Page 1

Remote-Controlled

Installatio n and Operation

Manual DV17501.03

VHF-AM Transceiver

RT6512

Issue 06 April 2018

Article-No. 0645.702-071

Becker Avionics GmbH • Baden-Airpark B108 • 77836 Rheinmünster • Germany

+49 (0) 7229 / 305-0 • Fax +49 (0) 7229 / 305-217

http://www.becker-avionics.com • E-mail: info@becker-avionics.com

Page 2

Installation and Operation

Becker Avionics

Contact Data for

America, Australia, Japan

Approved Production and Maintenance Organization

Certificates see: http://www.becker-avionics.com/company-about/ →Certificates

Germany: Becker Avionics GmbH

Baden-Airpark B108

77836 Rheinmünster (Germany)

Tel.: + 49 (0) 7229 / 305-0

Fax: + 49 (0) 7229 / 305-217

Internet: www.becker -avionics.com

Email: info@becker-avionics.com

Sales:

Email: sales@becker-avionics.com,

Customer Service:

Email: support@becker-avionics.com

Email: info@beckerusa.com

WARNING - USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

• This document and other information from Becker Avionics GmbH provide product or system

options for further investigation by users having technical knowledge.

• The user is responsible for making the final selection of the system and components. The user

has to assure that all performance, endurance, maintenance, safety requirements of the

application are met and warnings be observed.

For this the user has to include all aspects of the application to be compliant with the applicable

industry standards and the requirements of the responsible aviation authority. The product

documentations from Becker Avionics GmbH have to be observed.

• To the extent that Becker Avionics GmbH provide component or system options based upon data

or specifications provided by the user, the user is responsible for determining that such data and

specifications are suitable and sufficient for all applications and reasonably foreseeable uses of

the components or systems.

Term definition: User in the sense of user, installer, installation company.

2 RT6512 DV17501.03 Issue 06 April 2018

Page 3

Becker Avionics

Installation and Operation

Preface

Remote

Dear Customer,

Thank you for purchasing a Becker Avionics product. We are pleased that you have chosen our

product and we are confident that it will meet your expectations.

For development of our products, the gui delines for highes t quality and reliab ility have been borne in

mind, supplemented by selection of high quality material, responsible production and testing in

accordance to the corresponding standards.

Our competent customer support department will respond on any technical question you may have.

Please do not hesitate to contact us at any time.

-Controlled VHF-AM Transceiver

DV17501.03 Issue 06 April 2018 RT6512 3

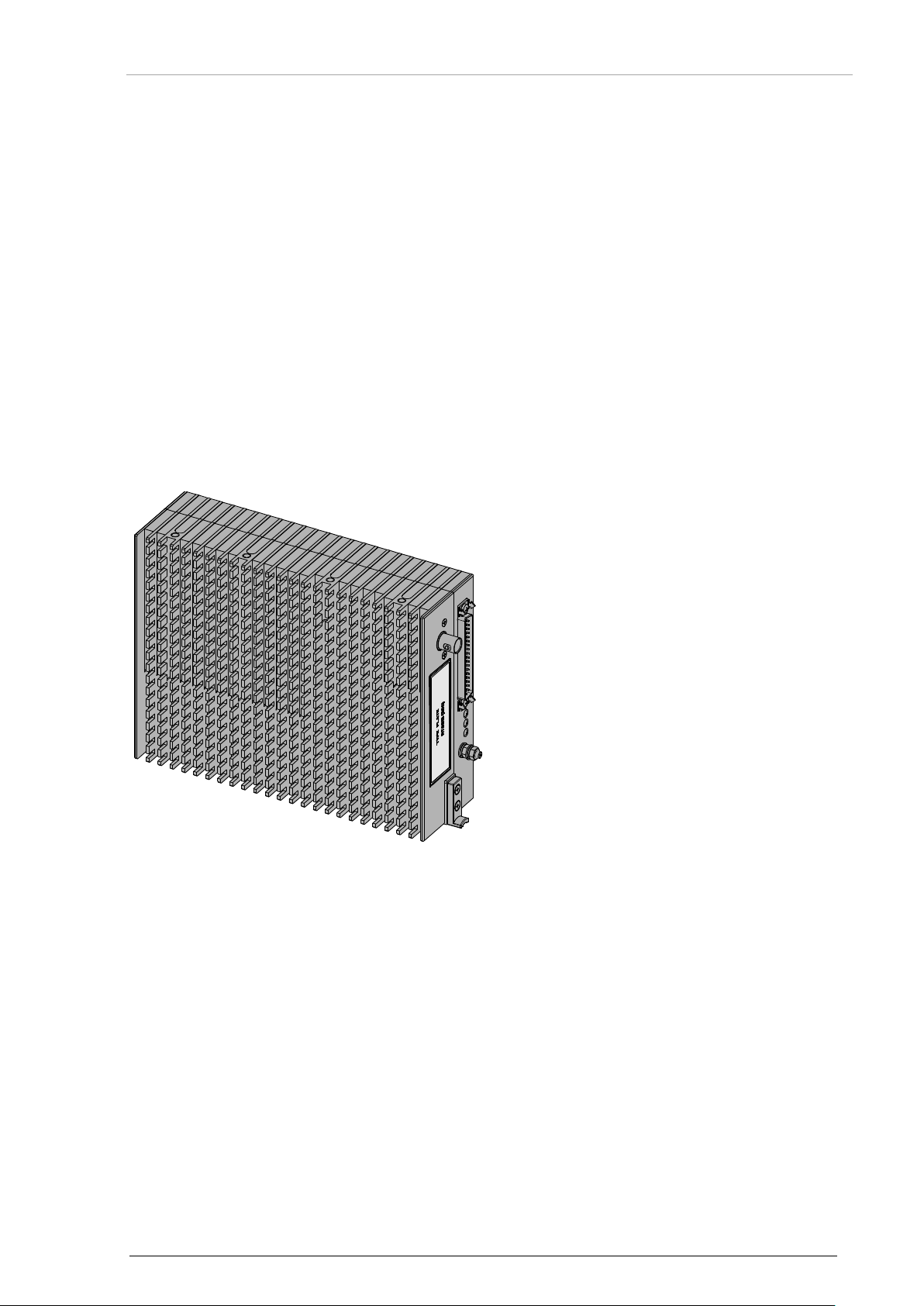

RT6512 (Remote Transceiver)

