Beckett SLD375, SL375, SL5125, SLD5125, SL6150 User Manual

...

INSTALLATION AND OPERATOR’S MANUAL

SL375 THRU SL7175

OIL FIRED CAST IRON BOILERS

Keep these instructions with the boiler at all times for

future reference

B

OYERTOWN FURNACE CO.

PO Box 100

B

OYERTOWN, PA 19512

1-610-369-1450

www.boyertownfurnace.com

1-10-06

g

g

2

Be Aware of Hazard Definitions

Danger

Warnin

Caution

Notice

Denotes presence of a hazard which, if ignored, will result in severe personal injury,

death or property damage

Denotes presence of a hazard which, if ignored could result in severe personal injury,

death or substantial property damage.

Denotes the presence of a hazard, which if ignored, could result in minor personal

injury or property damage

Intended to bring attention to information, but not related to personal injury or property

damage.

Danger

This equipment must be installed, adjusted, serviced and started only by a qualified service

agency – an individual or agency, licensed and experienced with all codes and ordinances, and who

is responsible for the installation and adjustment of the equipment. The installation must comply

with all local codes and ordinances and with the latest revision of the National Fire Protection

Standard for Oil Burning Equipment, NFPA 31.

Read all instructions before proceeding. Follow all instructions completely. Failure to follow these

instructions could result in equipment malfunction causing severe personal injury, death or

Warnin

substantial property damage.

Do not alter this boiler in any way. The manufacturer will not be liable for any damage resulting

from changes made in the field to the boiler or its components or from improper installation.

Failure to comply could result in severe personal injury, death, or substantial property damage.

Your oil fired boiler is designed to burn No. 1 and No. 2 heating oil only. Never use gasoline or a

mixture of gasoline and oil.

Do not store gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

The area around the boiler should be kept free and clear of combustible materials.

Never burn garbage or refuse in your boiler.

Never try to ignite oil by tossing burning papers or other material into your boiler.

Do not attempt to start the burner when excess oil has accumulated or the boiler is full of vapors.

D

o not operate boiler if the heat exchanger is damaged.

Do not jumper, attempt to bypass or override any of the safety limit controls.

Do not use this boiler if any part has been under water. Immediately call a qualified service

technician to inspect the boiler and replace any part of the boiler, control system or burner that has

been under water.

All installations must conform to the requirements of the authority having jurisdiction. Such

applicable requirements take precedence over the general instructions of this manual.

Where required by the authority having jurisdiction, the installation must conform to the American

Society of Mechanical Engineers Safety Code for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1.

NOTICE

Concealed Damage- If you discover damage to the burner, boiler or controls during

unpacking, notify the carrier at once and file the appropriate claim. When calling or writing about

the boiler please have the following information available: the boiler model number and serial

number which is located on the upper left front of the unit. Record the model and serial number for

future reference in the space provided in this manual.

Table of Contents

Ratings and Data………………………………………………………………………4

Clearances……………………………………………………………………..............5

Ventilation and Combustion Air………………………………………………………5

Boiler Assembly……………………………………………………………….............6

Temperature control Installation and Adjustment

Boiler Trim Piping

Jacket Installation

System Piping………………………………………………………………...……….9

Bypass Piping

Low Water Cut-Off

Relief Valves

Expansion Tanks

Venting Systems……………………………………………………………………...10

Chimney Venting

Direct Venting

Burner Installation……………………………………………………………….…...14

Oil Tank and Piping……………………………………………………………….….15

.

Wiring…………………………………………………………………………..……..15

Swing Door……………………………………………………………………..……..18

Opening the Door

Closing the Door

Door Hinge Reversal

Operation………………………………………………………………………..……..18

Sequence of Operation

Start Up

Start Up Equipment

Burner Adjustments

Control Circuit Safety Checks

Maintenance……………………………………………………………………..…….21

Boiler

Oil Burner

Vent System

Domestic Water Tank……………………………………………………………..…..22

..

