Page 1

Operating Instructions for

EK1960

TwinSAFE Compact Controller

Version:

Date:

1.3.1

2019-01-28

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................7

1.1 Notes on the documentation..............................................................................................................7

1.2 Safety instructions .............................................................................................................................8

1.2.1 Delivery state ..................................................................................................................... 8

1.2.2 Operator's obligation to exercise diligence ........................................................................ 8

1.2.3 Description of safety symbols ............................................................................................ 9

1.3 Documentation issue status ............................................................................................................10

1.4 Version history of the TwinSAFE product........................................................................................11

2 System description TwinSAFE...............................................................................................................12

2.1 Extension of the Beckhoff I/O system with safety functions ............................................................12

2.2 Safety concept.................................................................................................................................12

3 Product description.................................................................................................................................13

3.1 General description .........................................................................................................................13

3.2 Product designations .......................................................................................................................14

3.3 Inputs and outputs of the EK1960 ...................................................................................................15

3.4 Connection technology ....................................................................................................................18

3.4.1 Power supply spring contact strip .................................................................................... 18

3.4.2 Input and output spring contact strip................................................................................ 18

3.4.3 Relay contact spring contact strip.................................................................................... 18

3.5 Intended use....................................................................................................................................19

3.6 Technical data .................................................................................................................................20

3.6.1 Technical data – relay option........................................................................................... 22

3.7 Safety parameters ...........................................................................................................................24

3.8 Error response times .......................................................................................................................26

3.9 Characteristic curve of the inputs ....................................................................................................27

3.10 Test pulses for the outputs ..............................................................................................................27

3.11 Load characteristic curve – inductive load.......................................................................................29

3.12 Block diagram of the EK1960 ..........................................................................................................30

3.13 Address setting of the TwinSAFE compact controller .....................................................................31

3.14 Dimensions......................................................................................................................................32

3.15 Wiring examples ..............................................................................................................................32

3.15.1 Inputs and outputs ........................................................................................................... 32

3.15.2 Clocked signals................................................................................................................ 36

4 Operation..................................................................................................................................................37

4.1 Environmental conditions ................................................................................................................37

4.2 Installation ......................................................................................................................................37

4.2.1 Safety instructions ........................................................................................................... 37

4.2.2 Transport / storage .......................................................................................................... 37

4.2.3 Mechanical installation..................................................................................................... 37

4.2.4 Electrical installation ........................................................................................................ 40

4.3 Configuration of the controller in TwinCAT......................................................................................42

4.3.1 Configuration requirements ............................................................................................. 42

4.3.2 Insertion of a controller .................................................................................................... 42

EK1960 3Version: 1.3.1

Page 4

Table of contents

4.3.3 Creating a safety project in TwinCAT3 ........................................................................... 43

4.3.4 Downloading the safety application ................................................................................. 75

4.4 Info data...........................................................................................................................................79

4.4.1 Info data for the connection ............................................................................................ 79

4.4.2 Info data for function blocks............................................................................................. 80

4.4.3 Info data for the TwinSAFE group ................................................................................... 81

4.4.4 Info data for the device .................................................................................................... 82

4.5 Version history.................................................................................................................................83

4.6 User Administration .........................................................................................................................84

4.7 Backup/Restore ...............................................................................................................................86

4.8 Export/import of the safety project...................................................................................................90

4.9 Diag History tab ...............................................................................................................................92

4.10 TwinSAFE SC configuration ............................................................................................................93

4.11 Customizing / disabling TwinSAFE groups......................................................................................97

4.12 Saving the analog group inputs persistently..................................................................................100

4.13 New features in TC3.1 Build 4022.................................................................................................101

4.13.1 Group status .................................................................................................................. 101

4.13.2 Online view group ports................................................................................................. 103

4.13.3 Group templates ............................................................................................................ 103

4.13.4 Networks collapsable..................................................................................................... 103

4.13.5 Subfolder Alias Devices................................................................................................. 104

4.13.6 Goto linked element....................................................................................................... 105

4.13.7 Path view to linked signal .............................................................................................. 105

4.13.8 Multiline comments........................................................................................................ 106

4.13.9 Names of Alias Devices in the process image............................................................... 107

4.13.10 Project settings - Verification ......................................................................................... 108

4.13.11 Displaying the project size............................................................................................. 108

4.13.12 Copy and Paste for FBs and comments........................................................................ 109

4.13.13 Global settings in Visual Studio ..................................................................................... 111

4.13.14 Sorting ........................................................................................................................... 113

4.13.15 Direct mapping of local I/Os........................................................................................... 115

4.13.16 Backup/Restore settings................................................................................................ 116

4.13.17 Multiple download.......................................................................................................... 117

4.14 Diagnostics ....................................................................................................................................120

4.14.1 Diagnostic LEDs ............................................................................................................ 120

4.14.2 Status LEDs................................................................................................................... 122

4.14.3 Diagnostic objects.......................................................................................................... 123

4.14.4 Cycle time of the safety project...................................................................................... 124

4.14.5 Diagnosis History........................................................................................................... 125

4.15 Project design limits of the EK1960...............................................................................................128

4.16 Behavior when restarting...............................................................................................................128

4.17 Sync-Manager Configuration.........................................................................................................129

4.18 Reaction times of local signals ......................................................................................................131

4.19 TwinSAFE reaction times ..............................................................................................................131

4.20 Reaction times Bumper mode .......................................................................................................133

4.21 Reaction times ambient conditions................................................................................................133

EK19604 Version: 1.3.1

Page 5

Table of contents

4.22 Maintenance ..................................................................................................................................133

4.22.1 Cleaning......................................................................................................................... 133

4.23 Service life .....................................................................................................................................134

4.23.1 Decommissioning .......................................................................................................... 135

4.24 Firmware update of TwinSAFE products.......................................................................................136

5 Appendix ................................................................................................................................................139

5.1 Support and Service ......................................................................................................................139

5.2 Certificates.....................................................................................................................................140

EK1960 5Version: 1.3.1

Page 6

Table of contents

EK19606 Version: 1.3.1

Page 7

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Origin of the document

This documentation was originally written in German. All other languages are derived from the German

original.

Currentness

Please check whether you are using the current and valid version of this document. The current version can

be downloaded from the Beckhoff homepage at http://www.beckhoff.com/english/download/twinsafe.htm.

In case of doubt, please contact Technical Support [}139].

Product features

Only the product features specified in the current user documentation are valid. Further information given on

the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative.

Disclaimer

The documentation has been prepared with care. The products described are subject to cyclical revision. For

that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. We reserve the right to revise and change the documentation at any time

and without prior announcement. No claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATP®, SafetyoverEtherCAT®, TwinSAFE®, XFC® and XTS® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EK1960 7Version: 1.3.1

Page 8

Foreword

EtherCAT® and Safety over EtherCAT® are registered trademarks and patented technologies, licensed by

Beckhoff Automation GmbH, Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see chapter Product description);

• the TwinSAFE products are only operated in sound condition and in working order.

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental protection

aspects, and is familiar with the operating instructions and in particular the safety instructions contained

herein.

• the operating instructions are in good condition and complete, and always available for reference at the

location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all notes

remain legible.

EK19608 Version: 1.3.1

Page 9

1.2.3 Description of safety symbols

In these operating instructions the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to the environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Foreword

Tip or pointer

This symbol indicates information that contributes to better understanding.

EK1960 9Version: 1.3.1

Page 10

Foreword

1.3 Documentation issue status

Version Comment

1.3.1 • Layout corrected at chapter Sample program for parameterization

1.3.0 • Description of Module Fault Link active parameter added

• Description of Multiple Download added

• Description of input and output signals expanded

• Description of error response times added

• Version history of TwinSAFE product added

• Description of firmware update added

1.2.0 • Description of inductive load and free-wheeling diode changed

• New features TwinCAT 3.1 Build 4022 added

• Diagnosis history described

• Reaction times BumperMode and ambient conditions added

• Description TwinSAFE SC updated

• Description of Behavior when restarting added

• Project design limits adjusted

• Note to the permissible loads on the relay contacts added

1.1.0 • Note to the input and output process image added

• Description for Sync Manager configuration added

• TwinSAFE SC description updated

1.0.0 • Certificate added

• General document revision

• Description of input module 9 and 10 updated

0.7.0 • Load characteristics for inductive loads added

• Backup/Restore flow chart added

0.6.1 • User administration screenshots updated

• State and Diag of the TwinSAFE group updated

0.6.0 • Safety parameters adopted from review report

0.5.0 • Safety parameters revised

• Parameter values revised

• Diag messages added

0.4.0 • Safety concept requirements for the manual implemented

0.3.0 • Update of the designation of the contact points

• Addendum: illustration of the TwinSAFE compact controller without relay option

0.2.0 • Extension of the general description

• Description of diagnostic and status LEDs added

0.1.0 • Migration, layout adaptation

EK196010 Version: 1.3.1

Page 11

Foreword

1.4 Version history of the TwinSAFE product

This version history lists the releases of the software and hardware versions. A description of the respective

changes to the previous version is also listed.

Updated hardware and software

The TwinSAFE products are subject to a cyclical revision. We reserve the right to revise and

change the TwinSAFE products at any time and without notice.

These hardware and/or software changes do not give rise to any claims for changes to products

that have already been delivered.

A description of how a firmware update (software) can be carried out can be found in the chapter Firmware

update of TwinSAFE products [}136].

Date SW-Version HW-Version Changes

2017-05-02 01 00 • First Release

2017-07-14 02 01 • Optimized safety mat function

• Added support for backup/restore mode

• Protective circuit of the outputs changed

2018-09-19 03 01 • Local logic projects can now also be created without a linked

RUN signal.

• Time stamp for diagnostic messages corrected.

• FB Muting: After an FB error in the backwards operating mode,

the FB error can be acknowledged without restarting the

TwinSAFE group.

• An error acknowledgement is now required after a user has

logged in to the Logic without deleting the project.

• Support of Module Fault Link active parameter added.

• Firmware and vendor data CRCs can be read out in CoE objects.

