BEFCO CYCLONE SUPER-FLEX, 417-SFL, 415-SFL, 412-SFL, 420-SFL Operator's Manual

BEFCO®

Operator’s Manual

CYCLONE SUPER-FLEX

Gang Grooming Mower

412-SFL, 415-SFL, 417-SFL, 420-SFL

The operator’s manual is a technical service guide and must always accompany the machine.

Manual 961-208B

August 2018

SAFETY

Take note! This safety alert symbol found throughout this manual is used to call your

attention to instructions involving your personal safety and the safety of others. Failure to

follow these instructions can result in injury or death.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Signal Words

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal words for each have been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury.

INDEX

1 - GENERAL INFORMATION

2 - SAFETY PRECAUTIONS

3 - OPERATION

4 - MAINTENANCE

5 - REPAIR PROCEDURES

6 - TROUBLESHOOTING

7 - PRE-DELIVERY CHECKLIST

8 - WARRANTY

4

41.01 - General

41.02 - Warranty Information

51.03 - Model and Serial Number ID

6

62.01 - Preparation

72.02 - Starting and Stopping

72.03 - Messages and Signs

11

113.01 - Operational Safety

133.02 - Setup and Assembly Instructions

153.03 - Light Kit Installation

173.04 - Cutting Height Adjustment

183.05 - Pre-Operational Check

193.06 - Attaching to the Tractor

213.07 - Constant Velocity Driveline

213.08 - Hydraulic Lift System

223.09 - Frame Adjustments

263.10 - Start Up

283.11 - Working Speed

283.12 - Operating Techniques

303.13 - Uneven Terrain

31

314.01 - Maintenance Safety

324.02 - Service

354.03 - Blade Maintenance

374.04 - Belt Tension

384.05 - Belt Replacement

394.06 - Drivelines and Center Gearbox Timing

404.07 - Transport

414.08 - Storage

43

435.01 - Gearbox

435.02 - Blade Spindle

445.03 - Suggested Spare Parts

45

47

48

INDEX 3 BEFCO

CYCLONE SUPER-FLEX OPERATOR’S MANUAL

1 - GENERAL INFORMATION

Thank you and congratulations for having chosen our implement. Your new gang

grooming mower is a technologically advanced machine constructed of high quality,

sturdy components that will fulfill your working expectations. Read this manual carefully.

It will instruct you on how to operate and service your mower safely and correctly.

Failure to do so could result in personal injury and/or in equipment damage.

1.01 - General

The implement described in this manual is to be used with tractors with PTO at 540 rpm

and clockwise rotation.

CAUTION: Always ensure that the coupling of the implement with the tractor is

done at the same PTO speed and direction of rotation. Do not operate this

implement at a PTO speed or direction of rotation other than that shown on the

implement. Serious damage can occur to the machine and/or the operator.

CAUTION: Unless otherwise specified, all hardware is metric. Use only metric

tools on metric hardware. Other tools that do not fit properly can slip and cause

injury.

CAUTION: Right hand and left hand sides of the implement are determined by

facing in the direction the implement will travel when going forward (see fig. 2).

1.02 - Warranty Information

Carefully read the Warranty section1, detailing coverage and limitations of this warranty.

Warranty is provided for customers who operate and maintain their equipment as

described in this manual. Warranty registration is accomplished by the dealer by

completing and forwarding the Warranty Registration form to the Company, along with

a copy of the dealer’s invoice. It is in your best interest to insure that this has been

done.

Warranty does not cover the following:

1. Cleaning, transporting, mailing and service call charges.

1

GENERAL INFORMATION 4 BEFCO

See Chapter 8 - Warranty.

CYCLONE SUPER-FLEX OPERATOR’S MANUAL

2. Normal wear items such as belts, blades, bearings, drivelines, shear pins, slip

clutches, hydraulic hoses and seals, tires, etc.

3. Depreciation or damage caused by normal wear, accidents, improper maintenance,

improper protection or improper use.

4. The use of non-original spare parts and accessories.

Your Authorized Company Dealer has genuine parts in stock. Only these approved

replacement parts should be used.

