1 25.4 1.000 HS-CLH-04-*-100

3/4 26.7 1.050 HS-CLH-04-*-105

1 1/4 32.0 1.250 HS-CLH-05-*-125

1 33.4 1.315 HS-CLH-0

1 1/2 38.1 1.500 HS-CLH-05-*-150

1 1/4 42.2 1.660 HS-CLH-05-*-166

1 33.4 1.315 HS-CLH-06-*-132

1 1/4 42.2 1.660 HS-CLH-06-*-166

1 3/4 44.5 1.750 HS-CLH-06-*-175

1 1/2 48.3 1.900 HS-CLH-06-*-190

2 50.8 2.000 HS-CLH-06-*-200

2 1/8 54.0 2.125 HS-CLH-06-*-213

2 1/4 57.2 2.250 HS-CLH-06-*-225

2 60.3 2.

2 1/2 63.5 2.500 HS-CLH-06-*-250

2 3/4 69.9 2.750 HS-CLH-06-*-275

2 3/4 69.9 2.750 HS-CLH-07-*-275

2 1/2 73.0 2.875 HS-CLH-07-*-288

376.2 3.000 HS-CLH-07-*-300

33 1/2 88.9 3.500 HS-CLH-07-*-350

33 1/2 88.9 3.500 HS-CLH-08-*-350

4 102 4.000 HS-CL

4 4 1/2 114 4.500 HS-CLH-08-*-450

5127 5.000 HS-CLH-08-*-500

5127 5.000 HS-CLH-09-*-500

5 1/4 133 5.250 HS-CLH-09-*-525

5 141 5.563 HS-CLH-09-*-556

6 152 6.000 HS-CLH-09-*-600

6168 6.625 HS-CLH-09-*-663

6168 6.625 HS-CLH-10-*-663

8 2038.000 HS-CLH-10-*-800

8 219

Metric ØD

(mm)

20.0 0.790 HS-CLH-04-*-079

30.0 1.181 HS-CLH-04-*-118

Imperial

ØD (Inch)

375 HS-CLH-06-*-238

8.625 HS-CLH-10-*-863

Clamp Pair

(See material

code for *

LH-04-*-075

H-08-*-400

5-*-132

Clamp Pair Material Codes (*)

[PP] Polypropylene

P

S

A

Black Color

[SP] Santoprene

Beige Color

[AL] Aluminum

Aluminum Color

Custom Sizes

Custom sizescanbemade by specially

boring the clamppair to any desiredsize.

To order a specialsize, first find the

group that this will fall under. All groups

areavailable starting with 1/4 in. OD and

canbe useduptothe maximumODsize

in the chart below. This is expressedin

the

part number as a two-digit number

(G#). Once thegroup size hasbeen

determined, simply add the desired OD

of the line to be securedinthe3digit end

numberofthe clamppair (XXX) by

rounding the number to two decimals and

dropping th

e decimal point. The part

number will look like this:

HS-CLH-G#-*-XXX

Example: For a line wih OD of 1.08 in.,

this would fall within thegroup 4. The

Part number will be as follows:

HS-CLH-04-*-108

Special Bore Range by Group

Group (G#) Range

H3

H4

H5

H6

H7

H8

H9

H10

0.25 in. through 0.675 in.

0.25 in. through 1.050 in.

.

0.25 in through 1.660 in.

0.25 in. through 2.750 in.

0.25 in. through 3.500 in.

0.25 in. through 5.000 in.

0.25 in. through 6.625 in.

0.25 in. through 8.625 in.

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

13

Page 16

Heavy Series Pipe Clamps

Clamp Pair Dimensions

The robust Heavy Series design is larger and thicker than the Standard Series,

and is designed for the toughest applications. As a general rule, the outside

diameter of the line to be secured should not vary over or under the ØD

dimension in the chart by more than ½ of the tension clearance dimension

(dimension “O”). Heavy Series pipe clamps are available in sizes from ¼ in.

(6.35mm) through 8.625 in. (219mm) outside diameter sizes. If a required

size is not available, custom sizes can be made to order.