without mounting tray

Page 4

Installation and Operation

Becker Avionics

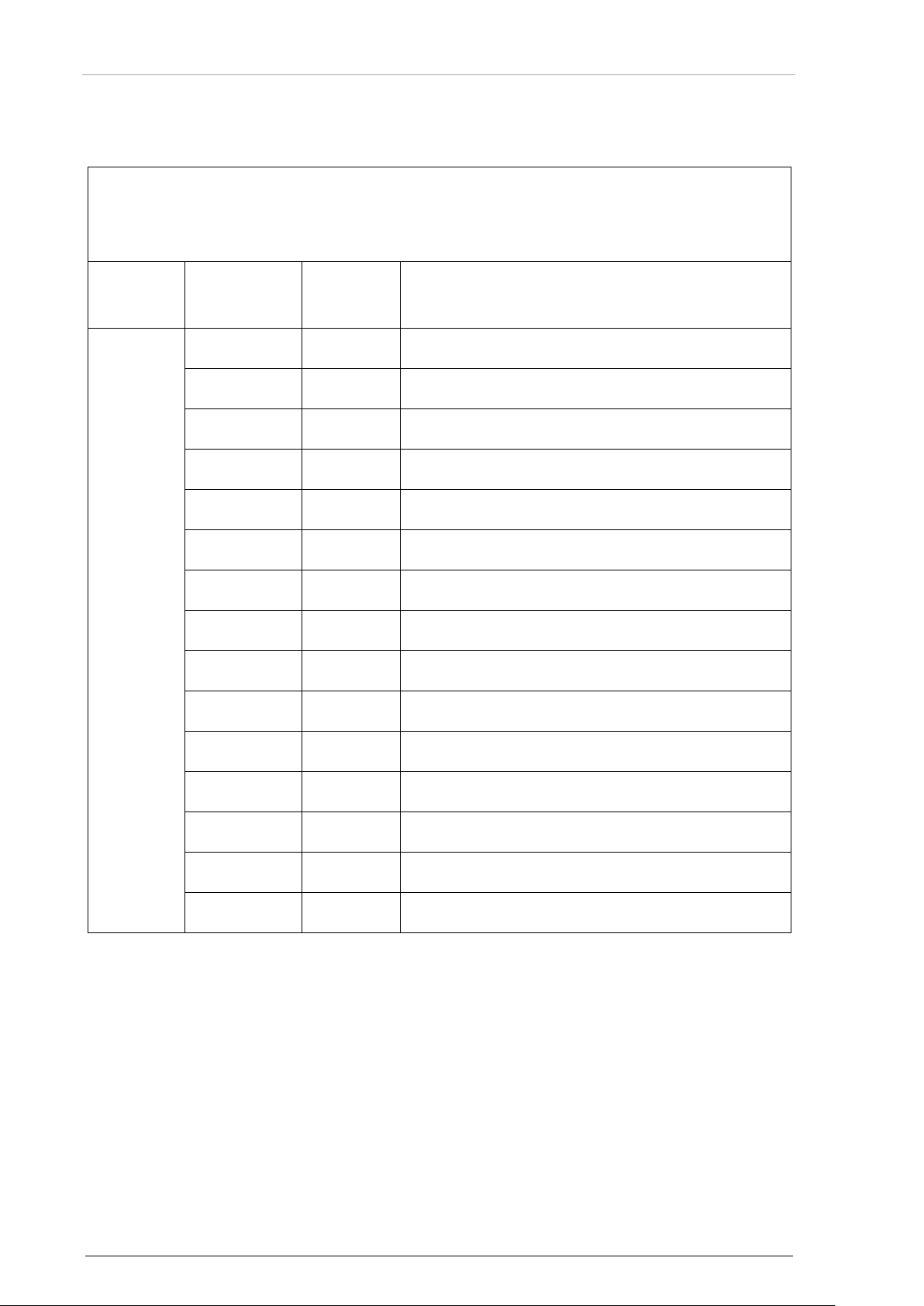

List of Effective Pages and Changes

Only technical relevant modifications are described in this table.

Document: DV17501.03 / issue 06 Article Number 0645.702-071

Cover Page 04/2018

Introduction 04/2018

Chapter 1 – 4 04/2018

Issue Page No.:

06

1-60 all Changed: Editorial adjustments.

-- all Added: Descriptions about RCU6512.

--

--

---

--

--

--

--

--

Section /

Chapter

Description

--

--

--

--

--

© by Becker Avionics GmbH / all rights reserved

4 RT6512 DV17501.03 Issue 06 April 2018

Page 5

Becker Avionics

Installation and Operation

Table of Contents

1 General Description .................................................................................................................... 11

1.1 Introduction.................................................................................................................................. 12

1.2 Purpose of Equipment ................................................................................................................. 13

1.3 Variants Overview ....................................................................................................................... 14

1.4 Associated Device s ..................................................................................................................... 14

1.5 Scope of Functionality ................................................................................................................. 15

Receive Mode ................................................................................................................... 15

Transmit Mode .................................................................................................................. 15

Emergency Mode .............................................................................................................. 15

Audio Inputs and Outputs ................................................................................................. 16

1.5.4.1 Microphone Input ......................................................................................................... 16

1.5.4.2 Audio Input LINE IN ..................................................................................................... 16

1.5.4.3 Audio Output LINE OUT .............................................................................................. 17

Control Inputs .................................................................................................................... 17

1.5.5.1 /ON (Unit Power ON/OFF Control) .............................................................................. 17

1.5.5.2 /PTT (Push-To-Talk) .................................................................................................... 17

1.5.5.3 /COM2 (Com Addressing Line) ................................................................................... 17

1.5.5.4 /SEL422 (Serial Interface Selection Line).................................................................... 17

1.5.5.5 /RX_ATT (External RX Attenuation Control) ............................................................... 18

1.5.5.6 /SERV_EN (Enabling the Setup Modes) ..................................................................... 18

1.5.5.7 /TX-ENABLE (Enabling the TX) ................................................................................... 18

1.5.5.8 /EMERG (Enabling the Emergency Mode) .................................................................. 18

Status and Control Outputs .............................................................................................. 19

1.5.6.1 /FAILURE ..................................................................................................................... 19

1.5.6.2 RX_AGC (AGC Voltage of the RX-RF-AGC) .............................................................. 19

1.5.6.3 /SQL_EVAL ................................................................................................................. 19

Digital Interfaces to the Control Unit ................................................................................. 20

1.5.7.1 Interface ARINC 429 .................................................................................................... 20

1.5.7.2 Interface RS422 ........................................................................................................... 20

1.6 Safety-Conscious Utilization ....................................................................................................... 20

1.7 Restriction for Use ....................................................................................................................... 21

1.8 Technical Data ............................................................................................................................ 22

General Characteristics .................................................................................................... 22

Typical Power Consumption ............................................................................................. 22

Receiver Data ................................................................................................................... 23

Transmitter Data ............................................................................................................... 24

Dimensions & Weight........................................................................................................ 24

Software ............................................................................................................................ 25

Hardware .......................................................................................................................... 25

Continued Airworthi nes s ................................................................................................... 25

Environmental Conditions ................................................................................................. 26

Certifications ..................................................................................................................... 27

1.8.10.1 RT6512 meets the Requirements of: ........................................................................... 27

1.8.10.2 Guidelines followed for Design and Development ....................................................... 27

1.8.10.3 FCC Approval .............................................................................................................. 28

1.9 Order Code.................................................................................................................................. 29

RT6512 ............................................................................................................................. 29

Accessories ....................................................................................................................... 29

2 Installation .................................................................................................................................... 31

2.1 Packaging, Transport, Storage ................................................................................................... 31

2.2 Device Assignment ..................................................................................................................... 32

Scope of Delivery .............................................................................................................. 32

Additional Required Equipment (optional) ........................................................................ 32

Type Plate ......................................................................................................................... 33

Meaning of Status LEDs ................................................................................................... 33

2.3 Mounting Requirements .............................................................................................................. 34

Mounting Distance ............................................................................................................ 34

Grounding ......................................................................................................................... 34

Antenna Cables ................................................................................................................ 35

2.3.3.1 Attenuation: Cable length versus coax cable type ...................................................... 35

Antenna Installation .......................................................................................................... 36

DV17501.03 Issue 06 April 2018 RT6512 5

Page 6

Installation and Operation

Becker Avionics

2.3.4.1 Required Antenna Type ............................................................................................... 36

2.3.4.2 Antenna Mounting Location ......................................................................................... 36

2.3.4.3 Recommendation for Installation of two RT6512 in one Aircraft ................................. 38

2.3.4.4 Radio Setting and Wiring for dual installation .............................................................. 38

2.4 Dimensions .................................................................................................................................. 39

RT6512 .............................................................................................................................. 39

RT6512 with Mounting Tray MT6512 ................................................................................ 40

2.5 Connector Pin Assignments ........................................................................................................ 41

Connector P1 (RT6512) .................................................................................................... 41

2.6 Equipment Configuration Samples .............................................................................................. 43

RT6512 with RCU6512 ..................................................................................................... 43

RT6512 with RMU5000 ..................................................................................................... 43

RT6512 with ARINC 429 Controller .................................................................................. 43

2.7 Aircraft Wiring .............................................................................................................................. 44

RT6512-(XX0) with RCU6512 as Primary Controller ........................................................ 45

RT6512-(XX0) with ARINC 429 Controller ........................................................................ 46

RT6512-(XX1) with ARINC 429 Controller ........................................................................ 47

2.8 Post Installation Tests ................................................................................................................. 48

Mechanical Installation and Wiring Check ........................................................................ 48

Power Supply .................................................................................................................... 48

Receiver / Transmitter Operation ...................................................................................... 48

Antenna Check .................................................................................................................. 48

Interference Check ............................................................................................................ 48

Flight Test Check .............................................................................................................. 50

3 Operating Instructions ................................................................................................................ 51

3.1 Device Description....................................................................................................................... 51

Device Assignment ........................................................................................................... 51

3.2 Operating with RCU6512 ............................................................................................................ 51

3.3 Operating with RMU5000 ............................................................................................................ 51

