Page 1

Documentation

EK110x, EK15xx

EtherCAT Bus Coupler

3.6

2017-10-05

Version:

Date:

Page 2

Page 3

Table of contents

EK110x, EK15xx 3Version: 3.6

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Overview EtherCAT Coupler .......................................................................................................... 5

1.2 Notes on the documentation........................................................................................................... 6

1.3 Safety instructions .......................................................................................................................... 7

1.4 Documentation issue status............................................................................................................ 8

1.5 Version identification of EtherCAT devices..................................................................................... 8

2 Product overview.....................................................................................................................................13

2.1 Overview of EtherCAT couplers ................................................................................................... 13

2.2 Coupler with RJ45 connection ...................................................................................................... 15

2.2.1 EK1100 ............................................................................................................................15

2.2.2 EK1101, EK1101-xxxx .....................................................................................................17

2.3 Coupler with M8 connection ......................................................................................................... 22

2.3.1 EK1100-0008 ...................................................................................................................22

2.4 Coupler with optical fiber connection ............................................................................................ 25

2.4.1 EK1501 ............................................................................................................................25

2.4.2 EK1501-0010 ...................................................................................................................27

2.5 Coupler with POF connection ....................................................................................................... 29

2.5.1 EK1541 ............................................................................................................................29

3 Basics .......................................................................................................................................................31

3.1 EtherCAT basics........................................................................................................................... 31

3.2 EtherCAT coupler port allocation.................................................................................................. 31

3.3 EtherCAT State Machine .............................................................................................................. 33

3.4 CoE - Interface: notes................................................................................................................... 34

3.5 EKxxxx - Optional Distributed Clocks support .............................................................................. 34

4 Mounting and wiring ...............................................................................................................................37

4.1 Instructions for ESD protection ..................................................................................................... 37

4.2 Installation on mounting rails ........................................................................................................ 37

4.3 Installation instructions for enhanced mechanical load capacity .................................................. 40

4.4 Installation positions ..................................................................................................................... 42

4.5 Connection system ....................................................................................................................... 43

4.6 Wiring............................................................................................................................................ 45

4.7 EtherCAT cabling – wire-bound.................................................................................................... 46

4.8 M8 Connector Cabling .................................................................................................................. 47

4.9 Nut torque for connectors ............................................................................................................. 49

4.10 Power supply, potential groups..................................................................................................... 50

4.11 Mounting of Passive Terminals..................................................................................................... 52

4.12 UL notice....................................................................................................................................... 52

4.13 ATEX - Special conditions (extended temperature range) ........................................................... 54

4.14 ATEX Documentation ................................................................................................................... 55

5 Commissioning/application notes .........................................................................................................56

5.1 Configuration overview ................................................................................................................. 56

5.2 Application notes .......................................................................................................................... 56

5.2.1 Optical fiber application notes..........................................................................................56

5.2.2 POF application notes......................................................................................................59

5.2.3 Notes regarding assembly of POF cables with the connector set ZS1090-0008.............62

Page 4

Table of contents

EK110x, EK15xx4 Version: 3.6

6 Error handling and diagnostics .............................................................................................................66

6.1 Diagnostic LEDs ........................................................................................................................... 66

7 Appendix ..................................................................................................................................................71

7.1 Safety instructions and behavioral rules for Class 1 laser ............................................................ 71

7.2 EtherCAT AL Status Codes .......................................................................................................... 71

7.3 Firmware compatibility .................................................................................................................. 71

7.4 Firmware Update EL/ES/EM/EPxxxx............................................................................................ 71

7.4.1 Device description ESI file/XML.......................................................................................72

7.4.2 Firmware explanation.......................................................................................................75

7.4.3 Updating controller firmware *.efw ...................................................................................76

7.4.4 FPGA firmware *.rbf.........................................................................................................78

7.4.5 Simultaneous updating of several EtherCAT devices......................................................82

7.5 Support and Service ..................................................................................................................... 83

Page 5

Foreword

EK110x, EK15xx 5Version: 3.6

1 Foreword

1.1 Overview EtherCAT Coupler

Connection RJ45

EK1100 [}15] - EtherCAT Bus Coupler

EK1101 [}17] - EtherCAT Bus Coupler with ID switch, Hot-Connect

EK1101-0080 [}18] - EtherCAT Bus Coupler with ID switch, Fast-Hot-Connect

Connection M8

EK1100-0008 [}22] - EtherCAT Bus Coupler

Connection Fiber optic

EK1501 [}25] - EtherCAT Bus Coupler with ID switch (Fiber Optic, Multimode)

EK1501-0010 [}27] - EtherCAT Bus Coupler with ID switch (Fiber Optic, Singlemode)

Connection Polymeric Optical Fiber

EK1541 [}29] - EtherCAT Bus Coupler with ID switch (Polymeric Optical Fiber)

Page 6

Foreword

EK110x, EK15xx6 Version: 3.6

1.2 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

Page 7

Foreword

EK110x, EK15xx 7Version: 3.6

1.3 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Attention

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Note

Tip or pointer

This symbol indicates information that contributes to better understanding.

Page 8

Foreword

EK110x, EK15xx8 Version: 3.6

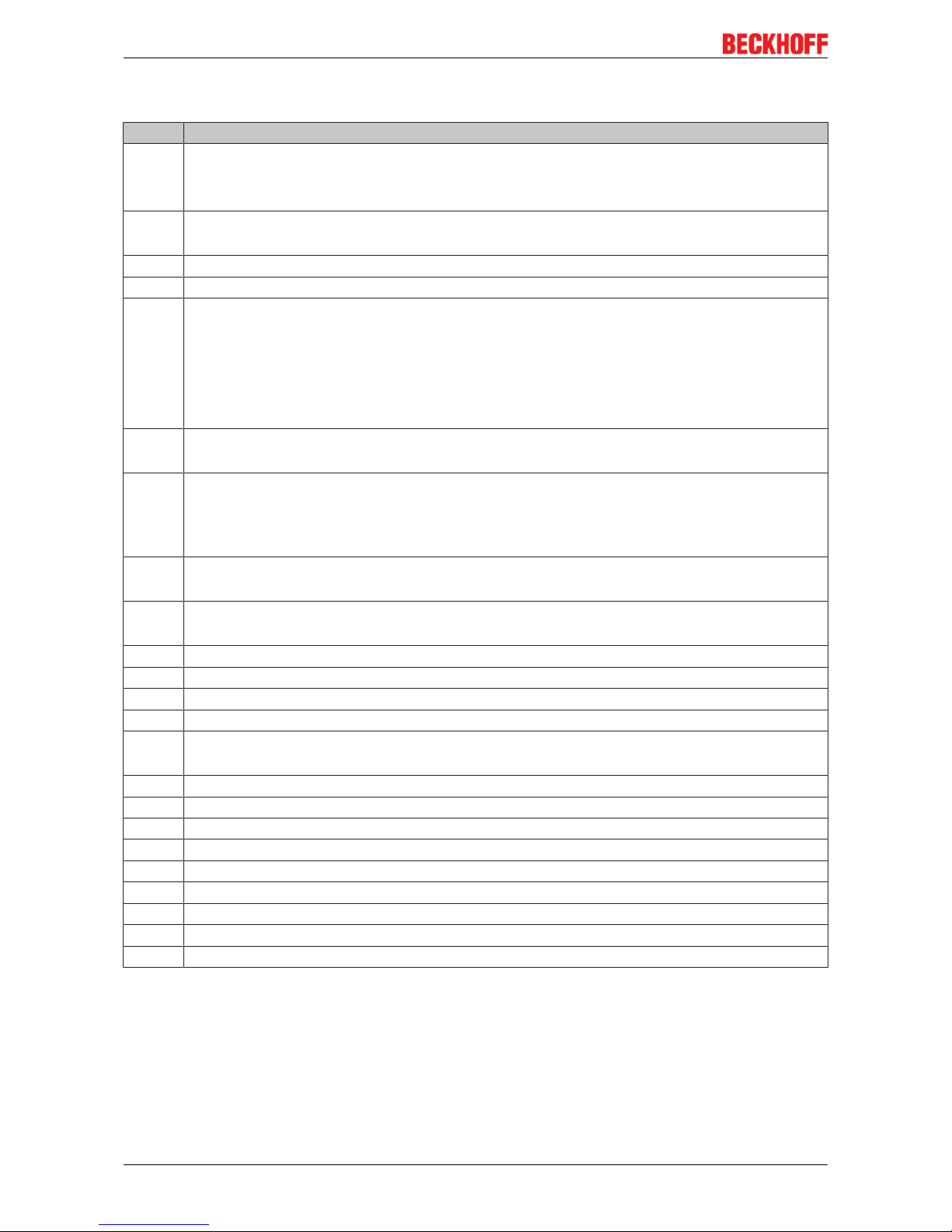

1.4 Documentation issue status

Version Modifications

3.6 • Update structure

• Update chapter "Technical data"

• Update chapter "Firmware Update EL/ES/EM/EPxxxx"

3.5 • Correction of LED description

• Update structure

3.4 • Update chapter "Mounting and wiring"

3.3 • Update chapter "Technical data"

3.2 • Update chapter "Notes on the documentation"

• Update chapter "Technical data"

• Addenda chapter "Instructions for ESD protection"

• Chapter "ATEX - Special conditions" replaced with chapter "ATEX - Special conditions

(extended temperature range)"

• Addenda chapter "ATEX - Documentation "

3.1 • Update chapter “Introduction”

• Update structure

3.0 • Migration

• Addenda of EK1100-0008 (EtherCAT coupler, with M8 sockets)

• Chapter “EtherCAT cabling – wire-bound” moved from chapter “Commissioning/application

notes” to chapter “Mounting and wiring”

2.3 • Update chapter "Technical data"

• Addenda chapter "Installation instructions for enhanced mechanical load capacity"

2.2 • Update chapter "Technical data"

• Update chapter "Power Supply, Potential Groups"