This limited warranty covers defective material and workmanship. The cost of normal

maintenance or repairs for accidents or improper use and related labor will be borne by

the owner.

1.03 - Model and Serial Number ID

Attached to the frame is an ID plate showing the model and the serial number. Record

your implement model and serial number in the space provided below. Your dealer

needs this information to give you prompt, efficient service when you order parts.

GENERAL INFORMATION 5 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

2 - SAFETY PRECAUTIONS

Safety is the primary concern in the design and manufacture of our products.

Unfortunately our efforts to provide safe equipment can be wiped out by a single

careless act of an operator.

In addition to the design and configuration of equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training

of personnel involved in the operation, transport, maintenance and storage of

equipment. It is the operator’s responsibility to read and understand all safety and

operating instructions in the manual and to follow these.

Allow only properly trained personnel to operate the mower. Working with unfamiliar

equipment can lead to careless injuries. Read this manual, and the manual for your

tractor, before assembly or operation, to acquaint yourself with the machines. It is the

mower owner’s responsibility, if this machine is used by any person other than yourself,

is loaned or rented, to make certain that the operator, prior to operating, reads and

understands the operator’s manuals and is instructed in safe and proper use.

2.01 - Preparation

1. Before operating equipment read and understand the operator’s manual and the

safety signs (see fig. 2).

2. Thoroughly inspect the implement before initial operation to assure that all

packaging materials, i.e. wires, bands, and tape have been removed.

3. Personal protection equipment including hard hat, safety glasses, safety shoes, and

gloves are recommended during assembly, installation, operation, adjustment,

maintaining and/or repairing the implement.

4. Operate the mower only with a tractor equipped with an approved

Roll-Over-Protective-System (ROPS). Always wear your seat belt. Serious injury or

even death could result from falling off the tractor.

5. Clear area to be cut of stones, branches or other debris that might be thrown,

causing injury or damage.

6. Operate only in daylight or good artificial light.

7. Ensure mower is properly mounted, adjusted and in good operating condition.

8. Ensure that all safety shielding and safety signs are properly installed and in good

condition.

SAFETY PRECAUTIONS 6 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

2.02 - Starting and Stopping

1. Be sure that no one is near the machine prior to engaging or while the machine is

working.

2. Be sure the tractor is in “Neutral” before starting engine.

3. Mower operating power is supplied from tractor PTO. Refer to your tractor manual

for PTO engagement and disengagement instructions. Always operate PTO at 540

rpm. Know how to stop the tractor and mower quickly in case of an emergency.

4. When engaging PTO, the engine rpm should always be low. Once engaged and

ready to start cutting, raise PTO speed to 540 rpm and maintain throughout cutting

operation.

5. Check the tractor master shield over the PTO stub shaft. Make sure it is in good

condition and fastened securely to the tractor. Purchase a new shield if old shield is

damaged or missing.

6. After striking an obstacle, disengage the PTO, shut the tractor down and thoroughly

inspect for damage before restarting.

7. Never engage the PTO until the mower is in the down position and resting on the

ground. Never raise the mower until all blades have come to a complete stop.

8. To park the vehicle safely, stop vehicle on a level surface (not on a slope),

disengage PTO, engage the parking brake, stop the engine, remove the key, and

wait for engine and all moving parts to stop before leaving the operator’s seat.

9. Stay clear of rotating drivelines. Entanglement in rotating driveline can cause serious

injury or death. Wear close fitting clothing. Stop the engine and be sure PTO

driveline is stopped before getting near it.

2.03 - Messages and Signs

1. Read and adhere to all safety and operating decals on this machine (see fig. 2).

2. Before dismounting tractor: Allow moving parts to stop, stop engine, set brake and

remove the key of unattended equipment.

3. Keep away from rotating blades and driveline.

4. Keep guards and shields in place and in good condition.

5. Do not mow with bystanders in area.

6. Allow no riders on tractor or mower.

7. Allow moving parts to stop before repair.

8. Securely support mower before working underneath.

9. Lock up raised wings before transport (see fig. 13).

Additional warning and operating decals are available at no extra charge. Please specify

model and serial number when ordering.

