Page 1

TwinCAT

Application Note DK9322-1109-0011

TwinCAT Supplement ‚RFID Reader Communication‘

TwinCAT RFID Library

Keywords

RFID

TwinCAT

Supplement

Reader

Middleware

Serial interface

PLC

The ‘TwinCAT PLC RFID Reader Communication’ supplement is a middleware for connecting RFID readers

by different manufacturers to TwinCAT PLC via an abstract interface. Communication between the reader

and TwinCAT PLC takes place via the serial interfaces EL60xx (Beckhoff EtherCAT Terminal system) and

KL60x1 (Beckhoff Bus Terminal system) or also via the COM port of the PC, so that automated detection of

the presence of tags can be used extending as far as write accesses to the production controller and other

applications.

Basic principles and advantages of RFID

RFID (radio frequency identification) is a contactless identification system for objects that is used in the manufacturing or

logistics controller in order to initiate further sequences and steps via presence detection. An RFID system consists of several

transponders (tags), a reader and software that evaluates the data from the tags. A tag contains an ID, which does not change

over the entire lifetime, and a memory in which data can be stored. In addition to presence detection, the memory can be

used to read or write further data. The size and writability of the memory (Write-once-Read-Only/Read-Write) of the tags are

manufacturer-specific.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

1

Page 2

Application Note DK9322-1109-0011

IPC

RFID reader

RFID tag

Areas of application

for RFID

Access systems

Payment systems

Credit chips

Immobiliser

Parts tracking

Tool identification

Product history

Process management

Security

Membership card

Time recording

Personnel

Tracking of hazardous goods

Servicing

Tracing

Waste management

Forgery-proofing

Goods marking

Goods flow

TwinCAT Supplement ‚RFID Reader Communication‘

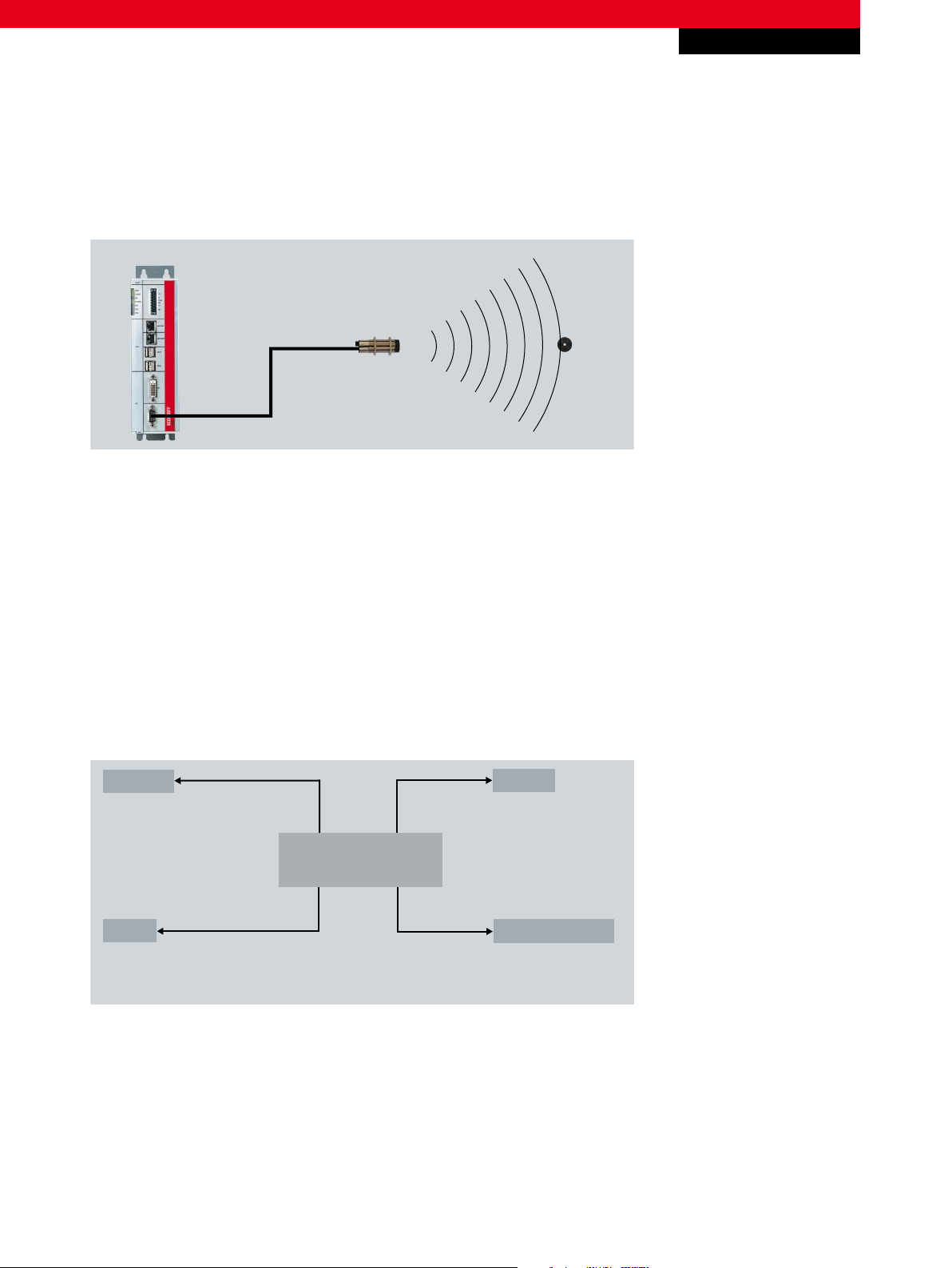

Fig. 1 Structure of an RFID connection

TwinCAT

The object to be detected is fitted with a tag that transmits its data as soon as the object is within range of the reader.

A specific alignment of the tag and the readers, such as is required with a barcode, is not necessary, since the data is

received contactlessly within the range cone of the reader. As opposed to barcodes, tag detection is also assured in poor

