Page 1

Documentation

EK9300

PROFINET-Bus Coupler for EtherCAT Terminals

Version:

Date:

3.2.6

2019-12-20

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

1.4 Version identification of EtherCAT devices .......................................................................................7

1.4.1 Beckhoff Identification Code (BIC)................................................................................... 12

2 Product overview.....................................................................................................................................14

2.1 EKxxxx - System overview ..............................................................................................................14

2.2 Technical data .................................................................................................................................15

2.3 Technical data PROFINET ..............................................................................................................16

3 Mounting and wiring................................................................................................................................17

3.1 Mounting..........................................................................................................................................17

3.1.1 Instructions for ESD protection ........................................................................................ 17

3.1.2 Dimensions ...................................................................................................................... 18

3.1.3 Installation on mounting rails – Bus Coupler ................................................................... 18

3.2 Wiring...............................................................................................................................................20

3.2.1 Power supply ................................................................................................................... 20

3.2.2 Ethernet ........................................................................................................................... 22

3.2.3 ATEX - Special conditions (standard temperature range) ............................................... 26

3.2.4 ATEX Documentation ...................................................................................................... 26

3.2.5 UL notice.......................................................................................................................... 27

4 Parameterization and commissioning...................................................................................................28

4.1 Meaning of the DIP switch...............................................................................................................28

4.2 Further interfaces ............................................................................................................................28

4.3 Setting the IP address .....................................................................................................................29

5 Configuration ...........................................................................................................................................30

5.1 Representation of an EtherCAT slave on PROFINET.....................................................................30

5.2 EK9300 configuration ......................................................................................................................34

5.3 EK9300 EtherCAT configuration .....................................................................................................36

5.4 EK9300 – Configuration example....................................................................................................40

5.5 From firmware Version 6 .................................................................................................................42

5.5.1 EK9300 - CoE data access over PROFINET .................................................................. 42

5.5.2 EK9300 - multi-configuration mode ................................................................................. 44

5.5.3 EK9300 - IO-LINK............................................................................................................ 46

5.6 From firmware version 8..................................................................................................................49

5.6.1 EBus Error Behaviour ...................................................................................................... 49

5.6.2 Activating the web page................................................................................................... 51

6 Ethernet ....................................................................................................................................................52

6.1 PROFINET system presentation .....................................................................................................52

7 Error handling and diagnosis.................................................................................................................54

7.1 Diagnostic LEDs ..............................................................................................................................54

8 Appendix ..................................................................................................................................................56

EK9300 3Version: 3.2.6

Page 4

Table of contents

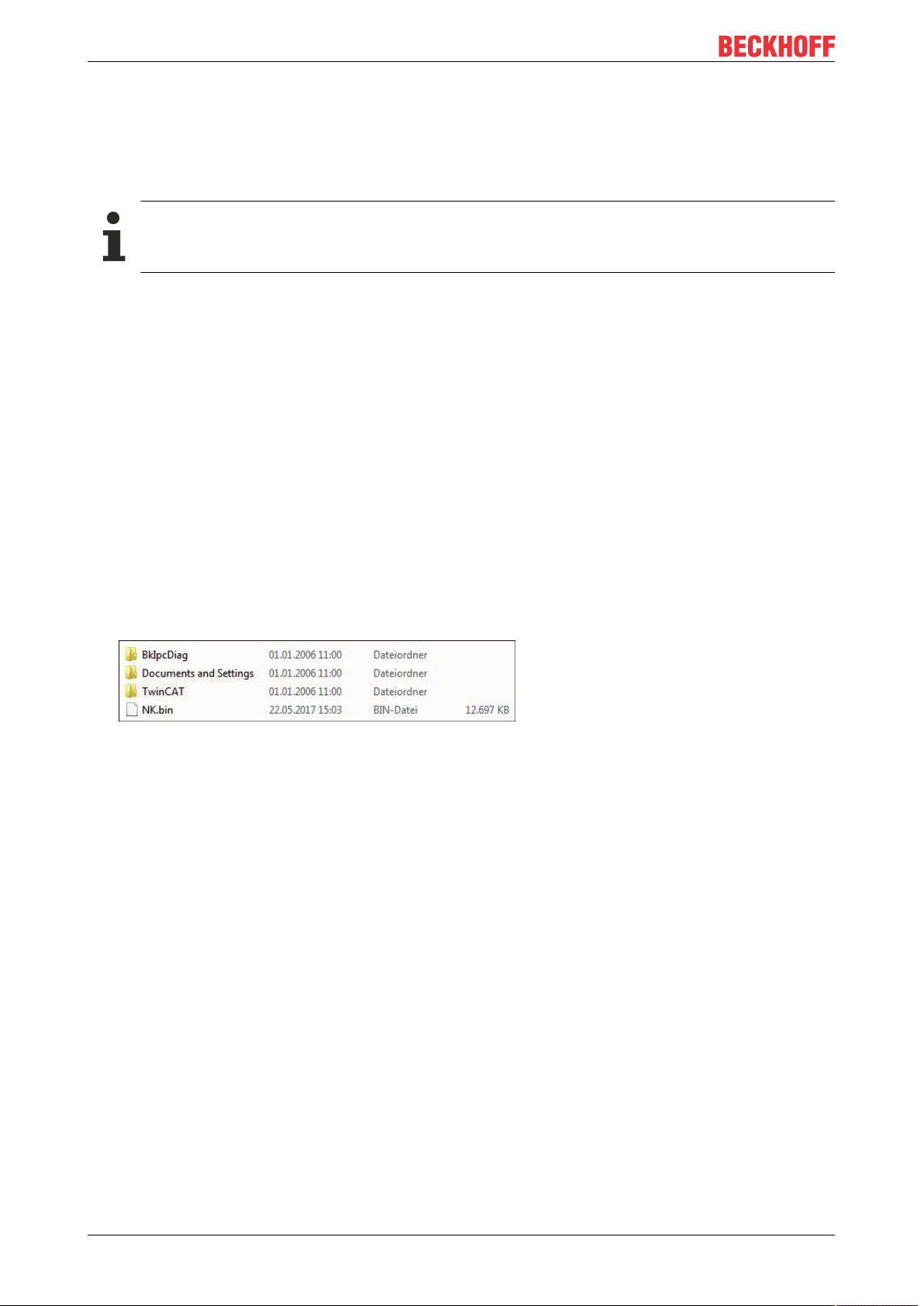

8.1 Update Bus Coupler image .............................................................................................................56

8.2 EK9300 – FAQ ................................................................................................................................57

8.3 List of Abbreviations ........................................................................................................................57

8.4 Support and Service ........................................................................................................................60

EK93004 Version: 3.2.6

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EK9300 5Version: 3.2.6

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EK93006 Version: 3.2.6

Page 7

1.3 Documentation issue status

Version Comment

3.2.6 • Update chapter “Configuration”

• Update structure

3.2.5 • Update chapter “Configuration”

• Update structure

3.2.4 • Update UL notice

3.2.3 • Update Technical data

• Update structure

3.2.2 • Update chapter “Update Bus Coupler image”

3.2.1 • Update chapter “Technical data”

3.2.0 • Configuration From firmware Version 8 added

• Update chapter “Technical data”

3.1.0 • Update chapter "Notes on the documentation"

• Update chapter "EK9300 - PROFINET" -> "EKxxxx - Systemübersicht"

• Update chapter "Technical data"

• Addenda chapter "Instructions for ESD protection"

• Addenda chapter "ATEX - Special conditions (standard temperature range)" and note

"ATEX Documentation"

• Addenda chapter "UL notice"

3.0.0 • Migration

• Update structure

2.1.0 • Chapter CoE data access over PROFINET added

• Chapter Multi-configuration mode added

• Chapter IO-LINK added

2.0.0 • Addenda and corrections

• First published

1.0.1 • Addenda and corrections

1.0.0 • Preliminary version

Foreword

1.4 Version identification of EtherCAT devices

Designation

A Beckhoff EtherCAT device has a 14-digit designation, made up of

• family key

• type

• version

• revision

Example Family Type Version Revision

EL3314-0000-0016 EL terminal

(12 mm, nonpluggable connection

level)

ES3602-0010-0017 ES terminal

(12 mm, pluggable

connection level)

CU2008-0000-0000 CU device 2008 (8-port fast ethernet switch) 0000 (basic type) 0000

EK9300 7Version: 3.2.6

3314 (4-channel thermocouple

terminal)

3602 (2-channel voltage

measurement)

0000 (basic type) 0016

0010 (highprecision version)

0017

Page 8

Foreword

Notes

• The elements mentioned above result in the technical designation. EL3314-0000-0016 is used in the

example below.

• EL3314-0000 is the order identifier, in the case of “-0000” usually abbreviated to EL3314. “-0016” is the

EtherCAT revision.

• The order identifier is made up of

- family key (EL, EP, CU, ES, KL, CX, etc.)

- type (3314)

- version (-0000)

• The revision -0016 shows the technical progress, such as the extension of features with regard to the

EtherCAT communication, and is managed by Beckhoff.

In principle, a device with a higher revision can replace a device with a lower revision, unless specified

otherwise, e.g. in the documentation.

Associated and synonymous with each revision there is usually a description (ESI, EtherCAT Slave

Information) in the form of an XML file, which is available for download from the Beckhoff web site.

From 2014/01 the revision is shown on the outside of the IP20 terminals, see Fig. “EL5021 EL terminal,

standard IP20 IO device with batch number and revision ID (since 2014/01)”.

• The type, version and revision are read as decimal numbers, even if they are technically saved in

hexadecimal.

Identification number

Beckhoff EtherCAT devices from the different lines have different kinds of identification numbers:

Production lot/batch number/serial number/date code/D number

The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker.

The serial number indicates the configuration in delivery state and therefore refers to a whole production

batch, without distinguishing the individual modules of a batch.

Structure of the serial number: KKYYFFHH

KK - week of production (CW, calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with

Ser. no.: 12063A02: 12 - production week 12 06 - production year 2006 3A - firmware version 3A 02 hardware version 02

Exceptions can occur in the IP67 area, where the following syntax can be used (see respective device

documentation):

Syntax: D ww yy x y z u

D - prefix designation

ww - calendar week

yy - year

x - firmware version of the bus PCB

y - hardware version of the bus PCB

z - firmware version of the I/O PCB

u - hardware version of the I/O PCB

Example: D.22081501 calendar week 22 of the year 2008 firmware version of bus PCB: 1 hardware version

of bus PCB: 5 firmware version of I/O PCB: 0 (no firmware necessary for this PCB) hardware version of I/O

PCB: 1

Unique serial number/ID, ID number

In addition, in some series each individual module has its own unique serial number.

See also the further documentation in the area

EK93008 Version: 3.2.6

Page 9

• IP67: EtherCAT Box

• Safety: TwinSafe

• Terminals with factory calibration certificate and other measuring terminals

Examples of markings

Fig.1: EL5021 EL terminal, standard IP20 IO device with serial/ batch number and revision ID (since

2014/01)

Foreword

Fig.2: EK1100 EtherCAT coupler, standard IP20 IO device with serial/ batch number

Fig.3: CU2016 switch with serial/ batch number

EK9300 9Version: 3.2.6

Page 10

Foreword

Fig.4: EL3202-0020 with serial/ batch number 26131006 and unique ID-number 204418

Fig.5: EP1258-00001 IP67 EtherCAT Box with batch number/ date code 22090101 and unique serial

number 158102

Fig.6: EP1908-0002 IP67 EtherCAT Safety Box with batch number/ date code 071201FF and unique serial

number 00346070

Fig.7: EL2904 IP20 safety terminal with batch number/ date code 50110302 and unique serial number

00331701

EK930010 Version: 3.2.6

Page 11

Foreword

Fig.8: ELM3604-0002 terminal with unique ID number (QR code) 100001051 and serial/ batch number

44160201

EK9300 11Version: 3.2.6

Page 12

Foreword

1.4.1 Beckhoff Identification Code (BIC)

The Beckhoff Identification Code (BIC) is increasingly being applied to Beckhoff products to uniquely identify

the product. The BIC is represented as a Data Matrix Code (DMC, code scheme ECC200), the content is

based on the ANSI standard MH10.8.2-2016.

Fig.9: BIC as data matrix code (DMC, code scheme ECC200)

The BIC will be introduced step by step across all product groups.

Depending on the product, it can be found in the following places:

• on the packaging unit

• directly on the product (if space suffices)

• on the packaging unit and the product

The BIC is machine-readable and contains information that can also be used by the customer for handling

and product management.

Each piece of information can be uniquely identified using the so-called data identifier

(ANSIMH10.8.2-2016). The data identifier is followed by a character string. Both together have a maximum

length according to the table below. If the information is shorter, spaces are added to it. The data under

positions 1 to 4 are always available.

The following information is contained:

EK930012 Version: 3.2.6

Page 13

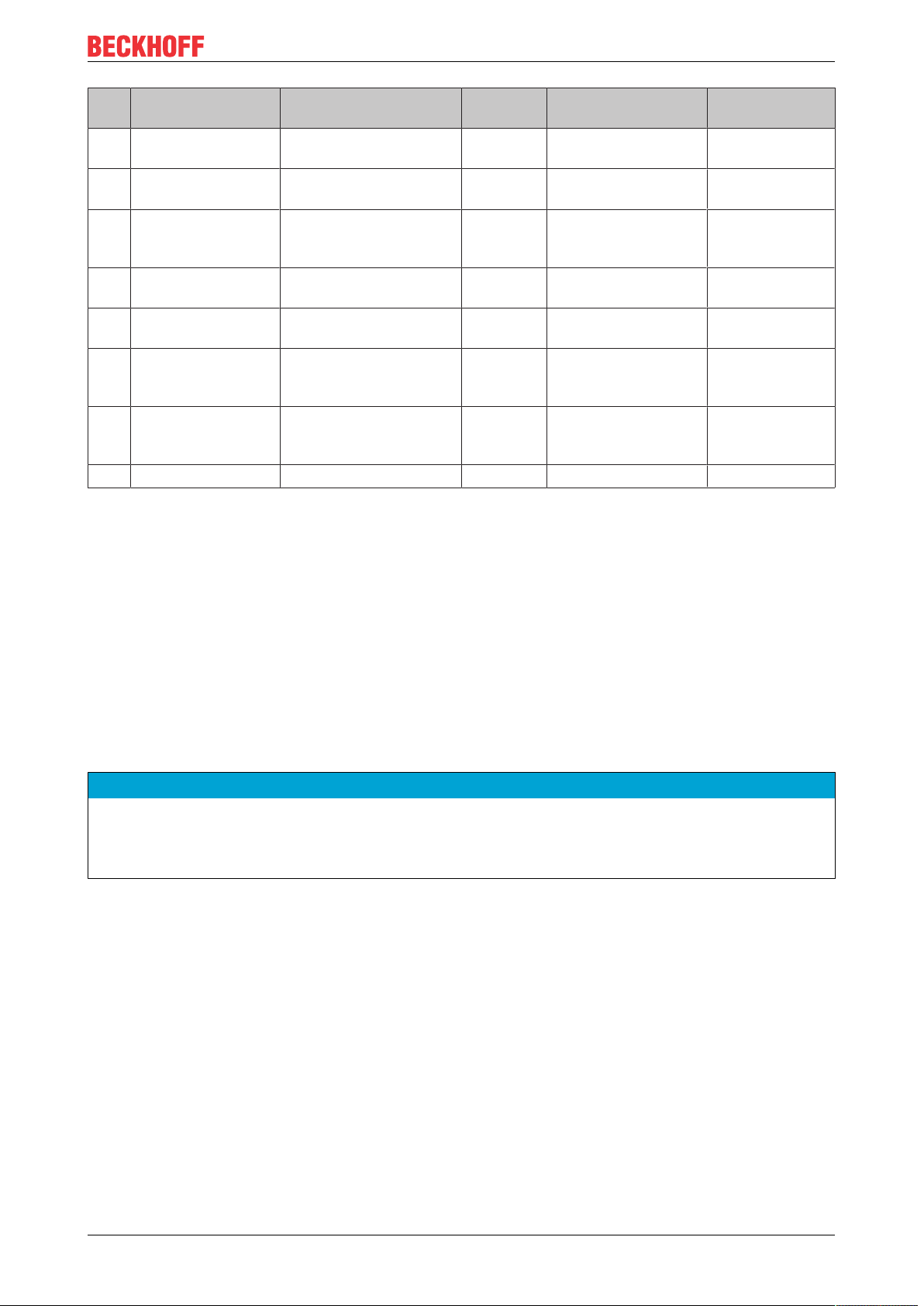

Item

Type of

no.

information

1 Beckhoff order

number

2 Beckhoff Traceability

Number (BTN)

3 Article description Beckhoff article

4 Quantity Quantity in packaging

5 Batch number Optional: Year and week

6 ID/serial number Optional: Present-day

7 Variant number Optional: Product variant

...