3.4 Operating with OEM Controller ................................................................................................... 51

3.5 Start-Up ....................................................................................................................................... 52

Built In Tests (BIT) ............................................................................................................ 52

3.5.1.1 Initiated Built In Test (IBIT) .......................................................................................... 54

3.5.1.2 Power On Built In Test (PBIT) ...................................................................................... 54

3.5.1.3 Continuous Built In Test (CBIT) ................................................................................... 54

3.5.1.4 Error Indication ............................................................................................................. 55

3.6 RS422 Protocol supported by RT6512 ....................................................................................... 57

3.7 ARINC 429 Protocol supported by RT6512 ................................................................................ 57

3.8 Contact Data ................................................................................................................................ 58

4 Index .............................................................................................................................................. 60

List of Figures

Figure 1: Standard Microphone Input Schematic ................................................................................................... 16

Figure 2: LINE_IN Schematic ................................................................................................................................. 16

Figure 3: LINE_OUT .............................................................................................................................................. 17

Figure 4: /FAILURE Output Schematic .................................................................................................................. 19

Figure 5: Type Plate (Example) .............................................................................................................................. 33

Figure 6: RT6512 with MT6512 - mounting area .................................................................................................... 34

Figure 7: Antenna Installation ................................................................................................................................. 36

Figure 8: RT6512 Dimensions (without and with Main Connector applied) ............................................................ 39

Figure 9: RT6512 with Mounting Tray MT6512 ...................................................................................................... 40

Figure 10: RT6512 with RCU6512 ......................................................................................................................... 43

Figure 11: RT6512 with RMU5000 ......................................................................................................................... 43

Figure 12: RT6512 with ARINC 429 Controller ...................................................................................................... 43

Figure 13: RT6512-(XX0) with RCU6512 as Primary Controller ............................................................................ 45

Figure 14: RT6512-(XX0) with ARINC 429 Controller ............................................................................................ 46

Figure 15: RT6512-(XX1) with ARINC 429 Controller ............................................................................................ 47

Figure 16: Thermal Behavior for TX Function ........................................................................................................ 53

6 RT6512 DV17501.03 Issue 06 April 2018

Page 7

Becker Avionics

Installation and Operation

List of Abbreviations

List of Abbreviations

A3E

Amplitude modulation double-sideband with full carrier

AGC

Automatic Gain Control

AM

Amplitude Modulation

AOC

Air Operations Centre

ARINC

Aeronautical Radio Incorporated

ARINC 429

Data bus for commercial aircraft

ATS

Air Traffic Services

BIT

Built In Test

BNC

Bayonet Neill Concelman (connector)

CBIT

Continuous Built In Test

CU

Control Unit

DAL

Design Assurance Level

DC

Direct Current

EUROCAE

European Organization for Civil Aviation Equipment

EASA

European Aviation Safety Agency

FAA

Federal Aviation Administration

IBIT

Initiated Built In Test

n/a

not applicable

LED

Light Emitting Diode

OEM

Original Equipment Manufacturer

PBIT

Power On Built In Test

PSB

Power Supply Board

PTT

Push To Talk

RCU

Remote Control Unit

RMU

Radio Management Unit

RX

Receiver

Std

Standard

TX

Transmitter

VDC

Volts Direct Current

VHF

Very High Frequency

VSWR

Voltage Standing Wave Ratio

TufLok®

Registered trademark. Thread loc kin g patch

ELASTOSIL®

Registered trademark. Silicon produ cts.

DV17501.03 Issue 06 April 2018 RT6512 7

Page 8

Installation and Operation

Becker Avionics

Units

A

Ampere

mA

Milliampere

°C

Degree Celsius

dBm

Power ratio in Decibel referenced to 1 mW

dB

Decibel

ft

Foot

g

Gram

in

Inch

kHz

Kilohertz

MHz

Megahertz

mm

Millimeter

NM

Nautical Mile

kΩ

Resistance kilo Ohm

Ohm (Ω)

Resistance

ppm

Part per million

s

Second

V

Volt

mV

Millivolt

W

Watt

mW

Milliwatt

Indicates a hazardous situation which, if not avoided, will result in death or serious

Indicates a hazardous situation which, if not avoided, could result in death or

Indicates a hazardous situation which, if not avoided, could result in minor or

Is used to address practices not related to physical injury.

Safety instructions (or equivalent) signs indicate specific safety-related

Units

General Safety Instructions

injury.

serious injury.

moderate injury.

instructions or procedures.

8 RT6512 DV17501.03 Issue 06 April 2018

Page 9

Becker Avionics

Installation and Operation

Disposal

The packaging material is inflammable, if it is disposed of improperly by

The device(s) may be installed on an aircraft only by an approved aeronautical

The user is responsible for a safe installation and/or additional safety measures

burning, toxic fumes may develop.

This product contains materials that fall under the special disposal regulation, which corresponds to

the EC directive for dangerous disposal material. We recommend disposing of the respective materials

in accordance with the respectively valid environmental laws.

• Dispose circuit boards via a technical waste dump which is allowed to take on e.g.

electrolytic aluminium capacitors. Do under no circumstances dump the circuit boards with

normal waste dump.

Warranty Conditions

company (e.g. EASA Part 145) which shall also examine and verify the

User conversions and changes are not permitted.

Any change on the product, made by the user, excludes any liability of Becker Avionics GmbH.

• For installation, opening the device is not required.

• Do not make any modifications to the device, except for those described in the manual.

• Make connections to the inputs, outputs and interfaces only in the manner described in

the manual.

• Install the devices according to the instructions.

We cannot provide any guarantee for other mounting methods.

installation.

Conditions of Utilization

General introductory notes

With this device you b ought a product, which was manufactured and tested before delivery with th e

utmost care.

Please take your t ime to read the f ollowing notes, whic h you should follo w closely during insta llation

and operation.

Otherwise, all claims under the warranty will become void an d a reduced service life or even parti al

damage is not excludable.

in order to prevent damages to persons or the electric installations of the

airplane. In case of deviations to the descriptions in this document perform all

work in accordance with the airplane service manual or take the AC43-13, in its

latest revision, into account.

Additional Conditions of Utilization

Please refer to "Safety-Conscious Utilization", page 20.

Non-Warranty Clause

We checked the co nte nts o f this publication for com pli ance with the associat ed h ard a nd s of tware. We

can however, not exclude discrepancies and do therefore not accept any liability for the exact

compliance. The inf ormation in this public at ion is u nde r goin g a regularly review, necessary correc tio ns

will be part of the subsequent issues of this publication.

DV17501.03 Issue 06 April 2018 RT6512 9

Page 10

Installation and Operation

Becker Avionics

Blank Page

10 RT6512 DV17501.03 Issue 06 April 2018

Page 11

Becker Avionics

General Description

Introduction

1 General Description

In this chapter you can read about:

1.1 Introduction.................................................................................................................................. 12

1.2 Purpose of Equipment ................................................................................................................. 13

1.3 Variants Overview ....................................................................................................................... 14

1.4 Associated Devices ..................................................................................................................... 14

1.5 Scope of Functionality ................................................................................................................. 15

Receive Mode ................................................................................................................... 15

Transmit Mode .................................................................................................................. 15

Emergency Mode .............................................................................................................. 15

Audio Inputs and Outputs ................................................................................................. 16

Control Inputs .................................................................................................................... 17

Status and Control Outputs .............................................................................................. 19

Digital Interfaces to the Control Unit ................................................................................. 20

1.6 Safety-Conscious Utilization ....................................................................................................... 20

1.7 Restriction for Use ....................................................................................................................... 21

1.8 Technical Data ............................................................................................................................ 22

General Characteristics .................................................................................................... 22

Typical Power Consumption ............................................................................................. 22

Receiver Data ................................................................................................................... 23

Transmitter Data ............................................................................................................... 24

Dimensions & Weight........................................................................................................ 24

Software ............................................................................................................................ 25

Hardware .......................................................................................................................... 25

Continued Airworthi nes s ................................................................................................... 25

Environmental Conditions ................................................................................................. 26

Certifications ..................................................................................................................... 27

1.9 Order Code.................................................................................................................................. 29

RT6512 ............................................................................................................................. 29

Accessories ....................................................................................................................... 29

This manual describes the Becker Avionics remote-controlled VHF-AM transceiver RT6512-(XXX).

