Page 1

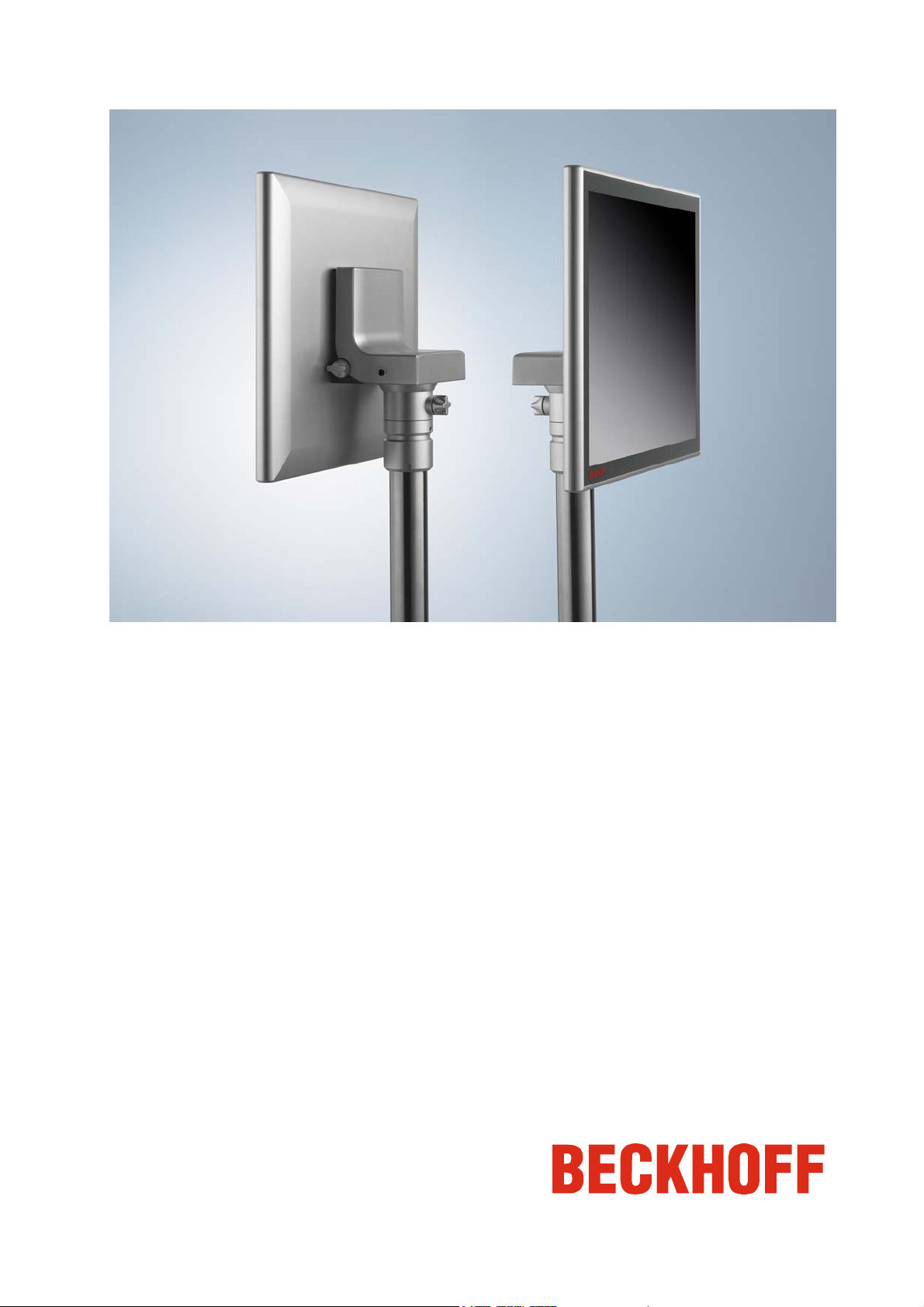

Installation and Operating instructions for

CP39xx

Multi-touch Control Panel with

DVI/ USB Extended interface

Version: 1.7

Date: 2014-10-07

Page 2

Page 3

Table of contents

Table of contents

1 Foreword 3

1.1 Notes on the Documentation 3

1.1.1 Liability Conditions 3

1.1.2 Trademarks 3

1.1.3 Patent Pending 3

1.1.4 Copyright 3

1.1.5 State at Delivery 3

1.1.6 Delivery conditions 3

1.2 Description of safety symbols 4

1.3 Basic safety measures 5

1.4 Operator’s obligation to exercise diligence 6

1.4.1 National regulations 6

1.4.2 Procedure in the event of a fault 6

1.4.3 Operator requirements 6

2 Product Description 7

2.1 Product overview 7

2.2 Appropriate Use 8

2.3 Access to the connectors 8

2.3.1 Fitted without mounting arm adapter 8

2.3.2 Fitted with mounting arm adapter 9

2.3.3 Installing the Cables 10

2.4 Interfaces 10

2.4.1 Power Supply (X101) 11

2.4.2 DVI-E Input (Digital Visual Interface-Extended) (X102) 11

2.4.3 USB-E Input (X 103) 12

2.4.4 USB interface at the mounting arm adapter (optional) 12

2.4.5 Protective Earthing 13

2.5 Connection Kits/ Connection Cables 13

2.5.1 Connection Kits for DVI-E/ USB-E connection, optional 13

3 Installation 14

3.1 Transport and Unpacking 14

3.1.1 Transport 14

3.1.2 Unpacking 14

4 Mounting 15

4.1.1 Earthing measures 15

4.2 Mounting arm installation (optional) 16

CP39xx 1

Page 4

Table of contents

4.2.1 Mounting the mounting arm tube 17

4.3 Connecting the Control Panel 18

4.3.1 Connecting cables 18

4.3.2 Protective Earthing 18

5 Operating Instructions 19

5.1 Switching the Control Panel on and off 19

5.1.1 Switching on 19

5.1.2 Shutting down and switching off 19

5.2 Operation 19

5.2.1 Setting the transmission rate 20

5.3 Servicing and maintenance 20

5.3.1 Cleaning 20

5.3.2 Maintenance 20

5.4 Emergency procedures 20

5.5 Shutting down 20

5.5.1 Disposal 20

6 Troubleshooting 21

7 Assembly dimensions 22

8 Technical Data 23

9 Appendix 24

9.1 Beckhoff Support and Service 24

9.1.1 Beckhoff branches and partner companies 24

9.1.2 Beckhoff company headquarters 24

9.2 Approvals for USA and Canada 25