Explanation Data

Beckhoff order number 1P 8 1P072222

Unique serial number,

see note below

description, e.g.

EL1008

unit, e.g. 1, 10, etc.

of production

serial number system,

e.g. with safety products

number on the basis of

standard products

Foreword

Number of digits

identifier

S 12 SBTNk4p562d7

1K 32 1KEL1809

Q 6 Q1

2P 14 2P401503180016

51S 12 51S678294104

30P 32 30PF971, 2*K183

incl. data identifier

Example

Further types of information and data identifiers are used by Beckhoff and serve internal processes.

Structure of the BIC

Example of composite information from item 1 to 4 and 6. The data identifiers are marked in red for better

display:

BTN

An important component of the BIC is the Beckhoff Traceability Number (BTN, item no.2). The BTN is a

unique serial number consisting of eight characters that will replace all other serial number systems at

Beckhoff in the long term (e.g. batch designations on IO components, previous serial number range for

safety products, etc.). The BTN will also be introduced step by step, so it may happen that the BTN is not yet

coded in the BIC.

NOTE

This information has been carefully prepared. However, the procedure described is constantly being further

developed. We reserve the right to revise and change procedures and documentation at any time and without prior notice. No claims for changes can be made from the information, illustrations and descriptions in

this information.

EK9300 13Version: 3.2.6

Page 14

Product overview

2 Product overview

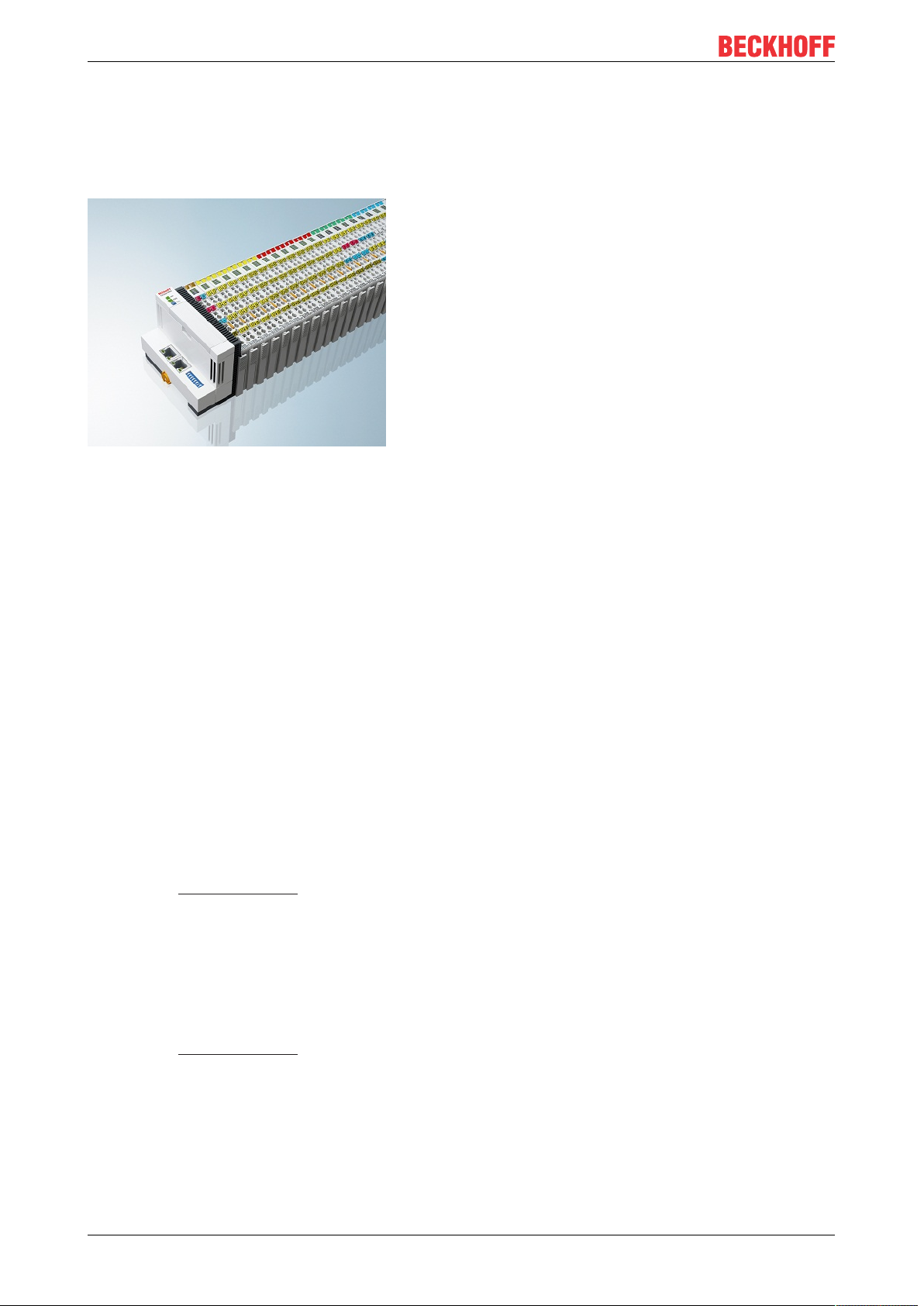

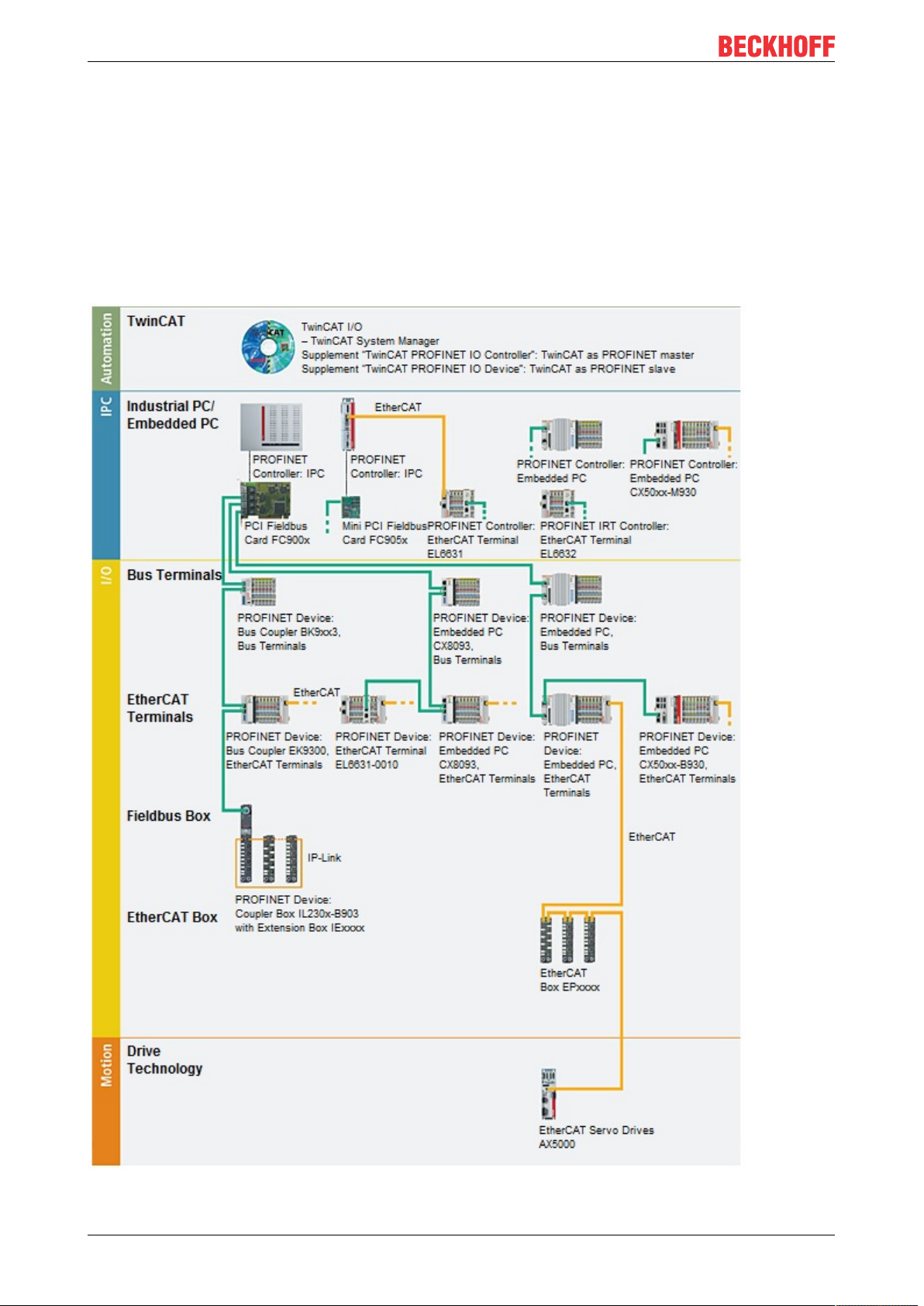

2.1 EKxxxx - System overview

Fig.10: EtherCAT Terminals at an EKxxxx series Bus Coupler

The Bus Couplers from the EKxxxx series allow EtherCAT Terminals to be operated on conventional fieldbus

systems. The ultra-fast, high-performance EtherCAT Terminals with their large range of signal types are thus

also available for other fieldbus and Industrial Ethernet systems.

The EKxxxx Bus Couplers are fieldbus slaves and contain an EtherCAT master for the EtherCAT terminals.

They convert the telegrams from the higher-level fieldbus systems into the E-bus signal representation. A

station consists of an EKxxxx and a number of EtherCAT Terminals.

The EKxxxx is integrated in exactly the same way as the Bus Couplers from the BKxxxx series via the

corresponding fieldbus system configuration tools and the associated configuration files, such as GSD, ESD

or GSDML.

EtherCAT makes a very flexible topology configuration possible. Thanks to the Ethernet physics, long

distances can also be bridged without the bus speed being affected. When changing to the field level –

without a control cabinet – the EtherCAT Box modules (EPxxxx) in protection class IP65 can also be

connected to the EK9xxx.

Bus Couplers for various fieldbus systems

The variants from the EKxxxx series differ from one another by the interface for the higher-level fieldbus

system.

An overview of the various Beckhoff Bus Couplers covering the most important fieldbus systems can be

found on the Beckhoff Website.

Embedded PCs with fieldbus interface and decentralized control

The TwinCAT-programmable variant is the CX80xx Embedded PC series.

The variants from the CX80xx series differ from one another by the interface for the higher-level fieldbus

system and the possibility to program it.

An overview of the various Beckhoff Embedded PCs covering the most important fieldbus systems can be

found on the Beckhoff Website.

EK930014 Version: 3.2.6

Page 15

Product overview

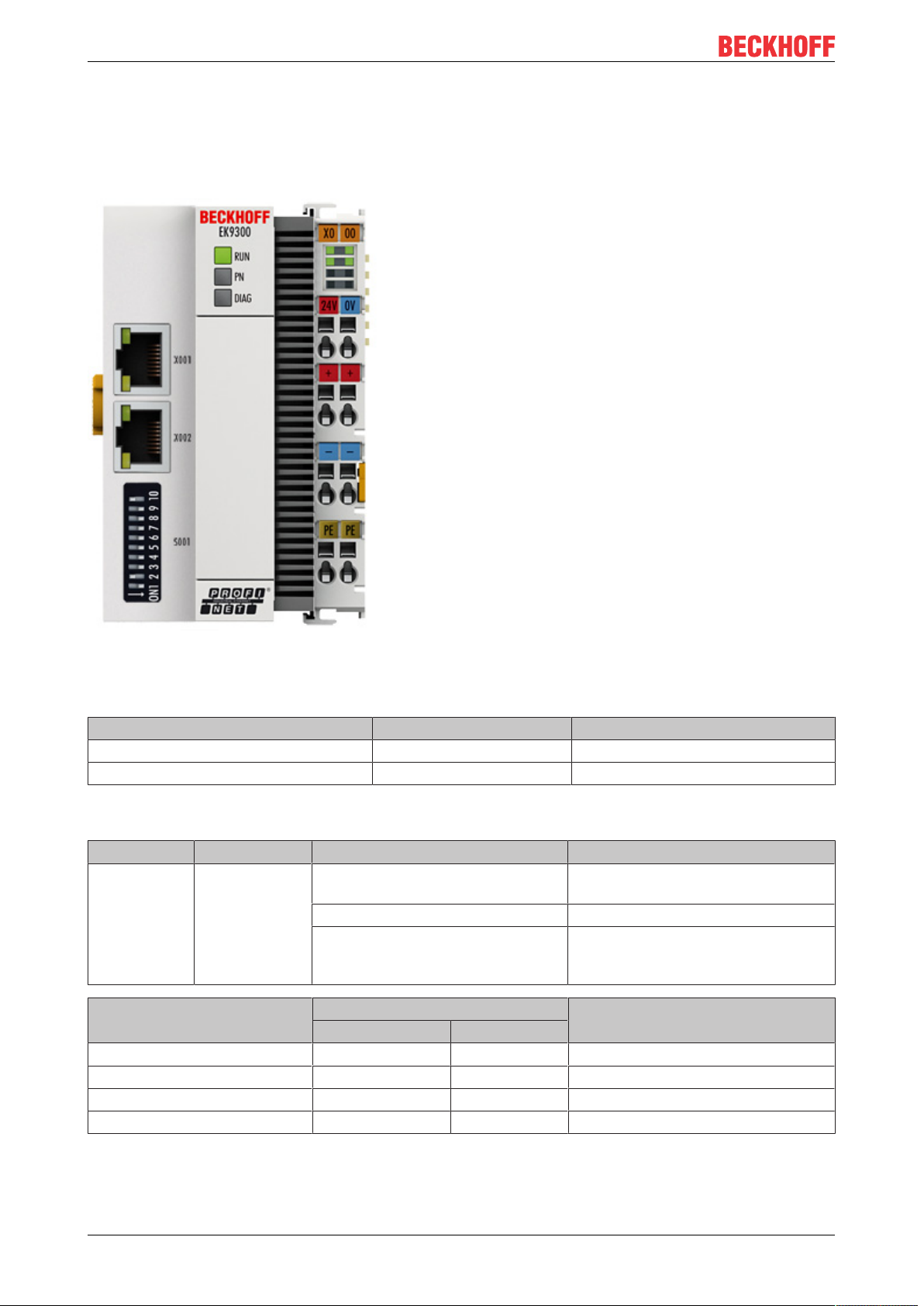

2.2 Technical data

Technical data EK9300

Protocol PROFINET

Interfaces 2 x Ethernet 100 Mbit/s, 1 x USB device (behind the front flap)

Bus interface 2 x RJ 45 (switched)

I/O connection E-Bus (EtherCAT terminals)

Web-based Management

I/O terminals E-bus (EL, ES, EP)

Power supply 24VDC (-15%/+20%)

Input current 120mA typ. + (total E-bus current)/4

Power contacts 24VDC max./10A max.

