GT-600/GT-800

Portable Appliance Tester

Users Manual

GB

GT-600/GT-800 Instruction Manual

2

GT-600/GT-800 Instruction Manual

c

R

AMPROBE

GT-600/GT-800

Instruction Manual

2012 BEHA-AMPROBE

3

GT-600/GT-800 Instruction Manual

Table of Contents:

Safety information, Warning ..................................................................................... 6

Introduction ............................................................................................................... 7

Product description ................................................................................................... 7

Scope of Supply ......................................................................................................... 8

Available Accessories ................................................................................................ 8

Transport and Storage .............................................................................................. 8

Safety Measures ........................................................................................................ 9

Appropriate Usage .................................................................................................. 10

Operation Elements and Connectors ..................................................................... 11

Front panel of the GT-600 Tester ........................................................................... 11

Front panel of the GT-800 Tester ........................................................................... 12

Cover of the GT-600 Tester ...................................................................................... 13

Cover of the GT-800 Tester ...................................................................................... 14

Preparation of the GT-600/GT-800 Tester ............................................................... 15

Turning on the GT-600/GT-800 Tester .................................................................... 15

Test lead compensation .......................................................................................... 15

Limit value setting ................................................................................................... 16

Start of the measurement ....................................................................................... 16

External Voltage Display ......................................................................................... 16

Testing Appliances .................................................................................................. 16

Visual Inspection ..................................................................................................... 17

Protective Bonding Test 5 A / 0.2 A (RPE) ............................................................... 18

Insulation Resistance Test 250 V / 500 V (RISO) ...................................................... 21

Substitute Leakage Current Test (ISUB) .................................................................. 24

Protective Conductor Current Test (IPE()) .............................................................. 26

Touch Current Test (IT) ............................................................................................ 28

Power, Load Current Test (P/IL) ............................................................................... 31

Clamp Current Test ( ) (GT-800 only) ............................................................... 33

IEC CORD Test (CORD/PRCD) ................................................................................... 35

PRCD Test (CORD/PRCD) (GT-800 only) .................................................................... 37

Protective Extra Low Voltage Test (PELV) .............................................................. 40

Safety Extra Low Voltage Test (SELV) ..................................................................... 41

AUTO Test (GT-800 only) .......................................................................................... 42

Menu Functions ....................................................................................................... 46

General operation instructions ............................................................................... 46

MEMORY Menu ....................................................................................................... 47

OPERATOR Menu .................................................................................................... 47

AUTO-TEST Menu .................................................................................................... 48

SETUP Menu ............................................................................................................ 49

LANGUAGE Menu ................................................................................................... 50

CONTRAST Menu ..................................................................................................... 50

TESTER INFO Menu .................................................................................................. 50

Memory Features .................................................................................................... 51

Memory Structure ................................................................................................... 51

General Memory Operations .................................................................................. 53

Memorizing Example .............................................................................................. 54

Recall Data ............................................................................................................... 56

Entry of Memory Address Using External Keyboard ............................................. 57

Entry of Memory Address Using Barcode Reader .................................................. 59

4

GT-600/GT-800 Instruction Manual

Maintenance ............................................................................................................ 60

Cleaning ................................................................................................................... 60

Calibration Interval ................................................................................................. 60

Fuse Replacement ................................................................................................... 61

List of Possible Displayed Errors ............................................................................. 62

Reset of the GT-600/GT-800 Tester ........................................................................ 63

Pre-Tests and Protection ......................................................................................... 64

Technical Specifications .......................................................................................... 67

Limited Warranty and Limitation of Liability ......................................................... 74

Service ...................................................................................................................... 74

5

GT-600/GT-800 Instruction Manual

Safety information, Warning

Measurements of the electrical safety on appliances should only be carried out

by properly trained and competent persons!

Carefully read the safety information before using the appliance tester

GT-600/GT-800.

References marked on the instrument or in this instruction manual:

Warning of a potential danger, comply with instruction manual.

☞

Reference, please pay utmost attention.

Caution, dangerous voltage. Danger of electrical shock.

Symbol for marking of electrical and electronic equipment

(WEEE Directive).

Conformity symbol, the instrument complies with the valid

directives. It complies with the EMC Directive and the Low

Voltage Directive.

WARNING

The instruction manual contains information and references, necessary for

safe operation and maintenance of the instrument. Prior to using the

instrument, the user is kindly requested to thoroughly read the

instruction manual and comply with it in all sections.

Failure to read the instruction manual or to comply with the warnings

and references contained herein can result in serious bodily injury or

instrument damage.

6

GT-600/GT-800 Instruction Manual

Introduction

You have acquired a high-quality measurement instrument manufactured by

BEHA-AMPROBE, which will enable you to perform repeatable measurements

for a very long period of time.

The portable appliance tester GT-600/GT-800 is a measurement instrument used

for safety inspection on electrical appliances complying with VDE 0701-0702 and

documentation of test results.

Product description:

Protective bonding resistance measurement (RPE), test current 0.2 A AC and 5

A AC. The test is carried out on plugged and also on permanently connected

appliances.

Insulation resistance measurement (RISO), test voltage 500 VDC (and 250 VDC

GT-800 only). Appliances class I with heater, class I, class II and class III can be

tested.

Substitute leakage current measurement (ISUB), test voltage 45 V AC.

Appliances class I and class II can be tested.

Protective conductor current measurement (IPE()), differential method.

Touch current measurement (IT) direct method.

Apparent power, active power, mains voltage, load current and power factor

PF measurement (P/IL).

Protective conductor current IPE and load current IL measurement ( ),

clamp method (GT-800 only).

IEC CORD test (PE continuity, insulation resistance, L continuity, N continuity,

L/N shorted).

Test of portable RCD (PRCD), PE continuity, TEST button, output insulation

resistance, PE current, functional test at L disconnection, functional test at N

disconnection, trip out time at IN/2, trip out time at IN, trip out time at 5

IN, tripping current (GT-800 only).

Protective extra low voltage (PELV) measurement.

Safety extra low voltage (SELV) measurement.

AUTO Test (13 factory-programmed AUTO-Tests, 17 customer-created AUTO-

Tests) (GT-800 only).

Extremely easy operation using the rotary switch and the START/STOP

button.

Automatic start and save function for protective bonding resistance

measurement allows both-hands measurements on measured objects that

are difficult to access.

Compensation of test lead resistance for protective bonding resistance

measurement.

Calculation of limits for protective bonding resistance.

Automatic mains voltage polarity exchange at protective conductor current

and touch current measurements (GT-800 only).

Data memory for over 1000 measurement results.

Integrated interface (USB 2.0) for transfer of measurement results to PC.

Separate interface (USB 2.0) for connection of optional USB barcode reader,

USB keyboard, USB memory stick or USB printer.

7

GT-600/GT-800 Instruction Manual

Graphic LC-Display for measurement values, limit values and test parameters.

Compact plastic housing with accessory bag.

Connection diagrams and limit values in instrument’s cover.

Limit values adjustable through measurement range in all functions (except

P/IL and CLAMP).

Visual and acoustic warnings in case of exceeded limit value.

Limits predefined for German and English region.

Real time clock for documentation of test results.

Single or continuous measurements.

Adjustable measurement times in single measurement mode.

Three selectable languages (English, German and French)

Scope of Supply

1 pc Portable Appliance Tester GT-600/GT-800 with permanently connected

mains cable (Schuko)

1 pc Accessory bag (fixed to housing)

1 pc Test lead, 1.5 m, 600 V CAT III, black

1 pc Alligator Clip 10 A, 600 V, CAT II, black

1 pc Test tip 4 mm, 600 V CAT II, black

1 pc USB interface cable

1 pc CD with USB drivers and instruction manuals

1 pc Instruction manual in English/German/French

Available Accessories

PC Software for creation of test reports “es control prof“ (No. 2390081)

USB Barcode reader (BC-MT204S, No. 3504407)

USB Keyboard English version (KBUK-MT204S, No. 3504395)

USB Keyboard German version (KBGE-MT204S, No. 3504388)

Current clamp adapter CHB-1 (No. 2390055) measuring range 0.001 A ... 60 A

(for leakage/load current measurements)

Clamp Adapter ACF-6A (No. 2743889)

PE Socket adapter Adapter-PE (No. 4151659)

Brush test probe PAT-BRUSH (No. 4151667)

Transport and Storage

Please keep the original packaging for potential later transport, e.g. for

calibration. Any transport damage due to faulty packaging will be excluded

from warranty claims.

Instruments must be stored in dry and closed areas. In case of an instrument

being transported in extreme temperatures, a recovery time of minimum 2 hours

is required prior to instrument operation.

8

GT-600/GT-800 Instruction Manual

Safety Measures

The GT-600/GT-800 appliance tester has been built and tested in compliance with

the valid safety regulations and left the factory in safe and perfect condition. In

order to maintain this condition and to ensure safe instrument operation, the

user must pay attention to the references and warnings contained within this

instruction manual.

WARNING, DANGER OF ELECTRICAL SHOCK

In order to avoid electrical shock, the valid safety and national regulations

regarding excessive contact voltages must receive utmost attention when

working with voltages exceeding 120V DC or 50V RMS AC.

The respective accident prevention regulations established by the national

health & safety board for electrical systems and equipment must be strictly

met at all times.

Prior to any operation, ensure that the instrument, test leads, mains cable

and accessories are in perfect condition.

The instrument may only be connected to mains voltage as indicated in the

technical specification section.

The instrument may only be used within the operating ranges as specified in

the technical specification section.

Only touch test leads and test probes at handle area provided. Never directly

touch test probes. Direct contact to measurement connectors or test probes

must be avoided at any time.

The instrument may only be used in dry and clean environments. Dirt and

humidity reduce insulation resistance and may lead to electrical shocks, in

particular for high voltages.

Never use the instrument in precipitation such as dew or rain. In case of

condensation due to temperature jumps, the instrument may not be used.

A perfect display of measurement values may only be ensured within the

temperature range of 0 °C to +40 °C.

Prior to opening the instrument ensure that it is switched off and

disconnected from all current circuits.

To ensure a safe measurement only use original test leads and accessories.

If the operator’s safety is no longer guaranteed, the instrument is to be put

out of service and protected against use. The safety can no longer be

guaranteed if the instrument (or test leads):

– shows obvious damage

– does not carry out the desired measurements

– has been stored for too long under unfavourable conditions

– has been subjected to mechanical stress during transport.

Dangerous voltages may be present on appliances or device under test (DUT)

caused by insulation test. Do not touch the appliances under test, danger of

electrical shock!

Start any test series by protective bonding resistance measurement.

At protective bonding resistance test, insulation test and substitute leakage

test, unit under test must be voltage-free. If necessary check the unit is

voltage-free i.e. by using a voltage tester.

Accidental measurement of a defective unit may trip an RCD (residual

current device).

9

GT-600/GT-800 Instruction Manual

Appropriate Usage

WARNING

The instrument may only be used under those conditions and for those

purposes for which it was conceived. For this reason, in particular the safety

references, the technical data including environmental conditions and the

usage in dry environments must be followed.

When modifying the instrument, the operational safety is no longer ensured.

The instrument may only be opened by an authorised service technician.

Before opening, the instrument must be switched off and disconnected from

any electrical circuit.

10

GT-600/GT-800 Instruction Manual

Operation Elements and Connectors

Front panel of the GT-600 Tester

Figure 1: Operational elements and connectors on GT-600 Tester

11

GT-600/GT-800 Instruction Manual

Front panel of the GT-800 Tester

Figure 2: Operational elements and connectors on GT-800 Tester

1 ....... Mains input fuse F1 T16 A (H) / 250 V, 5 × 20 mm

2 ....... Mains input fuse F2 T16 A (H) / 250 V, 5 × 20 mm

3 ....... Soft menu keys F1 ... F4

4 ....... ON/OFF mains switch with red pilot lamp

5 ....... Functional menu keys F4 ... F8, SAVE (to save test result), RCL (to recall

saved test result), MENU (to use menu functions) and EXIT (to exit current

menu level)

6 ....... Measurement function selector switch

7 ....... START/STOP button (to start or stop selected measurement function)

8 ....... ON red pilot lamp, measurement active

9 ....... Test/mains socket

10 ..... Fuse for RPE function F3 FF6.3 A (H) / 250 V, 5 × 20 mm

11 ..... CLAMP input connector (GT-800 only)

12 ..... Green test socket (PROBE 1)

13 ..... Red test socket (PROBE 2)

14 ..... IEC test socket (for CORD test and PRCD test)

15 ..... USB2 interface for USB barcode reader, keyboard or memory stick

16 ..... USB1 interface for PC

17 ..... Graphic LC-Display for measurement values, limit values and parameters.

