Page 1

Documentation | EN

EK1322

2-port EtherCAT P junction with feed-in

2021-03-01 | Version: 1.1

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

1.4 Version identification of EtherCAT devices .......................................................................................7

1.4.1 Beckhoff Identification Code (BIC)................................................................................... 11

2 Product overview.....................................................................................................................................13

2.1 Introduction......................................................................................................................................13

2.2 EtherCATP .....................................................................................................................................13

2.3 Technical data .................................................................................................................................14

2.4 Start .................................................................................................................................................14

3 Basics communication ...........................................................................................................................16

3.1 System properties............................................................................................................................16

3.2 EtherCAT basics..............................................................................................................................19

3.3 EtherCAT State Machine.................................................................................................................19

3.4 CoE - Interface: notes......................................................................................................................20

3.5 Distributed Clock .............................................................................................................................20

3.6 EtherCAT P introduction..................................................................................................................20

4 Mounting and wiring................................................................................................................................24

4.1 Installation on mounting rails ...........................................................................................................24

4.2 Installation positions ........................................................................................................................26

4.3 Connection system ..........................................................................................................................28

4.4 Positioning of passive Terminals .....................................................................................................31

4.5 ATEX - Special conditions (standard temperature range) ...............................................................32

4.6 Continuative documentation for ATEX and IECEx ..........................................................................33

4.7 Connection EK1322.........................................................................................................................33

4.8 EtherCAT P connection ...................................................................................................................34

4.9 Nut torque for connectors ................................................................................................................36

4.10 Cabling ............................................................................................................................................36

4.11 EtherCAT P cable conductor losses M8..........................................................................................40

5 Commissioning........................................................................................................................................41

5.1 EK1322 - Configuration by means of the TwinCAT System Manager.............................................41

6 Error handling and diagnostics..............................................................................................................49

6.1 Diagnostic LED................................................................................................................................49

7 Appendix ..................................................................................................................................................51

7.1 EtherCAT AL Status Codes.............................................................................................................51

7.2 Firmware compatibility.....................................................................................................................51

7.3 Firmware Update EL/ES/EM/ELM/EPxxxx ......................................................................................51

7.3.1 Device description ESI file/XML....................................................................................... 52

7.3.2 Firmware explanation ...................................................................................................... 55

7.3.3 Updating controller firmware *.efw................................................................................... 56

7.3.4 FPGA firmware *.rbf......................................................................................................... 58

7.3.5 Simultaneous updating of several EtherCAT devices...................................................... 62

EK1322 3Version: 1.1

Page 4

Table of contents

7.4 Support and Service ........................................................................................................................63

EK13224 Version: 1.1

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EK1322 5Version: 1.1

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EK13226 Version: 1.1

Page 7

1.3 Documentation issue status

Version Modifications

1.1 • Addenda within „Firmware Update EL/ES/ELM/EM/EPxxxx"

• Addenda within chapter „Version identification of EtherCAT devices“ of chapter

„Beckhoff Identification Code (BIC)“

• Addenda within chapter „Support and Service“ (appendix)

• Chapter „Safety instructions“ updated

• Chapter „EtherCAT P cable conductor losses M8“ updated

• Chapter „ATEX - Special conditions“ updated

1.0 • 1st public issue

0.1 • 1st version

1.4 Version identification of EtherCAT devices

Designation

A Beckhoff EtherCAT device has a 14-digit designation, made up of

Foreword

• family key

• type

• version

• revision

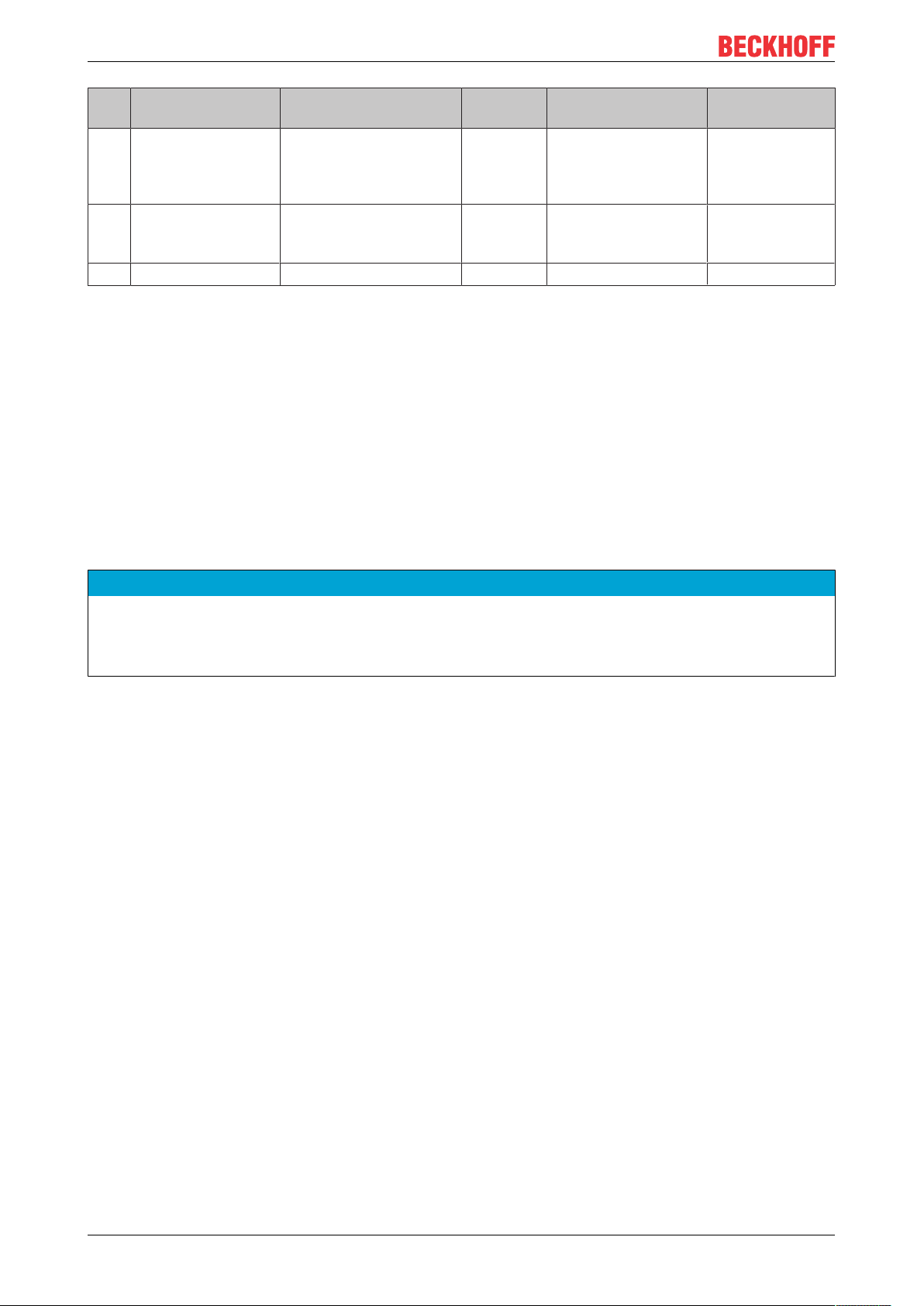

Example Family Type Version Revision

EL3314-0000-0016 EL terminal

(12 mm, nonpluggable connection

level)

ES3602-0010-0017 ES terminal

(12 mm, pluggable

connection level)

CU2008-0000-0000 CU device 2008 (8-port fast ethernet switch) 0000 (basic type) 0000

Notes

• The elements mentioned above result in the technical designation. EL3314-0000-0016 is used in the

example below.

• EL3314-0000 is the order identifier, in the case of “-0000” usually abbreviated to EL3314. “-0016” is the

EtherCAT revision.

• The order identifier is made up of

- family key (EL, EP, CU, ES, KL, CX, etc.)

- type (3314)

- version (-0000)

• The revision -0016 shows the technical progress, such as the extension of features with regard to the

EtherCAT communication, and is managed by Beckhoff.

In principle, a device with a higher revision can replace a device with a lower revision, unless specified

otherwise, e.g. in the documentation.

Associated and synonymous with each revision there is usually a description (ESI, EtherCAT Slave

Information) in the form of an XML file, which is available for download from the Beckhoff web site.