SAFETY PRECAUTIONS 7 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

l

C

Fig. 2 - Safety decals, main frame; replace immediately if damaged.

1

4

5

2

3

6

right side

left side

22

1

7

Yellow reflective deca

7

8

8

Red reflective decal

8

3

3

456

SAFETY PRECAUTIONS 8 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

Safety decals, decks; replace immediately if damaged.

SAFETY PRECAUTIONS 9 BEFCO

placed under belt shieldsplaced under belt shields

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

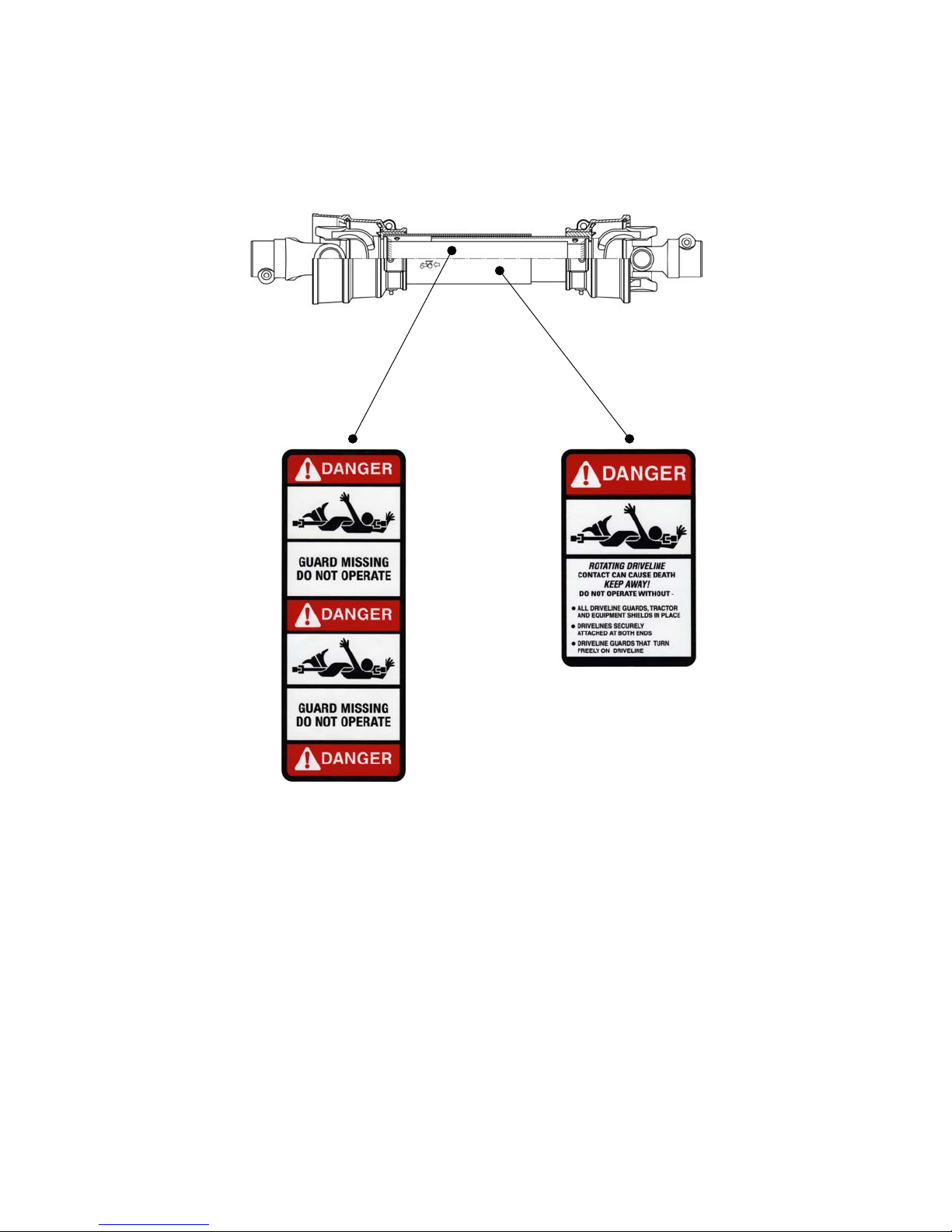

Safety decals, drivelines; replace immediately if damaged.

