Page 1

Operating instructions for

KL3311, KL3312, KL3314 and

KL3302

Single-, Two- and Four-Channel Analog Input Terminals

for Thermocouples

Version: 3.4

Date: 2008-05-19

Page 2

Table of contents

Table of contents

1. Foreword 1

Notes on the documentation 1

Safety Instructions 2

2. Technical data 3

3. Connection 3

KL3311 3

KL3312 (KL3302) 4

KL3314 4

4. Functional description 5

5. Terminal configuration 8

6. Register Description 9

General Description of Registers 9

Terminal-specific register description 12

Control and Status byte 14

Register communication 15

7. Appendix 17

Mapping 17

Register Table 20

Support and Service 21

KL3311, KL3312, KL3314 and KL3302

Page 3

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products describe d satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the statements of this manual represent s a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

KL3311, KL3312, KL3314 and KL3302 1

Page 4

Foreword

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the

Attention

environment.

This symbol indicates information that contributes to better understanding.

i

Note

2 KL3311, KL3312, KL3314 and KL3302

Page 5

Technical data

Technical data

Technical data KL3311 KL3302* KL3312 KL3314

Number of inputs

Power supply

Thermocouple sensor type

Connection

Temperature range within the respective defined range of the sensor

Resolution

Broken lead detection

Conversion time

Meas. error (total meas.

range)

Electrical isolation

Current consumption from

K-Bus

Bits width in process

image

Configuration

Weight

Operating temperature

Storage temperature

Relative humidity

Vibration / shock

resistance

EMC resistance burst / ESD

Installation position

Protection class

1 2 2 4

via the K-Bus

Types J, K, L, B, E, N, R, S, T, U (default setting type K), mV measurement

2 wire

(Default: type K; -100° ... 1370°C)

0.1°C per digit

yes no yes yes

~ 200 ms ~ 250 ms

< ± 0.5% (of the full scale value)

500 V

typically 65 mA

Input: 1 x 16 bits of data

(1 x 8 bits control/status

optional)

no address setting, configuration via bus coupler or controller

approx. 70 g

0°C ... +55°C

-25°C ... +85°C

95 % no condensation

according to EN 60068-2-6 / EN 60068-2-27, EN 60068-2-29

according to EN 61000-6-2 / EN 61000-6-4

any

IP20

(K-Bus/signal voltage)

rms

Input: 2 x 16 bits of data

(2 x 8 bits control/status

optional)

Input: 4 x 16 bits of data

(4 x 8 bits control/status

optional)

*) KL3302 is no longer available and was replaced with KL3312.

