Page 1

S80 with

• MLS Basic Card

• MLS Professional Card

en

Assembly and Operating Instructions

Door Control Unit

Important information for:

•

Fitters

• Electricians

• Users

Please forward accordingly!

These instructions must be kept for future reference.

Becker-Antriebe GmbH

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Assembly and Operating Instructions

Table of Contents

Introduction ................................................................................................................................................................2

Warranty .....................................................................................................................................................................2

Safety instructions ......................................................................................................................................................3

Basic safety measures .................................................................................................................................................3

Intended use .............................................................................................................................................................. 4

Abbreviations used ......................................................................................................................................................4

Overview of unit .......................................................................................................................................................... 4

Overview of functions ..................................................................................................................................................5

Installing the control unit ..............................................................................................................................................6

Fitting and removing a control card ............................................................................................................................... 6

Electrical connection ................................................................................................................................................... 7

Operator controls ........................................................................................................................................................7

Checking the direction of movement .............................................................................................................................8

Setting the door end limits ...........................................................................................................................................8

Electrical connection/operation of external control sensors and safety devices ................................................................9

Connection and function of the switching outputs .........................................................................................................11

Retrotting and operation of radio control system ........................................................................................................ 12

Setting the DIP switches ............................................................................................................................................ 14

Indicator LED’s ......................................................................................................................................................... 15

Overview of control times ........................................................................................................................................... 16

What should I do if ... ? ............................................................................................................................................... 16

Position of terminals and components ........................................................................................................................ 17

General wiring diagram .............................................................................................................................................. 18

Specications ........................................................................................................................................................... 19

Introduction

When installing the equipment and setting the functions, please observe the Operating and Installation Instructions.

Note

These Operating and Installation Instructions apply to the S80 Door Control Unit with MLS Basic Card and

MLS Professional Card for actuating drives with mechanical limit switching.

Warranty

Structural modications and incorrect installation which are not in accordance with these and our other instructions can result

in serious injuries, e.g. crushing of limbs. Therefore, structural modications may only be carried out with our prior approval

and strictly in accordance with our instructions, particularly the information contained in these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is not permitted.

The end product manufacturer and tter have to ensure that all the current statutory, ofcial and, in particular, EMC regulations are adhered to during utilisation of our products, especially with regard to end product manufacture, installation and

customer advice.

2

Page 3

Safety instructions

The following safety instructions and warnings serve to avert dangers and to prevent personal injuries and damage to property. Please retain these instructions for future reference.

Caution

Attention

Note

Denotes a potentially hazardous situation. If this is not avoided, injuries can

result.

Denotes a potentially hazardous situation. If this is not avoided, the product

or property in its vicinity can be damaged.

Denotes hints for use and other useful information.

Basic safety measures

Caution

Please read this manual thoroughly before carrying out work on the system. Always observe the manual

and the safety instructions contained in it.

• When the control is opened, there is an electrical voltage of up to 400 V. Danger to life due to electric shock.

• Work on the electrical equipment must only be carried out by a qualied electrician.

• Only use the control in accordance with its intended use!

• Never decommission or bypass safety devices.

• Do not operate the system if the safety devices are damaged.

• Fault elimination must only be performed by an authorised technician. In the event of a system malfunction, the

system must be shut down immediately and the malfunction rectied as quickly as possible. The system must

only be commissioned by an authorised technician.

• Observe the generally applicable legal regulations (safety, accident prevention) as well as these safety instructions, particularly the regulation of the employers’ liability insurance associations, EN 12453 “Requirements

for safe use of power-operated doors” as well as the relevant applicable VDE standards.

• The operator must ensure that the system is only operated in perfect condition and that the safety devices are

checked regularly for functional efciency by an expert (before commissioning and as required, but at least

once a year; at least once every six months if a non self-testing light barrier is used). Proof of the necessary

checks must be provided in the form of a test report. This test report must be led in the log book.

• The estimated service life of the control is 100.000 operations.

• Drives with connection cable H05VVF are to be used only inside the building. In case of installation outside,

the cable is to be protected inside conduit.

3

Page 4

Assembly and Operating Instructions

Intended use

The control unit must be used as intended with Becker door drives with mechanical limit switches. If other controls are used,

the warranty entitlement will become invalid! This control must not be used for doors which have not been designed for this

type of control!

Abbreviations used

IMP - Impulse Button

LS - Photoelectric Barrier

MLS - Mechanical Limit Switch (mechanical limit switching)

ELS - Electronic Limit Switch (electronic limit switching)

SKS/USA - Bottom Rail Sensor

VES - Pre-Limit Switch

AUTO/WZL - Automatic Closing/Reclosing (Wiederzulauf)

BES - Becker Electronic System

DW Testing - Pressure Switch Testing (pneumatic safety edge)