12

GT-600/GT-800 Instruction Manual

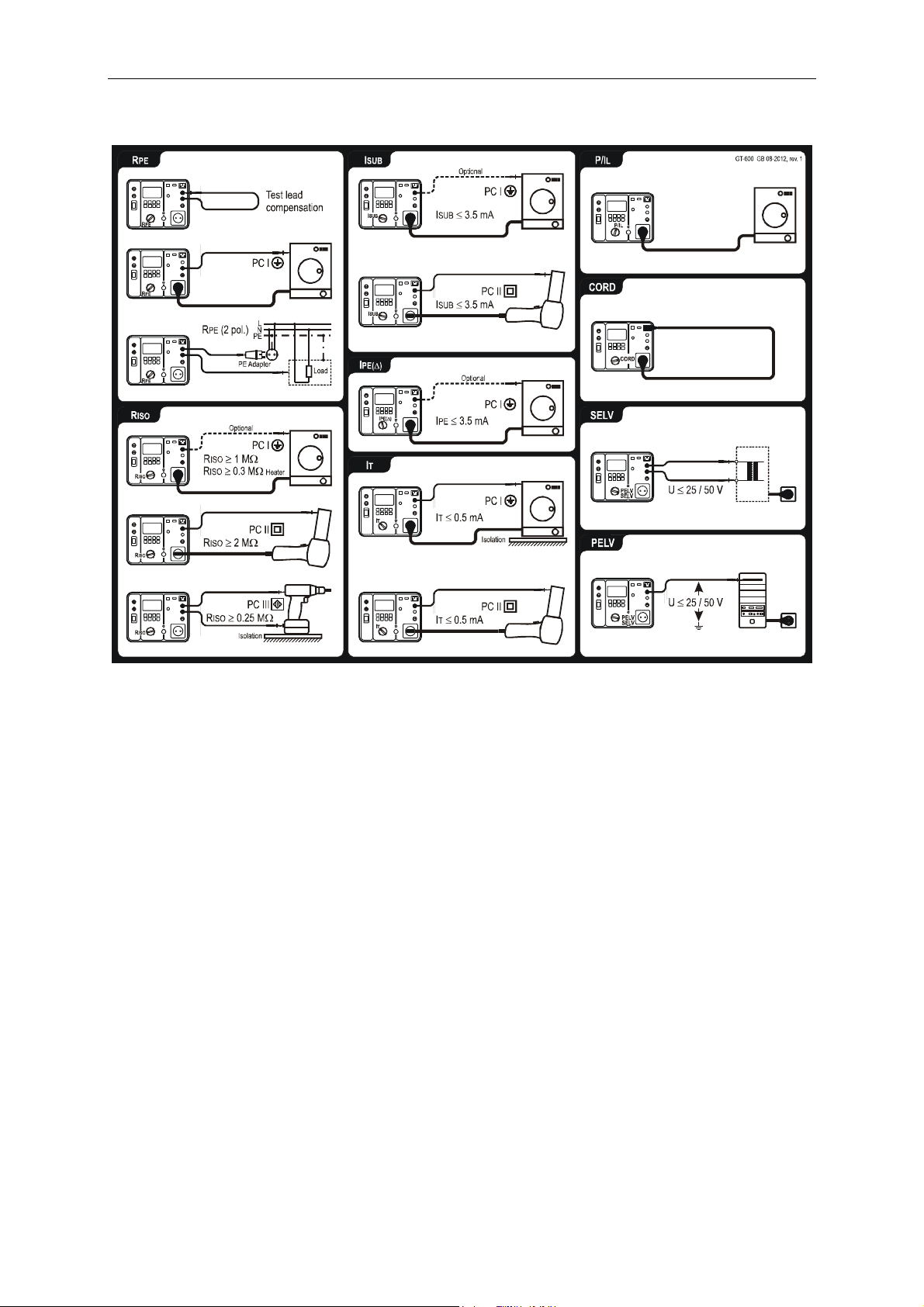

Cover of the GT-600 Tester, connection diagrams and limit values

Figure 3: Brief instructions with limit values (GT-600)

13

GT-600/GT-800 Instruction Manual

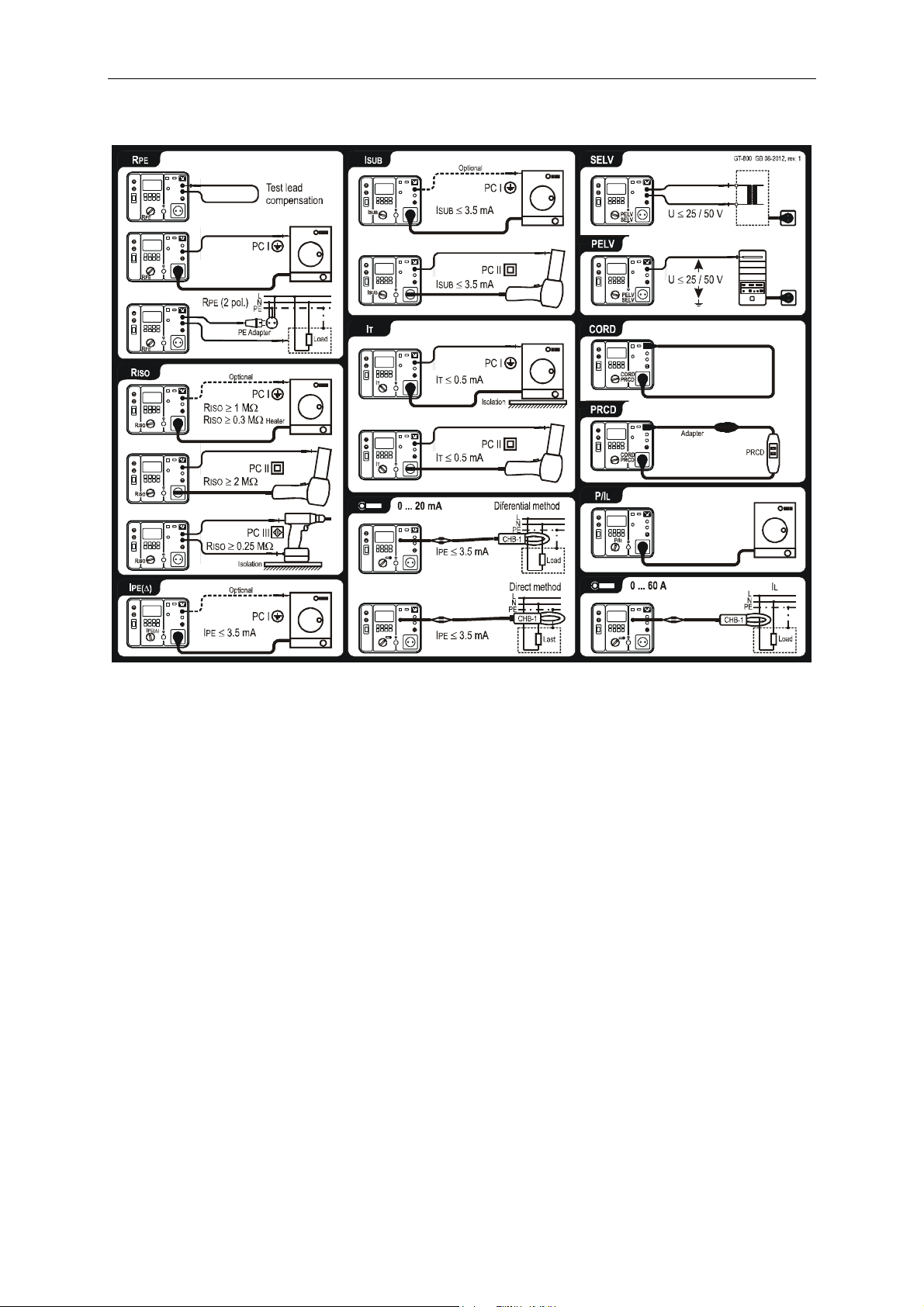

Cover of the GT-800 Tester, connection diagrams and limit values

Figure 4: Brief instructions with limit values (GT-800)

Measurement accessories are stored in the accessory bag on the top of the

tester.

14

GT-600/GT-800 Instruction Manual

Preparation of the GT-600/GT-800 Tester

Turning on the GT-600/GT-800 Tester

1) Connect the GT-600/GT-800 to a correctly installed Schuko mains socket.

2) Use the mains switch “ON/OFF“ (4) to turn on the GT-600/GT-800.

3) After turning on the GT-600/GT-800, pilot lamp of the power switch (4)

will switch on and the display (17) will show idle readout of selected

function. The GT-600/GT-800 is now ready for use.