2.1 • Update Technical data

2.0 • Update structure

1.9 • Update connection diagram

1.8 • Addenda EK1101-0080

1.7 • Update Power Supply, Potential Groups

• Notes re. POF coupler added

1.6 • EK1541 added

1.5 • Addenda DC support

1.4 • GND concept added

1.3 • EK1101, EK1501, EK1501-0010 added

1.2 • New safety instructions added, corrections

1.1 • Port assignment added

1.0 • Technical data added

0.2 • Minor corrections

0.1 • First preliminary version

1.5 Version identification of EtherCAT devices

Designation

A Beckhoff EtherCAT device has a 14-digit designation, made up of

• family key

• type

Page 9

Foreword

EK110x, EK15xx 9Version: 3.6

• version

• revision

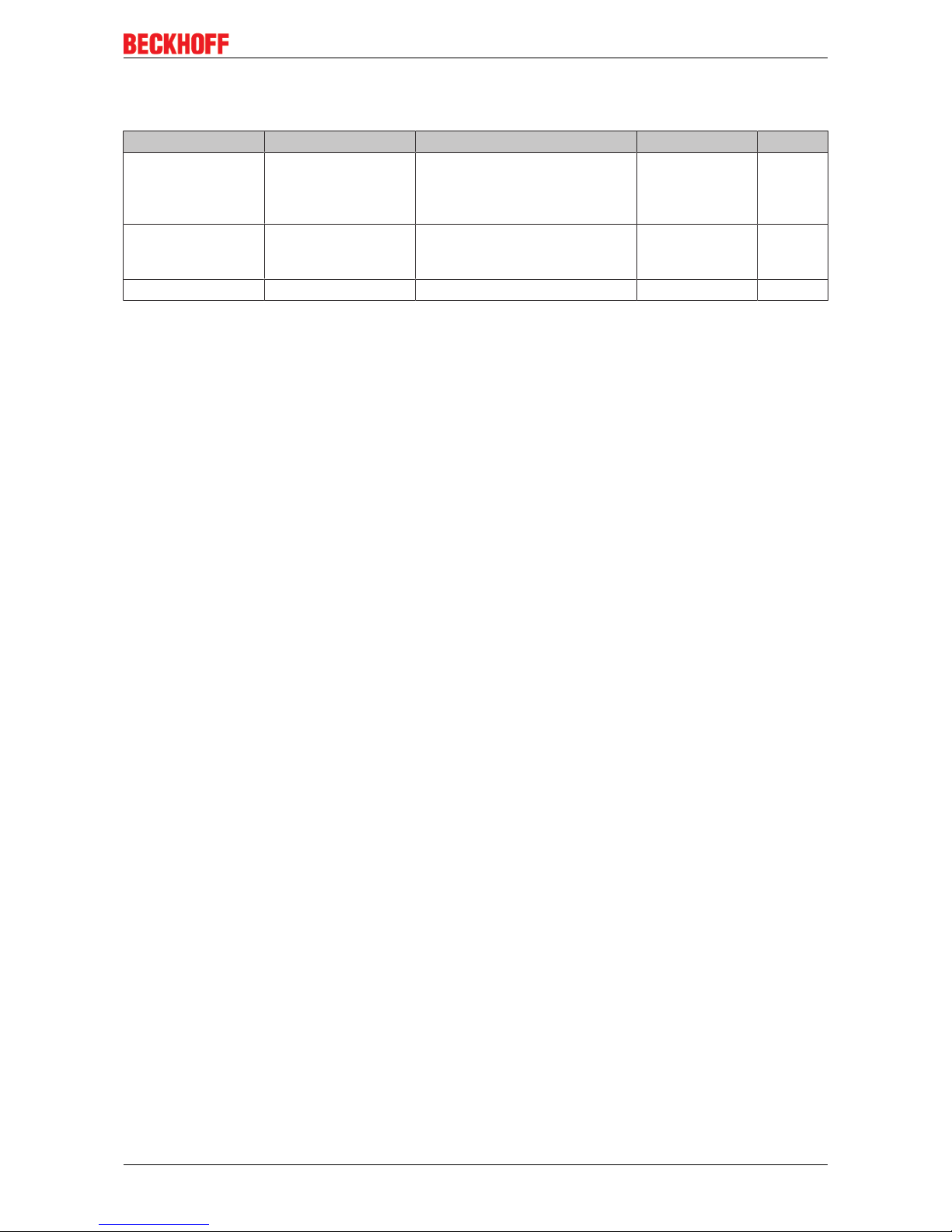

Example Family Type Version Revision

EL3314-0000-0016 EL terminal

(12 mm, nonpluggable connection

level)

3314 (4-channel thermocouple

terminal)

0000 (basic type) 0016

ES3602-0010-0017 ES terminal

(12 mm, pluggable

connection level)

3602 (2-channel voltage

measurement)

0010 (highprecision version)

0017

CU2008-0000-0000 CU device 2008 (8-port fast ethernet switch) 0000 (basic type) 0000

Notes

• The elements mentioned above result in the technical designation. EL3314-0000-0016 is used in the

example below.

• EL3314-0000 is the order identifier, in the case of “-0000” usually abbreviated to EL3314. “-0016” is the

EtherCAT revision.

• The order identifier is made up of

- family key (EL, EP, CU, ES, KL, CX, etc.)

- type (3314)

- version (-0000)

• The revision -0016 shows the technical progress, such as the extension of features with regard to the

EtherCAT communication, and is managed by Beckhoff.

In principle, a device with a higher revision can replace a device with a lower revision, unless specified

otherwise, e.g. in the documentation.

Associated and synonymous with each revision there is usually a description (ESI, EtherCAT Slave

Information) in the form of an XML file, which is available for download from the Beckhoff web site.

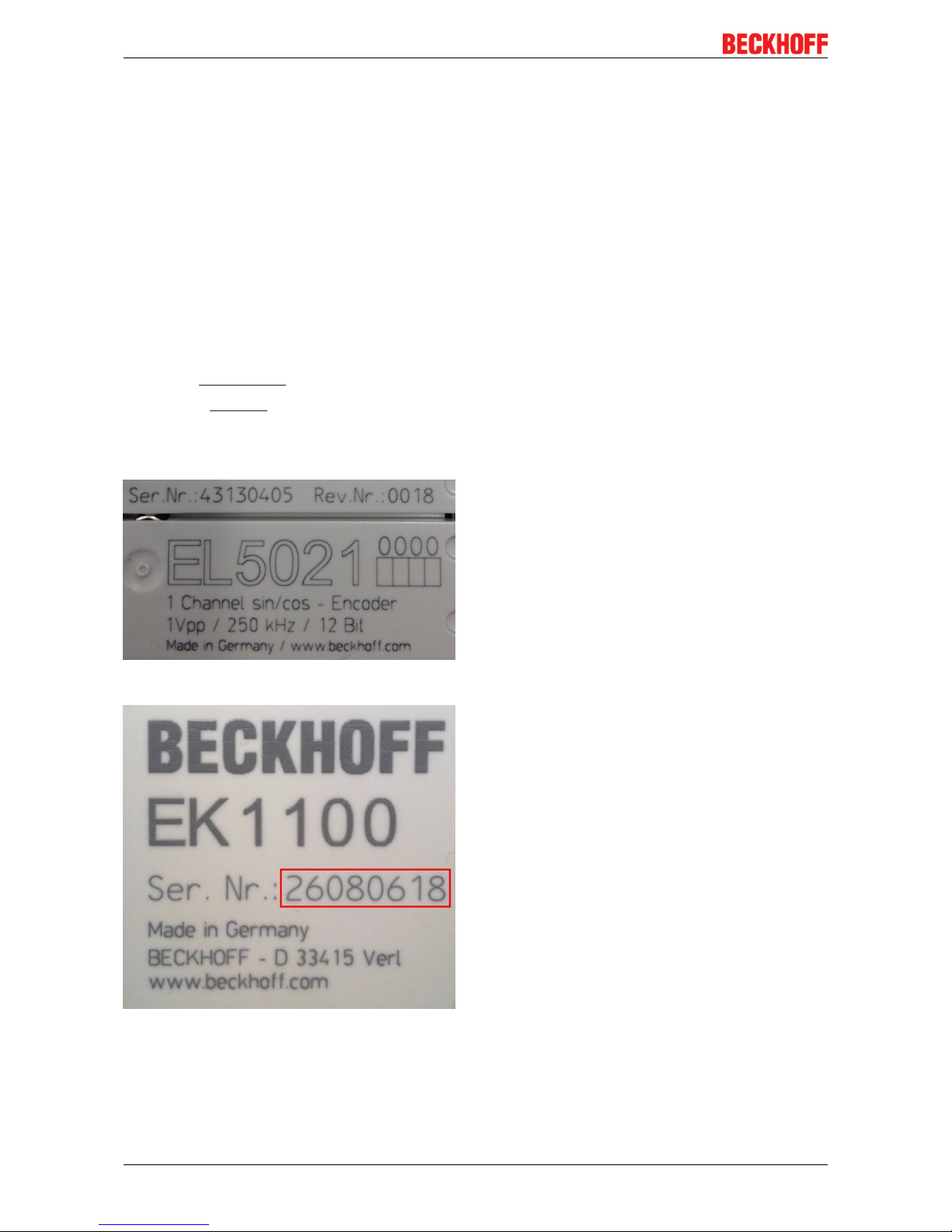

From 2014/01 the revision is shown on the outside of the IP20 terminals, see Fig. “EL5021 EL terminal,

standard IP20 IO device with batch number and revision ID (since 2014/01)”.

• The type, version and revision are read as decimal numbers, even if they are technically saved in

hexadecimal.

Identification number

Beckhoff EtherCAT devices from the different lines have different kinds of identification numbers:

Production lot/batch number/serial number/date code/D number

The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker.

The serial number indicates the configuration in delivery state and therefore refers to a whole production

batch, without distinguishing the individual modules of a batch.

Structure of the serial number: KKYYFFHH

KK - week of production (CW, calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with

Ser. no.: 12063A02: 12 - production week 12 06 - production year 2006 3A - firmware version 3A 02 hardware version 02

Exceptions can occur in the IP67 area, where the following syntax can be used (see respective device

documentation):

Syntax: D ww yy x y z u

Page 10

Foreword

EK110x, EK15xx10 Version: 3.6

D - prefix designation

ww - calendar week

yy - year

x - firmware version of the bus PCB

y - hardware version of the bus PCB

z - firmware version of the I/O PCB

u - hardware version of the I/O PCB

Example: D.22081501 calendar week 22 of the year 2008 firmware version of bus PCB: 1 hardware version

of bus PCB: 5 firmware version of I/O PCB: 0 (no firmware necessary for this PCB) hardware version of I/O

PCB: 1

Unique serial number/ID, ID number

In addition, in some series each individual module has its own unique serial number.

See also the further documentation in the area

• IP67: EtherCAT Box

• Safety: TwinSafe

• Terminals with factory calibration certificate and other measuring terminals

Examples of markings

Fig.1: EL5021 EL terminal, standard IP20 IO device with batch number and revision ID (since 2014/01)

Fig.2: EK1100 EtherCAT coupler, standard IP20 IO device with batch number

Page 11

Foreword

EK110x, EK15xx 11Version: 3.6

Fig.3: CU2016 switch with batch number

Fig.4: EL3202-0020 with batch numbers 26131006 and unique ID-number 204418

Fig.5: EP1258-00001 IP67 EtherCAT Box with batch number 22090101 and unique serial number 158102

Fig.6: EP1908-0002 IP67 EtherCAT Safety Box with batch number 071201FF and unique serial number

00346070

Page 12

Foreword

EK110x, EK15xx12 Version: 3.6

Fig.7: EL2904 IP20 safety terminal with batch number/date code 50110302 and unique serial number

00331701

Fig.8: ELM3604-0002 terminal with ID number (QR code) 100001051 and unique serial number 44160201

Page 13

Product overview

EK110x, EK15xx 13Version: 3.6

2 Product overview

2.1 Overview of EtherCAT couplers

An EtherCAT coupler is required in order to connect EtherCAT Terminals with E-bus-communication (series

ELxxxx, ESxxxx, EMxxxx) to an EtherCAT network. This coupler relays the communication from the higherlevel EtherCAT network to the terminals, or functions as a master itself and generates telegrams. Beckhoff

offers different components for different application scenarios.

The selection of the correct coupler depends on the following criteria:

• is a local small controller needed?

• is the coupler to be connected via copper cable or optical fiber cable?

• is the coupler to be addressed via IP or is it located in the unswitched network?

• is the coupler to be controlled via EAP (EtherCAT Automation Protocol) or EtherCAT Device Protocol?

• required protection class: IP20 or higher?

• is the coupler to be plugged in at different places at the network using the HotConnect technique?

A coupler connects the added terminals to the right; it can be connected to the higher level network to the

left. Couplers that support the EtherCAT Device Protocol ‘to the left’ must be connected there to an

EtherCAT master.

Fig.9: EtherCAT coupler communication diagram

The following features overview can be used for selection (Beckhoff EtherCAT couplers):