EK1960 11Version: 1.3.1

Page 12

System description TwinSAFE

2 System description TwinSAFE

2.1 Extension of the Beckhoff I/O system with safety functions

The TwinSAFE products from Beckhoff enable convenient expansion of the Beckhoff I/O system with safety

components, and integration of all the cabling for the safety circuit within the existing fieldbus cable. Safe

signals can be mixed with standard signals as required. The transfer of safety-related TwinSAFE telegrams

is handled by the standard controller. Maintenance is simplified significantly thanks to faster diagnosis and

simple replacement of components.

The following basic functionalities are included in the TwinSAFE components:

digital inputs (e.g. EL19xx, EP1908), digital outputs (e.g. EL29xx), drive components (e.g. AX5805) and logic

units (e.g. EL6900, EL6910). For a large number of applications, the complete safety sensor and actuator

technology can be wired on these components. The required logical link of the inputs and the outputs is

handled by the EL69xx. In addition to Boolean operations, the EL6910 now also enables analog operations.

2.2 Safety concept

TwinSAFE: Safety and I/O technology in one system

• Extension of the familiar Beckhoff I/O system with TwinSAFE components

• Safe and non-safe components can be combined as required

• Logical link of the I/Os in the EL69xx TwinSAFE logic terminal

• Suitable for applications up to SIL3 according to EN61508:2010 and Cat4, PLe according to

ENISO13849-1:2015

• Safety-relevant networking of machines via bus systems

• In the event of an error, all TwinSAFE components always switch to the wattless and therefore safe

state

• No safety requirements for the higher-level standard TwinCAT system

Safety over EtherCAT protocol (FSoE)

• Transfer of safety-relevant data via any media (“genuine black channel”)

• TwinSAFE communication via fieldbus systems such as EtherCAT, Lightbus, PROFIBUS, PROFINET

or Ethernet

• IEC 61508:2010 SIL 3 compliant

• FSoE is IEC standard (IEC 61784-3-12) and ETG standard (ETG.5100)

Fail-safe principle (fail stop)

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system component or the

overall system must never lead to a dangerous condition. The safe state is always the switched off and

wattless state.

CAUTION

Safe state

For all TwinSAFE components the safe state is always the switched-off, wattless state.

EK196012 Version: 1.3.1

Page 13

Product description

3 Product description

3.1 General description

EK1960 – TwinSAFE-Compact-Controller

The EK1960 is a TwinSAFE controller with 20 fail-safe inputs and 24 fail-safe outputs. The EK1960-2600

and EK1960-2608 variants feature an additional four relays, each with one make contact.

The EK1960 TwinSAFE compact controller is suitable for safety applications up to SIL 3 according to

IEC62061 and IEC61508 and up to Cat. 4, PL e according to ENISO13849-1:2015. (See following list for

restrictions):

• The single-channel relay output is suitable up to Cat. 2, PL d

• The two-channel relay output (use of two relay contacts in series) is suitable up to Cat. 3, PL d or Cat.

4, PL e, depending on the number of actuations. Cat. 4, PL e requires an actuation at least once per

month, Cat. 3, PL d at least once per year.

• The safe input for the safety mat operation mode is limited to Cat. 2, PL d.

Special proof tests are not necessary during the entire lifetime of the EK1960 on account of the high level of

diagnostic coverage.

The EK1960 can be used in three different application cases:

• As a stand-alone TwinSAFE compact controller without the use of an EtherCAT network with 20 inputs

and 24 outputs. An extension with terminals to the right of the EK1960 on the E-bus is not possible in

this operation mode.

• As a TwinSAFE compact controller integrated into an EtherCAT network. The EK1960 can be

extended with standard and safety terminals on the E-bus connection and via the EtherCAT network.

• As a TwinSAFE I/O module. The logic on the TwinSAFE compact controller is not used. The coupler

can be addressed by a TwinSAFE logic terminal as an I/O module with 20 inputs and 24 outputs.

The inputs of the EK1960 can be used as digital 24 V inputs. They can be fed to the safe input either with

static 24 VDC or with a clock from one of the TwinSAFE outputs of the EK1960 or via an external clock source

via, for example, a switch contact. Inputs 17 to 20 can additionally be switched to a safety mat operation

mode (Bumper Mode On) . Only safety mats operating according to the resistance-change principle are

supported. The safety mats can also be cascaded in accordance with the manufacturer's specifications. The

inputs can be parameterized in groups of two.

The outputs can be parameterized in groups of four. It is possible to set the mark-to-space-ratio and the

activation as a clock source for the safe inputs.

EK1960 13Version: 1.3.1

Page 14

Product description

Fig.1: EK1960-260x TwinSAFE-Compact-Controller

The EK1960 without relay option has a dummy cap on X4.

Fig.2: EK1960-000x TwinSAFE compact controller without relay option

3.2 Product designations

Product designation Description

EK1960-0000 EK1960 with EtherCAT RJ45 connections – without relay option

EK1960-0008 EK1960 with EtherCAT M8 connections – without relay option

EK1960-2600 EK1960 with EtherCAT RJ45 connections – with four potential-free contacts

(NO)

EK1960-2608 EK1960 with EtherCAT M8 connections – with four potential-free contacts (NO)

ZS2003-0001 Spare part, power supply spring contact strip, 4-pole

Contact spacing 3.5 mm

ZS2003-0002 Spare part, input/output spring contact strip, 10-pole

Contact spacing 3.5 mm

ZS2003-0003 Spare part, relay contact spring contact strip, 10-pole

Contact spacing 5.0 mm (EK1960-260x only)

EK196014 Version: 1.3.1

Page 15

Product description

3.3 Inputs and outputs of the EK1960

NOTE

Fuses for the EK1960

Fuses must be provided for the power supplies of the EK1960 2 A each for US and UP (X3) and 5 A each for

UP1 to UP6 (X5, X7, X9).

plug contact Name Description

EtherCAT (X1) EtherCAT 1 EtherCAT connection 1

(RJ45 or M8)

EtherCAT (X2) EtherCAT 2 EtherCAT connection 2

(RJ45 or M8)

Power (X3) 1 U

s

2 0V GND

3 U

p

4 0V GND

Relais (X4)

1 4.1 Input to Relay 1 make contact

(EK1960-260x only)

2 4.2 Input to Relay 2 make contact

3 4.3 Input to Relay 3 make contact

4 4.4 Input to Relay 4 make contact

5 n.c. not used

6 n.c. not used

7 4.5 Output to Relay 1 make contact

8 4.6 Output to Relay 2 make contact

9 4.7 Output to Relay 3 make contact

10 4.8 Output to Relay 4 make contact

Output (X5) 1 5.1 Output 1 from U

2 5.2 Output 2 from U

3 5.3 Output 3 from U

4 5.4 Output 4 from U

5 U

P1

6 5.5 Output 5 from U

7 5.6 Output 6 from U

8 5.7 Output 7 from U

9 5.8 Output 8 from U

10 U

P2

Control voltage 24 VDC (SELV/PELV)

Supply of power for internal logic and E-bus connection

Peripheral voltage 24VDC (SELV/PELV)

Supply of power for relays and inputs in the safety mat operation mode

(Channel7.FSOUT RelaisModule.Channel1.Output)

(Channel7.FSOUT RelaisModule.Channel2.Output)

(Channel7.FSOUT RelaisModule.Channel3.Output)

(Channel7.FSOUT RelaisModule.Channel4.Output)

(Channel7.FSOUT RelaisModule.Channel1.Output)

(Channel7.FSOUT RelaisModule.Channel2.Output)

(Channel7.FSOUT RelaisModule.Channel3.Output)

(Channel7.FSOUT RelaisModule.Channel4.Output)

(Channel1.FSOUT Module 1.Channel1.Output)

(Channel1.FSOUT Module 1.Channel2.Output)

(Channel1.FSOUT Module 1.Channel3.Output)

(Channel1.FSOUT Module 1.Channel4.Output)

Peripheral voltage U

(Channel2.FSOUT Module 2.Channel1.Output)

(Channel2.FSOUT Module 2.Channel2.Output)

(Channel2.FSOUT Module 2.Channel3.Output)

(Channel2.FSOUT Module 2.Channel4.Output)

Peripheral voltage U

P1

P1

P1

P1

24 VDC (SELV/PELV)

P1

P2

P2

P2

P2

24V

P2

DC

(SELV/PELV)

EK1960 15Version: 1.3.1

Page 16

Product description

plug contact Name Description

Input (X6) 1 6.1 Input 1

2 6.2 Input 2

3 6.3 Input 3

4 6.4 Input 4

5 6.5 Input 5

6 6.6 Input 6

7 6.7 Input 7

8 6.8 Input 8

9 6.9 Input 9

10 6.10 Input 10

Output (X7) 1 7.1 Output 9 from U

2 7.2 Output 10 from U

3 7.3 Output 11 from U

4 7.4 Output 12 from U

5 U

P3

6 7.5 Output 13 from U

7 7.6 Output 14 from U

8 7.7 Output 15 from U

9 7.8 Output 16 from U

10 U

P4

Input (X8) 1 8.1 Input 11

2 8.2 Input 12

3 8.3 Input 13

4 8.4 Input 14

5 8.5 Input 15

6 8.6 Input 16

7 8.7 Input 17

8 8.8 Input 18

9 8.9 Input 19

10 8.10 Input 20

(Channel8.FSIN Module 1.Channel1.Input)

(Channel8.FSIN Module 1.Channel2.Input)

(Channel9.FSIN Module 2.Channel1.Input)

(Channel9.FSIN Module 2.Channel2.Input)

(Channel10.FSIN Module 3.Channel1.Input)

(Channel10.FSIN Module 3.Channel2.Input)

(Channel11.FSIN Module 4.Channel1.Input)

(Channel11.FSIN Module 4.Channel2.Input)

(Channel12.FSIN Module 5.Channel1.Input)

(Channel12.FSIN Module 5.Channel2.Input)

(Channel3.FSOUT Module 3.Channel1.Output)

(Channel3.FSOUT Module 3.Channel2.Output)

(Channel3.FSOUT Module 3.Channel3.Output)

(Channel3.FSOUT Module 3.Channel4.Output)

Peripheral voltage U

(Channel4.FSOUT Module 4.Channel1.Output)

(Channel4.FSOUT Module 4.Channel2.Output)

(Channel4.FSOUT Module 4.Channel3.Output)