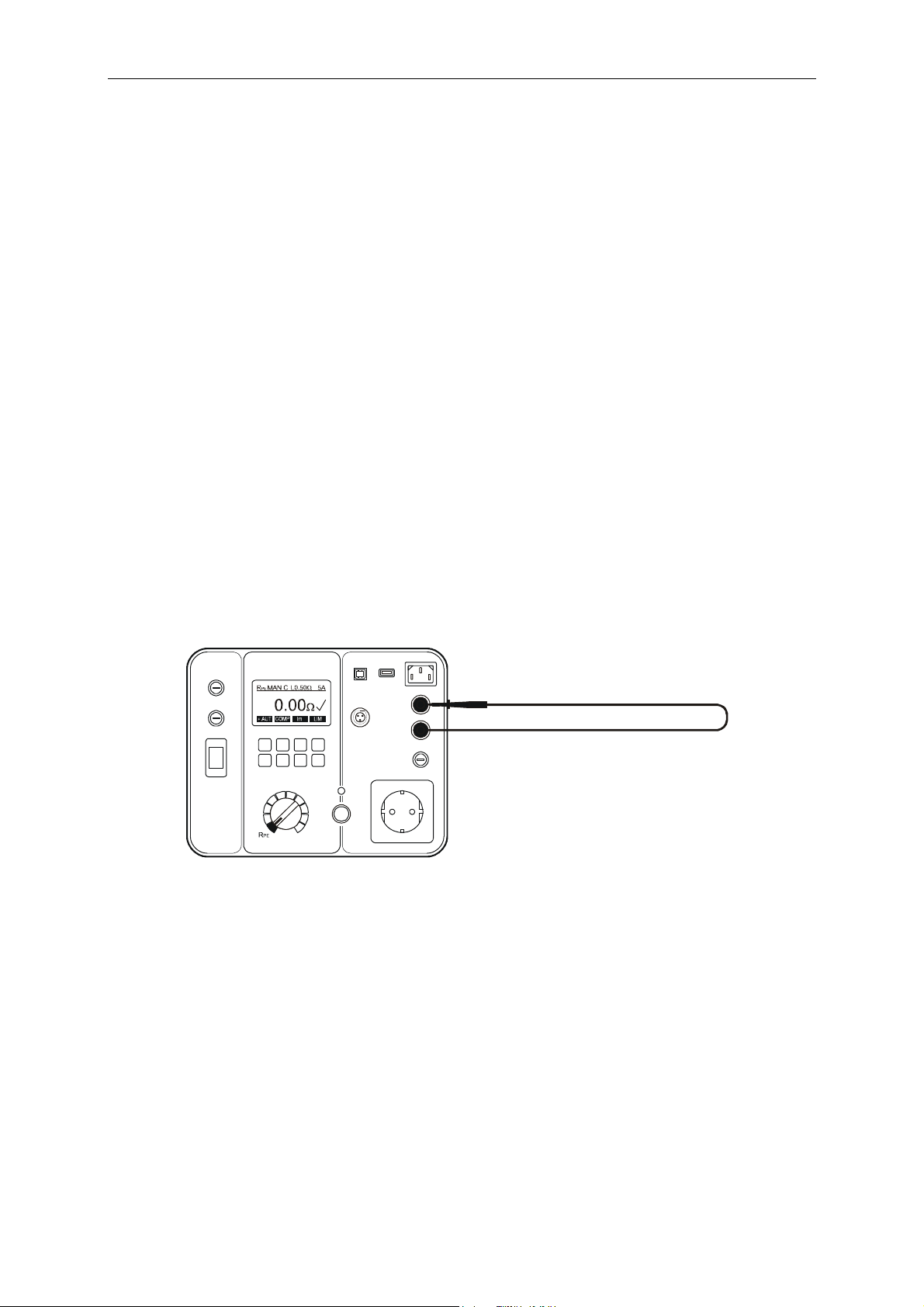

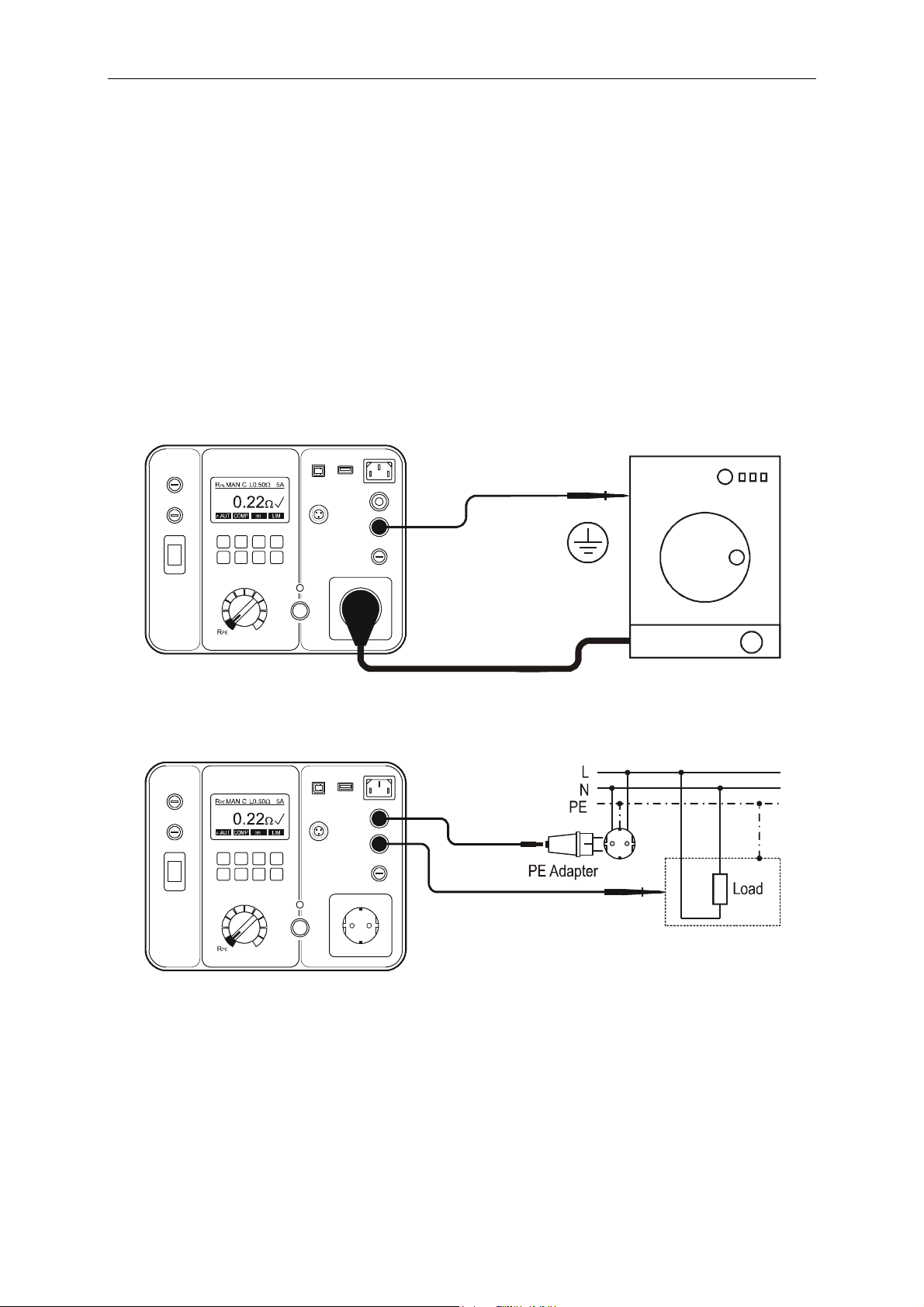

Test lead compensation

The GT-600/GT-800 appliance tester leaves the factory with uncompensated test

lead. We recommend to compensate test lead before starting the RPE tests,

otherwise result may not be correct and warning note “TEST LEAD NOT

COMPENSATED” will be displayed for a moment after pressing the “START” key.

1) Set the measurement function selector (6) to RPE position.

2) Connect test lead according to the figure below.

3) Press the “COMP” key (soft menu key F2) then start the measurement

by pressing the “START” button (7). Pilot lamp “ON” (8) indicates the

active measurement, then the result using uncompensated test lead is

displayed for a moment. Another regular measurement is done

automatically using compensated test lead, now the result should be

nearly zero. In the upper display line the character “C“ (Compensated)

appears as the information that test lead is compensated.

Figure 5: Connection for test lead compensation

☞ The compensation is used in all further RPE measurements. It will be

active even after switching off the GT-600/GT-800 appliance tester.

☞ The compensation is always carried out using test current of 5 A.

Cancel actual test lead compensation:

Open test loop (disconnect test lead from terminal PROBE 1 or PROBE 2) and

carry out the compensation as described above. The result >11.00 will be

displayed and “C” mark will disappear from the top display line.

15

GT-600/GT-800 Instruction Manual

Limit value setting

Limit value is offered in all functions except in P/IL and CLAMP. For limit value

setting press the “LIM” key (soft menu key F4) then use the soft menu keys “+”,

“–“, “STD” (Standard) or “CALC” (Calculation). The soft menu key F8 “EXIT” can

be used to exit limit value setting display.

☞ In case that test result comply with set limit value, the mark “ ” is

displayed and two short sound signals are present after finishing the

measurement. In case of non-compliance, the mark “X” is displayed and

one longer sound signal is present after finishing the measurement. The

limit value is saved as a parameter of the measurement result and is

transferred to PC in case of data transfer.

Start of the measurement

For single measurement press the START key and release it. In this case

measurement time is defined in MENU/SETUP/MEASUREMENT TIMES menu,

see the chapter “SETUP menu” on page 49. Watch elapsed time on displayed

bar graph during the measurement.

For continuous measurements press and keep pressing the START key for at

least 2 seconds until “CONT” (continuous) information is displayed.

Measurement time is limited to 5 minutes in this case. Continuous

measurement is available in all functions except in CORD, PRCD and AUTO

test.

External Voltage Display

If there is a dangerous external voltage present on test terminals prior to a

test or during it, the warning message “EXTERNAL VOLTAGE!“ will appear on

the display and the start of the measurement is blocked. Remove the external

voltage!

If an external voltage is applied to test terminals during the test in R

ISO

function, wrong measurement values may be displayed.

Please remove external voltage from any test terminal

immediately if “ EXTERNAL VOLTAGE!” warning is displayed.

Testing Appliances

WARNINGS

Before commencing any testing you are strongly advised to make reference to

the local regulations and standards for safety at works regulations and any

relevant publications from the Health and Safety Executive.

The appliance must be switched on for all tests.

When conducting tests do not touch the appliance as some tests involve high

voltages and high currents.

16

GT-600/GT-800 Instruction Manual

The tests should only be performed by competent persons who are familiar

with the requirements of the type of tests suitable for portable appliances.

It is potentially hazardous for both user and appliance should the wrong type

of tests be undertaken or if testing is carried out in an incorrect sequence.

It is important that you fully understand the various tests required and how

they should be performed.

The appliance must have passed the visual inspection, the protective bonding

resistance test (class I), and the insulation test (in this sequence) prior to any

other test. If any of these fail further testing must be stopped and any faults

must be rectified.

During the protective conductor current test, the touch current test and the

load test, the appliance will be energized at mains voltage. For this purpose,

switch on the appliance. Appliances driven by motors or equipped with

heating units may present a danger for the person testing (comply with the

appliance instruction manual!). Please ensure that the appliance is in a safe

condition to run and secure prior to testing.

Visual Inspection

Visually inspect the appliance before starting electrical tests.

Check the appliance for the following:

Condition of the appliance cables, i.e. no cuts, cracks or any physical damage

to the outer insulation layer.

Condition of the plug, cable securely attached, no signs of overheating and

that fitted fuses are correctly rated.

Any signs of damage, and that any mains or control switches will physically

switch on and off.

Any sockets for sign of overheating or physical damage.

17

GT-600/GT-800 Instruction Manual

Protective Bonding Test 5 A / 0.2 A (RPE)

The protective bonding test measures the resistance between PE terminal of test

socket and PROBE 1 terminal. This test applies to class I appliances only.

Remarks:

To obtain correct protective bonding test results you must have

compensated (zeroed) the test lead, see the section “Test lead

compensation” on page 15.

Connect the appliance and the earth bond test lead according to the figure 6

or 7.

You should use the lower test current 0.2 A for certain appliances. Please

refer to local appliance test standards and guidance material.

During the measurement flex the flexible cord along its length to help find

any broken conductors or poor quality joints.

Figure 6: Protective bonding test connections at appliance with mains plug

Figure 7: Protective bonding test connections at permanently connected

appliance

18

GT-600/GT-800 Instruction Manual

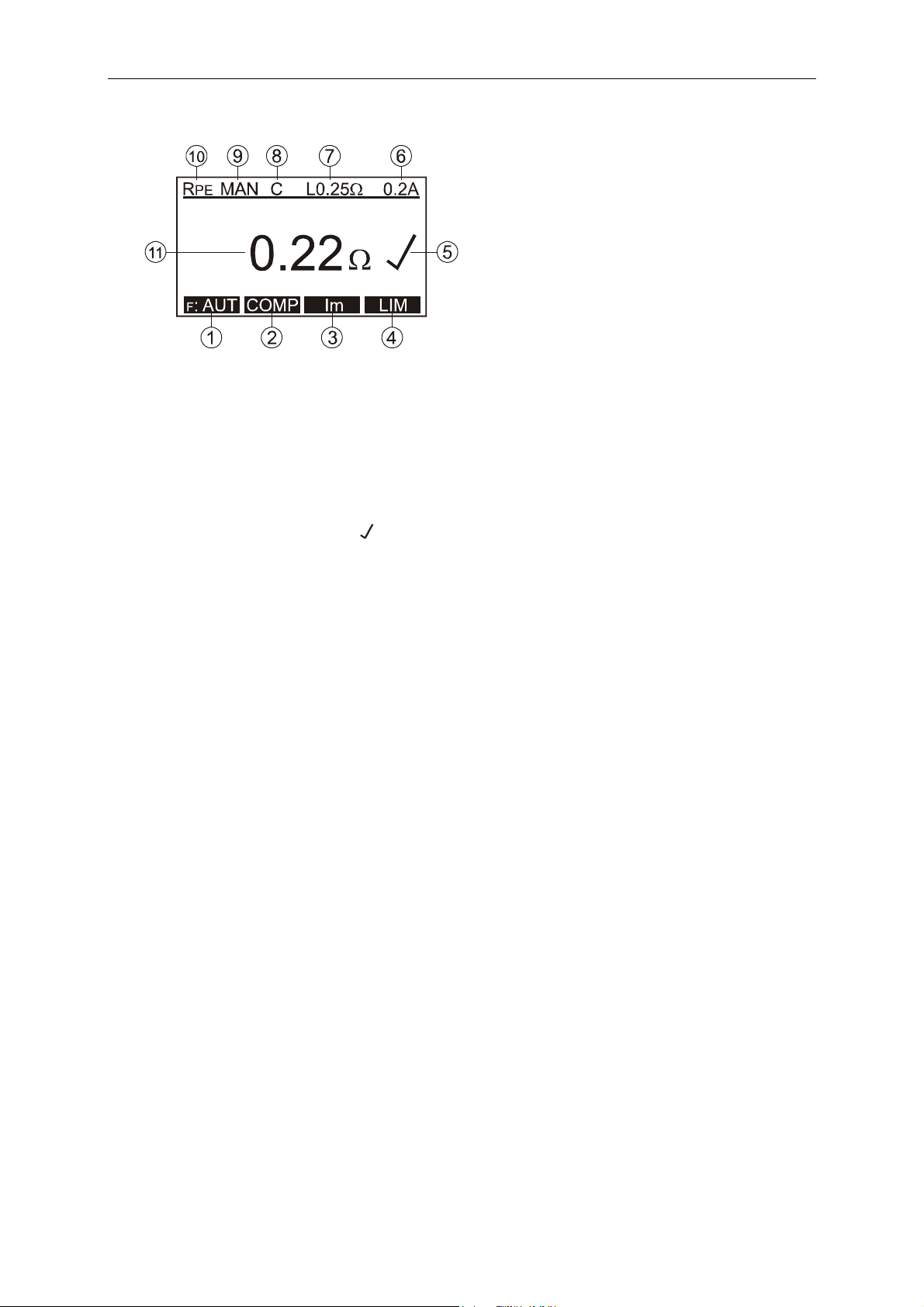

Display explanation:

Figure 8: Display in protective bonding test RPE

1 ...... “F: AUT” / “F: MAN” soft menu key, for selection of automatic /

manual start and store function.

2 ....... “COMP” soft menu key, for test lead compensation.

3 ...... “Im” soft menu key, for test current selection (0.2 A or 5 A).

4 ...... “LIM” soft menu key, for pass/fail limit value setting.

5 ...... Test result status ( ... result OK, X ... result not OK).

6 ...... Selected test current (0.2 A or 5 A).

7 ...... Pre-set pass/fail limit value.