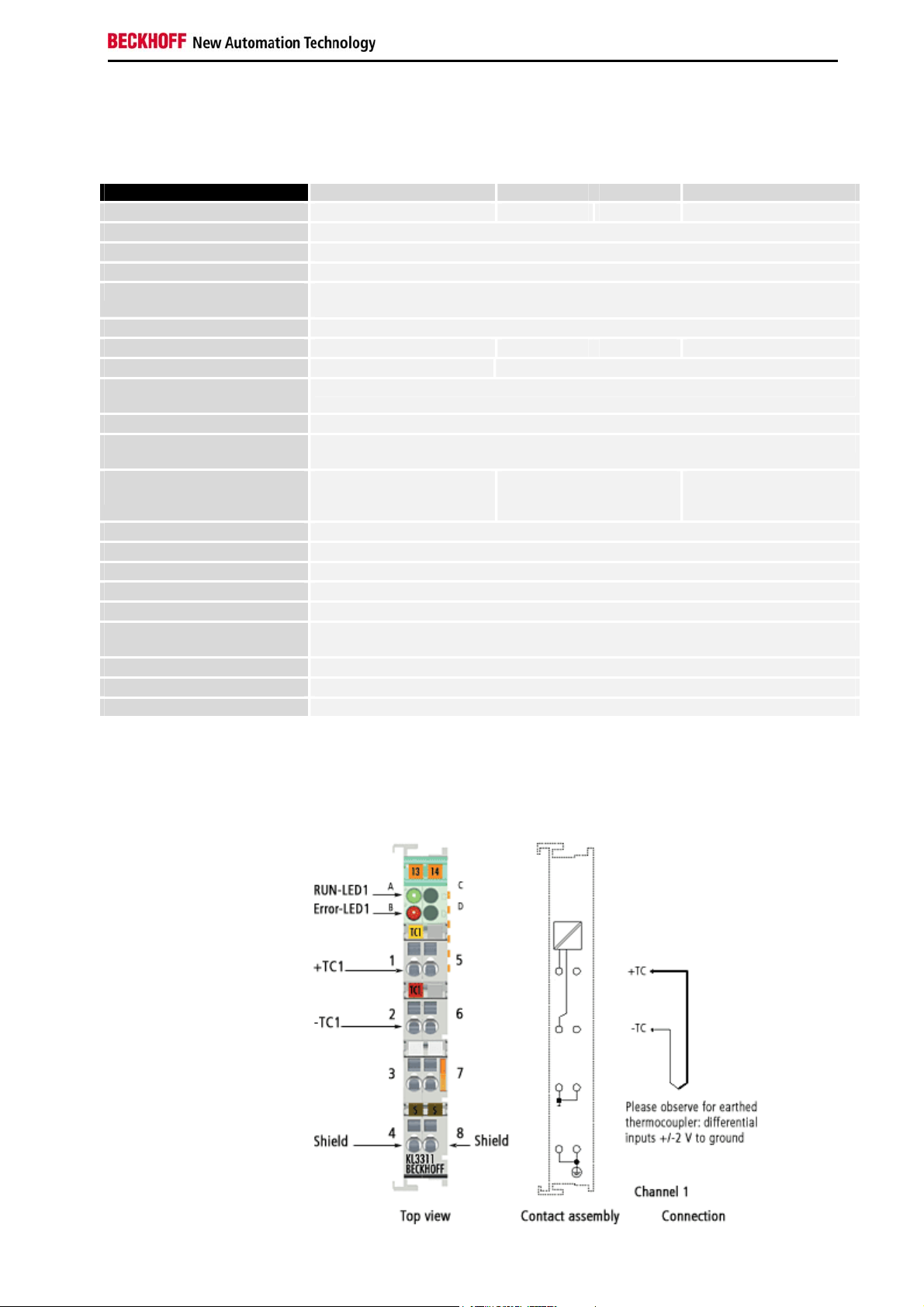

Connection

KL3311

KL3311, KL3312, KL3314 and KL3302 3

Page 6

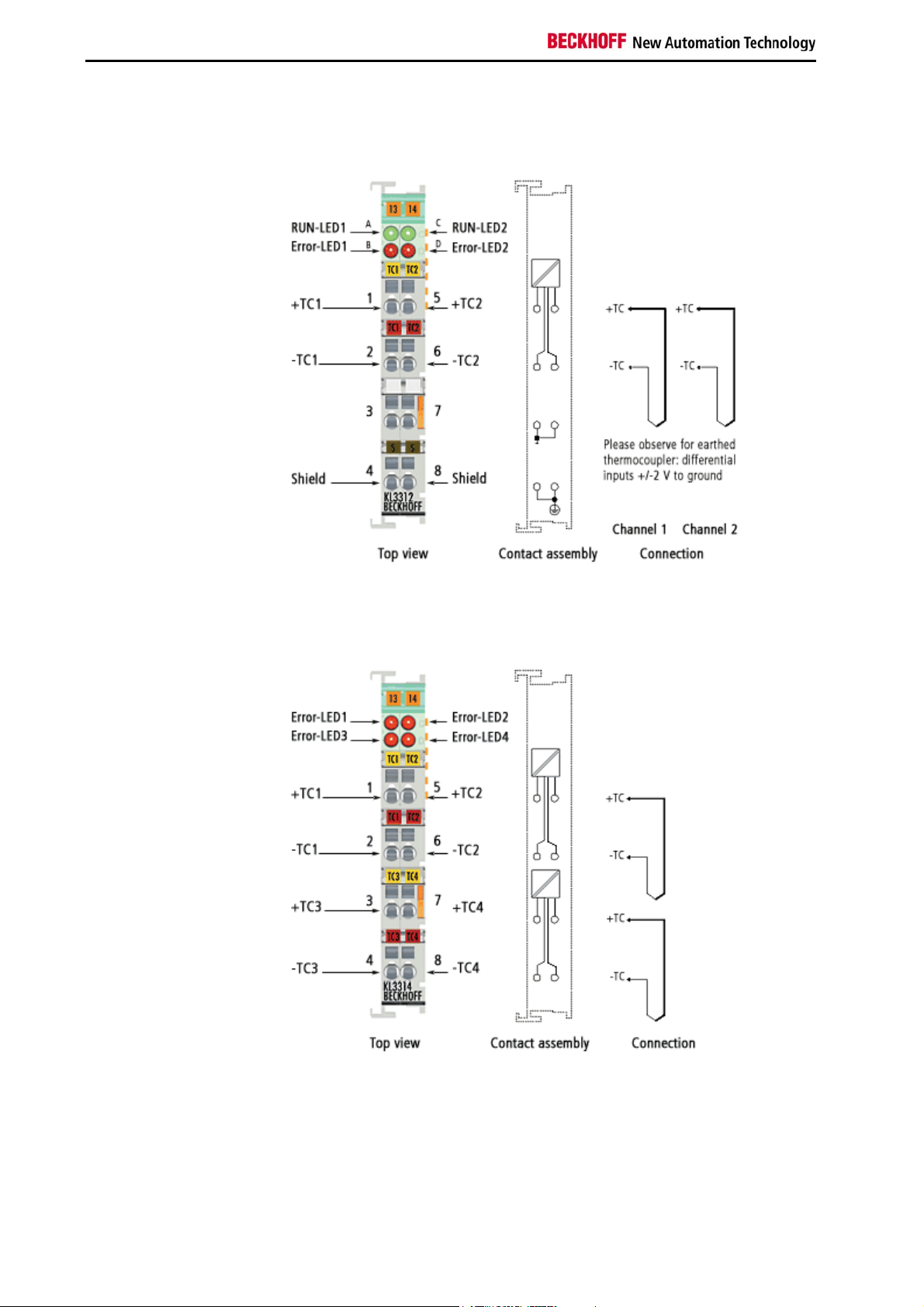

Connection

KL3312 (KL3302)

KL3314

4 KL3311, KL3312, KL3314 and KL3302

Page 7

Functional description

Functional description

The thermocouple terminals KL3311, KL3302 (without broken wire

detection), KL3312 and KL3314 can evaluate type J, K, B, E, N, R, S, T, U

and L thermocouples. The characteristic curves are linearized and the

reference temperature determined directly within the terminal.

Temperatures are output in 1/10°C. The terminal is fully configurable via

the Bus Coupler or the control. Different output formats may be selected or

own scaling activated. In addition, linearization of the characteristic curve

and determination and calculation of the reference temperature

(temperature at the terminal connection contacts) can be switched off.

Functioning Thermocouples can be classified as active measuring sensors. They

exploit the thermo-electric effect (Seebeck, Peltier, Thomson). Where two

electrical conductors of different materials (e.g. iron and constantan) make

contact, charge is transferred across the contact surface. A contact

potential develops, and is strongly dependent on temperature. The

thermally generated voltage is both a function of the temperature being

measured, T, and of the reference temperature, T

, at the point where

v

contact is made with the thermocouple. Since the coefficients are

determined at a reference temperature of 0°C, it is necessary to

compensate for the effect of the reference temperature. This is done by

converting the reference temperature into a reference voltage that depends

on the type of thermocouple, and adding this to the measured thermal

voltage. The temperature is found from the resulting voltage and the

corresponding curve.