placed on outer tube

placed on outer shield

SAFETY PRECAUTIONS 10 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

3 - OPERATION

The Cyclone Super-Flex represents the most advanced proposal for reducing labor cost

without sacrificing quality of cut. The high cutting speed of 8-10 mph along with the wide

working widths of up to 20’, allows for a reduction in man-hours and lower fuel cost for

the maintenance of large grass areas such as sport fields, parks, golf courses and sod

farms.

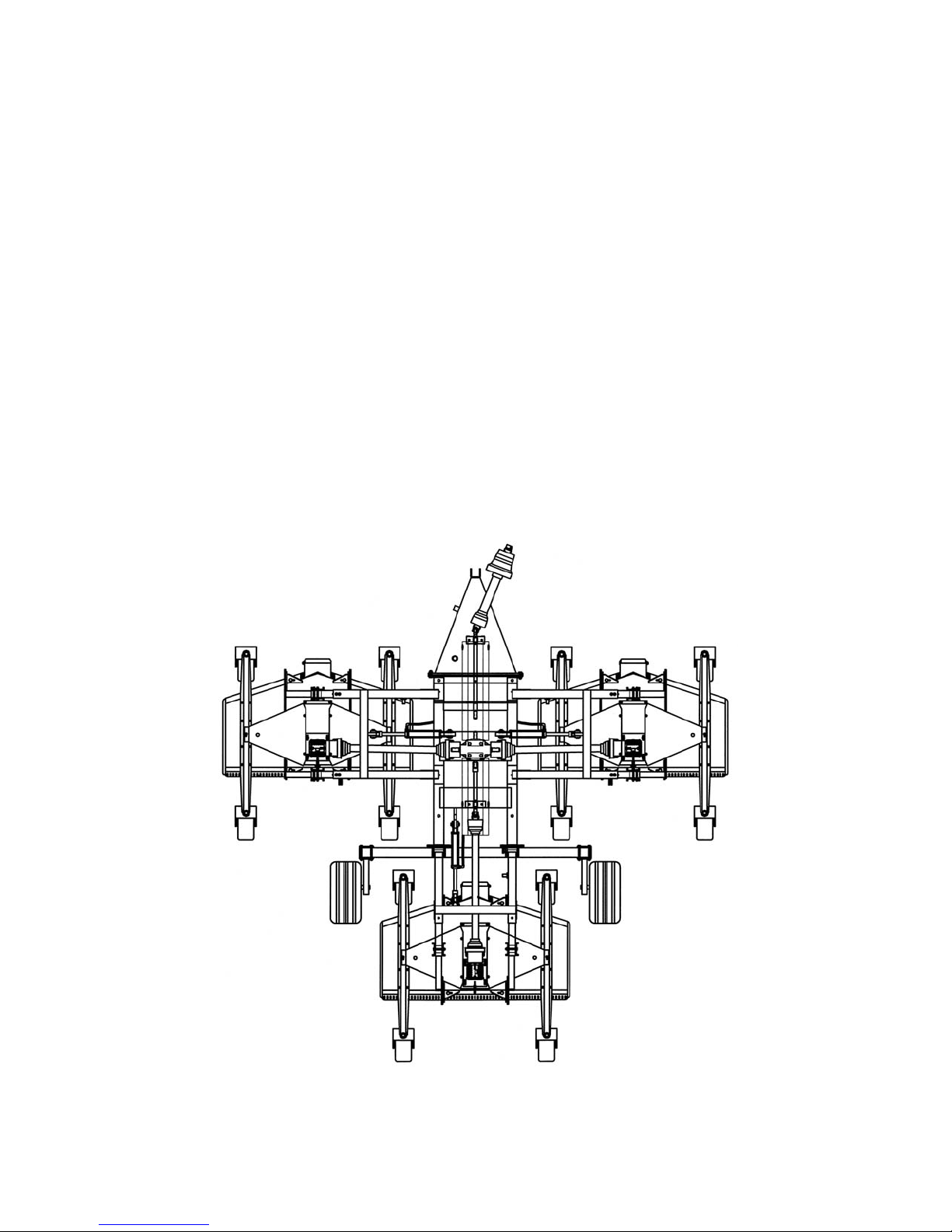

The Cyclone Super-Flex consists of a frame-carrier, mechanically connecting a trio of

C50 rear discharge grooming mowers. The Cyclone Super-Flex can be used on tractors

with horsepower ranging from 35 to 80. The tractor

angle driveline, to a 4 way splitter gearbox. The side and rear output shafts transfer

power to the individual speed multiplier gearboxes on each mower.

The 12’ model consists of two 4’ wing units and one 5’ rear unit, the 15’ model consists

of two 5’ wing units and one 6’ rear unit, the 17’ model consists of three 6’ decks and

the 20’ model consists of three 7’ decks.

Each individual mower works completely independent from the others. They are

connected to the frame by floating arms. All mowers have four wheels allowing free

floating over uneven terrain. Even over rolling ground, the cut is accurate and uniform.

After mowing, during transport and for storage or maintenance, all three mowers can be

raised up hydraulically to a vertical position. During transport or maintenance

operations, it is imperative to be sure the wing mowers are locked in place with the

automatic locking system. To transport over extended distances, the wings should be

locked in their 90 degree vertical position with the transport locks and the metal

transport braces added to the two wing units for added safety. The two transport wheels

allow the Cyclone Flex mower, in its closed and locked position, to be transported safely

on lawns or private roads. The tires are not suitable for extended road travel.

The decks can be raised for easy cleaning and quick blade changes. Top grease fittings

make the greasing of hubs and spindles simple and quick.

PTO is connected, through a wide

CAUTION: Our mowers are designed considering safety as the most important

aspect and are the safest available in today’s market. Unfortunately, human