8 ...... Test lead compensation mark (C ... compensated, blank .. not

compensated).

9 ...... Selected mode of start and save function (MAN, AUT).

MAN (Manual) ... Use START key to start the measurement.

AUT (Automatic) ... The test is started automatically after connecting

PROBE 1 to conductive part of tested appliance. Result is

automatically stored to last selected storage address. START key is not

active in this mode.

10 .... Function selected by the rotary switch (6).

11 .... Test result and unit.

Note:

In case that protective bonding test fails, the pass/fail limit value can be

recalculated by using the “LIM” and “CALC” keys and entering the length

and cross section of the mains lead. The last measurement value will be

deleted, and a new test has to be performed.

19

GT-600/GT-800 Instruction Manual

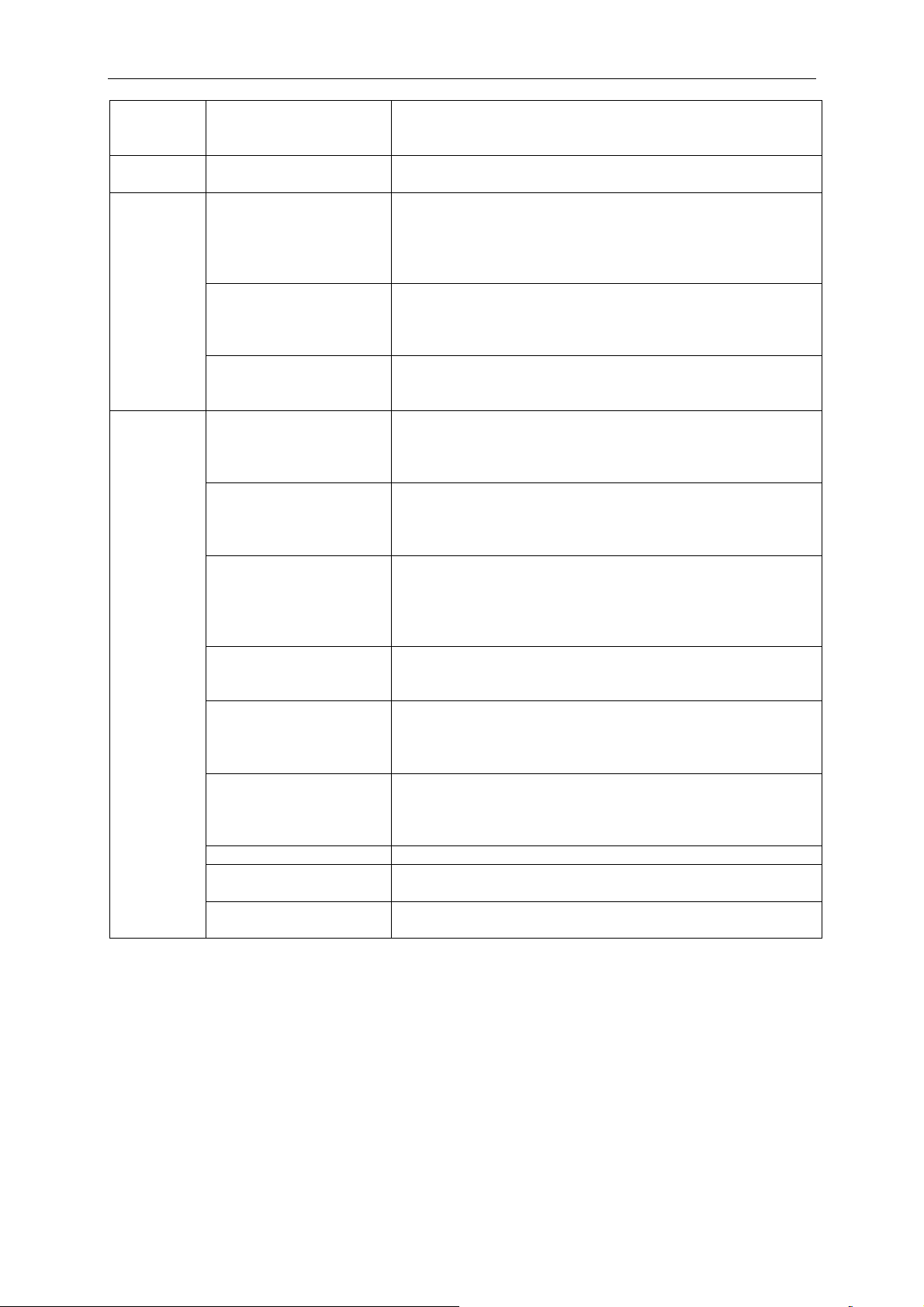

Pass/fail limit value calculation:

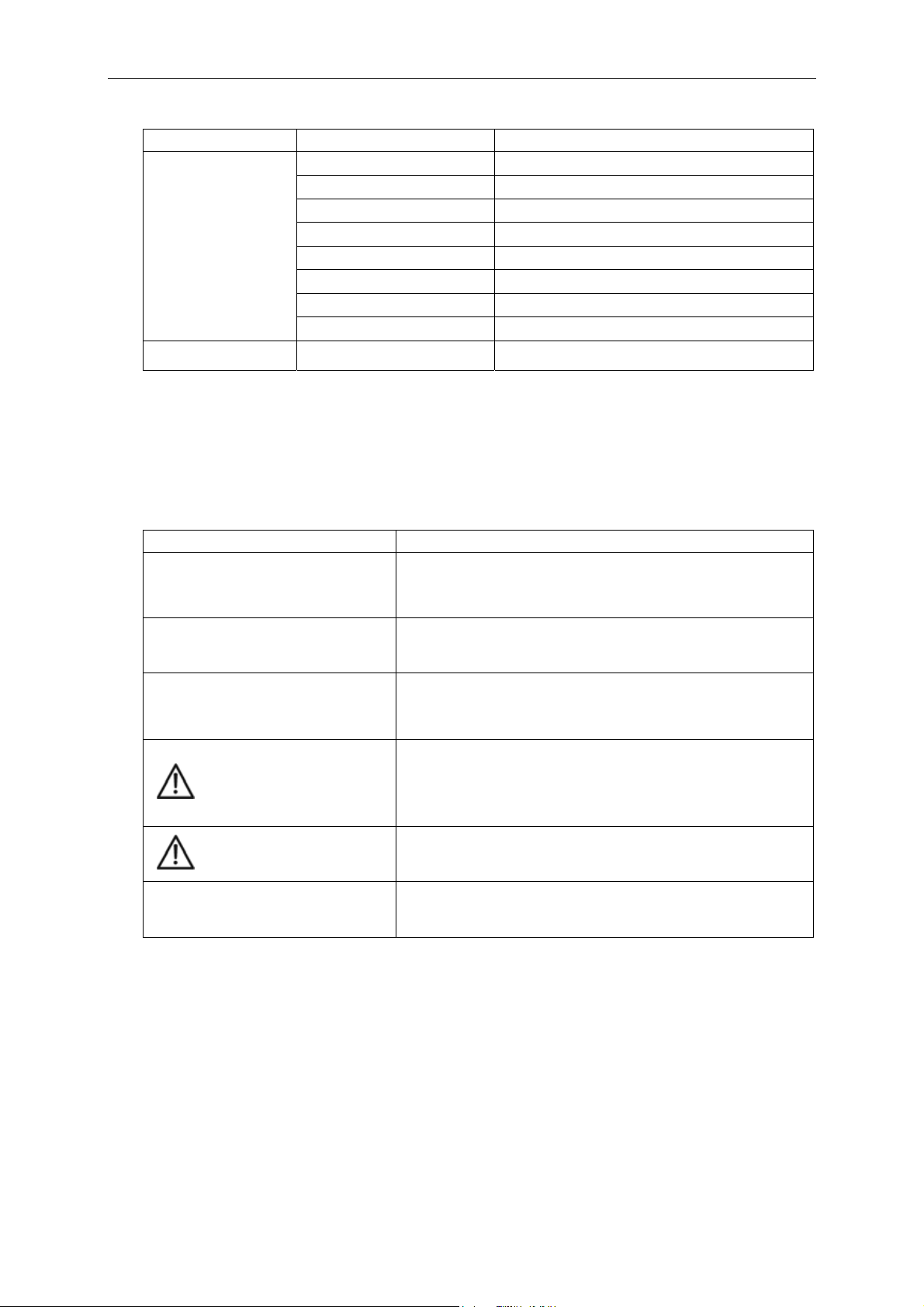

Cross section A Cable length L Limit value

5 m 0.3

5 ... 12.5 m 0.4

12.5 ... 20 m 0.5

1.5 mm2

20 ... 27.5 m 0.6

27.5 ... 35 m 0.7

35 ... 42.5 m 0.8

42.5 ... 50 m 0.9

50 m 1.0

2.5 ... 50 mm2 1 ... 50 m (res. 0.5 m)

RLIM = .L/A

Where:

... 0.01786 mm2/m (specific resistance of Cu)

L .. cable length in m

A .. cross section in mm2

Specific information that can be shown on the display:

Information displayed Description

TEST LEAD

NOT COMPENSATED

Test lead is not compensated (no “C” mark on

the display)! It is recommended to

compensate the test lead.

>5, NOT COMPENSATED

Compensation was not successfully done due

to too high compensation value (>5.00 )!

Test lead is wrong compensated (negative RPE

COMP?

result 0.05 ). Compensate the test lead

again.

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 2. Reconnect

USE PROBE 1

>11.00 X

it to PROBE 1.

RPE value higher than 11.00 (over-range),

possibly because of open test lead.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

20

GT-600/GT-800 Instruction Manual

Insulation Resistance Test 250 V / 500 V (RISO)

The insulation resistance test measures the resistance of the insulation between:

L/N terminals of test socket and PE terminal of test socket in parallel with

PROBE 2 (at class I and class II). L/N terminals are shorted by the tester for this

test.

Test probe PROBE 1 and test probe PROBE 2 (at class III).

Warnings

The test voltage is either 500 V (or 250 Vd.c. at GT-800 only). Do not

touch the appliance during the insulation test! If the test fails, any metal

part of the appliance could become live!

Always make sure that the test has completed before disconnecting the

appliance leads to ensure that all capacitances have discharged!

Cautions

Do not perform the Insulation test on appliances that failed the

protective bonding test or the visual inspection test.

The insulation test may not be suitable for some types of appliances. For

these appliances an alternative test may be conducted such as touch

current, protective conductor current or substitute leakage current test.

It is essential to refer to the local appliance test standards and/or

reference material for the safe applicability of these alternative tests.

Test voltage of 500 V may not be suitable for some appliances that

contain overvoltage protection devices (e.g. varistors) in its installation.

For these appliances test voltage of 250 V shall be used, refer to the

local appliance test standards and/or follow the manufacturer

recommendations.

Remarks:

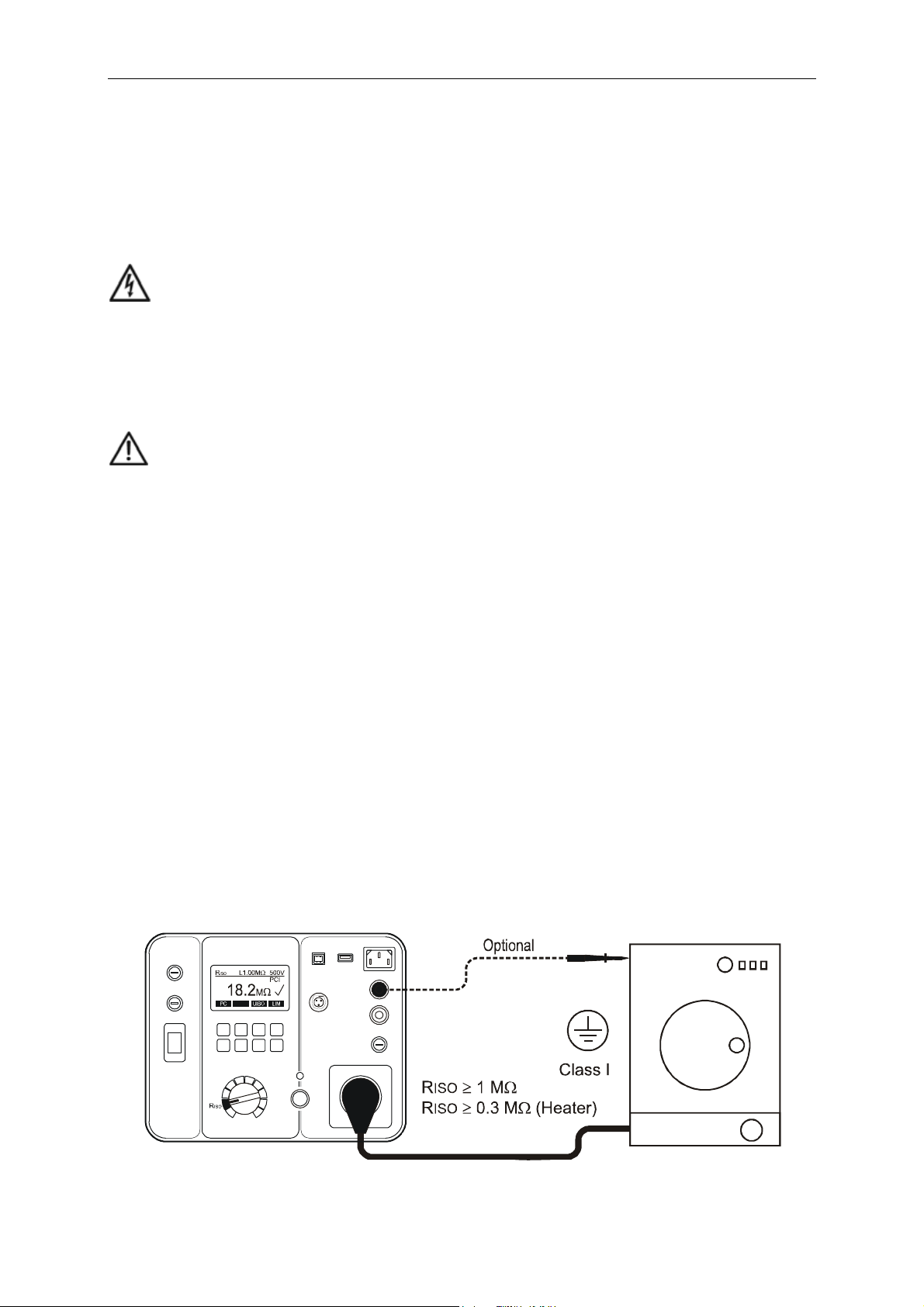

Connect the appliance and the test lead according to the figure 9, 10 or 11.