Clamp Pair Dimensional Information

Clamp Pair P/N

Behringer

Group

H3

H4

H5

H6

H7

H8

H9

H10

Metric ØD

(mm)

6.4 0.250 HS-CLH-03-*-025

9.5 0.375 HS-CLH-03-*-038

10.0 0.405 HS-CLH-03-*-041

12.7 0.500 HS-CLH-03-*-050

13.7 0.540 HS-CLH-03-*-054

16.0 0.620 HS-CLH-03-*-062

17.1 0.675 HS-CLH-03-*-068

19.0 0.750 HS-CLH-04-*-075

20.0 0.790 HS-CLH-04-*-079

21.3 0.840 HS-CLH-04-*-084

22.2 0.870 HS-CLH-04-*-087

25.4 1.000 HS-CLH-04-*-100

26.7 1.050 HS-CLH-04-*-105

30.0 1.181 HS-CL

32.0 1.250 HS-CLH-05-*-125

33.4 1.315 HS-CLH-05-*-132

38.1 1.500 HS-CLH-05-*-150

42.2 1.660 HS-CLH-05-*-166

33.4 1.315 HS-CLH-06-*-132

42.2 1.660 HS-CLH-06-*-166

44.5 1.750 HS-CLH-06-*-175

48.3 1.900 HS-CLH-06-*-190

50.8 2.000 HS-CLH-06-*-200

54.0 2.125 HS-CLH-

57.2 2.250 HS-CLH-06-*-225

60.3 2.375 HS-CLH-06-*-238

63.5 2.500 HS-CLH-06-*-250

69.9 2.750 HS-CLH-06-*-275

69.9 2.750 HS-CLH-07-*-275

73.0 2.875 HS-CLH-07-*-288

76.2 3.000 HS-CLH-07-*-300

88.9 3.500 HS-CLH-07-*-350

88.9 3.500 HS-CLH-

102.0 4.000 HS-CLH-08-*-400

114.0 4.500 HS-CLH-08-*-450

127.0 5.000 HS-CLH-08-*-500

127.0 5.000 HS-CLH-09-*-500

133.0 5.250 HS-CLH-09-*-525

141.0 5.563 HS-CLH-09-*-556

152.0 6.000 HS-CLH-09-*-600

168.0 6.625 HS-CLH-09-*-663

168.0 6.625 HS-CLH-10-*-663

203.0 8.625 HS-C

219.0 8.000 HS-CLH-10-*-863

Imperial

ØD (Inch)

(See page 13 for

complete order

numbers)

H-04-*-118

06-*-213

08-*-350

LH-10-*-800

L CHOW

2.250 in.

(57 mm)

2.750 in.

(70 mm)

3.344 in.

(87 mm)

4.500 in.

(115 mm)

6.000 in.

(152 mm)

8.063 in.

(205 mm)

9.750 in.

(248 mm)

12.500 in.

(318

mm)

1.300 in.

(33 mm)

1.770 in.

(45 mm)

2.360 in.

(60 mm)

3.530 in.

(90 mm)

4.810 in.

(122 mm)

6.620 in.

(168 mm)

8.060 in.

(205 mm)

10.430 in.

(265 mm)

1.375 in.

(35 mm)

1.875 in.

(48 mm)

2.375 in.

(60 mm)

3.500 in.

(89 mm)

4.750 in.

(121 mm)

6.625 in.

(168 mm)

7.875 in.

(200 mm)

10.625 in.

(270 mm)

0.063 in.

(1.6 mm)

0.063 in.

(1.6 mm)

0.063 in.

(1.6 mm)

0.125 in.

(3.2 mm)

0.125 in.

(3.2 mm)

0.188 in.

(4.8 mm)

0.188 in.

(4.8 mm)

0.188 in.

(4.8 mm)

Industrial Pipe Clamps

Weight

Ea.

1.188 in.

(30.2 mm)

1.188 in.

(30.2 mm)

1.188 in.

(30.2 mm)

1.688 in.

(43 mm)

2.188 in.

(55.6 mm)

3.25 in.

(82.6 mm)

3.438 in.

(87.3 mm)

4.438 in.

