Page 1

Documentation

KL3102, KL3112, KL3122

Dual-Channel Analog Input Terminals,-10 V to +10 V, 0/4 mA to

20 mA

Version:

Date:

3.2

2019-10-15

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

1.4 Beckhoff Identification Code (BIC) ....................................................................................................7

2 Product Overview ....................................................................................................................................10

2.1 Overview of two-channel analog input terminals .............................................................................10

2.2 KL3102 - Introduction ......................................................................................................................10

2.3 KL3102 - Technical data..................................................................................................................11

2.4 KL3112, KL3122 - Introduction........................................................................................................12

2.5 KL3112, KL3122 - Technical data ...................................................................................................13

2.6 Basic function principles ..................................................................................................................14

3 Mounting and wiring................................................................................................................................16

3.1 Instructions for ESD protection........................................................................................................16

3.2 Installation on mounting rails ...........................................................................................................16

3.3 Installation instructions for enhanced mechanical load capacity .....................................................20

3.4 Connection ......................................................................................................................................20

3.4.1 Connection system .......................................................................................................... 20

3.4.2 Wiring............................................................................................................................... 23

3.4.3 Shielding .......................................................................................................................... 24

3.5 KL3102 - Connection and LED description .....................................................................................25

3.6 KL3112, KL3122 - Connection and LED description .......................................................................26

3.7 ATEX - Special conditions (standard temperature range) ...............................................................27

3.8 ATEX Documentation ......................................................................................................................28

4 Configuration Software KS2000.............................................................................................................29

4.1 KS2000 - Introduction......................................................................................................................29

4.2 Sample program for KL register communication via EtherCAT on KL3314 exemplary...................30

5 Access from the user program ..............................................................................................................33

5.1 Terminal configuration .....................................................................................................................33

5.2 Mapping in the Bus Coupler ............................................................................................................34

5.2.1 KL3102, KL3112, KL3122................................................................................................ 35

5.3 Register overview ............................................................................................................................35

5.4 Register description.........................................................................................................................36

5.5 Control and status byte....................................................................................................................41

5.5.1 Process data exchange ................................................................................................... 41

5.5.2 Register communication .................................................................................................. 42

5.6 Examples of Register Communication ............................................................................................43

5.6.1 Example 1: reading the firmware version from Register 9............................................... 43

5.6.2 Example 2: Writing to an user register............................................................................. 44

6 Appendix ..................................................................................................................................................47

6.1 Support and Service ........................................................................................................................47

KL3102, KL3112, KL3122 3Version: 3.2

Page 4

Table of contents

KL3102, KL3112, KL31224 Version: 3.2

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

KL3102, KL3112, KL3122 5Version: 3.2

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

KL3102, KL3112, KL31226 Version: 3.2

Page 7

1.3 Documentation issue status

Version Comment

3.2 • Update chapter “Instructions for ESD protection”

• Chapter “Beckhoff Identification Code (BIC)” added

3.1 • Example program added to chapter “KS2000 Configuration software“

• Design of the safety instructions adapted to IEC 82079-1

3.0 • Migration

• Update Technical data

• Structure update

• Chapter Mounting and wiring added

• Chapters KS2000 configuration software and Access from the user program added

Firmware and hardware versions

Foreword

Documentation,

Version

3.1 3B 09 3B 05 3B 05

3.0 3B 09 3B 05 3B 05

KL3102 KL3112 KL3122

Firmware Hardware Firmware Hardware Firmware Hardware

The firmware and hardware versions (delivery state) of the terminal can be found in the serial number printed

on the side.

Syntax of the serial number

Structure of the serial number: WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with ser. no.: 35 04 1B 01:

35 - week of production 35

4 - year of production 2004

1B - firmware version 1B

1 - hardware version 1

1.4 Beckhoff Identification Code (BIC)

The Beckhoff Identification Code (BIC) is increasingly being applied to Beckhoff products to uniquely identify

the product. The BIC is represented as a Data Matrix Code (DMC, code scheme ECC200), the content is

based on the ANSI standard MH10.8.2-2016.

KL3102, KL3112, KL3122 7Version: 3.2

Page 8

Foreword

Fig.1: BIC as data matrix code (DMC, code scheme ECC200)

The BIC will be introduced step by step across all product groups.

Depending on the product, it can be found in the following places:

• on the packaging unit

• directly on the product (if space suffices)

• on the packaging unit and the product

The BIC is machine-readable and contains information that can also be used by the customer for handling

and product management.

Each piece of information can be uniquely identified using the so-called data identifier

(ANSIMH10.8.2-2016). The data identifier is followed by a character string. Both together have a maximum

length according to the table below. If the information is shorter, spaces are added to it. The data under

positions 1 to 4 are always available.

The following information is contained:

Item

Type of

no.

information

1 Beckhoff order

number

2 Beckhoff Traceability

Number (BTN)

3 Article description Beckhoff article

4 Quantity Quantity in packaging

5 Batch number Optional: Year and week

6 ID/serial number Optional: Present-day

7 Variant number Optional: Product variant

...

Explanation Data

identifier

Beckhoff order number 1P 8 1P072222

Unique serial number,

see note below

description, e.g.

EL1008

unit, e.g. 1, 10, etc.

of production

serial number system,

e.g. with safety products

number on the basis of

standard products

S 12 SBTNk4p562d7

1K 32 1KEL1809

Q 6 Q1

2P 14 2P401503180016

51S 12 51S678294104

30P 32 30PF971, 2*K183

Number of digits

incl. data identifier

Example

KL3102, KL3112, KL31228 Version: 3.2

Page 9

Foreword

Further types of information and data identifiers are used by Beckhoff and serve internal processes.

Structure of the BIC

Example of composite information from item 1 to 4 and 6. The data identifiers are marked in red for better

display:

BTN

An important component of the BIC is the Beckhoff Traceability Number (BTN, item no.2). The BTN is a

unique serial number consisting of eight characters that will replace all other serial number systems at

Beckhoff in the long term (e.g. batch designations on IO components, previous serial number range for

safety products, etc.). The BTN will also be introduced step by step, so it may happen that the BTN is not yet

coded in the BIC.

NOTE

This information has been carefully prepared. However, the procedure described is constantly being further

developed. We reserve the right to revise and change procedures and documentation at any time and without prior notice. No claims for changes can be made from the information, illustrations and descriptions in

this information.

KL3102, KL3112, KL3122 9Version: 3.2

Page 10

Product Overview

2 Product Overview

2.1 Overview of two-channel analog input terminals

Module Signal voltage Signal current Filter

KL3102 [}10]

KL3112 [}12]

KL3122 [}12]

2.2 KL3102 - Introduction

-10V ... +10V 50Hz, configurable

0mA ... 20mA 50Hz, configurable

4mA ... 20mA 50Hz, configurable

Fig.2: KL3102

Two-channel analog input terminal -10V…+10V

The analog input terminal KL3102 processes signals in the range of -10V to +10V. The voltage is digitized

to a resolution of 16bits, and is transmitted, electrically isolated, to the higher-level automation device. The

input channels of one Bus Terminal have differential inputs and possess a common, internal ground

potential. The KL3102 combines two channels in a single housing. The two LEDs give an indication of the

data exchange with the Bus Coupler.

KL3102, KL3112, KL312210 Version: 3.2

Page 11

Product Overview

2.3 KL3102 - Technical data

Technical data KL3102

Number of inputs 2

Power supply for the electronics via the K-bus

Signal voltage -10V … +10V

Technology Differential input

Internal resistance >200kΩ

Common-mode voltage U

Resolution 16bit (for the 0V to 10V range from: resolution 15bit)

Conversion time 140ms, configurable to 2ms

Filter 50Hz, configurable

Measuring error (total measuring

range)

Electrical isolation 500V (K-bus / signal voltage)

Current consumption K-bus typically 65mA

Bit width in the K-bus I/O Input: 2 x 16bits of data (2 x 8bits control/status optional)

Configuration No address or configuration settings

Weight approx. 70g

Dimensions (WxHxD) approx. 15mmx100mmx70mm (width aligned: 12mm)

Mounting [}16]

Permissible ambient temperature

range during operation

Permissible ambient temperature

range during storage

Permissible relative air humidity 95%, no condensation

Vibration / shock resistance

EMC immunity/emission conforms to EN61000-6-2 / EN61000-6-4

Protection class IP20

Installation position variable

Approval

CM

max. 35V

<±0.3% relative to full scale value

on 35mm mounting rail according to EN60715

0°C ... + 55°C

-25°C ... + 85°C

conforms to EN60068-2-6/ EN60068-2-27, see also Installation

instructions for enhanced mechanical load capacity [}20]

CE, cULus, ATEX [}27]

KL3102, KL3112, KL3122 11Version: 3.2

Page 12

Product Overview

2.4 KL3112, KL3122 - Introduction

Fig.3: KL3112, KL3122

Two-channel analog input terminals 0mA...20mA and 4mA...20mA

The analog input terminals process signals in the range of

• KL3112: 0mA ... 20mA

• KL3122: 4mA ... 20mA.

The current is digitized to a resolution of 16bits (default: 15bits), and is transmitted, in an electrically

isolated form, to the higher-level automation device. The input channels of the Bus Terminals have

differential inputs and possess a common, internal ground potential. The terminals combine two channels in

a single housing. A wire breakage or overload condition are detected, and the terminal state is relayed to the

controller via the K-bus. The Run LEDs indicate the data exchange with the Bus Coupler, while the Error

LEDs indicate overload.

KL3102, KL3112, KL312212 Version: 3.2

Page 13

Product Overview

2.5 KL3112, KL3122 - Technical data

Technical data KL3112 KL3122

Number of inputs 2

Power supply for the electronics via the K-bus

Signal voltage 0mA…20mA 4mA…20mA

Technology Differential input

Internal resistance 50Ω measuring resistance, load: 60Ω + diode voltage

Common-mode voltage U

CM

Resolution 15bits (configurable to 16bits)

Conversion time 140ms, configurable to 2ms

Filter 50Hz, configurable

Measuring error (total measuring

range)

Surge voltage resistance 35V

Electrical isolation 500V (K-bus / signal voltage)

Current consumption K-bus typically 60mA

Bit width in the K-bus I/O Input: 2 x 16bits of data (2 x 8bits control/status optional)

Configuration No address or configuration settings

Weight approx. 70g

Dimensions (WxHxD) approx. 15mmx100mmx70mm (width aligned: 12mm)

Mounting [}16]

Permissible ambient temperature

range during operation

Permissible ambient temperature

range during storage

Permissible relative air humidity 95%, no condensation

Vibration / shock resistance

EMC immunity/emission conforms to EN61000-6-2 / EN61000-6-4

Protection class IP20

Installation position variable

Approval

max. 35V

<±0.3% of the full scale value

DC

on 35mm mounting rail according to EN60715

0°C ... + 55°C

-25°C ... + 85°C

conforms to EN60068-2-6/ EN60068-2-27, see also Installation

instructions for enhanced mechanical load capacity [}20]

CE, cULus, ATEX [}27]

KL3102, KL3112, KL3122 13Version: 3.2

Page 14

Product Overview

2.6 Basic function principles

The analog input terminals process signals in the range of:

KL3102: -10V ... +10V

KL3112: 0mA ... 20mA

KL3122: 4mA ... 20mA

with a resolution of up to 16bits (65535 steps). The terminal inputs are differential inputs with common

ground. Due to the differential inputs, the terminals are particularly suitable for floating measuring of voltage

drops. In the standard version, a filter with a stop frequency (64.5dB) of 50Hz is active. The filter constant

and the associated conversion time are configurable in a wide range.

The green Run LEDs indicate the operating state of the associated terminal channel.

• On: Normal operation

• Off: Watchdog-timer overflow has occurred. If no process data are transmitted by the Bus Coupler for

100ms, the green LEDs go out.

The red ERROR LEDs indicate an overflow.