Page 14

Product overview

EK110x, EK15xx14 Version: 3.6

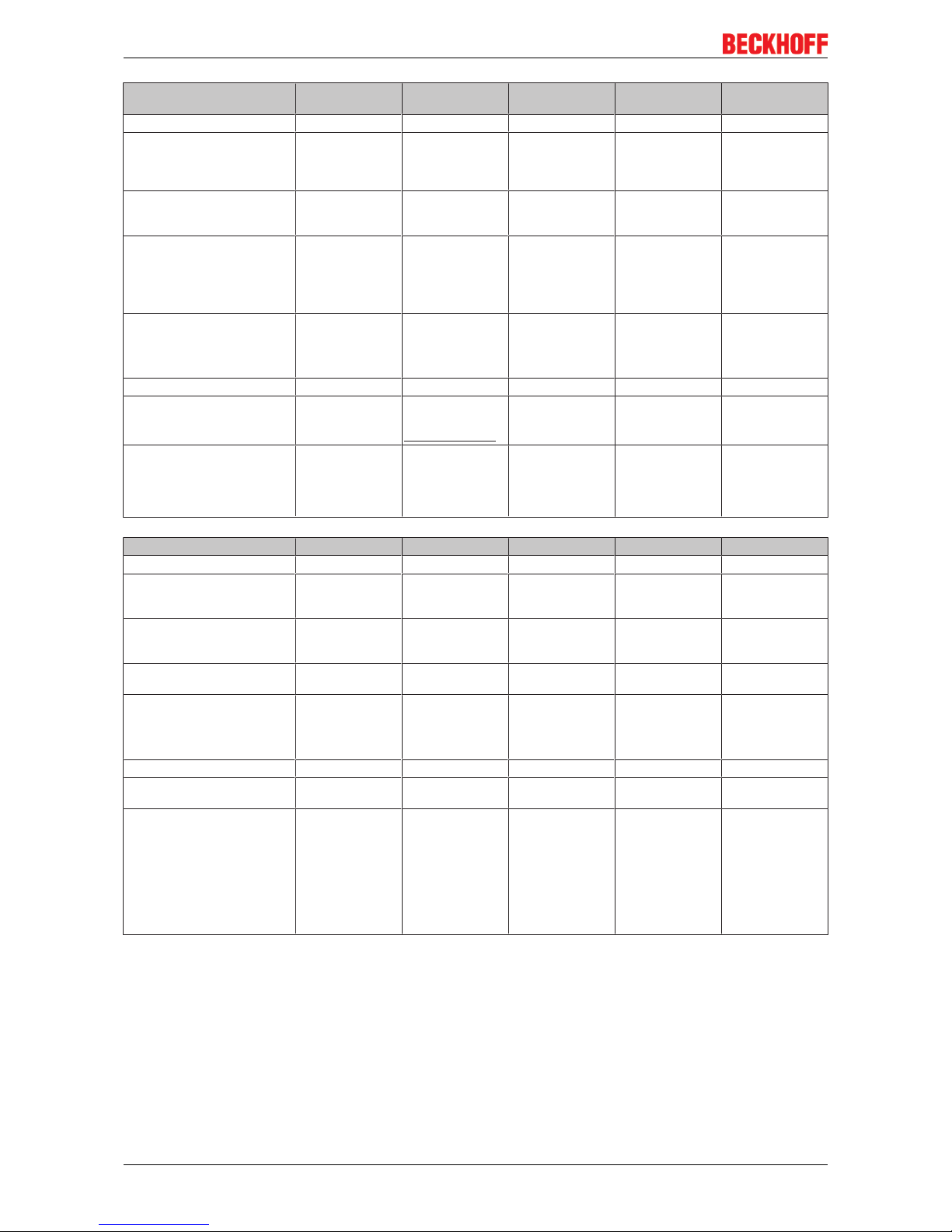

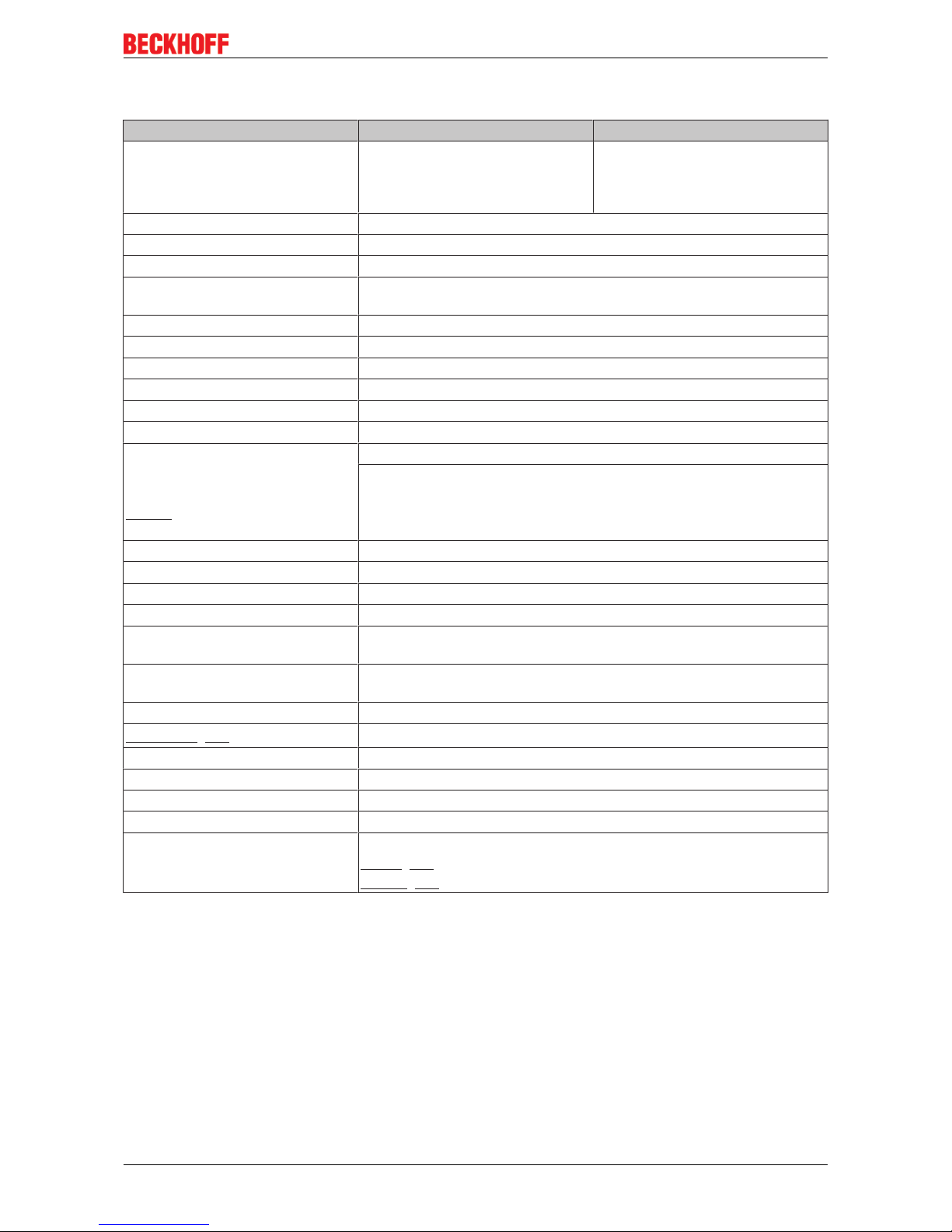

Characteristic EK1100 EK1101

EK1101-0080

EK1501 EK1501-0010 EK1541

Protection class IP20 IP20 IP20 IP20 IP20

Higher level

network technology

100 MBit FastEthernet

(100BASE-TX)

100 MBit FastEthernet

(100BASE-TX)

100 MBit FastEthernet

(100BASE-FX)

100 MBit FastEthernet

(100BASE-FX)

100 MBit FastEthernet

(100BASE-FX)

POF

Higher level

network - max. connection

length

100 m 100 m 2 km 20 km 50m

Higher level

network connection technology

RJ45 RJ45 SC duplex

Multi-mode optical

fiber cable

SC duplex

Single-mode optical fiber cable

Versatile Link

POF duplex connector

Polymeric Optical

Fiber

higher-level

network protocol

EtherCAT Device

Protocol

(formerly Direct

Mode)

EtherCAT Device

Protocol

(formerly Direct

Mode)

EtherCAT Device

Protocol

(formerly Direct

Mode)

EtherCAT Device

Protocol

(formerly Direct

Mode)

EtherCAT Device

Protocol

(formerly Direct

Mode)

integrated PLC - - - - -

supports HotConnect with address setting on the device

- yes

EK1101-0080:

Fast-Hot-Connect

yes yes yes

Note The EK1100 is the

"standard" coupler

for use directly on

the EtherCAT master.

Characteristic EK18xx EK9000 EKx000 EPxxxx CX8000

Protection class IP20 IP20 IP20 IP67 IP20

Higher level

network technology

100 MBit FastEthernet

(100BASE-TX)

100 MBit FastEthernet

(100BASE-TX)

diverse

see doc.

100 MBit FastEthernet

(100BASE-TX)

100 MBit FastEthernet

(100BASE-TX)

Higher level

network - max. connection

length

100 m 100 m see doc. 100 m 100 m

Higher level

network connection technology

RJ45 RJ45 see doc. M8 RJ45

higher-level

network protocol

EtherCAT Device

Protocol

(formerly Direct

Mode)

EAP see doc. EtherCAT Device

Protocol

(formerly Direct

Mode)

EtherCAT Device

Protocol

(formerly Direct

Mode)

integrated PLC - - - - yes

supports HotConnect with address setting on the device

- - - - -

Note The EK18xx de-

vices integrate a

coupler for application directly at the

EtherCAT master

and digital inputs

and outputs without

additional wiring.

The EK9000 can

be controlled in a

switched EtherCAT

network with directed IP addressing.

If the EK9000 is

provided with another fieldbus connection, this gives

rise to the appropriate EKx000 coupler.

Technologically,

each EP Box represents a self-contained EtherCAT

coupler with internally added I/O

functions.

The CX8000 appears to the higher

level EtherCAT

network as an

EtherCAT slave

while at the same

time managing its

attached I/Os as a

master.

Page 15

Product overview

EK110x, EK15xx 15Version: 3.6

2.2 Coupler with RJ45 connection

2.2.1 EK1100

2.2.1.1 EK1100 - Introduction

EK1100 EtherCAT Coupler

The EK1100 coupler connects the EtherCAT Device Protocol with the EtherCAT Terminals (ELxxxx/ESxxxx/

EMxxxx). One station consists of a coupler, any number of EtherCAT Terminals and a bus end terminal, e.g.

EL9011.

The coupler converts the telegrams from Ethernet 100BASE-TX to E-bus signal representation in passing

with minimum latency The coupler is connected to the network via the upper Ethernet interface. The lower

RJ-45 socket may be used to connect further EtherCAT devices in the same strand.

The coupler supplies the connected terminals with the necessary E-bus current for communication. The

coupler can supply a maximum of 5V/2A. Power feed terminals (e.g. EL9410) must be integrated if more

current is required.

In the EtherCAT network, the EK1100 coupler can be installed anywhere in the Ethernet signal transfer

section (100BASE-TX). The coupler thereby processes exclusively unaddressed MAC Broadcast telegrams

of the type EtherCAT Device Protocol from the EtherCAT master. Since directed addressing via MAC

Unicast or IP addressing is not used, neither a switch nor a router can be used.

Quick links

• EtherCAT basics [}31]

• Configuration instructions [}56]

• Diagnostic LEDs [}66]

Page 16

Product overview

EK110x, EK15xx16 Version: 3.6

2.2.1.2 EK1100 - Technical data

Technical data EK1100

Task within the EtherCAT system Coupling of EtherCAT Terminals (ELxxxx) to

100BASE-TX EtherCAT networks

Number of EtherCAT Terminals Up to 65535 in the overall system

Number of peripheral signals max. 4.2GB addressable IO points

Transmission medium at least Ethernet CAT-5 cable

Cable length between two Bus Couplers max. 100m (100BASE-TX)

Protocol / Baud rate EtherCAT Device Protocol / 100MBaud

HotConnect no

Delay typical 1µs

Bus connection 2 x RJ45

Power supply 24VDC (-15%/+20%)

Current consumption 70mA + (E-bus current)/4

E-bus power supply (5 V)

(at higher current consumption the EL9410 power

feed terminal can be used in addition)

max. 2000mA (-25°C ... +55°C)

max. 1000mA (> +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 44mm x 100mm x 68mm

Weight approx. 105g

Permissible ambient temperature range during

operation

-25°C ... +60°C

Permissible ambient temperature range during

storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6/EN 60068-2-27,

see also Installation instructions [}40] for terminals

with increased mechanical load capacity

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

ATEX [}54]

cULus [}52]