carelessness can override the safety features built into our machines. Injury

prevention and work safety, aside from the features on our mowers, are very

much due to the responsible use of the equipment. It must always be operated

prudently following with great care, the safety instructions laid out in this manual.

OPERATION 11 BEFCO

3.01 - Operational Safety

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

1. The use of this equipment is subject to certain hazards which cannot be prevented

by mechanical means or product design. All operators of this equipment must read

and understand this entire manual, paying particular attention to safety and

operating instructions, prior to using.

2. Do not operate the tractor and mower when you are tired, sick or when using

medication.

3. Keep all helpers and bystanders at least 300 feet from a rotary mower. Only properly

trained people should operate this machine.

4. When this machine is operated in populated areas where thrown objects could injure

persons or property, standard equipment safety chain shielding (which is designed

to reduce the possibility of thrown objects) must be installed.

5. The majority of accidents involve entanglements on the driveline, injury of

bystanders by objects thrown by the rotating blades, and operators being knocked

off the tractor by low hanging limbs and then being run over by the mower. Accidents

are most likely to occur with machines that are loaned or rented to someone who

has not read the operator’s manual and is not familiar with a rotary mower.

6. Always stop the tractor, set brake, shut off the tractor engine, remove the ignition

key, lower implement to the ground and allow mower blades to come to a complete

stop before dismounting tractor. Never leave equipment unattended with the tractor

running.

7. Never place hands or feet under mower with tractor engine running or before you

are sure all motion has stopped. Stay clear of all moving parts.

8. Do not allow riders on the mower or tractor at any time. There is no safe place for

riders.

9. Do not operate unless all personnel, livestock and pets are at least 300 feet away to

prevent injury by thrown objects.

10.Before backing up, disengage the mower and look behind carefully.

11.Install and secure all guards and shields before starting or operating.

12.Keep hands, feet, hair and clothing away from moving parts.