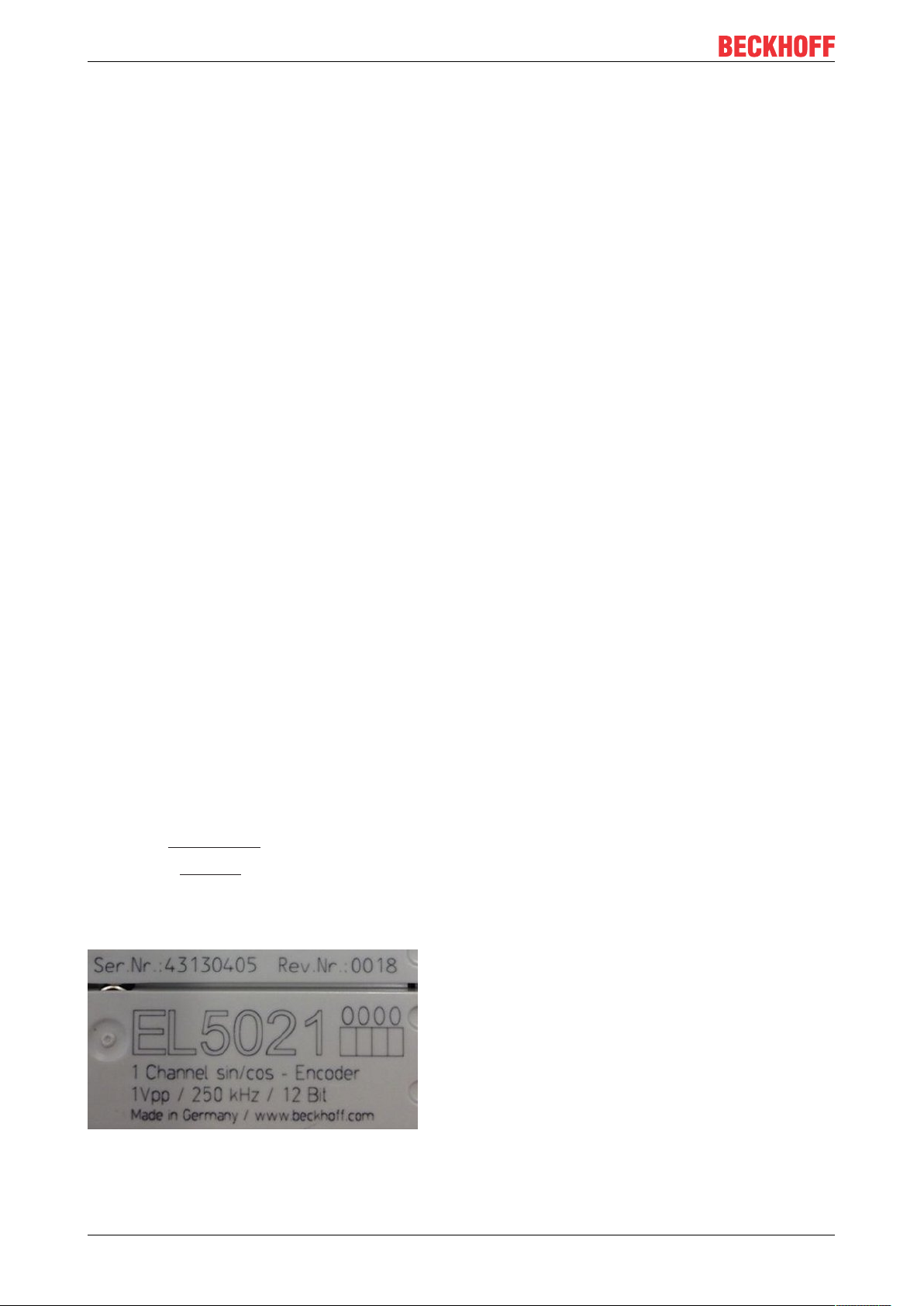

From 2014/01 the revision is shown on the outside of the IP20 terminals, see Fig. “EL5021 EL terminal,

standard IP20 IO device with batch number and revision ID (since 2014/01)”.

• The type, version and revision are read as decimal numbers, even if they are technically saved in

hexadecimal.

3314 (4-channel thermocouple

terminal)

3602 (2-channel voltage

measurement)

0000 (basic type) 0016

0010 (highprecision version)

0017

EK1322 7Version: 1.1

Page 8

Foreword

Identification number

Beckhoff EtherCAT devices from the different lines have different kinds of identification numbers:

Production lot/batch number/serial number/date code/D number

The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker.

The serial number indicates the configuration in delivery state and therefore refers to a whole production

batch, without distinguishing the individual modules of a batch.

Structure of the serial number: KKYYFFHH

KK - week of production (CW, calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with

Ser. no.: 12063A02: 12 - production week 12 06 - production year 2006 3A - firmware version 3A 02 hardware version 02

Exceptions can occur in the IP67 area, where the following syntax can be used (see respective device

documentation):

Syntax: D ww yy x y z u

D - prefix designation

ww - calendar week

yy - year

x - firmware version of the bus PCB

y - hardware version of the bus PCB

z - firmware version of the I/O PCB

u - hardware version of the I/O PCB

Example: D.22081501 calendar week 22 of the year 2008 firmware version of bus PCB: 1 hardware version

of bus PCB: 5 firmware version of I/O PCB: 0 (no firmware necessary for this PCB) hardware version of I/O

PCB: 1

Unique serial number/ID, ID number

In addition, in some series each individual module has its own unique serial number.

See also the further documentation in the area

• IP67: EtherCAT Box

• Safety: TwinSafe

• Terminals with factory calibration certificate and other measuring terminals

Examples of markings

Fig.1: EL5021 EL terminal, standard IP20 IO device with serial/ batch number and revision ID (since

2014/01)

EK13228 Version: 1.1

Page 9

Fig.2: EK1100 EtherCAT coupler, standard IP20 IO device with serial/ batch number

Foreword

Fig.3: CU2016 switch with serial/ batch number

Fig.4: EL3202-0020 with serial/ batch number 26131006 and unique ID-number 204418

EK1322 9Version: 1.1

Page 10

Foreword

Fig.5: EP1258-00001 IP67 EtherCAT Box with batch number/ date code 22090101 and unique serial

number 158102

Fig.6: EP1908-0002 IP67 EtherCAT Safety Box with batch number/ date code 071201FF and unique serial

number 00346070

Fig.7: EL2904 IP20 safety terminal with batch number/ date code 50110302 and unique serial number

00331701

Fig.8: ELM3604-0002 terminal with unique ID number (QR code) 100001051 and serial/ batch number

44160201

EK132210 Version: 1.1

Page 11

Foreword

1.4.1 Beckhoff Identification Code (BIC)

The Beckhoff Identification Code (BIC) is increasingly being applied to Beckhoff products to uniquely identify

the product. The BIC is represented as a Data Matrix Code (DMC, code scheme ECC200), the content is

based on the ANSI standard MH10.8.2-2016.

Fig.9: BIC as data matrix code (DMC, code scheme ECC200)

The BIC will be introduced step by step across all product groups.

Depending on the product, it can be found in the following places:

• on the packaging unit

• directly on the product (if space suffices)

• on the packaging unit and the product

The BIC is machine-readable and contains information that can also be used by the customer for handling

and product management.

Each piece of information can be uniquely identified using the so-called data identifier

(ANSIMH10.8.2-2016). The data identifier is followed by a character string. Both together have a maximum

length according to the table below. If the information is shorter, spaces are added to it. The data under

positions 1 to 4 are always available.

