Page 1

S30, S30-V..

en

Assembly and Operating Instructions

Door control unit

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

4023 630 402 0b15/01/2018

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Table of contents

General ................................................................................................................ 3

Warranty .............................................................................................................. 3

Safety instructions ................................................................................................ 4

Intended use ........................................................................................................ 6

Abbreviations/symbols in these instructions............................................................ 7

Assembly ............................................................................................................. 8

Electrical connection............................................................................................. 9

Controls ..............................................................................................................10

Checking the running direction .............................................................................10

Setting the door limit positions ..............................................................................11

Connection and function of external control sensors and safety devices ...................14

Setting the DIP switches .......................................................................................18

Status indications ................................................................................................18

Maintenance .......................................................................................................20

Cleaning..............................................................................................................20

Technical data .....................................................................................................20

Wiring .................................................................................................................22

Declaration of conformity .....................................................................................24

2

Page 3

General

This door control unit is a high-quality product with the following performance characteristics:

• Evaluation of safety sensors on the door (e.g. closing edge surveillance, pull-in

safety device and similar)

• Evaluation of additional safety devices on the door (e.g. light barriers, light grids

and similar)

• Evaluation of control sensors on the door (e.g., pull switch, induction loop and sim-

ilar)

• Evaluation of EMERGENCY STOP control sensors

• Supplying sensors and control sensors with 12 V safety extra-low voltage

• Operation of application-specific outputs

Please observe these Assembly and Operating Instructions when installing and setting

up the equipment.

Explanation of pictograms

CAUTION

ATTENTION

CAUTION indicates a hazardous situation

which, if not avoided, could result in injury.

ATTENTION indicates measures that must be

taken to avoid damage to property.

Denotes user tips and other useful information.

Warranty

Structural modifications and incorrect installation which are not in accordance with

these and our other instructions can result in serious injuries, e.g., crushing of limbs.

Therefore, structural modifications may only be carried out with our prior approval and

strictly in accordance with our instructions, particularly the information contained in

these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is

not permitted.

The end product manufacturer and fitter have to ensure that all the relevant current

statutory, official and, in particular, EMC regulations are adhered to during utilisation of

our products, especially with regard to end product manufacture, installation and customer advice.

3

Page 4

Safety instructions

The following safety instructions and warnings are intended to avert hazards and to

prevent property damage and personal injury. It is important to follow these instructions.

General information

• In addition to the fire and accident prevention regulations, the safety

instructions given in EN 12453, EN 12445, EN 12978, VDE 0100, EN

50110, EN 60204, EN 50178, EN 60335 and ASR A1.7 must be observed.

• All work, including maintenance and cleaning, on electrical installa-

tions as well as other system parts must always be performed by

trained technicians, in particular qualified electricians.

• The limits given in the technical data must not be exceeded.

• The illustrations contained in these instructions are intended as an

aid to understanding how the product operates. Therefore, the illustrations may differ from the actual display on the product.

Caution

• When electrical or electronic equipment and units are

operated, certain components are live. Physical injuries

or damage to property can result in the event of unauthorised interventions or failure to heed warnings.

• When moving the doors in dead-man mode it is neces-

sary to ensure that the door region is visible to the operator, since safety equipment such as the safety edge of

the light barrier is not effective in this operating mode.

• Operating the control unit when the housing is open is

not allowed.

Attention

• Turning on or operating a control unit when dew is

present on the unit is not allowed. It can lead to the control unit being ruined.

4

Page 5

Operating notes

• Do not allow children to play with permanently mounted regulating

or control devices.

• Keep remote control units out of the reach of children.

• Systems have to be checked regularly by authorised specialists for

wear and damage.

• It is forbidden to use a damaged controller.

• To avoid damage to the operator controls, they should not be

touched with sharp objects. Only use your fingers to use the operator controls.

• Do not operate equipment if people or objects are within the danger

zone.

• The control unit is designed to have a service life of 100,000 operat-

ing cycles.

Caution

• If the connecting cable of this unit is damaged, it must

be replaced by the manufacturer or their customer service department or a similarly qualified person in order

to avoid hazards.

Notes on electrical connection and assembly

• All applicable standards and regulations for electrical installation

must be complied with.

• Disconnect the electrical supply from the equipment before in-

stalling and connecting accessories and extras, and protect against

unauthorised reconnection in accordance with the safety regulations.