Trouble Shooting Guide………………………………………………………..……...23

Parts Diagrams…………………………………………………………………..……..25

Warranty …………………………………………………………………………..…..26

3

4

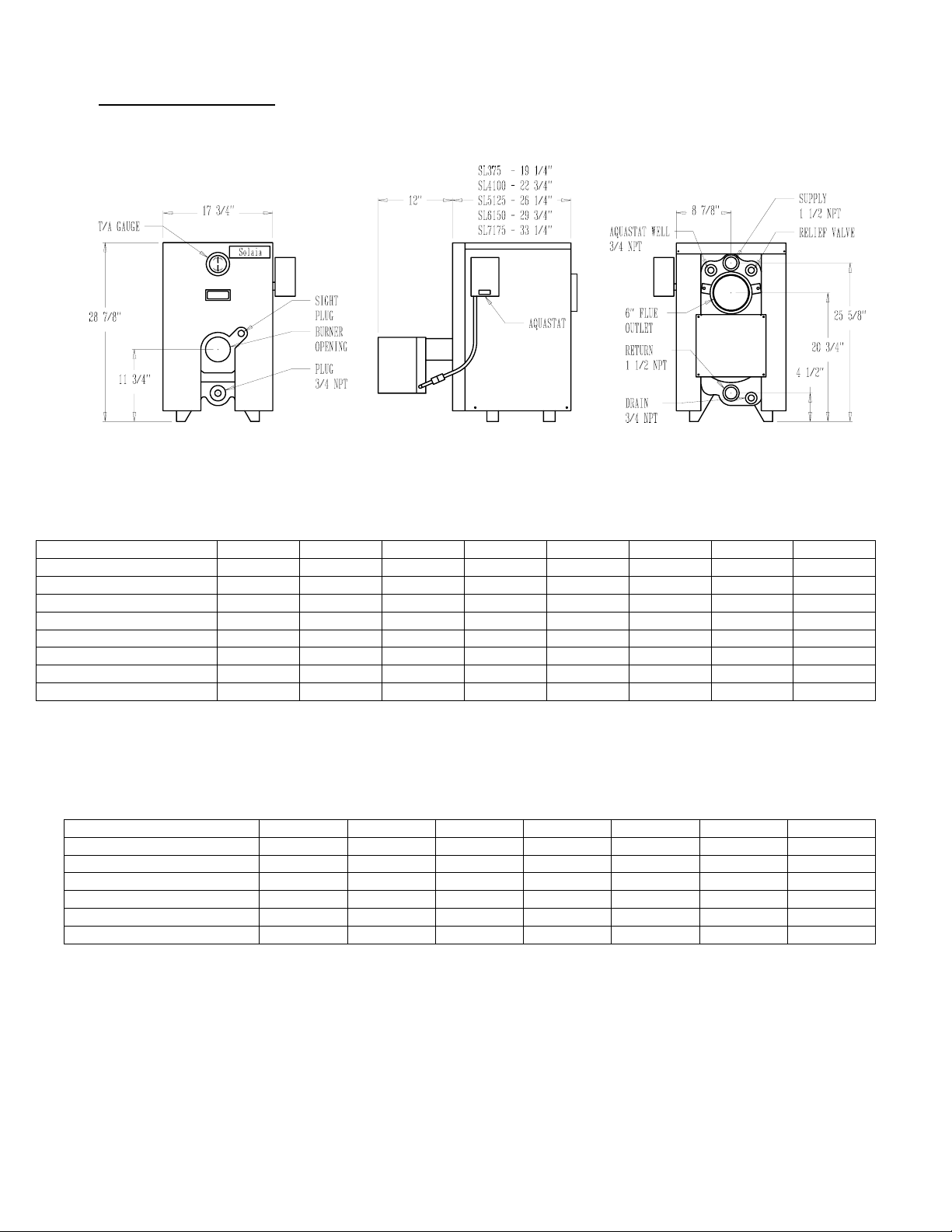

Ratings and Data

Boiler Model No. SL375 SLD375 SL4100 SLD4100 SL5125 SLD5125 SL6150 SL7175

Firing Rate - #2 Fuel 0.75 0.75 1.00 1.00 1.25 1.25 1.50 1.75

Input BTU/HR 105,000 105,000 140,000 140,000 175,000 175,000 210,000 245,000

DOE Capacity BTU/HR 91,000 91,000 122,000 122,000 153,000 153,000 184,000 208,250

Net IBR Rating BTU/HR 79,000 79,000 106,000 106,000 133,000 133,000 160,000 181,100