Page 17

Product overview

EK110x, EK15xx 17Version: 3.6

2.2.2 EK1101, EK1101-xxxx

2.2.2.1 EK1101 - Introduction

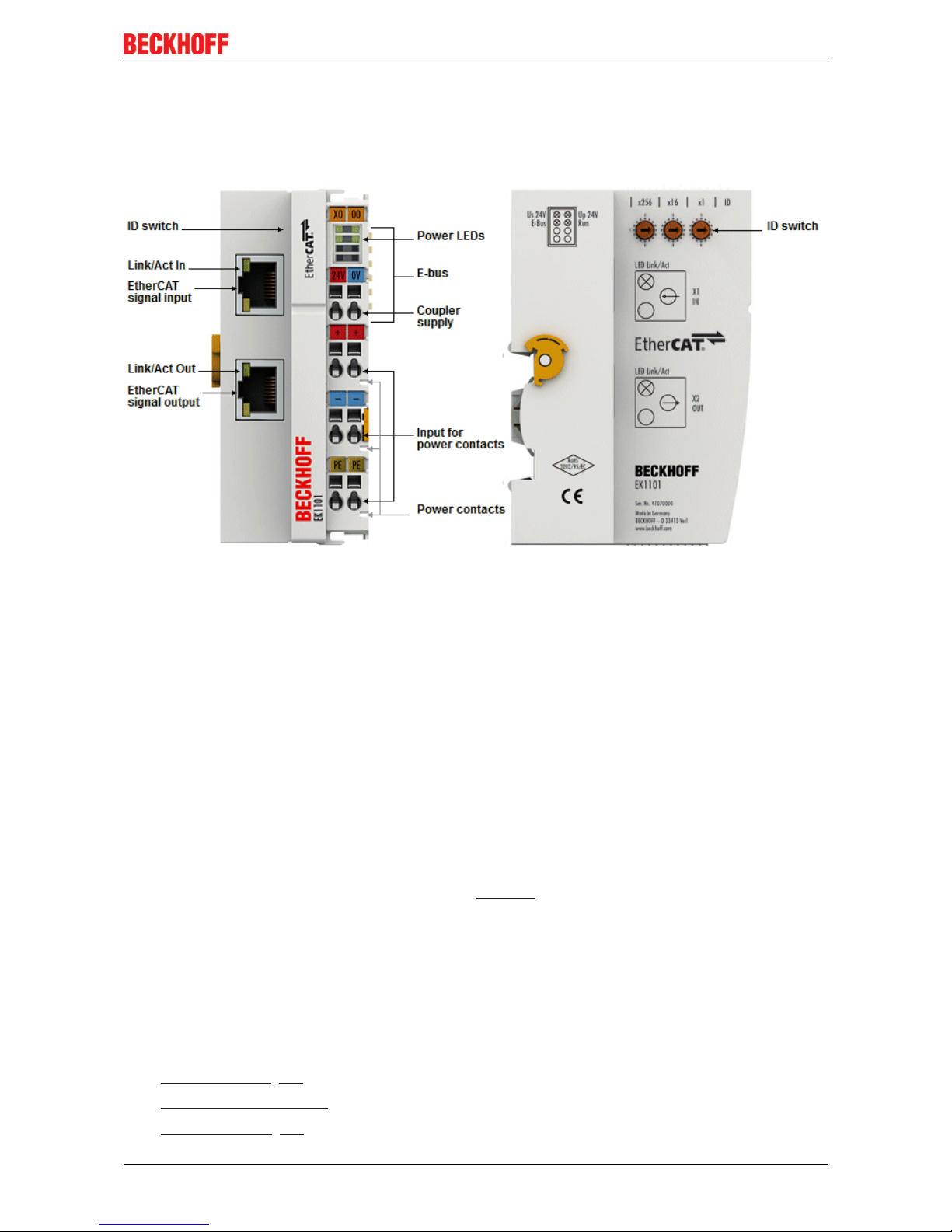

EK1101 EtherCAT coupler with ID switch

The EK1101 coupler connects the EtherCAT Device Protocol with the EtherCAT Terminals (ELxxxx/ESxxxx/

EMxxxx). One station consists of a coupler, any number of EtherCAT Terminals and a bus end terminal, e.g.

EL9011.

The coupler converts the telegrams from Ethernet 100BASE-TX to E-bus signal representation in passing

with minimum latency The coupler is connected to the network via the upper Ethernet interface. The lower

RJ-45 socket may be used to connect further EtherCAT devices in the same strand.

The coupler supplies the connected terminals with the necessary E-bus current for communication. The

coupler can supply a maximum of 5 V/2 A. Power feed terminals (e.g. EL9410) must be integrated if more

current is required.

In the EtherCAT network, the coupler can be installed anywhere in the Ethernet signal transfer section

(100BASE-TX). The coupler thereby processes exclusively unaddressed MAC Broadcast telegrams of the

type EtherCAT Device Protocol from the EtherCAT master. Since directed addressing via MAC Unicast or IP

addressing is not used, neither a switch nor a router can be used.

The EK1101 supports the HotConnect procedure, see EtherCAT documentation. The characteristics of the

EK1101 in relation to this are:

• ID can be set on the device via 3 rotary selector switches within the range 0 to 4095 (hexadecimal)

• the ID is readable online by the EtherCAT master via the process data

• if the EtherCAT master supports HotConnect, then an I/O group can be adopted dynamically into the

EtherCAT communication. This group can then be located at any position within the EtherCAT network.

Variable topologies are therefore easily implementable.

Quick links

• EtherCAT basics [}31]

• Configuration instructions

• Diagnostic LEDs [}66]

Page 18

Product overview

EK110x, EK15xx18 Version: 3.6

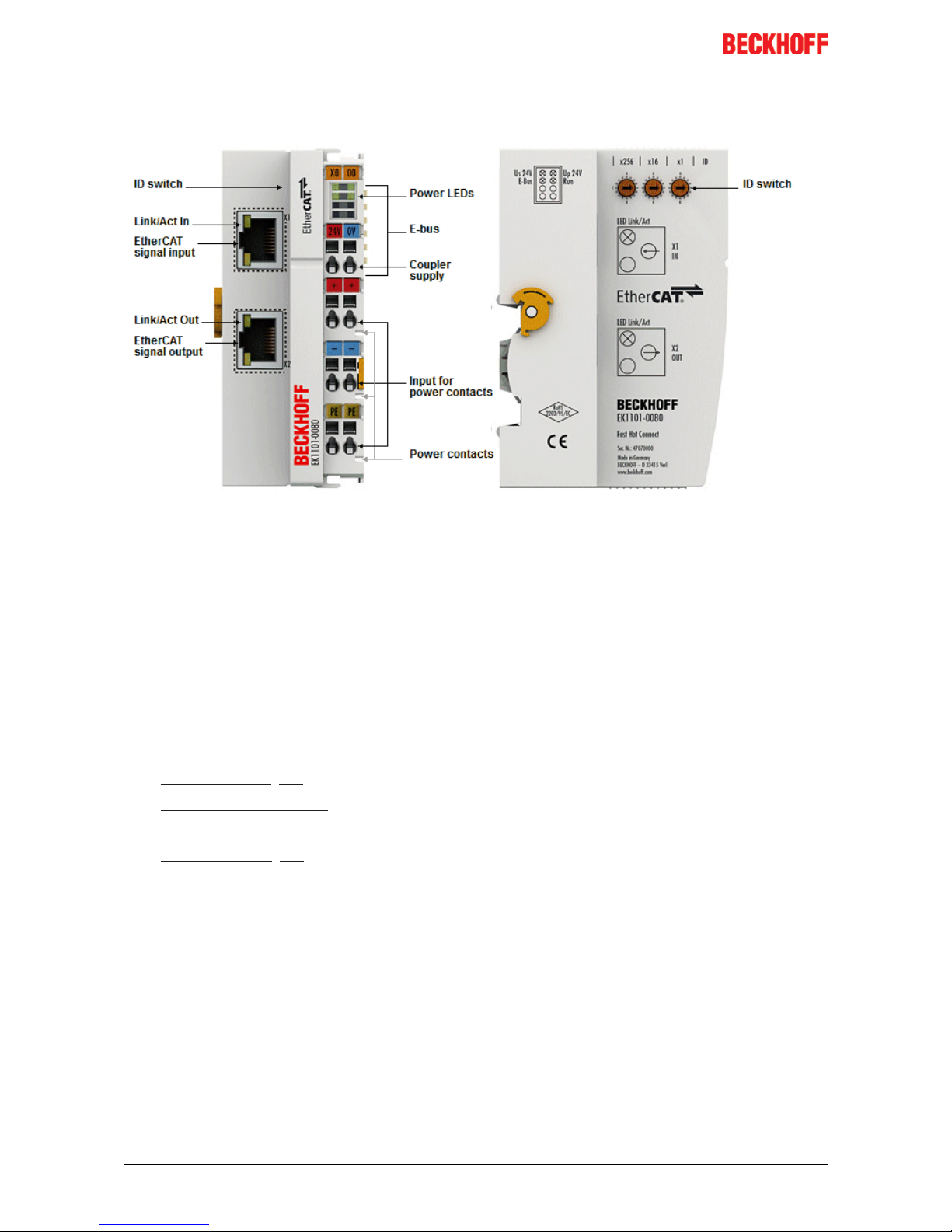

2.2.2.2 EK1101-0080 - Introduction

EK1101-0080 EtherCAT coupler with ID switch

The EK1101-0080 EtherCAT coupler with Fast Hot Connect technology is an extension of the EK1101

coupler.

Hot Connect is an EtherCAT feature for changing topologies through direct coupling or uncoupling during

operation. Coupled EtherCAT components are already quickly linked to the data communication after

connection as standard. Fast hot-connect technology further reduces the connection time significantly,

enabling even faster tool changes. Fast hot-connect ports may only be connected to each other, which is

why they are specially identified.

The EK1101-0080 EtherCAT coupler with Fast Hot Connect is complemented by the EK1122-0080

EtherCAT junction with Fast Hot Connect.

Quick links

• EtherCAT basics [}31]

• Configuration instructions

• Notes on Fast Hot Connect [}19]

• Diagnostic LEDs [}66]

Page 19

Product overview

EK110x, EK15xx 19Version: 3.6

2.2.2.3 EK1101, EK1101-0080 - Technical data

Technical data EK1101 EK1101-0080

Task within the EtherCAT system Coupling of EtherCAT Terminals

(ELxxxx) to 100BASE-TX

EtherCAT networks

Coupling of EtherCAT Terminals

(ELxxxx) to 100BASE-TX

EtherCAT networks,

Fast Hot Connect technology

Number of EtherCAT Terminals up to 65535 in the overall system

Number of peripheral signals max. 4.2GB addressable IO points

Transmission medium at least Ethernet CAT-5 cable

Cable length between two Bus

Couplers

max. 100m (100BASE-TX)

Protocol / Baud rate EtherCAT Device Protocol / 100MBaud

HotConnect max. number of configurable IDs: 4096

Delay typical 1µs

Bus connection 2 x RJ45

Power supply 24VDC (-15%/+20%)

Current consumption 70mA + (E-bus current)/4

E-bus power supply (5 V)

depending on ambient temperature

(at higher current consumption the

EL9410 power feed terminal can be

used in addition)

max. 2000mA (-25°C ... +55°C)

max. 1000mA (> +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 44mm x 100mm x 68mm

Weight approx. 105g

Permissible ambient temperature

range during operation

-25°C ... +60°C

Permissible ambient temperature

range during storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

ATEX [}54]

cULus [}52]

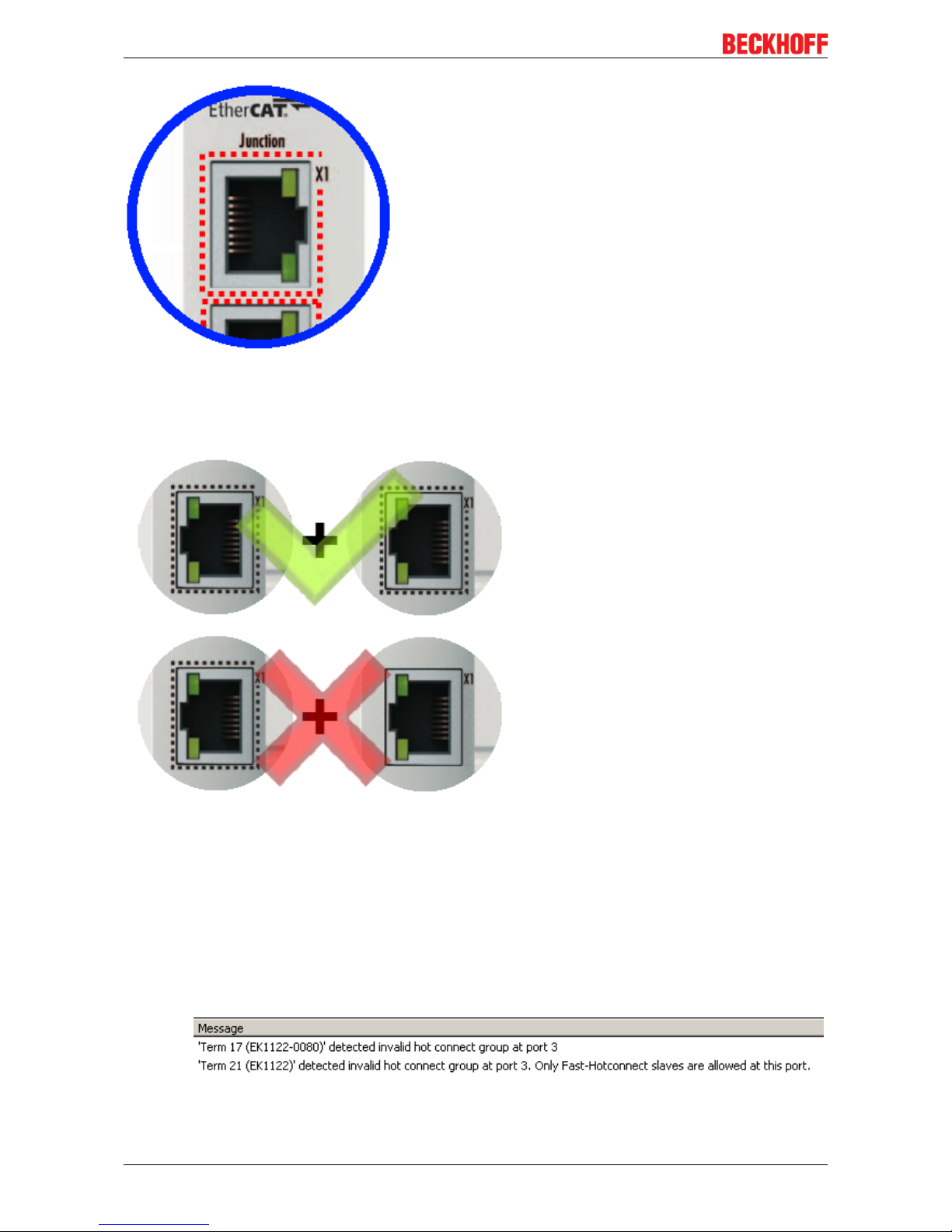

2.2.2.4 Notes re. EtherCAT Fast Hot Connect technology

EtherCAT components that support Fast Hot Connect enable a faster fieldbus boot up following the

establishment of a connection. The boot up depends in detail on the number of devices, the topology and

activated Distributed Clocks. Whereas the normal establishment of a connection and communication takes

several seconds, less than 1 second is possible with FHC components.