• On: Measured current outside the measuring range (> 20mA)

• Off: Current in valid range

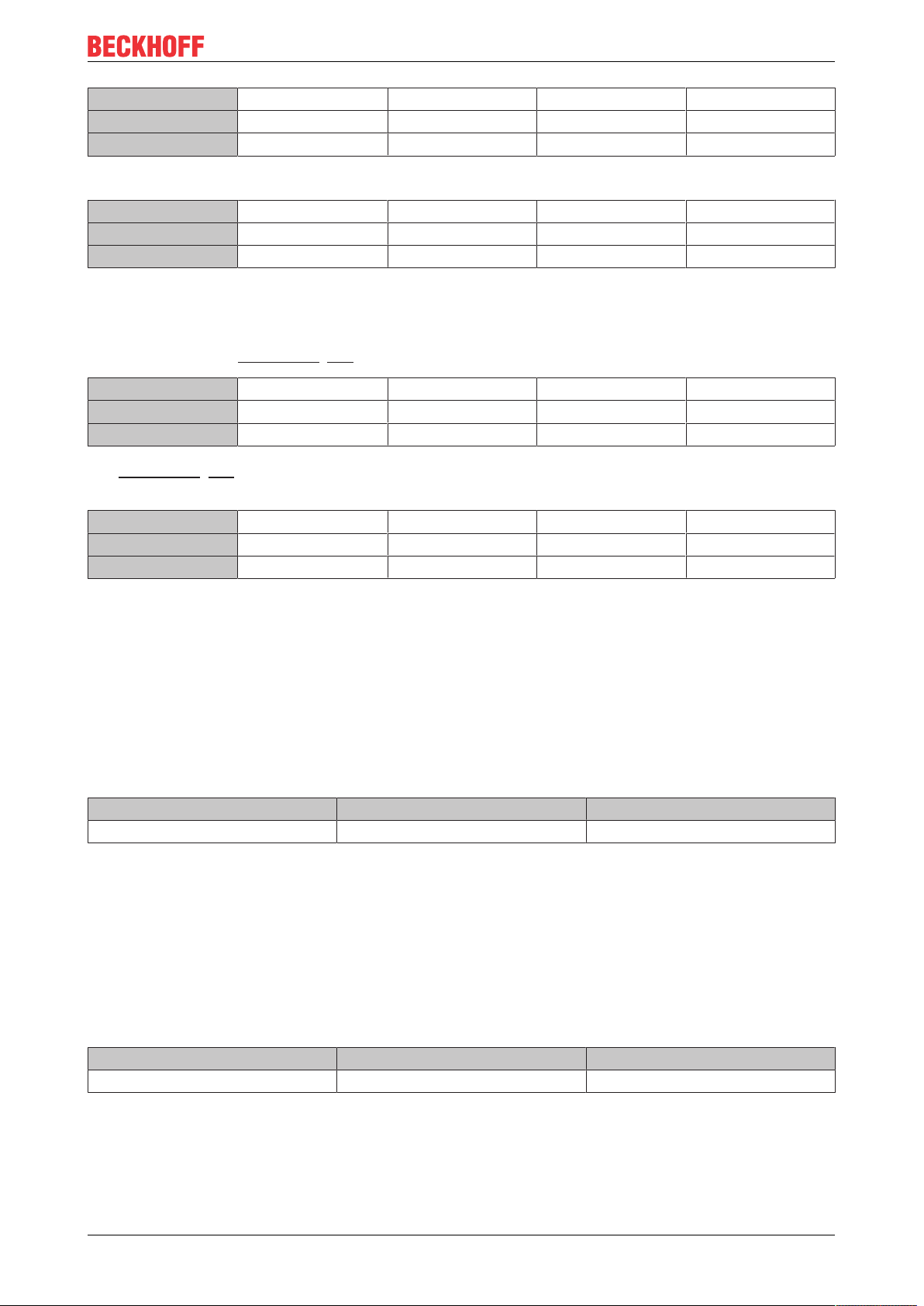

KL3102 - Output format of the process data

In the delivery state the process data are shown in two's complement form (integer -1 corresponds to

0xFFFF). Other presentation types can be selected via the feature register (R32) [}38] (e.g.signed amount

representation, Siemens output format).

Measured value Output

KL3102 dec hex

-10V -32768 0x8000

-5V -16383 0xC001

0V 0 0x0000

5V 16383 0x3FFF

10V 32767 0x7FFF

KL3112, KL3122 - Output format of the process data

In the delivery state the process data are shown in two's complement form (integer -1 corresponds to

0xFFFF). Other presentation types can be selected via the feature register (R32 [}38]) (e.g.signed amount

representation, Siemens output format).

Measured value Output

KL3112 KL3122 dec hex

0mA 4mA 0 0x0000

10mA 12mA 16383 0x3FFF

20mA 20mA 32767 0x7FFF

Calculation of process data

The terminal continuously records measured values and stores the raw values of its A/D converter in register

R0 [}36] (RAM ). The calculation of the correction with the calibration values takes place after each

sampling of the analog signal. This is followed by manufacturer and user scaling:

The process data that are transferred to the Bus Coupler are calculated using the following equations:

KL3102, KL3112, KL312214 Version: 3.2

Page 15

Product Overview

Y_a = (B_a + X_adc) * A_a

Y_aus = Y_a

Y_1 = B_h + A_h * Y_a

Y_aus = Y_1

Y_2 = B_w + A_w * Y_a

Y_aus = Y_2

Y_1 = B_h + A_h * Y_a

Y_2 = B_w + A_w * Y_1

Y_aus = Y_2

(1.0) Neither user nor manufacturer scaling is active.

(1.1) Manufacturer scaling active: (Default setting)

(1.2) User scaling active

(1.3)

(1.4)

Manufacturer and user scaling active

Key

Name Designation Register

X_adc Output value of the A/D converter -

Y_aus Process data for controller -

B_a Vendor calibration: Offset

A_a Vendor calibration: Gain

B_h Manufacturer scaling: Offset

A_h Manufacturer scaling: Gain

B_w User scaling: Offset

A_w User scaling: Gain

R17 [}37]

R18 [}38]

R19 [}38]

R20 [}38]

R33 [}38]

R34 [}39]

The equations of the straight line are enabled via register R32 [}38]

Fig.4: KL3102, KL3112, KL3122 - Data flow

KL3102, KL3112, KL3122 15Version: 3.2

Page 16

Mounting and wiring

3 Mounting and wiring

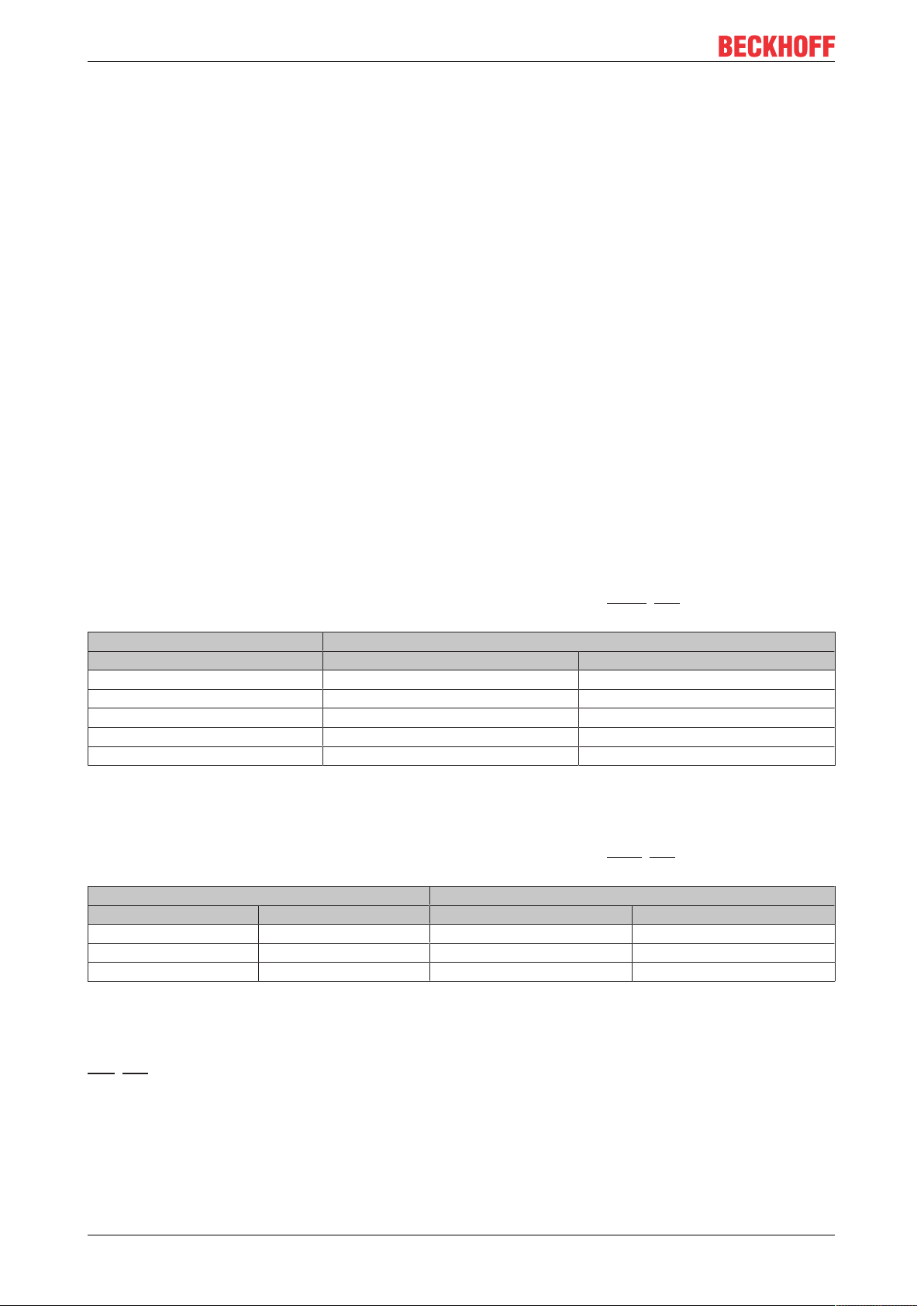

3.1 Instructions for ESD protection

NOTE

Destruction of the devices by electrostatic discharge possible!

The devices contain components at risk from electrostatic discharge caused by improper handling.

• Please ensure you are electrostatically discharged and avoid touching the contacts of the device directly.

• Avoid contact with highly insulating materials (synthetic fibers, plastic film etc.).

• Surroundings (working place, packaging and personnel) should by grounded probably, when handling

with the devices.

• Each assembly must be terminated at the right hand end with a KL9010 bus end terminal, to ensure the

protection class and ESD protection.

Fig.5: Spring contacts of the Beckhoff I/O components

3.2 Installation on mounting rails

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the bus terminals!

KL3102, KL3112, KL312216 Version: 3.2

Page 17

Assembly

Mounting and wiring

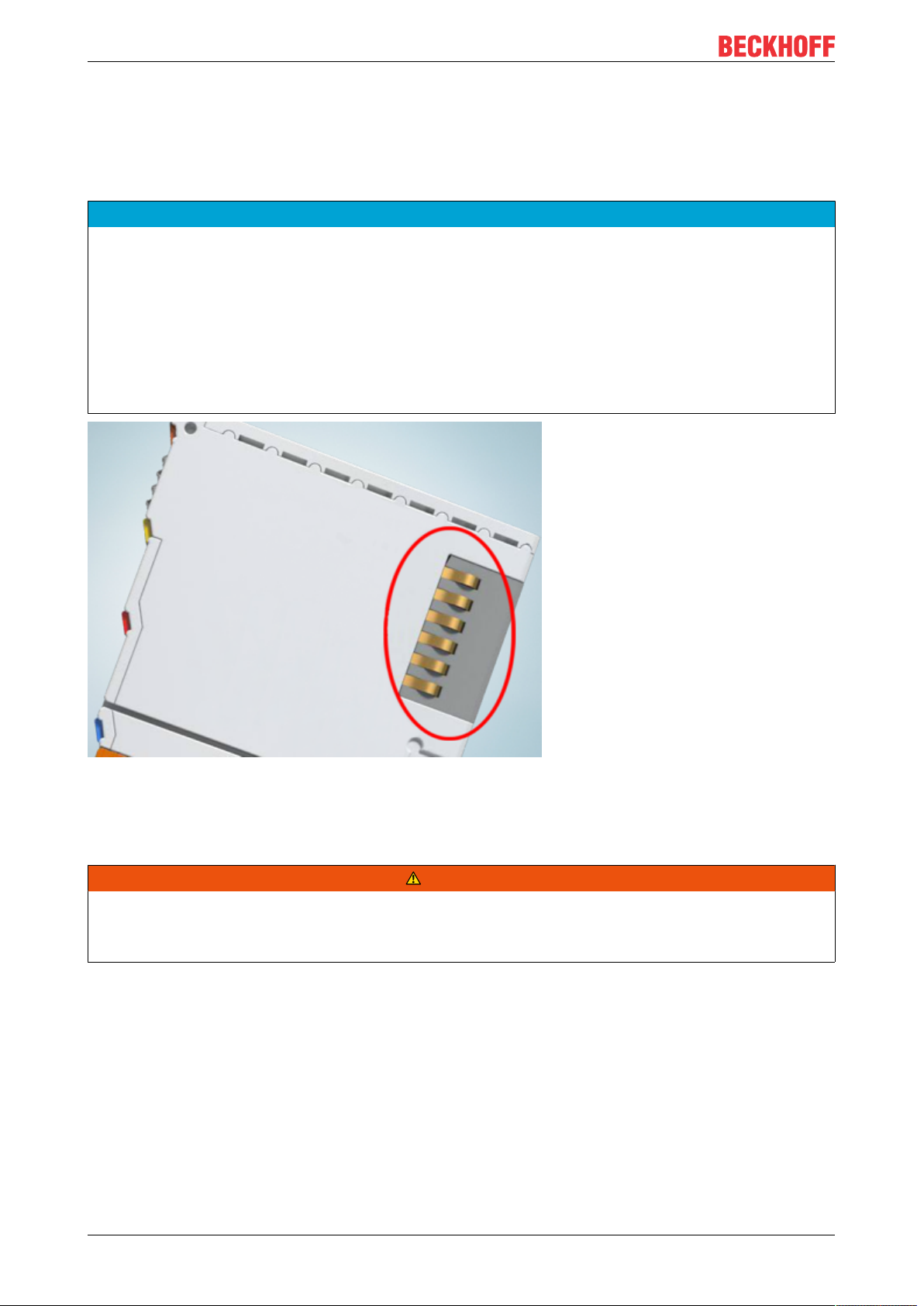

Fig.6: Attaching on mounting rail

The bus coupler and bus terminals are attached to commercially available 35mm mounting rails (DIN rails

according to EN60715) by applying slight pressure:

1. First attach the fieldbus coupler to the mounting rail.

2. The bus terminals are now attached on the right-hand side of the fieldbus coupler. Join the components with tongue and groove and push the terminals against the mounting rail, until the lock clicks

onto the mounting rail.

If the terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting rail. At

the installation, the locking mechanism of the components must not come into conflict with the fixing

bolts of the mounting rail. To mount the mounting rails with a height of 7.5mm under the terminals

and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets).