Net Rating Sq. Ft. 526 526 707 707 887 887 1,067 1,207

AFUE Rating 85.5 85.5 86.5 86.5 86.9 86.9 86.9 85.0

Water Capacity 3.6 3.6 4.3 4.3 5.1 5.1 5.8 6.5

Approx. Shipping Weight 300 300 350 350 390 390 430 470

Cabinet Height 28 7/8" 28 7/8" 28 7/8" 28 7/8" 28 7/8" 28 7/8" 28 7/8"

Cabinet Width 17 3/4" 17 3/4" 17 3/4" 17 3/4" 17 3/4" 17 3/4" 17 3/4"

Cabinet Length 19 1/4" 19 1/4" 22 3/4" 22 3/4" 26 1/4" 29 3/4" 33 1/4"

Supply Outlet Height C.L. 25 3/8" 25 3/8" 25 3/8" 25 3/8" 25 3/8" 25 3/8" 25 3/8"

Return Outlet Height C.L. 4 1/2" 4 1/2" 4 1/2" 4 1/2" 4 1/2" 4 1/2" 4 1/2"

Flue Outlet Diameter 6" 6" 6" 6" 6" 6" 6"

Flue Outlet Height C.L. 20 3/4" 20 3/4" 20 3/4" 20 3/4" 20 3/4" 20 3/4" 20 3/4"

Installation Clearances

Boilers in rooms shall be installed with the clearances from combustible materials not

WARNING

less than indicated below. Combustible materials are those made of or surfaced with wood,

compressed paper, plant fibers, plastics, or other material that will ignite and burn, whether flame

proofed or not, or whether plastered or not.

The boiler must not be installed on combustible flooring. The boiler is approved for installation on

non combustible flooring only. The boiler must not be installed on carpeting or vinyl flooring

Consult NFPA-31 for construction techniques where the above minimum clearances cannot be obtained

Note: When installed in a utility room, the door should be wide enough to allow the largest boiler part to

enter, or to permit replacement of another appliance such as a water heater.

Minimum clearances to combustible construction are as follows:

TOP - 24 IN.

FRONT - 12 IN.

FLUE CONNECTOR SINGLE WALL VENT PIPING - 9 IN.

FLUE CONNECTOR DOUBLE WALL INSULATED DIRECT VENT PIPING – 2”

REAR - 2 IN.

SIDES - 2 IN.

Minimum recommended clearances for service and access are as follows:

TOP - 24 IN.

FRONT - 24 IN. FROM BUNER

FLUE CONNECTOR - 9 IN.

REAR - 18 IN.

SIDES - 12 IN.

5

Ventilation and Combustion Air

Warning…

combustion air must be supplied at all times.

Ventilation of boiler room must be adequate enough to provide sufficient air for combustion.

When a boiler is located in an unconfined space in a building of conventional frame or masonry construction

infiltration may provide adequate air for combustion and ventilation. If there is any doubt, install air supply

provisions for combustion and ventilation in accordance with section 5.3, Air for Combustion and

Ventilation, of the NFPA54 1988 code, it is recommend that you follow, the applicable provisions of the

local building codes as well.

When a boiler is installed in a confined space, in a building of unusually tight construction, air for

combustion and room ventilation must be obtained from the outdoors or from spaces freely communicating

with the outdoors. A permanent opening or openings having a total free area of not less than 1 square inch

per 5,000 BTU per hour of total input rating of all appliances shall be provided. Ducts may be used to convey

make-up air from the outdoors and shall have the same cross-sectional area of openings to which they are

connected.

When air for combustion and room ventilation is from inside buildings, the confined space shall be provide

with two permanent openings, one starting 12 inches from the top and one 12 inches from the bottom of the

enclosed space. Each opening shall have a minimum free area of 1 square inch per one thousand (1,000)

BTU per hour of the total input rating of all appliances in the enclosed space, but must not be less than one

Air openings to combustion area MUST NOT BE OBSTRUCTED. Adequate

6

hundred (100) square inches. These openings must freely communicate with the interior areas having adequate

infiltration from the outside.

When the boiler is installed in a confined space and all air is provided from the outdoors, the confined space

shall be provided with two permanent openings, one commencing within 12 inches from the top, and one

commencing 12 inches from the bottom of the enclosure. The openings shall communicate directly, or by

ducts, with the outdoors or spaces (crawl or attic) that freely communicate with the outdoors. One of the

following methods must be used to provide adequate air for ventilation and combustion.