The t ype plate on your device shows the part number for identification purposes (see "T ype Plate",

page 33).

Before starting operati on of the device(s) please read t his manual c arefull y, with particul ar attention t o

the description referring to your device(s).

DV17501.03 Issue 06 April 2018 RT6512 11

Page 12

General Description

Becker Avionics

Introduction

1.1 Introduction

The technical information in this document applies to the described product(s) RT6512-(XXX). For

further descriptions we are using the term RT6512 instead writing the complete model number.

If a description ref ers to only one of the product var iants its full nam e, e.g. "RT6512-(100)", will be

used.

The manuals Maintenance & Repair (M&R) and Installation & Operation (I&O) contain the following

sections:

Section

DV 17501.04

M&R

DV 17501.03

I&O

General Description X X

Installation X X

Operation Instructions X X

Theory of Operation X N/A

Maintenance and Repair X N/A

Illustrated Parts List X N/A

Modification and Changes X N/A

Circuit Diagrams X N/A

Certifications X N/A

Attachments X N/A

12 RT6512 DV17501.03 Issue 06 April 2018

Page 13

Becker Avionics

General Description

Purpose of Equipment

1.2 Purpose of Equipment

The mechanical design of the remote-controlled VHF-AM transceiver RT6512 is rugge dized and well

suited for installati on in the av ion ics c ompartment (non-press ur ized a nd not temperature control led) by

means of a mounting tra y and in all types of aircraft.

The remote-controlled VHF-AM transceiver RT6512 meets RTCA and EUROCAE airworthiness

requirements applicable at the time the unit received certification. There are no restrictions for

installation of the u nit as long as it w ill be installed in areas, where data of the proven env ironmental

categories will not exceed.

• RT6512 is a simplex vo ice c ommunication system in the standard avionics VHF frequency

range 118.000...136.975 MHz (136.9916 MHz with 8.33 kHz channel spacing) or opti ona l

with extended frequency range up to 155.975 MHz and uses stan dard amplitude

modulation (A3E). RT6512 is capable to operate in both, the 25 or 8.33 kHz channel

spacing is primarily intended for aeronautical operational control (AOC) and air traffic

services (ATS) safety communications.

• RT6512 uses ARINC 429 and RS422 interfaces for communication with a co ntro l dev ice.

• RT6512 provides frequency and mode control, either by means of the Becker RCU6512 or

RMU5000 controller using the RS422 communication port, or by means of any OE

oduct using the standard ARINC 429 communication bus.

pr

• With transmitter power of 20W, RT6512 is able to support simultaneous communication

over a range exceeding 200 NM direct line of sight, within the frequency range.

M

DV17501.03 Issue 06 April 2018 RT6512 13

Page 14

General Description

Becker Avionics

RT

6512

- ( X X X

)

Device

Function/Manufacturer

RCU6512

Becker Avionics Remote Control Unit

RMU5000

Becker Avionics Radio Management Unit

Control unit

Gables G7610 (Control unit for VHF-COMM only)

Control unit

Universal RCU

Glass cockpit

Genesys IDU680

Associated Devices

1.3 Variants Overview

Within the part number, the meaning of "RT6512-(XXX)", is:

Type Identifier

Model Number

1.4 Associated Devices

Following devices can operate with RT6512-(XXX):

0 – Standard

1 – with Emergency Mode

0 - Standard

1 – Std. Freq. Range 118...136.975 MHz

2 – Ext. Freq. Range 118...155.975 MHz

14 RT6512 DV17501.03 Issue 06 April 2018

Page 15

Becker Avionics

General Description

Scope of Functionality

1.5 Scope of Functionality

RT6512 performs AM (amplitude modulation) voice communication.

Mechanics: Case serves as heat sink:

Front side conta ins the main connect or for connection to the aircraft wiri ng system, and the a ntenna

jack. Three front panel LEDs indicate basic information about overall equipment status.

Receive Mode

RT6512 is equipped with a high-quality Class C, E and H2 receiver:

• Standard sensitivity 5 µV, high dynamic range, and high blocking rejection.

• It can receive a weak signal while a 2

transmitting.

• The RT6512 can operate with offset carrier in both 25 kHz and 8.33 kHz channel spacing.

Transmit Mode

RT6512 is equipped with a high-quality Class 3 and 5 transmitter:

• Output power of 20 W under standard operating conditions.

• Output power of at least 16 W under the specified environmental operating conditions

(when using antenna with VSWR≤2:1, for VSWR>3:1 outp ut po wer lowers ).

• AM depth >70% - standard value for airborne application.

• During transmission, the transmitter delivers a natural sidetone signal, which is available

on the LINE_OUT output (if enabled).

• RT6512 is equipped with a protective function to prevent from blocking the frequency

channel by a stuck transmit button or a short circuit on the key line.

• RT6512 provides status information if device is transmitting via serial protocol (RS422 and

ARINC 429). This status can be used to inform the crew about terminated transmission

(as required by TSO-C128a/ETSO-2C128).

• RT6512 transmitter is protected from overheating. VSWR on antenna connector is also

monitored. See "Status and Control Outputs", page 19 for details.

nd

VHF-AM transceiver in the same aircraft is

Emergency Mode

• The RT6512-(201) var ia nt suppor ts Em ergency Mode in which device is automaticall y tuned to

emergency channel 121.500 MHz in 25 kHz channel spacing.

• External control of transceiver is prohibited with remaining device status monitoring.