Power supply I/O terminals 2A

Max. power loss 3 W

Electrical isolation 500V (power contact/supply voltage/Ethernet)

Max. size of process data max. 1440 bytes In- and Output data

Dimensions (W x H x L) 64mm x 100mm x 73mm

Operating/storage temperature 0…+55°C/-25…+85°C

Relative humidity 95 % no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protect. class / installation pos. IP20/any

Approvals CE

from firmware version 8 [}49]

cULus

ATEX [}26]

IECEx

System data PROFINET (EK9300)

Number of I/O modules depending on controller

Number of I/O points depending on controller

Transmission medium 4 x 2 twisted pair copper cable category 5 (100 Mbit/s)

Cable length 100m

Data transfer rate 100 Mbit/s

Topology Star-form cabling, line topology

EK9300 15Version: 3.2.6

Page 16

Product overview

2.3 Technical data PROFINET

Technical data Ethernet EK9300

Number of ports 2

integrated switch 2 x Ethernet 100 Mbit/s, 1 x USB device (behind the front flap)

Bus interface 2 x RJ 45 (switched)

100 Mbit/s Yes, full-duplex PROFINET

Autocrossing Yes

Protocol

PROFINET IO DEVICE Yes

ADS Interface Yes

Services

IRT no

TCP/IP ADS Yes

Shared Device Yes

Prioritized startup no

MRP Yes

SNMP Yes

LLDP Yes

ARP Yes

LLDP Yes

DHCP Yes

Diagnosis/Status/Alarm

RUN LED Yes, green/red

PN LED Yes, green/red

DIAG LED Yes, green/red

Connection display LINK TX/RX Yes

Alarms Yes

Diagnostic messages Yes

EK930016 Version: 3.2.6

Page 17

Mounting and wiring

3 Mounting and wiring

3.1 Mounting

3.1.1 Instructions for ESD protection

NOTE

Destruction of the devices by electrostatic discharge possible!

The devices contain components at risk from electrostatic discharge caused by improper handling.

• Please ensure you are electrostatically discharged and avoid touching the contacts of the device directly.

• Avoid contact with highly insulating materials (synthetic fibers, plastic film etc.).

• Surroundings (working place, packaging and personnel) should by grounded probably, when handling

with the devices.

• Each assembly must be terminated at the right hand end with an EL9011 or EL9012 bus end cap, to ensure the protection class and ESD protection.

Fig.11: Spring contacts of the Beckhoff I/O components

EK9300 17Version: 3.2.6

Page 18

Mounting and wiring

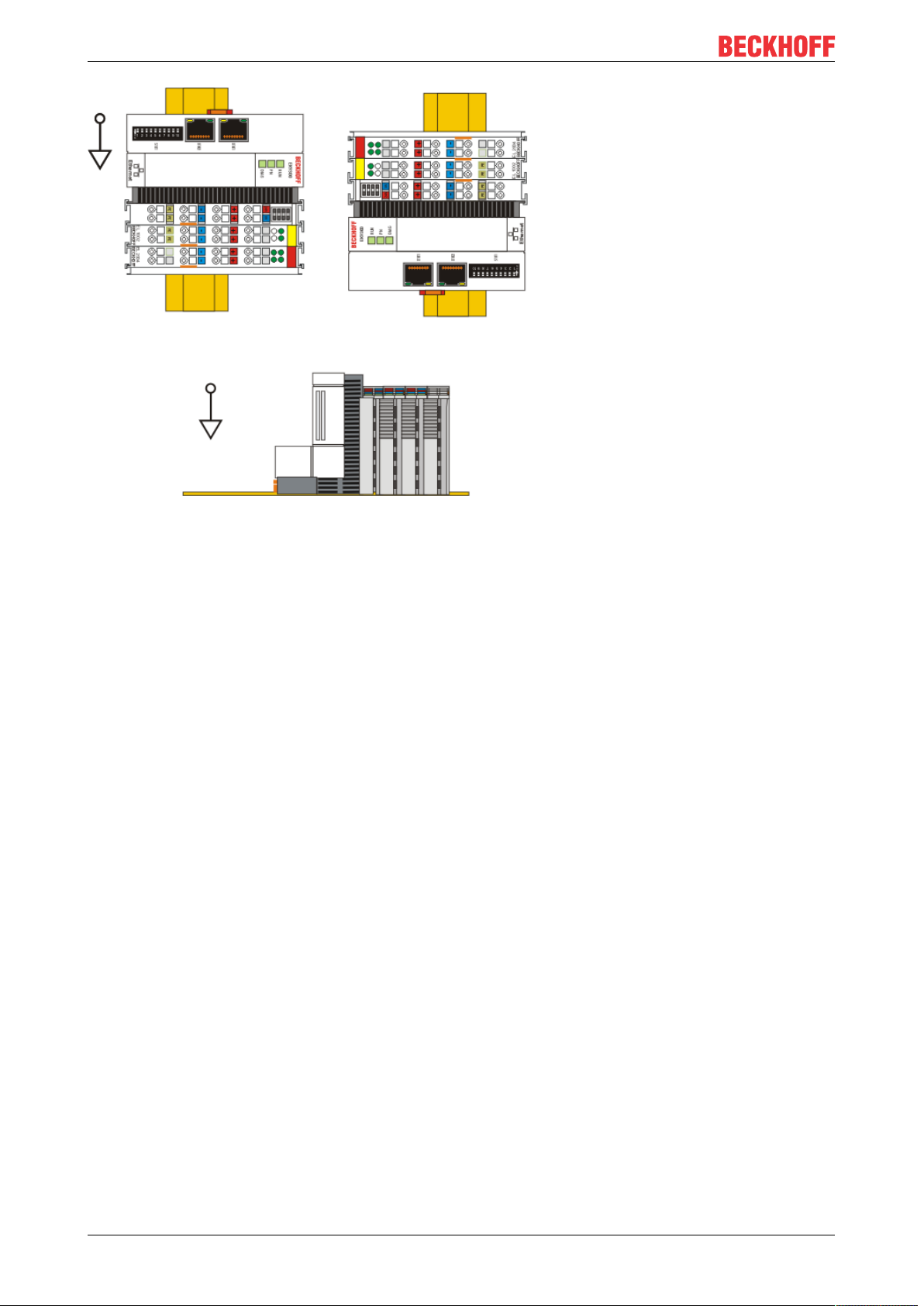

3.1.2 Dimensions

The following illustrations show the dimensions of the Bus Couplers.

Drawings in DWF and STEP format can be found in the Download section of the Beckhoff website.

Fig.12: EK9xxx – dimensions taking the EK9300 as an example

3.1.3 Installation on mounting rails – Bus Coupler

Snapping onto the mounting rail

The Bus Coupler can simply be snapped onto the mounting rail. To this end position the block on the

mounting rail and push it slightly until it engages on the right-hand side. This is indicated by a distinct click.

Use a screwdriver to push up the lock on the left-hand side, thereby turning it and causing it to engage

audibly.

Fig.13: EK9300 - Snapping onto the mounting rail

NOTE

Avoid damage!

Do not force the module or apply excessive pressure!

EK930018 Version: 3.2.6

Page 19

Mounting and wiring

Installation positions

The installation position of the Bus Coupler is arbitrary.

NOTE

Installation position of EtherCAT terminals

Observe the installation position of the EtherCAT terminals used – not all of them have an arbitrary installation position. Pay attention to the respective EtherCAT infrastructure components and installation instructions.

Fig.14: Recommended distances for standard installation position

NOTE

Comply with the permitted installation position and minimum distances!

We recommend the installation in the horizontal position for optimum ventilation. Furthermore, it is not necessary with this installation position to check whether there are terminals present that may only be installed

horizontally.

Other installation positions are allowed, but not recommended.

EK9300 19Version: 3.2.6

Page 20

Mounting and wiring

Fig.15: Other installation positions

3.2 Wiring

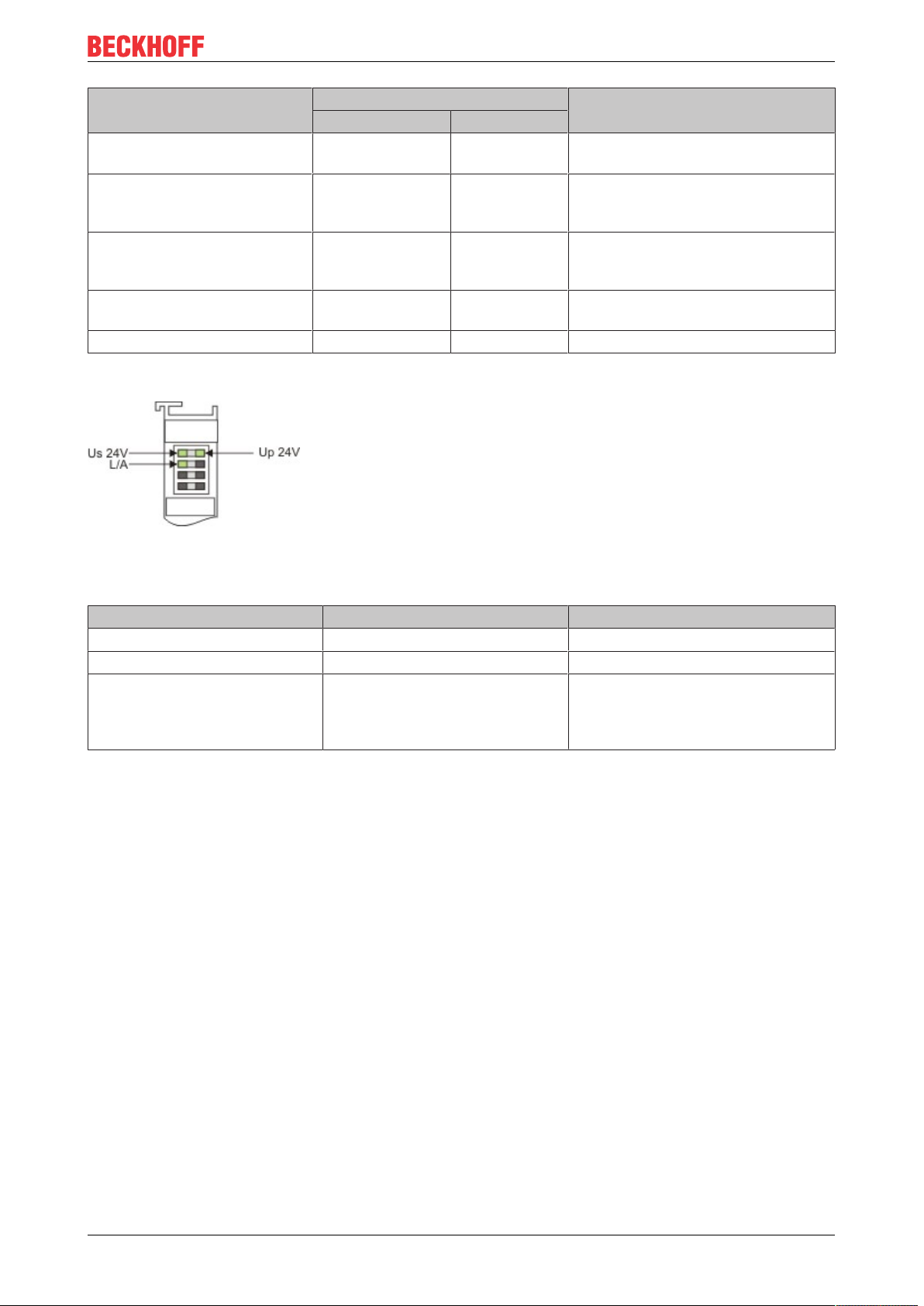

3.2.1 Power supply

The power supply unit is equipped with an I/O interface, which permits connection of the Beckhoff Bus

Terminals. The power is supplied via the upper spring-loaded terminals with the designations "24V and

"0V".

The supply voltage supplies the EK system and, via the terminal bus, the Bus Terminals with a voltage of 24

VDC (-15%/+20%). The dielectric strength of the power supply is 500 V. Since the terminal bus (E-bus) only

transfers data, a separate power supply is required for the Bus Terminals. This is provided by means of the

power contacts, which are not connected to the power supply.

EK930020 Version: 3.2.6

Page 21

Mounting and wiring

Fig.16: Bus Coupler EK9xxx power supply

Requirements for the 24 V power supply

In order to guarantee the operation of the Bus Coupler and the terminal segment in all cases, the power

supply unit must supply 2.0 A at 24 V.

LED

If the power supply unit is connected correctly and the power supply is switched on, the two upper LEDs in

the terminal prism are green. The left LED (Us) indicates the CPU supply. The right LED (Up) indicates the

terminal supply. The other LEDs indicate the Terminal Bus status. A detailed description of the LEDs can be

found in section "LED troubleshooting".

PE power contacts

NOTE

Power contact “PE”

The "PE" power contact must not be used for other potentials.