1. When directly communicating with the outdoors, each opening shall have a minimum free area of 1

square inch per 4,000 BTU per hour of total input rating of all equipment in the enclosure.

2. When communicating with the outdoors by means of vertical ducts, each opening shall have a minimum

free area 1 square inch per 4,000 BTU per hour of total input rating of all appliances in the enclosed

space.

3. If horizontal ducts are used, each opening shall have a minimum free area 1 square inch per 2,000 BTU

per hour total input rating of all appliances in the enclosed space.

4. When ducts are used, they shall be on the same cross sectional are as the free area of the openings to

which they connect. The minimum dimensions of rectangular air ducts shall not be less than 3 inches.

In calculating free area using louvers, grills or screens for the above, consideration shall be given to their

blocking effect. Screens used shall not be smaller than ¼ inch mesh. If free area through a design of louver

of grill is known, it should be used in calculating the size opening required to provide the free area specified.

If the design and free area is knot known, it may be assumed that wood louvers will have 20-25% free area

and metal louvers and grills will have 60-75% free area. Louvers and grills shall be fixed in the open

position or interlocked with the boiler so that they are opened automatically during boiler operation.

Boiler Assembly

LOCATE BOILER…in front of final position before removing crate.

PROVIDE A LEVEL SOLID BASE as near chimney or direct vent as possible and centrally located with

respect to the heat distribution system as practical.

The boiler must be placed within distances from boiler room walls and ceilings that comply with existing

building codes and for ease of service.

THE BOILER IS SHIPPED AS A PACKAGED UNIT OR A KNOCK DOWN UNIT

THE PACKAGED BOILER IS SHIPPED IN TWO PACKAGES.

a. Boiler and Cabinet Assembled and Crated

b. Burner/Parts Box – Includes burner, aquastat and trim piping

THE KNOCK DOWN BOILER IS SHIPPED IN THREE PACKAGES

a. Casting strapped to a skid

b. Cabinet Parts Box

1. (2) Upper mounting brackets

2. (2) Lower mounting brackets

3. (4) Lower mounting spacers

4. (1) Right side panel

5. (1) Left side panel

c. Burner/Parts Box – Includes burner, aquastat and trim piping

6. (1) Rear panel

7. (1) Top panel

8. (1) Front door panel

9. (15) Sheet metal screws

10. (2) Plastic anti short bushing

LOCATE THE BOILER in the position to be assembled and piped.

Remove crate, plastic protective wrapper and INSPECT FOR DAMAGE. All equipment is carefully

manufactured, inspected and packaged by experienced workers. Our responsibility ceases upon delivery of

the crated boiler to the carrier in good condition. ANY CLAIMS FOR DAMAGE OR SHORTAGE IN

SHIPMENT MUST BE FILED IMMEDIATELY against the carrier by the consignee.

Temperature Controls Installation and Adjustment

1. After cabinet installation is complete install the temperature control on the right side of the boiler.

a) Carlin Aquastat – Attach the 4 x 4 Junction box supplied with the Carlin control using the 1/2”

electrical box connector attached to the side of the jacket.

b) Honeywell L7248A1000 – Remove sensor wires which are fed through the 1/2” box connector.

Attach the aquastat to the 1/2” box connector. Remove jacket top panel. Loosen and remove the wire

clamp on the immersion well and remove sensor wires from the immersion well. Run the sensor lead

through the aquastat and reinstall into the immersion well. Replace the wire clamp and tighten to secure

sensor leads in the immersion well.

c) Honeywell L7248C1022 – Remove sensor wires which are fed through the 1/2” box connector.

Remove the 1/2” box connector from the jacket side panel and insert the Heyco bushing in the hole.

Run the sensor wires through the hole in the jacket panel. Attach the aquastat to the jacket side panel

using sheet metal screws and the holes provided in the jacket panel. The sensor wires should be run

through the bottom knockout in the aquastat. The rubber grommet provided with the sensor wires is to

be securely inserted into the aquastat knockout.

2. Connect the sensor leads to the appropriate temperature control terminals.

3. Connect your line voltage and thermostat wires if applicable to the control. See electrical diagrams for

proper connections.