Properties and system behavior

• Fast Hot Connect is supported from TwinCAT 2.11R3 Build 2221.

• Fast Hot Connect ports are specially marked.

Page 20

Product overview

EK110x, EK15xx20 Version: 3.6

Fig.10: Identification of FHC port at EK1122-0080 and EK1101-0080

• Standard EtherCAT devices may not be connected to Fast Hot Connect ports. This is to be ensured by

measures on the application side, which is easy to implement by means of the topology change that is

usually carried out mechanically in such applications.

Fig.11: Recommended combination of Ethernet ports

• If corresponding ports are nevertheless connected, a power reset of the devices involved (branch

terminal and coupler/box) is required.

• With Fast Hot Connect devices the establishment of an Ethernet connection is accelerated compared

to the normal Fast Ethernet connection.

If in addition the use of Distributed Clocks functions is omitted in the entire topology, then the

resynchronization time of the components is also dispensed with. Group boot up of < 1 second is then

possible, from plugging in the Ethernet connection to the OP state.

• An incorrect port allocation is detected in the TwinCAT ADS Logger

Page 21

Product overview

EK110x, EK15xx 21Version: 3.6

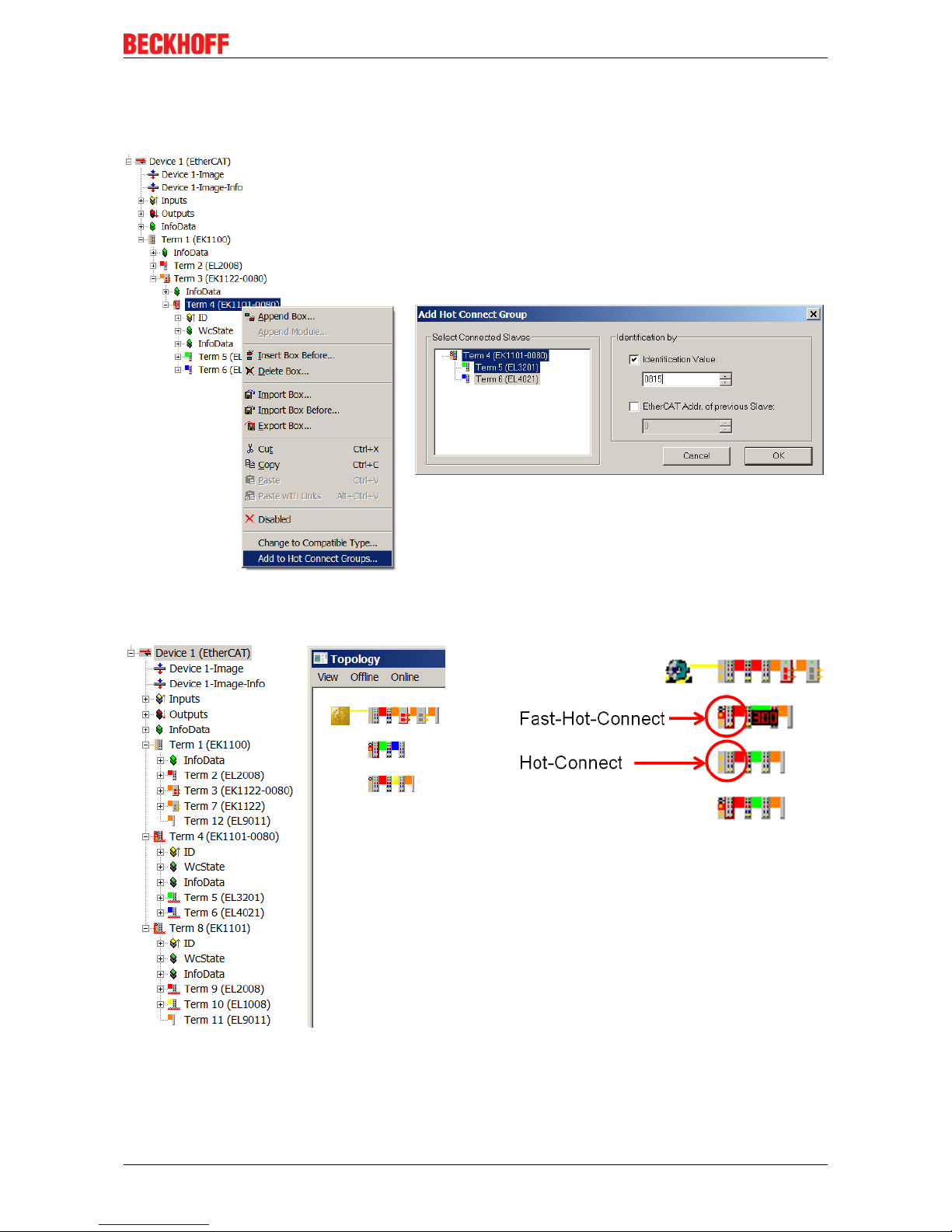

Configuration

The configuration of Fast Hot Connect groups in the TwinCAT System Manager takes place in exactly the

same way as Hot Connect groups, specifying the associated group ID.

Fig.12: Configuration of a Fast Hot Connect group

Corresponding Fast Hot Connect ports are marked red in the TwinCAT System Manager.

Fig.13: Marking in the TwinCAT System Manager

A configuration of FHC groups is possible only if at least 1 corresponding junction is present e.g.

EK1122-0080.

Page 22

Product overview

EK110x, EK15xx22 Version: 3.6

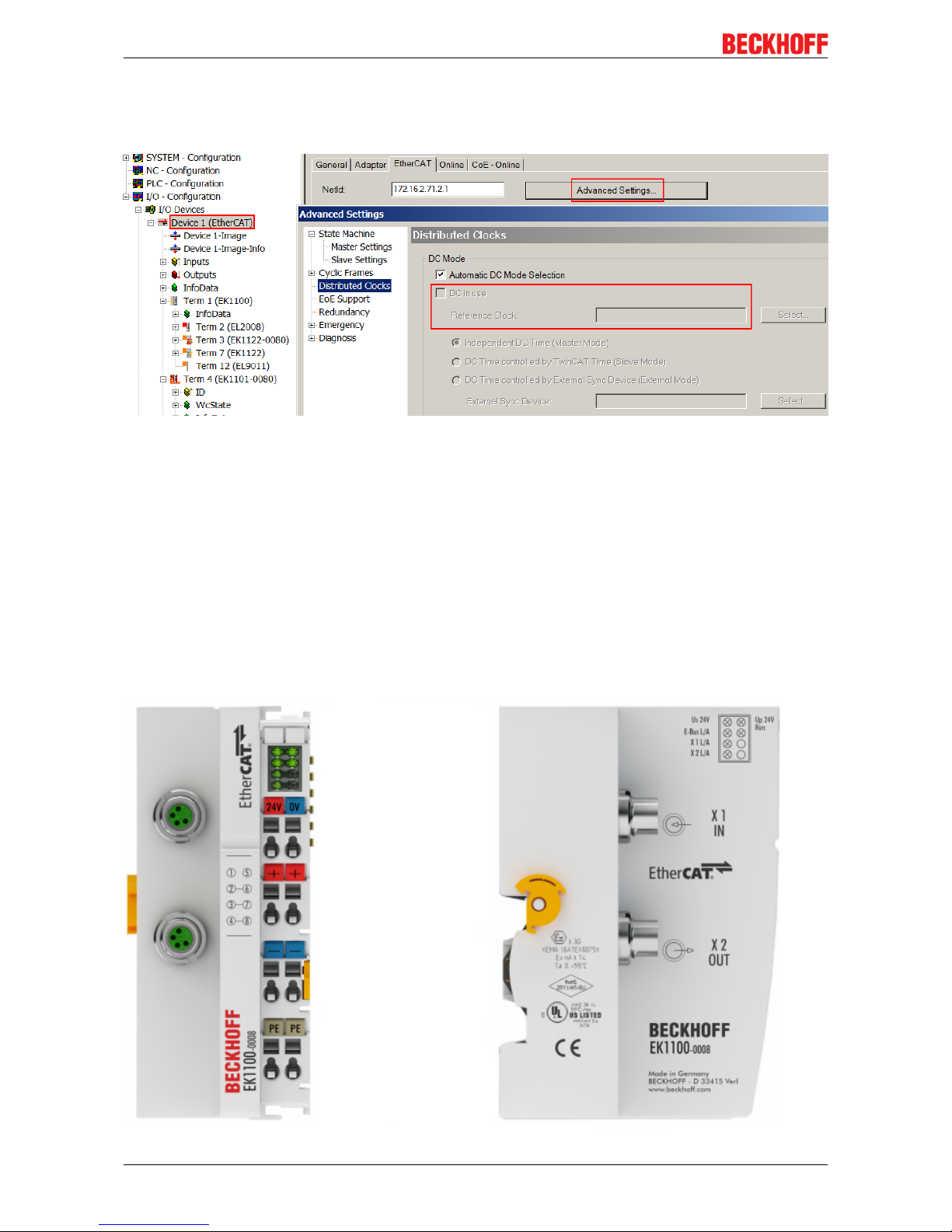

Distributed Clocks

If no Distributed Clocks functions are used, this is visible in the master settings by the absence of "DC in

use":

Fig.14: DC master setting

This setting is automatically selected by the System Manager if there are no EtherCAT slaves in the

configuration in which Distributed Clocks is activated. "DC in use" should not be randomly deactivated by the

user, because otherwise these devices will no longer function.