U

= U

k

meas

+ U

ref

T

= f(Uk)

aus

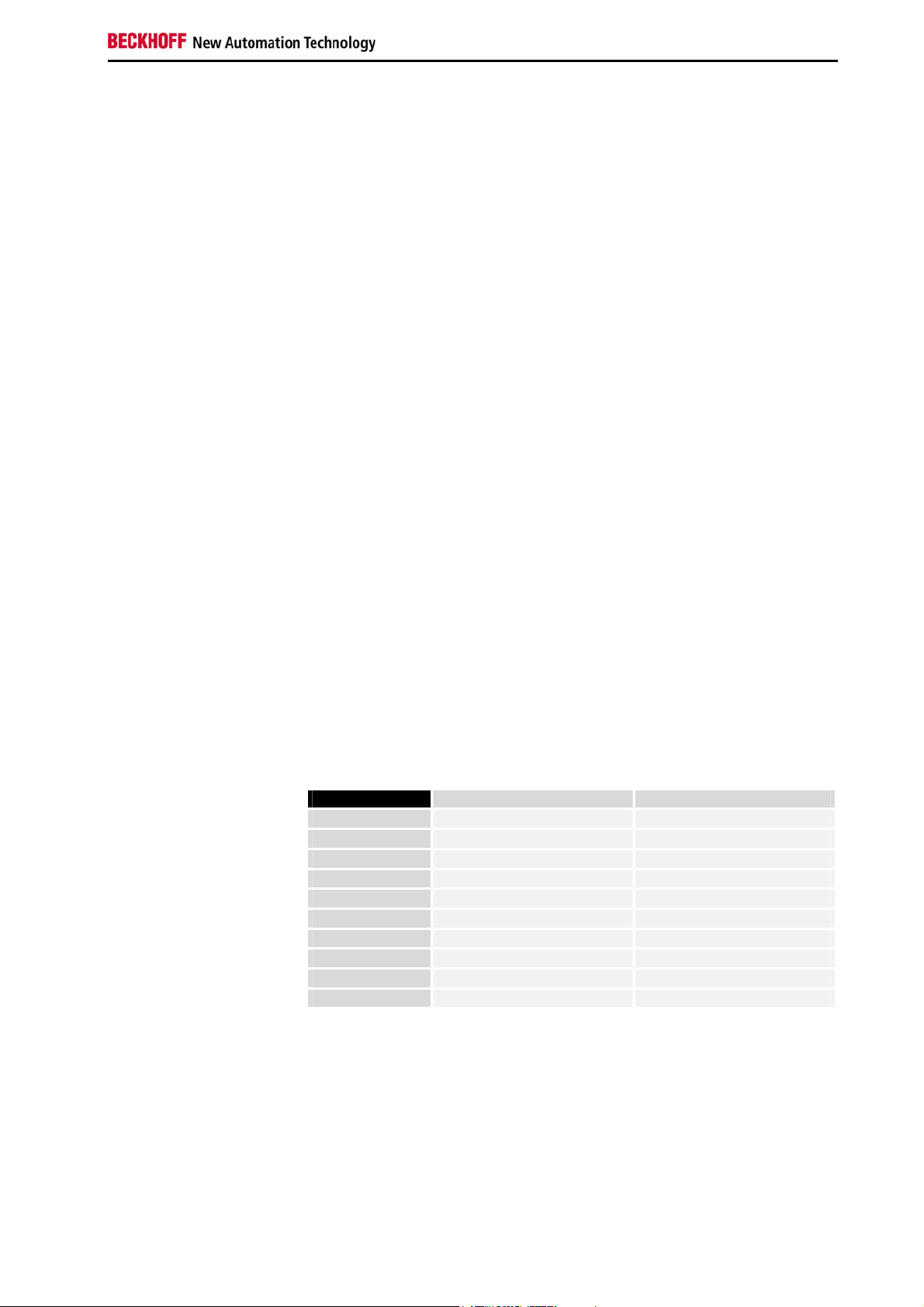

Process data output format In the delivery state, the measured value is displayed in increments of

1/10 °C in two's complement format (integer). Other display types can be

selected via the feature register (e.g. sign/amount representation, Siemens

output format).

Measured value Hexadecimal output Signed integer output

-200.0°C

-100.0°C

-0.1°C

0.0°C

0.1°C

100.0°C

200.0°C

500.0°C

850.0°C

1,000.0°C

0xF830 -2000

0xFC18 -1000

0xFFFF -1

0x0000 0

0x0001 1

0x03E8 1000

0x07D0 2000

0x1388 5000

0x2134 8500

0x2710 10000

Voltage limits U

k

> U

: Bits 1 and 6 (over range and error bits) in the status byte are

kmax

set. The linearization of the characteristic curve is continued with the

coefficients of the upper range limit up to the limit stop of the A/D converter

or to the maximum value of 0x7FFF.

KL3311, KL3312, KL3314 and KL3302 5

Page 8

Functional description

U

k

< U

: Bits 0 and 6 (under range and error bits) in the status byte are

kmin

set. The linearization of the characteristic curve is continued with the

coefficients of the lower range limit up to the limit stop of the A/D converter

or to the minimum value of 0x8000.

For over range or under range the red error LED is switched on.

LED display The four LEDs indicate the operating state of the associated terminal

channels.

Green LEDs: RUN (not applicable for KL3314)

• On: normal operation

• Off: Watchdog-timer overflow has occurred. If no process data are

transmitted by the Bus Coupler for 100 ms, the green LEDs go out.