9.3 FCC Approvals for the United States of America 25

9.4 FCC Approval for Canada 25

2 CP39xx

Page 5

Foreword

1 Foreword

1.1 Notes on the Documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

1.1.1 Liability Conditions

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the

modification of products that have already been supplied may be made on the basis of the data, diagrams

and descriptions in this documentation.

1.1.2 Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

1.1.3 Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications

or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other

countries.

1.1.4 Copyright

©

Beckhoff Automation GmbH.

The reproduction, distribution and utilization of this document as well as the communication of its contents

to others without express authorization are prohibited. Offenders will be held liable for the payment of

damages. All rights reserved in the event of the grant of a patent, utility model or design.

1.1.5 State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

1.1.6 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

CP39xx 3

Page 6

Foreword

1.2 Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to

the associated safety instructions.

Acute risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is immediate

DANGER

WARNING

CAUTION

danger to life and health of individuals!

Risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is danger to life and

health of individuals!

Hazard to individuals!

If you do not adhere the safety advise adjoining this symbol, there is obvious hazard to

individuals!

Hazard to devices and environment

Attention

Note

If you do not adhere the notice adjoining this symbol, there is obvious hazard to

materials and environment.

Note or pointer

This symbol indicates information that contributes to better understanding.

4 CP39xx

Page 7

Foreword

1.3 Basic safety measures

Before the Industrial PC is switched off, software that is running must be properly closed.

Otherwise it is possible that data on the storage medium is lost. Please read the section Switching the

Control Panel on and off.