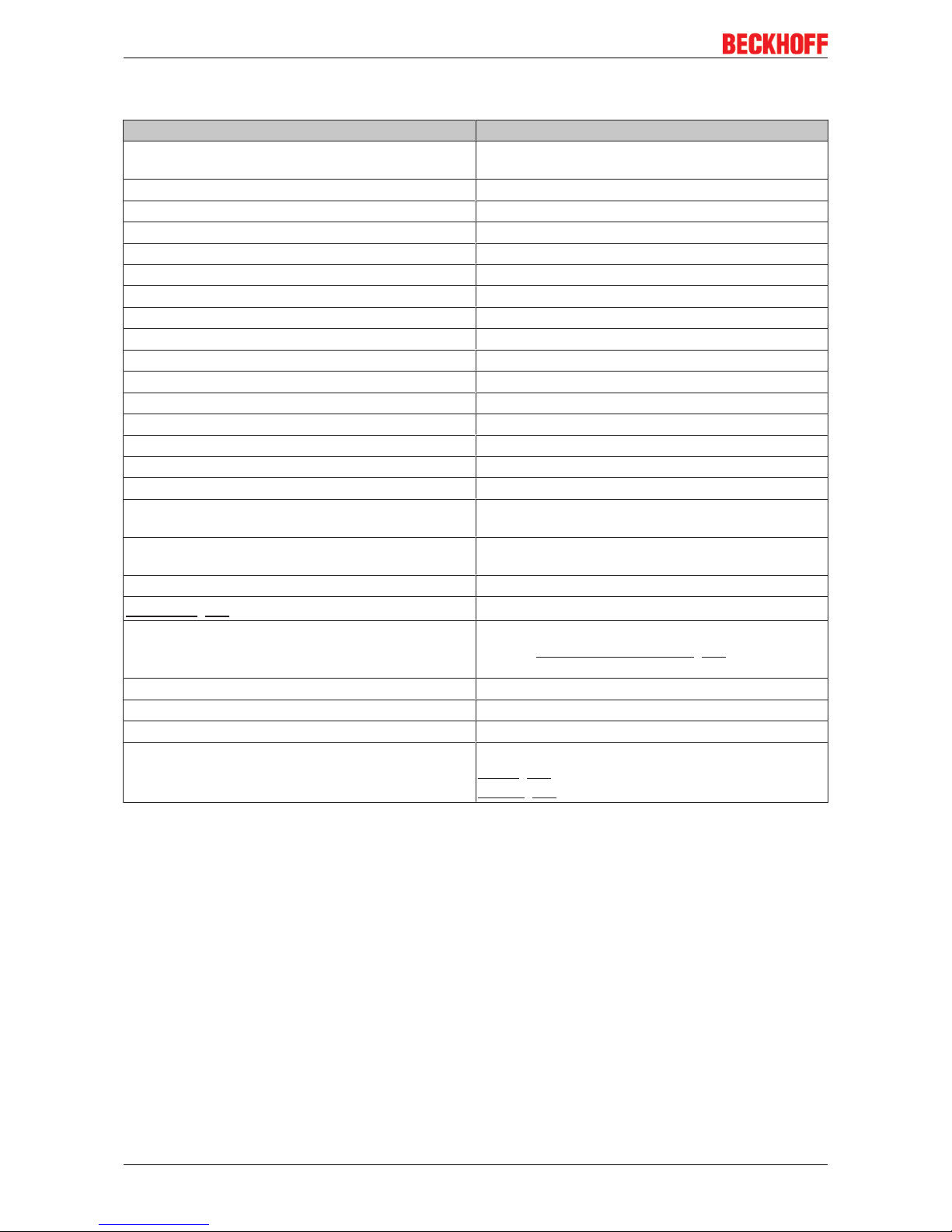

2.3 Coupler with M8 connection

2.3.1 EK1100-0008

2.3.1.1 EK1100-0008 - Introduction

Page 23

Product overview

EK110x, EK15xx 23Version: 3.6

EtherCAT coupler EK1100-0008 (M8 connection)

The EK1100-0008 coupler connects EtherCAT with the EtherCAT Terminals (ELxxxx/ESxxxx). One station

consists of a coupler EK1100-0008, any number of EtherCAT Terminals and a bus end terminal.

The coupler converts the telegrams from Ethernet 100BASE-TX to E-bus signal representation. Compared to

EK1100 the EK1100-0008 has two M8 sockets instead of two RJ45 sockets, compatible to the ones of the

EtherCAT-Boxes.

The upper Ethernet interface is used to connect the coupler to the network; the lower M8 socket serves for

the optional connection of further EtherCAT devices in the same strand.

The coupler supplies the connected terminals with the necessary E-bus current for communication. The

coupler can supply a maximum of 5V/2A. Power feed terminals (e.g. EL9410) must be integrated if more

current is required.

In the EtherCAT network, the EK1100-0008 coupler can be installed anywhere in the Ethernet signal transfer

section (100BASE-TX) except onto the switch directly. By using respective powerful Ethernet cables e.g.

ZK1090-3131-1xxx distances of 100m are also possible via M8.

Quick links

• EtherCAT basics [}31]

• Configuration instructions [}56]

• Diagnostic LEDs [}66]

Page 24

Product overview

EK110x, EK15xx24 Version: 3.6

2.3.1.2 EK1100-0008 - Technical data

Technical data EK1100-0008

Task within the EtherCAT system Coupling of EtherCAT Terminals (ELxxxx) to

100BASE-TX EtherCAT networks

Number of EtherCAT Terminals up to 65535 in the overall system

Transmission medium at least EtherCAT CAT-5 cable

Cable length between two Bus Couplers max. 100m (100BASE-TX)

Transfer rate 100MBaud

Configuration Not required

Delay typical 1µs

Bus interface 2 x M8

Power supply 24VDC (-15%/+20%)

Current consumption from US 70mA + (∑ E-Bus-Strom/4)

Current consumption from UP Load

Power supply E-bus max. 2000mA (-25°C ... +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 44mm x 100mm x 68mm

Weight approx. 105g

Permissible ambient temperature range during

operation

-25°C ... +60°C

Permissible ambient temperature range during

storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35 mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6/EN 60068-2-27,

see also Installation instructions [}40] for terminals

with increased mechanical load capacity

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

ATEX [}54]

cULus [}52]

Page 25

Product overview

EK110x, EK15xx 25Version: 3.6

2.4 Coupler with optical fiber connection

2.4.1 EK1501

2.4.1.1 EK1501 - Introduction

EK1501 EtherCAT coupler with ID switch, multimode optical fiber connection

The EK1501 coupler connects the EtherCAT Device Protocol with the EtherCAT Terminals (ELxxxx/ESxxxx/

EMxxxx). One station consists of a coupler, any number of EtherCAT Terminals and a bus end terminal, e.g.

EL9011.

The coupler converts the telegrams from Ethernet 100BASE-FX to E-bus signal representation in passing

with minimum latency The upper Ethernet interface is used to connect the coupler to the network; the lower

SC socket serves for the optional connection of further EtherCAT devices in the same strand.

The coupler supplies the connected terminals with the necessary E-bus current for communication. The

coupler can supply a maximum of 5V/2A. Power feed terminals (e.g. EL9410) must be integrated if more

current is required.

In the EtherCAT network, the coupler is used at an arbitrary place in the Ethernet signal transmission range

(100BASE-FX). The coupler thereby processes exclusively unaddressed MAC Broadcast telegrams of the

type EtherCAT Device Protocol from the EtherCAT master. Since directed addressing via MAC Unicast or IP

addressing is not used, neither a switch nor a router can be used.

The multimode glass fiber connection enables distances of up to 2 km between two couplers.

The coupler supports the HotConnect technique; see the basic EtherCAT documentation regarding this. The

characteristics of the EK1501 in relation to this are:

• ID can be set on the device via 3 rotary selector switches within the range 0 to 4095 (hexadecimal)

• the ID is readable online by the EtherCAT master via the process data

Page 26

Product overview

EK110x, EK15xx26 Version: 3.6

• if the EtherCAT master supports HotConnect, then an I/O group can be adopted dynamically into the

EtherCAT communication. This group can then be located at any position within the EtherCAT network.

Variable topologies are therefore easily implementable.

Quick links

• EtherCAT basics [}31]

• Application notes [}56]

• Diagnostic LEDs [}66]

2.4.1.2 EK1501 - Technical data

Technical data EK1501

Task within the EtherCAT system Coupling of EtherCAT Terminals (ELxxxx) to

100BASE-FX EtherCAT networks

Number of EtherCAT Terminals up to 65535 in the overall system

Number of peripheral signals max. 4.2GB addressable IO points

Transmission medium Multimode glass fiber (MM)

Cable length between two Bus Couplers max. 2km (100BASE-FX)

Transceiver wavelength typically 1300nm

Protocol / Baud rate EtherCAT Device Protocol / 100MBaud

HotConnect max. number of configurable IDs: 4096

Delay typical 1µs

Bus connection 2 x SC Duplex

Power supply 24VDC (-15%/+20%)

Current consumption 130mA + (E-bus current)/4

E-bus power supply (5 V)

depending on ambient temperature

(at higher current consumption the EL9410 power

feed terminal can be used in addition)

max. 2000mA (-25°C ... +55°C)

max. 1000mA (> +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500 V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 49mm x 100mm x 70mm

Weight approx. 190g

Permissible ambient temperature range during

operation

-25°C ... +60°C (extended temperature range)

Permissible ambient temperature range during

storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35 mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

ATEX [}54]

cULus [}52]

Page 27

Product overview

EK110x, EK15xx 27Version: 3.6

2.4.2 EK1501-0010

2.4.2.1 EK1501-0010 - Introduction

EK1501-0010 EtherCAT coupler with ID switch, single-mode optical fiber connection

The EK1501-0010 coupler differs from the EK1501 only in the transceiver used. Transmission ranges of up

to 20 km can be attained with the single-mode technique using appropriate optical fiber cables.

An attenuation budget of 10 dBm is available between the EK1501-0010 and the associated EK1521-0010

branch. The following factors can be taken as a basis for the estimation of the attenuation:

• Two SC plug connectors: 0.25 dBm each

• typical optical fiber cable with 0.4 dB/km attenuation

The sum of all attenuations may not exceed 10 dBm. The installed fiber optic section is to be validated by

measurement if necessary.

Quick links

• EtherCAT basics [}31]

• Application notes [}56]

• Diagnostic LEDs [}66]

Page 28

Product overview

EK110x, EK15xx28 Version: 3.6

2.4.2.2 EK1501-0010 - Technical data

Technical data EK1501-0010

Task within the EtherCAT system Coupling of EtherCAT Terminals (ELxxxx) to

100BASE-FX EtherCAT networks

Number of EtherCAT Terminals up to 65535 in the overall system

Number of peripheral signals max. 4.2GB addressable IO points

Transmission medium Single mode glass fiber (SM)

Cable length between two Bus Couplers max. 20km (100BASE-FX)

Transceiver wavelength typically 1300nm

Protocol / Baud rate EtherCAT Device Protocol / 100MBaud

HotConnect max. number of configurable IDs: 4096

Delay typical 1µs

Bus connection 2 x SC Duplex

Power supply 24VDC (-15%/+20%)

Current consumption 150mA + (E-bus current)/4

E-bus power supply (5 V)

depending on ambient temperature

(at higher current consumption the EL9410 power

feed terminal can be used in addition)

max. 2000mA (-25°C ... +55°C)

max. 1000mA (> +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 49mm x 100mm x 70mm

Weight approx. 190g

Permissible ambient temperature range during

operation

-25°C ... +60°C (extended temperature range)

Permissible ambient temperature range during

storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

ATEX [}54]

cULus [}52]

Page 29

Product overview

EK110x, EK15xx 29Version: 3.6

2.5 Coupler with POF connection

2.5.1 EK1541

2.5.1.1 EK1541 - Introduction

EK1541 EtherCAT coupler with ID switch, POF connection

The EK1541 Coupler connects EtherCAT with the EtherCAT Terminals (ELxxxx). A station consists of an

EK1541 coupler, any number of EtherCAT Terminals, an EL9011 bus end cap or an EK1110 EtherCAT

extender.

The coupler converts the telegrams from Ethernet 100BASE-FX-POF physics to E-bus signal representation

in passing with minimum latency The Polymeric Optical Fiber (POF) connection enables distances of up to

50 m between two couplers. Unlike the glass fiber, the POF fiber is easily wireable in the field. The EK1541

has three hexadecimal ID switches for assigning an ID to a group of EtherCAT components.

The coupler supplies the connected terminals with the necessary E-bus current for communication. The

coupler can supply a maximum of 5V/2A. Power feed terminals (e.g. EL9410) must be integrated if more

current is required.

The device supports the HotConnect procedure, see EtherCAT documentation. The characteristics of the

EK1541 in relation to this are:

• ID can be set on the device via 3 rotary selector switches within the range 0 to 4095 (hexadecimal)

• the ID is readable online by the EtherCAT master via the process data

• if the EtherCAT master supports HotConnect, then an I/O group can be adopted dynamically into the

EtherCAT communication. This group can then be located at any position within the EtherCAT network.

Variable topologies are therefore easily implementable.