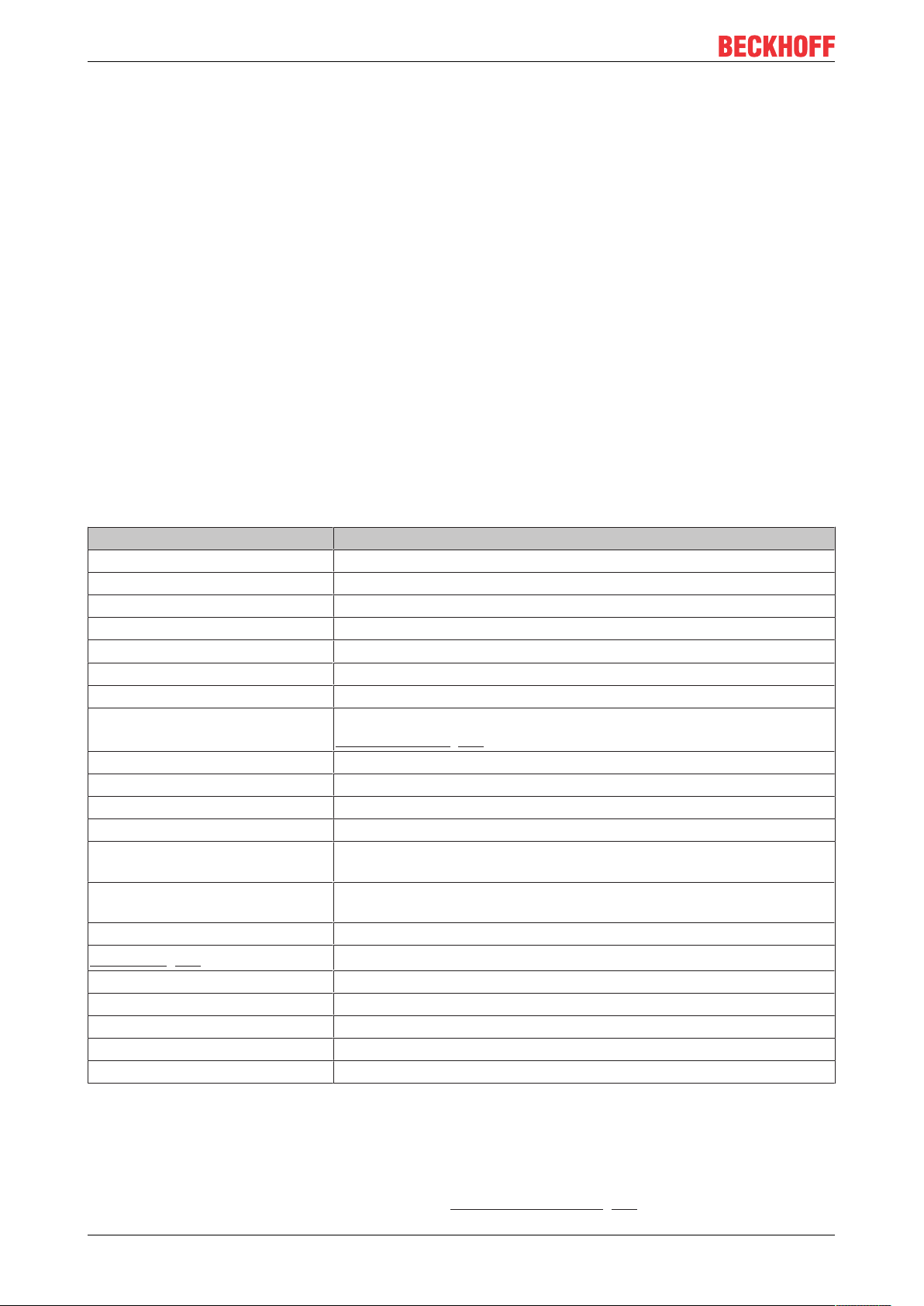

The following information is contained:

Item

Type of

no.

information

1 Beckhoff order

number

2 Beckhoff Traceability

Number (BTN)

3 Article description Beckhoff article

4 Quantity Quantity in packaging

5 Batch number Optional: Year and week

Explanation Data

identifier

Beckhoff order number 1P 8 1P072222

Unique serial number,

see note below

description, e.g.

EL1008

unit, e.g. 1, 10, etc.

of production

S 12 SBTNk4p562d7

1K 32 1KEL1809

Q 6 Q1

2P 14 2P401503180016

Number of digits

incl. data identifier

Example

EK1322 11Version: 1.1

Page 12

Foreword

Item

Type of

no.

information

6 ID/serial number Optional: Present-day

7 Variant number Optional: Product variant

...

Further types of information and data identifiers are used by Beckhoff and serve internal processes.

Structure of the BIC

Example of composite information from item 1 to 4 and 6. The data identifiers are marked in red for better

display:

BTN

An important component of the BIC is the Beckhoff Traceability Number (BTN, item no.2). The BTN is a

unique serial number consisting of eight characters that will replace all other serial number systems at

Beckhoff in the long term (e.g. batch designations on IO components, previous serial number range for

safety products, etc.). The BTN will also be introduced step by step, so it may happen that the BTN is not yet

coded in the BIC.

Explanation Data

identifier

51S 12 51S678294104

serial number system,

e.g. with safety products

or calibrated terminals

30P 32 30PF971, 2*K183

number on the basis of

standard products

Number of digits

incl. data identifier

Example

NOTE

This information has been carefully prepared. However, the procedure described is constantly being further

developed. We reserve the right to revise and change procedures and documentation at any time and without prior notice. No claims for changes can be made from the information, illustrations and descriptions in

this information.

EK132212 Version: 1.1

Page 13

2 Product overview

2.1 Introduction

EK1322 | 2‑port EtherCAT P junction with feed‑in

Product overview

Fig.10: EK1322

The 2‑port EK1322 EtherCAT P junction enables configuration of EtherCAT P star topologies. The ports can

be used to connect individual EtherCAT P devices or whole EtherCAT P strands. The EK1322 can be

installed at any point in an EtherCAT strand between the EtherCAT Terminals (ELxxxx). The front terminal

points are used for the system and sensor supply US and the peripheral voltage for actuators UP for the

EtherCAT P outputs. In addition to the Run LED and the link and activity status of the respective port, two

status LEDs indicate the state of the US and UP voltages, as well as overload and short‑circuit events.

2.2 EtherCATP

EtherCATP combines communication and power in a single 4-wire standard Ethernet cable. The 24VDC

supply of the EtherCATP slaves and the connected sensors and actors is integrated within this bus system:

US (system- and Sensor supply) and UP (peripheral voltage for actors) are electrical isolated with 3A current

available for the connected components. All the benefits of EtherCAT, such as freedom in topology design,

high speed, optimum bandwidth utilization, telegram processing on-the-fly, highly precise synchronization,

extensive diagnostics functionality, etc. are all retained while integrating the voltages.

With EtherCATP technology, the currents are coupled directly into the wires of the 100 Mbit line, enabling

the realization of a highly cost-effective and compact connection. In order to rule out the possibility of

incorrect connections to standard EtherCAT slaves and, thus possible defects, a new plug family has been

specially developed for EtherCATP. The plug family covers all applications from the 24 V I/O level up to

drives with 400 V AC or 600 V DC and a current of up to 64 A.

EtherCATP offers extensive savings potential:

• elimination of separate supply cables

• low wiring effort and significant time savings

EK1322 13Version: 1.1

Page 14

Product overview

• sources of error are reduced

• minimization of installation space for drag-chains and control cabinets

• smaller and tidier cable trays

• smaller sensors and actuators through the elimination of separate supply cables

As is typical with EtherCAT, the user benefits from the wide choice in topology and can combine line, star

and tree architectures with one another in order to achieve the least expensive and best possible system

layouts. Unlike the traditional Power over Ethernet (PoE), devices can also be cascaded using EtherCATP

and supplied with power from one power supply unit.

When designing a machine, the individual consumers, cable lengths and cable types are configured with tool

assistance and this information is used to create the optimum layout of the EtherCATP network. Since it is

known what sensors and actuators will be connected and which ones will be operated simultaneously, the

power consumption can be accounted for accordingly. For example, if two actuators never switch

simultaneously from a logical point of view, they also never need the full load simultaneously. The result is

further savings potential in terms of the required supplies and power supply units.

Also see about this

2 EtherCAT P introduction [}20]

2.3 Technical data

Technical data EK1322

Task in the EtherCAT system coupling of EtherCAT P junctions

Data transfer medium EtherCAT P cable, shielded, to 100BASE-TX EtherCAT P networks

Businterface 2 x M8 socket, shielded, screw type, EtherCAT-P-coded

Power supply external feed-in: 24 V DC for US and U

Total current max. 3 A each US and UP for feed-in

Current consumption from U

Current consumption from U

S

P

typ. 3 mA

typ. 3 mA

Current rating per port max. 3 A each US and UP (note the total current, see chapter

Commissioning [}41])

Current consumption E-bus typ. 200 mA

Electrical isolation 500 V (supply voltage US / supply voltage UP / EtherCAT)

Dimensions (W x H x D) approx. 24 mm x 100 mm x 62 mm

Weight approx. 100 g

Permissible ambient temperature

0°C ... +55°C

range during operation

Permissible ambient temperature

-25°C ... + 85°C

range during storage

Permissible relative humidity 95%, no condensation

Mounting [}24]

on 35 mm mounting rail conforms to EN 60715

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE

P

2.4 Start

For commissioning:

• mount the EK1322 as described in the chapter Mounting and wiring [}24]

EK132214 Version: 1.1

Page 15

Product overview

• configure the EK1322 in TwinCAT as described in chapter Parameterization and commissioning

[}41].

EK1322 15Version: 1.1

Page 16

Basics communication

3 Basics communication

3.1 System properties

Protocol

The EtherCAT protocol is optimized for process data and is transported directly within the Ethernet frame

thanks to a special Ether-type. It may consist of several sub-telegrams, each serving a particular memory

area of the logical process images that can be up to 4 gigabytes in size. The data sequence is independent

of the physical order of the Ethernet terminals in the network; addressing can be in any order. Broadcast,

Multicast and communication between slaves are possible. Transfer directly in the Ethernet frame is used in

cases where EtherCAT components are operated in the same subnet as the control computer.