(Channel4.FSOUT Module 4.Channel4.Output)

Peripheral voltage U

(Channel13.FSIN Module 6.Channel1.Input)

(Channel13.FSIN Module 6.Channel2.Input)

(Channel14.FSIN Module 7.Channel1.Input)

(Channel14.FSIN Module 7.Channel2.Input)

(Channel15.FSIN Module 8.Channel1.Input)

(Channel15.FSIN Module 8.Channel2.Input)

(digital - Digital Mode On,

safety mat operation mode (resistance change) - Bumper Mode On)

(Channel16.FSIN Module 9.Channel1.Input)

(digital - Digital Mode On,

safety mat operation mode (resistance change) - Bumper Mode On)

(Channel16.FSIN Module 9.Channel2.Input)

(digital - Digital Mode On,

safety mat operation mode (resistance change) - Bumper Mode On)

(Channel17.FSIN Module 10.Channel1.Input)

(digital - Digital Mode On,

safety mat operation mode (resistance change) - Bumper Mode On)

(Channel17.FSIN Module 10.Channel2.Input)

P3

P3

P3

P3

24V

24V

(SELV/PELV)

DC

(SELV/PELV)

DC

P3

P4

P4

P4

P4

P4

EK196016 Version: 1.3.1

Page 17

Product description

plug contact Name Description

Output (X9) 1 9.1 Output 17 from U

(Channel5.FSOUT Module 5.Channel1.Output)

2 9.2 Output 18 from U

(Channel5.FSOUT Module 5.Channel2.Output)

3 9.3 Output 19 from U

(Channel5.FSOUT Module 5.Channel3.Output)

4 9.4 Output 20 from U

(Channel5.FSOUT Module 5.Channel4.Output)

5 U

P5

Peripheral voltage U

6 9.5 Output 21 from U

(Channel6.FSOUT Module 6.Channel1.Output)

7 9.6 Output 22 from U

(Channel6.FSOUT Module 6.Channel2.Output)

8 9.7 Output 23 from U

(Channel6.FSOUT Module 6.Channel3.Output)

9 9.8 Output 24 from U

(Channel6.FSOUT Module 6.Channel4.Output)

10 U

P6

Peripheral voltage U

P5

P5

P5

P5

24V

24V

(SELV/PELV)

DC

(SELV/PELV)

DC

P5

P6

P6

P6

P6

P6

NOTE

Protected wiring

If the wiring of the outputs or the connected actuators leaves the control cabinet, the user must ensure that

the wiring is protected.

WARNING

Active loads

The use of active loads (with their own power supply) is not permissible unless the manufacturer of the load

ensures the non-reactivity of the power supply to the control signal.

DANGER

Clocked signals within a sheathed cable

Are clocked signals of different output modules used within a sheathed cable, a failure of a module, such as

cross-circuit or external power supply must lead to a switch off of all these modules. This switch off must be

performed by the user program.

From firmware version 03 and revision -0021 the parameter Module Fault Link active is available. If the parameter is set to TRUE for all modules involved, all these modules are set to the error state in the event of a

module error. This parameter is set to TRUE by default.

EK1960 17Version: 1.3.1

Page 18

Product description

3.4 Connection technology

3.4.1 Power supply spring contact strip

The power supply spring contact strip is required for the X3 connection.

Item number ZS2003-0001

Number of contacts 4

Contact spacing 3.5 mm

Connection methods Spring-loaded terminal technology

Wire cross-section (solid-wire) 0.2 – 1.5 mm²

Wire cross-section (fine-wire) 0.2 – 1.5 mm²

Conductor cross-sectional area – fine wire (with wire-

end ferrules with plastic collars)

Conductor cross-sectional area – fine wire (with wire-

end ferrules without plastic collars)

Strip length 8 - 9 mm

0.25 – 0.75 mm²

0.25 – 1.5 mm²

3.4.2 Input and output spring contact strip

The input and output spring contact strip is required for the connection X5 to X9.

Item number ZS2003-0002

Number of contacts 10

Contact spacing 3.5 mm

Connection methods Spring-loaded terminal technology

Wire cross-section (solid-wire) 0.2 – 1.5 mm²

Wire cross-section (fine-wire) 0.2 – 1.5 mm²

Conductor cross-sectional area – fine wire (with wire-

end ferrules with plastic collars)

Conductor cross-sectional area – fine wire (with wire-

end ferrules without plastic collars)

Strip length 8 - 9 mm

0.25 – 0.75 mm²

0.25 – 1.5 mm²

3.4.3 Relay contact spring contact strip

The relay contact spring contact strip is required for the connection X4 (EK1960-260x only).

Item number ZS2003-0003

Number of contacts 10

Contact spacing 5.0 mm

Connection methods Spring-loaded terminal technology

Wire cross-section (solid-wire) 0.2 – 2.5 mm²

Wire cross-section (fine-wire) 0.2 – 2.5 mm²

Conductor cross-sectional area – fine wire (with wire-

end ferrules with plastic collars)

Conductor cross-sectional area – fine wire (with wire-

end ferrules without plastic collars)

Strip length 9 - 10 mm

0.25 – 1.5 mm²

0.25 – 2.5 mm²

EK196018 Version: 1.3.1

Page 19

Product description

3.5 Intended use

WARNING

Caution - Risk of injury!

The TwinSAFE compact controller may only be used for the purposes described below!

The TwinSAFE compact controller expands the application range of the Beckhoff EtherCAT system by

functions that enable it to be used in the field of machine safety as well. The TwinSAFE compact controller is

designed for machine safety functions and the directly associated industrial automation tasks. It is therefore

approved only for applications with a defined fail-safe state. This safe state is the wattless state.

The EK1960 TwinSAFE compact controller is suitable for operation as

• Stand-alone Safety Controller

• a safety controller within an EtherCAT network

• a safety I/O device within an EtherCAT network with, for example, an EL6910 as TwinSAFE Master

WARNING

System limits

The TÜV-Süd certificate applies to the EK1960, the function blocks available in it, the documentation and

the engineering tool. Approved engineering tools are TwinCAT 3.1, TwinSAFE Loader and CODESYS

Safety for EtherCAT Safety Module. Any deviations from the procedures or tools, particularly externally

generated xml files for TwinSAFE import or externally generated automatic project creation procedures, are

not covered by the certificate.

WARNING

Power supply

The TwinSAFE compact controller must be supplied with 24 VDC by an SELV/PELV power supply unit with

an output voltage limit U

of 36 VDC. Failure to observe this can result in a loss of security.

max

WARNING

Commissioning test

Before the EK1960 can be used for the safety task, the user must carry out a commissioning test so that

sensor and actuator wiring errors can be ruled out.

CAUTION

Note the Machinery Directive

The TwinSAFE compact controller may only be used in machines within the meaning of the Machinery Directive.

CAUTION

Ensure traceability

The buyer has to ensure the traceability of the device via the serial number.

EK1960 19Version: 1.3.1

Page 20

Product description

3.6 Technical data

Product designation EK1960

Number of inputs 20

Number of outputs 24 (+ 4 optional relay outputs)

Cable length between sensor and input 30 m (if cables with a cross-sectional area of 0.75mm²

are used)

Cable length between output and actuator 30 m (if cables with a cross-sectional area of 0.75mm²

are used)

Minimum/maximum logic cycle time approx. 1 ms / according the project size

Fault response time ≤ watchdog times

Watchdog time min. 2ms, max. 60,000ms

Input process image Dynamic, according to the TwinSAFE configuration in

TwinCAT3

Output process image Dynamic, according to the TwinSAFE configuration in

TwinCAT3

Supply voltage (SELV/PELV) 24VDC (–15%/+20%)

Provide a 2 A fuse for US and U

E-bus power supply (5 V) max. 500mA

(In the case of higher current consumption,

P

please use the EL9410 power feed terminals in addition!)

Signal voltage inputs

see Characteristic curve of the inputs [}27]

Output module (4 channels) 24VDC (–15% / +20%) SELV/PELV for UP1 to U

max. 2A per channel

min. 30 mA with a test pulse length of 400 µs and

resistive load

Simultaneity factor 50% per module

Provide 5 A fuse for each U

Px

Diagnostic thresholds:

>4V -> high signal is detected

<2.4V -> low signal is detected

Permissible actuators

• inductive loads (see also Load characteristic curve –

inductive load [}29])

(A free-wheeling diode must be provided on the load)

• resistive loads

• capacitive loads

Current consumption of the modular electronics

at 24VDC (without current consumption of

sensors/actuators)

US typ. 80 mA

UP typ. 2 mA

UP1 to UP6 each typ. 2mA

Dimensions (W x H x D) 230.5mmx 100mmx 58.6mm

Weight approx.560g (EK1960-260x)/

approx.500g(EK1960-000x)

Permissible ambient temperature (operation) -25 °C to +55 °C

Permissible ambient temperature (transport/

-40 °C to +70 °C

storage)

Permissible humidity 5% to 95%, non-condensing

permissible air pressure

(operation/storage/transport)

750hPa to 1100hPa

(this corresponds to an altitude of approx. -690m to

2450m above sea level, assuming an international

standard atmosphere)

P6

EK196020 Version: 1.3.1

Page 21

Product description

Product designation EK1960

Climate category according to EN 60721-3-3 3K3

(the deviation from 3K3 is possible only with optimal

environmental conditions and also applies only to the

technical data which are specified differently in this

documentation)

Permissible level of contamination

according to EN 60664-1

Inadmissible operating conditions TwinSAFE controllers must not be used under the

Vibration/shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/emission conforms to EN61000-6-2/ EN61000-6-4

Shocks 15 g with pulse duration 11 ms in all three axes

Protection class as per IEC 60529 IP20

Permitted operating environment In the control cabinet or terminal box, with minimum

Correct installation position

Technical approvals CE, TÜV SÜD

level of contamination 2

(comply with the chapter Cleaning [}133])

following operating conditions:

• under the influence of ionizing radiation (exceeding the

natural background radiation)

• in corrosive environments

• in an environment that leads to impermissible soiling of

the controller

protection class IP54 according to IEC60529

see chapter Installation position and minimum distances

[}38]

NOTE

Protective circuit

No protective circuit is integrated in the output circuit of the EK1960, so it is necessary to provide a freewheeling diode on the actuator for inductive loads. However, it must be borne in mind that the free-wheeling

diode may prolong the switch-off times of the actuator.