4. Honeywell L7248 - The overall range of the High Limit is from 130

set in the range of 180

5. Carlin 90200A- A manually adjusted potentiometer is used to set the High Limit, typically it would be

set in the range of 180

0

F to 2000F.

o

F to 200oF. The high limit differential is preset to 250F

0

F to 2200F. Typically it would be

Boiler Trim Piping

1. Knocked down- Install the ¾” temperature control immersion well in upper right side tapping of the rear

boiler section. Install the temperature sensor all the way into the well until it hits bottom and fasten in

place with the retaining clip (Honeywell) or retaining nut (Carlin) as provided.

2. Pipe in pressure relief valve with ¾” street elbow and with the ¾” x 3” nipple in upper left side of the

rear section. Relief valve discharge must be piped to a safe place of discharge.

3. Pipe in boiler drain with ¾” x ½” reducing coupling and the ¾” x 3” nipple in the lower left side rear

section.

4. Install ¾” pipe plug in the lower portion of the front section.

5. Knocked down – Pipe in boiler gauge with ½” x ¼” reducing bushing in upper front section.

7

(2)

g

8

Jacket installation

1. Open Cabinet Parts Box Check for damages. Damage claims must be filed immediately with carrier.

2. Install the (4) 3/4” OD x 1-9/16” bottom bracket spacers onto the tie rods, followed by the bottom

brackets, with the tabs pointing outward, which are fastened in place with the 10mm nuts provided.

3. Mount top brackets on the boiler tie rods with the tabs pointing outward. Fasten in place between the

10mm nuts provided on the casting. Insert the two anti-short bushings into the holes on the right hand

side in the upper brackets.

4. Install right side jacket panel to the upper and lower brackets with sheet metal screws provided.

5. Install the ½” electrical connector required for the Carlin control or the Honeywell L7248A1000

through the hole in the front part of the right side jacket panel and tighten in place with the locknut

provided. Install the Heyco bushing in the hole when using the Honeywell L7248C1022.

6. Install the left side jacket panel, to the upper and lower brackets with the sheet metal screws provided.

7. Install the Honeywell L7248A1000 aquastat onto the box connector using the clamping screw or screw

the Honeywell L7248C1022 directly to the right side jacket panel.

8. Install the sensor wires.

a) Honeywell L7248A1000 – Run the sensor wires through the hole in the aquastat and out the box

connector. Run the sensor wires through the holes in the upper brackets and insert into

immersion well. Fasten the wires into the well using the wire clamp provided. Snap sensor

wires into control.

b) Honeywell L7248C1022 – Run the sensor wires through the Heyco bushing. Run the sensor

wires through the holes in the upper brackets and insert into immersion well. Fasten the wires

into the well using the wire clamp provided. Remove one of the unused knockouts in the

bottom of the aquastat. Insert sensor wire through the knockout securing with grommet

supplied. Snap sensor wires into control.

c) Carlin Control – Install the box provided with the control onto the box connector. Run the

sensor wires through the hole in the aquastat and out the box connector. Run the sensor wires

through the holes in the upper brackets and insert into immersion well. Fasten the wires into the

well. Insert sensor wires into control.

9. Install the top panel by sliding it in from the front catching the top panel’s lower edge under the sides

upper edges. Slide back till the top drops over the back edge, fasten with the sheet metal screws

provided.

10. Install the back panel with the small notches facing up and fasten with sheet metal screws provided.

11. Install the jacket front panel by lining up the (4) mounting screws on the front of the two sides with the

keyhole slots on the front panel and lower in to place.

12. Transfer the boiler serial number located on the left front leg onto the rating label on the jacket front

panel in the upper left corner.