Switch off all parts of the equipment, then uncouple the Control Panel

Before opening the housing, and whenever the Control Panel is not being used for

Warning

Disconnect the device by unplugging the connectors on the rear side of the Control Panel.

Items of equipment that have been switched off must be secured against being switched on again.

Warning

control purposes (such as during functional checks after a repair), all parts of the

equipment must first be switched off, after which the Control Panel is to be

disconnected from the equipment.

Do not exchange any parts when under power

When components are being fitted or removed, the supply voltage must be switched

off.

Fitting work on the Control Panel can result in damage:

• if metal objects such as screws or tools fall onto operating circuit boards

• if connecting cables internal to the Panel PC are removed or inserted during

operation.

CP39xx 5

Page 8

Foreword

1.4 Operator’s obligation to exercise diligence

The operator must ensure that

• the product is only used as intended (see chapter Product Description)

• the product is in a sound condition and in working order during operation

• the product is operated, maintained and repaired only by suitably qualified and authorized

personnel

• the personnel is instructed regularly about relevant occupational safety and environmental

protection aspects, and is familiar with the operating manual and in particular the safety notes

contained herein

• the operation manual is in good condition and complete, and always available for reference at the

location of the product.

Do not open the housing of the Control Panel!

For technical support contact Beckhoff Service.

Note

1.4.1 National regulations

Depending on the type of machine and plant in which the Control Panel is used, national regulations

governing the controllers of such machines will apply, and must be observed by the operator. These

regulations cover, amongst other things, the intervals between inspections of the controller. The operator

must initiate such inspections in good time.

1.4.2 Procedure in the event of a fault

In the event of faults at the Control Panel, the list in the section Troubleshooting can be used to determine

the measures to be taken.

1.4.3 Operator requirements

Anyone who uses the Control Panel must have read these operating instructions and must be familiar

with all the functions of the software installed on the Industrial PC to which he has access.

6 CP39xx

Page 9

Product Description

2 Product Description

2.1 Product overview

Front view of CP39xx

The new Beckhoff panel generation with industry-standard multi-touch display offers a feature-laden

solution for any application. The wide selection of models offers different display sizes and formats as

well as custom designs. Even for single-touch users, this new panel generation offers an excellent priceto-performance ratio and represents an economical alternative to other systems.

The multi-touch Control Panel offer the following benefits:

• display sizes from 7-inch to 24-inch (16:9, 5:4, 4:3), landscape and portrait orientation

• multi-touch (PCT): e.g. for 5-finger or 2-hand touch operation

• high touch-point density for safe operation

• aluminium housing with glass front, IP65

• integrated DVI/USB extension technology:

– DVI-E and USB-E 2.0 enable remote panel operation at a distance of up to 50 m from the PC

– USB-E 2.0 transmits USB 2.0 with 480 Mbit/s

– DVI-E input is compatible to the standard DVI output of a PC

• optional 1-Port-USB interface at the mounting arm adapter or in the front of the Panel

• optional electromechanical push-button extension

• optional mounting arm system.

CP39xx 7

Page 10

Product Description

2.2 Appropriate Use

The multi-touch Control Panel CP39xx is designed for industrial application in machine and plant

engineering. A multi-touch display is accommodated in a stainless steel housing. For mounting the

Control Panel there are 4 threaded holes M6 in the connection block at the rear cover.

Optionally a rotatable and tiltable mounting arm adapter is available by the order option C9900-M750/

C9900-M751 (C9900-M752/ C9900-M753 if provided with push-button extension).

The DVI/USB extension technology integrated in the CP39xx Control Panel enables remote Panel

operation at a distance of up to 50 m from the PC via a standard cable.

Risk of explosion!

The Control Panel must not be used where there is a risk of explosion.

Danger

2.3 Access to the connectors

2.3.1 Fitted without mounting arm adapter

The connectors of the Control Panel are located in the connection block at the rear side of the housing.

The connectors will be plugged from the bottom.

Picture: Connection block

For the pin assignment see chapter Interfaces.