KL3102, KL3112, KL3122 17Version: 3.2

Page 18

Mounting and wiring

Disassembly

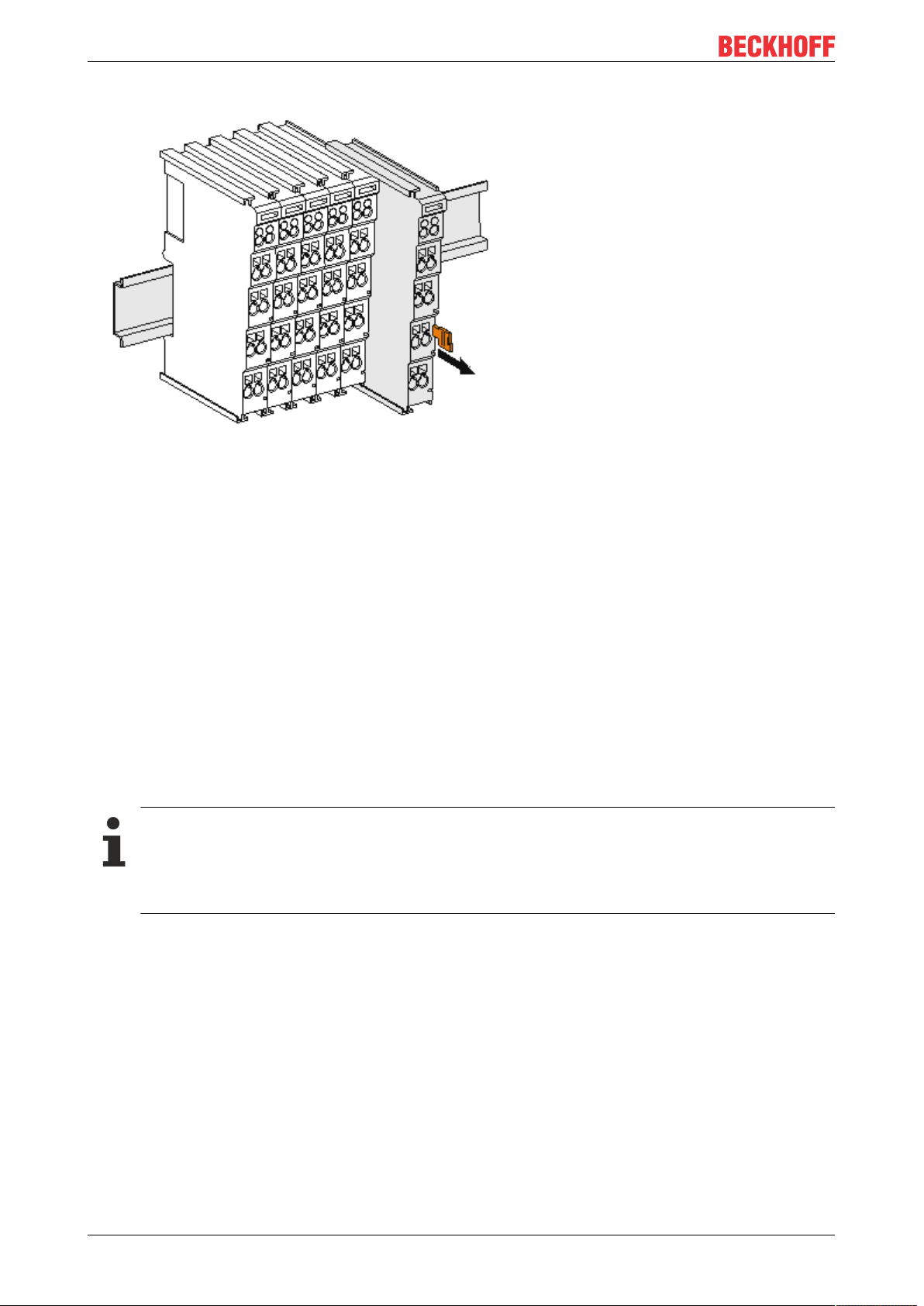

Fig.7: Disassembling of terminal

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

1. Pull the terminal by its orange-colored lugs approximately 1cm away from the mounting rail. In doing

so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of

the bus terminal block easily without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal out of the bus terminal block.

Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the bus terminal block. The power contacts are supplied via terminals on the Bus Coupler (up to 24V)

or for higher voltages via power feed terminals.

Power Contacts

During the design of a bus terminal block, the pin assignment of the individual Bus Terminals must

be taken account of, since some types (e.g. analog Bus Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed Terminals (KL91xx, KL92xx

or EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

KL3102, KL3112, KL312218 Version: 3.2

Page 19

Fig.8: Power contact on left side

Mounting and wiring

NOTE

Possible damage of the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the

mounting rail. This may lead to incorrect results during insulation testing or to damage on the terminal (e.g.

disruptive discharge to the PE line during insulation testing of a consumer with a nominal voltage of 230V).

For insulation testing, disconnect the PE supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further feed points for testing, these Power Feed Terminals can be released and pulled at

least 10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

KL3102, KL3112, KL3122 19Version: 3.2

Page 20

Mounting and wiring

3.3 Installation instructions for enhanced mechanical load capacity

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminal system into a safe, de-energized state before starting mounting, disassembly or

wiring of the Bus Terminals!

Additional checks

The terminals have undergone the following additional tests:

Verification Explanation

Vibration 10 frequency runs in 3 axes

6 Hz < f < 60 Hz displacement 0.35 mm, constant amplitude

60.1Hz<f<500Hz acceleration 5g, constant amplitude

Shocks 1000 shocks in each direction, in 3 axes

25 g, 6 ms

Additional installation instructions

For terminals with enhanced mechanical load capacity, the following additional installation instructions apply:

• The enhanced mechanical load capacity is valid for all permissible installation positions

• Use a mounting rail according to EN 60715 TH35-15

• Fix the terminal segment on both sides of the mounting rail with a mechanical fixture, e.g. an earth

terminal or reinforced end clamp

• The maximum total extension of the terminal segment (without coupler) is:

64 terminals (12 mm mounting with) or 32 terminals (24 mm mounting with)

• Avoid deformation, twisting, crushing and bending of the mounting rail during edging and installation of

the rail

• The mounting points of the mounting rail must be set at 5 cm intervals

• Use countersunk head screws to fasten the mounting rail

• The free length between the strain relief and the wire connection should be kept as short as possible. A

distance of approx. 10 cm should be maintained to the cable duct.

3.4 Connection

3.4.1 Connection system

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the bus terminals!

Overview

The Bus Terminal system offers different connection options for optimum adaptation to the respective

application:

• The terminals of ELxxxx and KLxxxx series with standard wiring include electronics and connection

level in a single enclosure.

KL3102, KL3112, KL312220 Version: 3.2

Page 21

Mounting and wiring

• The terminals of ESxxxx and KSxxxx series feature a pluggable connection level and enable steady

wiring while replacing.

• The High Density Terminals (HD Terminals) include electronics and connection level in a single

enclosure and have advanced packaging density.

Standard wiring (ELxxxx / KLxxxx)

Fig.9: Standard wiring

The terminals of ELxxxx and KLxxxx series have been tried and tested for years.

They feature integrated screwless spring force technology for fast and simple assembly.

Pluggable wiring (ESxxxx / KSxxxx)

Fig.10: Pluggable wiring

The terminals of ESxxxx and KSxxxx series feature a pluggable connection level.

The assembly and wiring procedure is the same as for the ELxxxx and KLxxxx series.

The pluggable connection level enables the complete wiring to be removed as a plug connector from the top

of the housing for servicing.

The lower section can be removed from the terminal block by pulling the unlocking tab.

Insert the new component and plug in the connector with the wiring. This reduces the installation time and

eliminates the risk of wires being mixed up.

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3

mm. The maximum height of the terminal remains unchanged.

A tab for strain relief of the cable simplifies assembly in many applications and prevents tangling of individual

connection wires when the connector is removed.

Conductor cross sections between 0.08mm2 and 2.5mm2 can continue to be used with the proven spring

force technology.

The overview and nomenclature of the product names for ESxxxx and KSxxxx series has been retained as

known from ELxxxx and KLxxxx series.

KL3102, KL3112, KL3122 21Version: 3.2

Page 22

Mounting and wiring

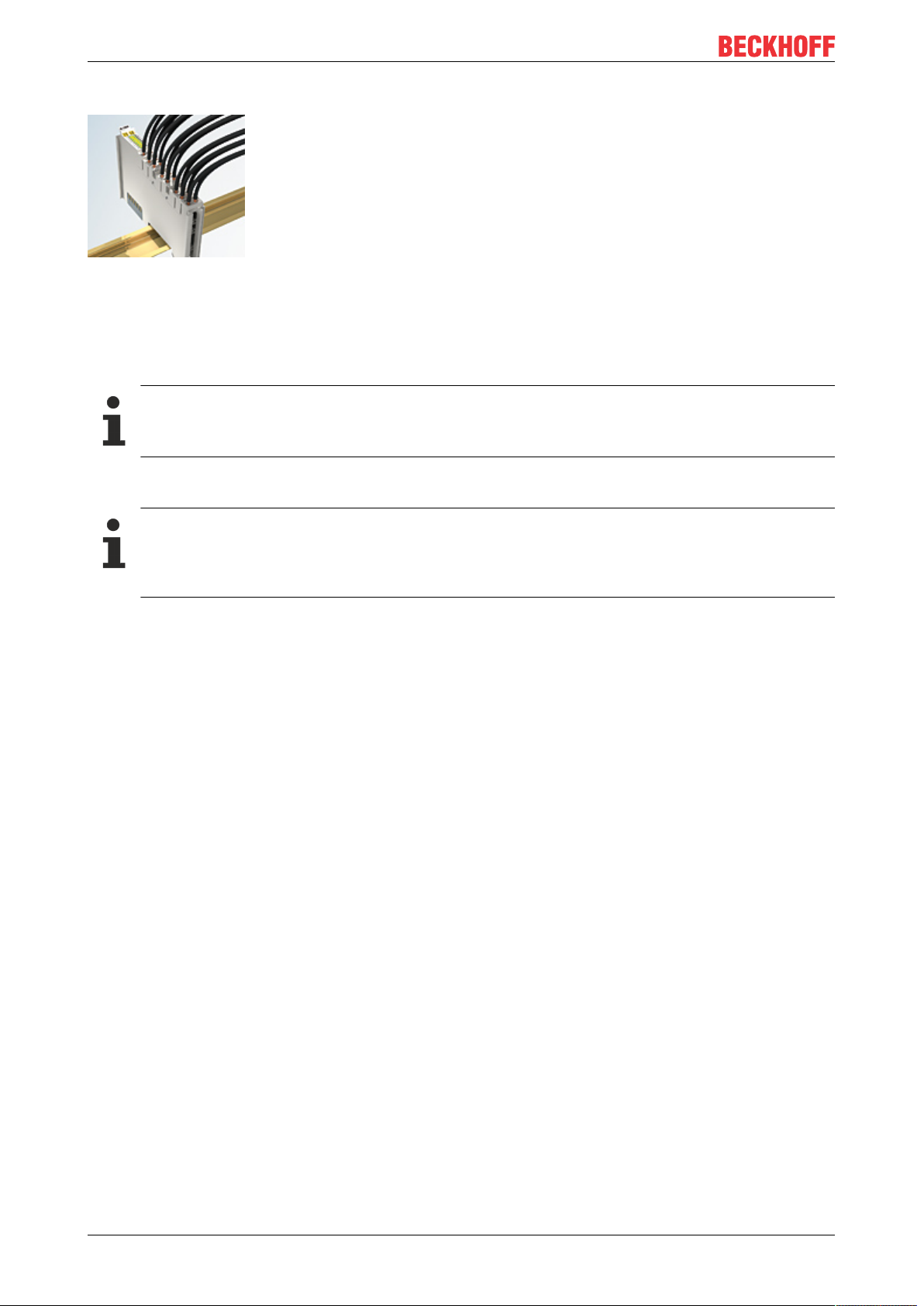

High Density Terminals (HD Terminals)

Fig.11: High Density Terminals

The Bus Terminals from these series with 16 terminal points are distinguished by a particularly compact

design, as the packaging density is twice as large as that of the standard 12mm Bus Terminals. Massive

conductors and conductors with a wire end sleeve can be inserted directly into the spring loaded terminal

point without tools.

Wiring HD Terminals

The High Density (HD) Terminals of the ELx8xx and KLx8xx series doesn't support pluggable

wiring.

Ultrasonically "bonded" (ultrasonically welded) conductors

Ultrasonically “bonded" conductors

It is also possible to connect the Standard and High Density Terminals with ultrasonically

"bonded" (ultrasonically welded) conductors. In this case, please note the tables concerning the

wire-size width below!

KL3102, KL3112, KL312222 Version: 3.2

Page 23

Mounting and wiring

3.4.2 Wiring

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the Bus Terminals!

Terminals for standard wiring ELxxxx/KLxxxx and for pluggable wiring ESxxxx/KSxxxx

Fig.12: Connecting a cable on a terminal point

Up to eight terminal points enable the connection of solid or finely stranded cables to the Bus Terminal. The

terminal points are implemented in spring force technology. Connect the cables as follows:

1. Open a terminal point by pushing a screwdriver straight against the stop into the square opening

above the terminal point. Do not turn the screwdriver or move it alternately (don't toggle).

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal point closes automatically when the pressure is released, holding the wire securely and

permanently.

See the following table for the suitable wire size width.

Terminal housing ELxxxx, KLxxxx ESxxxx, KSxxxx

Wire size width (single core wires) 0.08 ... 2.5mm

Wire size width (fine-wire conductors) 0.08 ... 2.5mm

Wire size width (conductors with a wire end sleeve) 0.14 ... 1.5mm

2

2

2

0.08 ... 2.5mm

0,08 ... 2.5mm

0.14 ... 1.5mm

2

2

2

Wire stripping length 8 ... 9mm 9 ... 10mm

High Density Terminals (HD Terminals [}22]) with 16 terminal points

The conductors of the HD Terminals are connected without tools for single-wire conductors using the direct

plug-in technique, i.e. after stripping the wire is simply plugged into the terminal point. The cables are

released, as usual, using the contact release with the aid of a screwdriver. See the following table for the

suitable wire size width.