(113 mm)

0.07 lbs

0.09 lbs

0.15 lbs

0.35 lbs

0.78 lbs

2.31 lbs

2.59 lbs

7.73 lbs

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

14

Page 17

Heavy Series Pipe Clamps

X

X

X

:

X

Securing Plate Selection and Dimensions

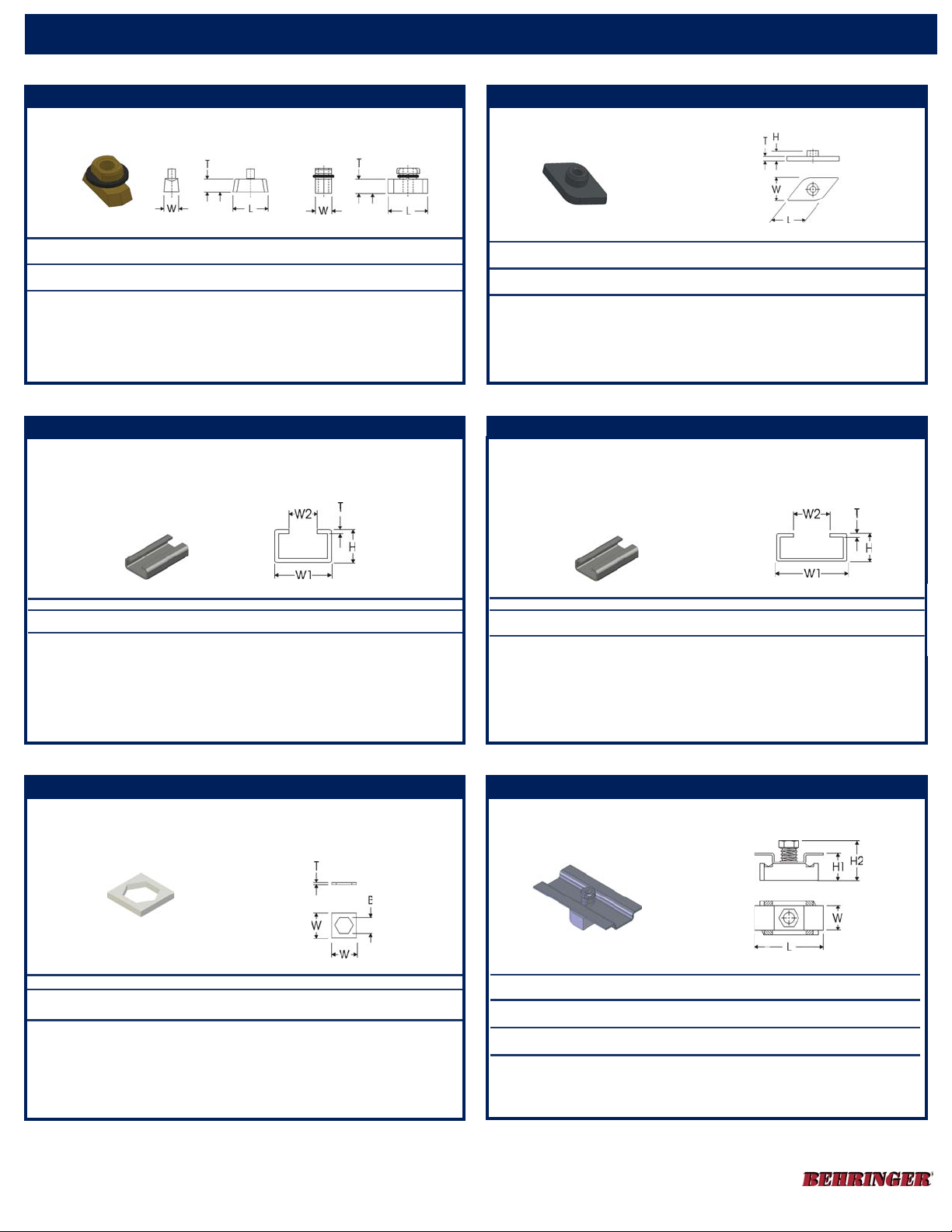

Single Weld Plate [SWP]

The typical mounting configuration is where the clamp is

welded to the support structure.

Industrial Pipe Clamps

Single Cover Plate [SCP]

The cover plate is the standard top fixture for securing the

clamp with hexagon head bolts.

Group Order Number L1 L2W T H Thread Weight

H3

HS-SWP-03-*

H4

HS-SWP-04-*

H5

HS-SWP-05-*

H6

HS-SWP-06-*

H7

HS-SWP-07-*

H8

HS-SWP-08-*

H9

HS-SWP-09-*

H10

HS-SWP-10-*

*Materials: C Plain Carbon Steel (Standard Material)

Threads: omit As ordered above, the weld plates have standard UNC thread

-MET

2.875 in.

(73 mm)

3.375 in.