8 CP39xx

Page 11

Product Description

2.3.2 Fitted with mounting arm adapter

If the Control Panel is fitted with a mounting arm adapter (order option C9900-M750 to C9900-M753), the

connectors are located behind the cover (1).

1

You can easily lever up the cover in direction of the arrow with a suitable tool. After removing the cover

you have access to the connections (2).

2

The installation of the cover takes place in reverse order.

CP39xx 9

Page 12

Product Description

2.3.3 Installing the Cables

After opening the connection area you have access to the connections of the Control Panel. The cables

with the connectors have to be threaded through the mounting arm tube before connecting them in the

connection area.

Note cable routing

It is absolutely necessary to install the cables as shown in the picture. Otherwise

Attention

cables can be damaged by rotating or tilting the mounting arm adapter.

2.4 Interfaces

X103

USB-E Input

X102

DVI-E Input

X101

Power

Ground

10 CP39xx

Page 13

Product Description

2.4.1 Power Supply (X101)

X101

SG 4-pole M12 built-in-PCB-sold. IP67 BINDER (BINDER 09-3431-90-04 prod. 763 M12X1)

View solder connection sided

The power supply for the Control Panel is established via the 4-pole M12 socket (X101). The protection

class of the circular plug-in connector accords to the IP67-standard.

Pin Signal Pin Signal

1 + 24V 3 GND

2 GND 4 + 24V

2.4.2 DVI-E Input (Digital Visual Interface-Extended) (X102)

X102

SG 19-pole M16 built-in-PCB-sold. IP67 BINDER (BINDER 09-0463-90-19 prod. 723 M16X0,75)

View solder connection sided

The DVI-E connection (X102) is used for transferring the video signal from the Industrial PC to the Control

Panel. The protection class of the circular plug-in connector accords to the IP67-standard.

The graphics signal is transferred directly via a DVI cable over a distance of 50 m max. Such a cable

length leads to strong distortion of the graphics signal on arrival at the Control Panel. The CP39xx Control

Panel features a signal processor that restores the DVI signal. The PC requires a conventional DVI

output.

The transmission rate of the DDC file has to be limited

Note

At large distance between PC and Control Panel, the transmission rate of the DDC file

has to be limited.

See also chapter Setting the transmission rate.

Pin Signal Pin Signal

A Shield L IN_TMDS_C+

B IN_TMDS_2+ M GND

C GND N IN_TMDS_2-

D IN_TMDS_1- O IN_TMDS_1+

E GND P GND

F IN_TMDS_0- R IN_TMDS_0+

G GND S HPD_DVI

H + 5V_DVI T GND

I DDC DAT U IN_TMDS_C-

K I2C-CLK

CP39xx 11

Page 14

Product Description

2.4.3 USB-E Input (X 103)

X103

SG 8-pole M9 built-in-PCB-sold. IP67 BINDER (BINDER 09-0427-30-08 prod. 712 M9X0,5)

View solder connection sided

The Control Panel is connected with the CU8801 USB to USB extended converter box via the USBExtended input (X103).

In order to realize a distance of 50 m without hubs, with USB extended the USB signal is converted so

that it can be transferred via 50 m CAT5 cables commonly used for Ethernet wiring. In the Control Panel

the signal is converted back to USB.

Pin Signal Pin assignment

1 15 V 15V USB_E

2 GND GND

3 Tx USB Rx+

4 RX USB Tx+

5 RX USB Tx-

6 Tx USB Rx-

7 15 V 15V USB_E

8 GND GND

2.4.4 USB interface at the mounting arm adapter (optional)

Optionally the Control Panel is fitted with a USB-2.0 Interface (order option C9900-E274).

The interface is located at the mounting arm adapter behind a screw cap, the protection class accords to

the IP67-standard.

USB Interface

12 CP39xx

Page 15

Product Description

2.4.5 Protective Earthing

The low resistance protective earthing connection of the Control Panel is established via the ground bolt,

which is located next to the connections or in the connection area (if provided with a mounting arm

adapter).

Malfunction possible with missing ground connection

A proper ground connection of the device is absolutely necessary for the correct

Note

function of the touchscreen.

2.5 Connection Kits/ Connection Cables

One 4-pole power supply connector is provided with the Control Panel.