Overview of unit

Basic Control Unit S80

MLS Basic Card

MLS Professional Card

4

Page 5

Overview of functions

Function MLS Basic Card MLS Professional Card

Setting mode (up/down in dead-man mode) X X

Automatic ascent (UP) X X

Automatic descent (DOWN) X

Anti-pull-in cable safety X X

Slack rope switch debounced X X

Button input: UP/STOP/DOWN/STOP X

Automatic closing X

Partial opening X

Pneumatic safety edge X

Electrical safety edge X

Safety edge switchover: 1.2 kOhm/8.2 kOhm X

Optoelectronic safety edge: FRABA OSE X

Photoelectric barrier X

Yard light X

Trafc lights/door status indicator X X

Warning lamp X

Power supply lamp X X

LED UP X X

LED DOWN X X

LED Operating status X

LED ERROR Code X

LED Safety edge X

LED Pre-limit switch X

Voltage output (24 V DC / 200 mA) X X

1)

Operates only when a safety edge is used

1)

5

Page 6

Assembly and Operating Instructions

Installing the control unit

Install the control unit so that the operator controls are readily accessible. The cover of the housing with the 3-way pushbutton

switch has to be removed for installation purposes.

The unit is mounted on the wall with four 4 mm dia. screws (max. head dia. 8 mm) using the four fastening holes, which also

take the screws to t the cover, in accordance with the dimensioned drawing on the bottom of the housing.

If necessary, you can t more cable glands for sensor cables and indicating cables.

Attention

When removing housing knockouts in order to t more cable glands, take care not to damage any compo-

nents on the control boards or the housing itself. Only t sealing cable glands which ensure the housing

has the correct degree of protection.

When retting the cover, ensure that the seal and the seal groove are clean and that the cover is mounted

properly.

Tighten up the housing cover screws carefully. Only then will the IP 65 degree of housing protection remain intact.

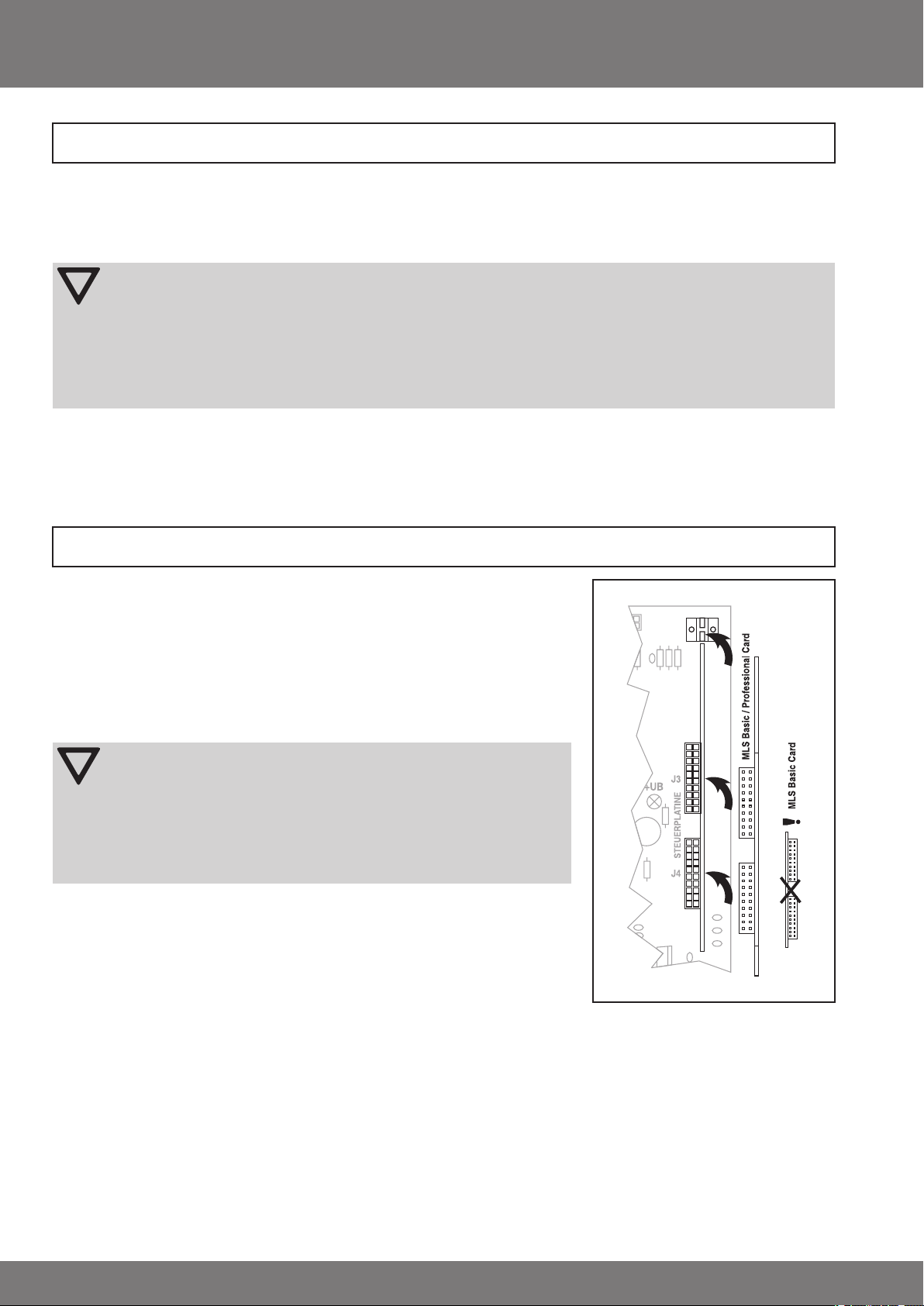

Fitting and removing a control card

The S80 door control system for drives with mechanical limit switching can be converted/upgraded by changing plug-in control cards. The following control cards

are available:

• MLS Basic Card

• MLS Professional Card

Before changing a control card, disconnect the entire door control unit from the

mains and open the cover of the control box.