(86 mm)

4.000 in.

(102 mm)

5.875 in.

(149 mm)

7.375 in.

(187 mm)

10.000 in.

(254 mm)

11.750 in.

(298 mm)

14.500 in.

(368 mm)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

By adding the "-MET" designation after the ma

the threads will be metric

1.30 in.

(33 mm)

1.77 in.

(45 mm)

2.36 in.

(60 mm)

3.53 in.

(90 mm)

4.81 in.

(122 mm)

6.62 in.

(168 mm)

8.06 in.

(205 mm)

10.43 in.

(265 mm)

1.25 in.

(32 mm)

1.25 in.

(32 mm)

1.25 in.

(32 mm)

1.75 in.

(45 mm)

2.25 in.

(57 mm)

3.00 in.

(76 mm)

3.50 in.

(89 mm)

4.50 in.

(114 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.375 in.

(10 mm)

0.375 in.

(10 mm)

0.500 in.

(13 mm)

0.500 in.

(13 mm)

0.750 in.

(19 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.380 in.

(10 mm)

0.472 in.

(12 mm)

0.680 in.

(17 mm)

0.755 in.

(19 mm)

0.755 in.

(19 mm)

terial designation above,

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

7/16 - 14 UNC

(M12 metric)

5/8 - 11 UNC

(M16 metric)

3/4 - 10 UNC

(M20metric

7/8 - 9 UNC

(M24 metric)

1-1/8 - 7 UNC

(M30 metric)

0.34 lbs

0.39 lbs

0.45 lbs

1.10 lbs

1.71 lbs

4.15 lbs

)

5.83 lbs

3.65 lbs

1

Double Weld Plate [DWP]

Double weld plates are used to make a double heavy clamp,

with both sets of clamp halves in line with the piping. This

design can accommodate double the operating pressure as

the single heavy pip

e clamps.

Group Order Number L1 L2WT

H3

HS-SCP-03-*

H4

HS-SCP-04-*

H5

HS-SCP-05-*

H6

HS-SCP-06-*

H7

HS-SCP-07-*

H8

HS-SCP-08

H9

HS-SCP-09-*

H10

HS-SCP-10-*

*Materials: C Plain Carbon Steel (Standard Material)

2.250 in.

(57 mm)

2.750 in.

(70 mm)

3.344 in.

(85 mm)

4.500 in.

(114 mm)

6.000 in.

(152 mm)

8.063 in.

-*

(205 mm)

9.750 in.

(248 mm)

12.500 in.

(318 mm)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

1.30 in.

(33 mm)

1.77 in.

(45 mm)

2.36 in.

(60 mm)

3.53 in.

(90 mm)

4.81 in.

(122 mm)

6.62 in.

(168 mm)

8.06 in.

(205 mm)

10.43 in.

(265 mm)

1.25 in.

(32 mm)

1.25 in.

(32 mm)

1.25 in.

(32 mm)

1.75 in.

(45 mm)

2.25 in.

(57 mm)

3.00 in.

(76 mm)

3.50 in.

(89 mm)

4.50 in.

(114 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.375 in.

(10 mm)

0.375 in.

(10 mm)

0.500 in.

(13 mm)

0.500 in.

(13 mm)

0.750 in.

(19 mm)

ØD

0.438 in.

(11 mm)

0.438 in.

(11 mm)

0.438 in.

(11 mm)

0.500 in.

(13 mm)

0.688 in.

(18 mm)

0.813 in.

(21 mm)

0.938 in.

(24 mm)

1.188 in.

(30 mm)

Weight

0.21 lbs

0.26 lbs

0.32 lbs

0.77 lbs

1.28 lbs

3.19 lbs

4.58 lbs

11.31 lbs

Double Cover Plate [DCP]

Double cover plates are used to make a double heavy clamp,

with both sets of clamp halves in line with the piping. This

design can accommodate double the operating pressure of

the single heavy pip

e clamps.

50 in.

ØD

0.438 in.

(11 mm)

0.438 in.

(11 mm)

0.438 in.

(11 mm)

0.500 in.

(13 mm)

0.688 in.

(18 mm)

0.813 in.

(21 mm)

0.938 in.

(24 mm)

1.188 in.