The protective circuit must limit the induced voltage at the output to an amount of less than 29V. Thus, R/C

circuits and varistors are typically unsuitable.

EK1960 21Version: 1.3.1

Page 22

Product description

3.6.1 Technical data – relay option

Product designation EK1960-260x

Contacts 1NO / 1NC

Make contact material (NO) AgNi+0.2 µm Au

Feedback contact material (NC) AgNi+5 µm Au

Coil voltage 24V

Maximum continuous current, NO contact

(when used in safety applications)

Maximum switching current (NO contact) 8A

Minimum switching current (NO contact) 10mA (AgNi)

Switching capacity according to IEC/EN

60947-5-1

AC15

DC13

Switching frequency (maximum) 20 switching cycles / s

Response time ≤ 15ms (typically10ms)

Release time ≤ 5ms (typically2ms)

DC

DC13 (24VDC) I=2A

AC15 (230VAC) I=3A

250VAC/3A

24VDC/2A

NOTE

Allowed loads of the relay option

The potential-free contacts of the relay option (X4) may only be connected to resistive and inductive loads.

Capacitive loads are not permissible.

Load limit curve

Fig.3: Load limit curve, make contact

EK196022 Version: 1.3.1

Page 23

Operating lifetime for contact material AgNi

Product description

Fig.4: Operating lifetime of the AgNi NO contact for DC1, DC13, AC1 and AC15

Reduction factor for inductive loads

Fig.5: Reduction factor for inductive loads

EK1960 23Version: 1.3.1

Page 24

Product description

3.7 Safety parameters

In the following tables the safety parameters are shown separately for inputs, logic and outputs. The PFH

values for the inputs, logic and outputs used must be added together for the complete safety loop. The

Safety-over-EtherCAT communication is included in the logic part.

General parameters EK1960

Lifetime [a] 20

Prooftest Intervall [a] HFT 1

Classification element

2)

1. Special proof tests are not necessary during the entire lifetime of the EK1960 TwinSAFE compact controller on account of the high level of diagnostic coverage.

2. Classification according to IEC 61508-2:2010 (see chapters 7.4.4.1.2 and 7.4.4.1.3)

The EK1960 TwinSAFE compact controller can be used for safety-related applications within the meaning of

IEC62061:2005/A2:2015 up to SILCL3 and IEC 61508:2010 up to SIL 3 and ENISO13849-1:2015 up to

Cat. 4, PL e. (See following note for restrictions):

CAUTION

1)

Type B

EK1960 category and performance level restrictions

• The single-channel relay output is suitable up to Cat. 2, PL d

• The two-channel relay output (use of two relay contacts in series) is suitable up to Cat. 3, PL d or Cat. 4,

PL e, depending on the number of actuations. Cat. 4, PL e requires an actuation at least once per

month, Cat. 3, PL d at least once per year.

• The safe input for the safety mat operation mode is limited to Cat. 2, PL d.

Further information on calculating or estimating the MTTFD value from the PFHD value can be found in the

TwinSAFE application manual or in ENISO13849-1:2015, TableK.1.

Relay output safety parameters (Cat. 4 – two-channel)

The following table contains the safety parameters for the two-channel relay output. This must be added to

the logic and input value to determine the total PFH value.

One actuation of the relay per hour is assumed for the calculation.

Relay output parameters (Cat. 4 – two-channel) Value

PFH

D

PFD

G

MTTF

D

DC

avg

Performance Level PL e

Category 4

SIL 3

1.46E-09

1.48E-06

high

high

Relay output safety parameters (Cat. 2 – single-channel)

The following table contains the safety parameters for the single-channel relay output. This must be added to

the logic and input value to determine the total PFH value.

One actuation of the relay per hour is assumed for the calculation.

EK196024 Version: 1.3.1

Page 25

Product description

Relay output parameters (Cat. 2 – single-channel) Value

PFH

PFD

MTTF

DC

avg

D

G

D

7.25E-10

6.42E-05

high

high

Performance Level PLd

Category 2

SIL 2

B

relay option values

10D

Characteristic numbers EK1960-260x

B

value (DC1324 VDC and I

10D

B

value (AD15230 VAC and I

10D

B

value (AD15230 VAC and I

10D

≤2A) 1,500,000 [switching cycles]

max

≤1A) 750,000 [switching cycles]

max

≤3A) 300,000 [switching cycles]

max

Digital input safety parameters

The following table contains the safety parameters for the digital input of the EK1960. This must be added to

the logic and input value to determine the total PFH value.

Digital input parameters Value

PFH

PFD

MTTF

DC

avg

D

G

D

6.4E-11

6.1E-06

high

high

Performance Level PL e

Category 4

SIL 3

Safety mat input safety parameters

The following table contains the safety parameters for the analog input in the safety mat operation mode of

the EK1960. This must be added to the logic and input value to determine the total PFH value.

Safety mat input parameters Value

PFH

PFD

MTTF

DC

avg

D

G

D

8.84E-10

7.5E-05

high

medium

Performance Level PLd

Category 2

SIL 2

Logic safety parameters

The following table contains the safety parameters for the logic module of the EK1960. This must be added

to the input and output value to determine the total PFH value. The Safety-over-EtherCAT communication is

included in the logic part.

EK1960 25Version: 1.3.1

Page 26

Product description

Logic parameters Value

PFH

PFD

MTTF

DC

avg

D

G

D

5.18E-09

4.32E-05

high

high

Performance Level PL e

Category 4

SIL 3

Output safety parameters

The following table contains the safety parameters for the digital output of the EK1960. This must be added

to the input and logic value to determine the total PFH value.

Digital output parameters Value

PFH

PFD

MTTF

DC

avg

D

G

D

1.5E-10

2.62E-07

high

high

Performance Level PL e

Category 4

SIL 3

Examples of safety loops

Characteristic numbers Sample 1 Sample 2 Sample 3 Sample 4

Safety mat input PLd, Cat. 2 8.48E-10 8.48E-10 8.48E-10 8.48E-10

Digital input PLe, Cat. 4 6.4E-11 6.4E-11

Logic PLe, Cat. 4 5.18E-09 5.18E-09 5.18E-09 5.18E-09 5.18E-09

Digital output PLe, Cat. 4 1.5E-10 1.5E-10 1.5E-10

Relay output

PLe, Cat. 4 1.46E-09 1.46E-09

(Cat. 4)

Relay output

PLd, Cat. 2 7.25E-10 7.25E-10

(Cat. 2)

Overall result

PFHD/ Performance

6.18E-09

PLd, Cat.2

5.39E-09

PLe, Cat.4

7.49E-09

PLd, Cat.2

6.75E-09

PLd, Cat.2

Level / Category

3.8 Error response times

The error response times depend, among other things, on the logic program used and the settings of the

MultiplierDiagTestPulse and ModuloDiagTestPulse parameters.

An error reaction for the tests of the I/O signals is realized by a weighted counter, therefore the switch-off

does not occur immediately at the first error of the diagnostic tests.

The maximum error reaction time results from the duration of the longest lasting test, this is the RAM test

and this is several hours.

EK196026 Version: 1.3.1

Page 27

Product description

3.9 Characteristic curve of the inputs

The characteristic curve of the inputs of the EK1960 is similar to type 3 according to EN 61131-2.

Fig.6: EK1960 input characteristic curve

3.10 Test pulses for the outputs

The output signals of each module of the EK1960 can be determined via the parameter Diag TestPulse

Active. The test pulses generated have a length of 400 µs, which is multiplied by the factor

MultiplierDiagTestPulse. This factor should be set to at least 2 for outputs with no load or only a small load,

so that a test pulse length of 800 µs results. The frequency of the test pulses results from the processing of

the input and output modules and the cycle time of the internal logic. For example, if the logic has a cycle

time of 2 ms and a ModuloDiagTestpulse of 0, a typical time b results in accordance with the following

calculation.

For each output module the resulting time is:

module time = (4 cycles feedback test + (4 cycles diagnostic test *(ModuloDiagTestPulse + 1))) *internal

cycle time*1.25* 4 outputs = (4 + (4 * 1)) * 2ms * 1.25 * 4 = 80ms

For the relay module the resulting time is:

Relay module time = 100 * internal cycle time * 1.25

The input modules each require one cycle. This results in a total time b of:

b=6 x module time + 1x relay module time + 10 x internal cycle timex1.25 (for the input modules)

Inserting the values, this produces:

b= (6 * 80ms) + (100 * 2ms * 1.25) + (10 * 2ms * 1.25) = 480ms + 250ms + 25ms = 755ms

The test pulse sequence is shown in the following table, where the time b typically elapses between a

channel test and a module switch test. The tests start over once they have been performed for all four

channels.

If the parameter Diag TestPulse for Inputs active is set in addition, all outputs of the module are switched on

and the test pulses shown here are similarly applied to the individual output channels. These signals can

then be used as clocked signals for the safe inputs. The module switch test is not performed in this operation

mode; instead, the four channels are tested directly in succession, leading to the time interval b between the

tests of the individual channels.

EK1960 27Version: 1.3.1

Page 28

Product description

Test Time until next test

Channel 1 (only channel 1 is tested) b

Module switch (all four channels are tested) b

Channel 2 (only channel 2 is tested) b

Module switch (all four channels are tested) b

Channel 3 (only channel 3 is tested) b

Module switch (all four channels are tested) b

Channel 4 (only channel 4 is tested) b

Module switch (all four channels are tested) b (next test channel 1)

NOTE

Length of the test pulses

When setting the test pulses, make sure that the connected actuator is not switched due to the test pulse

length.

The output signal must be 0 V for at least 200 µs within a test pulse. This is independent of the setting of

the parameter MultiplierDiagTestPulse.

Minimum load

The test pulse length of the outputs is set by default to 2 x 400 µs. This setting is suitable for typical

actuators with and without a protective circuit. The test pulse length can typically be reduced to 400

µs with a resistive load and a current of at least 30 mA.

Please observe the violation counter in the diagnostic history. If messages are displayed for the corresponding output module, this means that the setting of the test pulse length is borderline and may

need to be increased.