Red LEDs: ERROR

• On: Wire breakage. The resistance is in the invalid range of the

characteristic curve of the respective thermocouple.

• Off: The resistance is in the valid range of the characteristic curve.

Process data The process data that are transferred to the terminal bus are calculated

using the following equations:

X_ref: ADC value of the reference point

: Temperature of the reference point

T

ref

U

: Voltage value of the reference point

ref

X_R: ADC value of the temperature sensor

U

: Voltage value of the temperature sensor

m1

A_a, B_a: Manufacturer gain and offset compensation (R17, R18)

A_h, B_h: Manufacturer scaling

A_w, B_w: User scaling

U

: Sum of U

k

and Um1

ref

T: Measured temperature in 1/16 °C

T

: Tempe rature after manufacturer scaling (1/10 °C)

h

T

: Tempe ratu re after user scaling

a

T_AUS: Process data to PLC

a) Voltage value of the reference point:

T

= A00 * X_ (1.0)

ref

= a1 * T

U

ref

2

+ b1 * T

ref

+ c1 (1.1)

ref

b) Measured temperature in 1/16°C:

U

= A_a * X_m + B_a (1.2)

m1

U

= U

+ Um1 (1.3)

k

ref

T = a

2

* U

+ b0 * Uk + c0 (1.4)

0

k

c) Neither user nor manufacturer scaling are active:

T_AUS = T (1.5)

d) Manufacturer scaling active (factory setting):

T

= A_h * T + B_h (1.6)

h

Y_AUS = T

h

e) User scaling active:

Ta = A_w * T + B_w (1.7)

Y_AUS = T

a

f) Manufacturer and user scaling active: (1.8)

Y_1 = A_h * T + B_h

Y_2 = A_w * Y_1 + B_w

Y_AUS = Y_2

6 KL3311, KL3312, KL3314 and KL3302

Page 9

Functional description

1

LM334

X_vgl Tvgl

a1,b1,c

TThTa

Ta us

Output: microV

Tvgl

ADC

A00,B00

Uvgl

1:1 1:1 1:1

Output: Tvgl in °C

X_m

Um1

T

Uk

amount

rep.

A_h,B_h

A_a, B_a

Gain, Offset adjust.

Output: microV Output: T in 1/16°C

Connection Due to the differential inputs of the terminals, different connection types are

recommended depending on the type of thermocouple used.

For earthed thermocouples, ground is connected to the screen. If the

thermocouple has no earth connection, the ground, screen and -TC1 or TC2 contacts are connected with each other.

a0, b0, c0

temperature

manuf. scal.

Siemensformat

A_w,B_w

userscaling

MM

MM

Shield Shield

Earthed thermocouple Floating thermocouple

The examples show the situation for KL3312. For the KL3314, the screen

should be connected to an additional screen terminal (KL9195).

KL3311, KL3312, KL3314 and KL3302 7

Page 10

Terminal configuration

The terminals can be configured and parameterized via the internal register

BK2000 Lightbus Coupler In the BK2000 Lightbus coupler, the control and status byte is mapped in

Example for KL3312 (KL3302):

Terminal configuration

structure. Each terminal channel is mapped in the Bus Coupler. Depending

on the type of the Bus Coupler and the mapping configuration (e.g.

Motorola/Intel format, word alignment etc.) the terminal data are mapped in

different ways to the Bus Coupler memory. For parameterizing a terminal,

the control and status byte also has to be mapped.

addition to the data bytes. This is always located in the low byte at the

offset address of the terminal channel.

Beckhoff-Lightbus

bus coupler

BK2000

The terminal is

mapped in the

bus coupler.

C/S

Data H Data L

C/S

Data LData H

C/S

D1 - 1

D1 - 0

0 Offset Terminal1 Channel1 = 0

D0 - 1

C/S - 1

D0 - 0

C/S - 0

Offset Terminal2 Channel2 = 8

User data allocation depending

on mapping

Offset Terminal2 Channel1 = 4

KL3302, KL3312

LH

K-Bus

To the bus terminal

BK3000 PROFIBUS

coupler

Example for KL3312 (KL3302):

For the BK3000 PROFIBUS coupler, the master configuration should

specify for which terminal channels the control and status byte is to be

inserted. If the control and status byte are not evaluated, the terminals

occupy 2 bytes per channel:

• KL3311: 2 bytes of input data

• KL3312 (KL3302): 4 bytes of input data

• KL3314: 8 bytes of input data

Profibus bus coupler

BK3000

The terminal is

mapped in the

bus coupler.

0

Data L

Data H

C/S

D0 - 1

D1 - 1

C/S - 1

D0 - 0

D1 - 0

C/S - 0

The control-/status byte

must be inserted for

parameterization.

Offset Terminal2 Channel1 = 6

KL 3302/KL3312 Channel 2

Offset Terminal1 Channel2 = 3

KL 3302/KL3312 Channel1

Offset Terminal1 Channel1 = 0

K-Bus

To the bus terminal

8 KL3311, KL3312, KL3314 and KL3302

Page 11

Register Description

BK4000 Interbus Coupler The BK4000 Interbus Coupler maps the terminals in the delivery state with

2 bytes per channel:

• KL3311: 2 bytes of input data

• KL3312 (KL3302): 4 bytes of input data

• KL3314: 8 bytes of input data

Parameterization via the fieldbus is not possible. If the control and status

byte is to be used, the KS2000 configuration software is required.

Example for KL3312 (KL3302):

Interbus bus coupler

BK4000

The terminal is

mapped in the

bus coupler.

Data H

Data L

Data H

Data L

Data H

D0 - 1

D1 - 1

D0 - 0

D1 - 0

0

The control/status byte

must be inserted for

parameterization (KS2000).