13.This rotary mower is designed for use only on tractors with 540 rpm power take off.

14.Never operate tractor and mower under trees with low hanging limbs. Operators can

be knocked off the tractor and then run over by the rotating blades.

15. The rotating parts of this machine have been designed and tested for rugged use.

However, they could fail upon impact with heavy, solid objects such as steel guard

rails and concrete abutments. Such impact could cause the broken objects to be

thrown outward at very high velocities. To reduce the possibility of property damage,

serious injury, or even death, never allow the cutting blades to contact such

obstacles.

16.Frequently check mower blades. They should be sharp, free of nicks and cracks and

securely fastened.

17. Stop mower immediately upon striking an obstruction. Turn engine off, remove key,

inspect and repair any damage before resuming operation.

18. Stay alert for holes, rocks and roots in the terrain and other hidden hazards. Keep

away from drop-offs.

OPERATION 12 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

19.Use extreme care and maintain minimum ground speed when transporting on

hillside, over rough ground and when operating close to ditches or fences. Be careful

when turning sharp corners.

20. Reduce speed on slopes and sharp turns to minimize tipping or loss of control. Be

careful when changing directions on slopes. Do not start or stop suddenly on slopes.

Avoid operation on steep slopes.

21. When using a unit, a minimum 20% of tractor and equipment weight must be on

tractor front wheels. Without this weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a front end loader, front wheel

weights, ballast in tires or front tractor weights. When attaining a minimum 20% of

tractor and equipment weight on the front wheels, you must not exceed the ROPS

weight certification. Weigh the tractor and equipment. Do not guess or estimate!

2

22. Inspect the entire machine periodically

. Look for loose fasteners, worn or broken

parts, and leaky or loose fittings.

23. Use only the driveline supplied with the mower. Do not use it if it is missing any

shield or safety protection.

24. Pass diagonally through sharp dips and avoid sharp drops to prevent “hanging up”

tractor and mower.

25.Avoid sudden starts and stops while traveling up or downhill.

26. Always cut down slopes; never across the face. Avoid operation on steep slopes.

Slow down on sharp turns and slopes to prevent tipping and/or loss of control.

3.02 - Setup and Assembly Instructions

Notice to dealer: Pre-delivery setup and service including lubrication is the

responsibility of the authorized dealer. It is up to him to assure that the machine is in

perfect condition and ready to be used. It is his responsibility to ensure that the

customer is aware of all safety aspects and operational procedures for the mower. He

must also fill out the Pre-Delivery Checklist3 prior to delivering the mower.

At times, due to loading restraints the mower is shipped either with the three decks

separate from the frame or fully assembled but with the transport tires and the

telescopic wing arms retracted. It is the dealer’s responsibility to extend transport

tires and telescopic wing arms to proper operating width and to ensure final

assembly of the mower.

CAUTION: Stand clear of bands when cutting as they could be under sufficient

tension to cause them to fly loose. Take care in removing bands and wire, they

often have extremely sharp edges and cut very easily.

To hook the three mowers to the central frame, do the following:

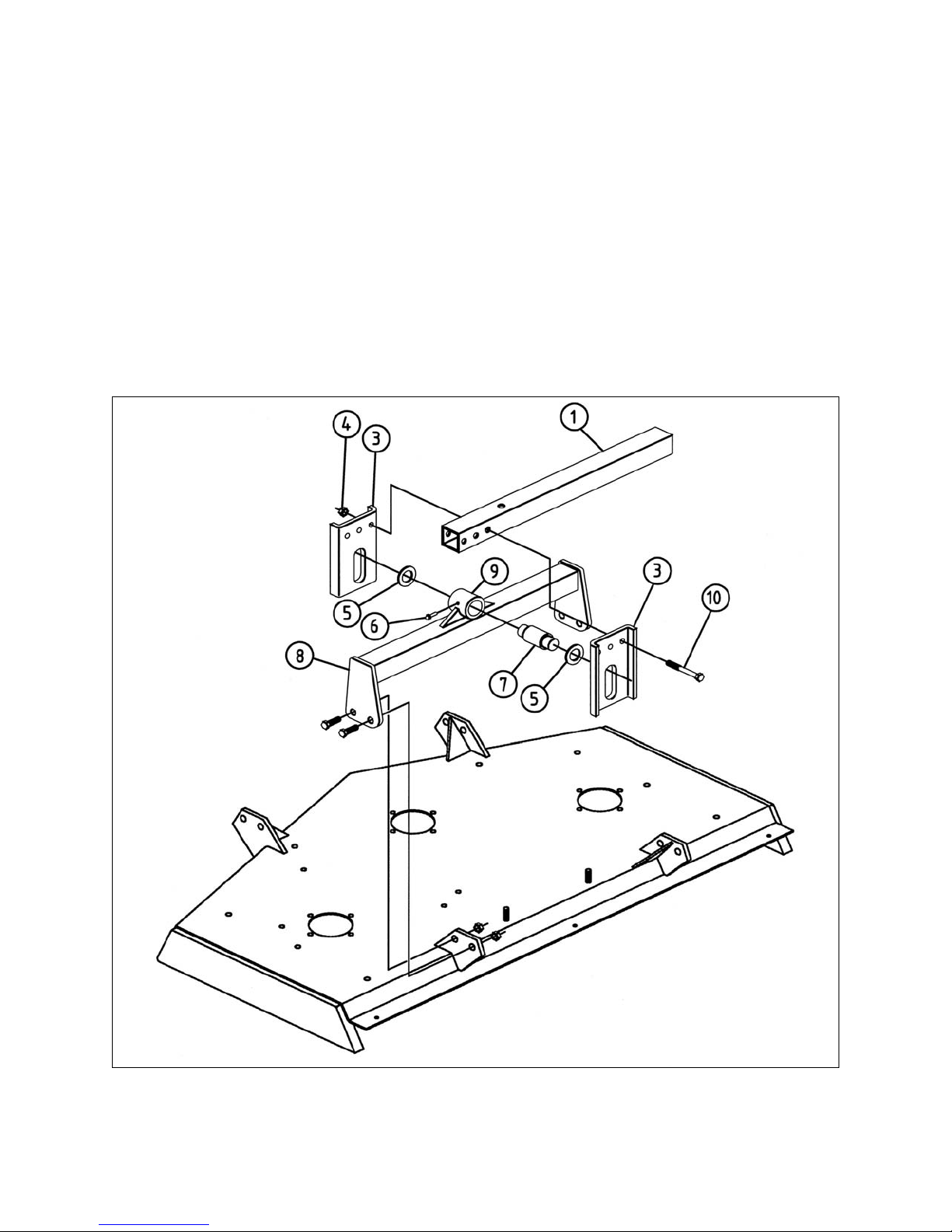

1. Position the decks complete with hitches (see #8, fig. 3) near the telescopic wing

arms (see #1, fig. 3) which are bolted into the lift arms.

2

3

See Chapter 4 - Maintenance.

See Chapter 7 - Pre-Delivery Checklist.

OPERATION 13 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

2. Insert the attaching pin (see #7, fig. 3) into the tube welded to the hitch (see #9, fig.

3). Place the shim washers (see #5, fig. 3) on either end of the attaching pin.

3. Place the two formed plates (see #3, fig. 3) on either end of the attaching pin (see

#7, fig. 3) with the bend facing outward.

4. With the wing arms down level with the mower decks, position the telescopic wing

arms (see #1, fig. 3) between the two formed plates (see #3, fig. 3). Attach them to

the bolts (see #10, fig. 3) provided.

5. Tighten the nuts (see #4, fig. 3) and bolts (see #10, fig. 3). Ensure after tightening

that the formed plates (see #3, fig. 3) move freely up and down over the attaching

pin (see #7, fig. 3).

6. Using the grease fitting on the hitch (see #6, fig. 3), grease the attaching pin and

formed plate.

OPERATION 14 BEFCO

Fig. 3 - Mowing unit assembly.

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

3.03 - Light Kit Installation

The light kit is an optional kit that can be purchased that contains two light assemblies,

two mounting brackets and wiring harness.