For electronic contactors that tend towards a capacitive behavior, it may be necessary to set the parameter MultiplierDiagTestPulse to 3 or higher.

EK196028 Version: 1.3.1

Page 29

Product description

3.11 Load characteristic curve – inductive load

If an external freewheeling diode is not used for inductive loads, the permissible maximum load can be taken

from the following characteristic curve.

Fig.7: Characteristic curve - inductive load

EK1960 29Version: 1.3.1

Page 30

Product description

3.12 Block diagram of the EK1960

The following block diagram shows the basic structure of the EK1960. The sub-modules shown exist several

times according to the information on the sub-modules.

Fig.8: Block diagram EK1960

EK196030 Version: 1.3.1

Page 31

Product description

3.13 Address setting of the TwinSAFE compact controller

Fig.9: Address selection switch of the EK1960

The TwinSAFE address of the controller must be set with the three rotary switches on the housing of the

EK1960 TwinSAFE controller. TwinSAFE addresses between 1 and 4095 are available.

Rotary switch Address

1 (top) 2 (center) 3 (bottom)

0 0 1 1

0 0 2 2

0 0 3 3

… … … …

0 0 F 15

0 1 0 16

0 1 1 17

… … … …

0 F F 255

1 0 0 256

1 0 1 257

… … … …

F F F 4095

WARNING

TwinSAFE address

Each TwinSAFE address must be unique within a network!

The address 0 is not a valid address.

EK1960 31Version: 1.3.1

Page 32

Product description

3.14 Dimensions

Fig.10: EK1960 dimensions

Width: 230.5mm

Height: 100mm

Depth: 58.6mm

3.15 Wiring examples

3.15.1 Inputs and outputs

Examples of the wiring of the individual connections of the EK1960 are shown in the following.

Power supply X3

The X3 connection is for the supply of power to the EK1960. The internal logic and the E-bus connection are

supplied via US, while UP supplies the relays and the safe inputs (safety mat operation mode). The GND

connections are internally bridged.

Fig.11: Power supply X3

EK196032 Version: 1.3.1

Page 33

Product description

Potential-free relay contacts C4 (EK1960-260x)

The relay contacts (four relays each with one make contact) are fed out to the X4 connection. The area

surrounded by the dotted line shows the make contacts of the individual relays.

Fig.12: Relay contact X4 (EK1960-260x only)

Digital outputs X5, X7 and X9

Connection X5, X7 and X9 must be supplied with 24VDC on contacts 5 and 10. These each supply four

outputs. The connected actuator is not fed back to the EK1960; instead it is wired directly to GND.

Fig.13: Digital outputs X5, X7 and X9

EK1960 33Version: 1.3.1

Page 34

Product description

Digital inputs X6, X8

The digital inputs are supplied with 24VDC signals. In the default setting, static or clocked signals are

supported. Safe outputs of the EK1960 can also be selected as the clock signal source.

Fig.14: Digital inputs X6 and X8

EK196034 Version: 1.3.1

Page 35

Product description

Safety mat connection example

Inputs 8.7 to 8.10 on connection X8 of the EK1960 can be configured for a safety mat operation mode. Only

safety mats operating according to the resistance-change principle may be used. Only 8K2 (8.2 kΩ)

termination resistors are supported.

CAUTION

Safety mat wiring

The ground connection of the safety mat used must be fed back to the EK1960 in accordance with the following diagram.

Fig.15: Safety mat wiring

EK1960 35Version: 1.3.1

Page 36

Product description

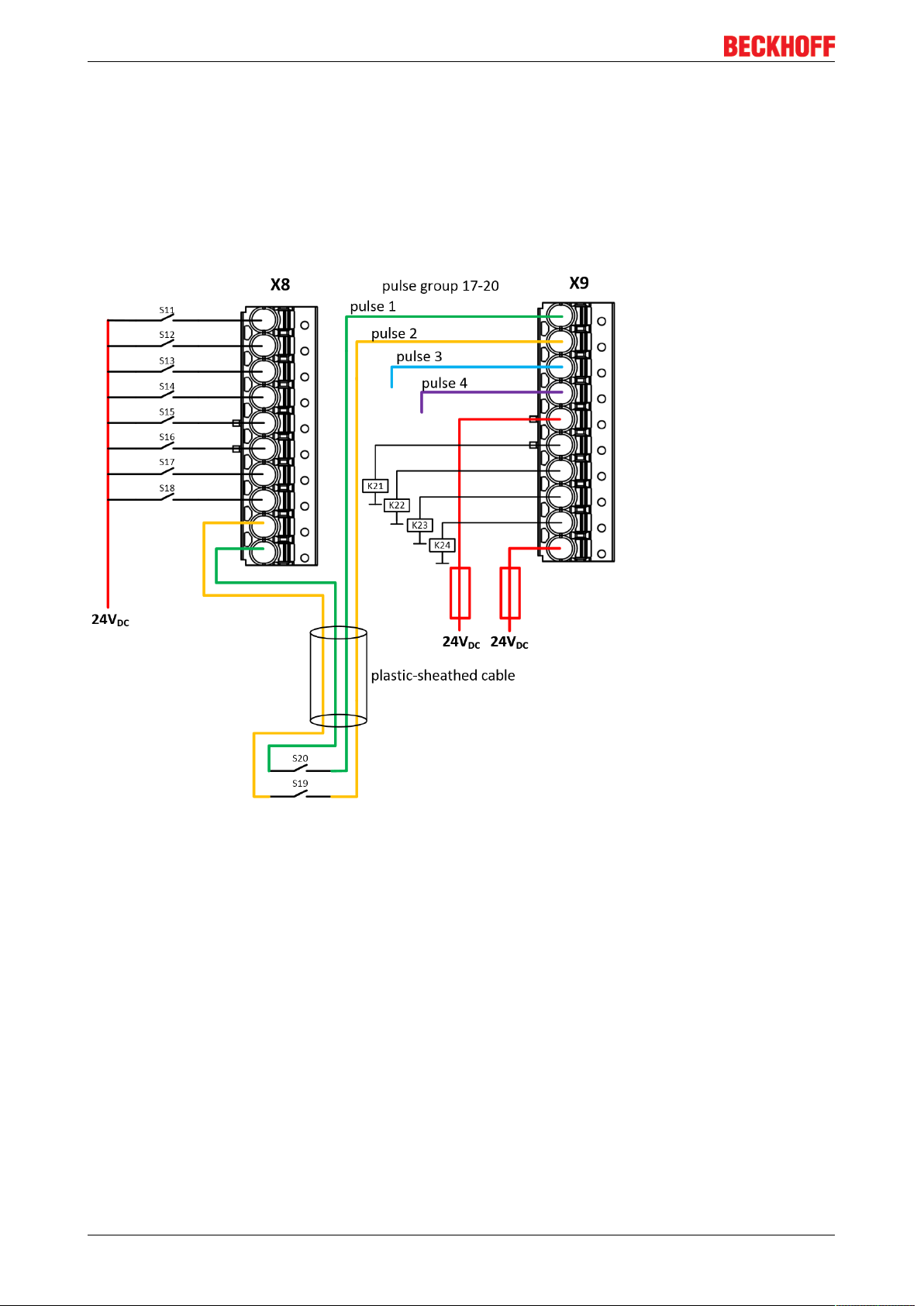

3.15.2 Clocked signals

All output groups (four outputs each) can be configured as clock outputs. The test pulses of the groups can

be set accordingly via parameters.

If a sensor such as a key switch (represented here by S19 and S20) is two-channel wired within one single

non-metallic sheathed cable, the two channels must be fed from different clock sources. This makes it

possible to detect cross-circuits or external power supplies within the common non-metallic sheathed cable

and to achieve a high level of diagnostic coverage.

Fig.16: Wiring example – clock outputs to inputs

EK196036 Version: 1.3.1

Page 37

Operation

4 Operation

4.1 Environmental conditions

Please ensure that the TwinSAFE components are only transported, stored and operated under the specified

conditions (see technical data)!

WARNING

Risk of injury!

The TwinSAFE components must not be used under the following operating conditions.

• under the influence of ionizing radiation (that exceeds the level of the natural environmental radiation)

• in corrosive environments

• in an environment that leads to unacceptable soiling of the TwinSAFE component

NOTE

Electromagnetic compatibility

The TwinSAFE components comply with the current standards on electromagnetic compatibility with regard

to spurious radiation and immunity to interference in particular.

However, in cases where devices such as mobile phones, radio equipment, transmitters or high-frequency

systems that exceed the interference emissions limits specified in the standards are operated near TwinSAFE components, the function of the TwinSAFE components may be impaired.

4.2 Installation

4.2.1 Safety instructions

Before installing and commissioning the TwinSAFE components please read the safety instructions in the

foreword of this documentation.

4.2.2 Transport / storage

Use the original packaging in which the components were delivered for transporting and storing the

TwinSAFE components.

CAUTION

Note the specified environmental conditions

Please ensure that the digital TwinSAFE components are only transported and stored under the specified

environmental conditions (see technical data).

4.2.3 Mechanical installation

4.2.3.1 De-energized condition

DANGER

Serious risk of injury!

Bring the bus system and the controller into a safe, de-energized state before installing, disassembling or

wiring of the controller!

EK1960 37Version: 1.3.1

Page 38

Operation

4.2.3.2 Control cabinet / terminal box

For operation, the TwinSAFE compact controller must be installed in a control cabinet or terminal box with

IP54 protection class according to IEC60529 as a minimum.

4.2.3.3 Installation position and minimum distances

For the prescribed installation position the mounting rail is installed horizontally and the mating surfaces of

the TwinSAFE compact controller point towards the front (see illustration below). The controller is ventilated

from below, which enables optimum cooling of the electronics through convection. The direction indication

“down” corresponds to the direction of positive acceleration due to gravity.

Fig.17: Installation position and minimum distances

In order to ensure optimum convection cooling, the distances to neighboring devices and to control cabinet

walls must not be smaller than those shown in the diagram.

4.2.3.4 Installation on mounting rails

The EK1960 is mounted on a DIN rail by inserting the device onto the DIN rail and then pressing it down

onto the rail as shown in the diagram below. In the case of flat DIN rails it may be better to position the

controller to the DIN rail from below and to snap it upwards onto the rail.