Note: Operators Remark

121.5 MHz = International voice aeronautical emergency.

123.1 MHz = International worldwide voice SAR use (e.g. Italy).

DV17501.03 Issue 06 April 2018 RT6512 15

Page 16

General Description

Becker Avionics

Scope of Functionality

Audio Inputs and Outputs

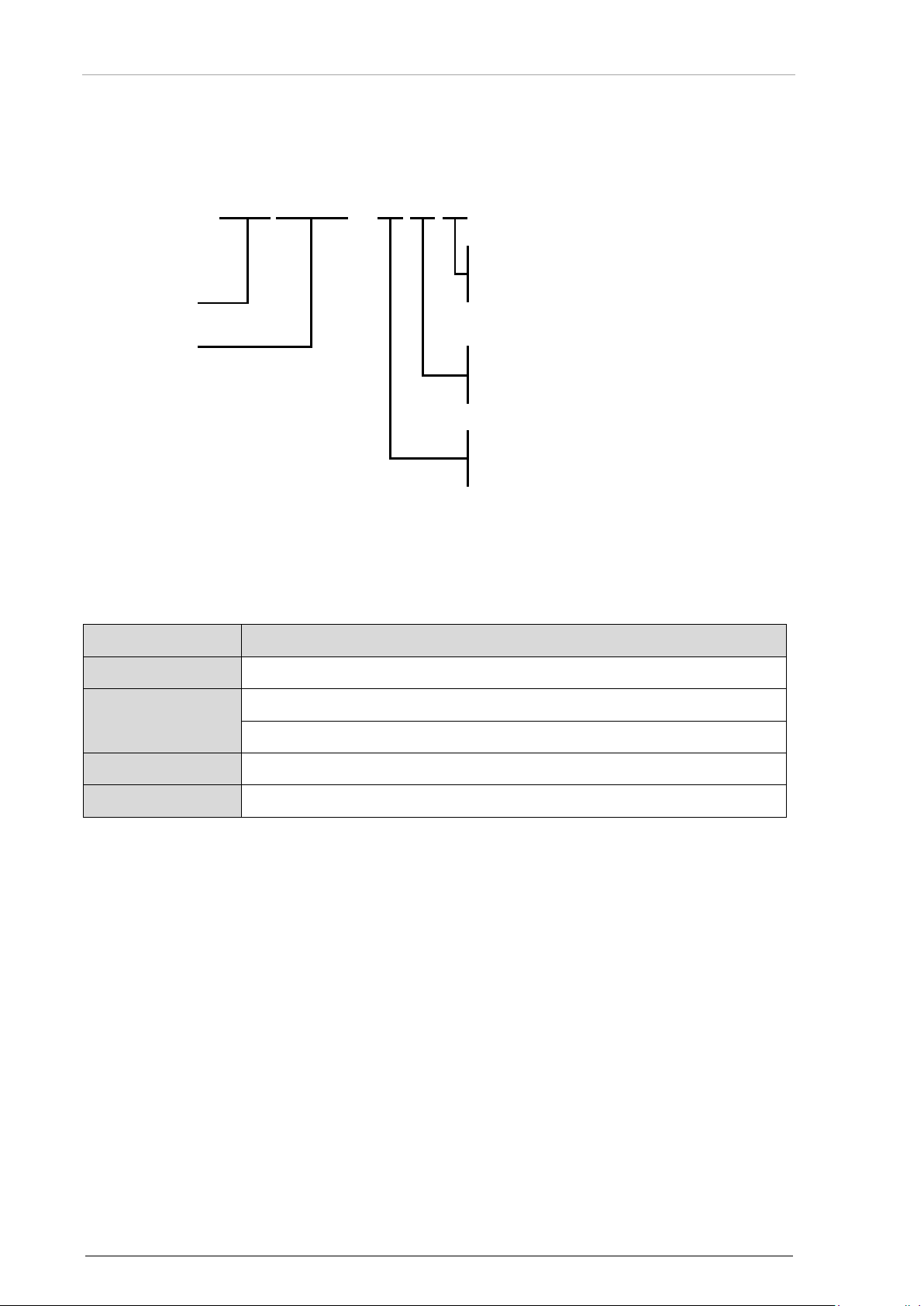

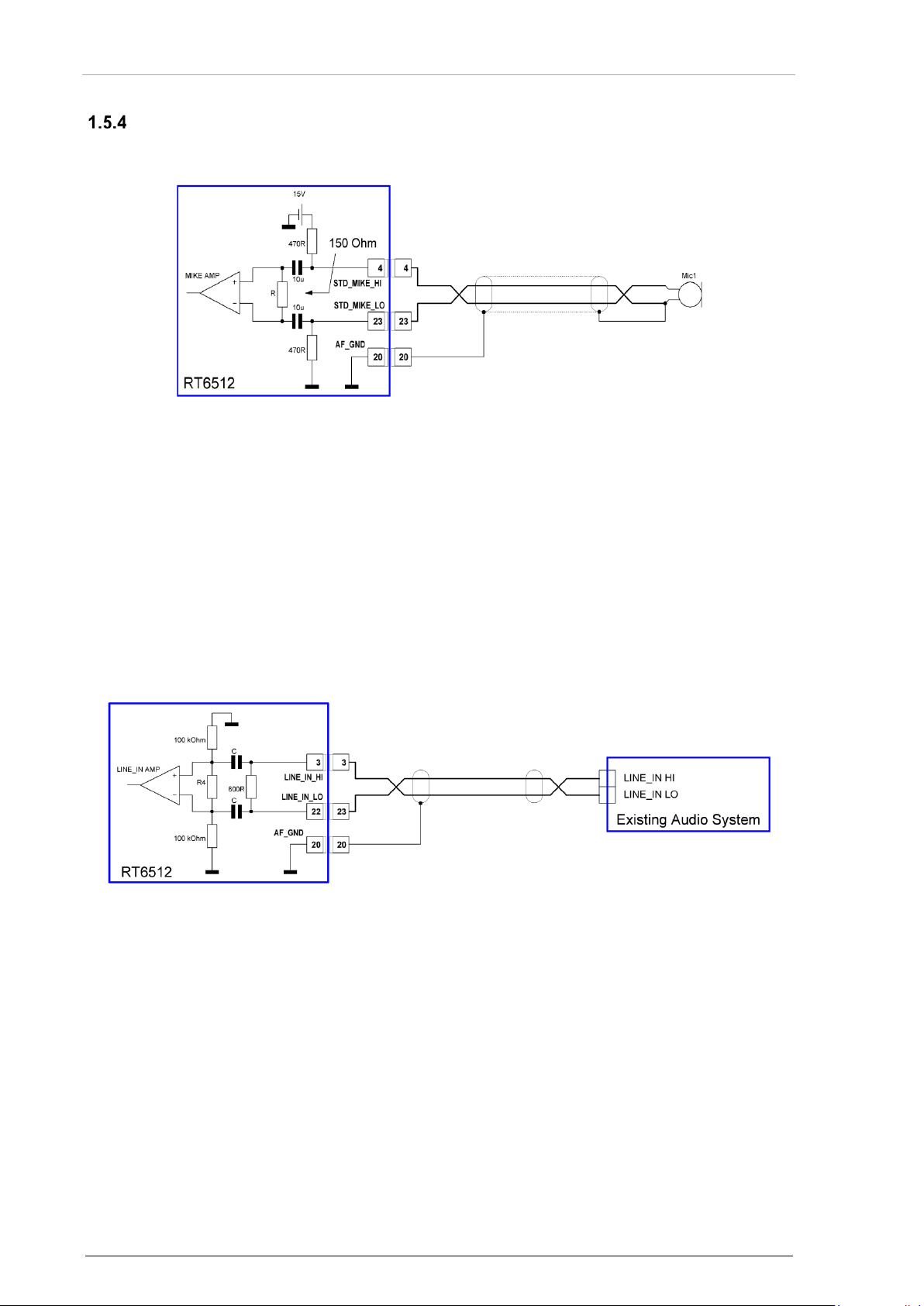

1.5.4.1 Microphone Input

Figure 1: Standard Microphone Input Schematic

RT6512 is designed for a standard microphone:

• Unbalanced,

• DC coupled,

• DC supplied from RT6512.

The bias current for s tandard microphone is drawn from RT6512 internal source 15 VDC via series

resistor 470 Ohm. The inp ut audio signal is routed to a dynamic compressor keeping the modulation

factor limited over a wide input voltage range. T he microphon e input uses the c able guard as ground

compensation so microphone input shall be connected exactly as specified on Installation diagrams.

1.5.4.2 Audio Input LINE IN

The RT6512 symmetr ical line input has no DC co nnection to ground. I nput impedance is 600 Ω. The

maximum input lev el without clipp ing can be set as high as 6 V. The input audio signal is routed to a

dynamic compressor keeping the modulation factor limited over a wide input voltage range.