Offset Terminal2 Channel1 = 6

Offset Terminal2 Channel1 = 4

Offset Terminal1 Channel2 = 2

Offset Terminal1 Channel1 = 0

K-Bus

Other Bus Couplers and

further information

i

Note

Parameterization with

KS2000

To the bus terminal

Further information about the mapping configuration of Bus Couplers can

be found in the Appendix of the respective Bus Coupler manual under

Master configuration.

The Appendix contains an overview of possible mapping configurations

depending on the parameters that can be set.

The parameterizations can be carried out independently of the fieldbus

system with the KS2000 configuration software via the serial configuration

interface in the Bus Coupler.

Register Description

Different operating modes or functionalities may be set for the complex

terminals. The General Description of Registers explains those register

contents that are the same for all complex terminals.

The terminal-specific registers are explained in the following section.

Access to the internal terminal registers is described in the Register

Communication section.

Complex terminals that possess a processor are able to exchange data bi-

General Description of Registers

directionally with the higher-level controller. These terminals are referred to

below as intelligent Bus Terminals. These include analog inputs, analog

outputs, serial interface terminals (RS485, RS232, TTY etc.), counter

terminals, encoder interface, SSI interface, PWM terminal and all other

parameterizable terminals.

KL3311, KL3312, KL3314 and KL3302 9

Page 12

Register Description

The main features of the internal data structure are the same for all the

intelligent terminals. This data area is organized as words and comprises

64 registers. The important data and parameters of the terminal can be

read and set through this structure. It is also possible for functions to be

called by means of corresponding parameters. Each logical channel in an

intelligent terminal has such a structure (4-channel analog terminals

therefore have 4 sets of registers).

This structure is divided into the following areas:

(A detailed list of all registers can be found in the Appendix.)

Register Application

0 to 7

8 to 15

16 to 30

31 to 47

48 to 63

Process variables

Type register

Manufacturer parameters

User parameters

Extended user area

Process variables

R0 to R7: Registers in the internal RAM of the terminal

The process variables can be used in addition to the actual process image.

Their function is specific to the terminal.

R0 to R5: Terminal-specific registers

The function of these registers depends on the respective terminal type

(see terminal-specific register description).

R6: Diagnostic register

The diagnostic register can contain additional diagnostic information. Parity

errors, for instance, that occur in serial interface terminals during data

transmission are indicated here.

R7: Command register

High-Byte_Write = function parameter

Low-Byte_Write = function number

High-Byte_Read = function result

Low-Byte_Read = function number

Type register

R8 to R15: Registers in the internal ROM of the terminal

The type and system parameters are hard programmed by the

manufacturer, and the user can read them but cannot change them.

R8: Terminal type

The terminal type in register R8 is needed to identify the terminal.

R9: Software version (X.y)

The software version can be read as a string of ASCII characters.

R10: Data length

R10 contains the number of multiplexed shift registers and their length in

bits.

The Bus Coupler sees this structure.

R11: Signal channels

Related to R10, this contains the number of channels that are logically

present. Thus for example a shift register that is physically present can

perfectly well consist of several signal channels.

R12: Minimum data length

The particular byte contains the minimum data length for a channel that is

to be transferred. If the MSB is set, the control and status byte is not

necessarily required for the terminal function and is not transferred to the

control, if the Bus Coupler is configured accordingly.

10 KL3311, KL3312, KL3314 and KL3302

Page 13

Register Description

R13: Data type register

Data type register

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x11

0x12 Structure 1 byte n bytes with variable l ogical channel

0x13

0x14 Structure 1 byte n words with variable l ogical channel

0x15

0x16 Structure 1 byte n double words with variable logical

Terminal with no valid data type

Byte array

Structure 1 byte n bytes

Word array

Structure 1 byte n words

Double word array

Structure 1 byte n double words

Structure 1 byte 1 double word

Structure 1 byte 1 double word

Byte array with variable logical channel length

length (e.g. 60xx)

Word array with variable logical channel length

length

Double word array with variable logical channel length

channel length

R14: Reserved

R15: Alignment bits (RAM)

The alignment bits are used to place the analog terminal in the Bus

Coupler on a byte boundary.

Manufacturer parameters

R16 to R30: Manufacturer parameter area (SEEROM)

The manufacturer parameters are specific for each type of terminal. They

are programmed by the manufacturer, but can also be modified by the

controller. The manufacturer parameters are stored in a serial EEPROM in

the terminal, and are retained in the event of voltage drop-out.

These registers can only be altered after a code-word has been set in R31.

User parameters

R31 to R47: User parameter area (SEEROM)

The application parameters are specific for each type of terminal. They can

be modified by the programmer. The application parameters are stored in a

serial EEPROM in the terminal, and are retained in the event of voltage

drop-out. The user area is write-protected by a code-word.

R31: Code-word register in RAM

i

Note

The code-word 0x1235 must be entered here so that parameters in the

user area can be modified. If any other value is entered into this register,

the write-protection is active. When write protection is not active, the code

word is returned when the register is read. If the write protection is active,

the register contains a zero value.

R32: Feature register

This register specifies the terminal's operating modes. Thus, for instance, a

user-specific scaling can be activated for the analog I/Os.

R33 to R47 Terminal-specific Registers

The function of these registers depends on the respective terminal type

(see terminal-specific register description).

Extended application region

R47 to R63

Extended registers with additional functions.

KL3311, KL3312, KL3314 and KL3302 11

Page 14

Register Description

Process variables

Manufacturer parameters

Terminal-specific register description

R0: Raw ADC value (X_R)

This register contains the unfiltered ADC value of the connected element

according to (Eq. 0.1)

(0x0000 corresponds to approx. -125mV, 0x8000 to approx. 0V, 0xFFFF to

approx. 125 mV, i.e. gain and offset errors are present)

R1 to R5: Reserved

R6: Diagnostic register

High byte: reserved

Low byte: status byte

R17: Hardware compensation - offset (B_a)

16 bit signed integer

This register is used for offset compensation of the terminal (Eq. 1.2).