KL3102, KL3112, KL3122 23Version: 3.2

Page 24

Mounting and wiring

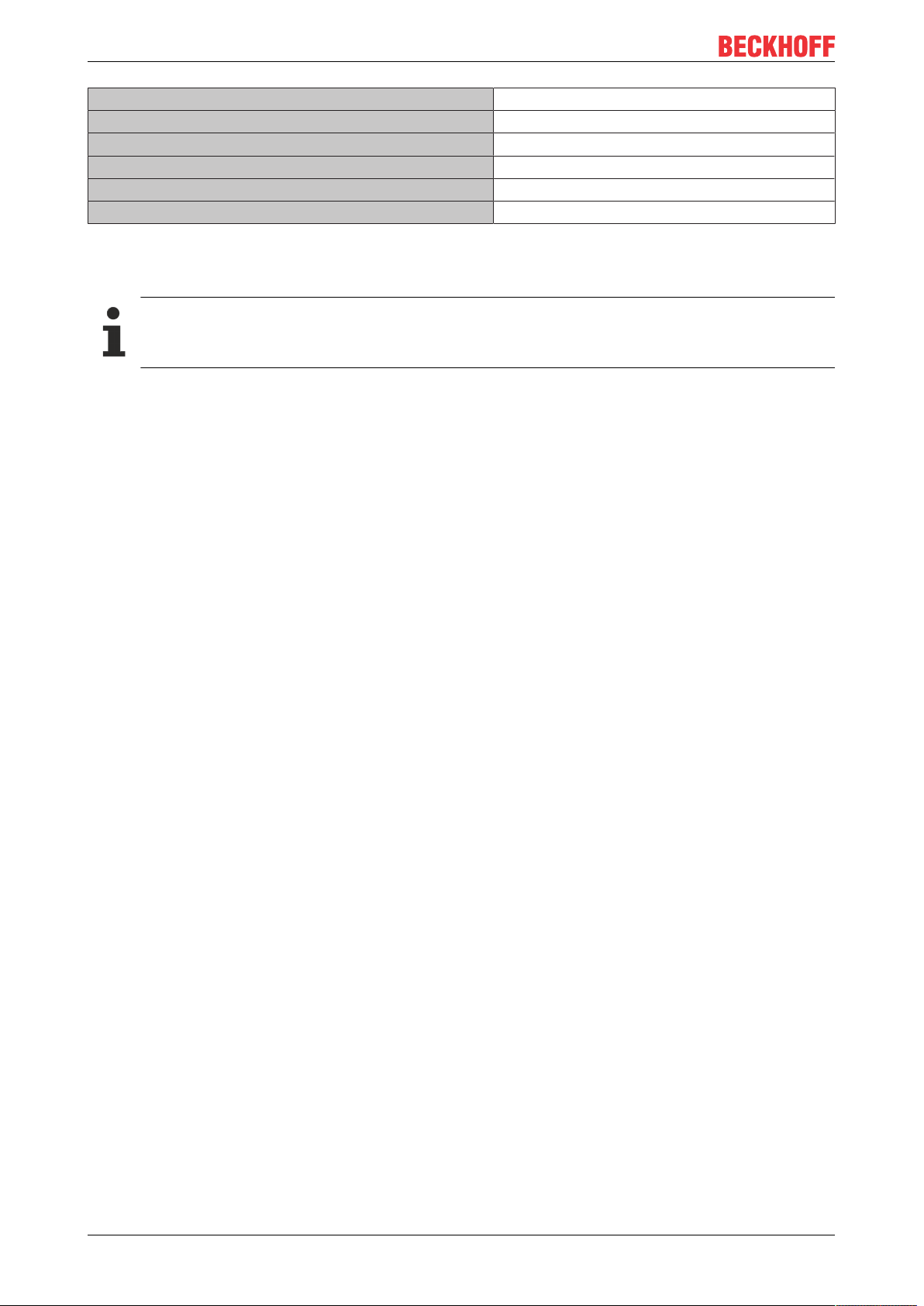

Terminal housing High Density Housing

Wire size width (single core wires) 0.08 ... 1.5mm

Wire size width (fine-wire conductors) 0.25 ... 1.5mm

Wire size width (conductors with a wire end sleeve) 0.14 ... 0.75mm

Wire size width (ultrasonically “bonded" conductors) only 1.5mm

2

2

2

2

Wire stripping length 8 ... 9mm

3.4.3 Shielding

Shielding

Encoder, analog sensors and actors should always be connected with shielded, twisted paired

wires.

KL3102, KL3112, KL312224 Version: 3.2

Page 25

Mounting and wiring

3.5 KL3102 - Connection and LED description

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminal system into a safe, voltage-free state before starting mounting, disassembly or

wiring of the Bus Terminals!

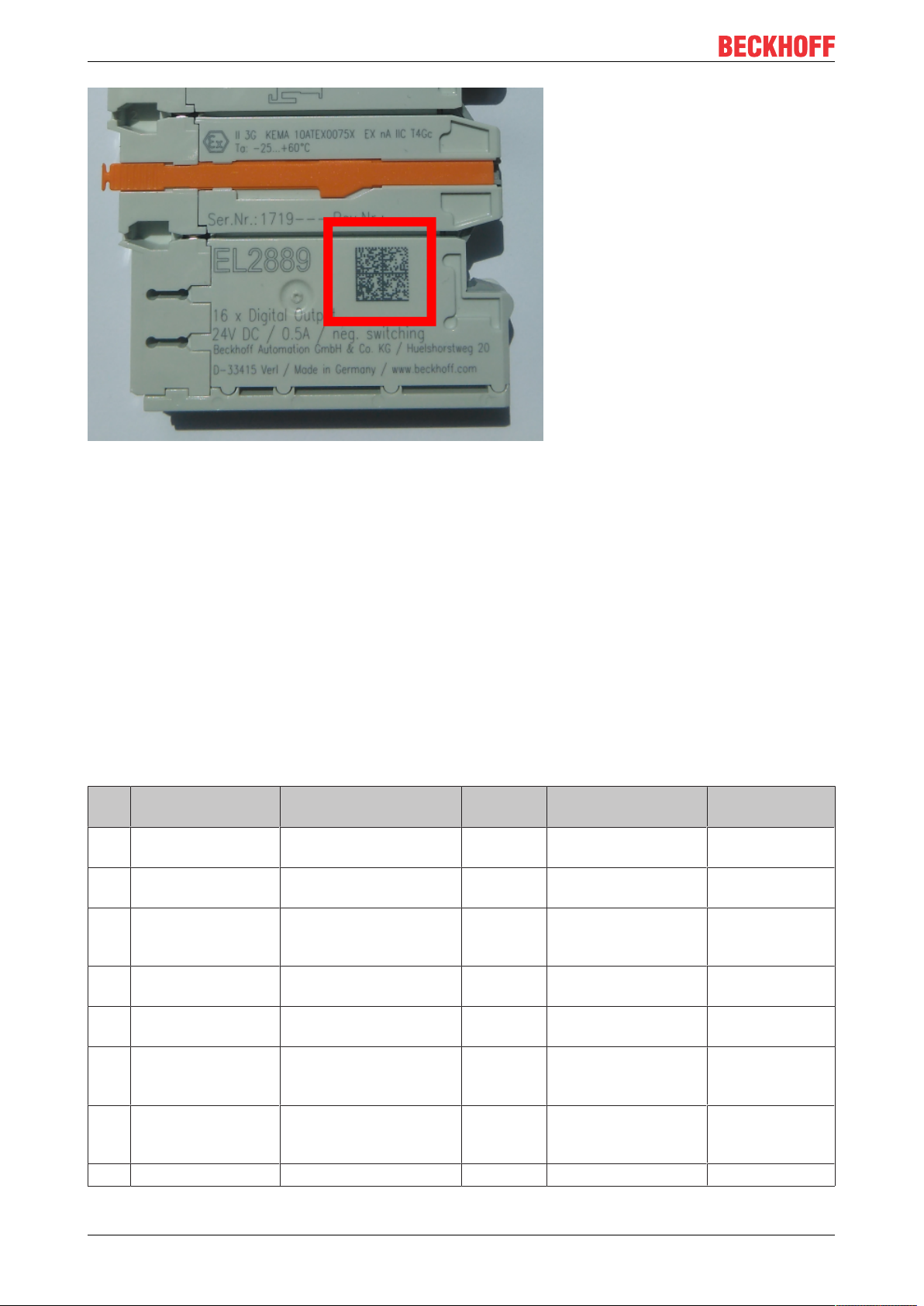

Fig.13: KL3102

KL3102 - Connection

Terminal point No. Comment

+Input 1 1 + Input 1

-Input 1 2 - Input 1

GND 3 Internal ground (internally connected to terminal point 7)

Shield 4 PE contact (internally connected to terminal point 8)

+Input 2 5 + Input 2

-Input 2 6 - Input 2

GND 7 Internal ground (internally connected to terminal point 3)

Shield 8 PE contact (internally connected to terminal point 4)

KL3102 - LEDs

LED Color Description

Run LED1

Run LED2

green On: Normal operation

Off: Watchdog timer overflow has occurred. If no process data is transmitted to the Bus Coupler

for 100ms, the green LEDs go out

KL3102, KL3112, KL3122 25Version: 3.2

Page 26

Mounting and wiring

3.6 KL3112, KL3122 - Connection and LED description

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminal system into a safe, voltage-free state before starting mounting, disassembly or

wiring of the Bus Terminals!