16 RT6512 DV17501.03 Issue 06 April 2018

Figure 2: LINE_IN Schematic

Page 17

Becker Avionics

General Description

Scope of Functionality

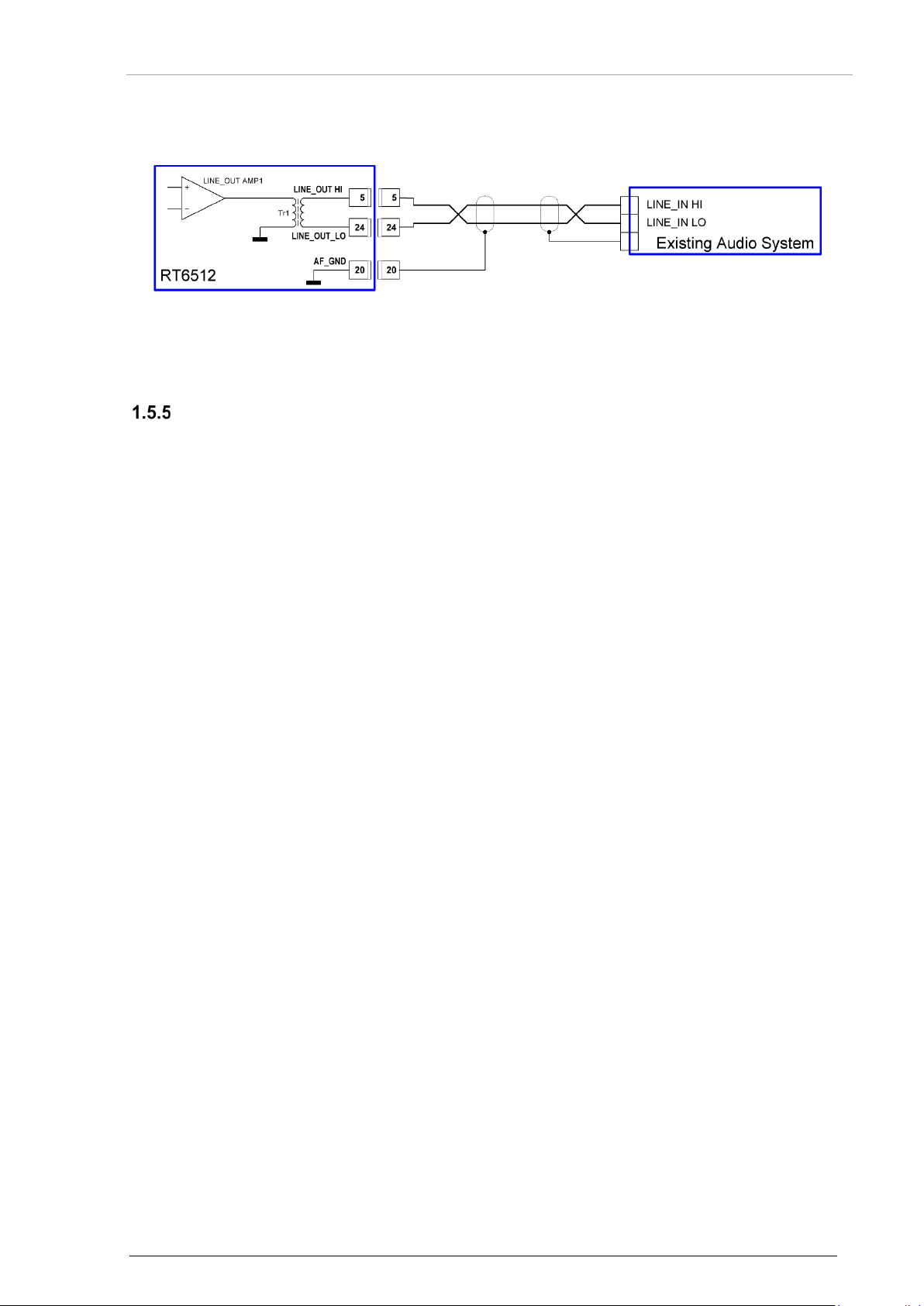

1.5.4.3 Audio Output LINE OUT

Figure 3: LINE_OUT

The audio output LINE OUT design is symmetrical an d has no DC con necti on to gr ound. If volume set

to maximum, the audio output power delivered is 100…125 mW into 600 Ω or 200 mW into 150 Ω.

Control Inputs

1.5.5.1 /ON (Unit Power ON/OFF Control)

/ON signal to switch ON/OFF the RT6512.

The /ON line is used to activate an internal electronic switch to power-up the unit.

It is active if the level on th e /ON pin is less than 4.0 V or a resistance of less than 1 kΩ connects to

ground.

The /ON line is inactive if the level on the /ON pin is higher than 8.0 V or a resistance higher

than 50 kΩ connects to ground.

1.5.5.2 /PTT (Push-To-Talk)

/PTT is used to initiate transmission.

It is active when /PTT-input level is below 4.0 V, or a resistance to ground of less than 1 kΩ.

The /PTT line is inactive if the level on the /PTT-input is higher than 8.0 V, or a resistance higher

than 50 kΩ connects to ground.

1.5.5.3 /COM2 (Com Addressing Line)

/COM2 defines device sub address for ARINC communication.

The device detects a LOW state (Active state) on the /COM2 input when an external resistance of

lower than 1 kΩ is connected to ground.

The device detects a HIG H state (Inactive state) on the /CO M2 input when an external res istance of

higher than 50 kΩ is connected to ground.

• Com addressing line bit:

o LOW (Active) state selects COM2.

o HIGH (Inactive) state selects COM1.

1.5.5.4 /SEL422 (Serial Interface Selection Line)

/SEL422 selects RS422 or ARINC 429 communication.

The device detects a LOW state (Active state) on the /SEL422 input when an external resistance of

lower than 1 kΩ is connected to ground.

The device detects a HIGH state on the /SEL422 input when an external resistance of higher

than 50 kΩ is connected to ground.

• Serial interface selecti on line:

o LOW (Active) state selects RS422.

o HIGH (Inactive) state selects ARINC.

DV17501.03 Issue 06 April 2018 RT6512 17

Page 18

General Description

Becker Avionics

For an aircraft installation /TX-ENAB L E input shall be connected to ground

Scope of Functionality

1.5.5.5 /RX_ATT (External RX Attenuation Control)

/RX_ATT reduces the RF gain of the RX section to reduce cross talk effects.

The /RX_ATT line is us ed for an optiona l desensitizati on of the RT6512 rec eiver. The des ensitization

nd

can be required wh en a 2

st

line from 1

VHF-AM trans c eiv er s ha ll be connected to /RX _ AT T input of 2nd device and / PT T from 2nd

device shall be connected to /RX_ATT input of the 1

VHF-AM transc eiver i n th e s ame aircraft is transm ittin g. In s uch c as e / PT T

st

device.

The /RX_ATT is active if /RX_ATT-input level is less than 4.0 V, or a resistance less than 1 kΩ

connects to ground.

The /RX_ATT line is inac tive if the level on the /RX_ATT -input is higher than 8.0 V, or a resistance

higher than 50 kΩ connects to ground.

1.5.5.6 /SERV_EN (Enabling the Setup Modes)

/SERV_EN enables the setup modes.

/SERV_EN is a read/write access for all setup data, not available for standard user

The device detects a LOW state (Active sta te) on the /SER V_EN input when an e xter nal res istance of

lower than 1 kΩ is connected to ground.

The device detects a HIGH state ( Inactive s tate) on the / SERV_EN input when an ex ternal r esistanc e

of higher than 50 kΩ is connected to ground.

1.5.5.7 /TX-ENABLE (Enabling the TX)

/TX-ENABLE enables the transmitter.

RT6512 detects a low state on the /TX_ENABLE in put when an external resist ance lower than 1 kΩ

connects to ground.

RT6512 is detecting high state on the /TX_ENABLE input when an external resistance higher

than 50 kΩ connects to ground. In such case transmission is permanently blocked.

directly on the main connector. / TX-ENABLE line cannot be routed as part

of installation cable bundle.

Note: Do not apply DC voltage above 5 Volts to /TX_ENABLE to avoid

device damage!

1.5.5.8 /EMERG (Enabling the Emergency Mode)

/EMERG enables the Emergency Mode for variant –(201) only.

RT6512-(201) detects a low stat e on the /EMERG in put when an external r esistance lower tha n 1 kΩ

connects to ground. In such case transceiver activates Emergency Mode operation.

RT6512-(201) is detecting high state on the /EMERG input when an external resistance higher

than 50 kΩ connects to ground.

18 RT6512 DV17501.03 Issue 06 April 2018

Page 19

Becker Avionics

General Description

Scope of Functionality

Status and Control Outputs

1.5.6.1 /FAILURE

Figure 4: /FAILURE Output Schematic

This /FAILURE output is coupled to the status shown at th e status LEDs mounted at the connec tor

side of RT6512. It corresponds to OR function of the r ed and the yellow LEDs. When the test func tion

is not ok, the transistor in the /FAILURE output is ON.

This output is an open collector (drain) type with capability to:

• Draw maximum 100 mA current to ground with a voltage drop of less than 2.5 V

(corresponding LEDs is on),

• Draw maximum 0.1 mA current to ground for output voltage 28.0 V when in "inactive" state

(corresponding LEDs are off).

It can be used to dr ive an external relay if 100 mA output current limit at t he supply voltag e 28.0 V is

not sufficient. This /FAILU RE output is protec ted against spikes produced f rom a relay. See "Status &

Error Indication", page 55.

1.5.6.2 RX_AGC (AGC Voltage of the RX-RF-AGC)

The AGC output is a DC coupled output of the RF-AGC used in the receiver.

The output voltage v aries monotonic within the ra nge of 0...5 V, when the i nput level at the antenna

input is varied from -105...+13 dBm.

For all antennas input le vels from -120...-105 dBm the output v oltage is positive and no t higher than

the output voltage which can be obtained at -105 dBm.

1.5.6.3 /SQL_EVAL

This digital output indicates that the audio signal from the receiver is available on the LINE_OUT.