(30 mm)

Group Order Number L1 L2WT H Thread Weight

H3

HS-DWP-03-*

H4

HS-DWP-04-*

H5

HS-DWP-05-*

H6

HS-DWP-06-*

H7

HS-DWP-07-*

H8

HS-DWP-08-*

H9

HS-DWP-09-*

H10

HS-DWP-10-*

*Material C Plain Carbon Steel (Standard Material)

Threads

omit As ordered above, the weld plates have standard UNC thread

-MET

2.875 in.

(73 mm)

3.375 in.

(86 mm)

4.000 in.

(102 mm)

5.875 in.

(149 mm)

7.375 in.

(187 mm)

10.000 in.

(254 mm)

11.750 in.

(298 mm)

14.500 in.

(368 mm)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

By adding the "-MET" designation after the material designation above,

the threads will be metric

1.30 in.

(33 mm)

1.77 in.

(45 mm)

2.36 in.

(60 mm)

3.53 in.

(90 mm)

4.81 in.

(122 mm)

6.62 in.

(168 mm)

8.06 in.

(205 mm)

10.43 in.

(265 mm)

2.50 in.

(63 mm)

2.50 in.

(63 mm)

2.50 in.

(63 mm)

3.50 in.

(89 mm)

4.50 in.

(114 mm)

7.00 in.

(178 mm)

7.00 in.

(178 mm)

9.375 in.

(238 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.313 in.

(8 mm)

0.375 in.

(10 mm)

0.375 in.

(10 mm)

0.500 in.

(13 mm)

0.500 in.

(13 mm)

0.750 in.

(19 mm)

0.313 in.

(8 mm)

in.

0.313

(8 mm)

0.313 in.

(8 mm)

0.380 in.

(10 mm)

0.472 in.

(12 mm)

0.680 in.

(17 mm)

0.755 in.

(19 mm)

0.755 in.

(19 mm)

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

7/16 - 14 UNC

(M12 metric)

5/8 - 11 UNC

(M16 metric)

3/4 - 10 UNC

(

M20 metric)

7/8 - 9 UNC

(M24 metric)

- 7 UNC

1-1/8

(M30 metric)

0.72

0.78

0.90

2.20

3.42

8.30

11.75

28.00

Group Order Number L1 L2W T

H3

HS-DCP-03-*

H4

HS-DCP-04-*

H5

HS-DCP-05-*

H6

HS-DCP-06-*

H7

HS-DCP-07-*

H8

HS-DCP-08-*

H9

HS-DCP-09-*

H10

HS-DCP-10-*

*Materials: C Plain Carbon Steel (Standard Material)

2.250 in.

(57 mm)

2.750 in.

(70 mm)

3.344 in.

(85 mm)

4.500 in.

(114 mm)

6.000 in.

(152 mm)

8

(205 mm)

9.750 in.

(248 mm)

12.500 in.

(318 mm)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

.063 in.

1.30 in.

(33 mm)

1.77 in.

(45 mm)

6 in.

2.3

(60 mm)

3.53 in.

(90 mm)

4.81 in.

(122 mm)

6.62 in.

(168 mm)

8.06 in.

(205 mm)

10.43 in.

(265 mm)

2.50 in.

(63 mm)

2.50 in.

(63 mm)

2.50 in.

(63 mm)

3.50 in.

(89 mm)

4.50 in.

(114 mm)

7.00 in.

(178 mm)

7.00 in.

(178 mm)

9.375 in.

(238 mm)

0.313 in.

0.313 in.

0.313 in.

0.375 in.

(10 mm)

0.375 in.

(10 mm)

0.500 in.

(13 mm)

0.500 in.

(13 mm)

0.7

(19 mm)

(8 mm)

(8 mm)

(8 mm)

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

15

Weight

0.42 lbs

0.52 lbs

0.64 lbs

1.54 lbs

2.56 lbs

6.38 lbs

9.16 lbs

22.62 lbs

Page 18

r

t

r

t

1-1/8

UNC (M30

)

*

r

W

X

r

W

t

Heavy Series Pipe Clamps

Fastening Hardware Selection and Dimensions

Hexagon Head Bolt [HEX] Stacking Bolt [STB]

The Hexagon Head Bolt is used when using clamps with cover

plates.

Industrial Pipe Clamps

The Stacking Bolt is used when another clamp module will be

stacked on top of the bottom or existing module. The head of the

stacking bolt has a female thread for the next bolt to engage.