Quick links

• EtherCAT basics [}31]

• Application notes [}59]

Page 30

Product overview

EK110x, EK15xx30 Version: 3.6

• Diagnostic LEDs [}66]

2.5.1.2 EK1541 - Technical data

Technical data EK1541

Task within the EtherCAT system Coupling of EtherCAT Terminals (ELxxxx) to

100BASE-FX EtherCAT POF networks

Number of EtherCAT Terminals up to 65534 in the overall system

Number of peripheral signals max. 4.2GB addressable IO points

Transmission medium Polymeric Optical Fiber

Cable length between two Bus Couplers max. 50m (100BASE-FX-POF)

Transceiver wavelength 650nm

Laser class 1, see note [}71]

Protocol / Baud rate EtherCAT Device Protocol / 100MBaud

HotConnect max. number of configurable IDs: 4096

Delay typical 1µs

Bus connection 2 x versatile link for POF duplex connector

(connector set ZS1090-0008)

Power supply 24VDC (-15%/+20%)

Input current 130mA + (total E-bus current)/4

Current consumption 24 V DC typ. 70mA

E-Bus current consumption -

E-bus power supply (5 V)

depending on ambient temperature

(at higher current consumption the EL9410 power

feed terminal can be used in addition)

max. 2000mA (-25°C ... +55°C)

max. 1000mA (> +55°C)

Power contacts max. 24VDC, max. 10A

Electrical isolation 500V (power contact/supply voltage/EtherCAT)

Dimensions (W x H x D) approx. 49mm x 100mm x 70mm

Weight approx. 190g

Permissible ambient temperature range during

operation

-25°C ... +60°C (extended temperature range)

Permissible ambient temperature range during

storage

-40°C ... + 85°C

Permissible relative humidity 95%, no condensation

Mounting [}37]

on 35 mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

cULus [}52]

Page 31

Basics

EK110x, EK15xx 31Version: 3.6

3 Basics

3.1 EtherCAT basics

Please refer to the chapter EtherCAT System Documentation for the EtherCAT fieldbus basics.

3.2 EtherCAT coupler port allocation

According to the EtherCAT specification, an ESC (EtherCAT Slave Controller, hardware processing unit of

the EtherCAT protocol) can have 1 to 4 ports, which it controls itself. Via an open port it can handle outgoing

and incoming Ethernet traffic.

The following figure shows the direction of data flow in a fully connected EK1100 (or EK1100-0008) as an

example:

Fig.15: Example: EK1100 / EK1100-0008 EtherCAT coupler with 3 ports

The port assignment in the case of the EK1101, EK1501 and EK1501-0010, EK1814 applies accordingly.

Page 32

Basics

EK110x, EK15xx32 Version: 3.6

Fig.16: Internal and external port assignment for Bus Coupler EK1100 and EK1100-0008

Frame processing sequence

The EtherCAT frame arriving at the EtherCAT signal input is passed on by Port 0 (A) to the EtherCAT

processing unit.

• The EtherCAT frame arrives at Port 1 (B) and the data frame departs via Port 1 (B) to the following slave in

the EtherCAT terminal network (if a slave is connected there and reports ‘Link’).

• After the arrival of the data frame at Port 1 (B) from the terminal network, this is passed on to Port 2 (C) and

leaves the coupler at the following EtherCAT output (if a slave is connected there and reports ‘Link’).

• The data frame arrives at Port 2 (C). This is now forwarded to port 0 (A) and leaves the EK1100 /

EK1100-0008 via the EtherCAT input.

Note

Processing of the data

The data in the EtherCAT datagrams are processed only between Ports 0 (A) and 3 (D) in

the EtherCAT processing unit. The non-implemented (internal) Port 3 (D) is considered to

be closed and passes on the datagram to Port 1 (B).

Page 33

Basics

EK110x, EK15xx 33Version: 3.6

3.3 EtherCAT State Machine

The state of the EtherCAT slave is controlled via the EtherCAT State Machine (ESM). Depending upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the bootup of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Boot

The regular state of each EtherCAT slave after bootup is the OP state.

Fig.17: States of the EtherCAT State Machine

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before

it acknowledges the change of state, the EtherCAT slave copies current input data into the associated DPRAM areas of the EtherCAT slave controller (ECSC).

Page 34

Basics

EK110x, EK15xx34 Version: 3.6

In Safe-Op state mailbox and process data communication is possible, although the slave keeps its outputs

in a safe state, while the input data are updated cyclically.

Note

Outputs in SAFEOP state

The default set watchdog monitoring sets the outputs of the module in a safe state - depending on the settings in SAFEOP and OP - e.g. in OFF state. If this is prevented by deactivation of the watchdog monitoring in the module, the outputs can be switched or set

also in the SAFEOP state.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

Boot

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

3.4 CoE - Interface: notes

This device has no CoE.

Detailed information on the CoE interface can be found in the EtherCAT system documentation on the

Beckhoff website.

3.5 EKxxxx - Optional Distributed Clocks support

Basic principles Distributed Clocks (DC)

The EtherCAT Distributed Clocks system comprises local clocks that are integrated in the EtherCAT slaves

and are synchronized by the EtherCAT master via special datagrams. Not all EtherCAT slaves support the

Distributed Clocks procedure. It is only supported by slaves whose function requires it. In the TwinCAT

System Manager a slave indicates its DC capability by showing “DC” in the settings dialog.

Fig.18: DC tab for indicating the Distributed Clocks function

Once of these local clocks is the reference clock, based on which all other clocks are synchronized. See also

explanatory notes in the Basic EtherCAT documentation. The reference clock must be the first DC-capable

EtherCAT slave. By default TwinCAT therefore selects the first DC-capable device as reference clock. This is

shown (and can be modified by the user) under advanced properties of the EtherCAT master. The standard

setting should not be changed, except in cases where external synchronization is recommended in the

relevant documentation, for example.

Page 35

Basics

EK110x, EK15xx 35Version: 3.6

Fig.19: Advanced Distributed Clocks settings in the EtherCAT master

The figure shows how TwinCAT selects the EL1252 as reference clock by default, since the preceding

components do not support DC.

Settings EtherCAT device

System and infrastructure devices such as EK1100 or EK1122 couplers and junction etc. do not require

Distributed Clocks to function properly. Nevertheless, it may be topologically expedient to designate the first

coupler in an EtherCAT system as reference clock, for example. For this reason, from a certain level the

infrastructure components are able to operate as reference clocks, based on special configuration settings.

According to the following table (DC support from rev/firmware version), the components support activation

of distributed clocks:

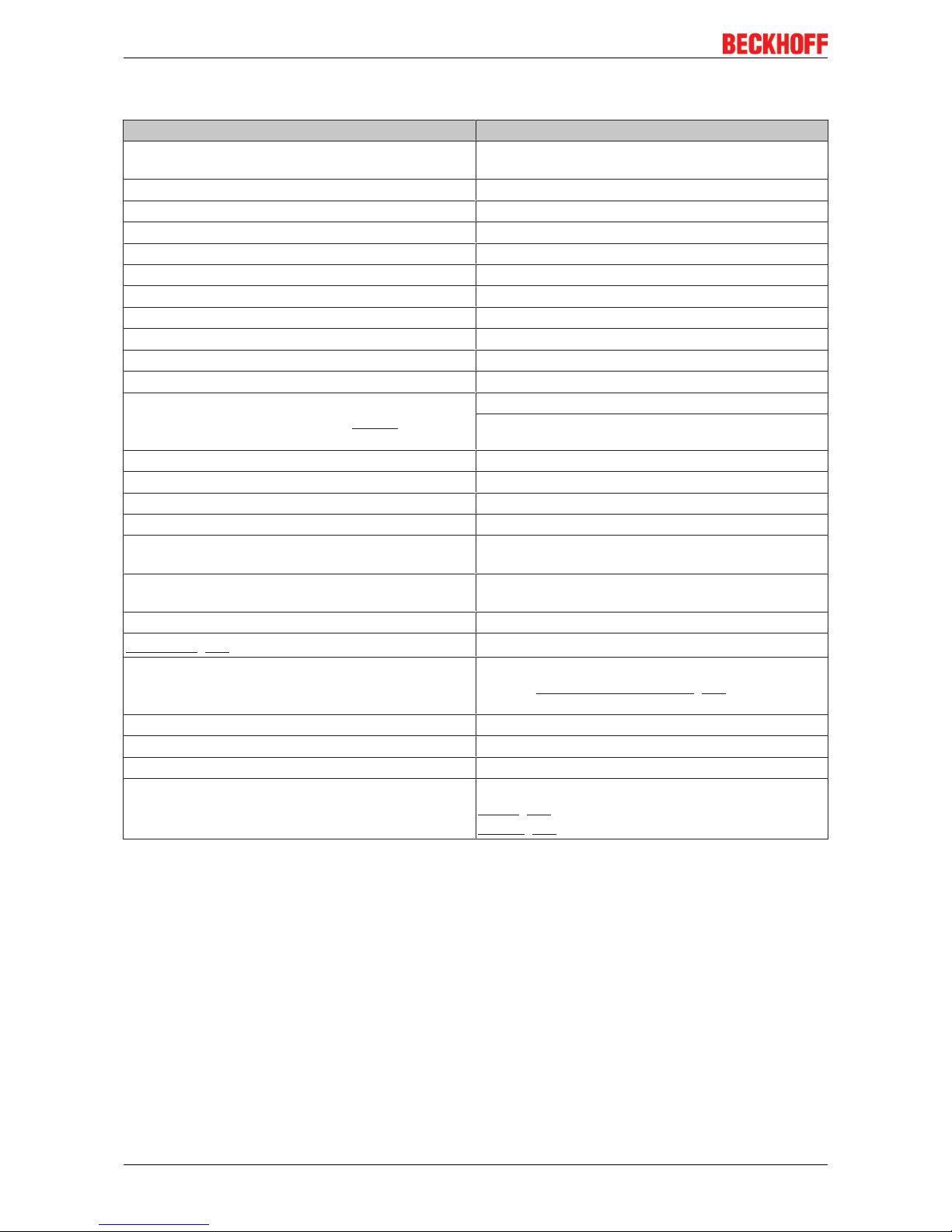

Device XML revision in the configura-

tion

Serial number of the component

BK1150 from BK1150-0000-0016 from firmware 01: xxxx01yy

CU1128 from CU1128-0000-0000 from firmware 00: xxxx00yy

EK1100 from EK1100-0000-0017 from firmware 06: xxxx06yy

EK1101 from EK1101-0000-0017 from firmware 01: xxxx01yy

EK1501 from EK1501-0000-0017 from firmware 01: xxxx01yy

EK1501-0010 from EK1501-0010-0017 from firmware 02: xxxx02yy

EK1122 from EK1122-0000-0017 from firmware 01: xxxx02yy

EK1521 from EK1521-0000-0018 from firmware 03: xxxx03yy

EK1541 from EK1541-0000-0016 from firmware 01: xxxx01yy

EK1561 from EK1561-0000-0016 from firmware 01: xxxx01yy

EK1521-0010 from EK1521-0010-0018 from firmware 03: xxxx03yy

EK1814 from EK1814-0000-0016 from firmware 00: xxxx00yy

To ensure that TwinCAT uses such a component as DC reference clock, a manual intervention during the

configuration setup is required, as shown here using the EK1100 as an example.

The checkboxes “Cyclic Mode Enable” and “Use as potential Reference Clock” must be set.

Page 36

Basics

EK110x, EK15xx36 Version: 3.6

Fig.20: TwinCAT setting for using this component as reference clock

Note

Activation of Distributed Clocks support

The (synchronization) procedure described here is only successful for the components described above. The checkboxes can be set for other components, too, although the hardware does not support this function, unless specified in the respective documentation. In

particularly, please note that after commissioning the component may not be replaced with

a previous version without DC support.

Page 37

Mounting and wiring

EK110x, EK15xx 37Version: 3.6

4 Mounting and wiring

4.1 Instructions for ESD protection

Attention

Destruction of the devices by electrostatic discharge possible!

The devices contain components at risk from electrostatic discharge caused by improper

handling.

ü Please ensure you are electrostatically discharged and avoid touching the contacts of

the device directly.

a) Avoid contact with highly insulating materials (synthetic fibers, plastic film etc.).

b) Surroundings (working place, packaging and personnel) should by grounded probably,

when handling with the devices.

c) Each assembly must be terminated at the right hand end with an EL9011 bus end cap,

to ensure the protection class and ESD protection.

Fig.21: Spring contacts of the Beckhoff I/O components

4.2 Installation on mounting rails

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

disassembly or wiring of the Bus Terminals!

Page 38

Mounting and wiring

EK110x, EK15xx38 Version: 3.6

Assembly

Fig.22: Attaching on mounting rail

The Bus Coupler and Bus Terminals are attached to commercially available 35mm mounting rails (DIN rails

according to EN60715) by applying slight pressure:

1. First attach the Fieldbus Coupler to the mounting rail.

2. The Bus Terminals are now attached on the right-hand side of the Fieldbus Coupler. Join the components with tongue and groove and push the terminals against the mounting rail, until the lock clicks

onto the mounting rail.

If the Terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Note

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting

rail. At the installation, the locking mechanism of the components must not come into conflict with the fixing bolts of the mounting rail. To mount the mounting rails with a height of

7.5mm under the terminals and couplers, you should use flat mounting connections (e.g.

countersunk screws or blind rivets).