EK9300 21Version: 3.2.6

Page 22

Mounting and wiring

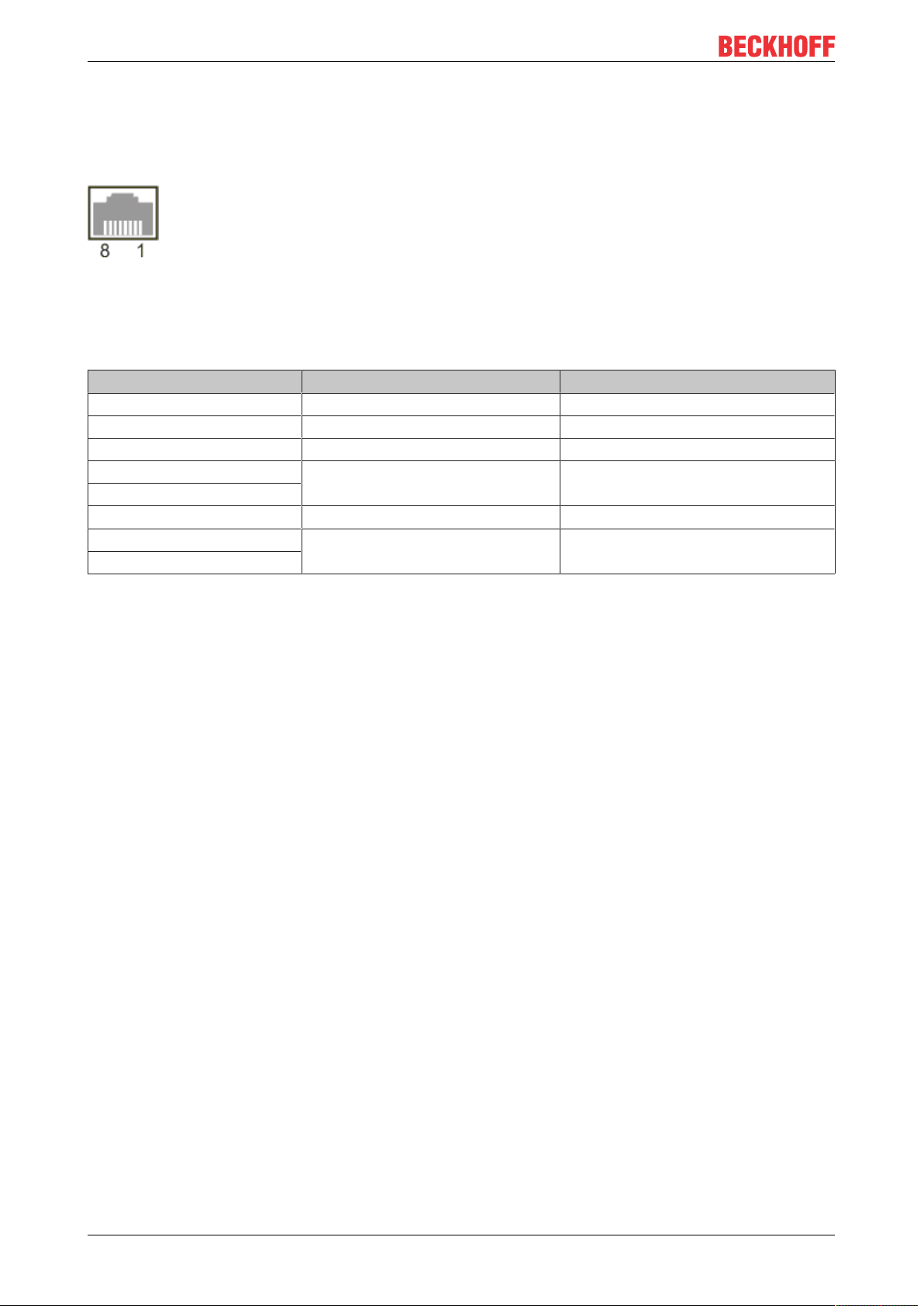

3.2.2 Ethernet

3.2.2.1 Ethernet connections

Fig.17: RJ45 interface

Assignment of the RJ45 interface, port (switched)

EK9xxx: X001/ X002

PIN Signal Description

1 TD + Transmit +

2 TD - Transmit -

3 RD + Receive +

4 connected reserved

5

6 RD - Receive -

7 connected reserved

8

EK930022 Version: 3.2.6

Page 23

Mounting and wiring

3.2.2.2 Ethernet cable

Transmission standards

10Base5

The transmission medium for 10Base5 consists of a thick coaxial cable ("yellow cable") with a max.

transmission speed of 10Mbit/s arranged in a line topology with branches (drops) each of which is

connected to one network device. Because all the devices are in this case connected to a common

transmission medium, it is inevitable that collisions occur often in 10Base5.

10Base2

10Base2 (Cheaper net) is a further development of 10Base5, and has the advantage that the coaxial cable is

cheaper and, being more flexible, is easier to lay. It is possible for several devices to be connected to one

10Base2 cable. It is frequent for branches from a 10Base5 backbone to be implemented in 10Base2.

10BaseT

Describes a twisted pair cable for 10Mbit/s. The network here is constructed as a star. It is no longer the

case that every device is attached to the same medium. This means that a broken cable no longer results in

failure of the entire network. The use of switches as star couplers enables collisions to be reduced. Using

full-duplex connections they can even be entirely avoided.

100BaseT

Twisted pair cable for 100Mbit/s. It is necessary to use a higher cable quality and to employ appropriate

hubs or switches in order to achieve the higher data rate.

10BaseF

The 10BaseF standard describes several optical fiber versions.

EK9300 23Version: 3.2.6

Page 24

Mounting and wiring

Short description of the 10BaseT and 100BaseT cable types

Twisted-pair copper cable for star topologies, where the distance between two devices may not exceed 100

meters.

UTP

Unshielded twisted pair

This type of cable belongs to category 3, and is not recommended for use in an industrial environment.

S/UTP

Screened/unshielded twisted pair (screened with copper braid)

Has an overall shield of copper braid to reduce influence of external interference. This cable is

recommended for use with Bus Couplers.

FTP

Foiled shielded twisted pair (screened with aluminum foil)

This cable has an overall shield of laminated aluminum and plastic foil.

S/FTP

Screened/foiled-shielded twisted pair (screened with copper braid and aluminum foil)

Has a laminated aluminum screen with a copper braid on top. Such cables can provide up to 70dB reduction

in interference power.

STP

Shielded twisted pair

Describes a cable with an outer screen, without defining the nature of the screen any more closely.

S/STP

Screened/shielded twisted pair (wires are individually screened)

This identification refers to a cable with a shield for each of the two wires as well as an overall shield.

ITP

Industrial Twisted-Pair

The structure is similar to that of S/STP, but, in contrast to S/STP, it has only one pair of conductors.

EK930024 Version: 3.2.6

Page 25

Mounting and wiring

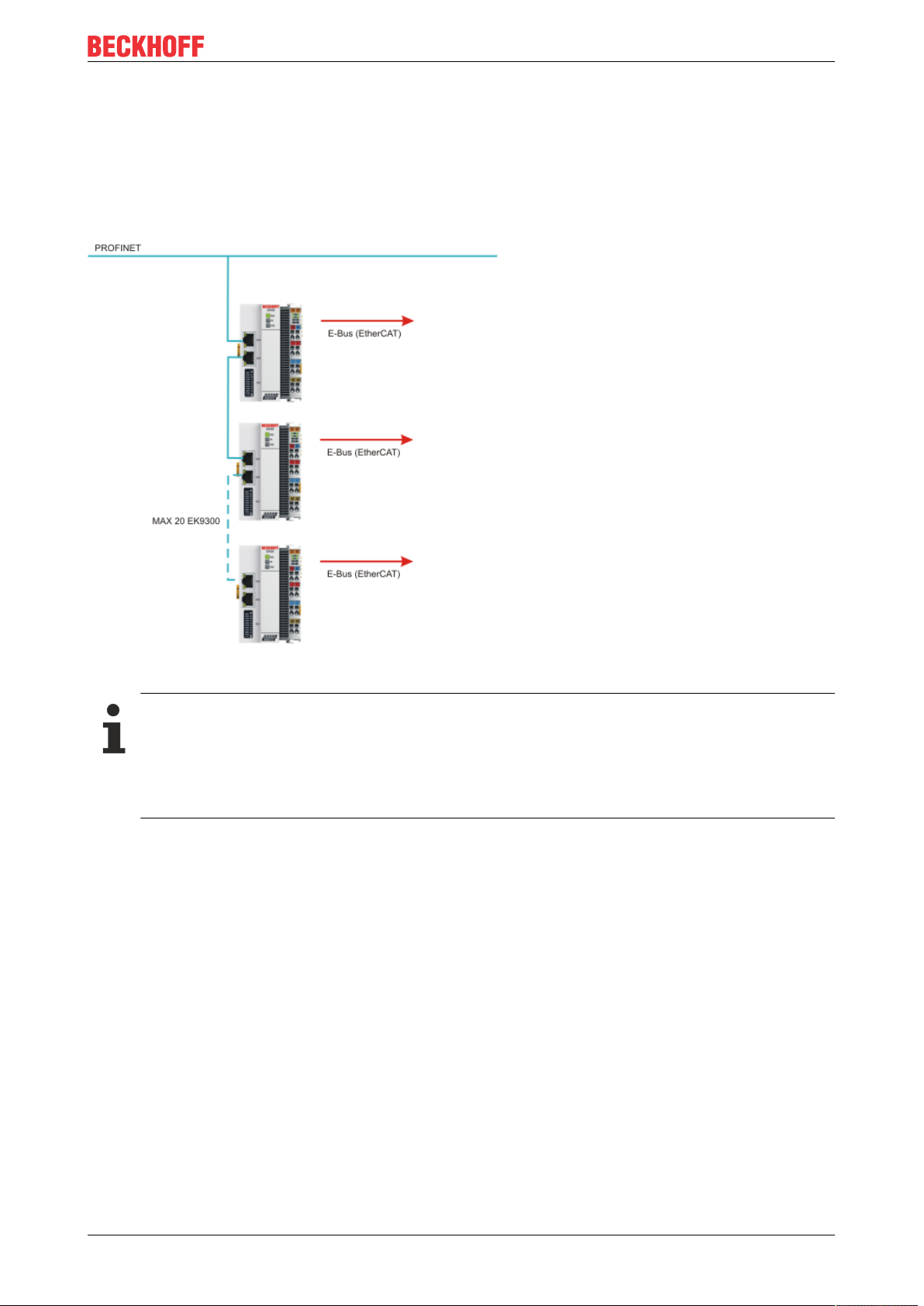

3.2.2.3 EK9300 PROFINET topology sample

EK9300

The construction of the EK9300 can take place in a line, with adherence to the following points:

- Maximum 20 couplers one behind the other

- No switches should be usedin the line

Fig.18: EK9300 - Topology sample

Use of switches without LLDP

PROFINET uses the LLDP protocol for the topology recognition. The topology recognition and the

associated PROFINET services will not work properly if the switch that you use does not support

this. In addition, this results in increased network traffic, which is multiplied further with each switch

port and connected PROFINET device. The effects of this can be communication errors extending

up to the aborting of communication with individual PROFINET devices.

EK9300 25Version: 3.2.6

Page 26

Mounting and wiring

3.2.3 ATEX - Special conditions (standard temperature range)

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus components with

standard temperature range in potentially explosive areas (directive 2014/34/EU)!

• The certified components are to be installed in a suitable housing that guarantees a protection class of at

least IP54 in accordance with EN60079-15! The environmental conditions during use are thereby to be

taken into account!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observe the permissible ambient temperature range of 0 to 55°C for the use of Beckhoff fieldbus components standard temperature range in potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The individual terminals may only be unplugged or removed from the Bus Terminal system if the supply

voltage has been switched off or if a non-explosive atmosphere is ensured!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

• The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the supply voltage has

been switched off or if a non-explosive atmosphere is ensured!

• Address selectors and ID switches may only be adjusted if the supply voltage has been switched off or if

a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0:2012+A11:2013

• EN 60079-15:2010

Marking

The Beckhoff fieldbus components with standard temperature range certified according to the ATEX directive

for potentially explosive areas bear one of the following markings:

II 3GKEMA 10ATEX0075 X Ex nA IIC T4 GcTa: 0…+55°C

or

II 3GKEMA 10ATEX0075 X Ex nC IIC T4 GcTa: 0…+55°C

3.2.4 ATEX Documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

Pay also attention to the continuative documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

that is available in the download area of the Beckhoff homepage http:\\www.beckhoff.com!

EK930026 Version: 3.2.6

Page 27

Mounting and wiring

3.2.5 UL notice

Application

Beckhoff EtherCAT modules are intended for use with Beckhoff’s UL Listed EtherCAT System only.

Examination

For cULus examination, the Beckhoff I/O System has only been investigated for risk of fire

and electrical shock (in accordance with UL508 and CSAC22.2 No.142).

For devices with Ethernet connectors

Not for connection to telecommunication circuits.

Basic principles

UL certification according to UL508 with limited power consumption. The current consumed by the device is

limited to a max. possible current consumption of 4A. Devices with this kind of certification are marked by

this sign:

Application

If terminals certified with restrictions are used, then the current consumption at 24VDC must be limited

accordingly by means of supply

• from an isolated source protected by a fuse of max. 4A (according to UL248) or

• from a voltage supply complying with NECclass2.

A voltage source complying with NECclass2 may not be connected in series or parallel with another

NECclass2compliant voltage supply!

These requirements apply to the supply of all EtherCAT bus couplers, power adaptor terminals, Bus

Terminals and their power contacts.

EK9300 27Version: 3.2.6

Page 28

Parameterization and commissioning

4 Parameterization and commissioning

4.1 Meaning of the DIP switch

10-pole DIP switch S001

The DIP switch has the following meaning for the Ethernet interfaces X001 and X002, which are switched:

Fig.19: DIP switch S001: Left off ”0“, right on “1”

DIP 9 DIP 10 Description

DIP 1..8

0 0 Last byte of the IP

address via DIP switches

1 to 8

0 1 DHCP

DIP switch 1 to 8 set to

OFF

DHCP

DIP switch 1 to 8 set to

ON

1 0 Reserved

1 1 PROFINET-compliant

DIP switch 1 to 8 set to

OFF

PROFINET with fixed

name

DIP switch 1 to 8 set to

ON

Restart behavior Behavior with factory set-

tings

• PN name from memory

• IP address via DIP switches

172.16.17.xxx (xxx DIP

switch)

SNM 255.255.0.0

• PN name from memory

• IP address and SNM via

DHCP

• PN name from memory

• IP address from memory

• PN name from memory

• IP address from memory

• PN name via

DIP switch 1 to 8

• IP address from memory

• PN name becomes empty

string

• IP address via DIP switches

172.16.17.xxx (xxx DIP

switch)

SNM 255.255.0.0

• PN name becomes empty

string

• IP address and SNM via

DHCP

• PN name becomes empty

string

• IP address 0.0.0.0

• PN name becomes empty

string

• IP address 0.0.0.0

• PN name via

DIP switch 1 to 8

• IP address 0.0.0.0

2-pole DIP switch (under the flap between the battery and the SD card slot)

DIP switch (red) Meaning

1 off and 2 off normal mode, coupler is started

1 on and 2 off The EK starts in Config Mode; the internal Flash memory can be accessed via the

USB interface (for example for an image update).

1 off and 2 on Manufacturer's setting

1 on and 2 on No function so far

4.2 Further interfaces

Additional interfaces are located under the flap of the EK9xx0.

EK930028 Version: 3.2.6

Page 29

Parameterization and commissioning

Fig.20: Additional interfaces of the EK9xx0

Battery

No battery is required for the EK9xx0, therefore this option is not included.

Red DIP switch

Default setting is OFF/OFF.

In order, for example, to load new firmware to the EK via USB, the first DIP switch must be set to “1” before

switching on. If the RUN LED lights up blue, the EK can be connected to the PC by a USB cable. The PC

then finds the internal Flash as the storage medium. The storage medium may not be formatted!

Micro SD card

Alternatively the firmware can also be loaded to an SD card. Booting always takes place from the SD card if

there is one in the slot. This can be used, for example, to test a firmware before copying it to the EK’s

internal Flash.

USB interface

The USB interface can only be used if the “red” DIP switch has been set accordingly. See “Red DIP switch”.

4.3 Setting the IP address

Usually the IP address is assigned by the PROFINET controller. By default the EK9300 has no IP address.

An IP address is necessary, however, in order to reach the device by ADS. This can be assigned by DHCP

(a DHCP server must be present) or a fixed IP address can be used. See chapter DIP switch [}28].

If the PROFINET controller is connected, the IP address assigned by the controller is used for PROFINET

communication. The fixed IP address or the one assigned by the DHCP is overwritten.

A further possibility is to communicate with the EK9300 via the IP address assigned by the controller; to do

this, however, the device must have been initialized at least once by the PROFINET controller/engineering.