• Only use spare parts, tools and accessory devices which have been

approved by the manufacturer. Unapproved third-party products or

modifications to the system and its accessories represent a risk to

your safety and the safety of others. This means that the use of unapproved third-party products, or modifications which have not

been agreed with or approved by us, are prohibited. We do not accept liability for damage or injury arising from such actions.

5

Page 6

• Operating the control unit with a detached CEE plug is only permiss-

ible if the mains supply can be isolated from all poles of the control

unit using an appropriate switch. The mains plug, or any switch used

as a substitute, must be easily accessible.

Caution

• The potential-free signal relay may only be used for

switching low voltage. The switching of mains voltage is

not permitted.

Commissioning notes

• The setting of the parameters, limit positions, jumpers and other op-

erator controls must only be carried out by trained personnel.

Caution

• The setting of the parameters and limit positions, and

the function of the safety devices must be checked by

trained technicians.

Intended use

The control unit in these instructions is exclusively designed for indoor use for the operation of roller doors, vertical lift gates, sectional doors, flexible (fabric) doors or indirectly operated door systems.

This type of control unit must not be used in potentially explosive areas.

The mains cable and any other connected cables are not designed for carrying the

control unit. Therefore always carry the control unit by the housing.

Other applications, uses and modifications are not permitted in order to protect the

safety of the users and others, since these actions can impair the system’s safety and

carry the risk of personal injury and property damage. The manufacturer does not accept liability for damage or injury arising from such actions.

Always observe the information in these instructions when operating or repairing the

system. The manufacturer does not accept liability for damage or injury resulting from

improper use.