EK196038 Version: 1.3.1

Page 39

Operation

Fig.18: Mounting the EK1960 on the DIN rail

The EK1960 is released from the DIN rail by opening the two clamps on top of or underneath the device. To

do this, insert a screwdriver into the recess provided and open the clamp until it latches.

Fig.19: DIN rail clamp closed

Once the two upper or lower clamps are unlocked, the device can be taken off the DIN rail in an upward or

downward direction.

Fig.20: DIN rail clamp opened

EK1960 39Version: 1.3.1

Page 40

Operation

4.2.4 Electrical installation

4.2.4.1 Overvoltage protection

If protection against overvoltage is necessary in your system, provide an overvoltage protective circuit (surge

filter) for the power supply to the TwinSAFE compact controller.

4.2.4.2 Wiring

The connectors support the push-in wiring of individual wires and fine-wire conductors with wire-end sleeves.

In the case of multi-wire and fine-wire conductors, the latch must be depressed to connect the conductor with

the contact point.

Depress the latch with a screwdriver, insert the conductor and release the latch.

Fig.21: ZS2003-0002 Depressing the latch

EK196040 Version: 1.3.1

Page 41

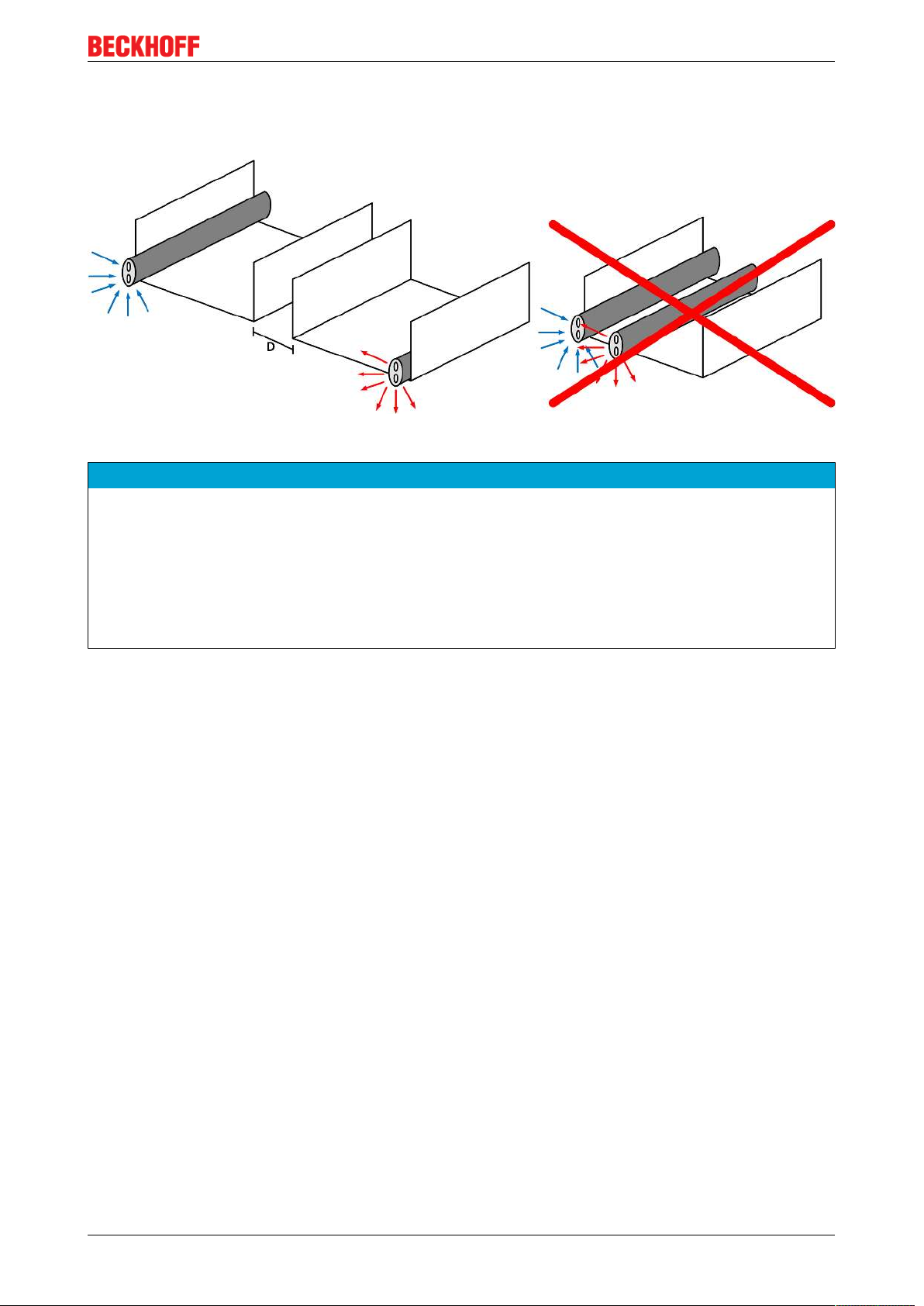

4.2.4.3 Signal cables

Cable routing

Fig.22: Cable routing

Operation

NOTE

Route the signal cable separately

The signal cable must be routed separately from potential sources of interference, such as motor supply cables, 230 VAC power cables etc.!

Interference caused by cables routed in parallel can influence the signal form of the test pulses and thus

cause diagnostic messages (e.g. sensor errors or OpenLoad errors).

D: Distance between the cable ducts should be as large as possible

blue arrows: signal line

red arrows: potential source of interference

The common routing of signals together with other clocked signals in a common cable also reduces the

maximum propagation, since crosstalk of the signals can occur over long cable lengths and cause diagnostic

messages.

EK1960 41Version: 1.3.1

Page 42

Operation

4.3 Configuration of the controller in TwinCAT

CAUTION

Do not change CoE objects!

Do not make modifications to the CoE objects of the TwinSAFE compact controller. Any modifications of

the CoE objects (e.g. via TwinCAT 3) will permanently set the controller to the Fail-Stop state or lead to unexpected behavior of the controller!

4.3.1 Configuration requirements

Version 3.1 build 4020 or higher of the TwinCAT automation software is required for configuring the EL6910.

The current version is available for download from the Beckhoff website (www.beckhoff.de).

TwinCAT support

The EK1960 cannot be used under TwinCAT 2

4.3.2 Insertion of a controller

An EK1960 is inserted in exactly the same way as any other Beckhoff EtherCAT device. In the list, open

Safety Terminals and select the EK1960.

Fig.23: Inserting an EK1960

EK196042 Version: 1.3.1

Page 43

Operation

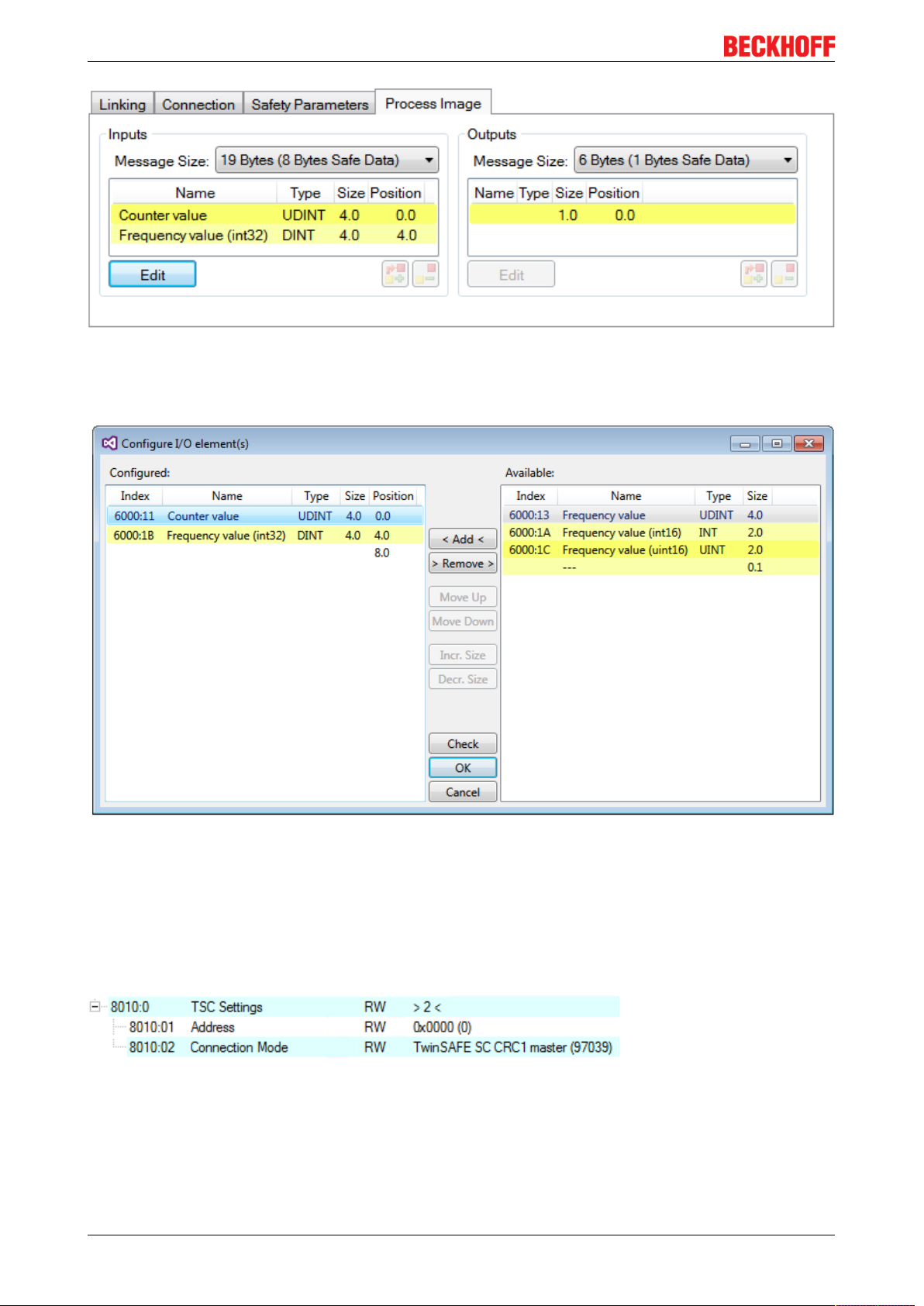

Size of the process image

The process image of the EL6910 is adjusted dynamically, based on the TwinSAFE configuration

created in TwinCAT 3.