lighting conditions and in the case of dirty surfaces. Since RFID has short detection times and many tags can be detected

simultaneously (bulk reading ability), the individual goods on an entire pallet of different goods, for example in a goods

reception area, can be identified individually without having to take the container apart. Thus, all goods can be identified

within a very short space of time and their data made available for further processing. RFID offers many advantages over other

identification systems and is now used as an industrial standard in almost all industries.

Fig. 2 Areas of application of RFID

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

2

Page 3

Application Note DK9322-1109-0011

Wear and tear

Procurement costs

high

low

Barcode

Influence of dirt/moistrue

Influence of optical coverage failure

high

no or little influence

no or little influence

variable

depends on the technique

Manufacture by customer possible not possible

Data density low high

Bulk reading capability

Unauthorised copying

not possible

easy

possible

difficult or impossible

Complexity of the application high very easy

RFID

FB_Reader

eCommand

stAccessData

stCtrl

stCfg

bExecute

tTimeout

RxBuffer

TxBuffer

bBusy

bError

iErrorID

iErrCodeRcv

bResponseRcv

eResponse

stLowLevel

stReaderCfg

stReaderInfo

stTranspInfo

eManufacturer

TwinCAT Supplement ‚RFID Reader Communication‘

Fig. 3 Differences between barcode and RFID

TwinCAT

TwinCAT PLC RFID Reader Communication

In order to connect RFID readers to the controller, up to now the appropriate protocols had to be implemented for the various

readers on the basis of the serial interfaces. With the ‘TwinCAT PLC RFID Reader Communication’ TwinCAT library, a general,

abstract interface has been developed that can be used for any supported reader. The user sees only one block in the user

interface. The corresponding protocols have already been implemented internally for different readers; special adaptations to a

reader can be carried out simply via the configuration setting. The TwinCAT library is based on the IEC 61131-3 standard, with

which the data from the tags can be directly accessed or changed. This way, alongside the mere presence detection, the writing

of the RFID tags is also integrated into the PLC automation.