Page 39

Mounting and wiring

EK110x, EK15xx 39Version: 3.6

Disassembly

Fig.23: Disassembling of terminal

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

1. Pull the terminal by its orange-colored lugs approximately 1cm away from the mounting rail. In doing

so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of

the bus terminal block easily without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal out of the bus terminal block.

Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the bus terminal block. The power contacts are supplied via terminals on the Bus Coupler (up to 24V)

or for higher voltages via power feed terminals.

Note

Power Contacts

During the design of a bus terminal block, the pin assignment of the individual Bus Terminals must be taken account of, since some types (e.g. analog Bus Terminals or digital 4channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed

Terminals (KL91xx, KL92xx or EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

Page 40

Mounting and wiring

EK110x, EK15xx40 Version: 3.6

Fig.24: Power contact on left side

Attention

Possible damage of the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively

coupled to the mounting rail. This may lead to incorrect results during insulation testing or

to damage on the terminal (e.g. disruptive discharge to the PE line during insulation testing

of a consumer with a nominal voltage of 230V). For insulation testing, disconnect the PE

supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further

feed points for testing, these Power Feed Terminals can be released and pulled at least

10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

4.3 Installation instructions for enhanced mechanical load

capacity

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminal system into a safe, de-energized state before starting mounting,

disassembly or wiring of the Bus Terminals!

Additional checks

The terminals have undergone the following additional tests:

Verification Explanation

Vibration 10 frequency runs in 3 axes

6 Hz < f < 60 Hz displacement 0.35 mm, constant amplitude

60.1Hz<f<500Hz acceleration 5g, constant amplitude

Shocks 1000 shocks in each direction, in 3 axes

25 g, 6 ms

Page 41

Mounting and wiring

EK110x, EK15xx 41Version: 3.6

Additional installation instructions

For terminals with enhanced mechanical load capacity, the following additional installation instructions apply:

• The enhanced mechanical load capacity is valid for all permissible installation positions

• Use a mounting rail according to EN 60715 TH35-15

• Fix the terminal segment on both sides of the mounting rail with a mechanical fixture, e.g. an earth

terminal or reinforced end clamp

• The maximum total extension of the terminal segment (without coupler) is:

64 terminals (12 mm mounting with) or 32 terminals (24 mm mounting with)

• Avoid deformation, twisting, crushing and bending of the mounting rail during edging and installation of

the rail

• The mounting points of the mounting rail must be set at 5 cm intervals

• Use countersunk head screws to fasten the mounting rail

• The free length between the strain relief and the wire connection should be kept as short as possible. A

distance of approx. 10 cm should be maintained to the cable duct.

Page 42

Mounting and wiring

EK110x, EK15xx42 Version: 3.6

4.4 Installation positions

Attention

Constraints regarding installation position and operating temperature range

Please refer to the technical data for a terminal to ascertain whether any restrictions regarding the installation position and/or the operating temperature range have been specified. When installing high power dissipation terminals ensure that an adequate spacing is

maintained between other components above and below the terminal in order to guarantee

adequate ventilation!

Optimum installation position (standard)

The optimum installation position requires the mounting rail to be installed horizontally and the connection

surfaces of the EL/KL terminals to face forward (see Fig. “Recommended distances for standard installation

position”). The terminals are ventilated from below, which enables optimum cooling of the electronics through

convection. "From below" is relative to the acceleration of gravity.

Fig.25: Recommended distances for standard installation position

Compliance with the distances shown in Fig. “Recommended distances for standard installation position” is

recommended.

Other installation positions

All other installation positions are characterized by different spatial arrangement of the mounting rail - see

Fig “Other installation positions”.

The minimum distances to ambient specified above also apply to these installation positions.

Page 43

Mounting and wiring

EK110x, EK15xx 43Version: 3.6

Fig.26: Other installation positions

4.5 Connection system

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

disassembly or wiring of the Bus Terminals!

Overview

The Bus Terminal system offers different connection options for optimum adaptation to the respective

application:

• The terminals of ELxxxx and KLxxxx series with standard wiring include electronics and connection

level in a single enclosure.

• The terminals of ESxxxx and KSxxxx series feature a pluggable connection level and enable steady

wiring while replacing.

• The High Density Terminals (HD Terminals) include electronics and connection level in a single

enclosure and have advanced packaging density.

Page 44

Mounting and wiring

EK110x, EK15xx44 Version: 3.6

Standard wiring (ELxxxx / KLxxxx)

Fig.27: Standard wiring

The terminals of ELxxxx and KLxxxx series have been tried and tested for years.

They feature integrated screwless spring force technology for fast and simple assembly.

Pluggable wiring (ESxxxx / KSxxxx)

Fig.28: Pluggable wiring

The terminals of ESxxxx and KSxxxx series feature a pluggable connection level.

The assembly and wiring procedure for the KS series is the same as for the ELxxxx and KLxxxx series.

The KS/ES series terminals enable the complete wiring to be removed as a plug connector from the top of

the housing for servicing.

The lower section can be removed from the terminal block by pulling the unlocking tab.

Insert the new component and plug in the connector with the wiring. This reduces the installation time and

eliminates the risk of wires being mixed up.

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3

mm. The maximum height of the terminal remains unchanged.

A tab for strain relief of the cable simplifies assembly in many applications and prevents tangling of individual

connection wires when the connector is removed.

Conductor cross sections between 0.08mm2 and 2.5mm2 can continue to be used with the proven spring

force technology.

The overview and nomenclature of the product names for ESxxxx and KSxxxx series has been retained as

known from ELxxxx and KLxxxx series.

High Density Terminals (HD Terminals)

Fig.29: High Density Terminals

The Bus Terminals from these series with 16 terminal points are distinguished by a particularly compact

design, as the packaging density is twice as large as that of the standard 12mm Bus Terminals. Massive

conductors and conductors with a wire end sleeve can be inserted directly into the spring loaded terminal

point without tools.

Page 45

Mounting and wiring

EK110x, EK15xx 45Version: 3.6

Note

Wiring HD Terminals

The High Density (HD) Terminals of the ELx8xx and KLx8xx series doesn't support pluggable wiring.

Ultrasonically "bonded" (ultrasonically welded) conductors

Note

Ultrasonically “bonded" conductors

It is also possible to connect the Standard and High Density Terminals with ultrasonically

"bonded" (ultrasonically welded) conductors. In this case, please note the tables concerning the wire-size width below!

4.6 Wiring

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

disassembly or wiring of the Bus Terminals!

Terminals for standard wiring ELxxxx/KLxxxx and for pluggable wiring ESxxxx/KSxxxx

Fig.30: Connecting a cable on a terminal point

Up to eight terminal points enable the connection of solid or finely stranded cables to the Bus Terminal. The

terminal points are implemented in spring force technology. Connect the cables as follows:

1. Open a terminal point by pushing a screwdriver straight against the stop into the square opening

above the terminal point. Do not turn the screwdriver or move it alternately (don't toggle).

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal point closes automatically when the pressure is released, holding the wire securely and

permanently.

See the following table for the suitable wire size width.

Page 46

Mounting and wiring

EK110x, EK15xx46 Version: 3.6

Terminal housing ELxxxx, KLxxxx ESxxxx, KSxxxx

Wire size width (single core wires) 0.08 ... 2.5mm

2

0.08 ... 2.5mm

2

Wire size width (fine-wire conductors) 0.08 ... 2.5mm

2

0,08 ... 2.5mm

2

Wire size width (conductors with a wire end sleeve) 0.14 ... 1.5mm

2

0.14 ... 1.5mm

2

Wire stripping length 8 ... 9mm 9 ... 10mm

High Density Terminals (HD Terminals [}44]) with 16 terminal points

The conductors of the HD Terminals are connected without tools for single-wire conductors using the direct

plug-in technique, i.e. after stripping the wire is simply plugged into the terminal point. The cables are

released, as usual, using the contact release with the aid of a screwdriver. See the following table for the

suitable wire size width.

Terminal housing High Density Housing

Wire size width (single core wires) 0.08 ... 1.5mm

2

Wire size width (fine-wire conductors) 0.25 ... 1.5mm

2

Wire size width (conductors with a wire end sleeve) 0.14 ... 0.75mm

2

Wire size width (ultrasonically “bonded" conductors) only 1.5mm

2

Wire stripping length 8 ... 9mm

4.7 EtherCAT cabling – wire-bound

The cable length between two EtherCAT devices must not exceed 100 m. This results from the FastEthernet

technology, which, above all for reasons of signal attenuation over the length of the cable, allows a maximum

link length of 5 + 90 + 5 m if cables with appropriate properties are used. See also the Design

recommendations for the infrastructure for EtherCAT/Ethernet.

Cables and connectors

For connecting EtherCAT devices only Ethernet connections (cables + plugs) that meet the requirements of

at least category 5 (CAt5) according to EN 50173 or ISO/IEC 11801 should be used. EtherCAT uses 4 wires

for signal transfer.

EtherCAT uses RJ45 plug connectors, for example. The pin assignment is compatible with the Ethernet

standard (ISO/IEC 8802-3).

Pin Color of conductor Signal Description

1 yellow TD + Transmission Data +

2 orange TD - Transmission Data -

3 white RD + Receiver Data +

6 blue RD - Receiver Data -

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between

EtherCAT devices from Beckhoff.

Note

Recommended cables

Suitable cables for the connection of EtherCAT devices can be found on the Beckhoff website!

E-Bus supply

A bus coupler can supply the EL terminals attached to it with the E-bus system voltage of 5V; a coupler

usually has a load capacity of up to 2 A in this situation (see documentation for the respective devices).

Information on how much current each EL terminal requires from the E-bus supply is available online and in

the catalogue. If the added terminals require more current than the coupler can supply, then power feed

terminals (e.g. EL9400) must be inserted at appropriate places in the terminal strand.

Page 47

Mounting and wiring

EK110x, EK15xx 47Version: 3.6

The pre-calculated theoretical maximum E-bus current is displayed in the TwinCAT System Manager. A

shortfall is marked by a negative total amount and an exclamation mark; a power feed terminal is to be

placed before such a position.

Fig.31: System manager current calculation

Attention

Attention! Malfunction possible!

The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in

a terminal block!

4.8 M8 Connector Cabling

A list of the EtherCAT cable, power cable, sensor cable, Ethernet-/EtherCAT connectors and the field

assembled connectors can be found at the following link: http://download.beckhoff.com/download/

document/catalog/main_catalog/english/Beckhoff_EtherCAT-Box-Accessories.pdf

You can find the corresponding data sheets at the following link: http://beckhoff.de/english/fieldbus_box/

data_sheets.htm?id=69033899254355

EtherCAT cable

Fig.32: ZK1090-3131-0xxx

Page 48

Mounting and wiring

EK110x, EK15xx48 Version: 3.6

For connecting EtherCAT devices only shielded Ethernet cables that meet the requirements of at least

category 5 (CAT5) according to EN 50173 or ISO/IEC 11801 should be used.

Note

Recommendations about cabling

You may get detailed recommendations about cabling EtherCAT from the documentation

"Recommendations for the design of the infrastructure for EtherCAT/Ethernet", that is available for download at www.Beckhoff.com.

EtherCAT uses 4 wires for signal transfer.

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between

EtherCAT devices from Beckhoff.

M8 Connector pin assignment

Signal Description Pin (M8)

Tx+ Transmit Data+ 1

Tx- Transmit Data- 4

Rx+ Receive Data+ 2

Rx- Receive Data- 3

Shield Shielding Housing

Page 49

Mounting and wiring

EK110x, EK15xx 49Version: 3.6

4.9 Nut torque for connectors

Fig.33: X1 and X2 of EK1100-0008

For usage of the EtherCAT connectors M8 of EK1100-0008 the following have to be noticed:

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm. When using the torque control

screwdriver ZB8800 is also a max. torque of 0.5Nm permissible.

Fig.34: EtherCAT Box with M8 connectors

Page 50

Mounting and wiring

EK110x, EK15xx50 Version: 3.6

4.10 Power supply, potential groups

Bus Coupler power supply

The Bus Couplers require a 24 V DC supply for their operation. The connection is made by means of the

upper spring-loaded terminals labelled 24V and 0V. The supply voltage is used by the Bus Coupler

electronics and for direct voltage generation for the E-bus. The voltage generation for the E-bus takes place

in a DC/DC converter without electrical isolation.

The EK1xxx units supply the E-bus with max. 2,000 mA E-bus current. Power feed terminals are to be

inserted if the added terminals require more current.

Input for power contacts

The bottom six connections with spring-loaded terminals can be used to feed the supply for the peripherals.