Optionally prefabricated connection cables for the DVI-E/ USB-E connection are available.

2.5.1 Connection Kits for DVI-E/ USB-E connection, optional

The following connection kits are available:

Connection kit DVI-E/ USB-E connection

C9900-K630

C9900-K631

C9900-K632

C9900-K633

C9900-K634

C9900-K635

C9900-K636

Connection kit 3 m for CP39xx including:

3 m DVI cable, 3 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter CU8801

for mounting rail installation close to the PC and 1 m USB cable to connect the USB to

USB-E-2.0 converter to the PC

Connection kit 5 m for CP39xx including:

5 m DVI cable, 5 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter CU8801

for mounting rail installation close to the PC and 1 m USB cable to connect the USB to

USB-E-2.0 converter to the PC

Connection kit 10 m for CP39xx including:

10 m DVI cable, 10 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter

CU8801 for mounting rail installation close to the PC and 1 m USB cable to connect

the USB to USB-E-2.0 converter to the PC

Connection kit 20 m for CP39xx including:

20 m DVI cable, 20 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter

CU8801 for mounting rail installation close to the PC and 1 m USB cable to connect

the USB to USB-E-2.0 converter to the PC

Connection kit 30 m for CP39xx including:

30 m DVI cable, 30 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter

CU8801 for mounting rail installation close to the PC and 1 m USB cable to connect

the USB to USB-E-2.0 converter to the PC

Connection kit 40 m for CP39xx including:

40 m DVI cable, 40 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter

CU8801 for mounting rail installation close to the PC and 1 m USB cable to connect

the USB to USB-E-2.0 converter to the PC

Connection kit 50 m for CP39xx including:

50 m DVI cable, 50 m CAT5 cable for USB-E-2.0, USB to USB-E-2.0 converter

CU8801 for mounting rail installation close to the PC and 1 m USB cable to connect

the USB to USB-E-2.0 converter to the PC

CP39xx 13

Page 16

Installation

3 Installation

3.1 Transport and Unpacking

The specified storage conditions must be observed (see chapter Technical Data).

3.1.1 Transport

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts.

During transport, your Control Panel should therefore be protected from excessive mechanical stress.

Therefore, please use the original packaging.

Danger of damage to the unit

If the device is transported in cold weather or is exposed to extreme variations in

Attention

Prior to operation, the unit must be allowed to slowly adjust to room temperature. Should condensation

occur, a delay time of approximately 12 hours must be allowed before the unit is switched on.

temperature, make sure that moisture (condensation) does not form on or inside the

device.

3.1.2 Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

If you notice any shipping damage or inconsistencies between the contents and your order, you should

notify Beckhoff Service.

14 CP39xx

Page 17

Mounting

4 Mounting

The Control Panel will be mounted with 4 threaded screws M6 at the connection block at the rear cover

(see chapter Assembly dimensions).

Optionally the assemblage occurs by using the mounting arm adapter (order option).

The ambient conditions specified for operation must be observed (see chapter Technical Data).

Please note the following points during installation of the Control Panel:

• Position the Control Panel in such a way that reflections on the screen are avoided as far as possible.

• Use the position of the screen as a guide for the correct installation height; it should be optimally

visible for the user at all times.

• The Control Panel should not be exposed to direct sunlight.

Avoid extreme environmental conditions

Extreme environmental conditions should be avoided as far as possible. Protect the

Attention

Control Panel from dust, moisture and heat.

4.1.1 Earthing measures

Earthing connections dissipate interference from external power supply cables, signal cables or cables to

peripheral equipment. Establish a low-impedance connection from the earthing point on the Control Panel

housing (see chapter Protective Earthing) to the central earthing point on the control cabinet wall, in

which the Panel is being installed.

Malfunction possible with missing ground connection

A proper ground connection of the device is absolutely necessary for the correct

Note

function of the touchscreen.

CP39xx 15

Page 18

Mounting

4.2 Mounting arm installation (optional)

The mounting arm adapter is designed for Rittal- and Rolec mounting arm systems with 48 mm tubes.