Fig. 4 TwinCAT function block for reader implementation

The system hardware, consisting of transponders and readers, can be chosen by the user according to his application and

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

3

Page 4

TwinCAT

Application Note DK9322-1109-0011

TwinCAT Supplement ‚RFID Reader Communication‘

procured externally. The RFID reader is connected to the industrial PC either via a serial interface (KL60x1 Bus Terminal | EL60xx

EtherCAT Terminal) or via the COM port. If the range is not sufficient for serial transmission, the connection point of the RFID

reader can be distributed anywhere in the I/O field using the corresponding coupler. The selected system can be integrated into

the automation environment via TwinCAT and the RFID reader supplement.

Advantages

In conjunction with the serial interfaces in terminal form, the RFID reader can be used in any fieldbus. Several readers can also

be integrated in the simplest way in the TwinCAT-encompassing automation world; all that is required for integrating several

readers is to create multiple instances of a function block. This way, even extensive applications that use different functions

of the RFID reader can easily be implemented. The implementation expenditure is very low, because the manufacturer-specific

interface protocol does not need to be researched in detail and implemented.

The handling and the interface of the PLC library are the same for all the supported RFID reader models. The frame structure,

the composition of the telegrams, the command name and other protocol specifications are performed automatically by the

library. This saves the user valuable development and implementation time and he can concentrate fully on his application.

Access to the RFID reader with tools from the Windows environment is similarly not a problem with the ‘Virtual Serial COM

Driver’ supplement for virtual interfaces.

If networking takes place at process control level, then detection of the RFID tags can take place at each station in order to

implement the traceability of components within the production process.

Practical application: detection of the presence of components

RFID is used to detect the presence of individual components within a production line for wooden products. The RFID tag is

attached to each component and is read by readers at different stations.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

4

Page 5

Application Note DK9322-1109-0011

Windows XP or

Windows CE

TwinCAT

Industrial PC

Hardware

management

KL/EL60xx

Fieldbus adapter

RS232

Tags

Option 2

RFID reader

Option 1

COM

port

TwinCAT PLC

RFID Reader Communication

TwinCAT Supplement ‚RFID Reader Communication‘

TwinCAT

Fig. 5 Two options for connecting the reader to the PLC

Various components are created from the blanks in order to minimise cutting waste. For this reason, the boards are fitted with

a tag after being cut to size and the ID is assigned to an order or an assembly within a database. Once the tags have been

written, the components are transported by conveyor belts and parts trolleys to the individual machining centres. Due to the

fully automated manufacturing, the boards reach speeds of 60 metres per minute on the conveyor belts. Since RFID, as opposed

to barcodes, allows detection without stopping and speed reduction, the selection of the branching points can be executed in

real-time. If the component passes a reader attached to the conveyor belt, the tag is read, the destination is recognised and the

points are set accordingly.

– TwinCAT PLC RFID Reader Communication www.beckhoff.com/TwinCAT-RFID-Reader

– Optional TwinCAT software packages www.beckhoff.com/supplements

– EtherCAT Terminal, RS232 interface www.beckhoff.com/EL6001

– EtherCAT Terminal, RS422/485 interface www.beckhoff.com/EL6021

– EtherCAT Terminal, 2-channel RS232 interface www.beckhoff.com/EL6002

– EtherCAT Terminal, 2-channel RS422/485 interface www.beckhoff.com/EL6022

– Busterminal, RS232 interface www.beckhoff.com/KL6001

– Busterminal, RS422/485 interface www.beckhoff.com/KL6021

– Busterminals www.beckhoff.com/Busterminal

– EtherCAT Terminals www.beckhoff.com/EtherCAT-Terminals

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

5

Page 6

Application Note DK9322-1109-0011

TwinCAT Supplement ‚RFID Reader Communication‘

TwinCAT

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, November 2009

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Beckhoff

New Automation Technology

6

Loading...

Loading...