For class I appliances no probe is required except if there are some metal

parts on the appliance which are not connected to PE terminal.

For class II appliances apply the test probe to any exposed metalwork on the

appliance. Do the test for all exposed metal parts on the appliance, partial

results must pass pre-set limit value.

Figure 9: Insulation resistance test connections at appliance class I

21

GT-600/GT-800 Instruction Manual

Figure 10: Insulation resistance test connections at appliance class II

Figure 11: Insulation resistance test connections at appliance class III

Display explanation:

Figure 12: Display in insulation resistance test RISO

1 ...... “PC” soft menu key, for selection of protection class (PC I-HEATER,

PC I, PC II or PC III).

2 ....... “UISO” soft menu key, for selection of test voltage (250 V or 500 V).

3 ...... “LIM” soft menu key, for pass/fail limit value setting.

4 ...... Test result status ( ... result OK, X ... result not OK).

5 ...... Selected protection class (PC I-HEATER, PC I, PC II or PC III).

6 ...... Selected test voltage 500 V (or 250 V at GT-800 only).

7 ...... Pre-set pass/fail limit value.

8 ...... Function selected by the rotary switch (6).

9 ...... Test result and unit.

22

GT-600/GT-800 Instruction Manual

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1. Reconnect

USE PROBE 2

it to PROBE 2.

>100M

>20.0M

RISO value higher than 100 M (over-range).

Measurement range in class I / II is 100 M.

RISO value higher than 20.0 M (over-range).

Measurement range in class III is 20.0 M.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

23

GT-600/GT-800 Instruction Manual

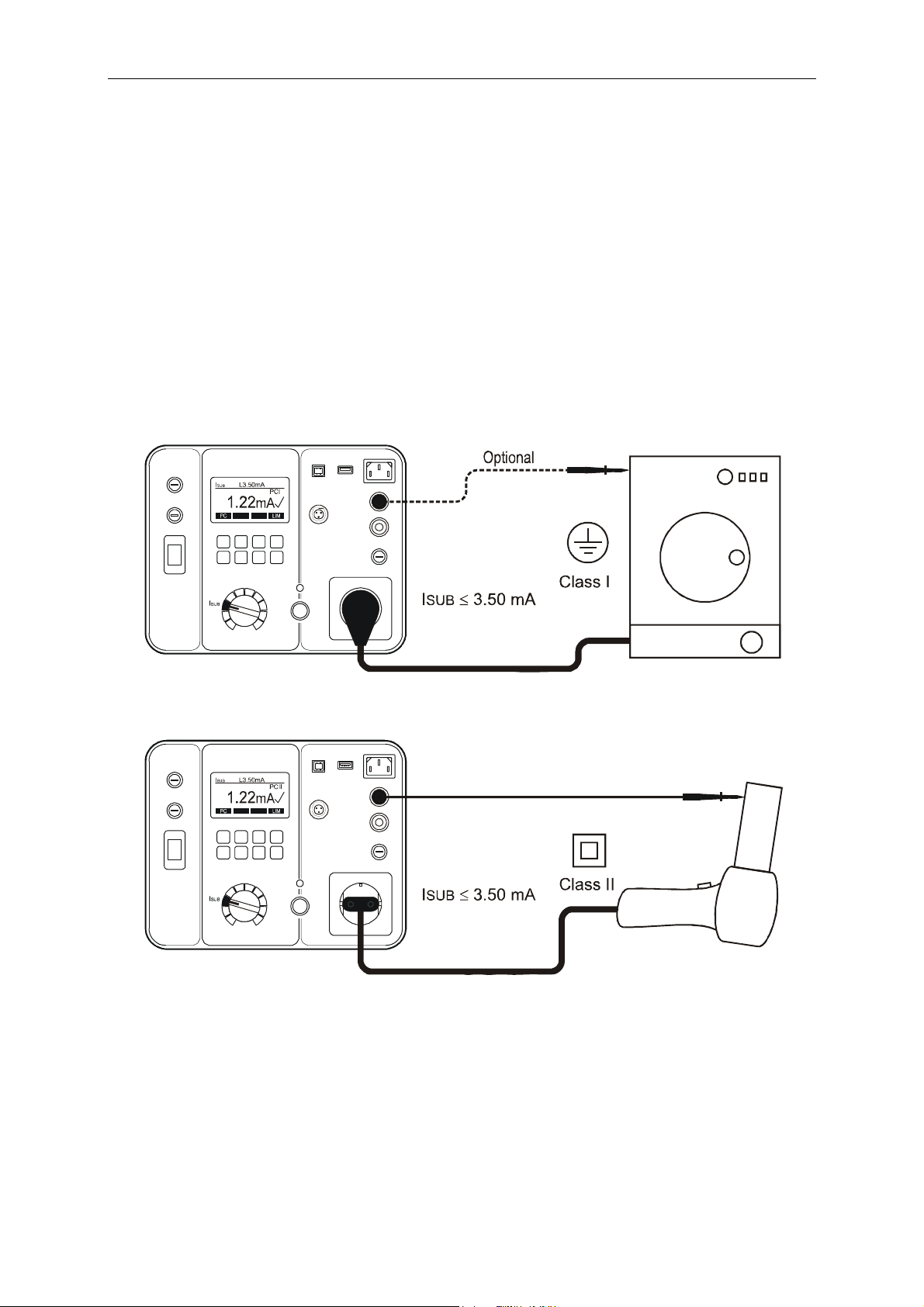

Substitute Leakage Current Test (ISUB)

The substitute leakage current test measures the leakage current between L/N

terminals of test socket and PE terminal of test socket in parallel with PROBE 2

(at class I, class II). L/N terminals are shorted by the tester for this test.

It is essential to refer to the local appliance test standards and/or guidance

material for the safe applicability of this test.

Remarks:

Connect the appliance and the test lead according to the figure 13 or 14.

For class I appliances no probe is required except if there are some metal

parts on the appliance not connected to PE terminal.

For class II appliances apply the test probe to any exposed metalwork on the

appliance. Do the test for all exposed metal parts on the appliance.

Figure 13: Substitute leakage current test connections at appliance class I

Figure 14: Substitute leakage current test connections at appliance class II

24

GT-600/GT-800 Instruction Manual

Display explanation:

Figure 15: Display in substitute leakage current test ISUB

1 ...... “PC” soft menu key, for selection of protection class (PC I or PC II).

2 ...... “LIM” soft menu key, for pass/fail limit value setting.

3 ...... Test result status ( ... result OK, X ... result not OK).

4 ...... Selected protection class (PC I or PC II).

5 ...... Pre-set pass/fail limit value.

6 ...... Function selected by the rotary switch.

7 ...... Test result and unit.

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1. Reconnect

USE PROBE 2

it to PROBE 2.

>20.0mA X ISUB result >20.0mA (over-range).

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

25

GT-600/GT-800 Instruction Manual

Protective Conductor Current Test (IPE())

The protective conductor current test measures the earth leakage current in the

protective conductor (PE) of appliances connected to the test/mains socket of the

GT-600/GT-800. The measurement is carried out by the differential method.

Warning

NEVER carry out this test unless you have first carried out a thorough

visual inspection followed by a test of the protective bonding resistance

(for class I appliances), and then a test of insulation resistance. You must

verify that these tests have passed before engaging the protective

conductor current test.

Caution

Live test! The appliance will be energized at mains voltage. For this

purpose switch on the appliance. Appliances driven by motors or

equipped with heating units may present a danger for the person

testing (comply with the appliance instruction manual!). Ensure that the

appliance is in a safe condition to run and secure it prior to testing.

Remarks:

Connect the appliance according to the figure 16.

If the protective conductor current is higher than 20.00 mA for 2 seconds,

the test will be interrupted automatically and “RANGE OVERLOAD” message

will be displayed.

The measurement must be performed in both positions of the mains plug,

the greater of the two values obtained must be used.

Figure 16: Protective conductor current test connections

26

GT-600/GT-800 Instruction Manual

+

Display explanation:

Figure 17: Display in protective conductor current test IPE

1 ...... “POL” soft menu key, for selection of mains voltage polarity (GT-800

only).

2 ...... “LIM” soft menu key, for pass/fail limit value setting.

3 ...... Test result status (

... result OK, X ... result not OK).

4 ...... Selected mains polarity (GT-800 only).

... phase connected to the right terminal of test socket.

... phase connected to the left terminal of test socket.

5 ...... Pre-set pass/fail limit value.

6 ...... Function selected by the rotary switch.

7 ...... Test result and unit.

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1.

USE PROBE 2

MAINS SWITCH ON

CONTINUE?

Reconnect it to PROBE 2.

Warning! Mains voltage will be applied to

test/mains socket after confirming this

message!

Note! No device is connected to test/mains

NO DEVICE

socket, or mains switch on device is not

switched ON!

>20.00mA X

IPE current higher than 20.00 mA (overrange).

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

27

GT-600/GT-800 Instruction Manual

Touch Current Test (IT)

The touch current test measures the leakage current from exposed conductive

parts of tested appliance via test probe PROBE 2 and internal resistance of

approx. 2 k to earth. The device under test is not necessary to be connected to

the test/mains socket of the GT-600/GT-800, it can be also externally powered.

The measurement is carried out by the direct method.

Warning

NEVER carry out this test unless you have first carried out a thorough

visual inspection, followed by a test of the protective bonding resistance

(for class I appliances), and then a test of insulation resistance. You must

verify that these tests have passed before engaging the touch current

test.

Caution

Live test! The appliance will be energized at mains voltage. For this

purpose, switch on the appliance. Appliances driven by motors or

equipped with heating units may present a danger for the person

testing (comply with the appliance instruction manual!). Ensure that the

appliance is in a safe condition to run and secure it prior to testing.

Remarks:

Connect the appliance and the test lead according to the figure 18 or 19.

For class I appliances apply the test probe to any metal part not connected to

PE terminal.

For class II appliances apply the test probe to any exposed metalwork on the

appliance.

If the touch current is higher than 2.00 mA for 2 seconds, the test will be

interrupted automatically and “RANGE OVERLOAD” message will be

displayed.

The measurement must be performed in both positions of the mains plug,

the greater of the two values obtained must be used.

Figure 18: Touch current test connections at appliance class I

28

GT-600/GT-800 Instruction Manual

Figure 19: Touch current test connections at appliance class II

Display explanation:

Figure 20: Display in touch current test IT

1 ...... “POL” soft menu key, for selection of mains voltage polarity (GT-800

only).

2 ...... “LIM” soft menu key, for pass/fail limit value setting.

3 ...... Test result status (

4 ...... Selected mains polarity (GT-800 only).

+ ... phase connected to the right terminal of test socket,

... phase connected to the left terminal of test socket.

5 ...... Pre-set pass/fail limit value.

6 ...... Function selected by the rotary switch.

7 ...... Test result and unit.

... result OK, X ... result not OK).

29

GT-600/GT-800 Instruction Manual

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in

EXTERNAL VOLTAGE

section “Pre-Tests and Protection,

Functions and Messages”.