DV17501.03 Issue 06 April 2018 RT6512 19

Page 20

General Description

Becker Avionics

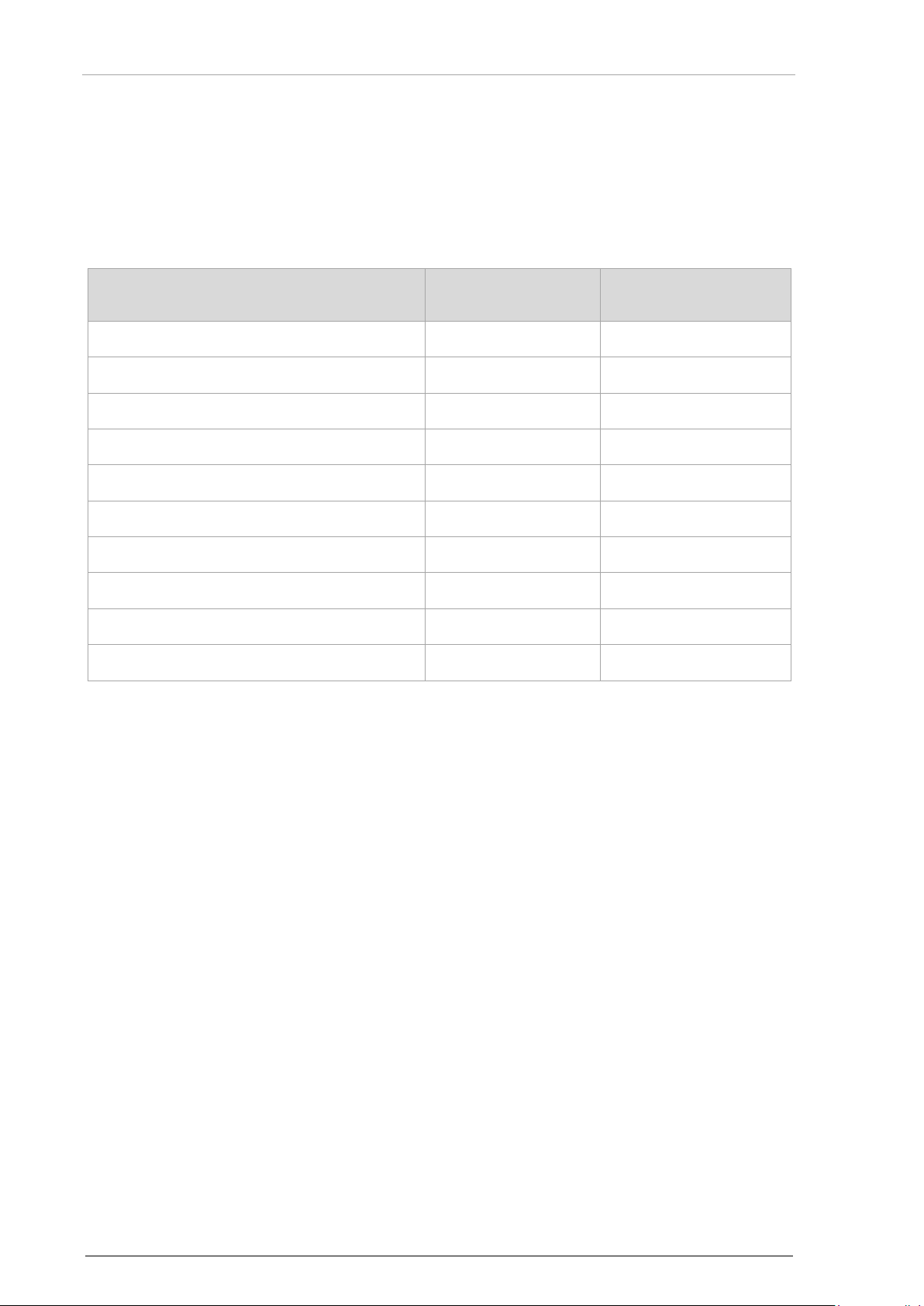

Name

Function / Remarks

ARI429_RX_A1

1st ARINC 429 Interface RX Line A

ARI429_RX_B1

1st ARINC 429 Interface RX Line B

ARI429_TX_A1

1st ARINC 429 Interface TX Line A

ARI429_TX_B1

1st ARINC 429 Interface TX Line B

ARI429_RX_A2

2nd ARINC 429 Interface RX Line A

ARI429_RX_B2

2nd ARINC 429 Interface RX Line B

ARI429_TX_A2

2nd ARINC 429 Interface TX Line A

ARI429_TX_B2

2nd ARINC 429 Interface TX Line B

Name

Function / Remarks

RS422_RX+

RS422 Interface RX Line B (high if idle)

RS422_RX-

RS422 Interface RX Line A (low if idle)

RS422_TX+

RS422 Interface TX Line B (high if idle)

RS422_TX-

RS422 Interface TX Line A (low if idle)

The device(s) may be installed on an aircraft only by an approved aeronautical

Safety-Conscious Utilization

This output is an open collector type with capability to:

• Draw maximum 100 mA current to ground with a voltage drop of less than 2.5 V

(corresponding LED(s) is on).

• Draw maximum 0.1 mA current to ground for output voltage 28.0 V when in "inactive" state

(corresponding LEDs are off).

• It can be used to drive an external relay, if 100 mA output current limit at the supply

voltage 28.0 V is not sufficient.

• This /SQL_EVAL output is protected against spikes produced from a relay.

• RX indication inactive (HIGH):

o Squelch ON but no audio goes out on LINE_OUT.

o RT6512 in TX mode.

• RX indication active (LOW), only possible in RX mode:

o Squelch ON and audio goes out on LINE_OUT.

o Squelch OFF (permanent audio out on LINE_OUT).

Digital Interfaces to the Con trol Uni t

1.5.7.1 Interface ARINC 429

1.5.7.2 Interface RS422

1.6 Safety-Conscious Utilization

For safe operation of the product, the following notes have to be observed:

company (e.g. EASA Part 145) which shall also examine and verify the

installation.

20 RT6512 DV17501.03 Issue 06 April 2018

Page 21

Becker Avionics

General Description

Restriction for Use

• The installation of the device into an aircraft may be carried out only by an

Excessive pulses on the DC bus of the aircraft may cause damage on electrical

The product is to be used inside the declared limits.

authorized installation company. The country regulations always have to be

observed.

• Use the product only within the specified conditions, see "Technical Data",

page 22.

Power supply:

• Do not connect the unit to AC sources.

• Make sure that the device is connected to the mandatory DC source, see

"Technical Data", page 22.

• Do not connect the device with reversed polarity to the DC source.

Circuit breaker:

• Use the recommended fuses in the power supply line to protect the

application, see "T ec hnica l Data", page 22.

circuits of any installed instrument.

Do not switch ON the device during engine start or shutdown.

1.7 Restriction for Use

DV17501.03 Issue 06 April 2018 RT6512 21

Page 22

General Description

Becker Avionics

Technical Data

RT6512

Specifications

Nominal supply voltage

28.0 VDC

Extended supply voltage

22.0…30.3 VDC

Emergency operation

18.0 VDC

Frequency range

RT6512-(100)

118.000...136.9916 MHz

RT6512-(200)

118.000...155.975 MHz

RT6512-(201)

118.000...155.975 MHz

Channel spacing

25 kHz

8.33/25 kHz (default)

Number of channels

8.33 kHz

2280

25 kHz

760

Storage Temperature range

-55...+85 °C

Operating Temperature range

-40...+70 °C

Operating Altitude

50 000 ft

Vibration

Category S (Curve M) + Category U (Curve G)

RT6512

Specifications

Receive mode

˂ 0.6 A

Transmit mode

˂ 7 A

Power-ON Time (PBIT dependent)

~ 4 s

Recommended power supply protection

10 A (e.g. Klixon 7277-2-10)

1.8 Technical Data

General Characteristics

Typical Power Consumption

22 RT6512 DV17501.03 Issue 06 April 2018

Page 23

Becker Avionics

General Description

Receiver Data

RT6512

Specifications

Sensitivity

≤ -93 dBm for a (S+N)/N ratio of 12 dB

Effective bandwidth

±2.78 kHz at the 6 dB points

±7.37 kHz at the 60 dB points

Effective bandwidth

±8 kHz at the 6 dB points

±17 kHz at the 40 dB points

±25 kHz at the 60 dB points

Squelch

level adjustable (by RCU6512 only)