6

Page 7

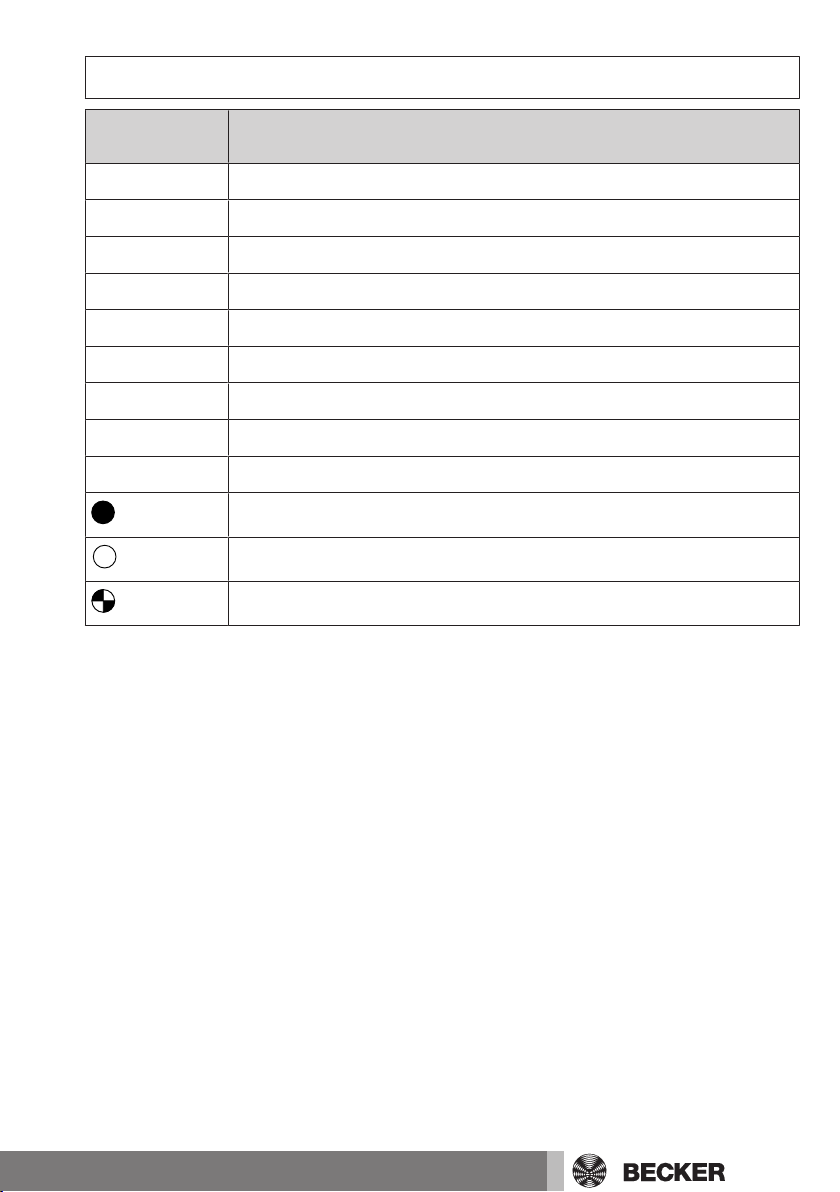

Abbreviations/symbols in these instructions

Abbreviation /

symbol

IMP

LS

SKS

DW testing

EL

OSE

NA

VES

AWZ

Description

Impulse button

Light barrier

Closing edge safety device

Pressure monitor testing

Electric safety edge

Optical safety device

Emergency Stop

Pre-limit switch

Automatic reclosing

LED lights up

LED off

LED flashes

7

Page 8

Assembly

Do not select an assembly location exposed to electromagnetic fields, such as locations in the direct vicinity of contactors (power relay), mains transformers, ignition

transformers, fluorescent tubes, etc., or their connecting cables. Protect the control

unit from direct sunlight and driving rain.

Open the cover of the control unit. Remove the cable from the cover and carefully place

the cover to one side. Remove the required cut-outs in the bottom part of the housing.

Cut in at the edges to make the cut-outs easier to remove.

Assemble the control unit at a suitable operating height (at least 1500 mm from the

ground). Mount the housing with 4 screws (max. diameter of screw head 7.5 mm) inserted through the holes provided in the corners.

Reconnect the cover cable and set the DIP switch. You can now close the control unit.

8

Page 9

Electrical connection

Caution

The control unit must only be connected by a qualified

electrician!

Observe the relevant VDE standards!

During all installation work, the equipment must always be

securely disconnected from the mains!

When connecting, refer to the technical data of the control

unit and the drive. The indicated maximum values must not

be exceeded! Only drives and associated connecting lines

with reinforced or double insulation to the control circuit

according to EN 60335 may be used.

Installing the mains connection

The operating voltage of the door control unit is 3 x 400 V AC, 50/60 Hz (L1, L2, L3, N,

PE). For connection to the mains, install an approx. 1.2 m long mains cable with CEE

16A/6h plug and a CEE 16A/6h socket in the immediate vicinity of the control unit in

such a way that the plug is easily accessible, or connect the control unit via a non-detachable installation cable (see “Position of the terminals and connecting diagram”).

Attention

For permanent installations, a main switch must be connected in the immediate vicinity of the control unit to the

power line or directly to the control unit. Protect the power

line for the control unit with a 3-phase AC automatic cutout with 3 x 10 A.

Connecting the drive to the control unit

To connect the Becker sectional door drive to the door control unit, connecting cables

are available in a variety of lengths. The connecting cable has a plug-in cable gland on

both sides. Connection is established via the 4-phase plug (M-motor) and the 8-phase

plug (E-limit switch).

The yellow/green protective conductor wire must be connected to the protective conductor terminal PE ( ).

9

Page 10

Controls

Labelling Function Function:

Brief actuation

OPEN OPEN command

STOP If drive is in motion: STOP

If drive is at a halt: Light on/

off if light function with

stopping time is set

CLOSE CLOSE command

Function:

Actuation > 5 sec.

Confirmation of a fault,

storage of a limit position

It is not possible to move the door while the "STOP" button

is actuated or a safety device in the emergency stop circuit has triggered.