EK9300 29Version: 3.2.6

Page 30

Configuration

5 Configuration

5.1 Representation of an EtherCAT slave on PROFINET

This section is intended to help explain the description of EtherCAT devices on another fieldbus system and

to obtain the corresponding information from the existing EtherCAT documentation. In the following terms

are explained for a better understanding.

• Introduction

EtherCAT devices such as EL terminals (ES, ELX, ELM), EP modules (ER, EQ, EPP) are EtherCAT slave

devices that always consist of process data and, if necessary, parameter data. As a rule, digital EtherCAT

devices have no configuration data. Complex EtherCAT devices usually always.

• Process data (PDO, process data object)

Almost all EtherCAT devices have process data1) that can be from 2 bits and up to several 100 bytes in size.

With complex EtherCAT devices, different structures and process data sizes can also be specified. These

are so-called Predefined PDOs.

The Predefined PDOs must be specified by the EtherCAT (EC) Master and must be known or set here when

the EC Master is started. There is always a Default Predefined PDO. Depending on the higher-level bus

system used, the PDO mapping can be set on the EC coupler via the higher-level fieldbus system (as with

PROFINET or PROFIBUS) or a configuration page (http protocol, as with ModbusTCP or EtherNet/IP).

1)

Except for e.g. the EK1100 coupler, which has neither process data nor configuration data, it is equipped with an EtherCAT ASIC and

is therefore also visible in the EtherCAT network without process data.

Parameter data (COE)

The parameter data of an EC slave are transmitted via COE (CAN over EtherCAT). As with CAN, these are

divided into objects, subobjects and data. Parameter data, for example, is data that sets the resistance value

for an EL3202 terminal, i.e. a temperature resistance terminal, such as PT100, PT1000, NI100, etc.

Only the application-specific COE data is made available for the EK coupler. Depending on the

superimposed bus system, all or only some COE objects can be accessed here.

Here, too, parameterization can take place via a website (http protocol) in the EC.

PROFINET

PROFINET device devices (slaves) must bring a GSDML file with them. The devices are described in this

GSDML (Download: Configuration file). The EK9300 is a modular device. This modular device consists of

the head-end station (the EK9300) and a number of EtherCAT devices that are connected to the EK9300.

This file (GSDML) must then be integrated in the PROFINET controller. Once this has been done, the

coupler and the EtherCAT Terminals can now be integrated and the corresponding settings made.

Predefined PDOs usually consist of different PDOs and are a compilation of different PDOs of the process

image.

This is illustrated below with the TwinCAT automation software:

EK930030 Version: 3.2.6

Page 31

Configuration

Fig.21: Typical configuration page of an EtherCAT Terminal

Legend:

1. The EtherCAT Terminal is inserted in the TwinCAT tree and has process data that can be linked to the PLC program.

2. View of the existing process data in bytes (exactly this number and size can be seen with PROFINET and the Siemens controller,

Siemens does not display the process data in more detail although they are described in the GSDML)

3. Display which PDOs are active in the process data

4. View of all PDOs

5. Detailed single PDOs which can be selected in "4”

6. Predefined PDOs

In the GSDML, only the predefined PDOs can be selected (6). If a different combination of PDOs is required,

this can only be done via a Beckhoff controller, such as the CX8093, which has a default PROFINET

interface and can be programmed with TwinCAT 2 (TwinCAT 3 requires a CX9020 with B930 interface, or

any Beckhoff controller with an EL6631-0010).

EK9300 31Version: 3.2.6

Page 32

Configuration

Fig.22: Example Mapping of an EL3162 in standard format ( 8 Byte IN / 0 Byte OUT)

Name Size (Variable) Bit offset

AI Standard Channel 1.BitArray

Status_Underrange BIT (BOOL) 0.0

Status_Overrande BIT (BOOL) 0.1

Status_Limit_1[0] BIT (BOOL) 0.2

Status_Limit_1[0] BIT (BOOL) 0.3

Status_Limit_1[0] BIT (BOOL) 0.4

Status_Limit_1[0] BIT (BOOL) 0.5

Status_Error BIT (BOOL) 0.6

Status_Sync error BIT (BOOL) 1.5

Status_TxPDO State BIT (BOOL) 1.6

Status_TxPDO Toggle BIT (BOOL) 1.7

AI Standard Channel 1.Value 16 BIT (INT) 2.0..3.7

AI Standard Channel 2.BitArray

Status_Underrange BIT (BOOL) 4.0

Status_Overrande BIT (BOOL) 4.1

Status_Limit_1[0] BIT (BOOL) 4.2

Status_Limit_1[0] BIT (BOOL) 4.3

Status_Limit_1[0] BIT (BOOL) 4.4

Status_Limit_1[0] BIT (BOOL) 4.5

Status_Error BIT (BOOL) 4.6

Status_Sync error BIT (BOOL) 5.5

Status_TxPDO State BIT (BOOL) 5.6

Status_TxPDO Toggle BIT (BOOL) 5.7

AI Standard Channel 2.Value 16 BIT (INT) 6.0..7.7

EK930032 Version: 3.2.6

Page 33

Configuration

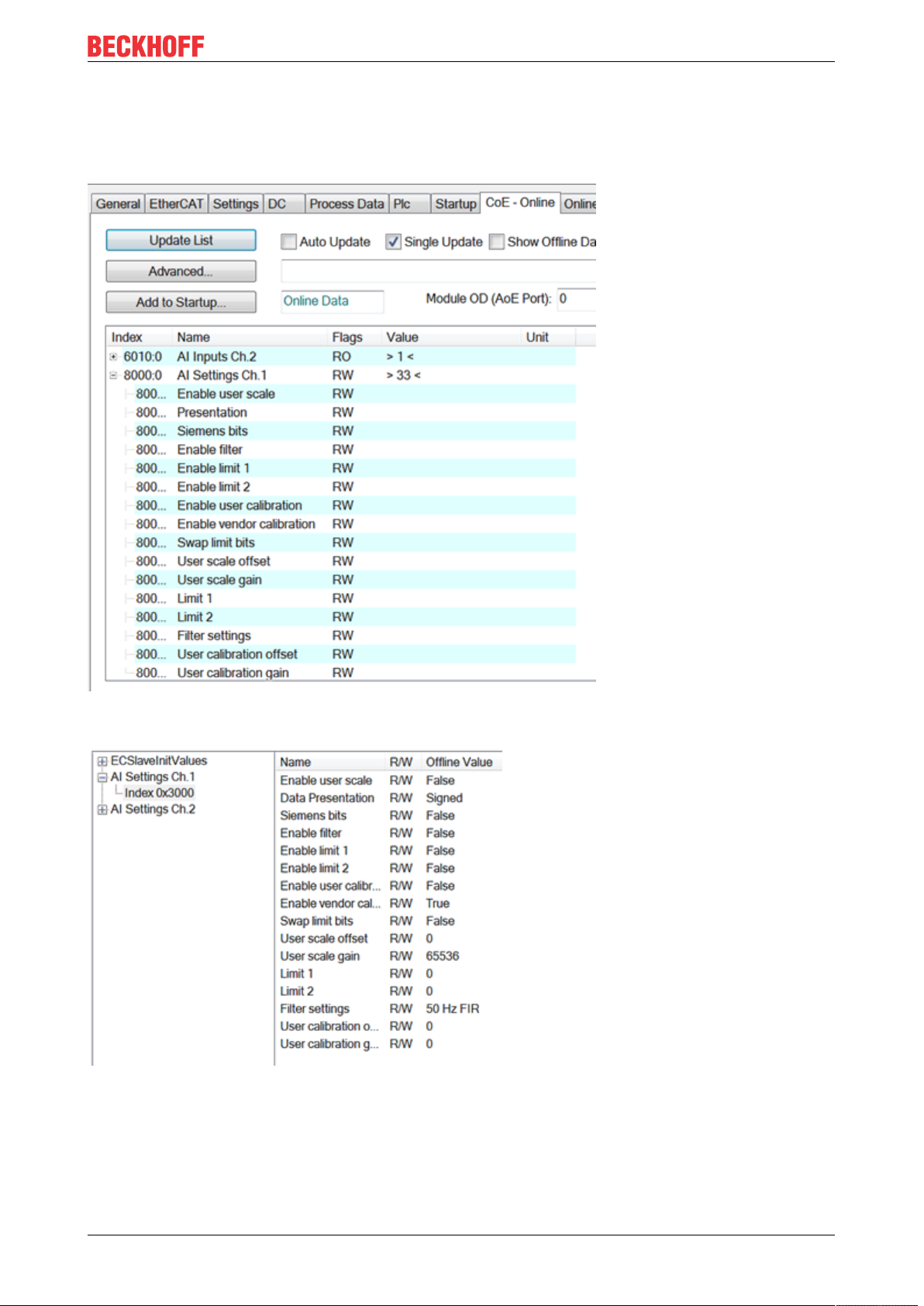

Parameter data

In the following, the parameter or configuration data will be explained. Most of the necessary configuration

data is contained in the GSDML; Beckhoff uses the same names and meanings here as on the EtherCAT

side, which is contained in the ESI file2) in the CoE description.

Fig.23: EtherCAT: Parameter data of the EL3162 of the ESI under TwinCAT

Fig.24: PROFINET: Parameter data of the EL3162 of the GSDML under TwinCAT

2)

The ESI file is the description file for EtherCAT masters (ESI EtherCAT slave information).

EK9300 33Version: 3.2.6

Page 34

Configuration

Parameter data of the EL3162 of the GSDML under TwinCAT

These parameters for the individual terminals can also be found in the configuration tool of your PROFINET

controller, regardless of which manufacturer you use here. You can also access individual parameters

acyclically via PROFINET and the record data. To do this, the PROFIENT controller must have an interface

to the record data. A CoE protocol description and how it can be used via PROFINET is described in the

EK9300 manual.

5.2 EK9300 configuration

GSDML file

Only terminals existing in the GSDML file are supported; extensions are possible however. The GSDML supports submodules; ascertain whether your PROFINET master/controller supports these

submodules. If this is not the case, some terminals cannot be used!

Alternatively the CX8093 can be used; this generally supports all EtherCAT slaves.

General

The EK9300 PROFINET coupler is always integrated with the help of a GSDML file in the controller (master).

The GSDML file contains all parameterization data necessary for the operation of the coupler on the

controller. The configuration tool reads this file and then provides the data to the user.

The respective terminals that are usable on the EK9300 are also specified in the GSDML file. Not all

EtherCAT terminals are supported. Therefore, ascertain beforehand whether the terminals that you wish to

use are also supported by the coupler.

Data in the DAP (Device Access Point)

2 x 2 bytes of data are located in the DAP of the GSDML file.

This is once the ECCycleCounter (2 bytes). This is incremented on each EtherCAT cycle (1ms), provided

that the EC master is in the "OP" state.

The status (2 BYTE) is located at the DAP. This indicates individual status information bit by bit. These are

currently occupied as follows:

• Bit 0 – IsSynchron – this is set if it is used as a PTP slave or IRT device and is synchronous.

• Bit 1 – IsPTPMaster – this is set if the EK9300 is operated as the PTP master.

• Bit 2 – ECFrameError – this is set if an EtherCAT problem is determined. In order to obtain further

information about this, the PROFINET diagnosis or the alarms must be read out.

Parameters in the DAP

Activate PN reset value – Off -> EtherCAT data are written to zero. On -> there is a possibility to use

another default value with outputs. With digital outputs, for example, the current output process value can be

frozen or set to 0 or 1 in case of a PROFINET communication error.

Data presentation – Intel Format data are represented in Intel format, Motorola Format data are

represented in Motorola format. In Word variables, for example, the high and low bytes are exchanged.

EBus error behavior – Set IOs to 0 -> input and output data are set to zero in case of an EC error. Legacy > input data retain their last state, but are no longer updated; output data can still be set (depending on the

position of the terminal).

Mapping

Typically the coupler is used in a group with terminals that are connected to the coupler. The terminals are

part of the GSDML; the terminals are parameterized from the PROFINET controller.

EK930034 Version: 3.2.6

Page 35

Configuration

The mapping is card-slot-oriented, i.e. you must enter the terminals in the hardware configurator in exactly

the same way as they are physically connected. It becomes a little more complicated if EtherCAT distributor

boxes are used. In this case it is important to know the order in which the other EtherCAT terminals were

entered into the process image (see EtherCAT Mapping [}36]).

Behavior when starting the Bus Coupler

All EtherCAT devices must always be present when starting the Bus Coupler (or resetting), i.e. all

EtherCAT slaves must be supplied with power before or at the same time so that the coupler on the

PROFINET also starts up properly.

A solution can be constructed more flexibly with the CX8093.

Configuration of the EtherCAT devices

There are 4 types of EtherCAT devices:

• EtherCAT devices without process data

• EtherCAT devices with “simple” process data but without parameterization (usually simple digital

terminals)

• EtherCAT devices with “simple” process data and with parameters (usually analog signals)

• EtherCAT devices with different process data and parameters (for example incremental encoders)

All of these must be entered in the configuration.

Grouping digital inputs and outputs (pack terminals)

The digital input and output terminals can also be grouped according to their process data. This option can

be used with 2 or 4-channel terminals. To do this a 2 or 4-channel pack terminal (without asterisk) must be

appended to the GSDML file. In order to fill the byte, a 2 or 4-channel pack terminal (with asterisk) must be

appended next. The terminals must be physically and systematically plugged in one behind the other or

logically. The byte limit must not be exceeded.

Sample:

2-channel pack (without asterisk), after that 3 modules from 2-channel pack terminals (with asterisk) may be

appended.

Not permitted:

2-channel pack (without asterisk), then 2 modules from 4-channel pack terminals (with asterisk). This

exceeds the byte limit.

EtherCAT terminals with different mapping options

Some EtherCAT terminals offer the option to represent different process data. These are represented

differently on the basis of the parameters. In the PROFINET controller such a terminal is represented by

submodules. The standard mapping is always integrated. If you want to use a different mapping that

deviates from the standard, then delete the standard submodule and insert the one that you wish to use. It

may be the case that, contradictory to the documentation for the EtherCAT terminal or EtherCAT box, not all

mappings can be used under the PROFINET coupler.