Attention

The regulations for handling elements with an electrostatic risk

must be complied with. The MLS Professional Card may only be

used in combination with a safety edge. When delivered, safety

devices may be bridged. When changing from the MLS Basic Card

to the MLS Professional Card, always ensure that no non-permissible bridging exists or, if such bridging does exist, ensure that it

is removed.

Carefully pull out the control card connected to slot J3/J4 and insert the new control card at slot J3/J4 on the S80 motherboard as illustrated opposite. With the

MLS Basic Card ensure that the board is the right way round.

6

Page 7

Electrical connection

Caution

The control unit may only be connected by an electrician.

Observe the relevant VDE standards.

During all installation work the equipment must always be securly disconnected from the mains.

When connecting, refer to the specications of the S80. The indicated maximum values are not to be

supassed!

Installing the Mains Connection

The working voltage of the S80 door control unit is 3-phase 400 V/230 V, 50 Hz. For connection to the main power supply,

please use a 1,2 m long cable and a 16A/6h CEE socket outlet with direct access to the control unit to ensure that the plug is

readily accessible. Alternatively, connect the control unit via a non-detachable installation cable complete with local isolation

(for the positions of the terminals and the wiring diagram refer to pages 37 and 38).

Attention

For xed installation, a main switch must be connected to the S80 control unit or directly to the power

line in reach of the control unit. Protect the mains lead for the control unit with a 3-phase AC automatic

cut-out (3 x 10 A).

Connecting the Drive to the Control Unit

The drive cable is usually already attached to the control unit. If not, connect the 12-core drive cable to terminals E and PE in

accordance with the wiring diagram. The 11 black wires of the drive cable are numbered 1 to 11, corresponding to the numbers

of terminals E. The green/yellow earth wire must be connected up to one of the 3 PE earth terminals ( ).

Operator controls

UP Button

If the MLS Professional Card is used, pressing the UP button opens the door and keeps it open. When the top end limit has

been reached or if a safety function responds, the door stops automatically. If the UP button is pressed whilst the door is closing, the door stops instantly and after a delay of 0.5 s (time Z0) it moves to the top end limit.

If the MLS Basic Card is used, the unit can either be in dead-man mode (the UP button has to be kept pressed - if it is released,

the door stops) or in automatic mode (the UP button is pressed once and the door moves automatically to the top end limit),

depending on the position of DIP switch DIP 1.

STOP Button

Pressing the STOP button stops the door instantly when it is opening or closing.

DOWN Button

If the MLS Professional Card and a safety edge are used, pressing the DOWN button closes the door automatically. If no safety

edge is connected, only the dead-man mode is possible. If the closing safety edge or the photoelectric barrier responds, the

door stops (safety edge: stopping time Z2 = 0.3 s, photoelectric barrier: stopping time Z0 = 0.5 s) and, depending on the setting (DIP switch 1.3), moves to the top end limit or clears an obstacle (clearance time Z1 = 2 s).

If the MLS Basic Card is used, only the dead-man mode is possible in the DOWN direction, i.e. the DOWN button has to be

kept pressed. If it is released, the door stops.

EMERGENCY OFF Button (optional)

If the EMERGENCY OFF button is pressed, the drive is switched off. The door is brought to a sustained halt and the LED +UB

lamp goes out. The door can only move again when the EMERGENCY OFF button has been unlocked.

Master Switch (optional)

With the master switch the system can be completely disconnected from the mains.

7

Page 8

Assembly and Operating Instructions

Checking the direction of movement

Note

In order to facilitate working on the

control unit, the cover can be offset

laterally and held in place by just two

screws. That way all operator controls and indicator lamps are accessible.

The direction of drive rotation depends on how the

three mains phases are connected to the control

unit; it has to be checked rst. To do this proceed

as follows:

• Insert the CEE plug into the CEE socket, or turn

on the isolator switch.

• Check to make sure the control unit is in setting

mode by verifying

- whether DIP switch DIP 1 is in the OFF posi-

tion (MLS Basic Card)

- whether the Pilot lamp is ashing (MLS Professional Card). If it is not, press the Prog programming button (for approx.

1 s) until the Pilot lamp begins to ash.

• Using the UP and DOWN buttons check whether the direction of door movement agrees with the buttons pressed. Also

observe the UP and DOWN direction indicator lamps on the motherboard of the S80.

If the direction of movement does not correspond to the button commands, proceed as follows:

• Disconnect the S80 control unit from the mains.