However, EtherCAT applications are not limited to a subnet: EtherCAT UDP packs the EtherCAT protocol

into UDP/IP datagrams. This enables any control with Ethernet protocol stack to address EtherCAT systems.

Even communication across routers into other subnets is possible. In this variant, system performance

obviously depends on the real-time characteristics of the control and its Ethernet protocol implementation.

The response times of the EtherCAT network itself are hardly restricted at all: the UDP datagram only has to

be unpacked in the first station.

Fig.11: EtherCAT Telegram Structure

Protocol structure: The process image allocation is freely configurable. Data are copied directly in the I/O

terminal to the desired location within the process image: no additional mapping is required. The available

logical address space is with very large (4 GB).

EK132216 Version: 1.1

Page 17

Basics communication

Topology

Line, tree or star: EtherCAT supports almost any topology. The bus or line structure known from the

fieldbuses thus also becomes available for Ethernet. Particularly useful for system wiring is the combination

of line and junctions or stubs. The required interfaces exist on the couplers; no additional switches are

required. Naturally, the classic switch-based Ethernet star topology can also be used.

Fig.12: EtherCAT Topology

Maximum wiring flexibility:

with or without switch, line or tree topologies, can be freely selected and combined.

Wiring flexibility is further maximized through the choice of different cables. Flexible and cost-effective

standard Ethernet patch cables transfer the signals in Ethernet mode (100Base-TX). The complete

bandwidth of the Ethernet network - such as different optical fibers and copper cables - can be used in

combination with switches or media converters.

Distributed Clocks

Accurate synchronization is particularly important in cases where spatially distributed processes require

simultaneous actions. This may be the case, for example, in applications where several servo axes carry out

coordinated movements simultaneously.

The most powerful approach for synchronization is the accurate alignment of distributed clocks, as described

in the new IEEE 1588 standard. In contrast to fully synchronous communication, where synchronization

quality suffers immediately in the event of a communication fault, distributed aligned clocks have a high

degree of tolerance vis-à-vis possible fault-related delays within the communication system.

EK1322 17Version: 1.1

Page 18

Basics communication

With EtherCAT, the data exchange is fully based on a pure hardware machine. Since the communication

utilizes a logical (and thanks to full-duplex Fast Ethernet also physical) ring structure, the mother clock can

determine the run-time offset to the individual daughter clocks simply and accurately - and vice versa. The

distributed clocks are adjusted based on this value, which means that a very precise network-wide timebase

with a jitter of significantly less than 1 microsecond is available.

However, high-resolution distributed clocks are not only used for synchronization, but can also provide

accurate information about the local timing of the data acquisition. For example, controls frequently calculate

velocities from sequentially measured positions. Particularly with very short sampling times, even a small

temporal jitter in the displacement measurement leads to large step changes in velocity. With EtherCAT new,

extended data types are introduced as a logical extension (time stamp and oversampling data type). The

local time is linked to the measured value with a resolution of up to 10 ns, which is made possible by the

large bandwidth offered by Ethernet. The accuracy of a velocity calculation then no longer depends on the

jitter of the communication system. It is orders of magnitude better than that of measuring techniques based

on jitter-free communication.

Performance

EtherCAT reaches new dimensions in network performance. Protocol processing is purely hardware-based

through an FMMU chip in the terminal and DMA access to the network card of the master. It is thus

independent of protocol stack run-times, CPU performance and software implementation. The update time

for 1000 I/Os is only 30 µs - including terminal cycle time. Up to 1486 bytes of process data can be

exchanged with a single Ethernet frame - this is equivalent to almost 12000 digital inputs and outputs. The

transfer of this data quantity only takes 300 µs.

The communication with 100 servo axes only takes 100 µs. During this time, all axes are provided with set

values and control data and report their actual position and status. Distributed clocks enable the axes to be

synchronized with a deviation of significantly less than 1 microsecond.

The extremely high performance of the EtherCAT technology enables control concepts that could not be

realized with classic fieldbus systems. For example, the Ethernet system can now not only deal with velocity

control, but also with the current control of distributed drives. The tremendous bandwidth enables status

information to be transferred with each data item. With EtherCAT, a communication technology is available

that matches the superior computing power of modern Industrial PCs. The bus system is no longer the

bottleneck of the control concept. Distributed I/Os are recorded faster than is possible with most local I/O

interfaces. The EtherCAT technology principle is scalable and not bound to the baud rate of 100 Mbaud –

extension to Gbit Ethernet is possible.

Diagnostics

Experience with fieldbus systems shows that availability and commissioning times crucially depend on the

diagnostic capability. Only faults that are detected quickly and accurately and which can be precisely located

can be corrected quickly. Therefore, special attention was paid to exemplary diagnostic features during the

development of EtherCAT.

During commissioning, the actual configuration of the I/O terminals should be checked for consistency with

the specified configuration. The topology should also match the saved configuration. Due to the built-in

topology recognition down to the individual terminals, this verification can not only take place during system

start-up, automatic reading in of the network is also possible (configuration upload).

Bit faults during the transfer are reliably detected through evaluation of the CRC checksum: The 32 bit CRC

polynomial has a minimum hamming distance of 4. Apart from breaking point detection and localization, the

protocol, physical transfer behavior and topology of the EtherCAT system enable individual quality

monitoring of each individual transmission segment. The automatic evaluation of the associated error

counters enables precise localization of critical network sections. Gradual or changing sources of error such

as EMC influences, defective push-in connectors or cable damage are detected and located, even if they do

not yet overstrain the self-healing capacity of the network.

Integration of standard Bus Terminals from Beckhoff

In addition to the new Bus Terminals with E-Bus connection (ELxxxx), all Bus Terminals from the familiar

standard range with K-bus connection (KLxxxx) can be connected via the BK1120 or BK1250 Bus Coupler.

This ensures compatibility and continuity with the existing Beckhoff Bus Terminal systems. Existing

investments are protected.

EK132218 Version: 1.1

Page 19

Basics communication

3.2 EtherCAT basics

Please refer to the EtherCAT System Documentation for the EtherCAT fieldbus basics.

3.3 EtherCAT State Machine

The state of the EtherCAT slave is controlled via the EtherCAT State Machine (ESM). Depending upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the bootup of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Boot

The regular state of each EtherCAT slave after bootup is the OP state.

Fig.13: States of the EtherCAT State Machine

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

EK1322 19Version: 1.1

Page 20

Basics communication

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before

it acknowledges the change of state, the EtherCAT slave copies current input data into the associated DPRAM areas of the EtherCAT slave controller (ECSC).

In Safe-Op state mailbox and process data communication is possible, although the slave keeps its outputs

in a safe state, while the input data are updated cyclically.

Outputs in SAFEOP state

The default set watchdog monitoring sets the outputs of the module in a safe state - depending on

the settings in SAFEOP and OP - e.g. in OFF state. If this is prevented by deactivation of the watchdog monitoring in the module, the outputs can be switched or set also in the SAFEOP state.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

Boot

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

3.4 CoE - Interface: notes

This device has no CoE.

Detailed information on the CoE interface can be found in the EtherCAT system documentation on the

Beckhoff website.

3.5 Distributed Clock

The distributed clock represents a local clock in the EtherCAT slave controller (ESC) with the following

characteristics:

• Unit 1 ns

• Zero point 1.1.2000 00:00

• Size 64 bit (sufficient for the next 584 years; however, some EtherCAT slaves only offer 32-bit support,

i.e. the variable overflows after approx. 4.2 seconds)

• The EtherCAT master automatically synchronizes the local clock with the master clock in the EtherCAT

bus with a precision of < 100 ns.

For detailed information please refer to the EtherCAT system description.

3.6 EtherCAT P introduction

One cable solution for the field level

With EtherCAT P, Beckhoff combines communication and power in a single 4-wire standard Ethernet cable.

The 24 V DC supply of the EtherCAT P slaves and of the connected sensors and actuators is integrated: US

(system and sensor supply) and UP (peripheral voltage for actuators) are electrically isolated from each

EK132220 Version: 1.1

Page 21

Basics communication

other and can each supply a current of up to 3 A to the connected components. At the same time, all the

benefits of EtherCAT, such as: Cascadable in all topologies (star, line, tree), telegram processing on-the-fly,

high data transfer rate 100Mbit/s full duplex, optimum bandwidth utilization, highly precise synchronization,

extensive diagnostics functionality, etc., are all retained.

The currents of US and UP are coupled directly into the wires of the 100 Mbit/s line, enabling the realisation of

a highly cost-effective and compact connection. EtherCATP offers benefits both for connection of remote,

smaller I/O stations in the terminal box and for decentralised I/O components locally in the process. The

function principle of the one cable solution for the field is shown in the following figure.