MAINS SWITCH ON

CONTINUE?

Warning! Mains voltage will be applied to

test/mains socket after confirming this

message!

Note! No device is connected to test/mains

NO DEVICE

socket, or mains switch on device not

switched ON!

Test lead is connected to PROBE 1.

USE PROBE 2

Reconnect it to PROBE 2.

>2.00mA X IT value higher than 2.00 mA (over-range).

Voltage higher than 50 V approx. is

VOLTAGE OVER RANGE

present on PROBE 2. Remove the voltage.

Current higher than 2 mA was flowing to

CURRENT OVER RANGE

test probe for 2 seconds.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

30

GT-600/GT-800 Instruction Manual

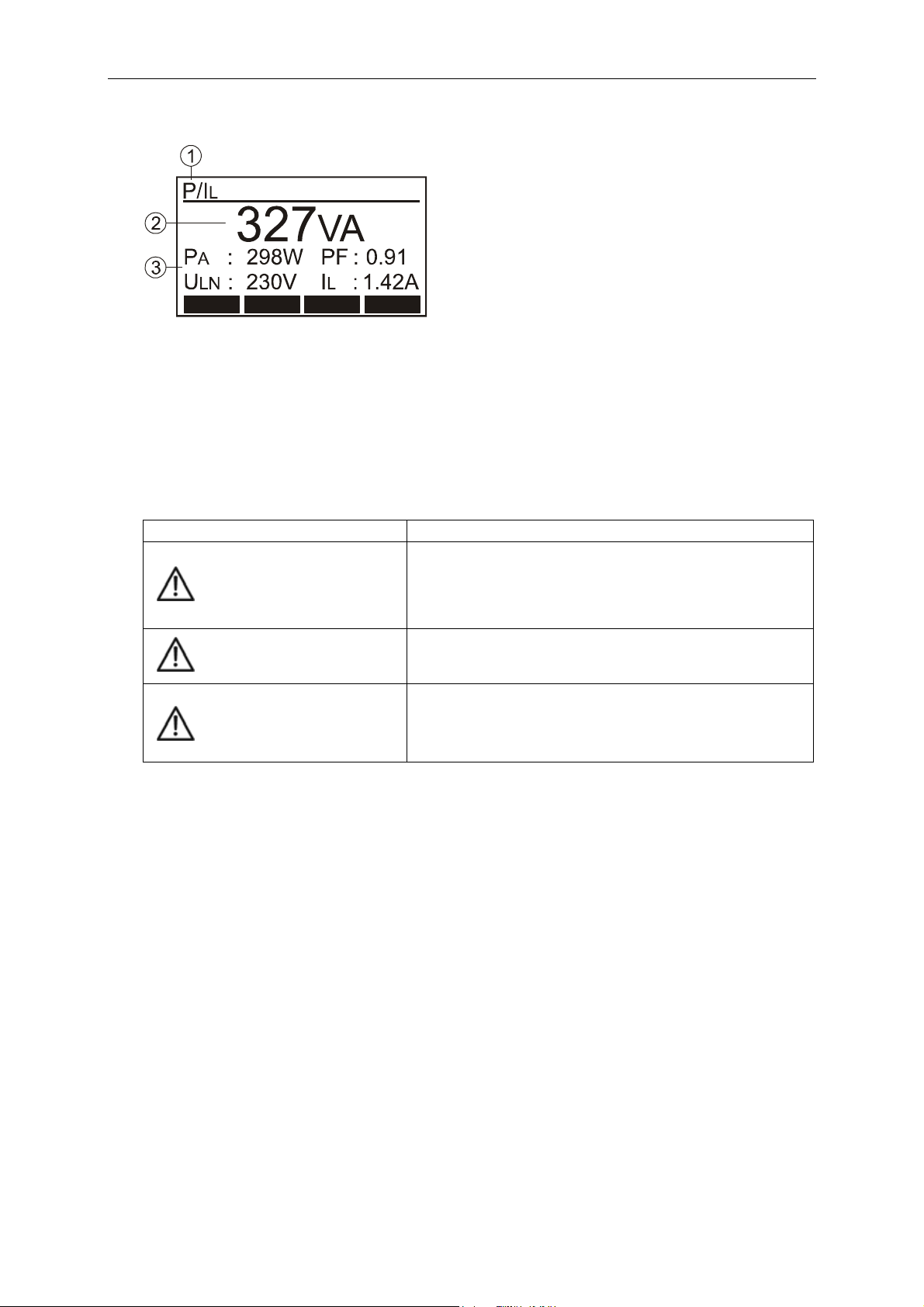

Power, Load Current Test (P/IL)

The power/load current test measures the apparent power S, active power PA,

mains voltage ULN, load current IL and power factor PF of the appliance,

connected to mains test/mains socket.

Warning

NEVER carry out this test unless you have first carried out a thorough

visual inspection, followed by a test of the protective bonding resistance

(for class I appliances), and then a test of insulation resistance and

protective conductor current or touch leakage test. You must verify that

these tests have passed before engaging this test.

Caution

Live test! The appliance will be energized at mains voltage. For this

purpose, switch on the appliance. Appliances driven by motors or

equipped with heating units may present a danger for the person

testing (comply with the appliance instruction manual!). Ensure that the

appliance is in a safe condition to run and secure it prior to testing.

Remarks:

Connect the appliance according to the figure 21.

If the load current is higher than 18.0 A for 10 seconds, the test will be

interrupted automatically and “RANGE OVERLOAD” message will be

displayed.

Figure 21: Power / Load current test connection

31

GT-600/GT-800 Instruction Manual

Display explanation:

Figure 22: Display in power / load current test P/IL

1 ...... Function selected by the rotary switch.

2 ...... Main result (apparent power in VA).

3 ...... Sub-results (active power PA in W, mains voltage ULN in V, power

factor PF and load current I

L in A)

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1 or to

DO NOT USE PROBES

MAINS SWITCH ON

CONTINUE?

PROBE 2. Disconnect it.

Warning! Mains voltage will be applied to

test/mains socket after confirming this

message!

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

32

GT-600/GT-800 Instruction Manual

Clamp Current Test ( ) (GT-800 only)

The test with the external clamp adapter measures the current in clamped

conductor. The function is intended to measure:

The protective conductor current (earth leakage current) in the protective

conductor (PE).

The load current in line (or neutral) conductor.

Remarks:

Connect the clamp according to the figure 23, 24 or 25.

Select appropriate measurement range by using soft menu key “RNG” (F1)

(0 ... 20 mA for leakage current or 0 ... 60 A for load current).

Figure 23: Protective conductor current test connection (differential method)

Figure 24: Protective conductor current test connection (direct method)

33

GT-600/GT-800 Instruction Manual

Figure 25: Load current test connection

Display explanation:

Figure 26: Display in CLAMP current test ( )

1 ...... “RNG” soft menu key, for selection of measurement range (0...20 mA

or 0...60 A).

2 ...... Selected measurement range.

3 ...... Function selected by the rotary switch.

4 ...... Test result and unit.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

34

GT-600/GT-800 Instruction Manual

IEC CORD Test (CORD/PRCD)

The IEC CORD test does a full test of IEC cords, extension leads and cable reels.

Following parameters are tested and measured:

Protective bonding resistance RPE

Insulation resistance RISO between PE and L/N conductors (L/N conductors are

shorted by the GT-600/GT-800 Tester)

L conductor continuity

N conductor continuity

L and N condition (OK/shorted).

CORD

Figure 27: CORD test connection

Display explanation:

Figure 28: Display in CORD test

1 ...... “TYPE” soft menu key, for selection of measurement function (CORD

or PRCD).

2 ....... “COMP” soft menu key, for lead compensation of test adapter.

3 ...... “LIM” soft menu key, for pass/fail limit value setting of protective

bonding.

4 ...... Test result status (

... result OK, X ... result not OK).

5 ...... Used test current 5.0 A (fixed parameter).

6 ...... Pre-set pass/fail limit value for protective bonding RPE.

7 ...... Function selected by the rotary switch and the “TYPE” key.

8 ...... Test parameters, set limit values, test results and units.

35

GT-600/GT-800 Instruction Manual

Procedure to test a mains cable extension leads or cable reels:

1) Use a standard IEC cable as a test adapter to connect tested mains

extension coupling to IEC connector (14) of the GT-600/GT-800 Tester.

2) Compensate the test adapter:

Connect the test adapter according to the figure 27 first and press the

“COMP” key and then START key. Compensation will be done then

another measurement will follow to show the efficiency of the

compensation.

3) Connect the mains extension or cable reel to be tested via the

compensated test adapter to GT-600/GT-800 according to the figure

below. Carry out the measurement by pressing the START key.

Figure 29: Cable reel or extension cable test connection

Cancel actual test lead compensation:

Remove any cable from IEC connector (14) and carry out the compensation.

Result >11.00 will be displayed and “C” mark will disappear from the top

display line.

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1 or to

DO NOT USE PROBES

PROBE 2. Disconnect it.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

36

GT-600/GT-800 Instruction Manual

PRCD Test (CORD/PRCD) (GT-800 only)

The PRCD test function of the GT-800 does a full test of PRCD 2-pole, 3-pole and

type S (AC types).

Following parameters are tested and measured:

Visual test

Confirm pass of visual test by the soft menu key “YES”.

Protective bonding continuity R

PE

The measurement is carried out by using test current of 5 A (fixed

parameter). The limit value for R

PE is adjustable by using the soft menu key

“LIM” in idle display mode. Also the limit value can be calculated on bases of

entered cross section and length of the PRCD cable.

Insulation resistance RISO

The insulation resistance is measured on the output side of the PRCD at open

PRCD switch by using test voltage of 500 V (fixed parameter). The limit value

for RISO is fixed and pre-set to 1.00 M.

Protective conductor current IPE

The measurement is done in two steps (two mains voltage polarities). The

polarity is exchanged automatically. The limit value for IPE is fixed and preset to 3.50 mA.

Functionality of the TEST button

After pressing the TEST button of the RCD, both L and N conductors must be

switched off from mains by the PRCD switch. The test result is displayed as

OK or FAILED.

Functional test at L disconnection

The GT-800 disconnects input L terminal, then both L and N conductors must

be switched off from mains by the PRCD switch. The test result is displayed as

OK or FAILED.

Functional test at N disconnection

The GT-800 disconnects input N terminal, then both L and N conductors must

be switched off from mains by the PRCD switch. The test result is displayed as

OK or FAILED.

Trip out time at IN/2

PRCD must not trip at this current, max. measurement time/range is 300 ms.

Trip out time at IN

PRCD must trip within 300 ms.

Trip out time at 5×IN

PRCD must trip within 40 ms.

Tripping current I

The test is carried out by using a ramp current starting at 0.5 IN and

increasing the test current by 0.05×IN per step up to IN. There are 11 test

steps, duration 300 ms per step, pause duration is 30 ms.

Trip out time at tripping current t/ I

The test is done in previous step, limit value is 300 ms.

37

GT-600/GT-800 Instruction Manual

Figure 30: PRCD test connection

Display explanation:

Figure 31: Display in PRCD test

1 ...... “ ” soft menu key, to move the cursor down when checking test

sub-results.

2 ...... “ ” soft menu key, to move the cursor up when checking test sub-

results.

3 ...... Test result status ( ... results OK, X ... results not OK).

4 ...... Selected nominal differential current IN (10 mA or 30 mA).

5 ...... Pre-set pass/fail limit value for protective bonding R

PE.

6 ...... Function selected by the rotary switch and the “TYPE” key.

7 ...... Test parameters, test results and units.

38

GT-600/GT-800 Instruction Manual

Specific information that can be shown on the display

Information displayed Description

External voltage is applied to one or more

test terminals, see the explanation in section

EXTERNAL VOLTAGE

“Pre-Tests and Protection, Functions and

Messages”.

Test lead is connected to PROBE 1 or to

DO NOT USE PROBES

PROBE 2. Disconnect it.

MAINS SWITCH ON

CONTINUE?

Warning! Mains voltage will be applied to

test socket after confirming this message!

ISUB > 3.50 mA

Substitute leakage current is higher than

3.50 mA. Dangerous, check the appliance!

There was no action (no key pressed) for

TIME OUT

more than 1 minute (repeat the test from

the beginning) or the PRCD is faulty.

PRCD ON Switch on PRCD

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

39

GT-600/GT-800 Instruction Manual

Protective Extra Low Voltage Test (PELV)

The test measures the protective extra low voltage between any accessible

conductive part of tested appliance and earth (PE).

Figure 32: PELV test connection

Display explanation:

Figure 33: Display in PELV test

1 ...... “SELV/PELV” soft menu key, for selection of measurement function

(SELV or PELV).