Register value approx. 0x0000

R18: Hardware compensation - gain (A_a)

This register is used for gain compensation of the terminal (Eq. 1.2).

Register value approx. 0x3D4X

R19: Manufacturer scaling - offset (B_h)

16 bit signed integer [0x0000]

This register contains the offset of the manufacturer's equation of the

straight line (1.6). The straight-line equation is activated via register R32.

R20: Manufacturer scaling - gain (A_h)

16 bits signed integer *2

This register contains the scale factor of the manufacturer's equation of the

straight line (1.6). The straight-line equation is activated via register R32.

R21: Manufacturer gain compensation for reference voltage

[approx. 0x01XX]

-8

[0x00A0]

12 KL3311, KL3312, KL3314 and KL3302

Page 15

Register Description

User parameters

R32: Feature register

[0x1006]

The feature register specifies the terminal's operating mode.

Feature bit

no.

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Bit 8

Bit 9

Bit 10

Bit

15,14,13,12

0 0 0 0

0 0 0 1 Type: K

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1 1 1

1 0 0 0

1 0 0 1

1 1 0 1

1 1 1 0

1 1 1 1

Description of the operating mode

1 User scaling (R33, R44) active [0]

1

1 Watchdog timer active [1]

1 Sign / amount representation [0]

1 Siemens output format [0]

1 Activates filter constant in R37 [0]

1

- reserved, do not change!

1 Reference temperature off [0]

- reserved, do not change!

1

Element

Type: L -25°C to 900°C

Type: J -100°C to 1,200°C

Type: E -100°C to 1,000°C

Type: T -100°C to 400°C

Type: N -100°C to 1,300°C

Type: U -25°C to 600°C

Type: B 600°C to 1,800°C

Type: R 0°C to 1,700°C

Type: S 0°C to 1,700°C

Output in μV

resolution

1 μV* 1.6 μV** ±30 mV

2 μV* 3.2 μV** ±60 mV

4 μV* 6.4 μV** ±120 mV (±80 mV for KL3314)

Manufacturer scaling (R19, R20)

active [1]

In the delivery state, the watchdog

timer is switched on.

Sign / amount representation is active

instead of two's-complement

representation. (-1 = 0x8001)

This bit is used for inserting status

information on the lowest 3 bits (see

below).

Deactivates the measuring current for

broken wire detection

Checking of the lower measuring range

limit not applicable. [0]

Valid measuring range

-100°C to 1,370°C

Valid measuring range

*) no scaling active

**) only manufacturer scaling active

Examples Bit 15 to 12: 1111, no scaling active:

The output format is as follows: 1 digit corresponds to 1/16 °C or to 4 μV

Bit 15 to 12: 1111, manufacturer scaling activated via bit 1 of the feature

register:

The output format is as follows: 1 digit corresponds to 1/10 °C or to 6.4 μV

KL3311, KL3312, KL3314 and KL3302 13

Page 16

Register Description

If the Siemens output format is selected, the lowest three bits are used to

assess the status. The process data is represented in bits 3 to 15, with bit

15 representing the sign bit. Scaling of the measurement reading according

to the Siemens standard has to be done via user scaling.

Measured

value

out of range

in range

Bit 15 ... 3

0 0 1

Process data 0 0 0

Bit 2

X

Bit 1

Error

Bit 0

Overflow

R33: User scaling - offset (B_w)

16 bit signed integer

This register contains the offset of the user straight-line equation (1.7). The

straight-line equation is activated via register R32.

R34: User scaling - gain (A_w)

16 bits signed integer* 2

-8

This register contains the scale factor of the user straight-line equation (1.7)

The straight-line equation is activated via register R32.

R35 and R36: reserved

R37: Filter constant

[0x0000]

This documentation applies to all terminals from software version 3x. The

i

Note

version number can be found within the serial number on the right-hand

side face of the terminal: xxxx3xxx

Example: 52983A2A ⇒ The firmware version is 3A.

Filter constants: First notch [Hz] Conversion time [ms]

0x0000 25 250

0x50 100 65

0xA0 50 125

0x140 25 250

0x280 12.5 500

Control and Status byte

Control byte for process

data exchange

Status byte for process

data exchange

The control byte is transmitted from the controller to the terminal. The

control byte is not used for KL331x and KL3302.

The status byte is transmitted from the terminal to the controller. The status

byte contains various status bits for the analog input channel:

status byte:

Bit 7 = 0

Bit 6 = 1

bin

: ERROR - general error bit

bin

Bit 5 to bit 2: reserved

Bit 1 = 1

Bit 0= 1

: Over range

bin

: Under range

bin

Compensation The terminals are compensated when delivered.

In order to compensate tolerances of the external components, gain and

offset registers for compensating the thermocouple voltage are

implemented for each channel, i.e. R17 (thermocouple voltage offset) and

R18 (thermocouple voltage gain). For compensating the reference point

temperature (temperature at the transition between the thermocouple and

14 KL3311, KL3312, KL3314 and KL3302

Page 17

Register Description

the terminal contacts), a gain register (R21) is implemented, which is

identical for both sets of registers.

Compensation can be carried out as follows:

First, the offset is carried out with 0V input voltage, reference temperature

deactivated and linearization switched off. 0xF100 is entered in the feature

register. This is followed by gain compensation with a maximum voltage of

125 mV (typical value: 70 mV). For this terminal setting with deactivated

manufacturer scaling, the voltage is displayed with 4 μV per digit.

Gain and offset compensation of the thermocouple voltage is carried out

separately for each channel.