Group Order Numbe

H3 HS-HEX-03-* 1.75 in. (44 mm)

H4 HS-HEX-04-* 2.25 in. (57 mm)

H5 HS-HEX-05-* 2.75 in. (70 mm)

H6 HS-HEX-06-* 4.00 in. (102 mm)

H7 HS-HEX-07-* 5.25 in. (133 mm)

H8 HS-HEX-08-* 7.50 in. (191 mm)

H9 HS-HEX-09-* 8.50 in. (216 mm)

H10 HS-HEX-10-* 11.50 in. (292 mm)

Materials: C Plain Carbon Steel (Standard Material)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

LThread Weigh

3/8 - 16 UNC (M10 metric)

3/8 - 16 UNC (M10 metric)

3/8 - 16 UNC (M10 metric)

7/16 - 14 UNC (M12 metric)

5/8 - 11 UNC (M16 metric)

3/4 - 10 UNC (M20 metric)

7/8 - 9 UNC (M24 metric)

- 7

metric

0.06 lbs.

0.08 lbs.

0.09 lbs.

0.18 lbs.

0.50 lbs.

0.97 lbs.

1.56 lbs.

3.53 lbs.

Strut Clip Nut [UCN]

The UCN Nut is used to adapt Behringer’s pipe clamps to standard

strut channel. This allows for even greater flexibility and mounting

possibilities.

Group Order Numbe

H3 HS-STB-03-*

H4 HS-STB-04-*

H5 HS-STB-05-*

H6 HS-STB-06-*

H7 HS-STB-07-*

H8 HS-STB-08-*

H9 HS-STB-09-*

H10 HS-STB-10-*

*Materials: C Plain Carbon Steel (Standa

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Z Zinc Plated Steel (Special Order)

L1 L2 L3 Thread Weigh

1.969 in.

(50 mm)

2.469 in.

(63 mm)

2.969 in.

(75 mm)

4.250 in.

(108 mm)

5.500 in.

(140 mm)

7.750 in.

(197 mm)

9.188 in.

(233 mm)

12.000 in.

(305 mm)

0.906 in.

(23 mm)

1.406 in.

(36 mm)

1.906 in.

(48 mm)

2.875 in.

(73 mm)

3.875 in.

(98 mm)

5.750 in.

(146 mm)

7.000 in.

(178 mm)

9.500 in.

(241 mm)

0.906 in.

(23 mm)

1.000 in.

(25.4 mm)

1.000 in.

(25.4 mm)

1.250 in.

(32 mm)

1.250 in.

(32 mm)

1.500 in.

(38 mm)

1.750 in.

(44 mm)

2.250 in.

(57 mm)

rd Material)

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

3/8 - 16 UNC

(M10 metric)

7/16 - 14 UNC

(M12 metric)

5/8 - 11 UNC

(M16 metric)

- 10 UNC

3/4

(M20 metric)

7/8 - 9 UNC

(M24 metric)

1-1/8 - 7 UNC

(M30 metric)

0.10 lbs

0.11 lbs

0.13 lbs

0.24 lbs

0.49 lbs

1.15 lbs

1.65 lbs

2.50 lbs

Safety Plate [SAF]

The Safety Plate is used in conjunction with the STB stacking bolts

above. This ensures that the stacking bolts will remain locked in

place when tightening the clamp module stacked above.

Group Order Numbe

H3 - H5

*Materials: C

Weight Ea.: Approx. 0.2 lbs. ea.

H6

HS-UCN-345

HS-UCN-06-*

T

Z

1.500 in.

(38 mm)

Plain Carbon Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

Zinc Plated Steel (Special Order)

L

0.866 in.

(22 mm)

-----

H1 H2 Thread

0.728 in.

(18.5 mm)

1.083 in.

(2.75 mm)

3/8 - 16

UNC

Group Order Numbe

H3 HS-SAF-03-*

H4 HS-SAF-04-*

H5 HS-SAF-05-*

H6 HS-SAF-06-*

H7 HS-SAF-07-*

H8 HS-SAF-08-*

H9 HS-SAF-09-*

H10 HS-SAF-10-*

*Materials: C Plain Carbon Steel (Standard Material)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

X AISI 316

Z Zinc Plated Steel (Special Order)

L1 L2

2.281 in.

(58 mm)

2.750 in.

(70 mm)

3.344 in.

(85 mm)

4.531 in.