TopBrackets

Immersion Well/

Sensor Leads

(4) Bottom

Bracket Spacers

(2) Bottom Brackets

Anti-Short

Bushin

s

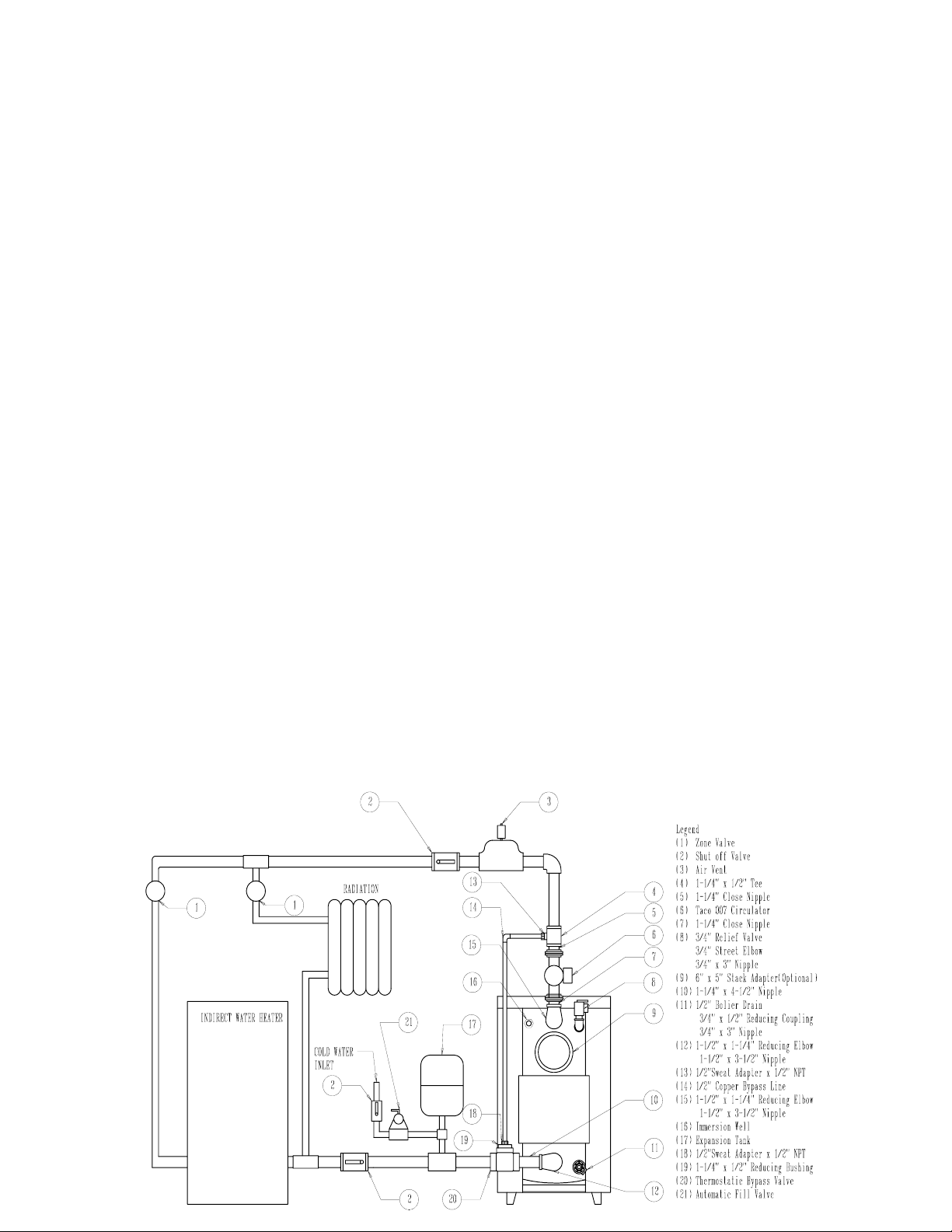

System Piping

9

Important…

SERVICEMEN

SOLAIA BOILERS HAVE A MAXIMUM OPERATING PRESSURE OF 58PSI

NOTE: If normal operating pressures are greater than 30psi please contact the manufacturer for required

trim.

Pipes that are connected to boiler fittings must be supported and placed so that they do not create stresses on

the boiler fittings themselves.

INSTALLATION MUST BE PERFORMED BY TECHNICALLY QUALIFIED

BY PASS PIPING IS REQUIRED ON ALL LOW MASS BOILERS WHERE THE BOILER

RETURN WATER TEMPERATURE COULD OPERATE BELOW 130ºF FOR EXTENDED

PERIODS OF TIME.

The Solaia boiler is a highly efficient low mass boiler in which care must be taken to ensure that high

volumes of low temperature water are not introduced into the boiler. Operating at return water temperatures

below 130ºF for extended periods of time will allow for the accumulation of condensation, scale and

increased soot formation in the boiler. Corrosion and eventual heat exchanger failure will result. A

thermostatic bypass valve is highly recommended on high water volume standing cast iron systems.