Depending on the order option the mounting arm can be installed from the bottom or from the top.

Order-Option Description

C9900-M750

C9900-M751

C9900-M752

C9900-M753

Rotatable and tiltable mounting arm adapter at the Control Panel CP3912 to CP3924

for Rittal- and Rolec mounting arm systems with 48 mm tube from the top

Rotatable and tiltable mounting arm adapter at the Control Panel CP3912 to CP3924

for Rittal- and Rolec mounting arm systems with 48 mm tube from the bottom

Rotatable and tiltable mounting arm adapter at the Control Panel CP3912 to CP3924

with push-button extension for Rittal- and Rolec mounting arm systems with 48 mm

tube from the top

Rotatable and tiltable mounting arm adapter at the Control Panel CP3912 to CP3924

with push-button extension for Rittal- and Rolec mounting arm systems with 48 mm

tube from the bottom

Tolerance of the mounting arm tube diameter

The mounting arm tube must have a diameter of 48 mm with a maximum tolerance of

Note

–0,1 mm/ +0,3 mm.

The mounting arm adapter enables to tilt the Control Panel at +/- 20° and to rotate it about +/- 165°.

Anti-twist protection

The mounting arm adapter is fitted with an anti-twist safeguard to avoid over winding

Note

the Control Panel and damaging the connecting cables.

The adapter is equipped with a brake mechanism for tilting the Control Panel, which can be adjusted with

a 5 mm allen key (1). Tightening the locating screw with star knob will protect the Control Panel against

distortion.

The hook wrench (3) allows mounting the mounting arm tube at the mounting arm adapter.

1

2

3

16 CP39xx

Page 19

Mounting

4.2.1 Mounting the mounting arm tube

After feeding the connection cables of the Control Panel through the mounting arm tube, the mounting

arm tube will be positioned into the mounting arm adapter. Now the mounting arm tube is tightened

carefully clockwise, using a hook wrench SW 58-62 (1).

Order Number Description

C9900-Z263

Hook wrench size 58 – 62 for tying up the slotted nut of the mounting arm adapter

C9900-M75x

1

Also the mounting arm tube is locked by tightening the allen screw with the 5 mm allen key (2).

2

CP39xx 17

Page 20

Mounting

4.3 Connecting the Control Panel

Risk of explosion!

The Control Panel must never be connected or disconnected in an area that is subject to

Danger

Attention

4.3.1 Connecting cables

The connections are located at the rear of the Control Panel and are documented in the chapter

Interfaces.

When connecting cables to the Control Panel, please adhere to the following order:

explosion hazard!

The mains plug must be disconnected

Please read the documentation for the external devices prior to connecting them!

During thunderstorms, plug connector must neither be inserted nor removed!

When disconnecting a plug connector, always handle it at the plug. Do not pull the cable!

• Disconnect the Control Panel from the power supply.

• Connect all cables at the Control Panel and at the devices to be connected.

• Ensure that all screw connections between connectors and sockets are tight!

• Reconnect all devices to the power supply.

4.3.2 Protective Earthing

The low resistance protective earthing connection of the Control Panel is established via the screw

connection, which is located in the connection area.

Malfunction possible with missing ground connection

A proper ground connection of the device is absolutely necessary for the correct

Note

function of the touchscreen.

18 CP39xx

Page 21

Operating Instructions

5 Operating Instructions

5.1 Switching the Control Panel on and off

5.1.1 Switching on

The Control Panel does not have its own mains power switch. As soon as the power supply is switched

on the Control Panel is activated.

5.1.2 Shutting down and switching off

Control software such as is typically used on Industrial PCs permits various users to be given different

rights. A user who may not close software may also not switch the Industrial PC off, since data can be

lost from the storage medium by switching off while software is running.

First shut down, then switch off!

If the Industrial PC is switched off as the software is writing a file to the storage

Warning

medium, the file will be destroyed. Control software typically writes something to the

storage medium every few seconds, so that the probability of causing damage by

switching off while the software is running is very high.

Switch off power supply

When you have shut down the Industrial PC, you have to switch off power supply for at

Warning

least 10 seconds before rebooting the system.