2 ...... “LIM” soft menu key, for pass/fail limit value setting (standard values

are 25 or 50 V).

3 ...... Test result status (

... result OK, X ... result not OK).

4 ...... Pre-set pass/fail limit value.

5 ...... Function selected by the rotary switch and the “SELV/PELV” key.

6 ...... Test result and unit.

Specific information that can be shown on the display

Information displayed Description

<10.0V PELV value lower than 10.0 V.

>150.0V

PELV value higher than 150.0 V. Remove the

voltage.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

40

GT-600/GT-800 Instruction Manual

Safety Extra Low Voltage Test (SELV)

The test measures the safety extra low voltage between two accessible

conductive parts of tested appliance.

Figure 34: SELV test connection

Display explanation:

Figure 35: Display in SELV test

1 ...... “PELV/SELV” soft menu key, for selection of measurement function

SELV or PELV).

2 ...... “LIM” soft menu key, for pass/fail limit value setting (standard values

are 25 or 50 V).

3 ...... Test result status (

... result OK, X ... result not OK).

4 ...... Pre-set pass/fail limit value.

5 ...... Function selected by the rotary switch and the “SELV/PELV” key.

6 ...... Test result and unit.

Specific information that can be shown on the display

Information displayed Description

<10.0V SELV value lower than 10.0 V.

>150.0V

SELV value higher than 150.0 V. Remove the

voltage.

In order to save displayed measurement result, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

41

GT-600/GT-800 Instruction Manual

AUTO Test (GT-800 only)

This is most common used test mode as it leads the operator through the whole

test procedure. There are 13 factory-programmed Auto-Tests and free space for

additional 17 customer-created ones.

Factory-programmed Auto-Tests for class I appliances (GERMAN REGION)

(listed figures are limit values in each test)

Tests 145 146 147 148 149 150 151 160 161

Visual Inspection Yes Yes Yes Yes Yes Yes Yes Yes Yes

Protective bonding

resistance 200 mA ()

Protective bonding

resistance 5 A ()

Insulation resistance 500 V

(M)

Substitute leakage current

(mA)

Protective conductor

current (mA)

0.30 - 0.30 0.30 0.30 - - - -

- 0.3 - - - 0.3 1.00 - -

1.00 1.00 0.30 - - 1.00 1.00 1.00 1.00

- - 3.50 - - 3.50 3.50 - -

3.50 3.50 - 3.50 3.50 - - 3.50 3.50

Touch current (mA) - - - - 0.50 - - - 0.50

Apparent power (kVA) 3.7 3.7 - 3.7 3.7 - - 3.7 3.7

Factory-programmed Auto-Tests for class II appliances (GERMAN REGION)

(listed figures are limit values in each test)

Tests 241 242 243 244

Visual Inspection Yes Yes Yes Yes

Protective bonding

resistance 200 mA ()

Protective bonding

resistance 5 A ()

Insulation resistance 500 V

(M)

Substitute leakage current

(mA)

Protective conductor

current (mA)

- - - -

- - - -

2.00 2.00 - -

- 0.50 - -

- - - 0.50

Touch current (mA) 0.50 - 0.50 Apparent power (kVA) 3.7 - 3.7 3.7

42

GT-600/GT-800 Instruction Manual

Factory-programmed Auto-Tests for class I appliances (ENGLISH REGION)

(listed figures are limit values in each test)

Tests 131 132 133 134 135 136 137

Visual Inspection Yes Yes Yes Yes Yes Yes Yes

Protective bonding

resistance 200 mA ()

Protective bonding

resistance 5 A ()

Insulation resistance 500 V

(M)

Substitute leakage current

(mA)

Protective conductor

current (mA)

- - 0.10 0.10 - 0.1 -

0.1 0.1 - - 0.1 - -

1.00 1.00 1.00 1.00 1.00 1.00 1.00

- - - - - - -

3.50 0.75 3.5 0.75 - - 3.50

Touch current (mA) - - - - - - Apparent power (kVA) 3.0 3.0 3.0 3.0 - - 3.7

Factory-programmed Auto-Tests for class II appliances (ENGLISH REGION)

(listed figures are limit values in each test)

Tests 231 232 233 234

Visual Inspection Yes Yes Yes Yes

Protective bonding

resistance 200 mA ()

Protective bonding

resistance 5 A ()

Insulation resistance 500 V

(M)

Substitute leakage current

(mA)

Protective conductor

current (mA)

- - - -

- - - -

2.00 2.00 2.00 2.00

- - - -

- - - 0.25

Touch current (mA) 0.25 0.25 - Apparent power (kVA) 3.0 - - 3.0

Note: AUTO-Test numbers 301 up to 317 are reserved for customer-created

AUTO Tests.

43

GT-600/GT-800 Instruction Manual

Idle display explanation:

Figure 36: Idle display in AUTO function

1 ...... “

” soft menu key, to move the cursor down in order to check the set of

tests to be done.

2 ...... “

” soft menu key, to move the cursor up in order to check the set of

tests to be done.

3 ...... “A

” soft menu key, to select appropriate AUTO Test (decreasing the

AUTO Test number).

4 ...... “A

” soft menu key, to select appropriate AUTO Test (increasing the

AUTO Test number).

5 ...... Protection class of selected AUTO Test.

6 ...... Appliance/AUTO-Test description.

7 ...... Number of selected AUTO Test.

8 ...... Tests, test parameters and limit values.

Test procedure:

- Select AUTO Test mode by using the rotary switch (6), idle display will

appear.

- Select appropriate AUTO Test by using the “A

” and “A ” soft menu

keys.

- Connect the appliance and test leads as required by the first test, e.g. R

(see the instructions for individual tests).

- Press the START key, visual inspection will be required.

- Do the visual inspection (see the section “Visual Inspection”). If the visual

test passes, confirm the action by pressing the “YES” soft menu key then

the next test is offered e.g. RPE.

- Connect test lead to the first accessible conductive part and press the

“START” key, measurement is carried out and test result is displayed.

- Repeat the test for all accessible conductive parts, then press the “NEXT”

key in order to move to the next test e.g. RISO. The worst RPE test result

(the highest) is displayed, ready for later memorizing.

- Do all tests required by selected AUTO Test following the same procedure

as for the first test.

- Press the “END” soft menu key after finishing all tests, display turns to

“check” mode, you may check all sub-results (worst result in each

function) by using the “

” and “ ” soft menu keys.

44

PE

GT-600/GT-800 Instruction Manual

R

T

K

In order to save displayed measurement results, press the “SAVE” function

key (F5) twice, for further instructions see the “Memorizing example”

section.

During the AUTO Test procedure the following soft menu keys can be offered:

IGN

Pressing the “IGNR” (Ignore) menu key the operator will ignore current

test result (for example, if it was carried out by mistake, or if it is out of

prescribed limit value).

Note! After pressing the “IGNR” menu key, previous worst result will be

displayed.

DEL

Pressing the “DEL” (Delete) menu key the operator will delete worst

result (for example, if current result was already ignored by pressing the “IGNR”

menu key).

Note! Be aware there will be no result available any more after pressing the

“DEL” menu key.

NEX

Pressing the “NEXT” menu key the operator will move to the next test

(for example from RPE to RISO test).

BAC

Pressing the “BACK” menu key the operator will move back to previous

test (for example from RISO to RPE test).

END

Pressing the “END” menu key the operator will end the AUTO Test

procedure and move to “check” mode. After pressing the “END” menu key you

may check all sub-results (worst result in each function) by using the “ ” and

“ ” soft menu keys.

45

GT-600/GT-800 Instruction Manual

Menu Functions

For further selections, entry and display of instrument’s settings, press the

“MENU” function key (F7), the following selection menu appears.

Figure 37: “Menu” display

1 ....... “▼” menu key (down) to move the cursor down

2 ....... “▲” menu key (up) to move the cursor up

3 ....... “ “ menu key (Enter)

4 ....... Selected menu function

5 ....... Other available menu functions

General operation instructions

Use the “▼” and “▲” menu keys to select desired menu function, then

confirm it by pressing the “” menu key.

Entered menu function may be aborted by pressing the “EXIT” function key

(F8).

By pressing the “” menu key the selected function will be activated.

46

GT-600/GT-800 Instruction Manual

MEMORY Menu

In this menu the following selections are available:

SAVE TO USB: Transfer of stored data to USB memory stick. The whole

storage (TOTAL), individual clients (CLI), individual

appliances (APP) or only individual measurement results

(0001) can be transferred. Data records to be transferred

can be selected by using the “◄”, “►” and “▼” menu

keys, transfer action must be confirmed by pressing the

“” menu key.

USB memory stick shall be connected to USB interface

USB2. Three sound signals will follow after plugging it to

USB2 connector as a confirmation the memory stick is

recognized by the GT-600/GT-800 Tester.

Note! The USB memory stick has to be FAT12, FAT16 or FAT32 formatted, sector

size 512 Byte.

CLEAR MEMORY: Erasing of measurement results. The whole memory

(TOTAL), individual clients (CLI), individual appliances

(APP) or only individual measurement results (0001) can

be erased. Data records to be erased can be selected by

using the “◄”, “►” and “▼” menu keys, the clear action

must be confirmed by pressing the “” menu key.

There is another possibility to clear only results under

selected address or to clear the results including selected

address.

MEMORY PROPERTY: Number of occupied/total available memory locations

(LOCATIONS), number of stored results (RESULTS) and

number of entered appliances / total available number of

appliances (200) (APPLIANCES) is displayed.

The results are written in a file that can be read by the optional software es

control.

OPERATOR Menu

Modify or enter the operator’s name by using the “▼”, “▲” and “” menu

keys then confirm it by pressing the “” menu key.

The operator can also be entered by using the optional barcode reader.

The operator and the date are attached to each measurement result

automatically when storing test results.

47

GT-600/GT-800 Instruction Manual

AUTO-TEST Menu

In this menu the following selections are available:

MODIFY / VIEW: Modify/view (customer-created AUTO Tests) or just view

(factory-programmed AUTO Tests).

Select the AUTO Test you wish to modify/view first by

using the “A▼” and “A▲” menu keys then confirm the

MODIFY/VIEW selection by pressing the “” menu key.

Now use the “▼”, “▲” menu keys to select the desired

AUTO Test step.

At customer-created AUTO Tests two menu keys “EDIT”

and “PAR” appear which allow the modification of the

selected AUTO Test step. “EDIT” key enables to remove

or add test step, “PAR” key enables to modify limit value

or test parameter (e.g. test voltage in RISO function).

RENAME AUTO-TEST: Select the AUTO Test you wish to rename first by using

the “A▼” and “A▲” keys then confirm the RENAME

AUTO Test selection by pressing the “” key. Use the

“▼”, “▲” and “” menu keys to create new name,

then confirm the new name by pressing the “” key.

CREATE AUTO-TEST: Create new AUTO Test as follows:

- Create the name of the new AUTO Test by using the

“▼”, “▲” and “” menu keys then confirm the

name by pressing the “” key.

- Select protection class of the new AUTO Test (PC I or

PC II) then confirm it by pressing the “” key.

- Select the tests to be contained in the new AUTO Test

by using the rotary switch and confirm each individual

test by the “” key. End the selection by pressing the

“END” key, the display turns to EDIT/ADJ mode.

Notes for setup of new AUTO Test!

Test current in R

PE test (5 A or 0.2 A) and test voltage in RISO test (500 V (HI)

or 250 V (LO)) can be selected by using the menu keys “Im” and “UISO”

during setup of new AUTO Test.

Measurement range in CLAMP test (0 ... 60 A (HI) or 0 ... 20 mA (LO)) can be

selected by using the menu key “RNG” during setup of new AUTO Test.

Limit value in RPE test is always copied from individual RPE test.

Limit value in P/IL test is always set to 3.7 kVA.

There is no limit value available in CLAMP test.

Limit value in all other tests is always set to standard value.

Edit (add/remove some tests) the AUTO Test by using the “EDIT” menu key

or adjust limit values and/or test parameters by using the “PAR” menu key.

COPY AUTO-TEST: Select the AUTO Test you wish to copy first by using the

“A▼” and “A▲” menu keys then confirm the COPPY

AUTO-TEST selection by pressing the “” menu key.

Confirm/abort offered selection by pressing the “YES” /

”NO” menu key.

48

GT-600/GT-800 Instruction Manual

DELETE AUTO-TEST: Select the AUTO Test you wish to delete first by using

the “A▼” and “A▲” menu keys then confirm the

DELETE AUTO TEST operation by pressing the “” menu

key. Confirm/abort the delete operation by pressing the

“YES” / ”NO” menu key.

SETUP Menu

In this menu the following selections are available:

MEASUREMENT TIMES: MAN, MAINS (manual tests that require mains voltage

on test socket). Measurement time can be adjusted to

10 ... 299 seconds.