• Change over two phases at the power supply terminals, e.g. the cables at terminals L1 and L3 (see positions of the terminals and the wiring diagram).

• Check the direction of movement again.

MLS Professional Card

MLS Basic Card

Setting the door end limits

Note

To set the door end limits you can also use the programming handset (Art. no. 4023 200 027 0).

The door end limits are set using the operating cams of the door drive. Proceed as described in the operating instructions for

the drive.

MLS Basic Card

Operating cams S7 and S8 (orange and green cams) serve to actuate the indicator outputs.

MLS Professional Card

Operating cam S7 (orange cam) serves as a pre-limit switch.

Note

When the ‘Partial opening’ function (half the height of the door) is activated, the setting of operating cam

S8 (green cam) serves as the top end limit.

The Testing pre-limit switch (S7, orange cam) must be set so that the maximum height of the door above

the ground is 50 mm. The VES lamp on the Professional Card serves as a check.

To leave the setting mode, press the Prog programming button on the MLS Professional Card again. When the Pilot LED is on

continuously, normal mode has been resumed.

8

Page 9

Electrical connection/operation of external control sensors

and safety devices

Note

Before connecting external control sensors you should rst check the direction of door movement and

set the end limits of the door drive.

Voltage output for external control devices (MLS Basic + MLS Professional)

A direct-current voltage is provided at terminals A- and B+ (24 V DC / 200 mA) for external control devices: U = 24 V DC, I

= 200 mA. This voltage output is protected by ne-wire fuse F2 with 200 mA slow-blow.

EMERGENCY STOP button (MLS Basic + MLS Professional)

An EMERGENCY STOP button can be connected to terminals A2 and B2. The jumper between terminals A2 and B2 (EMERGENCY STOP) must be removed to enable subsequent connection of an external EMERGENCY STOP button.

If the EMERGENCY OFF button is pressed, the drive is switched off. The door is brought to a permanent stop and the +UB LED

goes out. Door movement is only possible again after releasing the EMERGENCY STOP button.

External triple push button (MLS Basic + MLS Professional)

An external triple push button can be connected at terminals A3, B3, A4 and B4 (STOP ↓ ↑). This is identical in function to the

triple push button on the front of the control. The jumper between terminals A3 and B4 must be removed in order to connect

an external triple push button.

Wicket Door Switch / Spring Break Safety Device (MLS Basic and MLS Professional)

A wicket door switch and/or spring break safety device can also be connected across terminals A3 and B4, in series with

the STOP button of the external 3-way pushbutton switch if tted to connect a wicket door switch and/or spring break safety

device, remove the wire jumper across terminals A3 and B4.

Induction loop (MLS Basic + MLS Professional)

An induction loop for automatic door opening can also be connected at terminals A4 and B4, possibly in parallel with the

UP button of the external 3-way pushbutton. If possible, the induction loop should be set so that it gives a CONTINUOUS UP

COMMAND.

Slack Rope Switch (MLS Basic + MLS Professional)

A slack rope switch can be connected across terminals A10 and B10 (SCHLAFFSEIL/ÜL). For installation the wire jumper

across terminals A10 and B10 must be removed. This input is debounced via an internal timing element of approx. 0.1 s (de-

pending on the bounce of the switch). If the slack rope switch responds beyond that time, the door stops instantly no matter

what position it is in. All other door movements are inhibited for as long as the switch is being operated.

max

Caution

The “slack rope switch” input is not monitored to such an extent that errors can be ruled out. If a combined

slack rope/trap switch is used, this must be connected to the terminals A2 and B2 EMERGENCY-OFF.

Pull in safety cable/switch (MLS Basic and MLS Professional)

A safety switch can be connected across terminals A5 and B5 (STOP-UP) to prevent the curtain from being drawn in the UP

direction. For installation the wire jumper across terminals A5 and B5 must be removed. If this safety device responds during

upward movement, the door stops instantly. Upward movement remains inhibited. The door now has to be moved to the bottom end limit manually by pressing the DOWN button (↓).

Light barriers in use must comply with safety category 3 according to EN 954.

Only applies to MLS Professional Card

The control unit switches to the dead-man mode (inching mode). Only when the bottom limit position has been reached does

the control unit switch back to automatic mode.

External 1-way Switch (MLS Professional only)

An external 1-way pushbutton switch can be connected across terminals A13 and B13 (IMP). The pushbutton commands

are executed one after the other in the sequence UP - STOP - DOWN - STOP (pulse-edge evaluation when the button contact

closes). If there is a fault, the pushbutton commands are executed one after the other in the sequence UP - STOP - UP.

Partial Opening (MLS Professional only)

A switch can be connected across terminals A11 and B11 (half the door height) in order to activate the Partial Opening function (also called half door height). If Partial Opening is activated, the setting of limit switch S8 (green cam) of the drive serves

as the top end limit.

9

Page 10

Assembly and Operating Instructions

Automatic Closing

A switch can be connected across terminals A12 and B 12 (AUTO/WZL) in order to activate the Automatic Closing function.