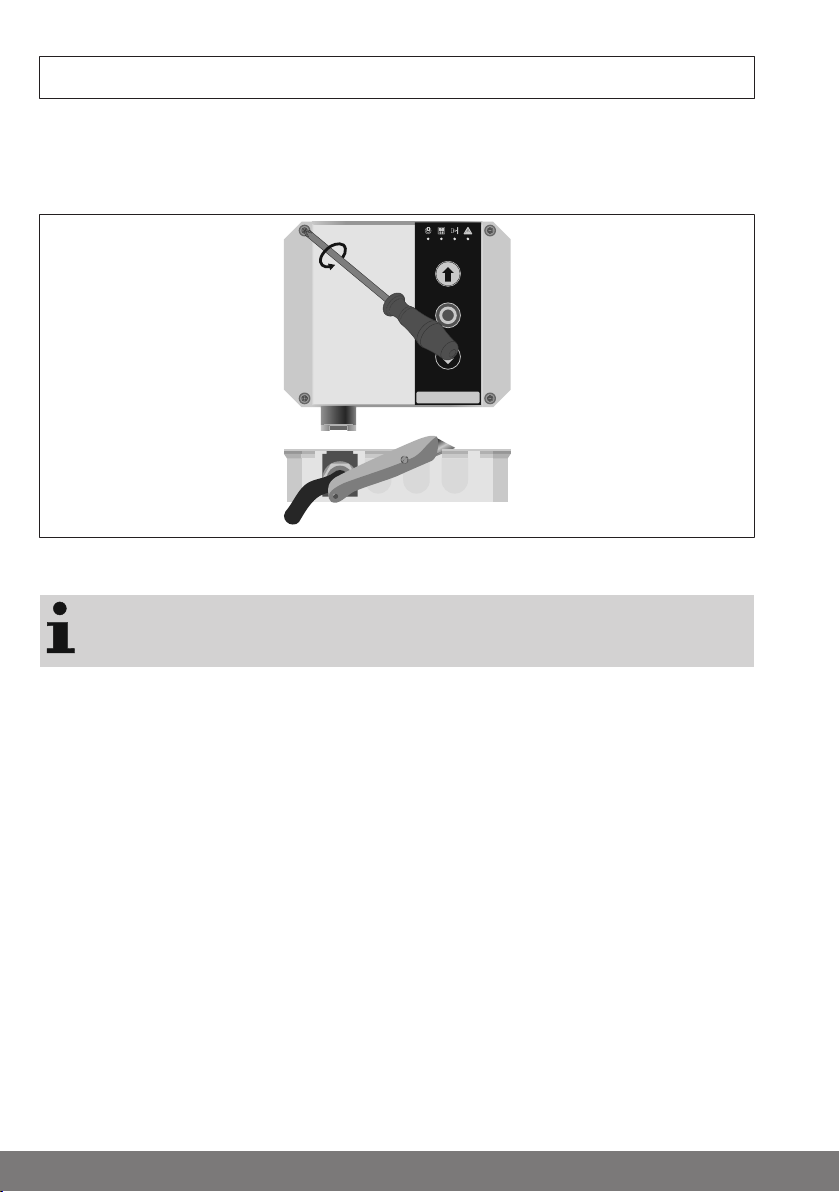

Checking the running direction

Open the cover of the door control unit by undoing the four cover screws and re-attach

the cover offset upwardly.

The direction of drive rotation depends on how the three mains phases are connected

to the control unit and has to be checked first. Proceed as follows:

• Move the door into the semi-opened position using the emergency manual opera-

tion function.

• Insert the CEE plug into the CEE socket or turn on the main switch.

• Check that the control unit is in the setting mode.

• Using the UP and CLOSE buttons, check whether the direction of movement of the

door corresponds to the buttons pressed.

If the direction of movement does not correspond to the button commands, proceed as

follows:

• Disconnect the control unit safely from the mains.

• Change over two phases at the mains connection terminals, e.g., the cables at ter-

minals L1 and L3 (refer to the "Complete connecting diagram").

• Check the direction of movement again.

10

Page 11

Setting the door limit positions

Check whether the control unit is in learning mode. The control unit is in learning mode

when all 4 LEDs are flashing and when there is no fault present. If not, proceed as follows:

1. Withdraw the plug from the limit switch "E".

2. Press the OPEN/STOP/CLOSE buttons on the membrane keypad simultaneously

until all the LEDs are flashing.

3. Put the limit switch plug back into "E".

4. Acknowledge the emergency stop message by pressing the Stop button.

5. All the LEDs flash. You can now train the limit positions.

Caution

After every amendment of the door limit positions, you

must carry out fine adjustment of the limit positions and

check the pre-limit switch.

Attention

The absolute value encoder in the drive cannot be set.

Before the door’s limit positions are programmed, the

safety edge of the door must be connected to the door

control unit (see the "Connection" chapter).