(115 mm)

5.938 in.

(151 mm)

8.000 in.

(203 mm)

9.750 in.

(248 mm)

12.438 in.

(316 mm)

H3-H7

1.300 in.

(33 mm)

1.770 in.

45 mm)

2.360 in.

(60 mm)

3.530 in.

(90 mm)

4.812 in.

(122 mm)

6.625 in.

(168 mm)

8.062 in.

(205 mm)

10.437 in.

(265 mm)

Grade Stainless Steel (A4 - 1.4401/1.4571)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.219 in.

(31 mm)

1.625 in.

(41 mm)

2.125 in.

(54 mm)

2.938 in.

(75 mm)

3

.438 in.

(87 mm)

4.438 in.

(113 mm)

0.125 in.

(3.2 mm)

0.125 in.

(3.2 mm)

0.125 in.

(3.2 mm)

0.188 in.

(4.8 mm)

0.188 in.

(4.8 mm)

0.375 in.

(9.5 mm)

0.375 in.

(9.5 mm)

0.250 in.

(6.3 mm)

Pipe Clamp Catalog BPCO7R1

© 2005. Behringer Corp. All Rights Reserved Industrial Pipe Clamps

16

H8-H10

T Weigh

0.06 lbs.

0.08 lbs.

0.11 lbs.

0.31 lbs.

0.58 lbs.

1.43 lbs.

2.17 lbs.

-

Page 19

X

X

X

X

Heavy Series Pipe Clamps

Rail and Strut Mounting Options

Industrial Pipe Clamps

Rail Nut [RCN]

Behringer’s rail nuts allow mounting of the heavy series clamps to

the RAL-4 Heavy series rail.

Group Order Number ØD1 ØD2 H1 H2 H3 Thread

H3

H4

HS-RCN-99-*-RN7

H5

H6

HS-RCN-99-*-RN8

H7

HS-RCN-99-*-RN9

H8

H9

H10

*Materials: C Plain Carbon Steel (Standard Material)

T AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

Z Zinc Plated Steel (Special Order)

0.698 in.

(17.8 mm)

0.778 in.

(19.8 mm)

0.938 in.

(23.8 mm)

AISI 316 Grade Stainless Steel (A4 - 1.4401/1.4571)

0.750 in.

(19 mm)

0.875 in.

(22.2 mm)

1.125 in.

(28.6 mm)

0.750 in.

(19 mm)

0.813 in.

(20.7 mm)

1.700 in.

(43.2 mm)

0.297 in.

(7.6 mm)

0.359 in.

(9.1 mm)

1.075 in.

(27.3 mm)

0.219 in.

(5.6 mm)

0.219 in.

(5.6 mm)

0.375 in.

(9.5

mm)

3/8 - 16 UNC

(M10 metric)

7/16 - 14 UNC

(M12 metric)

5/8 - 11 UNC

(M16 metric)

-N/A -----

Mounting Rail [RAL-2]

Behringer’s proprietary Heavy series RAL-2 is used to mount

clamps with Weld Plates (SWP). The weld plate slides into the rail,

eliminating the need for rail nuts. The RAL-2 fits Groups H3-H5

weld plates.

Mounting Rail [RAL-4] DIN 3015-2

Behringer’s Heavy series RAL-4 is used to mount clamps with

heavy rail nuts. This allows clamps from multiple groups to be

mounted to the same rail. The RAL-4 conforms to the DIN 3015-2

specification.

Group Order Number W1 W2 LTH

H3-H7

*Materials: C

XXX Length: 2ME

ST-RA4-99-*-XXX

T

Z

1ME 7.25 lbs ea.

1.563 in.

(40 mm)

Plain Carbon Steel (Standard Material)

AISI 304 Grade Stainless Steel (A2 - 1.4301/1.4305)

AISI 316 Grad

Zinc Plated Steel (Special Order)

78 in. (2 m) Length (Standard Length)

39 in. (1 m ) Length (Special Length)

Custom sizes available on request

0..469 in

(12 mm)

e Stainless Steel (A4 - 1.4401/1.4571)

See Below

0.188 in.

(5 mm)

14.5 lbs ea.

0.875 in.

(22 mm)

Mounting Rail [RAL-3]

Behringer’s proprietary Heavy series RAL-3 is used to mount

clamps with Weld Plates (SWP). The weld plate slides into the rail,