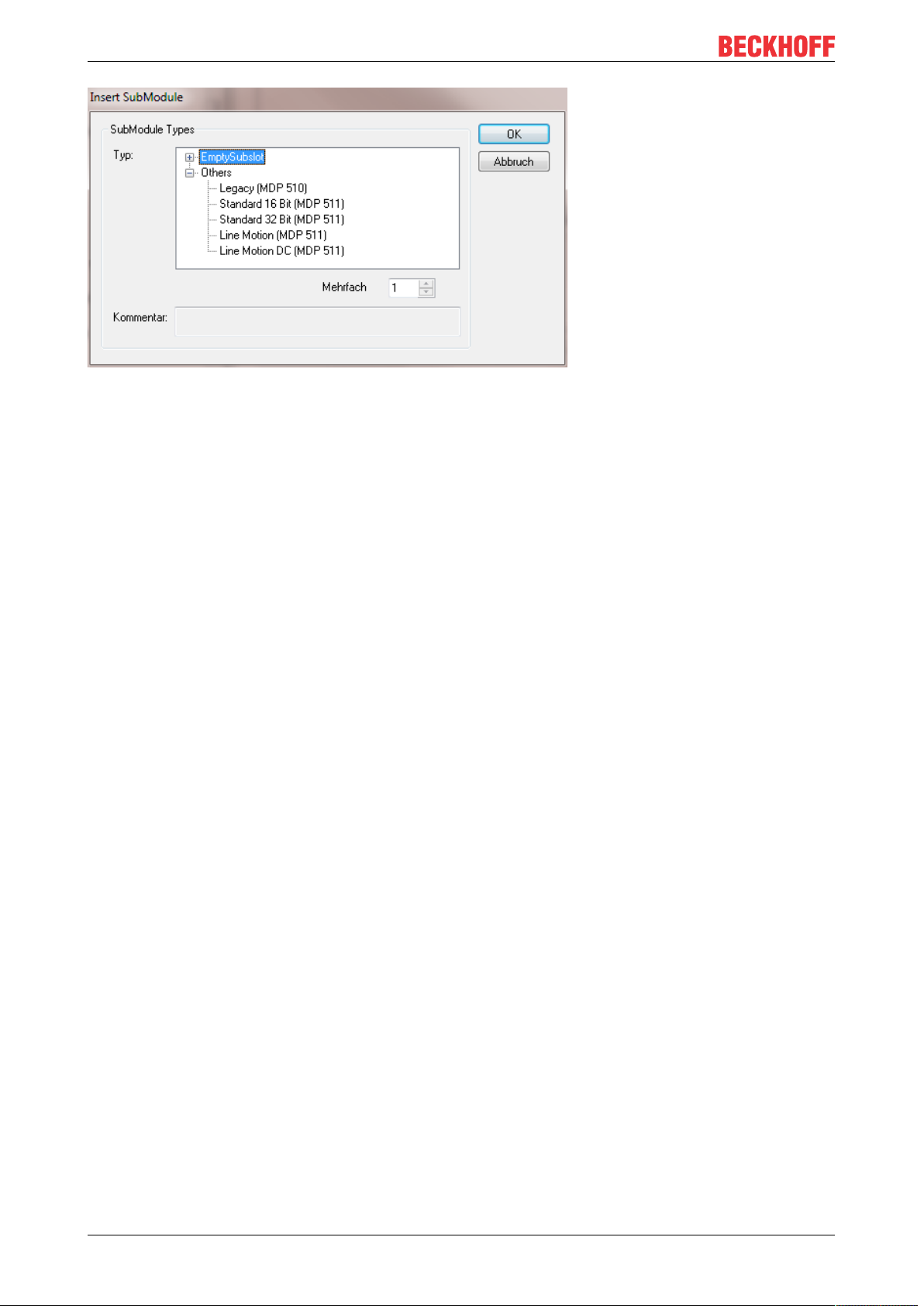

Example of an EL5101:

EK9300 35Version: 3.2.6

Page 36

Configuration

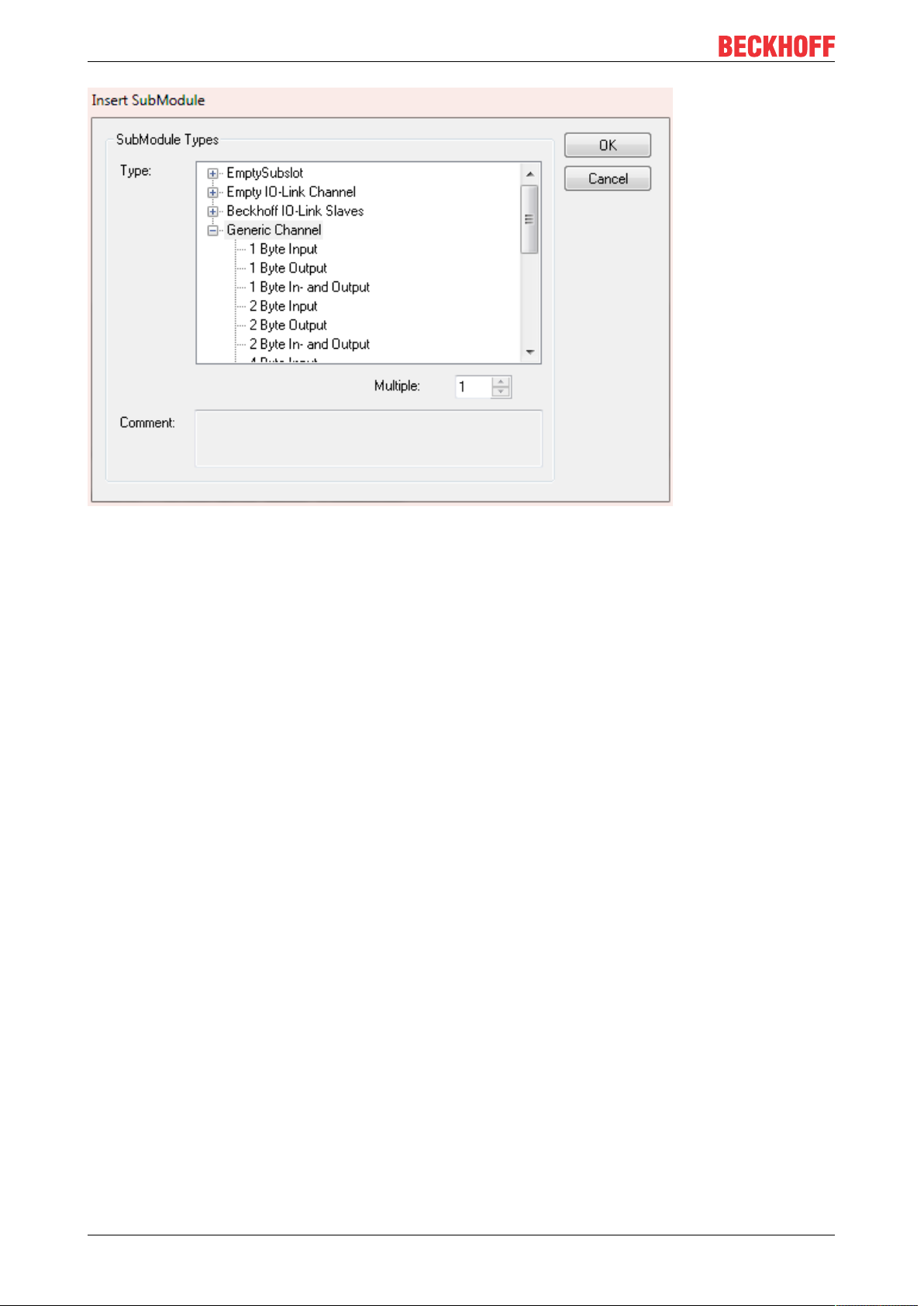

Fig.25: Inserting a sub-module

EtherCAT gateway terminals

The gateway terminals support several submodules; the first or basic module is loaded immediately, the

modules for the process data must be created. These must then also be parameterized on the master side of

the corresponding gateway. Not all features of a gateway terminal can be used on the EK9300.

EL6631-0010

The PROFINET device terminal enables two different PROFINET networks to be connected; only one device

interface is supported on the EK. A default station name can be assigned and IP settings made via

parameterization data (GSDML). Note that the complete maximum data length of the EL6631-0010 cannot

be used. The length is dependent on the other EtherCAT devices attached to the EK9300.

EL6731-0010

The PROFIBUS slave terminal enables communication with a PROFIBUS master. The PROFIBUS address

is specified via the parameter settings (in the GSDML) in the terminal. Only pure process data can be

exchanged.

EL6692

The EtherCAT slave terminal enables communication with a EtherCAT master. Only pure process data can

be exchanged.

EL6652-0010

The EtherNet/IP slave terminal enables communication with an EtherNet/IP master; only one slave interface

is supported on the EK. The IP address and subnet mask are specified via the parameter settings (in the

GSDML) of the terminal. Only pure process data can be exchanged. The terminal on the EK supports only

one slave interface.

5.3 EK9300 EtherCAT configuration

The EK9300 is an EtherCAT master with automatic configuration, i.e. all EtherCAT terminals must always be

present when switching on the system. Since the boot-up of the EK9300 generally takes considerably longer

than the start-up of the EtherCAT slave devices, the latter can be operated on the same power supply. With

decentralized EtherCAT slaves, care must be taken that they are switched on earlier or at the same time as

the supply voltage.

EK930036 Version: 3.2.6

Page 37

Configuration

Switching EtherCAT devices on or off during the runtime

If one or more EtherCAT devices should fail during the operating phase, a plug alarm is sent; the EK9300

remains in data exchange. The input data of all EtherCAT devices are invalid and are set to FALSE or

ZERO; the output data are no longer accepted. This also applies to the devices that are still in operation on

the EK9300. If you wish to use the option to plug in or unplug devices during the runtime, a further “Sync

Unit” must be configured. This is not possible with an EK9300. In this case use a CX8093.

EtherCAT devices that don’t exist in the GSDML

Some EtherCAT Slaves are not included in the GSDML and thus cannot be used (yet). The CX8093 can be

used here, since it supports all EtherCAT devices in principle.

EtherCAT topology

All EtherCAT devices must be entered in the order in which they map themselves on the EK9300 and thus

on the EtherCAT master. EtherCAT devices are addressed automatically; with a few exceptions all EtherCAT

Bus Terminals are equipped with an EtherCAT ASIC, which has to be entered in the system, i.e. the

PROFINET controller. EtherCAT Terminals without an ASIC are, for example, EL9400, EL9070 and other

EL9xxx. You can identify these EtherCAT Terminals using the technical data "Message to E-bus". If there is

a “-” here, this terminal does not have to be entered in the PROFINET controller.

EtherCAT devices are registered in the direction of the EtherCAT telegram.

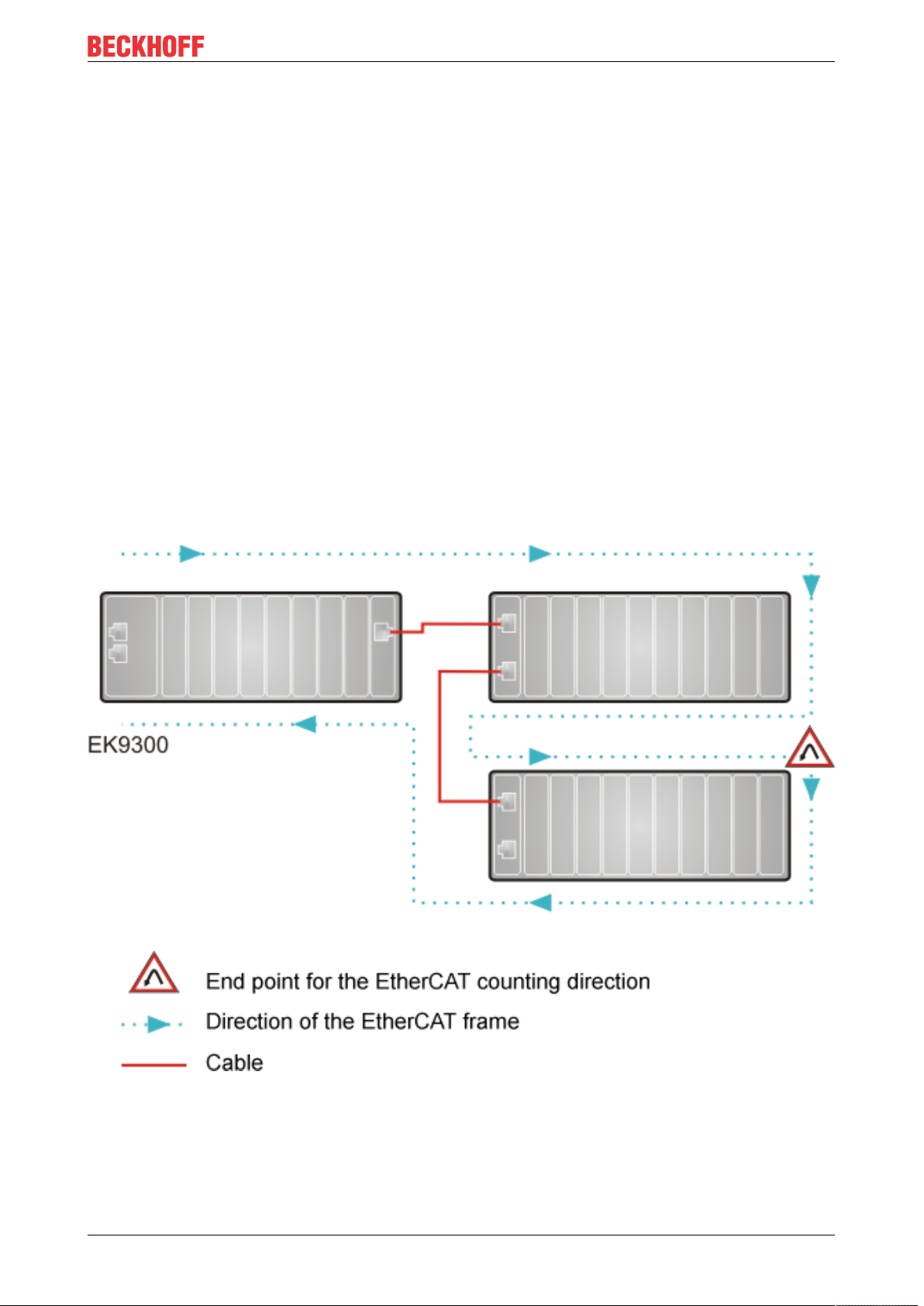

Sample configuration with EK1100 EtherCAT coupler

Fig.26: Sample configuration with EK1100 EtherCAT coupler

EK9300 37Version: 3.2.6

Page 38

Configuration

Sample configuration with EPxxxx EtherCAT Box

Fig.27: Sample configuration with EPxxxx EtherCAT Box

Sample configuration with EK1122 2-port EtherCAT junction

The counting direction is to be observed when using an EK1122. If EtherCAT junction 1 on the EK1122 is

connected, then the EtherCAT frame is forwarded here first (1); if junction 1 is not connected the frame on

junction 2 is sent (2), only after that does the sequence continue with the E-bus on the right-hand side (3).

Fig.28: Sample configuration with EK1122 2-port EtherCAT junction

If both junctions are not used, then junction 1 and 2 are short-circuited as it were and the EC frame

continues directly from the terminal to the right.

Note that in the PROFINET controller the modules are entered in the direction of the EtherCAT frame.