Fig.14: From EtherCAT to EtherCATP

The mechanical EtherCATP coding (see figure below) was developed to prevent potential damage caused

by incorrect connection with standard EtherCAT modules. The connector face consists of a centrally located

T-piece and a nose and a triangle outside, also the 4 contacts are arranged symmetrically.

EK1322 21Version: 1.1

Page 22

Basics communication

Fig.15: Connector face: EtherCAT, Power and EtherCAT P

System overview

The system overview (see following figure) shows the free choice of topology with IP 20 and IP 67 products.

Also the wide range of modules for different types of signals is significantly. EtherCATP can directly supply

the sensors/actuators. The sensors/actuators can be supplied directly with power via EtherCATP.

EK132222 Version: 1.1

Page 23

Basics communication

Fig.16: EtherCAT P: System overview for IP 20 and IP 67

EK1322 23Version: 1.1

Page 24

Mounting and wiring

4 Mounting and wiring

4.1 Installation on mounting rails

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the bus terminals!

Assembly

Fig.17: Attaching on mounting rail

The bus coupler and bus terminals are attached to commercially available 35mm mounting rails (DIN rails

according to EN60715) by applying slight pressure:

1. First attach the fieldbus coupler to the mounting rail.

2. The bus terminals are now attached on the right-hand side of the fieldbus coupler. Join the components with tongue and groove and push the terminals against the mounting rail, until the lock clicks

onto the mounting rail.

If the terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting rail. At

the installation, the locking mechanism of the components must not come into conflict with the fixing

bolts of the mounting rail. To mount the mounting rails with a height of 7.5mm under the terminals

and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets).

EK132224 Version: 1.1

Page 25

Mounting and wiring

Disassembly

Fig.18: Disassembling of terminal

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

1. Pull the terminal by its orange-colored lugs approximately 1cm away from the mounting rail. In doing

so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of

the bus terminal block easily without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal out of the bus terminal block.

Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the bus terminal block. The power contacts are supplied via terminals on the Bus Coupler (up to 24V)

or for higher voltages via power feed terminals.

Power Contacts

During the design of a bus terminal block, the pin assignment of the individual Bus Terminals must

be taken account of, since some types (e.g. analog Bus Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed Terminals (KL91xx, KL92xx

or EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

EK1322 25Version: 1.1

Page 26

Mounting and wiring

Fig.19: Power contact on left side

NOTE

Possible damage of the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the

mounting rail. This may lead to incorrect results during insulation testing or to damage on the terminal (e.g.

disruptive discharge to the PE line during insulation testing of a consumer with a nominal voltage of 230V).

For insulation testing, disconnect the PE supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further feed points for testing, these Power Feed Terminals can be released and pulled at

least 10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

4.2 Installation positions

NOTE

Constraints regarding installation position and operating temperature range

Please refer to the technical data for a terminal to ascertain whether any restrictions regarding the installation position and/or the operating temperature range have been specified. When installing high power dissipation terminals ensure that an adequate spacing is maintained between other components above and below the terminal in order to guarantee adequate ventilation!

Optimum installation position (standard)

The optimum installation position requires the mounting rail to be installed horizontally and the connection

surfaces of the EL/KL terminals to face forward (see Fig. Recommended distances for standard installation

position). The terminals are ventilated from below, which enables optimum cooling of the electronics through

convection. “From below” is relative to the acceleration of gravity.

EK132226 Version: 1.1

Page 27

Mounting and wiring

Fig.20: Recommended distances for standard installation position

Compliance with the distances shown in Fig. Recommended distances for standard installation position is

recommended.

Other installation positions

All other installation positions are characterized by different spatial arrangement of the mounting rail - see

Fig Other installation positions.

The minimum distances to ambient specified above also apply to these installation positions.

EK1322 27Version: 1.1

Page 28

Mounting and wiring

Fig.21: Other installation positions

4.3 Connection system

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the Bus Terminals!

Overview

The Bus Terminal system offers different connection options for optimum adaptation to the respective

application:

• The terminals of KLxxxx and ELxxxx series with standard wiring include electronics and connection

level in a single enclosure.

• The terminals of KSxxxx and ESxxxx series feature a pluggable connection level and enable steady

wiring while replacing.

• The High Density Terminals (HD Terminals) include electronics and connection level in a single

enclosure and have advanced packaging density.

Standard wiring

Fig.22: Standard wiring

The terminals of KLxxxx and ELxxxx series have been tried and tested for years.

They feature integrated screwless spring force technology for fast and simple assembly.

EK132228 Version: 1.1

Page 29

Mounting and wiring

Pluggable wiring

Fig.23: Pluggable wiring

The terminals of KSxxxx and ESxxxx series feature a pluggable connection level.

The assembly and wiring procedure for the KS series is the same as for the KLxxxx and ELxxxx series.

The KS/ES series terminals enable the complete wiring to be removed as a plug connector from the top of

the housing for servicing.

The lower section can be removed from the terminal block by pulling the unlocking tab.

Insert the new component and plug in the connector with the wiring. This reduces the installation time and

eliminates the risk of wires being mixed up.

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3

mm. The maximum height of the terminal remains unchanged.

A tab for strain relief of the cable simplifies assembly in many applications and prevents tangling of individual

connection wires when the connector is removed.

Conductor cross sections between 0.08mm2 and 2.5mm2 can continue to be used with the proven spring

force technology.

The overview and nomenclature of the product names for KSxxxx and ESxxxx series has been retained as

known from KLxxxx and ELxxxx series.

High Density Terminals (HD Terminals)

Fig.24: High Density Terminals

The Bus Terminals from these series with 16 connection points are distinguished by a particularly compact

design, as the packaging density is twice as large as that of the standard 12mm Bus Terminals. Massive

conductors and conductors with a wire end sleeve can be inserted directly into the spring loaded terminal

point without tools.

Wiring HD Terminals

The High Density Terminals of the KLx8xx and ELx8xx series doesn't support steady wiring.

Ultrasonically "bonded" (ultrasonically welded) conductors

Ultrasonically “bonded” conductors

It is also possible to connect the Standard and High Density terminals with ultrasonically

“bonded” (ultrasonically welded) conductors. In this case, please note the tables concerning the

wire-size width [}30] below!

EK1322 29Version: 1.1

Page 30

Mounting and wiring

Wiring

Terminals for standard wiring ELxxxx/KLxxxx and for pluggable wiring ESxxxx/KSxxxx

Fig.25: Mounting a cable on a terminal connection

Up to eight connections enable the connection of solid or finely stranded cables to the Bus Terminals. The

terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square opening

above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire securely and permanently.

Terminal housing ELxxxx, KLxxxx ESxxxx, KSxxxx

Wire size width 0.08 ... 2,5mm

2

0.08 ... 2.5mm

2

Wire stripping length 8 ... 9mm 9 ... 10mm

High Density Terminals ELx8xx, KLx8xx (HD)

The conductors of the HD Terminals are connected without tools for single-wire conductors using the direct

plug-in technique, i.e. after stripping the wire is simply plugged into the contact point. The cables are

released, as usual, using the contact release with the aid of a screwdriver. See the following table for the

suitable wire size width.

Terminal housing High Density Housing

Wire size width (conductors with a wire end sleeve) 0.14 ... 0.75mm

Wire size width (single core wires) 0.08 ... 1.5mm

Wire size width (fine-wire conductors) 0.25 ... 1.5mm

Wire size width (ultrasonically “bonded" conductors)

only 1.5mm2 (see notice [}29]!)

2

2

2

Wire stripping length 8 ... 9mm

EK132230 Version: 1.1

Page 31

Shielding

Shielding

Analog sensors and actors should always be connected with shielded, twisted paired wires.

4.4 Positioning of passive Terminals

Hint for positioning of passive terminals in the bus terminal block

EtherCAT Terminals (ELxxxx / ESxxxx), which do not take an active part in data transfer within the

bus terminal block are so called passive terminals. The passive terminals have no current consumption out of the E-Bus.

To ensure an optimal data transfer, you must not directly string together more than two passive terminals!

Examples for positioning of passive terminals (highlighted)

Mounting and wiring

Fig.26: Correct positioning

Fig.27: Incorrect positioning

EK1322 31Version: 1.1

Page 32

Mounting and wiring

4.5 ATEX - Special conditions (standard temperature range)

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus components with

standard temperature range in potentially explosive areas (directive2014/34/EU)!

• The certified components are to be installed in a suitable housing that guarantees a protection class of at

least IP54 in accordance with EN60079-15! The environmental conditions during use are thereby to be

taken into account!