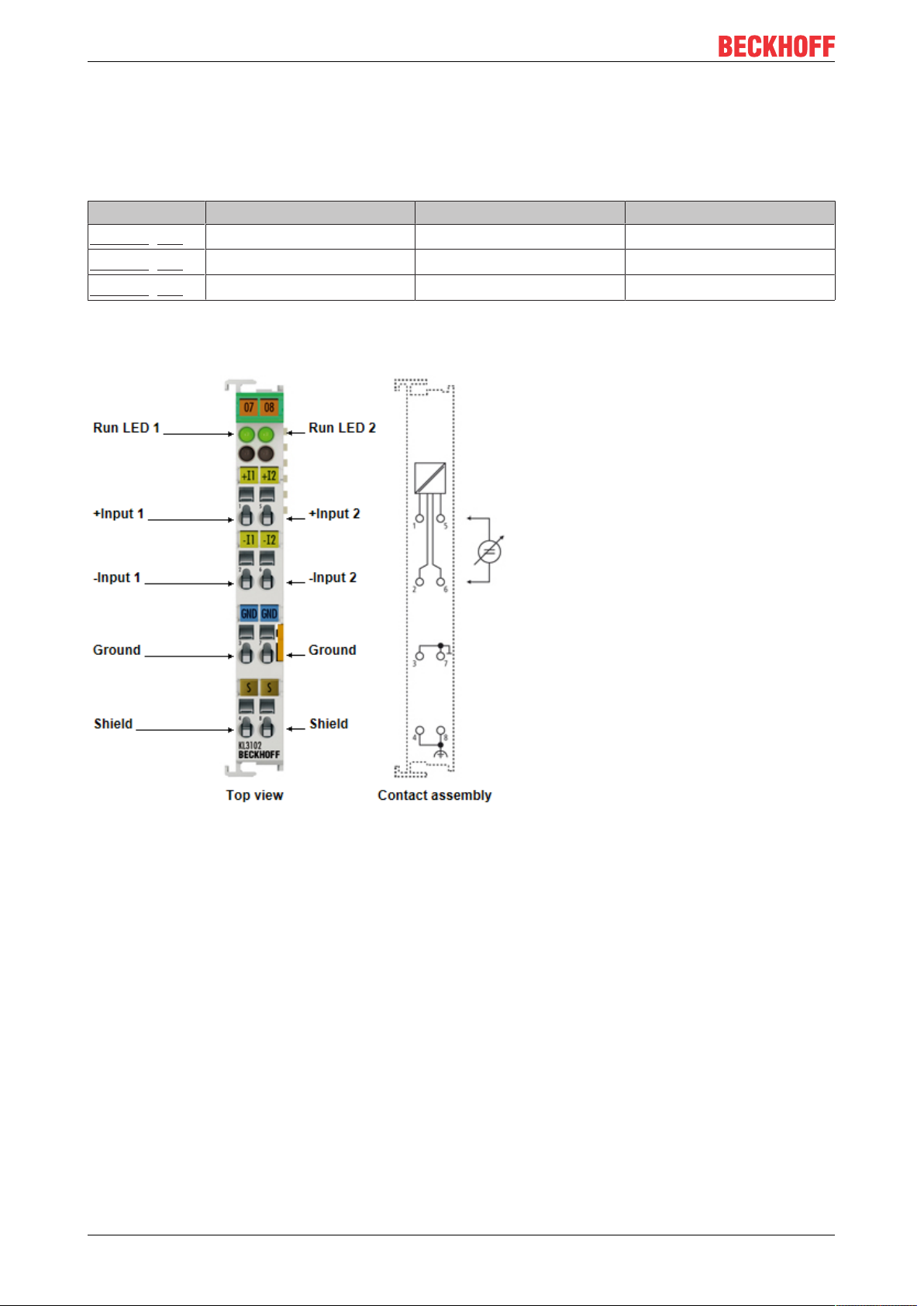

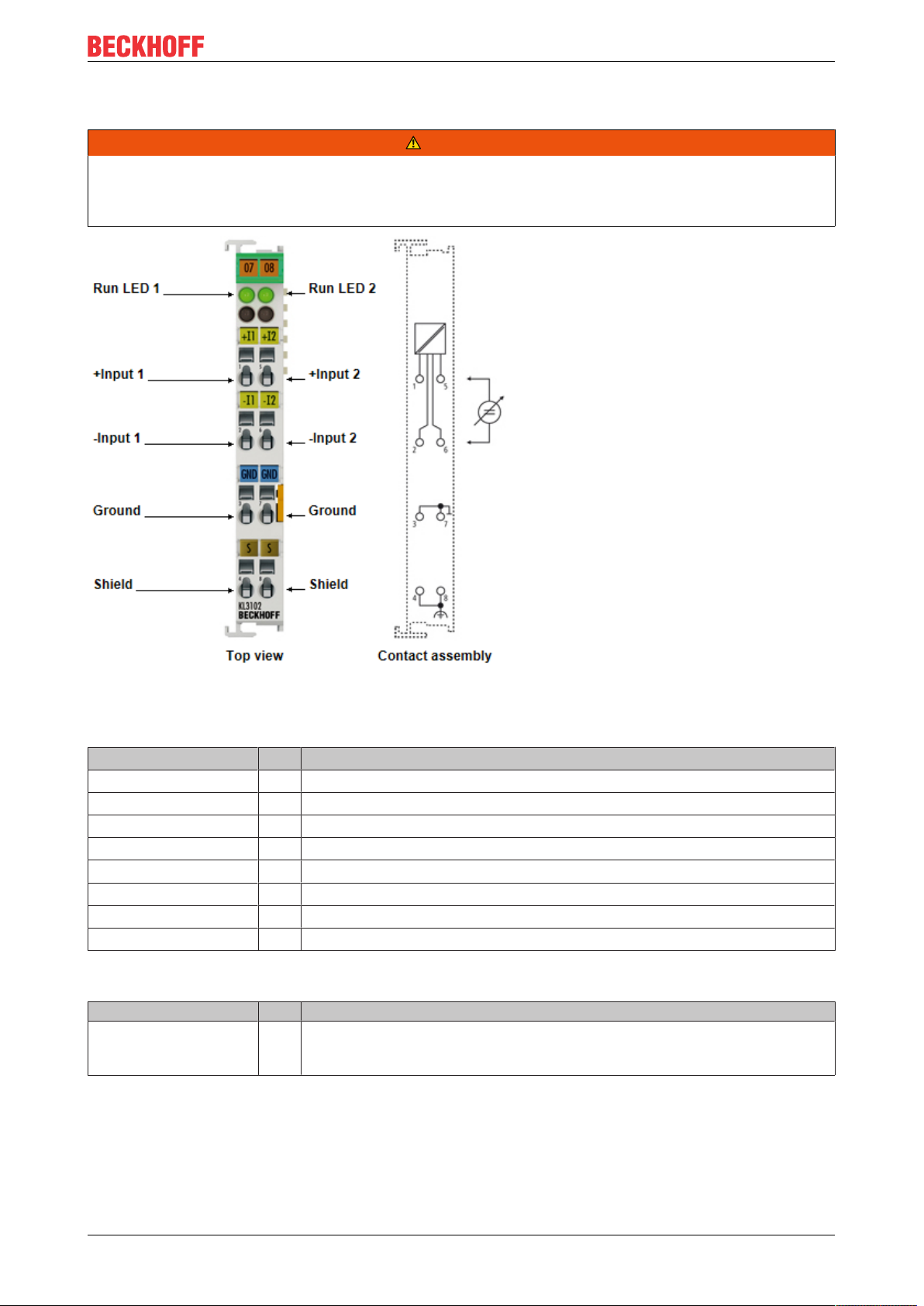

Fig.14: KL3112, KL3122

KL3112, KL3122 - Connection

Terminal point No. Comment

+Input 1 1 + Input 1

-Input 1 2 - Input 1

GND 3 Internal ground (internally connected to terminal point 7)

Shield 4 PE contact (internally connected to terminal point 8)

+Input 2 5 + Input 2

-Input 2 6 - Input 2

GND 7 Internal ground (internally connected to terminal point 3)

Shield 8 PE contact (internally connected to terminal point 4)

KL3112, KL3122 - LEDs

LED Color Description

Run LED1

Run LED2

Error LED1

Error LED2

green On: Normal operation

Off: Watchdog timer overflow has occurred. If no process data is transmitted to the Bus Coupler

for 100ms, the green LEDs go out

red On: Measured current outside the measuring range (>20mA)

Off: Current in valid range

KL3102, KL3112, KL312226 Version: 3.2

Page 27

Mounting and wiring

3.7 ATEX - Special conditions (standard temperature range)

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus components with

standard temperature range in potentially explosive areas (directive 2014/34/EU)!

• The certified components are to be installed in a suitable housing that guarantees a protection class of at

least IP54 in accordance with EN60079-15! The environmental conditions during use are thereby to be

taken into account!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observe the permissible ambient temperature range of 0 to 55°C for the use of Beckhoff fieldbus components standard temperature range in potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The individual terminals may only be unplugged or removed from the Bus Terminal system if the supply

voltage has been switched off or if a non-explosive atmosphere is ensured!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

• The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the supply voltage has

been switched off or if a non-explosive atmosphere is ensured!

• Address selectors and ID switches may only be adjusted if the supply voltage has been switched off or if

a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0:2012+A11:2013

• EN 60079-15:2010

Marking

The Beckhoff fieldbus components with standard temperature range certified according to the ATEX directive

for potentially explosive areas bear one of the following markings:

II 3GKEMA 10ATEX0075 X Ex nA IIC T4 GcTa: 0…+55°C

or

II 3GKEMA 10ATEX0075 X Ex nC IIC T4 GcTa: 0…+55°C

KL3102, KL3112, KL3122 27Version: 3.2

Page 28

Mounting and wiring

3.8 ATEX Documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

Pay also attention to the continuative documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

that is available in the download area of the Beckhoff homepage http:\\www.beckhoff.com!

KL3102, KL3112, KL312228 Version: 3.2

Page 29

Configuration Software KS2000

4 Configuration Software KS2000

4.1 KS2000 - Introduction

The KS2000 configuration software permits configuration, commissioning and parameterization of bus

couplers, of the affiliated bus terminals and of Fieldbus Box Modules. The connection between bus coupler/

Fieldbus Box Module and the PC is established by means of the serial configuration cable or the fieldbus.

Fig.15: KS2000 configuration software

Configuration

You can configure the Fieldbus stations with the Configuration Software KS2000 offline. That means, setting

up a terminal station with all settings on the couplers and terminals resp. the Fieldbus Box Modules can be

prepared before the commissioning phase. Later on, this configuration can be transferred to the terminal

station in the commissioning phase by means of a download. For documentation purposes, you are provided

with the breakdown of the terminal station, a parts list of modules used and a list of the parameters you have

modified. After an upload, existing fieldbus stations are at your disposal for further editing.

Parameterization

KS2000 offers simple access to the parameters of a fieldbus station: specific high-level dialogs are available

for all bus couplers, all intelligent bus terminals and Fieldbus Box modules with the aid of which settings can

be modified easily. Alternatively, you have full access to all internal registers of the bus couplers and

intelligent terminals. Refer to the register description for the meanings of the registers.

KL3102, KL3112, KL3122 29Version: 3.2

Page 30

Configuration Software KS2000

Commissioning

The KS2000 software facilitates commissioning of machine components or their fieldbus stations: Configured

settings can be transferred to the fieldbus modules by means of a download. After a login to the terminal

station, it is possible to define settings in couplers, terminals and Fieldbus Box modules directly online. The

same high-level dialogs and register access are available for this purpose as in the configuration phase.

The KS2000 offers access to the process images of the bus couplers and Fieldbus Box modules.

• Thus, the coupler's input and output images can be observed by monitoring.

• Process values can be specified in the output image for commissioning of the output modules.

All possibilities in the online mode can be used in parallel with the actual fieldbus mode of the terminal

station. The fieldbus protocol always has the higher priority in this case.

4.2 Sample program for KL register communication via EtherCAT on KL3314 exemplary

Using the sample programs

This document contains sample applications of our products for certain areas of application. The

application notes provided here are based on typical features of our products and only serve as examples. The notes contained in this document explicitly do not refer to specific applications. The

customer is therefore responsible for assessing and deciding whether the product is suitable for a

particular application. We accept no responsibility for the completeness and correctness of the

source code contained in this document. We reserve the right to modify the content of this document at any time and accept no responsibility for errors and missing information.

Program description / function

This example program (TwinCAT 3) provides change of single register values of the KL3314 as selection of

the element type, characteristical settings of the feature register R32 and user scaling offset and gain (R33/

R34) similar as per KS2000.

KL3102, KL3112, KL312230 Version: 3.2

Page 31

Configuration Software KS2000

Fig.16: Settings of KL3314 via visualisation of TwinCAT 3

At least following configuration setup shall be present:

[coupler (e.g. BK1120) or embedded PC] + KL3314 + KL9010.

Download:

https://infosys.beckhoff.com/content/1033/kl3102_kl3112_kl3122/Resources/zip/5996114571.zip

Preparations for starting the sample programs (tnzip file / TwinCAT 3)

• Click on the download button to save the Zip archive locally on your hard disk, then unzip the *.tnzip

archive file in a temporary folder.

Fig.17: Opening the *. tnzip archive

KL3102, KL3112, KL3122 31Version: 3.2

Page 32

Configuration Software KS2000

• Select the .tnzip file (sample program).

• A further selection window opens. Select the destination directory for storing the project.

• For a description of the general PLC commissioning procedure and starting the program please refer to

the terminal documentation or the EtherCAT system documentation.

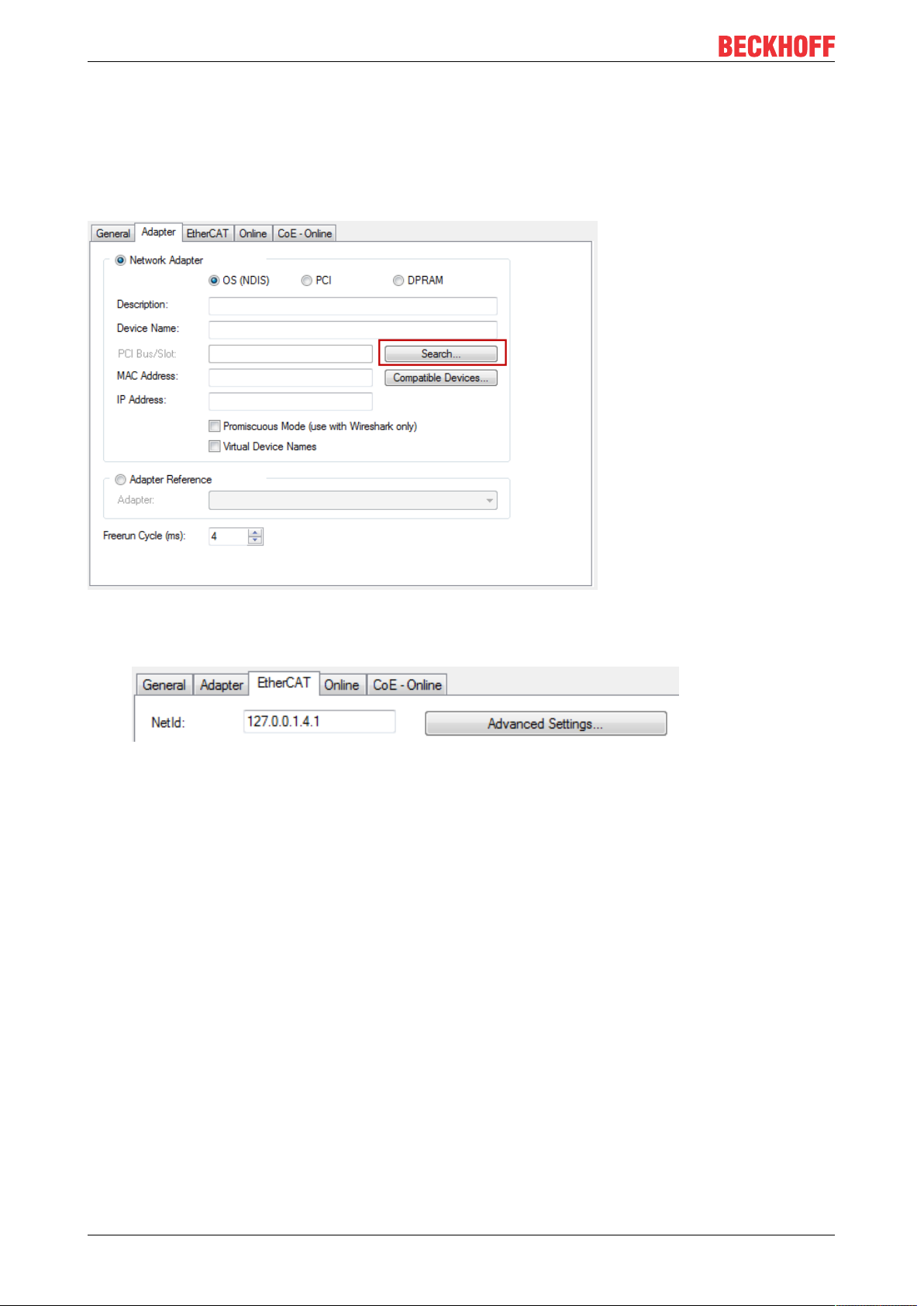

• The EtherCAT device of the example should usually be declared your present system. After selection

of the EtherCAT device in the “Solutionexplorer” select the “Adapter” tab and click on “Search...”:

Fig.18: Search of the existing HW configuration for the EtherCAT configuration of the example

• Checking NetId: the "EtherCAT" tab of the EtherCAT device shows the configured NetId:

.

The first 4 numbers have to be identical with the project NetId of the target system. The project NetId

can be viewed within the TwinCAT environment above, where a pull down menu can be opened to

choose a target system (by clicking right in the text field). The number blocks are placed in brackets

there next to each computer name of a target system.

• Modify the NetId: By right clicking on "EtherCAT device" within the solution explorer a context menu

opens where "Change NetId..." have to be selected. The first 4 numbers of the NetId of the target

computer have to be entered; the both last values are 4.1 usually.