When setting the limit positions, the process can be restarted by pressing the buttons OPEN/STOP/CLOSE on

the membrane keypad simultaneously until all LEDs flash.

The door limit positions are set directly in the control unit. Make sure that all the LEDs

are flashing. The control unit is in dead-man mode.

Description

1. Move Up or Down to check the direction of rotation.

2. Travel to the desired CLOSE limit position.

3. Press the Stop button for 3 seconds in order to

save the limit position.

11

Page 12

Description

4. For exact adjustment of the limit position, the

control unit will move the door in inching mode,

i.e., each time the OPEN/CLOSE buttons are

pressed, the control unit will only move the door

for approx. 50ms. This allows for exact adjustment

of the desired limit position.

5. Press the Stop button for 3 seconds in order to

save the limit position.

6. Travel to the desired OPEN limit position.

7. Press the Stop button for 3 seconds in order to

save the limit position.

8. For exact adjustment of the limit position, the

control unit will now move the door in inching

mode.

9. Press the Stop button for 3 seconds in order to

save the limit position.

12

Page 13

Description

10a. If a safety edge is connected, you train the

pre-limit switch as follows:

Place the VES gauge or a similar implement

(height: 30...40 mm, e.g. wooden slat, pipe or similar) on the ground under the door, in the middle of

the clearance of the door opening.

When the CLOSE button is pressed, the control

unit moves the door in maintained operation mode

(impulse mode) to the VES gauge. The control unit

saves this point as an internal pre-limit switch

(VES) and then moves away from the VES gauge. If

the door hits another obstacle, press the CLOSE

button again.

10b. If a safety edge is not connected, you train

the pre-limit switch as follows:

The control unit moves the door in dead-man

mode. Move the lower edge of the door to approx.

20 mm above the ground.

10c. With a safety edge connected without a prelimit switch:

Move the door to the CLOSED position.

11. Press the Stop button for 3 seconds in order

to save the limit position as an internal VES prelimit switch.

12. Move to the position wanted for masking the

light barrier. The light barrier is masked out below

the position of the lower edge of the door. If masking is not required, move the door to the CLOSED

position.

13. Press the Stop button for 3 seconds in order

to save the position.

13

Page 14

Description

14. Now the setting of the limit positions is complete.

To test the setting height of the internal VES pre-limit switch, place the VES gauge or a

similar implement (height: 50 mm, e.g. wooden slat, pipe or similar) on the ground under the door, in the middle of the clearance of the door opening. If the door hits the 50

mm high VES gauge or another implement, it must stop immediately and then move

away from the simulated obstacle (open).

If that is not the case, check the connection and the adjustment of the safety edge

again, and reprogram the door limit positions.

To check the functional switch-off of the safety edge by

the internal pre-limit switch (VES), always observe the EN

12445 standard: Safety in use of power operated doors –

test methods.

Connection and function of external control sensors

and safety devices

Before connecting external control sensors, you should

first check the direction of door movement and set the

limit positions of the door drive.

EMERGENCY STOP button

An EMERGENCY STOP button can be connected to the NA/NA terminals.

The drive is switched off by pressing the EMERGENCY STOP button. The door is

brought to a sustained halt. Door movement is only possible again after releasing the

EMERGENCY STOP button.

Wicket door switch

A forcibly operated wicket door switch can be connected to the NA/NA terminals. The

door is stopped when the wicket door is opened. For installation, the jumper between

terminals NA/NA must be removed.

External triple push button

An external triple push button can be connected to terminals FE1, FE2, FE3 and 12V

(STOP ↓ ↑). This is identical in function to the triple push button on the front of the control unit. The jumper between terminals FE1 and 12V must be removed in order to connect an external triple push button.

14

Page 15

Spring break safety device

A spring break safety device can additionally be connected to terminals FE1 and 12V,

possibly in series with the STOP button of the external triple push button. The jumper

between terminals FE1 and 12V must be removed in order to connect the spring break

safety device.

Induction loop

An induction loop for automatic door opening can also be connected to terminals FE2

and 12V, in parallel with the UP button of the external triple push button if required. If

possible, the induction loop should be set so that it gives a CONTINUOUS UP COMMAND.

Slack rope switch

A slack rope switch can be connected at the FE6 and 12V terminals. The jumper

between terminals FE6 and 12V must be removed at installation. This input is debounced via an internal timing element

of about 0.1 seconds. The door is stopped in any position if the slack rope switch is activated for longer than this period. For the duration of activation, all further door movement is prevented.