• For dust (only the fieldbus components of certificate no. KEMA10ATEX0075XIssue9): The equipment

shall be installed in a suitable enclosure providing a degree of protection of IP54 according to

EN60079-31 for group IIIA or IIIB and IP6X for group IIIC, taking into account the environmental conditions under which the equipment is used!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observe the permissible ambient temperature range of 0 to 55°C for the use of Beckhoff fieldbus components standard temperature range in potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The individual terminals may only be unplugged or removed from the Bus Terminal system if the supply

voltage has been switched off or if a non-explosive atmosphere is ensured!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

• The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the supply voltage has

been switched off or if a non-explosive atmosphere is ensured!

• Address selectors and ID switches may only be adjusted if the supply voltage has been switched off or if

a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0:2012+A11:2013

• EN 60079-15:2010

• EN 60079-31:2013 (only for certificate no. KEMA 10ATEX0075 X Issue 9)

EK132232 Version: 1.1

Page 33

Mounting and wiring

Marking

The Beckhoff fieldbus components with standard temperature range certified according to the ATEX directive

for potentially explosive areas bear one of the following markings:

II 3G KEMA 10ATEX0075 X Ex nA IIC T4 Gc Ta: 0 … +55°C

II 3D KEMA 10ATEX0075 X Ex tc IIIC T135°C Dc Ta: 0 ... +55°C

(only for fieldbus components of certificate no. KEMA 10ATEX0075 X Issue 9)

or

II 3G KEMA 10ATEX0075 X Ex nA nC IIC T4 Gc Ta: 0 … +55°C

II 3D KEMA 10ATEX0075 X Ex tc IIIC T135°C Dc Ta: 0 ... +55°C

(only for fieldbus components of certificate no. KEMA 10ATEX0075 X Issue 9)

4.6 Continuative documentation for ATEX and IECEx

Continuative documentation about explosion protection according to ATEX and

IECEx

Pay also attention to the continuative documentation

Notes on the use of the Beckhoff terminal systems in hazardous areas according to ATEX and

IECEx

that is available for download on the Beckhoff homepage https:\\www.beckhoff.com!

4.7 Connection EK1322

Fig.28: EK1322 feed-in connections

Terminal point Description

Name No.

US 24 V 1 +24V Feed-In US (System- and Sensor supply)

EK1322 33Version: 1.1

Page 34

Mounting and wiring

Terminal point Description

Name No.

US 0 V 2 0 V of System- and Sensor supply U

UP 24 V 3 +24V Feed-In UP (Peripheral voltage for Actors)

UP 0 V 4 0 V of Peripheral voltage for Actors U

S

P

Permitted conductor cross-sections of the terminal points for input US/U

P

The permitted conductor cross-sections and the strip length are shown in the following table.

Terminal points, clamping range 0.13 ... 1.5 mm

2

Wire cross-section (AWG) 28 – 14

Solid wire H05(07) V-U 0.2 ... 1.5 mm

Stranded wire H05(07) V-K 0.2 ... 1.5 mm

Stranded wire (with ferrule with collar DIN46 228/4) 0.25 ... 0.75 mm

Stranded wire (with ferrule DIN 46 228/1) 0.25 ... 1.5 mm

2

2

2

2

Strip length approx. 8 ... 9 mm

4.8 EtherCAT P connection

NOTE

Risk of damage to the device!

Bring the EtherCAT/EtherCATP system into a safe, powered down state before starting installation, disassembly or wiring of the modules!

The feeding and forwarding of EtherCATP is done via two EtherCAT-P-coded M8 connectors at the top of

the modules:

• IN: left M8 connector with EtherCAT-P-coding for feeding EtherCATP

• OUT: right M8 connector with EtherCATP for forwarding the supply voltages

Fig.29: EtherCAT-P-Box, Connectors for EtherCATP

Fig.30: Pin assignment M8, EtherCATP In and EtherCATP Out

EK132234 Version: 1.1

Page 35

The pins M8 connectors carry a maximum current of 3A.

Two LEDs display the status of the supply voltages.

Mounting and wiring

Control voltage US 24V

DC

Power is supplied to the fieldbus, the processor logic, the inputs and the sensors from the 24VDC control

voltage US.

Auxiliary voltage Up 24V

DC

The Auxiliary voltage UP supplies the digital outputs; it can be brought in separately. If the load voltage is

switched off, the fieldbus functions and the power supply and functionality of the inputs are retained.

NOTE

Pay attention to the maximum permissible current!

Pay attention also for the redirection of EtherCATP, the maximum permissible current for M8 connectors of

3A must not be exceeded!

EK1322 35Version: 1.1

Page 36

Mounting and wiring

4.9 Nut torque for connectors

Fig.31: M8 EtherCAT P connector

For mounting of the M8 EtherCAT P connector the following have to be noticed:

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm. When using the torque control

screwdriver ZB8800 is also a max. torque of 0.5Nm permissible.

Fig.32: EtherCAT Box with M8 connectors

4.10 Cabling

A list of EtherCATP cables, EtherCAT cables, power cables, sensor cables, Ethernet/EtherCAT connectors

and field-configurable connectors can be found under the following link: https://beckhoff.de/english/ethercat-

box/ethercat_box_cables.htm

You can find the corresponding data sheets at the following link: https://beckhoff.de/english/

downloadfinder/default.htm?id=109075571109075577&cat1=40717316&cat2=90800914

EtherCATP cable

For the EtherCATP connection are pre-assembled M8 cables in various lengths and the versions: plug –

open end, plug – plug or plug - socket available.

EK132236 Version: 1.1

Page 37

Mounting and wiring

Fig.33: EtherCAT P cable: ZK700x-0100-0xxx, ZK700x-0101-0xxx and ZK700x-0102-0xxx

For connecting EtherCATP devices only shielded Ethernet cables that meet the requirements of at least

category 5 (CAT5) according to EN 50173 or ISO/IEC 11801 should be used.

Recommendations about cabling

You may get detailed recommendations about cabling EtherCAT from the documentation "Infrastructure for EtherCAT/Ethernet", that is available for download at www.Beckhoff.com.

EK1322 37Version: 1.1

Page 38

Mounting and wiring

Fig.34: EtherCAT-P-Box-accessories

Number Description Link

1 Cables for EtherCAT signal in- and -output

2 Cables for EtherCAT P: Ultra-fast Communication and Power in

One Cable

3 Cables for EtherCAT signal in- and -output

4 Cables for M8 power supply

5 Cables for M8 I/O connection sockets

6 Cables for M12 I/O connection sockets

7 Shielded cables for M12 I/O connection sockets

EtherCATP connectors for field assembly

For EtherCATP are field installable M8 connectors as plug and as socket available.

RJ45 EtherCAT/Ethernet cable

M8 EtherCAT P cable

M8 EtherCAT cable

M8 Power cable

M8 Sensor cable

M12 Sensor cable

M12 Sensor cable, shielded

Fig.35: EtherCAT P: field assembly connectors

EK132238 Version: 1.1

Page 39

Sensor cable

Fig.36: Selection of different Sensor cables from Beckhoff

Mounting and wiring

EK1322 39Version: 1.1

Page 40

Mounting and wiring

4.11 EtherCAT P cable conductor losses M8

When using ZK700x-xxxx-0xxx EtherCATP cables it must be ensured that the voltage at the last device is

not less than the minimum rated voltage of 20.4 V according to the standard. Variations in the output voltage

from the power supply unit must also be taken into account. This ensures that the connected consumers,

sensors and actuators are operated within the permitted voltage range.

The voltage calculation tool [}42] integrated in TwinCAT can be used for the offline calculation of the cable

lengths.

The EPP9022-0060 box with diagnostics can be used for checking during operation.

Conductor losses on the EtherCATP cables

Fig.37: Conductor losses on the EtherCATP cables

Example

A 10 meter-long EtherCATP cable with a cross section of 0.34mm² has a voltage drop of ∼3.0V with a load

of 3A.

EK132240 Version: 1.1

Page 41

Commissioning

5 Commissioning

Note the total current of the device

The max. permissible total current applies to both ports X1 and X2 together. I.e. the feed in of US as

for UP the max. permissible current of 3A must not be exceeded (e.g. current of US for port X1 is

1.7A; then the max. permissible current of US for port X2 is equal or less than 1.3A).

5.1 EK1322 - Configuration by means of the TwinCAT System Manager

TwinCAT tree

Enter the EK1322 EtherCATP extension as an EtherCAT device in the TwinCAT System Manager in Config

mode under Devices. Any Terminals already connected to the network can also be read. This will cause all

the Bus Couplers with Bus Terminals and their configurations to be loaded. You can then adapt these to

meet your requirements.