In the next step, the temperature of the reference point is compensated. To

this end, a thermocouple has to be selected via the feature register, and

reference point temperature compensation must be active (R32 0x1006

type K). With short-circuited inputs (0 V), the temperature of the terminal

contacts is determined, and the temperature output by the terminal

(measured via an internal temperature sensor) is set accordingly (via R21).

The reference point temperature only has to be calibrated once for each

terminal, i.e. R21 is identical for both channels.

Register communication

Register access via

process data exchange

Bit 7=1

: Register mode

bin

If bit 7 of the control byte is set, then the first two bytes of the user data are

not used for exchanging process data, but are written into or read from the

terminal's register set.

Bit 6=0

Bit 6=1

: read

bin

: write

bin

Bit 6 of the control byte specifies whether a register should be read or

written. If bit 6 is not set, then a register is read out without modifying it.

The value can then be taken from the input process image.

If bit 6 is set, then the user data is written into a register. As soon as the

status byte has supplied an acknowledgement in the input process image,

the procedure is completed (see example).

Bit 0 to 5: Address The address of the register that is to be addressed is entered into bits 0 to

5 of the control byte.

Control byte in

register mode

MSB

REG=1 W/R A5 A4 A3 A2 A1 A0

REG = 0

REG = 1

W/R = 0

W/R = 1

: Process data exchange

bin

: Access to register structure

bin

: Read register

bin

: Write register

bin

A5...A0 = register address

Address bits A5 to A0 can be used to address a total of 64 registers.

KL3311, KL3312, KL3314 and KL3302 15

Page 18

Register Description

To the bus coupler

K-Bus

Control-/

status byte

C/S-bit 7

If control bit 6=0: read

If control bit 6=1: write

Complex bus te rmina l

Example 1 Reading of register 8 in the BK2000 with a KL3312 and the end terminal:

Example 2 Writing of register 31 in the BK2000 with an intelligent terminal and the end

The control or status byte occupies the lowest address of a logical channel.

The corresponding register values are located in the following 2 data bytes.

(The BK2000 is an exception: here, an unused (reserved) data byte is

automatically inserted after the control or status byte, and the register

value is therefore placed on a word boundary).

If the following bytes are transferred from the control to the terminal,

Byte

Name

Value

Byte 3 Byte 2 Byte 1 Byte 0

DataOUT 1 DataOUT 0 Not used Control byte

0xXX 0xXX 0xXX 0x88

the terminal returns the following type identifier (0x0CF0 corresponds to

unsigned integer 3312).

Byte

Name

Value

Byte 3 Byte 2 Byte 1 Byte 0

DataIN 1 DataIN 0 Not used Status byte

0x0C 0xF0 0x00 0x88

terminal:

If the following bytes (code word) are transferred from the control to the

terminal,

Byte

Name

Value

Byte 3 Byte 2 Byte 1 Byte 0

DataOUT 1 DataOUT 0 Not used Control byte

0x12 0x35 0xXX 0xDF

the code word is set, and the terminal returns the register address with bit

7 for register access as acknowledgement.

Byte

Name

Value

Byte 3 Byte 2 Byte 1 Byte 0

DataIN 1 DataIN 0 Not used Status byte

0x00 0x00 0x00 0x9F

User data

2 or mors bytes

H

L

If contr ol bit 7=0: input /output

If control bit 7=1:

registerconfiguration

If control bit 7=1:

adress in the control bit 0-5

Terminal´s

register set

64 words

63

0

H

L

16 KL3311, KL3312, KL3314 and KL3302

Page 19

Appendix

Default mapping for:

CANopen, CANCAL,

DeviceNet, ControlNet,

Modbus, RS232, RS485

Default mapping for:

PROFIBUS, Interbus

Default mapping for:

Lightbus, Ethernet,

EtherCAT and

Bus Terminal Controller

(BCxxxx, BXxxxx)

Legend See KL3312 mapping.

Appendix

Mapping

As already described in the Terminal Configuration section, each Bus

Terminal is mapped in the Bus Coupler. In the delivery state, this mapping

occurs with the default settings of the Bus Coupler for this terminal. The

default setting can be changed with the KS2000 configuration software or

with a master configuration software (e.g. TwinCAT System Manager or

ComProfibus).

If the terminals are fully evaluated, they occupy memory space in the input

and output process image.

The following tables provide information about the terminal mapping,

depending on the conditions set in the Bus Coupler.

KL3311

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D1 Ch0 D0

Motorola format: no 1 - Word alignment: any 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D0 Ch0 D1

Motorola format: yes 1 - Word alignment: any 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D0 Ch0 CB/SB

Motorola format: no 1 - Ch0 D1

Word alignment: no 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D1 Ch0 CB/SB

Motorola format: yes 1 - Ch0 D0

Word alignment: no 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: no 1 Ch0 D1 Ch0 D0

Word alignment: yes 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: yes 1 Ch0 D0 Ch0 D1

Word alignment: yes 2 - 3 - -

KL3311, KL3312, KL3314 and KL3302 17

Page 20

Appendix

KL3312 (KL3302)

Default mapping for:

CANopen, CANCAL,

DeviceNet, ControlNet,

Modbus, RS232, RS485

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D1 Ch0 D0

Motorola format: no 1 Ch1 D1 Ch1 D0

Word alignment: any 2 - 3 - -

Default mapping for:

PROFIBUS, Interbus

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D0 Ch0 D1

Motorola format: yes 1 Ch1 D0 Ch1 D1

Word alignment: any 2 - 3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D0 Ch0 CB/SB

Motorola format: no 1 Ch1 CB/SB Ch0 D1

Word alignment: no 2 Ch1 D1 Ch1 D0

3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D1 Ch0 CB/SB

Motorola format: yes 1 Ch1 CB/SB Ch0 D0

Word alignment: no 2 Ch1 D0 Ch1 D1

3 - -

Default mapping for:

Lightbus, Ethernet,

EtherCAT and

Bus Terminal Controller

(BCxxxx, BXxxxx)

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: no 1 Ch0 D1 Ch0 D0

Word alignment: yes 2 res. Ch1 CB/SB

3 Ch1 D1 Ch1 D0

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: yes 1 Ch0 D0 Ch0 D1

Word alignment: yes 2 res. Ch1 CB/SB

3 Ch1 D0 Ch1 D1

Legend Complete evaluation:

The terminal is mapped with control and status byte.