After resetting power supply the Industrial PC will start booting automatically.

5.2 Operation

The operation of the Control Panel occurs via the Touch Screen.

Risk of damaging the Touch Screen

The touch screen may only be actuated by finger tips or with the touch screen pen. The

Warning

Warning

operator may wear gloves but there must be no hard particles such as metal shavings,

glass splinters embedded in the glove.

Properly installation of the system and the multi-touch device

Capacitive Touch Screens use the functional principle of capacitive alternation of the

electrical field. Strong electrical fields can influence the functionality of the multi-touch

devices.

To ensure the correct function of the Touch Screen take care of a standardized

installation of all parts of the system and an EMC-environment conforming to

standards.

CP39xx 19

Page 22

Operating Instructions

5.2.1 Setting the transmission rate

At large distance between PC and Control Panel, the transmission rate of the DDC file has to be limited.

The DDC file is transmitted from the Control Panel to the PC in order to transfer the display information

like timing and resolution.

The video bios of the graphic card or, using the on-board graphic, the video bios of the motherboard

contains the definition of the transmission rate for the DDC file. This value has to be 50 kHz or less.

Otherwise the screen is not displayed or not until windows is started.

Windows graphic drivers also include a value for the transmission rate of the DDC file.

If Windows is running and no image is displayed, then use a graphic driver with a value of 50 kHz or less

for DDC file transmission.

5.3 Servicing and maintenance

5.3.1 Cleaning

Disconnect power supply

Switch off the device and all connected devices, and disconnect the device from the

DANGER

The device can be cleaned with a soft, damp cleaning cloth. Do not use any aggressive cleaning

materials, thinners, scouring material or hard objects that could cause scratches.

power supply.

5.3.2 Maintenance

The Control Panel is maintenance-free.

5.4 Emergency procedures

In case of fire, the Control Panel should be extinguished with powder or nitrogen.

5.5 Shutting down

5.5.1 Disposal

Observe national electronics scrap regulations

Observe the national electronics scrap regulations when disposing of the device.

Note

In order to dispose of the device, it must be removed and fully dismantled:

• Housing components (polycarbonate, polyamide (PA6.6)) are suitable for plastic recycling.

• Metal parts can be sent for metal recycling.

• Electronic parts such as disk drives and circuit boards must be disposed of in accordance with

national electronics scrap regulations.

20 CP39xx

Page 23

Troubleshooting

6 Troubleshooting

Pixel errors

Pixel errors in the TFT display are production-caused and represent no complaint-

Note

Note

Fault Cause Measures

reason!

Anomalies of the Touchscreen

Anomalies of the touchscreen sensor are production-caused and represent no

complaint-reason!

The Control Panel shows no

function

Computer boots, software starts,

but control does not operate

correctly

No screen Transmission rate is too high when

Malfunction of the touchscreen Bad or missing ground connection

Bad or missing ground connection

USB error while TwinCAT access

via USB

The Control Panel functions only

partially or only part of the time, e.g.

no or dark picture

No power supply to the Control

Panel/ Industrial PC

Cable not connected

Cause of the fault is either in the

software or in parts of the plant

outside the Industrial PC

using DVI cables longer than 20 m

of the device

of the user

Cycle time in TwinCAT is set on

10 ms (standard)

Faulty backlight in the display

Defective components in the

Control Panel

Check power supply cable

1. Correctly connect cable

2. Call Beckhoff Service

Call the manufacturer of the

machine or the software

Limit transmission rate for

DDC file to 50 kHz

Establish ground connection

User must stand on the floor

with ordinary shoes

Increase the cycle time up to

50 ms till 80 ms

Call Beckhoff Service

Call Beckhoff Service

CP39xx 21

Page 24

Assembly dimensions

7 Assembly dimensions

For the assembly dimensions of the Control Panels please visit our homepage. Here you will find the

actual drawings using the link:

http://download.beckhoff.com/download/Technical_Drawings/Industrial_PC/Control_Panel/CP39xx

Notice mounting orientation

The assembly of the unit must take place with the orientation diagrammed here.