4.3.3 Creating a safety project in TwinCAT3

Further documentation

Information regarding the TwinSAFE-blocks, -groups and -connections can be found in the TwinSAFE-Logik-FB Documentation available on the Beckhoff website under

http://www.beckhoff.de/german/download/twinsafe.htm.

4.3.3.1 Add new item

In TwinCAT 3 a new project can be created via AddNewItem… in the context menu of the Safety node.

Fig.24: Creating a safety project - Add New Item

The project name and the directory can be freely selected.

Fig.25: Creating a safety project - project name and directory

EK1960 43Version: 1.3.1

Page 44

Operation

4.3.3.2 TwinCAT Safety Project Wizard

In the TwinCATSafetyProject wizard you can then select the target system, the programming language, the

author and the internal project name. Select the setting HardwareSafetyPLC as the target system and the

graphical editor as the programming language. The author and the internal project name can be freely

selected by the user.

Fig.26: TwinCAT Safety Project Wizard

4.3.3.3 Target System

After creating the project with the Project Wizard, the safety project can be assigned to the physical EK1960

TwinSAFE controller by selecting the Target System node.

Fig.27: Selecting the Target System node

The target system is set to EK1960 via the drop-down list and linked with the EK1960 controller via the link

button next to Physical Device. If online ADS access to the controller is possible, the software version,

serial number, online project CRC and rotary switch address are automatically read from the controller. The

rotary switch address must correspond to the Safe Address set by the user.

EK196044 Version: 1.3.1

Page 45

Operation

Fig.28: Linking of target system and TwinSAFE compact controller

4.3.3.4 Alias devices

The communication between the safety logic and the I/O level is realized via an alias level. At this alias level

(subnode Alias Devices) corresponding alias devices are created for all safe inputs and outputs, and also for

standard signal types. For the safe inputs and outputs, this can be done automatically via the I/O

configuration.

The connection- and device-specific parameters are set via the alias devices.

Fig.29: Starting the automatic import from the I/O configuration

If the automatic import is started from the I/O configuration, a selection dialog opens, in which the individual

terminals to be imported can be selected.

EK1960 45Version: 1.3.1

Page 46

Operation

Fig.30: Selection from the I/O tree

The alias devices are created in the safety project when the dialog is closed via OK.

Alternatively, the user can create the alias devices individually. To this end select Add and New item from

the context menu, followed by the required device.

Fig.31: Creating alias devices by the user

EK196046 Version: 1.3.1

Page 47

Operation

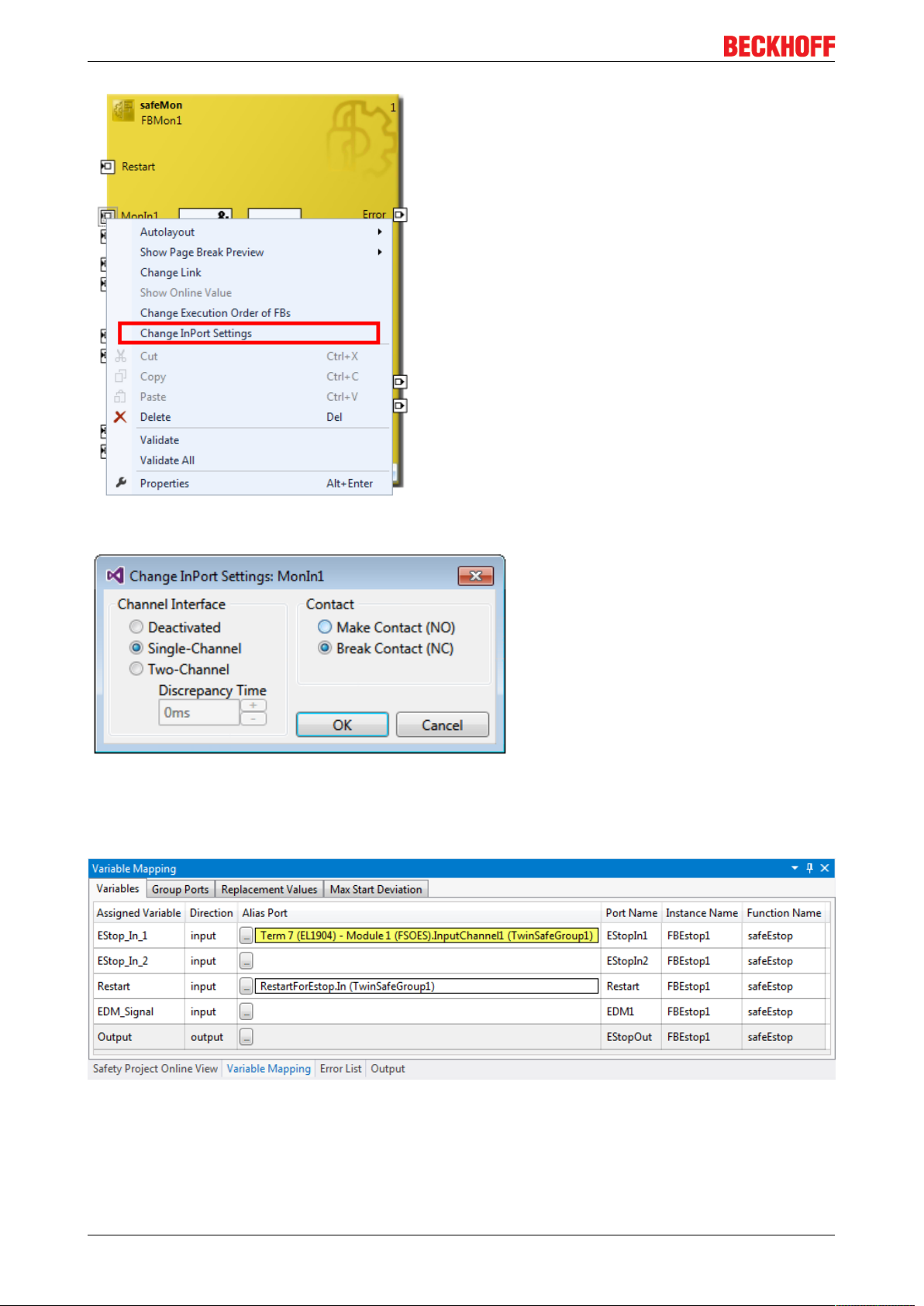

4.3.3.5 Parameterization of the alias device

The settings can be opened by double-clicking on the Alias Device in the safety project structure.

Fig.32: Alias Device in the safety project structure

The Linking tab contains the FSoE address, the checkbox for setting as External Device and the link to the

physical I/O device. If an ADS online connection to the physical I/O device exists, the DIP switch setting is

displayed. Re-reading of the setting can be started via the button . The links to the EL6910/EJ6910

process image are displayed under Full Name (input) and Full Name (output).

Fig.33: Links to EL6910/EJ6910 process image

The Connection tab shows the connection-specific parameters.

Fig.34: Connection-specific parameters

EK1960 47Version: 1.3.1

Page 48

Operation

Parameter Description User inter-

action required

Conn. no. Connection number - automatically assigned by the TwinCAT system No

Conn ID Connection ID: preallocated by the system, but can be changed by the user. A

Conn ID must be unique within a configuration. Duplicate connection IDs result in

an error message.

Mode FSoE master: EL6910/EJ6910 is FSoE master for this device.

FSoE slave: EL6910/EJ6910 is FSoE slave for this device.

Watchdog Watchdog time for this connection. A ComError is generated if the device fails to

return a valid telegram to the EL6910/EJ6910 within the watchdog time.

Module

Fault is

ComError

ComErrAck If ComErrAck is linked to a variable, the connection must be reset via this signal in

Info data The info data to be shown in the process image of the EL6910/EJ6910 can be

This checkbox is used to specify the behavior in the event of an error. If the

checkbox is ticked and a module error occurs on the Alias Device, this also leads

to a connection error and therefore to disabling of the TwinSAFE group, in which

this connection is defined.

the event of a communication error.

defined via these checkboxes. Further information can be found in the

documentation for TwinCAT function blocks for TwinSAFE Logic terminals.

Check

Check

Yes

Yes

Yes

Yes

The EL6910/EJ6910 support activation of a ComErrAck at each connection. If this signal is connected, the

respective connection must be reset after a communication error via the signal ComErrAck, in addition to the

ErrAck of the TwinSAFE group. This signal is linked via the link button next to COM ERR Ack. The

following dialog can be used for selecting an alias device. The signal can be cancelled via the Clear button in

the Map to dialog.