Caution

The “slack rope switch” input is not monitored to such an

extent that errors can be ruled out. If a combined slack

rope/trap switch is used, this must be connected to the

EMERGENCY STOP terminals NA/NA.

Pull-in safety device

A safety switch can be connected to terminals NA/NA (EMERGENCY STOP) as a pull-in

safety device. For installation, the jumper between terminals NA/NA must be removed.

External single push button

An external single push button can be connected to terminals FE4 and 12V (IMP).

With door control unit S30, S30-V2:

The commands are executed one after the other in the sequence OPEN / STOP /

CLOSE / STOP.

With door control unit S30-V1:

The door travels to the OPEN limit position when this is pressed. When in the OPEN limit

position, the controller closes. If pressed again while closing, the controller drives to

the OPEN limit position.

15

Page 16

Light barrier

+ V

+ V

0 V

0 V

12 V

FE 5

GND

Receiver

Transmitter

+ V

+ V

0 V

0 V

12 V

FE 5

GND

Receiver

Transmitter

+ V

+ V

0 V

0 V

12 V

FE 5

GND

Receiver

Transmitter

C

NO

A light barrier can be connected at the FE5 and 12V (LS) terminals. The jumper

between terminals FE5 and 12V must be removed at installation.

If the light barrier responds during travel in the DOWN direction, the door is brought to

an immediate halt. After an internal time of 0.3s has elapsed, the door control unit

opens the door again. The light barrier must be tested if it is used for protection against

personal injury. To do this, set DIP switch 8 to OFF, and activate the test function. Before every closing transit, the signal relay switches off, and so tests the signal from the

light barrier. If the test fails, the CLOSE journey is executed in dead-man mode. Use the

NO contact to switch the power supply to the light barrier transmitter off. Use the NC

contact if the light barrier has a test input.

PNP output Without testing With testing

Safety edge

The following safety edge systems can be connected to the door control unit itself:

• Pneumatic safety edge (DW).

• Electric safety edge (EL).

• Optical safety device (OSE).

The required sensor is integrated in the control unit (self-monitoring sensor as per

EN12453).

The pneumatic safety edge or the electric safety edge is connected to terminals SE1

and 12V (EL/DW) and monitored via a terminating resistor. This resistor must be connected to the pneumatic safety edge (pressure wave switch) contact or at the end of

the electrical safety edge, as shown in the complete connecting diagram.

Check the terminating resistance of factory-installed electrical safety edges. Safety

edges with a terminating resistance of 1.2kΩ or 8.2kΩ can be used.

The OSE optoelectronic safety edge is connected to the terminals SE1, GND and 12V

directly without a terminating resistor (GND – white wire, SE1 – green wire, 12V –

brown wire).

To adapt the control unit to the respective safety edge, set DIP switches 1, 2 and 3 according to the following table.

16

Page 17

Type of safety edge DIP 1 DIP 2 DIP 3

12 V

SE1

0 V

OSE

green = SE 1

white = 0 V

brown = 12 V

8K2

12 V

SE1

12 V

SE1

8K2

Pneumatic safety edge 1.2 kΩ ON ON OFF

Pneumatic safety edge 8.2 kΩ ON ON ON

Electric safety edge 1.2 kΩ ON OFF OFF

Electric safety edge 8.2 kΩ ON OFF ON

Optoelectronic safety edge OSE OFF OFF OFF

Caution

When using a pneumatic safety edge, the DIP switch 2

must always be set to the ON position, as otherwise it is

not possible to properly monitor the function of the pneumatic safety edge. On delivery, some safety devices may

be bridged. Before initial use, always check that no nonpermissible bridging exists.

If the safety edge is activated during travel in the DOWN direction, the door is stopped

instantly by the control unit. After an internal time of 0.3s has elapsed, the door control

unit opens the door again.