Fig. 4 - Light brackets assembly (left rear view).

1. rear wheel support

5

2. red light

3. amber light

4. nut PT M14

2

3

5. bolt HH M6x25

6. nut ES M6

7. left light bracket

7

8. light connector

6

8

4

1

To install the light kit do the following:

1. Remove light assemblies, light mounting brackets, wiring and cable loom from

packaging.

2. Support the rear frame on the side that you are working on. Loosen but do not

remove the bottom set of nuts on rear wheel support. Remove the top nuts leaving

bolts in place (see #4, fig. 4). Slide rear wheel support into operating position. Slide

the light bracket (see #7, fig. 4) over the top rear wheel bolts, replace nuts and

tighten. Note that there is a right and a left bracket.

3. Attach the light assembly to the light bracket using M6x25 hex head bolts and M6

elastic stop nuts supplied in the kit (see #5 & 6, fig. 4). The light wiring harness is

routed through the slot at the end of the light assembly. Repeat steps 2 and 3 for the

opposite side of the mower. Note: The amber lens (see #3, fig. 4) are always to the

outside of the mower frame and the red lens (see #2, fig. 4) to the inside (facing the

rear of the mower frame).

4. Remove from the mower frame the front input shaft protection, the center shaft

protection and the rear shaft protection. Lay wiring harness on a flat surface. Notice

that the wiring harness splits off into a right and a left section. These wires are

labeled respectively “R” and “L”. Cut the smaller 3/8” wire loom in half. Working from

the light connector, insert the left wiring into one piece of wire loom and the right

wiring into the other (see fig. 5).

OPERATION 15 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

Fig. 5 - Light kit layout.

slide plug end under

light mount plate

cable tie

route wiring harness

behind mower plate

cable tie

hydraulic cross

cable tie

front input shaft support

wire loom 3/8"

hydraulic hose

cable tie

wire loom 3/4"

light kit harness

5. Starting at the tractor connector, insert the wiring harness into the large 3/4” wire

loom. Slide the large 3/4” wire loom over the two smaller 3/8” pieces of wire loom

approximately 1”-2”. Secure with a cable tie (see fig. 5). Note: The wiring harness to

the tractor may be longer than necessary and can be shortened and rewired to the

tractor connector if needed.

6. The hydraulic supply line to the rear cylinder is routed through the right square tube

located underneath the front input shaft support. The light kit wiring is routed through

OPERATION 16 BEFCO

YCLONE SUPER-FLEX OPERATOR’S MANUAL

C

the left square tube of the input shaft support. Place a cable tie around the hydraulic

cross and light wiring harness but do not tighten at this time (see fig. 5).

7. Route the right and left light wiring harness alongside the hydraulic hose that

attaches to the rear cylinder (this hose is normally routed under the shaft protection

shields and located on the left side of the mower frame). At the rear of the mower

frame split off the right and left wiring. Route wiring along frame and plug wiring

harness into light plugs (see #8, fig. 4). Place cable ties as shown in the illustration

(see fig. 5) but do not tighten. Note: Because the rear wheel supports can be

adjusted in and out, be sure to leave extra wire to the light assemblies.

8. Wiring harness and hydraulic hoses should be clear of any moving parts. Once

wiring harness is in place, tighten cable ties and cut off excess. Plug in light

connector to the tractor to check light operation.

9. Replace all shields before operating the mower.

3.04 - Cutting Height Adjustment

WARNING: Keep hands and feet away from moving blades.

Be sure the tractor engine is off, parking brake is locked, and key is removed

before making any adjustments.

Never rely on the hydraulic system to hold the weight of the raised mowers.

Never walk or work under the raised mowers without first making sure the

automatic locking system is securely holding the wing units with the hydraulic

cylinders closed, and the hook is engaged to support the rear deck.

Fig. 6

The cutting height is

adjusted by moving

the height adjustment

spacers on the wheel

OPERATION 17 BEFCO

yokes above or below

the wheel arm.

Loading...

Loading...