Motorola format:

Motorola or Intel format can be set.

Word alignment:

The terminal is at word limit in the Bus Coupler.

Ch n SB: status byte for channel n (appears in the input process image).

Ch n CB: control byte for channel n (appears in the output process image).

Ch n D0: channel n, data byte 0 (byte with the lowest value)

Ch n D1: channel n, data byte 1 (byte with the highest value)

"-": This byte is not used or occupied by the terminal.

res.: reserved:

This byte occupies process data memory, although it is not used.

18 KL3311, KL3312, KL3314 and KL3302

Page 21

Appendix

KL3314

Default mapping for:

CANopen, CANCAL,

DeviceNet, ControlNet,

Modbus, RS232, RS485

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D1 Ch0 D0

Motorola format: no 1 Ch1 D1 Ch1 D0

Word alignment: any 2 Ch2 D1 Ch2 D0

3 Ch3 D1 Ch3 D0

Default mapping for:

PROFIBUS, Interbus

Conditions Word offset High byte Low byte

Complete evaluation: no 0 Ch0 D0 Ch0 D1

Motorola format: yes 1 Ch1 D0 Ch1 D1

Word alignment: any 2 Ch2 D0 Ch2 D1

3 Ch3 D0 Ch3 D1

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D0 Ch0 CB/SB

Motorola format: no 1 Ch1 CB/SB Ch0 D1

Word alignment: no 2 Ch1 D1 Ch1 D0

3 Ch2 D0 Ch2 CB/SB

4 Ch3 CB/SB Ch2 D1

5 Ch3 D1 Ch3 D0

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 Ch0 D1 Ch0 CB/SB

Motorola format: yes 1 Ch1 CB/SB Ch0 D0

Word alignment: no 2 Ch1 D0 Ch1 D1

3 Ch2 D1 Ch2 CB/SB

4 Ch3 CB/SB Ch2 D0

5 Ch3 D0 Ch3 D1

Default mapping for:

Lightbus, Ethernet,

EtherCAT and

Bus Terminal Controller

(BCxxxx, BXxxxx)

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: no 1 Ch0 D1 Ch0 D0

Word alignment: yes 2 res. Ch1 CB/SB

3 Ch1 D1 Ch1 D0

4 res. Ch2 CB/SB

5 Ch2 D1 Ch2 D0

6 res. Ch3 CB/SB

7 Ch3 D1 Ch3 D0

Conditions Word offset High byte Low byte

Complete evaluation: yes 0 res. Ch0 CB/SB

Motorola format: yes 1 Ch0 D0 Ch0 D1

Word alignment: yes 2 res. Ch1 CB/SB

3 Ch1 D0 Ch1 D1

4 res. Ch2 CB/SB

5 Ch2 D0 Ch2 D1

6 res. Ch3 CB/SB

7 Ch3 D0 Ch3 D1

Legend See KL3312 mapping.

KL3311, KL3312, KL3314 and KL3302 19

Page 22

Appendix

Register Table

These registers exist once for each channel.

Address Denomination Default value R/W Storage medium

R0

Raw ADC value variable R RAM

R1

reserved 0x0000 R

...

... ... ...

R5

reserved 0x0000 R

R6

Diagnostic register variable R RAM

R7

Command register not used 0x0000 R

R8

Terminal type 3302/3312 R ROM

R9

Software version number 0x???? R ROM

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21 Hardware compensation: Reference

R22

R30

R31

R32

R33

R34

R35

R36

R37

R63

Multiplex shift register 0x0218/0130 R ROM

Signal channels 0x0218 R ROM

Minimum data length 0x0098 R ROM

Data structure 0x0000 R ROM

reserved 0x0000 R

Alignment register variable R/W RAM

Hardware version number 0x???? R/W SEEROM

Hardware compensation: Offset specific R/W SEEROM

Hardware compensation: Gain specific R/W SEEROM

Manufacturer scaling: Offset 0x0000 R/W SEEROM

Manufacturer scaling: Gain 0x00A0 R/W SEEROM

specific R/W SEEROM

temperature

reserved 0x0000 R/W SEEROM

...

... ... ... ...

reserved 0x0000 R/W SEEROM

Code word register variable R/W RAM

Feature register 0x1006 R/W SEEROM

User scaling: Offset 0x0000 R/W SEEROM

User scaling: Gain 0x0100 R/W SEEROM

reserved 0x0000 R/W SEEROM

reserved 0x0000 R/W SEEROM

reserved 0x0138 R/W SEEROM

...

... ... ... ...

reserved 0x0000 R/W SEEROM

20 KL3311, KL3312, KL3314 and KL3302

Page 23

Appendix

Beckhoff and their partners around the world offer comprehensive service

Support and Service

and support, making available fast and competent assistance with all

questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local

support and service on Beckhoff products!

The addresses of Beckhoff's branch offices and representatives round the

world can be found on her internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff company headquarters

Beckhoff Automation GmbH

Eiserstr. 5

D-33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

web: http://www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not

only with the application of individual Beckhoff products, but also with

other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation

systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Centre supports you in all matters of after-sales

service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

KL3311, KL3312, KL3314 and KL3302 21

Loading...

Loading...