Example:

◦ NetId of project:myComputer (123.45.67.89.1.1)

◦ Entry via „Change NetId...“:123.45.67.89.4.1

KL3102, KL3112, KL312232 Version: 3.2

Page 33

Access from the user program

5 Access from the user program

5.1 Terminal configuration

The terminal can be configured and parameterized via the internal register structure. Each terminal channel

is mapped in the Bus Coupler. Mapping of the terminal data in the Bus Coupler memory may differ,

depending on the Bus Coupler type and the set mapping configuration (e.g.Motorola/Intel format, word

alignment etc.). For parameterizing a terminal, the control and status byte also has to be mapped.

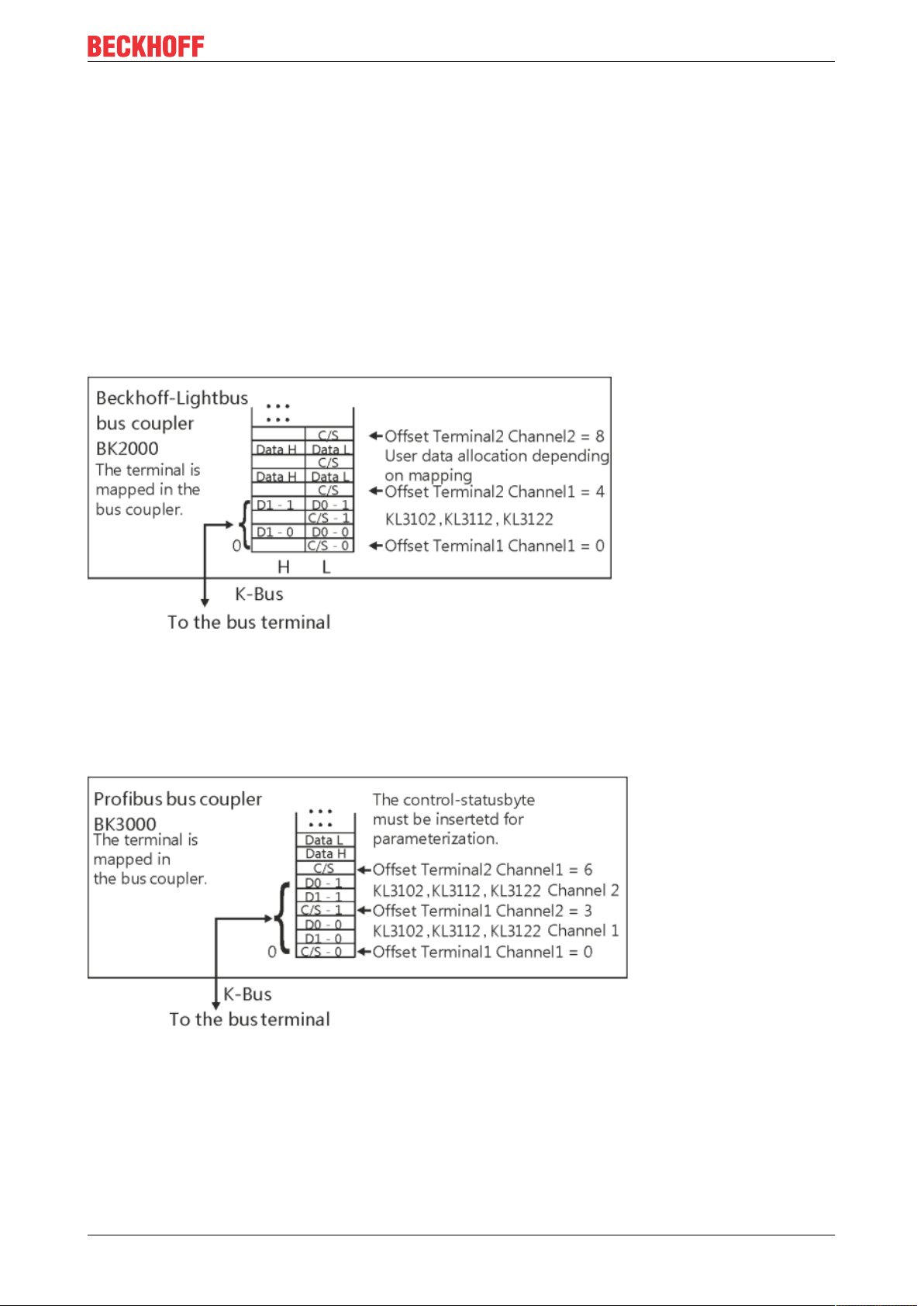

BK2000 Lightbus coupler

In the BK2000 Lightbus Coupler, the control/status byte is always mapped, in addition to the data bytes. This

is always located in the low byte at the offset address of the terminal channel.

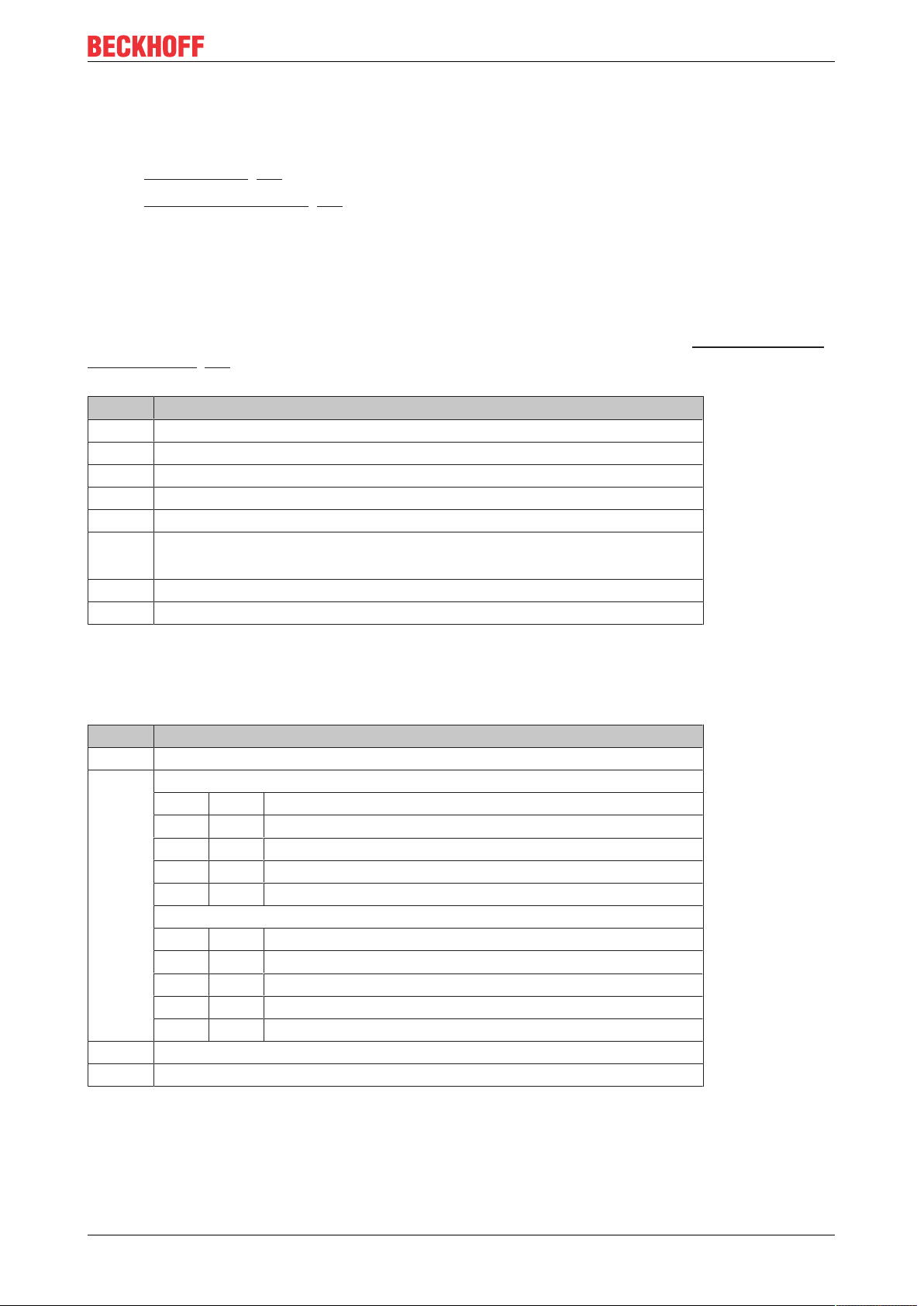

Fig.19: Mapping in the Lightbus Coupler - Example for KL3102, KL3112, KL3122

BK3000 Profibus coupler

For the BK3000 Profibus coupler, the master configuration should specify for which terminal channels the

control and status byte is to be inserted. If the control and status byte are not evaluated, the terminals

occupy 4bytes of input data (2 bytes per channel).

Fig.20: Mapping in the Profibus Coupler - Example for KL3102, KL3112, KL3122

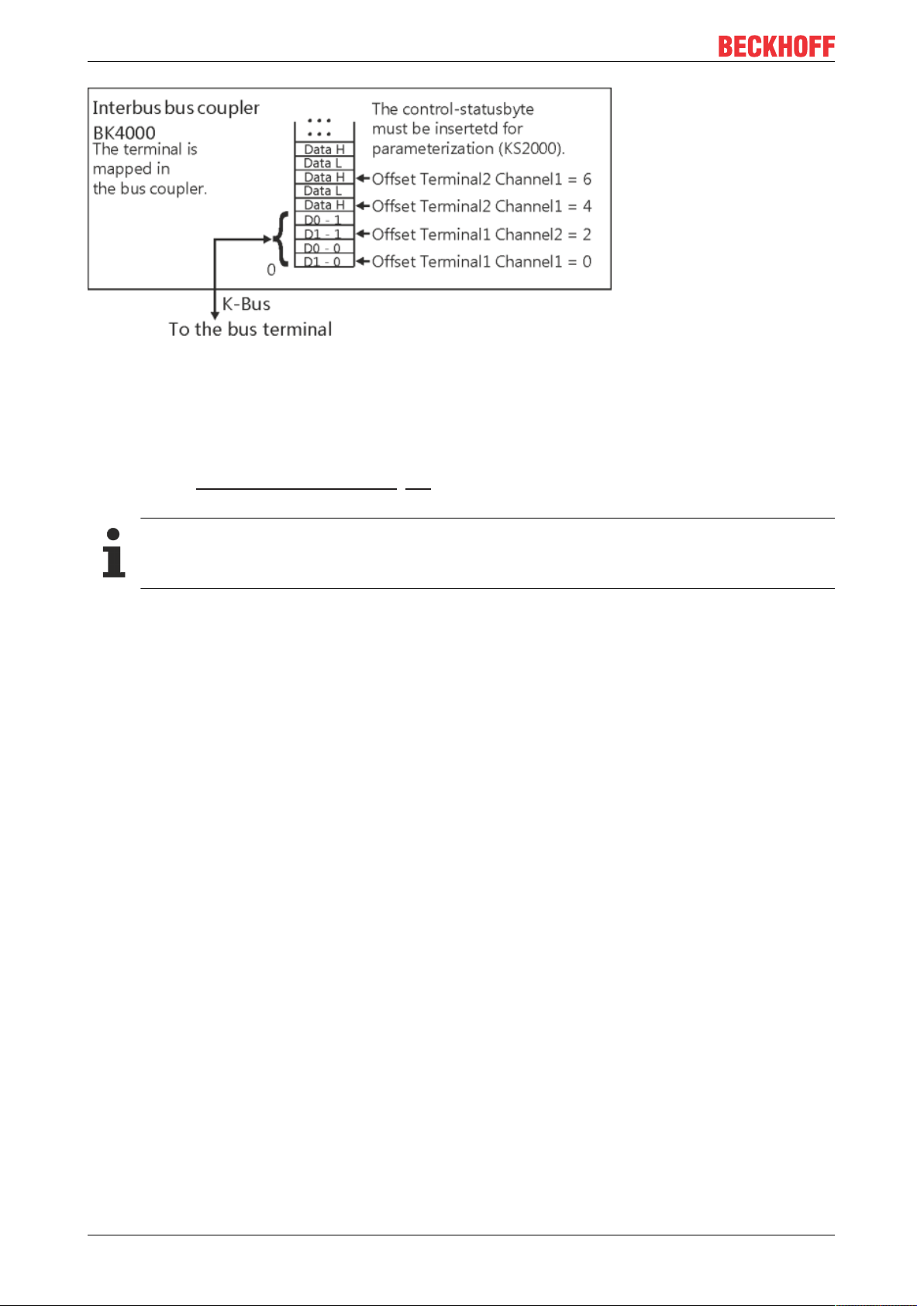

BK4000 Interbus Coupler

In delivery state the BK4000 Interbus Coupler maps the terminals with 4 bytes of input data (2bytes per

channel).

Parameterization via the fieldbus is not possible. If the control and status byte is to be used, the KS2000

configuration software is required.

KL3102, KL3112, KL3122 33Version: 3.2

Page 34

Access from the user program

Fig.21: Mapping in the Interbus Coupler - Example for KL3102, KL3112, KL3122

Other Bus Couplers and further information

Further information about the mapping configuration of Bus Couplers can be found in the Appendix of the

respective Bus Coupler manual under Master configuration.

The chapter on Mapping in the Bus Coupler [}34] contains an overview of possible mapping

configurations, depending on the configurable parameters.

Parameterization with KS2000

The KS2000 configuration software can be used for parameterizations via the serial interface of the

Bus Coupler, independent of the fieldbus system.

5.2 Mapping in the Bus Coupler

As already described in the Terminal Configuration chapter, each Bus Terminal is mapped in the Bus

Coupler. This mapping is usually done with the default setting in the Bus Coupler / Bus Terminal. The

KS2000 configuration software or a master configuration software (e.g.ComProfibus or TwinCAT System

Manager) can be used to change this default setting.

If the terminals are fully evaluated, they occupy memory space in the input and output process image.

The following tables provide information about how the terminals map themselves in the Bus Coupler,

depending on the parameters set.