If Automatic Closing is activated, the door is closed by the control unit after the automatic closing time (time Z4 = 60 s) has

elapsed. If the Early Warning function is activated (DIP switch 1.6 in the ON position), before commencing the automatic closing procedure an early warning is given by actuating relay 1 with an early warning time Z3 = 3 s.

By attaching the timer module to system plug X1 of the MLS Professional Card III, the reclosing time can be variably set between 2 and 240 s.

For a description of the timer module, see „Timer Module Technical Information“

Photoelectric Barrier (MLS Professional only)

A photoelectric barrier can be connected across terminals A7 and B7 (PB). For installation the wire jumper across terminals

A7 and B7 must be removed.

This control input has two functions:

• If the photoelectric barrier responds during downward movement (Fault2 lamp ashes), the door stops instantly. After an

internal time of 0.5 s (time Z0) has elapsed, the S80 opens the door again. Depending on the setting of DIP switch 1.3, the

control unit moves the door clear of the obstacle or to the top end limit.

• If the door is open or being opened and the light beam is interrupted and then released again, the automatic closing time

Z4 is reduced to 3 s in the event that DIP switch 1.8 is in the ON position. If DIP switch 1.8 is in the OFF position, the auto-

matic closing time Z4 will run again.

Safety Edge (MLS Professional only)

The following safety edge systems can be connected to door control unit S80 directly:

• Pneumatic safety edge or

• Electric safety edge or

• Optoelectronic safety edge: FRABA OSE

The sensor required is integrated into the control unit (self-monitoring sensor as per pr EN 12453). The pneumatic safety edge

or the electric safety edge is connected up to terminals A6 and B6 (SKS/USA). To ensure that the spiral rubber-insulated

cable is monitored, the 1.2 kW resistor clamped across terminals A6 and B6 is supplied with the unit. It must be connected

inside the pressure switch contact or at the end of the electric safety edge in accordance with the wiring diagram for the S80.

In the case of factory-assembled electric safety edges, check their terminating resistance. Safety edges with a 1.2 kΩ or 8.2

kΩ terminating resistor may be used. Connect the OSE optoelectronic safety edge made by FRABA to terminals A8, A9 and

B8 (OSE) direct without the need for any terminating resistor (A8 - brown wire, A9 - green wire, B8 - white wire). To adapt the

control unit to the respective safety edge, set DIP switches 1.1, 2.1 and 2.2 according to the following table.

Type of safety edge DIP 1.1 DIP 2.1 DIP 2.2

Pneumatic safety edge 1.2 kOhm ON ON ON

Pneumatic safety edge 8.2 kOhm ON ON OFF

Electric safety edge 1.2 kOhm OFF ON ON

Electric safety edge 8.2 kOhm OFF ON OFF

Optoelectronic safety edge FRABA OSE OFF OFF OFF

Caution

When using optoelectronic safety edge FRABA OSE DIP switch 2.1 must always be set to the OFF posi-

tion or else the self-monitoring system of the sensor integrated into the control unit will be deactivated.

If a pneumatic switching rail is used, DIP switch 1.1 must be set to the ON position, as otherwise the func-

tion of the pneumatic rail will not be correctly monitored. When delivered, safety devices may be bridged.

Before initial use, always check that no non-permissible bridging exists.

If the safety edge responds during downward movement (bottom rail sensor LED SKS/USA lights up), the door is stopped

instantly by the S80 control unit. After an internal time of 0.3 S. (time Z2) has elapsed, the S80 opens the door again.

Depending on the setting of DIP switch 1.3, the control unit moves the door clear of the obstacle or to the top end limit.

10

Page 11

Connection and function of the switching outputs

Switching Outputs

The S80 door control unit has two potential free relay switching outputs (changeover contacts, see wiring diagram) each with

a switching capacity of 250 V AC / 5 A.

MLS Basic Card

The relays are actuated by the operating cams S7 and S8 of the drive:

• The orange cam S7 de-energizes relay 2

• The green cam S8 de-energizes relay 1

As a result it is possible to implement, for example, a door status indicator.

MLS Professional Card

With the MLS Professional Card the two relays have different switching functions, depending on the settings of the DIP switches 1.5,1.6 and 1.7 in accordance with the following table.

Switching functions of the indicator outputs DIP 1.5 DIP 1.6 DIP 1.7

Door status

Relay 1 switches on at the top door end limit.

Relay 2 switches on at the bottom door end limit.

In the event of door movement, both relays are off.

Trafc lights + yard light with time delay

Relay 1 switches on at the top door end limit

(trafc light red/green via changeover contacts).

At the beginning of each door movement relay 2 switches on and remains on - at

the end of each door movement it switches off after a delay of 120s (time Z6).

Trafc lights + yard light control pulse

Relay 1 switches on at the top door end limit (trafc light red/green via change over

contacts). At the beginning of each door movement relay 2 switches on for 1s

(passing contact, pulse to actuate a time-delay relay).

Warning light + yard light with time delay

Relay 1 switches on when the door leaves either of the end limits and remains on.

At the beginning of each door movement relay 2 switches on and remains on 120s (time Z6) after the end of each door movement it switches off after a delay.

If automatic closing has been set, the two relays switch on as soon as the early

warning time (3 s, time Z3) begins.