EK930038 Version: 3.2.6

Page 39

Configuration

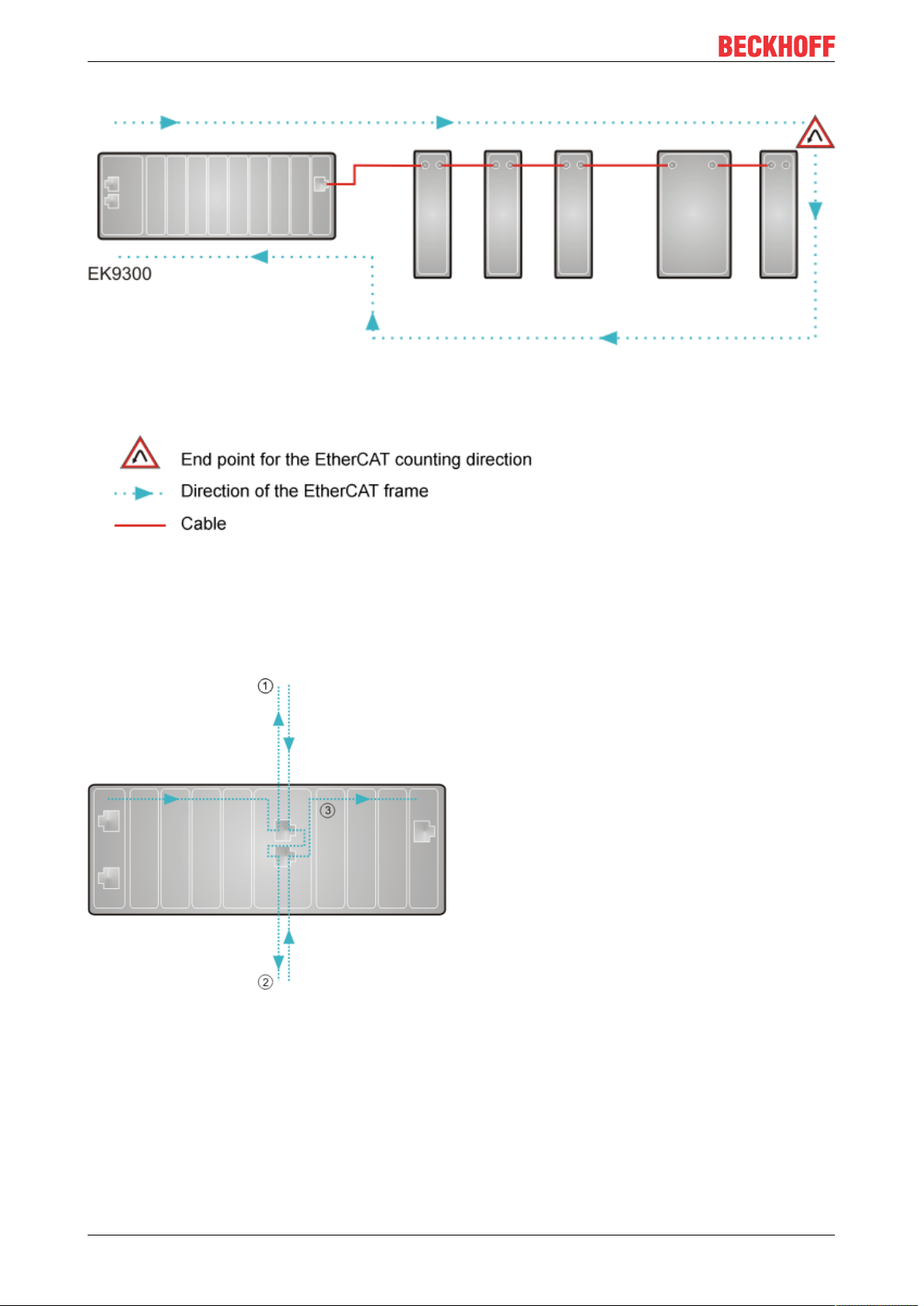

Sample configuration with EP1122 2-port EtherCAT junction

The counting direction is to be observed when using an EP1122; it is comparable with the EK1122. If

EtherCAT junction 1 on the EP1122 is connected, then the EtherCAT frame is forwarded here first (1); if

junction 1 is not connected the frame on junction 2 is sent (2), only after that does the sequence continue

with the EC-bus on the right-hand side (3).

Fig.29: Sample configuration with EP1122 2-port EtherCAT junction

If both junctions are not used, then junction 1 and 2 are short-circuited as it were and the EC frame

continues directly from the terminal to the right.

Note that in the Profinet controller the modules are entered in the direction of the EtherCAT frame.

Connection during operation

You cannot use the EP1122 and EK1122 for Hot Swap or connect or disconnect them during operation. The EP1122 and EK1122 are suitable in conjunction with the EK coupler only as topology extensions (star).

EK9300 39Version: 3.2.6

Page 40

Configuration

5.4 EK9300 – Configuration example

PDO Mapping

The process data on the EtherCAT side are described via the PDO Mapping. The individual terminals bring

along a pre-defined PDO mapping, i.e. a practical combination of individual PDOs, via the ESI file (EtherCAT

description file).

Fig.30: EK9300 - Predefined PDO selection dialog

These combinations are described in turn on the Profinet side using different submodules and thus process

data; i.e. each pre-defined PDO mapping has an associated submodule.

Fig.31: EK9300 Sub-modules

Such modular terminals always have a fixed submodule plugged into subslot 1 on the EK9300. This is the

placeholder for the terminal itself; i.e. the generally valid diagnosis for the terminal is operated via this. The

actual process data are plugged into subslot 2 and the PDO mapping on the EC-master is generated on their

basis.

SDO Mapping

Each of the plugged-in subslots can bring along parameterization data. The Service Data Objects (SDOs)

are transmitted via these data, i.e. the SDOs are mapped to record data sets. The objects 0x8xxx and

0xF8xx are always mapped. Since the indices on the PROFINET side are only vendor-specific from 0 0x7FFF, the EtherCAT objects 0x8xxx correspond to the PROFINET record indices 0x3xxx and the EC

objects 0xF8xx to the PROFINET index range 0x48xx. In PROFINET the records are always written during

the controller start-up phase; they are transferred internally to the EtherCAT master as start-up SDOs. This

means that the internal EC master is also restarted during a PROFINET restart.

EK930040 Version: 3.2.6

Page 41

Fig.32: PROFINET record indices 0x3xxx (corresponds to EtherCAT objects 0x8xxx)

Configuration

These data records can also be read and written during operation.

Commissioning EL7031

The default settings are adequate for initial commissioning, i.e. only the corresponding submodule needs to

be selected. The PDOs and SDOs of the terminal are parameterized on that basis. For example, if the

"Velocity Control" submodule is selected, only the Control_Enable bit needs to be set; subsequently turn the

motor by specifying a setpoint speed.

EK9300 41Version: 3.2.6

Page 42

Configuration

5.5 From firmware Version 6

5.5.1 EK9300 - CoE data access over PROFINET

Description

CoE means Can over EtherCAT. It enables access to all parameters of an EtherCAT device. The CoE data

model is based on the principles of CANopen and uses index and subindex for reading from and writing to

parameters, if the corresponding access is enabled.

Further information can be found here: System Documentation

Task

Parameters of an EtherCAT device can generally be set and parameterized via the parameters of the

GSDML file. However, in some applications it is necessary to change certain parameters at runtime or to

carry out optimizations during operation.

Solution

The CoE data are sent via acyclic PROFINET services (PROFINET index 0x200F). The position of the

EtherCAT device is specified via the slot number. The CoE data are then entered in the record data.During

reading they consist of CoE index and CoE subindex, during writing they consist of CoE index, CoE

subindex and the data to be sent.

Reading/writing sample

For reading, a WriteReq record must be sent first. This includes the CoE index and CoE subindex. After the

WriteRsp a ReadReq has to be sent in order to retrieve the data, which are then contained in the ReadRsp.

Writing takes place in the same way, except that WriteReq includes the data, and ReadRsp serves as

acknowledgement to indicate whether writing was successful.

Fig.33: CoE data access over PROFINET, read/write sample

EK930042 Version: 3.2.6

Page 43

Getting Started - Reading

Configuration

PROFINET record data

(write request)

Slot Position of the EtherCAT device

SubSlot 1 Sub-slot number, always "1"

Index 0x200F PROFINET index number

Length 4 Length of the following data

Data Bytes 1 and 2 SDO index

Delay time, we recommend 100..250 ms until the read request is sent, which includes an acknowledgment of

error-free writing.

PROFINET record data

(read request)

Slot Position of the EtherCAT device

SubSlot 1 Sub-slot number, always "1"

Index 0x200F PROFINET index number

Length Write

Data Write

Value Meaning

Slot number, position of the EtherCAT

(1...255)

Byte 3 CoE subindex

Byte 4 "0" reserve

Value Meaning

(1...255)

Answer

4

Byte 1 "1"

Byte 2 "0"

Byte 3 "0"

Byte 4 "0"

4 bytes + x bytes

Answer

Bytes 1..4 ADS error

Bytes 4..x CoE data

value

device

CoE data

Slot number, position of the EtherCAT

device

Length of the following data

CoE data

The response to the read request, i.e. the read response, includes the data. The first 4 bytes contain the

error code. This is "0" if the response is error-free. The error code is an ADS error code.Further information

can be found under the following link.

http://infosys.beckhoff.com/content/1031/tcsample/html/ads_returncodes.htm

Wireshark sample for reading (https://infosys.beckhoff.com/content/1033/ek9300/Resources/

zip/2609011595.zip)

Getting Started - Writing

PROFINET record data

(write request)

Slot Position of the EtherCAT device

SubSlot 1 Sub-slot number, always "1"

Index 0x200F PROFINET index number

Length 4 Length of the following data

Data Bytes 1..2 SDO index

Value Meaning

Slot number, position of the EtherCAT

(1...255)

Byte 3 SDO subindex

Byte 4 "1" constant

Bytes 5..8 length as DWORD

Bytes 9..x CoE data value

device

CoE data

Delay time, we recommend 250..500 ms until the read request is sent, which includes an acknowledgment of

error-free writing.

EK9300 43Version: 3.2.6

Page 44

Configuration

PROFINET record data

(read request)

Slot Position of the EtherCAT device

SubSlot 1 Sub-slot number, always "1"

Index 0x200F PROFINET index number

Length Write

Data Write

The response to the read request, i.e. the read response, includes confirmation that writing was

successful.The first 4 bytes contain the error code; "0" indicates error-free response. The error code is an

ADS error code.Further information can be found under the following link.

System docu

Wireshark sample for writing (https://infosys.beckhoff.com/content/1033/ek9300/Resources/

zip/2609013771.zip)

Value Meaning

Slot number, position of the EtherCAT

(1...255)

0

-

Answer

4

Write

ADS error code

device

Length of the following data

CoE data

Observe data format

During reading and writing, observe the data size and the format of the corresponding SDO parameters. We recommend reading the SDO data first, then interpret them and use the read data format

also for writing the CoE data (perhaps swap High/Low BYTE/WORD).

Start-up parameters overwrite CoE data

CoE data are typically not stored in the EtherCAT device. Ensure that start-up parameters (GSDML)

overwrite the CoE data during startup of the EK9300.

5.5.2 EK9300 - multi-configuration mode

Description

Multi-configuration mode enables users to operate different hardware, e.g. a EK9300 with varying EtherCAT

Terminals, with the same project configuration.

This description uses EtherCAT Terminals (ELxxxx) in the examples. The same principle applies to

EtherCAT Box modules (EPxxxx).

Task

The machine manufacturer has a machine, which is to be sold with different options. The options are usually

additional signals to be processed and logged, for which additional terminals are required.

For all these options the project configuration should be retained and only be varied via the software. The

actual machine options are included in the parameterization.

Solution

The multi-configuration mode is used to configure the maximum number of options in the project

configuration. If the machine has less than the maximum number of options, EtherCAT Terminals can be

omitted, since these signals are not required. Although unused EtherCAT Terminals are included in the

maximum project configuration, they can be disabled by the controller, so that the hardware and the

parameterized configuration match again. As soon as this is done, the EK9300 switches to normal data

exchange.

EK930044 Version: 3.2.6

Page 45

Configuration

Advantage

Less effort for creating and maintaining projects, since the same project configuration can be used for

different hardware.

Sample

The standard machine configuration, without options, consists of:

• 1 x EK9300

• 2 x EL2004

• 2 x EL1004

• 1 x EL5051

The following options can be added:

• With energy monitoring for logging the energy consumption: additionally an EL3403

• With automatic adjustable axis: additionally an EL7047

• With temperature measurement: additionally an EL3314

The maximum configuration (with optional terminals shown in italics) then looks as follows:

• 1 x EK9300

• 2 x EL2004

• 2 x EL1004

• 1 x EL5051

• 1 x EL3314

• 1 x EL7047

• 1 x EL3403

It is this maximum configuration that is reflected in the hardware configuration.

If the machine is ordered without options, the terminals EL3314, EL7047 and EL3403 have to be disabled in

the project configuration. The EK9300 is notified of the record data (acyclic communication) to indicate which

terminals are no longer required. The terminals are identified via their position.

Without options, two KL2004 are present (at position 1 and 2), two EL1004 (at position 3 and 4) and one

EL5051 (at position 5). The terminals at positions 6, 7 and 8 (optional terminals) must be disabled.

If the machine is ordered with the option "automatic adjustable axis", only terminals 6 and 8 have to be

disabled.

Position of optional terminals

Optional terminals can be connected at any position and may be disabled. They do not necessarily

have to be located at the end, as shown in the example.

First steps

In order to enable the EK9300 to operate in multi-configuration mode, MultiConfigurationMode must be set to

"TRUE" in the DAP (device access point).

There are two possible setting options.

Option 1

This is perhaps a version for testing, since the hardware configuration must be adjusted, which should

preferably be avoided.

In the DAP there is a MultiConfigurationMode setting with the slots. Here you can disable EtherCAT

Terminals, which are configured but not present.

EK9300 45Version: 3.2.6

Page 46

Configuration

For some PROFINET controllers this must happen on startup, while other PROFINET controllers enable it to

occur at runtime, which simplifies testing significantly. Disabling/enabling of terminals at runtime is a feature

of the PROFINET controller and may or may not be possible in practice, depending on the manufacturer of

the PROFINET controller.

Option 2

The configuration is sent by the PLC via the record data. Here too, the manufacturers offer different options.

Contact the manufacturer of your PROFINET controller, if you have any queries.

A requirement for option2 is that your PROFINET controller allows and supports access to the record data.

PROFINET record

Value Meaning

data (write request)

Slot* 0 Slot number, always "0"

SubSlot* 1 Sub-slot number, always "1"

Index 0#2010 PROFINET index number

Length variable Length of the following data

Data Each Bus Terminal requires 2 bits:

00

terminal present

bin

10

terminal not present

bin

Enabling/disabling of the EtherCAT devices

* For some PROFINET controllers these data are automatically taken from the GSDML and do not have to

be configured.

Procedure

Once the station has been configured, the following steps are required.

If the machine is ordered with the maximum configuration (with all options), generally no action is required,

since the hardware matches the project configuration.

If one of the options is not included, then hardware and project planning differ. The PROFINET coupler

indicates this via the message "Module difference".

Now disable the terminals, which are not present. When this is done, the message "Module Difference" is

removed from the coupler. If the message "Module Difference" remains, you may have the wrong slot or too

few slots disabled.

No subslots

Subslots are not counted and cannot be used for the multi-configuration mode.

Only slots can be used, irrespective of a module using subslots or not.

No Shared Device

The Shared Device feature cannot be used when the multi-configuration mode is used.

No pack or (*) terminals

Pack or (*) terminals cannot be used in multi-configuration mode.

5.5.3 EK9300 - IO-LINK

Description

The EK9300 (from firmware 6) supports the IO-Link master EL6224 (EtherCAT Terminal) and EP6224

(EtherCATBox). The GSDML file (from version GSDML-V2.32-beckhoff-EK9300-20160408.xml) includes

this IO-Link master. Each IO-Link device is addressed as a submodule and must be configured via the

GSDML file.

EK930046 Version: 3.2.6

Page 47

Configuration

Task

Connection of an IO-Link sensor to an EK9300.

Configuration of the process data

Each IO-Link device is added as a submodule. For each IO-Link device a submodule is used. The process

data size of the submodule must always be equal to or greater than that of the IO-Link device and must not

be less.