Fig.38: TwinCAT tree EK1322

Meaning of the PDO identifier

PDO identifier Typ State Description

Status U

(Undervoltage)

Status U

(Undervoltage)

WcState Bit 0/1 Each datagram of the device indicates its processing state here. This

InputToggle Bit 0/1 Toggles whenever new valid EtherCAT telegram was received

State UINT -

To add a EtherCAT P device to one of the two ports of the junction, right - click on the device in the Tree in

the subsequently opened context menu "Add New Item...":

P

S

Bit 0 Peripheral voltage for Actors UP >= 19.4 V, no overload/ no case of

shortcut

1 Peripheral voltage for Actors UP < 19.4 V or overload/ case of shortcut

(output current > 3 A)

Bit 0 System- and Sensor supply US >= 19.4 V, no overload/ no case of

shortcut

1 System- and Sensor supply US < 19.4 V or overload/ case of shortcut

(output current > 3 A)

allows monitoring for correct process data communication.

Status display of the “EtherCAT state machine” (see State, Online tab

[}47])

EK1322 41Version: 1.1

Page 42

Commissioning

In the window that opens therefore, the component to be inserted and the respective port (X1 or X2) on the

right side can be selected:

Fig.39: Add a EtherCAT P device to EK1322 in the TwinCAT tree

EtherCATP tab

From TwinCAT 3 Build 4020 TwinCAT has the tab “EtherCATP”. This tab contains a planning tool to

calculate voltages, currents and cable lengths of EtherCATP system. The figure below shows the tab

EtherCATP when no device is connected to the junction device (A).

EK132242 Version: 1.1

Page 43

Commissioning

Fig.40: Tab EtherCAT P: No device connected to junction device

Is a device connected to the junction device (A), the number/letter of the ports are displayed (see figure

below, B).

Fig.41: Tab EtherCAT P: One device connected to junction device

Are three devices connected to the three ports of the junction device (A), the ports are displayed (B) as

shown in the figure below.

EK1322 43Version: 1.1

Page 44

Commissioning

Fig.42: Tab EtherCAT P: Three devices connected to junction device

How you can see the topology of your EtherCATP system in TwinCAT, is described here [}47].

Port Identification of the ports with numbers / letters as described before

Wire Gauge Selection of the wire cross-sectional area of the cable which is to be used

AWG 22 = 0.34mm²

AWG 24 = 0.22mm²

AWG 26 = 0.14mm²

Length (m) Indication of the cable length which is to be used

Check EtherCATP

system

Type Listing of two voltages: Box supply US, Auxiliary voltage U

At least one device is connected to the controller, the connected EtherCATP system

can be checked.

P

Actual Voltage (V) The respective voltage at which the system is powered, can be entered manually.

The default setting is 24.00V.

Min. Voltage (V) The minimum voltage is preset by the device and described in the ESI file. The

EtherCATP system is to be interpreted after this voltage. It is valid not to fall short

this voltage.

Internal Load (A) The current which consume the device is read from the ESI file of the respective box.

Load (A) The total consumption of the connected sensors / actuators at the device can be

specified here,e.g. 100mA.

EK132244 Version: 1.1

Page 45

Commissioning

Load Type The characteristic of the load which is connected to the devices can be selected here.

Which of the three options is right for the connected load (Sw regulator, LDO,

Resistor), must be taken from the datasheet. In case of doubt please select the

default value “Sw Regulator”.

Sw Regulator: Switching regulators, consume more energy and therefore require an

efficient power supply.

LDO: Low drop voltage regulator, the energy demand is often small and the heat

dissipation is not a problem, e.g. proximity sensor.

Resistor: electronic, passive components e.g. relay, coil

If you click on the button “Check EtherCATP System”, all devices that are attached to your TwinCAT tree

are listed as shown in the following figure.

Fig.43: Check EtherCAT P System

Check US, CheckUPSelecting which of the two voltages is to be checked.

Name Designation of the in TwinCAT tree attached devices.

Supply Voltage (V) Voltage at which the device is provided. For device 1, the voltage can be entered

manually.

Min Voltage (V) See description above.

Input Resistance

(Ω)

Current (A) Display for the current.

Load (A) See description above.

Cable Length (m) The used cable length must be entered manually.

Wire Gauge See description above.

Example with problem case and troubleshooting

The following figure shows the planning of the EtherCATP system without a problem. All voltages in the

column “Supply Voltage (V)” are highlighted in green.

Input resistance, which is calculated over the cable length and cable cross-section.

EK1322 45Version: 1.1

Page 46

Commissioning

Fig.44: Check EtherCAT P system without problem

The following figure shows the planning of the EtherCATP system with a problem. The “Supply Voltage (V)”

of Box 5 drops below the “Min. voltage (V)”. The corresponding field is highlighted in red. The error occurs

because longer cables (adjustable in Cable Length (m)) and also AWG 24 instead of AWG 22 cables

(adjustable in Wire Gauge) be used.

Fig.45: Check EtherCAT P System with problem

This area offers the following three options to adjust the system so that there is no error:

Provide a higher voltage: There are max. 28.8V possible.

Use an EtherCATP cable with a larger wire cross sectional area (AWG 22 instead of AWG 24).

New voltage feed.

EK132246 Version: 1.1

Page 47

State, "Online" tab

Indicates the online status of the terminal.

Commissioning

Fig.46: State, "Online" tab

Value Description

0x___1 Slave in 'INIT' state

0x___2 Slave in 'PREOP' state

0x___3 Slave in 'BOOT' state

0x___4 Slave in 'SAFEOP' state

0x___8 Slave in 'OP' state

0x001_ Slave signals error

0x002_ Invalid vendorId, productCode... read

0x004_ Initialization error occurred

0x010_ Slave not present

0x020_ Slave signals link error

0x040_ Slave signals missing link

0x080_ Slave signals unexpected link

0x100_ Communication port A

0x200_ Communication port B

0x400_ Communication port C

0x800_ Communication port D

Topology of the EtherCATP system

You can view the topology of your EtherCATPsystem, as described in the figure below:

A: Click in the TwinCAT tree on „Device1 (EtherCAT)“

B: Click on tab „EtherCAT“

C: Click on button „Topology“

EK1322 47Version: 1.1

Page 48

Commissioning

D: The topology of your EtherCATP system is displayed. Here as example: Three devices are connected to

the three ports of the distributor device.

Fig.47: Topology of the EtherCAT P system

EK132248 Version: 1.1

Page 49

6 Error handling and diagnostics

6.1 Diagnostic LED

Error handling and diagnostics

Fig.48: EK1322 LEDs

LEDs for fieldbus diagnostics

LED Display State Description

Run green off INIT EtherCAT P module is in state Init

flashing

uniformly

flashing

slowly

on OP EtherCAT P module is in state Operational

LEDs for fieldbus diagnostics

LED Display State Description

X1 L/A green off - No connection on the previous EtherCAT P strand

on link Previous EtherCAT P device connected

flashing active Communication with previous EtherCAT P device

X2 L/A green off - No connection on the subsequent EtherCAT P strand

on link Subsequent EtherCAT P device connected

flashing active Communication with subsequent EtherCAT P device

PREOP EtherCAT P module is in state Pre-Operational

SAFEOP EtherCAT P module is in state Safe-Operational

EK1322 49Version: 1.1

Page 50

Error handling and diagnostics

LEDs power supply diagnostics

LED Display Description

U

S

green off System- and Sensor supply US not present

on System- and Sensor supply US present

red off System- and Sensor supply US >= 19.4 V, no overload/ no case of

shortcut

on System- and Sensor supply US < 19.4 V or overload/ case of

shortcut (output current > 3 A)

U

P

green off Peripheral voltage for Actors UP not present

on Peripheral voltage for Actors UP present

red off Peripheral voltage for Actors UP >= 19.4 V, no overload/ no case

of shortcut

on Peripheral voltage for Actors UP < 19.4 V or overload/ case of

shortcut (output current > 3 A)

EK132250 Version: 1.1

Page 51

Appendix

7 Appendix

7.1 EtherCAT AL Status Codes

For detailed information please refer to the EtherCAT system description.

7.2 Firmware compatibility

The EK1322 has no firmware.

7.3 Firmware Update EL/ES/EM/ELM/EPxxxx

This section describes the device update for Beckhoff EtherCAT slaves from the EL/ES, ELM, EM, EK and

EP series. A firmware update should only be carried out after consultation with Beckhoff support.

NOTE

Only use TwinCAT 3 software!

A firmware update of Beckhoff IO devices must only be performed with a TwinCAT 3 installation. It is recommended to build as up-to-date as possible, available for free download on the Beckhoff website https://

www.beckhoff.com/en-us/.

To update the firmware, TwinCAT can be operated in the so-called FreeRun mode, a paid license is not required.

The device to be updated can usually remain in the installation location, but TwinCAT has to be operated in

the FreeRun. Please make sure that EtherCAT communication is trouble-free (no LostFrames etc.).

Other EtherCAT master software, such as the EtherCAT Configurator, should not be used, as they may not

support the complexities of updating firmware, EEPROM and other device components.