Warning light ashing + yard light pulse

Relay 1 switches on when the door leaves either of the end limits and ashes at a

rate of 1 Hz.

At the beginning of each door movement relay 2 switches on for 1s

(passing contact, pulse to actuate a time-delay relay).

If automatic closing has been set, the two relays switch on as soon as the early

warning time (3 s, time Z3) begins.

Warning light ashing + yard light with time delay and early warning

Relay 1 switches on 3 s (early warning time Z3) before the door leaves either of

the end limits and remains on.

Relay 2 switches on 3 s (early warning time Z3) before beginning each door movement and remains on - at the end of each door movement it switches off with a

delay of 120s (time Z6).

Warning light ashing + yard light control pulse, with early warning

Relay 1 switches on for 3 s (early warning time Z3) before the door leaves either of

the end limits and ashes at a rate of 1 Hz.

Relay 2 switches on 3 s (early warning time Z3) before the beginning of each door

movement for 1 s (passing contact, pulse to actuate a time-delay relay).

OFF OFF OFF

ON OFF OFF

ON OFF ON

ON ON OFF

ON ON ON

OFF ON OFF

OFF ON ON

11

Page 12

Assembly and Operating Instructions

Retrofitting and operation of radio control system

Door control unit S80 with MLS Professional Card can be provided with a 1-channel or 4-channel radio remote control system.

If such a system has been ordered with the control unit, the radio

receiver will already have been installed in the control unit. If this

is the case, please proceed to the section “Operation”.

Note

The radio control system cannot be used in con-

junction with the MLS Basic Card. It will not operate.

If a radio remote control system is being retrotted, you must rst

install the receiver board on the motherboard. For this disconnect

the entire door control system from the mains.

Insert the radio control receiver board in slot J1 at the top right of the S80 motherboard, as shown on the drawing. Make sure

the board is the right way round.

Operation

1-channel radio remote control

The 1-channel radio remote control operates in the same way as the 1-way pushbutton switch. The pushbutton commands

are executed one after the other in the sequence UP - STOP - DOWN - STOP. If there is a fault, the pushbutton commands are

executed one after the other in the sequence UP - STOP - UP.

4-channel radio remote control

The 4-channel radio remote control has the following functions:

Button 1: As with the 1-channel pushbutton switch the pushbutton commands are executed one after the other in the se-

quence UP - STOP - DOWN - STOP. If there is a fault, the pushbutton commands are executed one after the other

in the sequence UP - STOP - UP.

Button 2: Operation identical to that of UP button.

Button 3: Operation identical to that of DOWN button. In the event of a fault this button is activated in the dead-man mode.

Button 4: Operation identical to that of STOP button.

receiver board

J1 FUNK

Caution

When using a radio control system the person controlling the door must have a clear view of the door and

its surrounding area during door movement and must not be in a dangerous position.

In setting mode and in the event of a malfunction, the radio receiver board must be removed from the PCB

slot J1.

Programming the Hand-held Transmitter Code

The hand-held radio control transmitter has been coded by the manufacturer. The radio control receiver must be set to this

code. To program the hand-held transmitter code in the radio control receiver proceed as follows:

• Press Program Channel 1 on the radio control receiver. The relevant red signal LED begins ashing. You can program the

hand-held transmitter code within the next 15 s.

• To do this press the button on the hand-held transmitter for approx. 2 s. The programming of the hand-held transmitter

code is conrmed by the signal LED on the receiver staying on continuously.

• Now let go of the button on the hand-held transmitter.

You can program the other 3 buttons on the four-channel receiver in the same way. All in all you can program up to 60 different transmitter codes (buttons) for each receiver. The 61st code will not be accepted by the receiver. In conjunction with the

1-channel receiver you can therefore use up to 60 1-channel hand-held transmitters and in conjunction with the 4-channel

receiver you can use up to 15 4-channel hand-held receivers (if all the buttons are used).

Note

You can combine all hand-held transmitters with all receivers.

Example:

You have an application with 4 doors each of which is controlled by an S80 with 1-channel radio control

receiver. If you use 4-channel hand-held transmitters and assign each button to one of the 4 receivers,

you can control all 4 doors independently of one another with just one hand-held transmitter. If you re-

quire more than 60 transmitter codes, please contact us. Here too we can offer customised solutions.

12

Page 13

Deleting All the Transmitter Codes Programmed

To delete the hand-held transmitter codes in the radio control receiver proceed as follows:

• Press Program Channel 1 on the radio receiver and keep it pressed. The red signal LED begins to ash slowly. After approx.

5 s the red signal lamp ashes quickly.

• Keep the button pressed until the red signal lamp goes out.

• When the signal lamp goes out, all the codes of the 1-channel radio control receiver and all 4 channels on the 4-channel

radio control receiver will have been deleted.

• Only now let go of the button again.