Warning

22 CP39xx

Page 25

Technical Data

8 Technical Data

Risk of explosion!

Do not use the Control Panel in areas of explosive hazard!

Danger

Pixel errors

Pixel errors in the TFT display are production-caused and represent no complaint-

Note

Note

Product name CP39xx

Dimensions (B x H x T) See chapter Assembly dimensions

Weight approx.

(with connection block/

with mounting arm adapter)

Supply voltage 24 V

Power consumption CP3907-0000: max. 12 W CP3918-0000: max. 25 W

UL-compliance

(in progress)

Integrated DVI/USB extension

technology

Optional interface 1-Port-USB-2.0 interface at the mounting arm adapter or in the front

Protection class Front side IP65, rear side IP65

Shock resistance

(Sinusoidal vibration)

Shock resistance

(Shock)

EMC compatibility Resistance to interference conforms to EN 61000-6-2

EMC compatibility Emission of interference conforms to EN 61000-6-4

Permissible ambient temperature 0°C to +55°C (operation)

Permissible relative humidity to 95%, no condensation

Transport and storage The same values for atmospheric humidity and shock resistance are

Certifications CE; UL in progress

reason!

Anomalies of the Touchscreen

Anomalies of the touchscreen sensor are production-caused and represent no

complaint-reason!

CP3907: 1.8 kg CP3918: 5.5 kg/ 6.3 kg

CP3912: 3.4 kg/ 4.2 kg CP3919: 6.1 kg/ 6.9 kg

CP3915: 3.9 kg/ 4.7 kg CP3921: 6.6 kg/ 7.4 kg

CP3916: 4.5 kg/ 5.3 kg CP3924: 7.6 kg/ 8.4 kg

(20.4 – 28.8 VDC)

DC

CP3912-0000: max. 16 W CP3919-0000: max. 25 W

CP3915-0000: max. 20 W CP3921-0000: max. 35 W

CP3916-0000: max. 22 W CP3924-0000: max. 45 W

• Using a power supply class 2 or

• Fuse protection with 4 A, according to UL 60950.2

chapter 2.5, table 2C

•

DVI-E and USB-E 2.0 enable remote panel operation at a distance

of up to 50 m from the PC

•

USB-E 2.0 transmits USB 2.0 with 480 Mbit/s

•

DVI-E input is compatible to the standard DVI output of a PC

EN 60068-2-6: 10 to 58 Hz: 0.035 mm

58 to 500 Hz: 0.5 G (~ 5 m/ s2)

EN 60068-2-27: 5 G (~ 50 m/ s2), duration: 30 ms

-25°C to +65°C (transport/ storage)

to be observed during transport and storage as in operation. Suitable

packaging of the Panel PC can improve the resistance to impact

during transport.

CP39xx 23

Page 26

Appendix

9 Appendix

9.1 Beckhoff Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

9.1.1 Beckhoff branches and partner companies

Please contact your Beckhoff branch office or partner company for local support and service on Beckhoff

products!

The contact addresses for your country can be found in the list of Beckhoff branches and partner

companies: www.beckhoff.com

9.1.2 Beckhoff company headquarters

Beckhoff Automation GmbH

Eiserstraße 5

33415 Verl

Germany

. You will also find further documentation for Beckhoff components there.

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.de

Web: http://www.beckhoff.de/

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: + 49 (0) 5246/963-157

Fax: + 49 (0) 5246/963-9157

E-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: + 49 (0) 5246/963-460

Fax: + 49 (0) 5246/963-479

E-mail: service@beckhoff.com

If servicing is required, please quote the project number of your product.

24 CP39xx

Page 27

Appendix

9.2 Approvals for USA and Canada

9.3 FCC Approvals for the United States of America

FCC: Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Technical modifications

Technological changes to the device may cause the loss of the FCC approval.

Note

9.4 FCC Approval for Canada

FCC: Canadian Notice

This equipment does not exceed the Class A limits for radiated emissions as described in the Radio

Interference Regulations of the Canadian Department of Communications.

CP39xx 25

Loading...

Loading...