KL3102, KL3112, KL312234 Version: 3.2

Page 35

Access from the user program

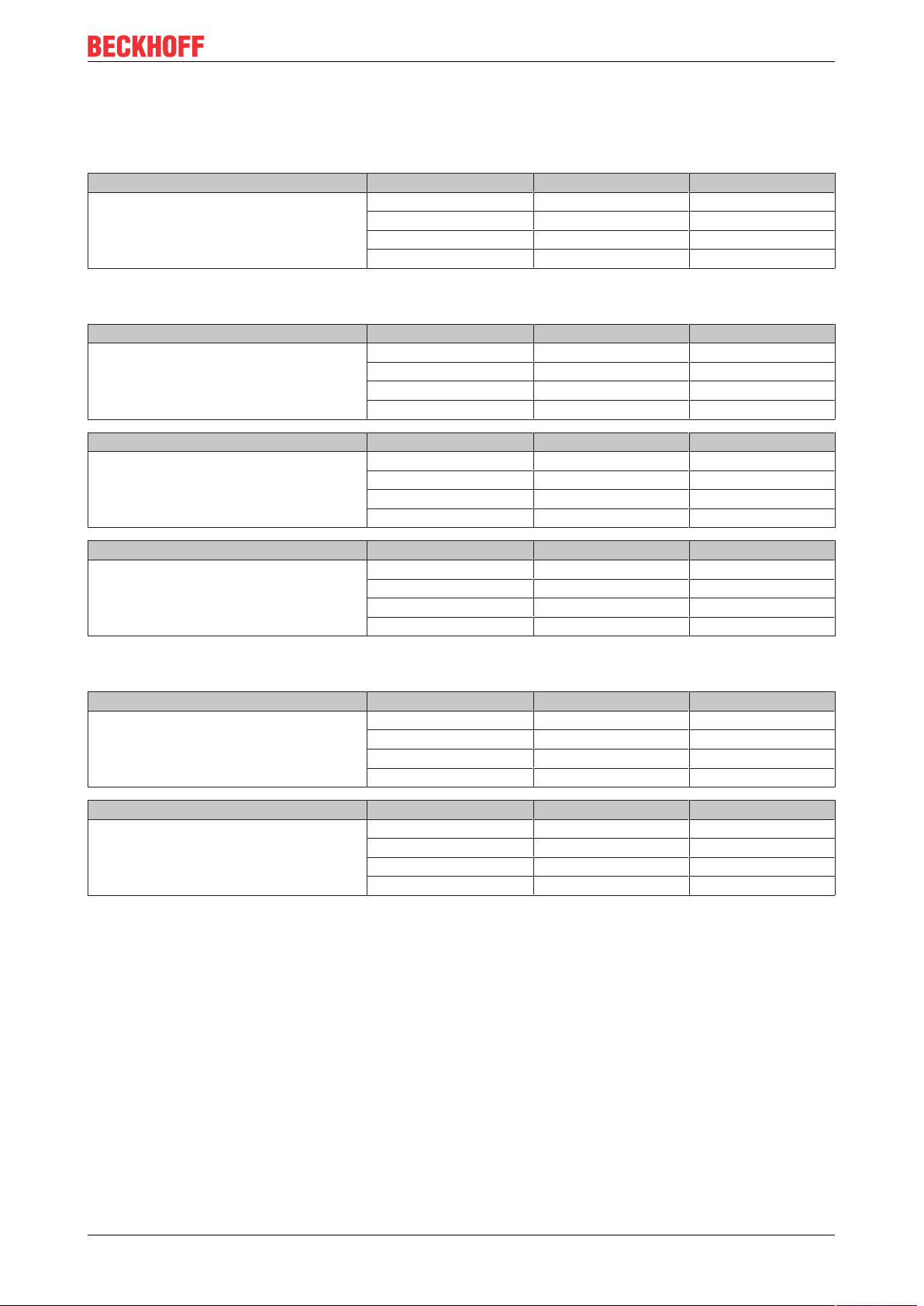

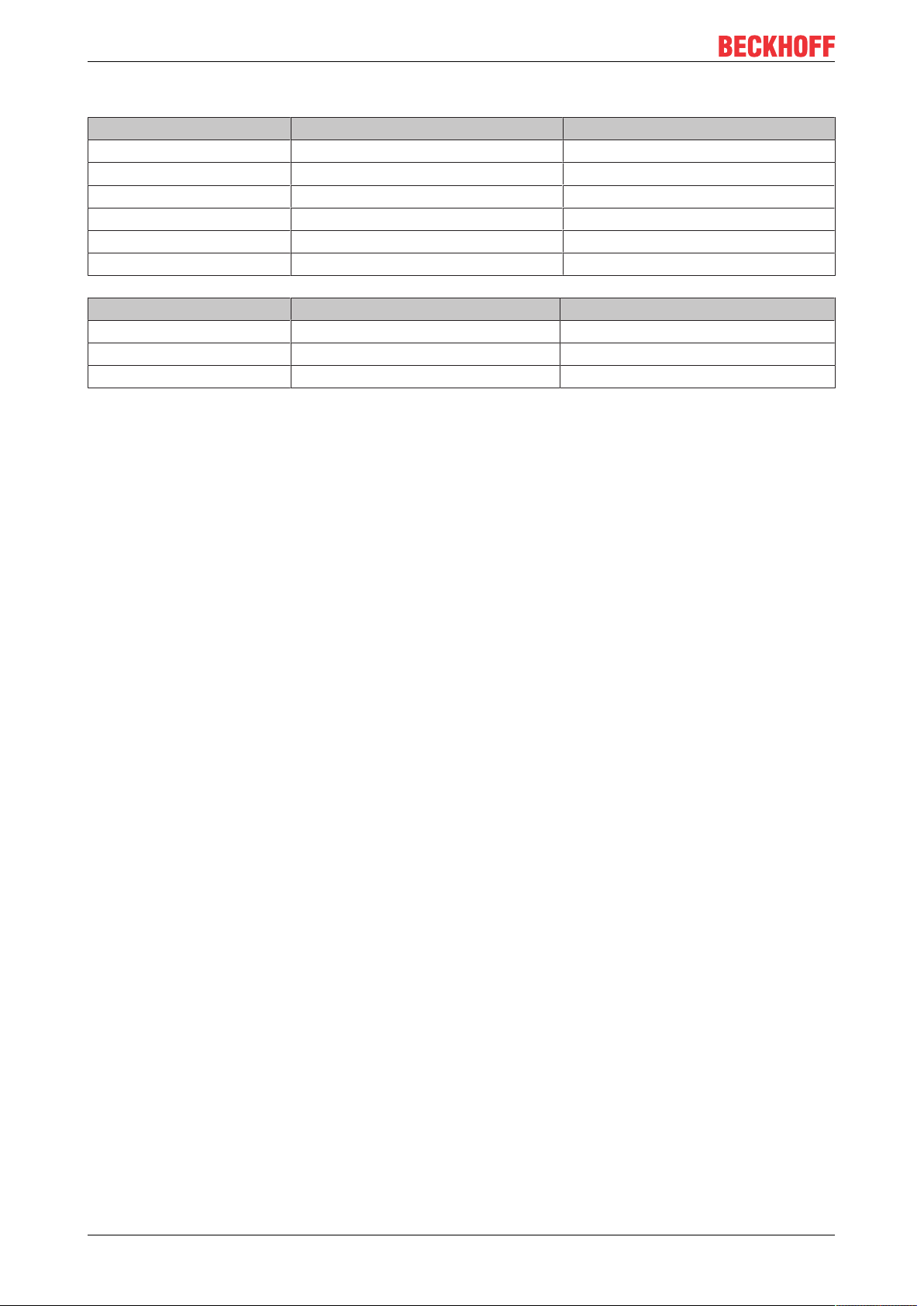

5.2.1 KL3102, KL3112, KL3122

Default mapping for: CANopen, CANCAL, DeviceNet, ControlNet, Modbus, RS232 and RS485 coupler

Conditions Word offset High byte Low byte

Complete evaluation: no

Motorola format: no

Word alignment: any

Default mapping for: Profibus and Interbus Coupler

Conditions Word offset High byte Low byte

Complete evaluation: no

Motorola format: yes

Word alignment: any

Conditions Word offset High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: no

0 Ch1 D1 Ch1 D0

1 Ch2 D1 Ch2 D0

2 - -

3 - -

0 Ch1 D0 Ch1 D1

1 Ch2 D0 Ch2 D1

2 - -

3 - -

0 Ch1 D0 Ch1 CB/SB

1 Ch2 CB/SB Ch1 D1

2 Ch2 D1 Ch2 D0

3 - -

Conditions Word offset High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: no

0 Ch1 D1 Ch1 CB/SB

1 Ch2 CB/SB Ch1 D0

2 Ch2 D0 Ch2 D1

3 - -

Default mapping for: Lightbus & Ethernet coupler and Bus Terminal Controller (BCxxxx, BXxxxx)

Conditions Word offset High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: yes

Conditions Word offset High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: yes

0 Res. Ch1 CB/SB

1 Ch1 D1 Ch1 D0

2 Res. Ch2 CB/SB

3 Ch2 D1 Ch2 D0

0 Res. Ch1 CB/SB

1 Ch1 D0 Ch1 D1

2 Res. Ch2 CB/SB

3 Ch2 D0 Ch2 D1

Key

Complete evaluation The terminal is mapped with control and status byte.

Motorola format Motorola or Intel format can be set.

Word alignment The terminal is positioned on a word boundary in the Bus Coupler.

Ch n CB Control byte for channel n (appears in the process image of the outputs).

Ch n SB Status byte for channel n (appears in the process image of the inputs).

Ch n D0 Channel n, data byte 0 (byte with the lowest value)

Ch n D1 Channel n, data byte 1 (byte with the highest value)

"-" This byte is not used or occupied by the terminal.

Res. Reserved: this byte is assigned to the process data memory, although it has no function.

5.3 Register overview

These registers exist once for each channel

KL3102, KL3112, KL3122 35Version: 3.2

Page 36

Access from the user program

Address Designation Default value R/W Storage medium

R0 [}36]

R1…R5 reserved 0x0000 R

R6 [}36]

R7 [}36]

R8 [}37]

R9 [}37]

R10 [}37]

R11 [}37]

R12 [}37]

R13 [}37]

R14 reserved 0x0000 R

R15 [}37]

R16 [}37]

R17 [}37]

R18 [}38]

R19 [}38]

R20 [}38]

R21…R30 reserved 0x0000 R/W SEEROM

R31 [}38]

R32 [}38]

R33 [}38]

R34 [}39]

R35 [}39]

R36 [}39]

R37 [}39]

R38…R47 reserved 0x0000 R/W SEEROM

Raw ADC value variable R RAM

Diagnostic register variable R RAM

Command register - reserved 0x0000 R

Terminal type e.g.3102 R ROM

Software version number 0x???? R ROM

Multiplex shift register 0x0218 R ROM

Signal channels 0x0218 R ROM

Minimum data length 0x0098 R ROM

Data structure 0x0000 R ROM

Alignment register variable R/W RAM

Hardware version number 0x???? R/W SEEROM

Hardware compensation: Offset specific R/W SEEROM

Hardware compensation: Gain specific R/W SEEROM

Manufacturer scaling: Offset 0x8000 R/W SEEROM

Manufacturer scaling: Gain 0x0100 R/W SEEROM

Code word register variable R/W RAM

Feature register 0x01106 R/W SEEROM

User scaling: Offset 0x0000 R/W SEEROM

User scaling: Gain 0x0100 R/W SEEROM

Threshold 1 0x0000 R/W SEEROM

Threshold 2 0x0000 R/W SEEROM

Filter constant 0x35C0 R/W SEEROM

5.4 Register description

The registers can be read or written via the register communication. They are used for the parameterization

of the terminal.

R0 to R7: Registers in the internal RAM of the terminal

The process variables can be used in addition to the actual process image. Their function is specific to the

terminal.

• R0 ADC raw value (X_R)

This register contains the raw ADC value with gain and offset error

• R1 to R5: Reserved

• R6: Diagnostic register

◦ High byte: reserved

◦ Low byte: Status byte

• R7: Command register

High-Byte_Write = function parameter

Low-Byte_Write = function number

High-Byte_Read = function result

Low-Byte_Read = function number

KL3102, KL3112, KL312236 Version: 3.2

Page 37

Access from the user program

R8 to R15: Registers in the internal ROM of the terminal

The type and system parameters are hard programmed by the manufacturer, and the user can read them

but cannot change them.

• R8: Terminal type

The terminal type in register R8 is needed to identify the terminal.

• R9: Software version (X.y)

The software version can be read as a string of ASCII characters.

• R10: Data length

R10 contains the number of multiplexed shift registers and their length in bits.

The Bus Coupler sees this structure.

• R11: Signal channels

Related to R10, this contains the number of channels that are logically present. Thus for example a

shift register that is physically present can perfectly well consist of several signal channels.

• R12: Minimum data length

The particular byte contains the minimum data length for a channel that is to be transferred. If the MSB

is set, the control and status byte is not necessarily required for the terminal function and is not

transferred to the control, if the Bus Coupler is configured accordingly.

• R13: Data type register

Data type register Meaning

0x00 Terminal with no valid data type

0x01 Byte array

0x02 Structure 1 byte n bytes

0x03 Word array

0x04 Structure 1 byte n words

0x05 Double word array

0x06 Structure 1 byte n double words

0x07 Structure 1 byte 1 double word

0x08 Structure 1 byte 1 double word

0x11 Byte array with variable logical channel length

0x12 Structure 1 byte n bytes with variable logical channel length (e.g. 60xx)

0x13 Word array with variable logical channel length

0x14 Structure 1 byte n words with variable logical channel length

0x15 Double word array with variable logical channel length

0x16 Structure 1 byte n double words with variable logical channel length

• R14: reserved

• R15: Alignment bits (RAM)

The alignment bits are used to place the analog terminal in the Bus Coupler on a byte boundary.