13

Page 14

Assembly and Operating Instructions

ON

DIP 1

ON

DIP 1

Setting the DIP switches

MLS Basic Card

Switch Position Illustration Function

ON

Automatic mode in UP direction

DIP 1

OFF

Dead-man mode in UP direction

MLS Professional Card

Switch Position Illustration Function

DIP 1.1

DIP 1.2

DIP 1.3

DIP 1.4

DIP

1.5/1.6

DIP 1.7

DIP 1.8

DIP 2.1

DIP 2.2

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON/ON

ON/OFF

OFF/ON

OFF/OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

DIP 1 DIP 2

ON DIP

1 2345678

DIP 1 DIP 2

ON DIP

1 2345678

DIP 1 DIP 2

ON DIP

1 2 345678

DIP 1 DIP 2

ON DIP

1 2 345678

DIP 1 DIP 2

ON DIP

123 45678

DIP 1 DIP 2

ON DIP

123 45678

DIP 1 DIP 2

ON DIP

123 4 5678

DIP 1 DIP 2

ON DIP

123 4 5678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

1234567 8

DIP 1 DIP 2

ON DIP

1234567 8

DIP 1 DIP 2

ON DIP

1234567 8

DIP 1 DIP 2

ON DIP

1234567 8

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

DIP 1 DIP 2

ON DIP

12345678

ON

Pneumatic (DW) safety edge connected, DW testing is activated

12

ON

Electric or FRABA OSE safety edge connected

12

Deactivate at the bottom end limit via switching pulse from the electric,

ON

pneumatic or optoelectronic safety edge

12

ON

Deactivate at the bottom end limit via the cam limit switches on the drive

12

ON

Move up to the top end limit after a safety stop

12

ON

Move clear of the obstacle after a safety stop with a clearance time Z1 = 2 s

12

Relieve the safety edge at the bottom end limit (reversing) with reversing

ON

time Z5 = 100 ms

12

ON

No relief (reversing) at the bottom end limit

12

Relay 1: warning light, early warning

ON

only for automatic closing

12

Relay 1: trafc lights,

ON

door at top end limit

12

Relay 1: warning light,

ON

always with early warning

12

Relay 1: door status,

ON

door at top end limit

12

Relay 1: warning light ashing,

ON

ash rate 1 Hz

12

Relay 1: warning light

ON

on continuously

12

Automatic closing time Z4 is reduced to 3 s after releasing the photoelec-

ON

tric barrier

12

ON

Automatic closing time (time Z4) re-runs via light barrier function.

12

ON

Electric or pneumatic safety edge connected

1 2

ON

Optoelectronic safety edge FRABA OSE connected

1 2

ON

Terminating resistance of safety edge = 1.2 kOhm

1 2

ON

Terminating resistance of safety edge = 8.2 kOhm

1 2

Relay 2: yard light

Relay 2: yard light

Relay 2: yard light

Relay 2: door status,

door at bottom end limit

Relay 2: yard light,

control pulse 1 s

Relay 2: yard light, remaining on

for 120 s (time Z6)

14

Page 15

Indicator LED’s

Basic Control Unit S80

LED Illustration Indication Meaning

POWER

+UB

on Power supply connected

off No power supply connected

UP

DOWN

AUF

ZU

on Door moves UP

on Door moves DOWN

MLS Professional Card

LED Illustration Indication Meaning

on Normal mode

Pilot

Betr

contin. ash Setting mode (dead-man mode)

In order to switch to normal mode (automatic), please push the programming button Prog.

STOP button pressed, wicket door switch/spring break safety device

triggered or Emergency Stop transistor faulty

Fault1

Stör1

on

1 ash Door running time exceeded

2 ashes Pre-limit switch testing set too high

3 ashes No switch pulse from the safety edge at the bottom end limit

4 ashes Limit switch Up and Down activated simultaneously.

contin. ash Internal communication fault or main processor faulty

on Hardware test routine being processed

1 ash Safety circuit of drive has been triggered

2 ashes Safety edge actuated just before downward movement of door or

internal bottom rail sensor faulty

Fault2

Stör2

3 ashes Slack rope switch/pull in cable safety/switch

4 ashes Internal communication fault or monitoring processor faulty

5 ashes

The door has run up against an obstacle 5 times because automatic

closing is activated

6 ashes The unit connected to system socket X1 is faulty

contin. ash Photoelectric barrier actuated

USA

VES

USA

VES

on Safety edge actuated

off Safety edge not actuated

on Pre-limit switch actuated

off Pre-limit switch not actuated

off DIP switch released/control times unchanged

Sonder

Sonder

1 ash DIP switch inhibited/control times unchanged

2 ashes DIP switch released/control times changed

on DIP switch inhibited/control times changed

15

Page 16

Assembly and Operating Instructions

Overview of control times

Time Duration Description

Z0

Z1

Z2

Z3

Z4

Z5

Z6

Z7

Z8

Z9

500 ms Stopping time for opposite UP command due to UP button or photoelectric barrier

2 s Clearance time when moving clear of an obstacle

300 ms Stopping time for opposite UP command due to safety edge

3 s Early warning time

60 s Closing time if automatic closing is activated; adjustable from 2 - 240 s when time module is mounted

100 ms Reversing time to relieve the safety edge

120 s Time the yard light remains on

90 s Maximum door running time for door run time monitoring

1 s Waiting time for safety edge signal at bottom end limit

6 s Monitoring time for monitoring the set height of the VES test

What should I do if ... ?