A thermostatic bypass valve will consistently ensure that return temperatures to the boiler exceed 130

all times. See Figure 1 for Thermostatic Bypass valve piping.

Instead of using a thermostatic bypass, bypass piping may be accomplished by placing a 3/4” bypass line

with a throttling valve for regulation between the supply piping and return piping. Boiler return water

temperatures must exceed 130ºF with the bypass properly adjusted.

Low water cut off

Hot water boilers installed above radiation level must be provided with a low water cut off device at time of

the boiler installation.

Relief Valves

Relief valves are to be properly piped in to conform to code standards. Discharge piping from the relief

valve must be piped to a drain or must terminate 6” above the floor to eliminate damage to the structure or

personal injury. It must not be piped to a point where freezing may occur.

Expansion Tanks

The expansion tank must be properly sized to the system requirements. An undersized expansion tank will

cause system water to be lost through the relief valve and make up water to be introduced through the fill

valve. Continual introduction of fresh water will cause boiler failure.

o

F at

10

VENTING

WARNING

Failure to follow all instructions can result in flue gas spillage and carbon monoxide

emissions, causing severe personal injury or death. All chimneys must meet the requirements of

NFPA 211 and NFPA 31

Chimney

The boiler must be connected to an adequate chimney or an approved venting system in accordance with

these instructions. An adequate chimney or venting system is one that is sealed and lined with the capability

of producing a -.04" W.C. flue draft and having the capacity to handle the amount of flue gas that is

introduced. A chimney with an internal construction of corrosion resistant tile, stainless steel, or some other

material that will withstand flue gas temperatures up to 1000

Masonry and metal chimneys shall be constructed in accordance with applicable building code

requirements. Masonry chimneys shall be lined with an approved clay tile liner or a listed chimney lining

system installed in accordance with manufacturers’ instructions and also meeting the requirements of

NFPA-211 Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances. Metal chimneys

also shall meet the requirements of NFPA-211. Factory built chimneys shall be listed and shall be installed

in accordance with their listing and NFPA-211.

Prior to installation of the boiler, the chimney or venting system shall be examined by the installer and

determined to be in good condition. All joints of the chimney must be tightly sealed. The inside of the

chimney should be free of all obstruction, such as loose brick, broken pieces of tile, or corroded metal. If

chimney flues are divided or there are multiple flues within one chimney, make sure there are no openings

in the partition separating the divided or individual flues. When a new appliance is connected to an existing

chimney, that chimney shall be brought up to current requirements. Chimneys which are relined shall be

done so with an approved liner that will resist corrosion, softening, or cracking from the flue gasses.

All chimney clean-out doors and flue connections must fit tightly so they will seal to avoid air

leakage.

The inside area of the chimney liner should equal, at a minimum,

furnace. If more than one appliance is installed, the area of both appliances shall be used in determining the

required inside area of the chimney.

The flue gas exit of a chimney shall be at least 3 feet above the highest point where it passes through the

roof of a building and at least 2 feet higher than any portion of a building within 10 feet of such chimney.

The chimney height will also be determined by the height of the surrounding trees, buildings and terrain.

When chimney downdraft conditions cause faulty operation that creates a hazard, corrective steps must be

taken.

When altering the surrounding obstructions is not possible, a chimney cap can be constructed on the top of

the chimney to avoid downdrafts. The chimney cap should be pyramid shaped on the top with a perfectly

flat surface immediately above the chimney outlet. The hood should be attached by four (4) iron supports.

The four iron supports should be equal in height to the width of the chimney opening. Four plates, flaring

down, can be added to help insure that the wind will pass straight over the chimney outlet.

Chimney Relining

A tile lined masonry chimney serving an oil fired boiler should comply with applicable building codes such

as NFPA-211. An additional listed lining may be required to reduce transient low draft during startup and

acid water condensation during cyclic operation. This is particularly true for high mass masonry chimneys

serving oil fired furnaces of higher efficiency. For masonry chimneys, local experience can indicate how

well construction has withstood the lower temperatures produced by higher efficiency furnaces.

0

F is required.

the area of the vent pipe exiting the