Fig.35: Selecting an alias device

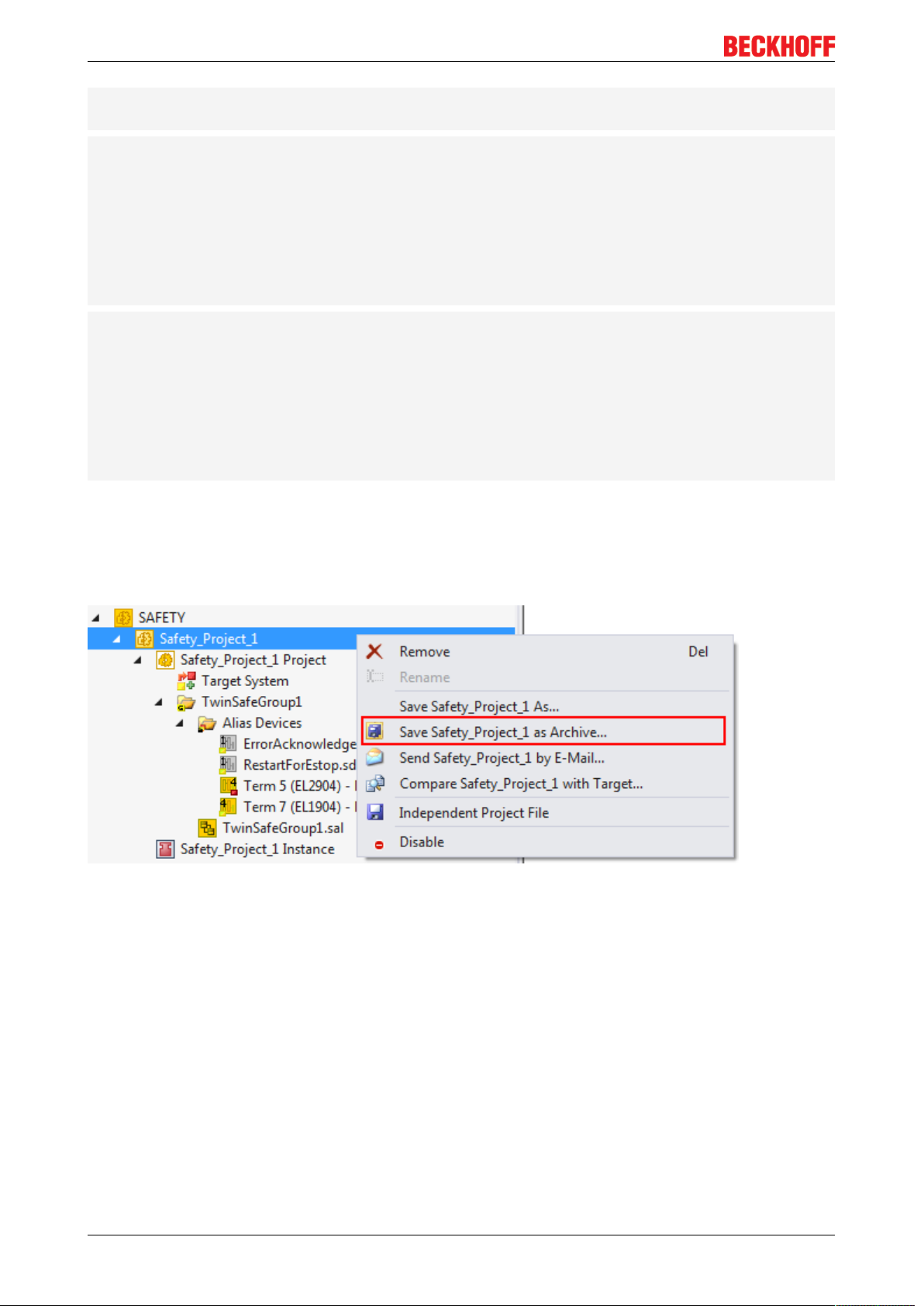

The safety parameters matching the device are displayed under the Safety Parameters tab. They have to be

set correctly to match the required performance level. Further information can be found in the TwinSAFE

application manual.

EK196048 Version: 1.3.1

Page 49

Fig.36: Safety parameter for the device

4.3.3.6 Connection to AX5805/AX5806

Operation

There are separate dialogs for linking an AX5805 or AX5806 TwinSAFE Drive option card, which can be

used to set the safety functions of the AX5000 safety drive options.

Creating and opening of an alias device for an AX5805 results in five tabs; the Linking, Connection and

Safety Parameters tabs are identical to other alias devices.

Fig.37: AX5000 safety drive functions

The General AX5805 Settings tab can be used to set the motor string and the SMS and SMA functions for

one or two axes, depending on the added alias device.

EK1960 49Version: 1.3.1

Page 50

Operation

Fig.38: AX5000 safety drive options - general AX5805 settings

The Process Image tab can be used to set the different safety functions for the AX5805.

Fig.39: AX5000 safety drive options - Process Image

The parameters under the General AX5805 Settings and Process Image tabs are identical to the parameters

under the Safety Parameters tab. Offers user-friendly display and editing of the parameters. The parameters

under the Safety Parameters tab can also be edited.

The parameters for this function can be set by selecting a function in the inputs or outputs and pressing the

Edit button. New safety functions can be added in the process image by selecting an empty field (---) and

pressing Edit.

The parameter list corresponding to the safety function can be shown; in addition, an optional diagram of the

function can be shown. At present the diagram is still static and does not show the currently selected values.

EK196050 Version: 1.3.1

Page 51

Operation

Fig.40: AX5000 safety drive options - Function Diagram

4.3.3.7 External connection

An external Custom FSoE Connection can be created for a connection to a further EL69x0, EJ6910, KL6904

or third-party device. If a dedicated ESI file exists for a third-party device, the device is listed as a selectable

safety device, and the Custom FSoE Connection option is not required.

EK1960 51Version: 1.3.1

Page 52

Operation

Fig.41: Creating an external connection (Custom FSoE Connection)

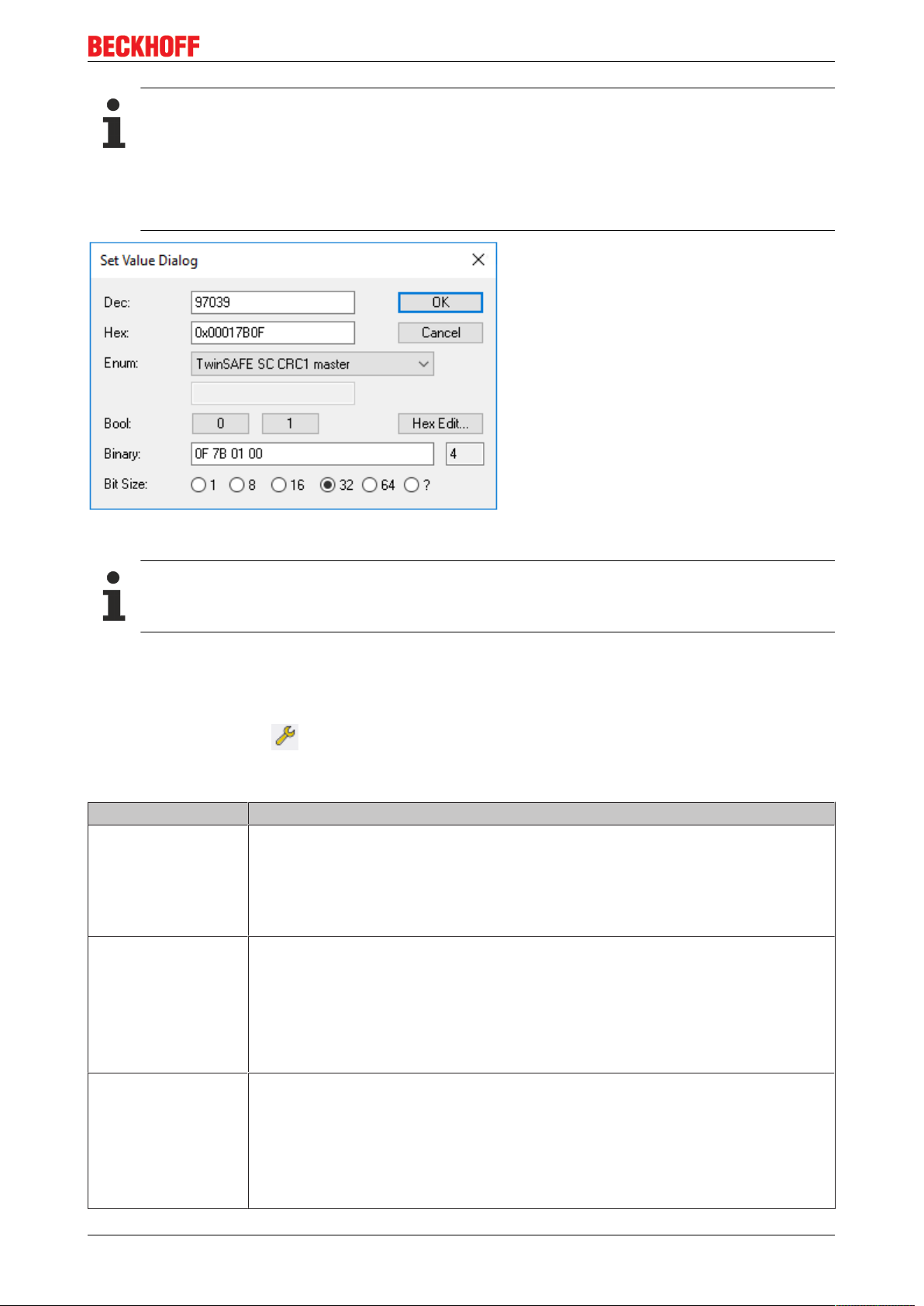

Before the connection can be used and linked further, the process image size must be parameterized. This

can be set under the Process Image tab. Suitable data types for different numbers of safety data are

provided in the dropdown lists for the input and output parameters.

Fig.42: Parameterization of the process image size

Once the size is selected, the individual signals within the telegram can be renamed, so that a corresponding

plain text is displayed when these signals are used in the logic. If the signals are not renamed, the default

name is displayed in the editor (Safe Data Byte 0[0], …).

EK196052 Version: 1.3.1

Page 53

Operation

Fig.43: Renaming the individual signals within the telegram

The connection is linked under the Linking tab. The Link button next to Full Name (input) and Full

Name (output) can be used to select the corresponding variable.

Fig.44: Selecting the variables

This can be a PLC variable, for example, which is then forwarded to the remote device or can be linked

directly with the process image of an EtherCAT Terminal (e.g. EL69x0 or EL6695).

EK1960 53Version: 1.3.1

Page 54

Operation

Fig.45: Direct linking with the process image of an EtherCAT Terminal

Further information can be found in the TwinCAT documentation for the variable selection dialog.

The Connection tab is used to set the connection-specific parameters.

Fig.46: Connection-specific parameters

EK196054 Version: 1.3.1

Page 55

Operation

Detailed information about the individual settings can be found in the following table.

Parameter Description User inter-

action required

Conn. no. Connection number: is automatically assigned by the TwinCAT system No

Conn ID Connection ID: preallocated by the system, but can be changed by the user. A

Conn ID must be unique within a configuration. Duplicate connection IDs result in

an error message

Mode FSoE master: EL6910/EJ6910 is FSoE master for this device.

FSoE slave: EL6910/EJ6910 is FSoE slave for this device.

Type None: Setting for third-party equipment, for which no ESI file is available.