If not all IO-Link channels are used, empty channels should be entered. For example, if sensors are only

connected to inputs 2 and 4 of the IO-Link master, while inputs 1 and 3 are unused, first enter an empty

channel as submodule, then the sensor at input 2, then another empty channel and finally the sensor at input

4. The first submodule used by the IO-Link master is a diagnostics module. This is always present when the

EL6224/EP6224 is added. This submodule contains the status of all connected IO-Link devices. If the sensor

is in IO-Link data exchange, this is indicated via the corresponding byte (0x03 means all OK).

Information on the status byte:

0x_0 = Port disabled

0x_1 = Port in std dig in

0x_2 = Port in std dig out

0x_3 = Port in communication OP

0x_4 = Port in communication COMSTOP / dig in Bit (only in std. IO Mode)

0x_8 = Process Data Invalid Bit

0x1_ = Watchdog detected

0x2_ = internal Error

0x3_ = invalid Device ID

0x4_ = invalid Vendor ID

0x5_ = invalid IO-Link Version

0x6_ = invalid Frame Capability

0x7_ = invalid Cycle Time

0x8_ = invalid PD in length

0x9_ = invalid PD out length

0xA_ = no Device detected

0xB_ = error PreOP/Data storage

Regarding the process data size of an IO-Link device, please refer to the documentation or consult the

manufacturer.

EK9300 47Version: 3.2.6

Page 48

Configuration

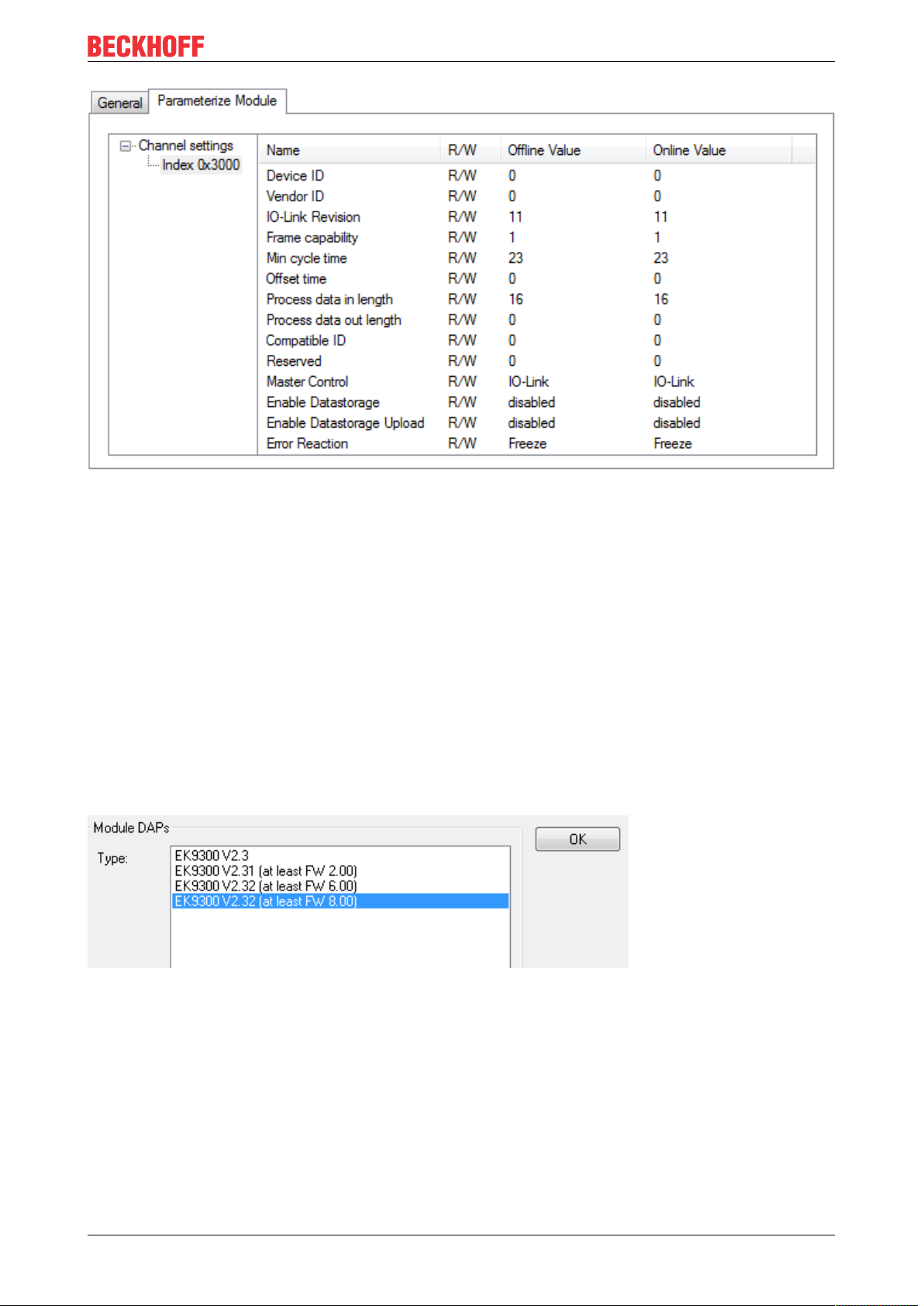

Fig.34: Inserting a "generic channel" (in the case of IO-Link devices from other manufacturers)

IO-Link devices from Beckhoff are automatically added with the required parameters. For devices from other

manufacturers please use a generic channel and select the process data size.

Configuration of the IO-Link device

The minimum settings required for operating an IO-Link device are:

IO-Link version: Generally 1.1; enter 11

Frame capability: Generally 1

Min. cycle time: Generally 2.3 ms, i.e. 23

Process data in / Out length: Variable (number in bits), for a size of 2 bytes input enter 16 for "Process data

in length".

Master control: set to IO-Link

All other settings are optional.

EK930048 Version: 3.2.6

Page 49

Fig.35: Configuration of the IO-Link device

Configuration

Reading/writing of parameters

Each IO-Link device has parameters, which can be read or written. The EK9300 does not support this

function. I.e. no parameters can be read or written. The communication of the EK9300 with the IO-Link

device is limited to the process data.

To access parameters of the IO-Link devices, use a Beckhoff controller (e.g. CX8093). Here you can read

the IODD file (IO-Link device description) and read or write the sensor data via the PLC.

5.6 From firmware version 8

In order to be able to use the updated firmware version 8, you have to use the corresponding GSDM device

description, from version GSDML-V2.32-beckhoff-EK9300-20170216.XML.

Add the corresponding GSDML DAP for the firmware (FW8.0).

Fig.36: Adding the GSDML DAP for firmware FW8.0

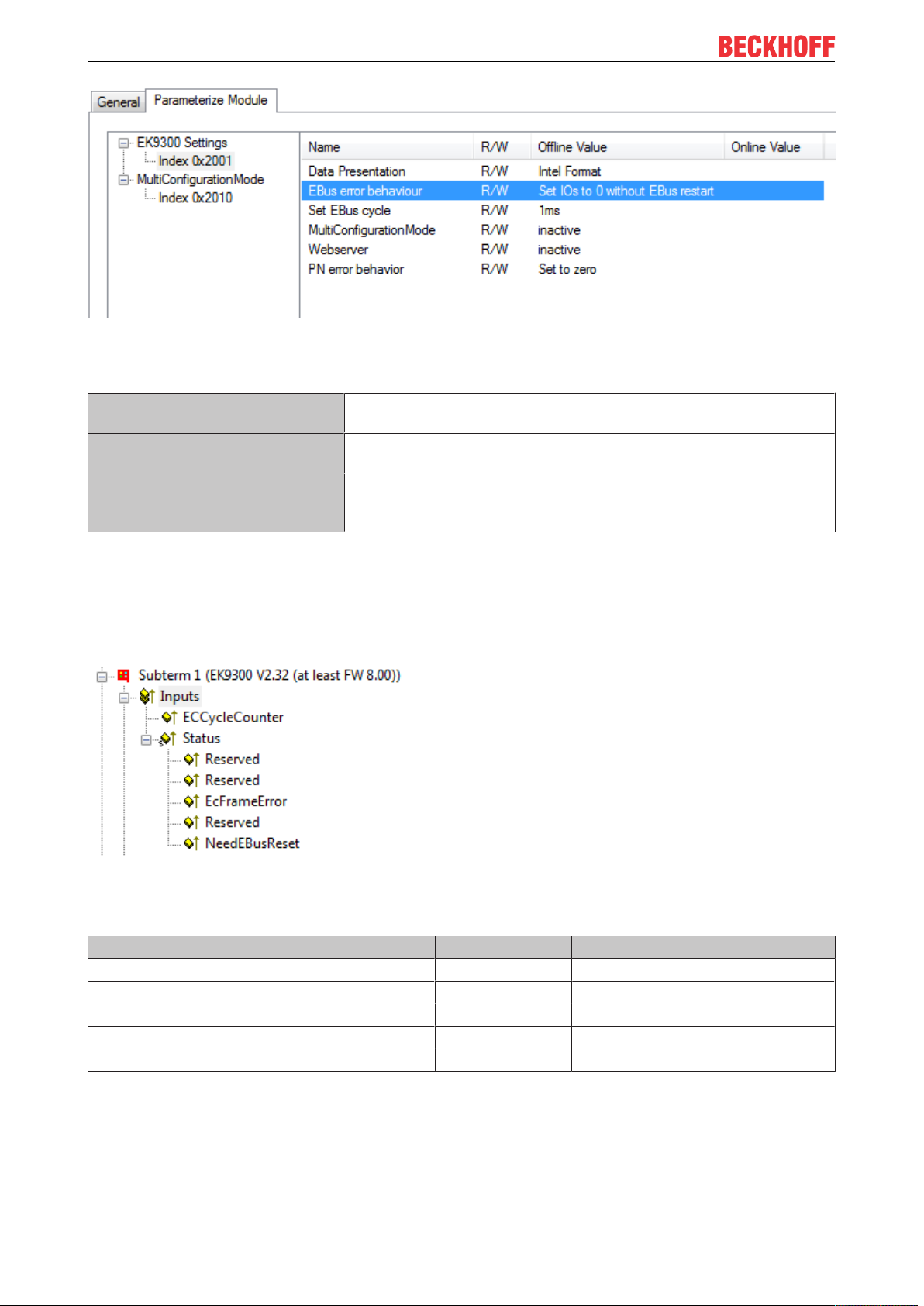

5.6.1 EBus Error Behaviour

The parameter EBus error behavior is new in firmware version 8.

EK9300 49Version: 3.2.6

Page 50

Configuration

Fig.37: The parameter EBus error behavior

This parameter is used to set the response to an E-bus error. The following options are available:

Legacy Output data is still written, input data is frozen and therefore no longer

current.

Set IOs to 0 Output data is written to zero; input data is written to zero; when the E-

bus is error-free, it automatically starts the data exchange.

Set IOs to 0 without EBus restart

(Default setting)

Output data is written to zero; input data is written to zero; when the Ebus is error-free, it can be activated again via the record data (see

below).

Activating the E-bus after an E-bus error

In the DAP, information about the E-bus is provided via the status DWord. When an error occurs in the Ebus, the bit EcFrameError is set (in the high word bit offset x.2). Once the error has been rectified and the

coupler is ready to restart the E-bus, the bit EcFrameError is reset and the flag NeedEBusRese is set in the

high word bit offset x.4.

Fig.38: Flag NeedEBusReset

The reset is issued via record data and is structured as follows.

PROFINET record data (write request) Value Meaning

Slot 0 Slot number

SubSlot 1 Sub slot number

Index 0x2013 Index Reset

Lenght 2 Data length

Data 0x1234 Value

Once the reset has been issued, the bit NeedEBusReset is reset.

EK930050 Version: 3.2.6

Page 51

Configuration

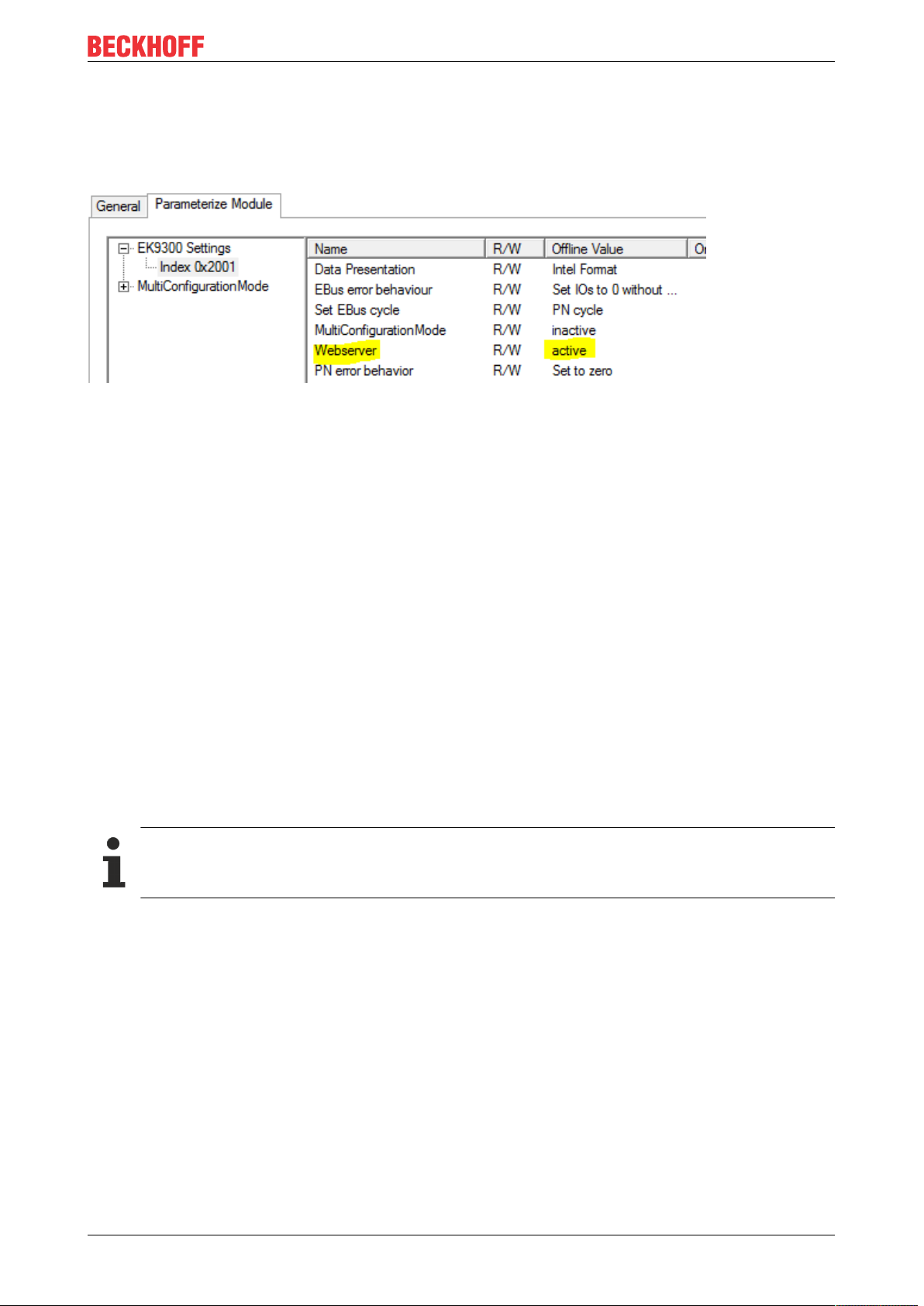

5.6.2 Activating the web page