Safety edge OSE Electric safety edge Pneumatic safety edge

17

Page 18

Setting the DIP switches

Switch Position Function

DIP 1

ON Electric or pneumatic safety edge is connected

OFF Optoelectronic safety edge OSE is connected

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

DIP 7

DIP 8

ON Pneumatic safety edge (DW) connected, pressure wave test-

ing is active

OFF Electric safety edge is connected

ON Terminating resistance of the safety edge = 8.2 kΩ

OFF Terminating resistance of the safety edge = 1.2 kΩ

ON Downward travel in maintained operation mode (only with

safety edge)

OFF Closing in dead-man mode

ON Reverse travel after time in presence of obstacle

OFF UP limit position in presence of obstacle

ON Automatic closing OFF

OFF Automatic closing 60 seconds ON

ON Switch off in CLOSED limit position via safety edge

OFF Switch off in CLOSED limit position via limit switch

ON Relay function door position limit position OPEN

OFF Relay function testing

Status indications

The status display shows the current status of the control unit. It can be found above

the OPEN button.

Description

Control unit ready for operation

Automatic closing activated

Safety input SE activated

Safety input SE negative testing, prelimit switch set too high

18

Page 19

Description

Light barrier LS activated

Light barrier LS negative testing

Error running time exceeded, rotational error, blockage

Stop, OPEN activated in limit position

Control unit defective, internal error

Emergency stop, slack rope activated, drive command error

Confirm by pressing and holding the

Stop button

Rotary encoder error

Rotary encoder communication error

Limit position overrun

No limit positions programmed

Lower limit position

Lower limit position, inching mode

Upper limit position

Upper limit position, inching mode

Pre-limit switch safety input (VES)

Light barrier muting

Caution

In the event of an internal error (no redundancy), the system switches to dead-man mode for safety-related reasons.

Closing is only possible using the CLOSE button on the

control unit.

1x

2x

3x

4x

19

Page 20

Testing

Pneumatic safety edges are tested for safety-related reasons during every downward

movement. This process is called testing.

Self-test

The control unit carries out a self-test periodically. The relays are controlled audibly.

Maintenance

This control unit is maintenance-free.

Cleaning

Only clean the outside of the housing with a suitable cloth. Do not use cleaning agents,

as these may damage the plastic.

Technical data

Type S30, S30-V..

Mains connection 400 V 3~N PE 50 Hz

Nominal motor rating max. 1.8 kW

Control voltage 12 V DC

Control power max. 200 mA

Housing dimensions (W x H x D) 155 x 130 x 50 mm

Weight approx. 0.5 kg (without connecting cable)

Degree of protection IP54

Ambient temperature range -5°C.....+50°C

On-site fuse protection 3 x 10 A

Limit switching electronic

Interface RS485

20

Page 21

Type S30, S30-V..

Secure functions

(EN ISO 13849-1:2008)

Relay Changeover contact potential-free 0.5 A /

Humidity Up to 95%, non-condensing

Vibration Low-vibration installation, e.g., on a brick

Assembly Vertical

Inputs (FE 1 – FE 6): typ. 12VDC / <10mA +/- 20%

Safety chain / EMERGENCY STOP It is imperative that all inputs are connec-

Safety edge: SE1 Category 2 / PL c

Light barrier with

testing

Emergency Stop Category 2 / PL c

12 VDC

wall

All inputs must be connected potentialfree:

min. signal duration for input control commands: > 100 ms

ted potential-free

Contact load rating: 200mA / 30VDC

Category 2 / PL c

Safety input SE1 For electric safety edges with 8.2 kΩ / 1.2

kΩ terminating resistance and for dynamic optical systems

21

Page 22

Mains connection

3~400 V

1 2 3 4 5 6 7 8

5

3 x 400 V AC / 50 - 60 Hz

ON

OFF

S3F – Safety limit switch emergency

operation

S4F – Thermoswitch

Membrane keypad

Wiring

22

Page 23

Wiring assignment K1 and K2

8K2

K1

K2 A

GND

12V SE1 FE2 FE3 FE4 FE6

12V

NO

NA NA FE1 12V 12V FE5

GND

NC C

K2

K1

PE

B

EMERGENCY STOP

Electric safety edge

OSE

brown = 12V

white = 0V

green = SE1

Pulse

Light barrier

Slack rope /

overload

Door position

limit position OPEN

STOP

Trap switch

or

combined

slack rope/

trap switch

Wicket door /

spring break

External

EMERGENCY

STOP

Ext. triple

push button

23

Page 24

Declaration of conformity

242526

Page 25

Page 26

Page 27

27

Page 28

Loading...

Loading...