Storage locations

An EtherCAT slave stores operating data in up to three locations:

• Depending on functionality and performance EtherCAT slaves have one or several local controllers for

processing I/O data. The corresponding program is the so-called firmware in *.efw format.

• In some EtherCAT slaves the EtherCAT communication may also be integrated in these controllers. In

this case the controller is usually a so-called FPGA chip with *.rbf firmware.

• In addition, each EtherCAT slave has a memory chip, a so-called ESI-EEPROM, for storing its own

device description (ESI: EtherCAT Slave Information). On power-up this description is loaded and the

EtherCAT communication is set up accordingly. The device description is available from the download

area of the Beckhoff website at (https://www.beckhoff.com). All ESI files are accessible there as zip

files.

Customers can access the data via the EtherCAT fieldbus and its communication mechanisms. Acyclic

mailbox communication or register access to the ESC is used for updating or reading of these data.

The TwinCAT System Manager offers mechanisms for programming all three parts with new data, if the

slave is set up for this purpose. Generally the slave does not check whether the new data are suitable, i.e. it

may no longer be able to operate if the data are unsuitable.

Simplified update by bundle firmware

The update using so-called bundle firmware is more convenient: in this case the controller firmware and the

ESI description are combined in a *.efw file; during the update both the firmware and the ESI are changed in

the terminal. For this to happen it is necessary

EK1322 51Version: 1.1

Page 52

Appendix

• for the firmware to be in a packed format: recognizable by the file name, which also contains the

revision number, e.g. ELxxxx-xxxx_REV0016_SW01.efw

• for password=1 to be entered in the download dialog. If password=0 (default setting) only the firmware

update is carried out, without an ESI update.

• for the device to support this function. The function usually cannot be retrofitted; it is a component of

many new developments from year of manufacture 2016.

Following the update, its success should be verified

• ESI/Revision: e.g. by means of an online scan in TwinCAT ConfigMode/FreeRun – this is a convenient

way to determine the revision

• Firmware: e.g. by looking in the online CoE of the device

NOTE

Risk of damage to the device!

ü Note the following when downloading new device files

a) Firmware downloads to an EtherCAT device must not be interrupted

b) Flawless EtherCAT communication must be ensured. CRC errors or LostFrames must be avoided.

c) The power supply must adequately dimensioned. The signal level must meet the specification.

ð In the event of malfunctions during the update process the EtherCAT device may become unusable and

require re-commissioning by the manufacturer.

7.3.1 Device description ESI file/XML

NOTE

Attention regarding update of the ESI description/EEPROM

Some slaves have stored calibration and configuration data from the production in the EEPROM. These are

irretrievably overwritten during an update.

The ESI device description is stored locally on the slave and loaded on start-up. Each device description has

a unique identifier consisting of slave name (9 characters/digits) and a revision number (4 digits). Each slave

configured in the System Manager shows its identifier in the EtherCAT tab:

Fig.49: Device identifier consisting of name EL3204-0000 and revision -0016

The configured identifier must be compatible with the actual device description used as hardware, i.e. the

description which the slave has loaded on start-up (in this case EL3204). Normally the configured revision

must be the same or lower than that actually present in the terminal network.

For further information on this, please refer to the EtherCAT system documentation.

EK132252 Version: 1.1

Page 53

Update of XML/ESI description

The device revision is closely linked to the firmware and hardware used. Incompatible combinations

lead to malfunctions or even final shutdown of the device. Corresponding updates should only be

carried out in consultation with Beckhoff support.

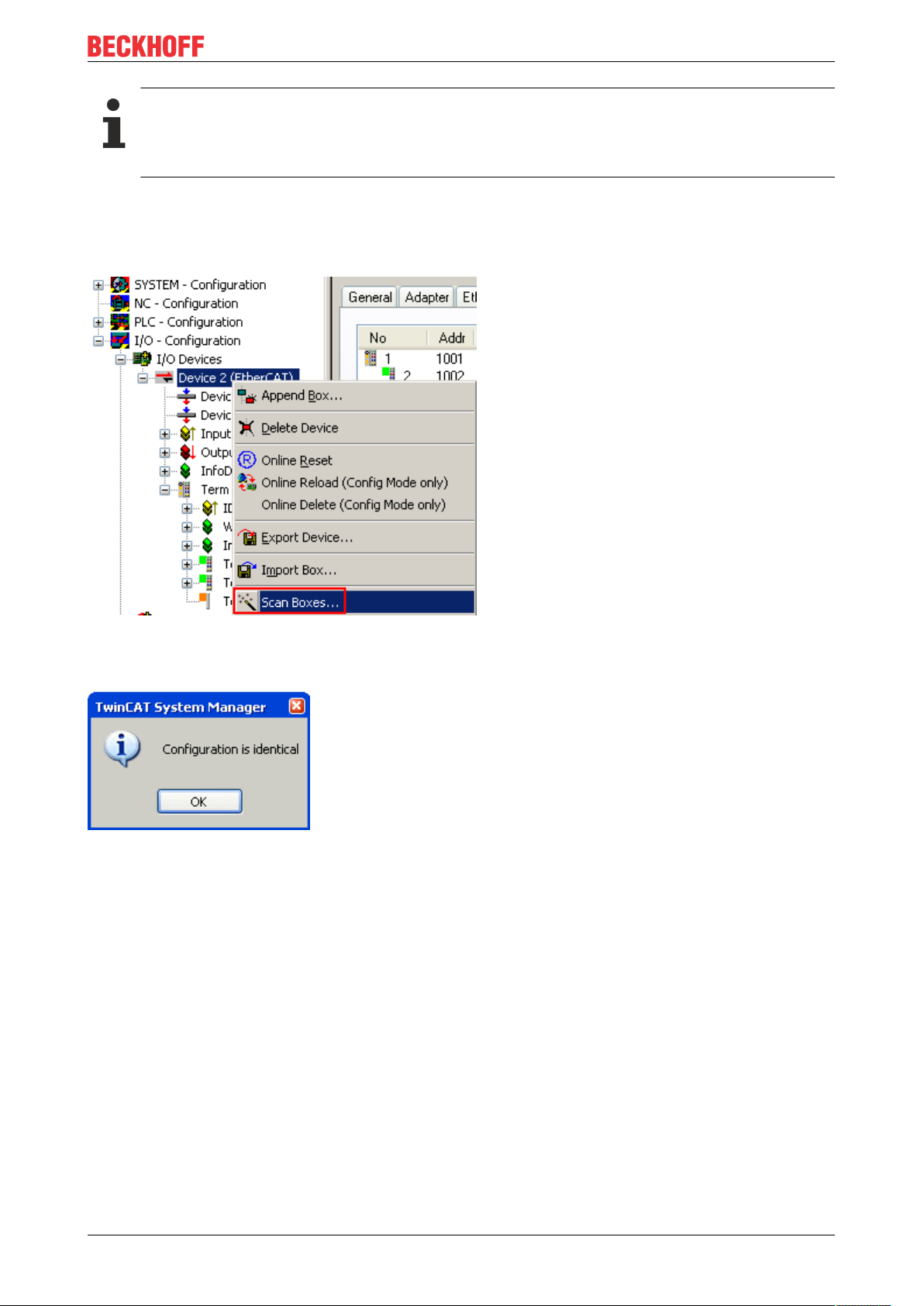

Display of ESI slave identifier

The simplest way to ascertain compliance of configured and actual device description is to scan the

EtherCAT boxes in TwinCAT mode Config/FreeRun:

Appendix

Fig.50: Scan the subordinate field by right-clicking on the EtherCAT device

If the found field matches the configured field, the display shows

Fig.51: Configuration is identical

otherwise a change dialog appears for entering the actual data in the configuration.

EK1322 53Version: 1.1

Page 54

Appendix

Fig.52: Change dialog

In this example in Fig. Change dialog, an EL3201-0000-0017 was found, while an EL3201-0000-0016 was

configured. In this case the configuration can be adapted with the Copy Before button. The Extended

Information checkbox must be set in order to display the revision.

Changing the ESI slave identifier

The ESI/EEPROM identifier can be updated as follows under TwinCAT:

• Trouble-free EtherCAT communication must be established with the slave.

• The state of the slave is irrelevant.

• Right-clicking on the slave in the online display opens the EEPROM Update dialog, Fig. EEPROM

Update

Fig.53: EEPROM Update

The new ESI description is selected in the following dialog, see Fig. Selecting the new ESI. The checkbox

Show Hidden Devices also displays older, normally hidden versions of a slave.

EK132254 Version: 1.1

Page 55

Fig.54: Selecting the new ESI

A progress bar in the System Manager shows the progress. Data are first written, then verified.

The change only takes effect after a restart.

Most EtherCAT devices read a modified ESI description immediately or after startup from the INIT.