R16 to R30: Manufacturer parameter area (SEEROM)

The manufacturer parameters are specific for each type of terminal. They are programmed by the

manufacturer, but can also be modified by the controller. The manufacturer parameters are stored in a serial

EEPROM in the terminal, and are retained in the event of voltage drop-out.

These registers can only be altered after a code word has been set in R31 [}38].

• R17: Hardware compensation - offset (B_a)

KL3102: [approx. 0x00XX], KL3112 & KL3122 [0xFBxx]

16bit signed integer*2^-16+1

This register is used for offset compensation of the terminal (Eq. 1.1 [}14]).

KL3102, KL3112, KL3122 37Version: 3.2

Page 38

Access from the user program

• R18: Hardware compensation - gain (A_a)

KL3102: [approx. 0x24XX], KL3112 & KL3122 [0x48xx]

16bit signed integer*2^-16+1

This register is used for gain compensation of the terminal (Eq. 1.1 [}14]).

1 corresponds to 0x0000, 2 corresponds to 0xFFFF

• R19: Manufacturer scaling - offset (B_h)

16bit signed integer [0x0000]

This register contains the offset of the manufacturer straight-line equation (equation 1.3 [}14]). The

straight-line equation is enabled via register R32.

• R20: Manufacturer scaling - gain (A_h)

KL3102: [0x0100], KL3112 and KL3122: [0x0000]

16bit signed integer*2-8

This register contains the scale factor of the manufacturer's equation of the straight line (Eq. 1.3 [}14]).

The straight-line equation is enabled via register R32.

1 corresponds to register value 0x0400.

R31 to R47: User parameter area (SEEROM)

The user parameters are specific for each type of terminal. They can be modified by the programmer. The

user parameters are stored in a serial EEPROM in the terminal, and are retained in the event of voltage

drop-out. The user area is write-protected by a code word.

• R31: Code word register in RAM

The code word 0x1235 must be entered here so that parameters in the user area can be modified.

If any other value is entered into this register, the write-protection is active. When write protection is

not active, the code word is returned when the register is read. If the write protection is active, the

register contains a zero value.

• R32: Feature register

KL3102: [0x1106], KL3112 and KL3122[0x0002]

This register specifies the operation modes of the terminal. Thus, forinstance, a user-specific scaling

can be enabled for the analog I/Os.

Value range of KL3112 and KL3122

For reasons of compatibility, 16bits signed integer is selected as the (standard) output format. The

positive value range for 0mA / 4mA to 20mA therefore extends from 0 to 32767 (0x7FFF). This

corresponds to 15bits. Manufacturer scaling must be disabled in order to exploit all 16bits of the

terminal.

Feature bit no. Description of the operation mode

Bit 0 1

Bit 1 1

Bit 2 0 Watchdog timer active [0]

Bit 3 1 Sign / amount representation [0]

Bit 4…7 - Reserved, don't change

Bit 9 1 Limit value 1 active [0]

Bit 10 1 Limit value 2 active [0]

Bit 11…15 - Reserved, don't change

User scaling (R33, R34 [}38]) active [0]

Manufacturer scaling (R19, R20 [}38]) active [1]

In the delivery state, the watchdog timer is switched on.

Signed amount representation is active instead of two's complement representation.

(-1=0x8001).

The process data are compared with limit value 1 (R35 [}39]), and appropriate status bits are

set.

The process data are compared with limit value 2 (R36 [}39]), and appropriate status bits are

set.

• R33: User scaling - offset (B_w)

16bit signed integer

This register contains the offset of the user straight-line equation (Eq. 1.4 [}14]). The straight-line

equation is enabled via register R32 [}38].

KL3102, KL3112, KL312238 Version: 3.2

Page 39

Access from the user program

• R34: User scaling - gain (A_w)

16bit signed integer*2

-8

This register contains the scaling factor of the user straight-line equation (Eq. 1.4 [}14]). The straightline equation is enabled via register R32 [}38].

• R35: Limit value 1 (Y_2)

[0x0000]

If the process data are outside this threshold, the appropriate bits are set in the status byte.

• R36: Limit value 2 (Y_2)

[0x0000]

If the process data are outside this threshold, the appropriate bits are set in the status byte.

• R37: Filter constants of the A/D converter, and configuration bits for the filter

(default value: 35C0

hex

)

The terminal has two low-pass filter stages:

◦ The first stage consists of a sinc3 filter, and is always active.

◦ The second stage consists of a 22nd order FIR filter. This can be deactivated.

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Name Filter constant Nf (Nf.11 to Nf.0) Zero Zero Skip Fast

Key

Bit Name Description Default

Stop

3

35C

hex

(860

dec

R37.15 Filter constant Nf

...

(Nf.11 - Nf.0)

R37.4

The filter constant Nf specifies the 3dB limit frequency of the sinc

filter. The value ranges from 150 to 2047.

The 3dB limit frequency F

and the 64.5dB stop frequency F

Limit

are calculated as follows: (see following table)

)

Skip = 0 F

Skip = 1 F

= 11981/Nf

limit

F

= 43008/Nf

stop

= 81076/Nf

limit

Bit Name Description Default

R37.3 Zero 0

R37.2 Zero 0

See note below 0

bin

bin

bin

0

bin

Do not change

Bits R37.2 and R37.3 must always be ZERO, otherwise errors will occur in the A/D converter!

Bit Name Description Default

R37.1 Skip 0

1

R37.0 Fast 0

1

FIR filter is enabled. 0

bin

FIR filter is bypassed.

bin

Fast Step Mode is disabled. 0

bin

Fast Step Mode is active: a fast reaction will follow jumps at

bin

the input, in spite of the filter stage being active. In this case

the filter is bypassed!

bin

bin

KL3102, KL3112, KL3122 39Version: 3.2

Page 40

Access from the user program

Examples

Value in R37 F

stop

Cycle time

0x35C0 50Hz 140ms

0x2660 70Hz 100ms

0x1330 140Hz 50ms

0x7FF1 40ms

0x3FF1 20ms

0x1001 <4ms

Value in R37 F

limit

Cycle time

0x7FF2 39.6Hz 40ms

0x3FF2 77.36Hz 20ms

0x1002 158Hz <4ms

KL3102, KL3112, KL312240 Version: 3.2

Page 41

Access from the user program

5.5 Control and status byte

The control and status byte is transmitted from the controller to the terminal. It can be used

• in register mode [}42] (REG = 1

• in process data exchange [}41] (REG = 0

) or

bin

).

bin

5.5.1 Process data exchange

Control byte in process data exchange (REG=0)

A gain and offset calibration of the terminal can be carried out with the control byte. The code word must be

entered in R31 [}38] so that the terminal calibration can be carried out. The gain and offset of the terminal

can then be calibrated. The parameter will only be saved permanently once the code word is reset!

Bit Description

Bit 7 0

Bit 6 1

Bit 5 reserved

Bit 4 1

Bit 3 1

Bit 2 0

Bit 1 1

Bit 0 1

bin

: Terminal compensation function is enabled

bin

: Gain calibration

bin

: Offset calibration

bin

: slower cycle = 1000ms

bin

1

: fast cycle = 50ms

bin

: up

bin

: down

bin

Status byte in process data exchange (REG=0)

The status byte is transferred from the terminal to the controller. The status byte contains various status bits

for the analog input channel:

Bit Description

Bit 7 0

Bit 6 1

bin

: Error (general error bit)

bin

Bit 5 Bit 4

0

0

1

1

0

bin

bin

bin

bin

bin

1

bin

0

bin

1

bin

Limit value 2 not enabled

Process data < limit value 2

Process data > limit value 2

Process data = limit value 2

Bit 3 Bit 2

0

0

1

1

Bit 1 1

Bit 0 1

0

bin

bin

bin

bin

bin

bin

bin

1

bin

0

bin

1

bin

: Overrange

: Underrange

Limit value 1 not enabled

Process data < limit value 1

Process data > limit value 1

Process data = limit value 1

KL3102, KL3112, KL3122 41Version: 3.2

Page 42

Access from the user program

5.5.2 Register communication

Register access via process data exchange

• Bit 7=1: Register mode

If bit 7 of the control byte is set, the first two bytes of the user data are not used for process data

exchange but written into the register set of the terminal or read from it.

• Bit 6=0: read, bit 6=1: write

Bit 6 of the control bytes is used to specify whether a register should be read or written.

◦ Bit 6=0: a register is read without changing it. The value can be found in the input process image.

◦ Bit 6=1: the user data are written to a register. The process is complete once the status byte in the

input process image has returned an acknowledgment (see example).

• Bit 0to 5: Address

The address of the register to be addressed is entered in bits 0 to 5 of the control byte.

Control byte in register mode (REG=1)

MSB

REG=1 W/R A5 A4 A3 A2 A1 A0

REG = 0

REG = 1

W/R = 0

W/R = 1

: Process data exchange

bin

: Access to register structure

bin

: Read register

bin

: Write register

bin

A5..A0 = register address

Addresses A5...A0 can be used to address a total of 64 registers.

Fig.22: Register mode control byte

The control or status byte occupies the lowest address of a logical channel. The corresponding register

values are located in the following 2 data bytes. (The BK2000 is an exception: here, an unused data byte is

inserted after the control or status byte, and the register value is therefore placed on a word boundary).

Example 1:

Reading of register 8 in the BK2000 with a KL3102 and the end terminal:

If the following bytes are transferred from the controller to the terminal,

KL3102, KL3112, KL312242 Version: 3.2

Page 43

Access from the user program

Byte Byte 3 Byte 2 Byte 1 Byte 0

Name DataOUT 1 DataOUT 0 Not used Control byte

Value 0xXX 0xXX 0xXX 0x88

The terminal returns the following type identifier (0x0C1E corresponds to unsigned integer 3102)

Byte Byte 3 Byte 2 Byte 1 Byte 0

Name DataIN 1 DataIN 0 Not used Status byte

Value 0x1E 0x0C 0x00 0x88

Example 2:

Write register 31 in the BK2000 with a KL3102 and the end terminal:

If the following bytes (code word [}38]) are transferred from the controller to the terminal,

Byte Byte 3 Byte 2 Byte 1 Byte 0

Name DataOUT 1 DataOUT 0 Not used Control byte

Value 0x12 0x35 0xXX 0xDF

The code word [}38] is set, and the terminal returns the register address with bit7 for register access as

acknowledgment.

Byte Byte 3 Byte 2 Byte 1 Byte 0

Name DataIN 1 DataIN 0 Not used Status byte

Value 0x00 0x00 0x00 0x9F

5.6 Examples of Register Communication

The numbering of the bytes in the examples corresponds to the display without word alignment.

5.6.1 Example 1: reading the firmware version from Register 9

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0x89 (1000 1001

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 specify the register number 9 with 00 1001

• The output data word (byte 1 and byte 2) has no meaning during read access. To change a register,

write the required value into the output word.

) 0xXX 0xXX

bin

.

bin

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x89 0x33 0x41

Explanation:

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the firmware version 0x3341 in the input data word (byte 1 and byte 2). This is to

be interpreted as an ASCII code:

◦ ASCII code 0x33 represents the digit 3

KL3102, KL3112, KL3122 43Version: 3.2

Page 44

Access from the user program

◦ ASCII code 0x41 represents the letter A

The firmware version is thus 3A.

5.6.2 Example 2: Writing to an user register

Code word

In normal mode all user registers are read-only with the exception of Register 31. In order to deactivate this write protection you must write the code word (0x1235) into Register 31. If a value other

than 0x1235 is written into Register 31, write protection is reactivated. Please note that changes to

a register only become effective after restarting the terminal (power-off/power-on).

I. Write the code word (0x1235) into Register 31.

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xDF (1101 1111

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

• The output data word (byte 1 and byte 2) contains the code word (0x1235) for deactivating write

protection.

) 0x12 0x35

bin

.

bin

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

II. Read Register 31 (check the set code word)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

.

bin

• The output data word (byte 1 and byte 2) has no meaning during read access.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0x12 0x35

bin

KL3102, KL3112, KL312244 Version: 3.2

Page 45

Access from the user program

Explanation:

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the current value of the code word register in the input data word (byte 1 and byte

2).

III. Write to Register 32 (change contents of the feature register)

Output data

Byte 0: Control byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xE0 (1110 0000

) 0x00 0x02

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 indicate register number 32 with 10 0000

.

bin

• The output data word (byte 1 and byte 2) contains the new value for the feature register.

CAUTION

Observe the register description!

The value of 0x0002 given here is just an example!

The bits of the feature register change the properties of the terminal and have a different meaning, depending on the type of terminal. Refer to the description of the feature register of your terminal (chapter Register

description) regarding the meaning of the individual bits before changing the values.

Input data (response from the Bus Terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xA0 (1010 0000

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

IV. Read Register 32 (check changed feature register)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xA0 (1010 0000

) 0xXX 0xXX

bin

) 0xXX 0xXX

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 indicate register number 32 with 10 0000

.

bin

• The output data word (byte 1 and byte 2) has no meaning during read access.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xA0 (1010 0000

) 0x00 0x02

bin

Explanation:

KL3102, KL3112, KL3122 45Version: 3.2

Page 46

Access from the user program

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the current value of the feature register in the input data word (byte 1 and byte 2).

V. Write Register 31 (reset code word)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xDF (1101 1111

) 0x00 0x00

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

.

bin

• The output data word (byte 1 and byte 2) contains 0x0000 for reactivating write protection.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

KL3102, KL3112, KL312246 Version: 3.2

Page 47

Appendix

6 Appendix

6.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49 5246 963 0

Fax: +49 5246 963 198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49 5246 963 157

Fax: +49 5246 963 9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49 5246 963 460

Fax: +49 5246 963 479

e-mail: service@beckhoff.com

KL3102, KL3112, KL3122 47Version: 3.2

Page 48