MAN, MAINS FREE (manual tests that do not require

mains voltage on test socket). Measurement time can

be adjusted to 3 ... 60 seconds.

AUTO, MAINS (AUTO Tests that require mains voltage

on test socket). Measurement time can be adjusted to

10 ... 299 seconds.

AUTO, MAINS FREE (AUTO Tests that do not require

mains voltage on test socket). Measurement time can

be adjusted to 3 ... 60 seconds.

DATE / CLOCK: Use the “▼”, “▲” and “” menu keys to set the actual

date and time for internal real time clock (RTC).

REGION: Select the region (GERMANY or ENGLAND) where the

GT-600/GT-800 will be used. Use the “▼”, “▲” and “”

menu keys to select appropriate one. Factoryprogrammed AUTO Testes and limit values of the tests

depend on selected region. See the section “AUTO

Test”.

BARCODE MODE: The mode relates to barcode reading of the appliance

code only (no effect when reading the client number).

STANDARD mode: The appliance barcode consists of

appliance identification code only.

COMBINED mode: The appliance barcode consists of

the AUTO Test code (first three digits) and the

appliance identification code (next 14 digits).

Advantage of COMBINED mode:

Appropriate AUTO test code can be dedicated to the

appliance meaning this AUTO test will be offered

automatically when AUTO function will be selected by

turning the rotary switch (6) to AUTO position.

Recognition of selected mode:

Selected mode will be identifiable in “SAVE” operation

through displayed “APP” (appliance) mark.

APP : COMPUTER ... STANDARD mode is selected.

APP : 145COMPUTER ... COMBINED mode is selected

with dedicated AUTO test No. 145.

ACOUSTIC SIGNAL: All acoustics signals can be activated / deactivated by

selecting “ACOUSTIC SIGNAL ON / OFF”.

49

GT-600/GT-800 Instruction Manual

LANGUAGE Menu

Use the “▼”, “▲” and “” menu keys to select desired language. The following

languages are available: ENGLISH, GERMAN and FRENCH.

CONTRAST Menu

Contrast of the display can be adjusted by using the “-“ and “+” menu keys.

TESTER INFO Menu

The following instrument information can be read in this menu: model, serial

number, catalogue number, firmware version and hardware version.

Figure 38: Tester info menu

50

GT-600/GT-800 Instruction Manual

Memory Features

Any memory address consists of a client name and appliance name. Site (SIT),

location (LOC) and description (DES) can be attached to the appliance. The

memory address should be entered / selected before storing measurement

results. Operator must be entered via menu OPERATOR before carrying out the

measurements as it is attached to any measurement result immediately after

finishing the measurement.

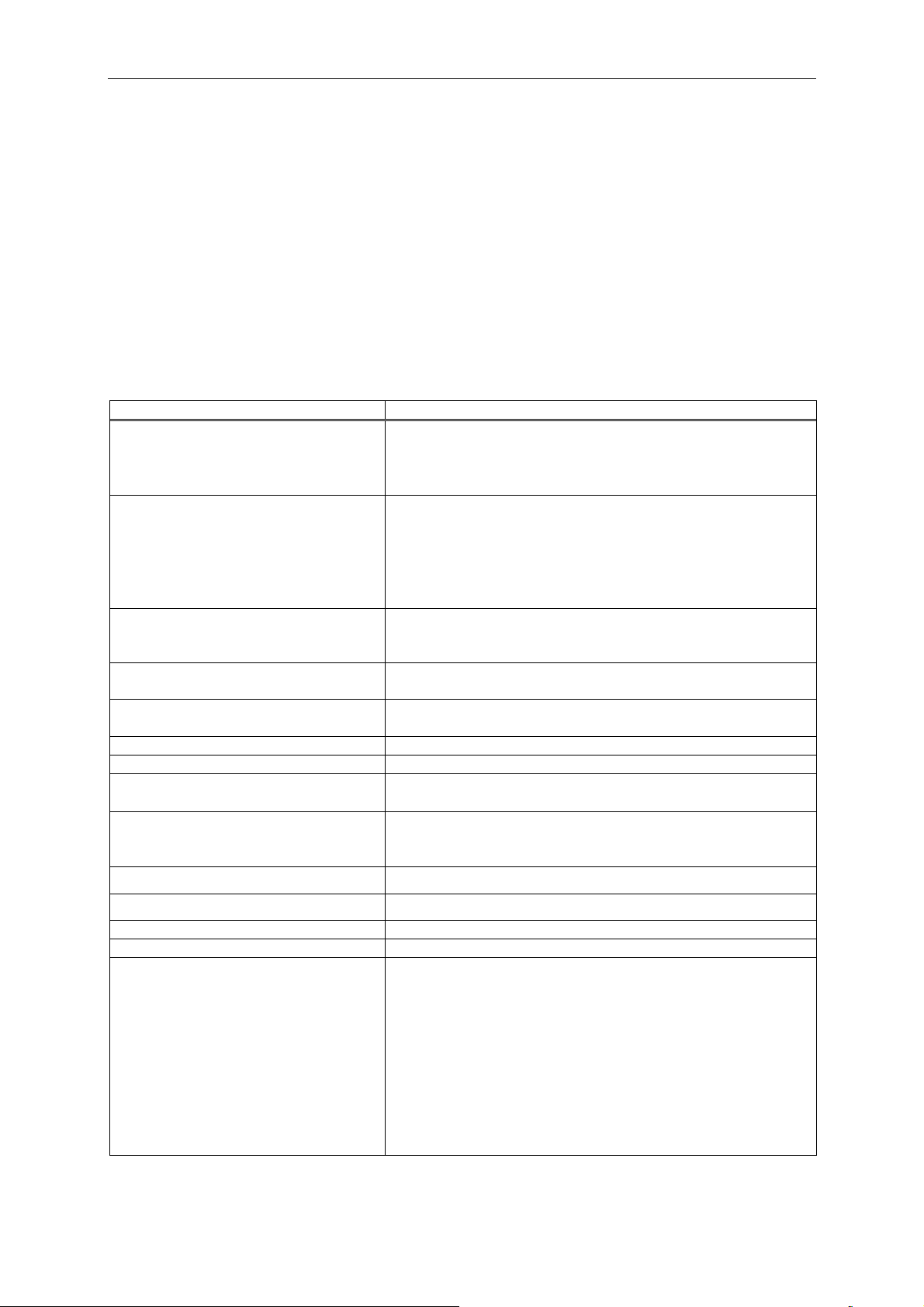

Memory Structure

Measurement result, limit value and parameters are saved to selected memory

address upon receiving the SAVE command. The following structure of the

memory address is offered:

Figure 39: Storage structure

CLI : Client/customer (max. 17 characters)

APP : Appliance identification code (max. 17 characters) (STANDARD Barcode

mode, see page 49)

APP : AUTO Test code (first three digits) and Appliance identification code (max.

14 characters) (COMBINED Barcode mode, see page 49)

SIT : Site (max. 17 characters)

LOC : Location/department (max. 17 characters)

DES : Description of appliance (max. 17 characters)

Nr. : Measurement number (4 digits)

51

GT-600/GT-800 Instruction Manual

Date (from RTC) and operator are attached to any measurement result

automatically after finishing the measurement.

In software es control the field “CLI” (client) is assigned to “Client”, the field

“SIT” (site) is assigned to “Site” and the field “LOC” (location) is assigned to

“location”. The field “APP” contains the identification No. of the appliance.

52

GT-600/GT-800 Instruction Manual

General Memory Operations

Menu keys “◄” and “►” : Select already entered name of client and

appliance. A new name can be created by

selecting the “NEW” name first (always available

on extremely right position, use the “►” menu

key to reach it) and obligatorily modifying it

afterwards.

Note! Storing results to the “NEW” name is disabled, a message “INVALID

NAME” will appear.

Menu key “MOD” : Modify already entered name or “NEW” name.

Menu key “ “ : Delete individual character on the left of the

cursor.

Menu keys “▼” and “▲” : Entry of characters, “A…Z, 0…9, +, -, _, /, #,

and space” can be selected. Cursor moves

to the next character automatically approx.

2 s after selecting previous one.

Menu key “” : Confirm the entry.

Function key “EXIT” : Entry will be aborted.

When entering fields for client, appliance, site, location and description,

alphanumeric characters (A…Z, 0…9), symbols (+, -, _, /, #) and space are

available.

When selecting the “Nr.” field (measurement number), numeric figures 0001

up to 1999 are available only. The number is automatically increased by 1 for

any next measurement to be saved.

The measurement number “Nr.” can be manually listed forward and

backward. It is also possible to overwrite already saved measurement result.

Default value for new names (client and appliance) is “NEW”.

53

GT-600/GT-800 Instruction Manual

Memorizing Example

In order to save measurement result to a particular storage address, follow the

following instructions:

1) Carry out the measurement.

2) Press the “SAVE” function key (5).

3) Level “CLI” (client) is already marked. Select already entered

client/customer by using the “◄” and “►” menu keys. If wished client

is not entered yet, then setup a new client by using menu key “►”,

offered default name is “NEW”. Press the “MOD” menu key and delete

default name “NEW” by using the “” menu key.

4) Enter a new client name, for example “CLIENT 001”, by using the “▼”

and “▲” menu keys. Confirm the entry by pressing the “” key, cursor

will move to the next address level (APP).

5) Select already entered appliance by using the “◄” and “►” menu keys.

If wished appliance is not entered yet, then setup a new one by using

the menu key “►”, offered default name is “NEW”. Press the “MOD”

menu key and delete default name “NEW” by using the “” menu key.

6) Enter a new appliance name for example “APPLIANCE 001” by using

the “▼” and “▲” menu keys. Confirm the entry by pressing the “”

menu key, cursor will move to site level (SIT).

Note! (GT-800 only)

If STANDARD barcode mode is selected (see page 49), then all 17

characters are reserved for appliance code.

If COMBINED barcode mode is selected, then first three digits are

reserved for AUTO test code and the rest 14 digits are reserved for

appliance code. First three digits must obligatory fit to one of available

AUTO test codes (145-151, 160, 161, 241-244, 131-137, 231-234, 301-

317), see the chapter “AUTO Test (GT-800 only)” on page 42 otherwise

warning “INVALID AUTO TEST” will be displayed after entering the

appliance.

Example 1:

APP :145COMPUTER (inversed APP presents selected COMBINED mode)

AUTO test 145 is dedicated to appliance COMPUTER, so this AUTO test

will be offered in AUTO function

Example 2:

APP :COMPUTER (non inversed APP presents selected STANDARD mode)

No AUTO test is dedicated to this appliance

7) Enter or modify already entered site by pressing the “MOD” key first

then using the “▼”, “▲” and “” menu keys. Confirm the entry by

pressing the “” menu key, cursor will move to location level (LOC).

Note! Entry of site is not obligatory as it is considered just an appendix

to the appliance.

8) Enter or modify already entered location by pressing the “MOD” key

first then using the “▼”, “▲” and “” menu keys. Confirm the entry

by pressing the “” menu key, cursor will move to description level

(DES).

Note! Entry of location is not obligatory as it is considered just an

appendix to the Appliance.

54

GT-600/GT-800 Instruction Manual

9) Enter or modify already entered description by pressing the “MOD” key

first then using the “▼”, “▲” and “” menu keys. Confirm the entry

by pressing the “” key, cursor will move to measurement number level

(Nr.).

Note! Entry of description is not obligatory as it is considered just an

appendix to the Appliance.

10) Press the “SAVE” function key again to store the measurement result,

memorizing is confirmed with double sound signal.

Figure 40: Memorizing address

If already occupied storage address (client or appliance) is selected when

storing measurement result, “BUSY” mark will appear on the display.

Previously stored result will be overwritten after pressing the “SAVE” key

again.

55

GT-600/GT-800 Instruction Manual

Recall Data

In order to recall stored measurement result, follow the following instructions:

1) Press the “RCL” key (5), level “CLI” (client) will be marked.

2) Select wished client name by using the “◄” and “►” menu keys.

3) Select the next storage level “APP” (appliance) by pressing the “▼”

menu key. Select wished appliance number by using the “◄” and “►”

menu keys.

4) Select the next storage level “Nr.” (measurement number) by pressing

the “▼” menu key. Select wished measurement number by using the

“◄” and “►” menu keys, then confirm the address selection by

pressing the “RCL” key again.

5) Confirm selected address by pressing the “RCL” function key (5) again

to recall stored measurement result. Now the operator can browse

among all measurement numbers under selected storage address, by

using the “◄” and “►” menu keys.

Figure 41: Recall address

Individual recalled measurement results can be directly deleted by pressing

the “CLR” menu key.

Storage address with the last stored measurement resuIt is offered always

after activating “RCL” operation.

56

GT-600/GT-800 Instruction Manual

Entry of Memory Address Using External Keyboard