Caution

All malfunctions must be rectied by qualied electricians!

Fault Possible cause and remedy

No reaction to pressing the button,

POWER lamp is not lit

No reaction to pressing the button,

POWER lamp is lit

No auxiliary power at terminals A-/B+

(24 V DC / 300 mA)

Note

Please also observe the indication of faults and errors by the LED’s on the pc board of the basic control

unit S80 and MLS Professional Card.

• Check supply voltage (terminals L3/L2/L1/N (MAINS)).

• Check miniature fuse F1 (400 mA, slow blow).

• Check EMERGENCY OFF button (terminals A2/B2

(EMERGENCY OFF)).

• Check safety circuit of the drive (terminals E1 ... E11,

emergency hand crank (chain), drive temperature, safety

limit switches (S1F/S2F, yellow cams).

• Check terminals A3/B4 (STOP), A5/B5 (STOP-UP), A7/

B7 (photoelectric barrier) and A10/B10 (SLACK ROPE).

If these pairs of terminals are not assigned, they must be

jumpered.

• Check whether you are using the correct control card

for the drive: MLS Basic Card/MLS Professional Card for

drives with mechanical limit switching, ELS Basic Card/

ELS Professional Card for drives with electronic limit

switching (BES).

• Check miniature fuse F2 (315 mA, slow blow).

16

Page 17

CONTROL PANEL

J3

J4

J2

+UB

J1 RADIO

F1

400 mA T

F2

200 mA T

321

W

MOTOR

E

L3L2L1

L1NN

8910

11

4

5

6

7

E

V U

PE

–A

2

3

456789101112

13

+B

2

3

4

5

6

7

89101112

13

CONTROL INPUTS

RELAY 1 RELAY 2

OPEN CLOSED

MAINS

RELAY 2

RELAY 1

MAIN SWITCH

(optional)

CONTACTOR

TRANSFORMER

Cycle

counter

(optional)

NOT-AUS

STOP-AUF

STOP

SKS/USA

IMP

AUTO/WZL

1/2 Torhöhe/STOP X

Überlastschalter

br

gn

ws

OSE

LS

24 V DC / 200 mA

Basic Control Unit S80

Position of terminals and components

MLS Basic Card

DIP 1

ON

MLS-Basic-Card

MLS Professional Card

Stör1 VES Sonder Betr USA

MLS-Professional-Card

X1

Stör2

Prog

ON DIP

12345678

EL

DW

OSE 8K2

ON

12

DIP 1

1K2

DIP 2

17

Page 18

Assembly and Operating Instructions

General wiring diagram

Drive with mechanical limit switching

S1F - Safety limit switch OPEN

Drive

S3F

123

Connect according to the numbers indicated

4

S4F

S1F

S5 S6 S7 S8

S2F

5 67891011PE

12

S2F - Safety limit switch CLOSE

S3F - Safety limit switch Emergency Operation

S4F - Thermal protection switch

S5 - Operation limit switch OPEN

S6 - Operation limit switch CLOSE

S7 - Pre-limit switch Testing

S8 - Function limit switch 1/2 door height

321 4567

WVU

Drive

Mains

PE

PE

PE

3 x 400 V / 230 V AC, 50/60 Hz

L3 L2 L1L1 NN

5

8910 11

Contactor

F2

Transformer

F2

200 mAT

Relay 1Relay 2

slack

rope

switch

External

Emergency

OFF-switch

Radio Control

green red

T

400 mA

A

Int. 3-way pushbutton switch

24 V DC / 200 mA

- 2345678910 11 12 13

- 2345678910 11 12 13

B

Wicket door/spring break safety

+UB

green

SKS/USA

Plug-in card

EL - E

lectric safety edge

or

DW -

Safety edge with DW contact (pneumatic)

R=1k2 / 8k2

OSE (FRABA)

optical safety edge

S=Transmitter

E=Receiver

Connection

white=B8

brown=A8

green=A9

R

18

STOP

Ext. 3-way pushbutton switch

OFF-switch

Emergency

DW

-UP

STOP

Tapping box

R

SKS / USA

FRABA OSE

LS

resistor

1.2 kOhm/8.2 kOhm

white=B8

brown=A8

green=A9

E

S

IMP

Slack rope/

Overload protection

AUTO/WZL

1/2 door height/Stop X

Page 19

Specications

Type S80 with MLS Basic Card MLS Professional Card

Power supply 3N~ 230/400 V 50/60 Hz

Rated output of motor 2.0 kW max.

Control voltage* 24 V DC

Control circuit max. 125 mA

Dimensions of housing 182 mm x 254 mm x 90 mm (W x H x D)

Weight approx. 1.5 kg (not incl. connecting cable)

Degree of protection IP65

Relay switching capacity each 250 V AC/5 A AC-1

Ambient temperature range 0 °C ... +50 °C

Battery backup on site 3 x 10 A

*) Basic insulation for operating voltage

19

Page 20

4023 630 822 0c 02/13

Loading...

Loading...