AGC characteristics

≤ 6 dB in range -102...+13 dBm

Distortion

≤ 5% at AM=30% 10 dB below rated output power

≤ 15% at AM=85% and rated output power

Audio frequency response

≤ 6 dB 350...2500 Hz

≥ 35 dB at 4000… 10000 Hz (Class H2 Receiver)

Audio noise level (S+N)/N

≥ 25 dB

Rated output power for LINE_OUT

≥ 100 mW into 600 Ω

Offset-carrier operation

YES (25/8.33 kHz), Class C and H2 Receiver

(8.33 kHz channel spacing)

(25 kHz channel spacing)

(8.33 kHz channel spacing)

Technical Data

≥ 200 mW into 150 Ω

DV17501.03 Issue 06 April 2018 RT6512 23

Page 24

General Description

Becker Avionics

Technical Data

RT6512

Specifications

Output power into 50 Ω

≥ 20 W in normal condition;

Frequency tolerance

≤ 5 ppm

Duty cycle

30 s (TX) : 270 s (RX)

Type of modulation

A3E

Modulation capability

≥ 70%

Distortion

≤ 10%

Audio frequency response

≤ 6 dB, 350...2500 Hz

Audio frequency response

≤ 6 dB, 300...3400 Hz

Line In

200…6000 mV compressor starting point, adjustable

(with compressor)

Input balanced, 600 Ω

Standard microphone

100…3000 mV compressor starting point, adjustable

(with compressor)

Input unbalanced, 150 Ω

Parasitic FM deviation

≤ 1 kHz

Sidetone signal on LINE_OUT

natural, adjustable*

Automatic shutdown of transmit mode

Factory configurable 30…180 s (default 35 s)

Transmitter class

Class 3, Class 5

RT6512

Specifications

Without cable connector (W x H x D)

60 x 153 x 210.5 mm (2.36 x 6.02 x 8.29 inch)

With cable connector (W x H x D)

60 x 153 x 258 mm(2.36 x 6.02 x 10.16 inch)

Material

AlCuMg1 Nickel Plated

Weight without mounting tray

2150 g

Weight with mounting tray

2400 g

Transmitter Data

(with and without modulation)

(8.33 kHz channel spacing)

(25 kHz channel spacing)

(≥ 16 W under all specified environmental conditions)

Clipping level 6 V

Clipping level 3 V

(stuck PTT)

*For detailed information refer to the manual RCU6512 Installation and Operation DV17551.03 (Articl e No. 0645.230 071)

Dimensions & Weight

24 RT6512 DV17501.03 Issue 06 April 2018

Page 25

Becker Avionics

General Description

Technical Data

Software

The design and deve lopment pr ocess es us ed for VHF transceiver RT 6512 software are in com pliance

with the rules given in EUROCAE/RTCA Document ED-12C/DO-178C.

Design Assurance Level’ (DAL) "C".

Hardware

The Complex Electron ic H a rdw are ( CEH) inclu de d int o VHF tr ansc e iv er R T 6512 h as been des i gne d in

accordance with EUROCAE/RTCA Document ED-80/DO-254; “Design Assurance Guidance for

Airborne Electronic Hardware” and satisfy criteria of:

Hardware Assurance Level (HAL) C

Continued Airworthiness

• The RT6512 maintenance is defined as "on condition" only.

• No scheduled or regular maintenance of this product is required.

• It is recommended to check the frequency accuracy of the airborne transceiver after

4 years.

DV17501.03 Issue 06 April 2018 RT6512 25

Page 26

General Description

Becker Avionics

Environmental Test

Section

Category

Remarks

Temperature and Altitude

4

D1

-

Ground Survival Low Temperature and

4.5.1

D1

Short-Time Operating Low

Operating Low Temperature Test

4.5.2

D1

Operating Low Temperature Test

Ground Survival High Temperature and

4.5.3

D1

Ground Survival High Temperature

Operating High Temperature Test

4.5.4

D1

+70 °C

In-Flight Loss of Cooling

4.5.5

Z

no test performed

Altitude Test

4.6.1

D1

non-pressurized; 50 000 ft

Decompression Test

4.6.2

-

no test performed

Overpressure Test

4.6.3

-

no test performed

Temperature Variation

5

B

no test performed

Humidity 6 B

no test performed

Operational Shocks & Crash Safety

7

B

no test performed

Vibration

8

S

Category S – Curve M

Explosion Proofness

9

X

no test performed

Waterproofness

10

W

no test performed

Fluids Susceptibilities

11

X

no test performed

Sand and Dust

12

X

no test performed

Fungus Resistance

13

X

no test performed

Salt Spray

14

X

no test performed

Magnetic Effect

15

Z

no test performed

Power Input

16

BXX

Normal: 22.0...30.3 V

Voltage Spike

17

A

no test performed

Audio Frequency Conducted

18

B

no test performed

Induced Signal Susceptibility

19

ACX

no test performed

Radio Frequency Susceptibility

20

WW

Conducted Susceptibility: Cat. W

Emission of Radio Frequency Energy

21

M

no test performed

Lightning Induced Transient Susceptibility

22

A3Z3XX

Pin tests:

Technical Data

Environmental Conditions

The following performance standards were proven under environmental test conditions in accordance

with the procedures set forth in EUROCAE/RTCA Document ED-14G/DO-160G.

Short-Time Operating Low Temperature

Test

Short-Time O perating Hig h Temperature

Test

U

Temperature Test

extended to -40 °C

extended to -40 °C

+85 °C

Short-Time Operating High

Temperature Test +70 °C

Category U – Curve G

Susceptibility

26 RT6512 DV17501.03 Issue 06 April 2018

Abnormal: 20.5...32.2 V

Emergency operation: 18.0 V

Radiated Susceptibility: Cat. W

Waveform A Level 3

Cable bundle tests:

Waveform Z Level 3

Page 27

Becker Avionics

General Description

Environmental Test

Section

Category

Remarks

Lightning Direct Effect s

23

X

no test performed

Icing

24

X

no test performed

Electrostatic Discharge (ESD)

25

A

-

Fire, Flammability

26

X

no test performed

Device

Approval

RT6512-(XXX)

EASA.21O.10060121

Number

Description

EASA ETSO-2C169a

"VHF Radio Communication T r ansc eiver Equ ipment Operating within Radio

FAA TSO-C169a

"VHF Radio Communication Transceiver Equipment Operating within Radio

EASA ETSO-2C128

"Devices That Prevent Blocked Channels Used in Two-Way Radio

FAA TSO-C128a

"Equipment That Prevents Blocked Channels Used in Two-Way Radio

Number

Description

EUROCAE ED-23C

"MOPS for Airborne VHF Receiver-Transmitter Operating in the Frequency

EUROCAE ED-67

"MOPS for Devices That Prevent Unintentional or Continuous

EUROCAE ED-18

"Audio Systems Characteristics and Minimum Performance Specifications"

EUROCAE ED-12C

"Software Considerations in Airborne Systems and Equipment Certification"

EUROCAE ED-14G

"Environmental Conditions and Test Procedures for Airborne Equipment"

RTCA DO-207

"MOPS For Device that Prevent Blocked Channels Used IN 2-Way-Radios

EUROCAE ED-80

"Design Assurance Guidance for Airborne Electronic Hardware"

FCC Part 87

"FCC-Standard Part 87 – Aviation Services"

Certifications

The remote-controlled VHF transceiver RT6512 is certified.

1.8.10.1 RT6512 meets the Requirements of:

Technical Data

Frequency Range 117.975 to 137.000 MHz"

Frequency Range 117.975 to 137.000 MHz"

Communications Due to Unintentional Transmissions"

Communications Due to Unintentional Transmissions"

1.8.10.2 Guidelines followed for Design and Development

RTCA DO-186B

Range 117.975 - 137.000 MHz"

Transmissions"

RTCA DO-170

RTCA DO-214A

RTCA DO-178C

RTCA DO-160G

Communications due to Unintentional Transmissions"

RTCA DO-254

DV17501.03 Issue 06 April 2018 RT6512 27

Page 28

General Description

Becker Avionics

Technical Data

Number

Description

ITU Radio Regulations,

ITU Radio Regulations.

ARINC

Mark 33 Digital Information Transfer System (DITS), Part 1

EIA-422-B

Electrical Characteristics of Balanced Voltage Digital Interface Circuits,

Volume 1

SPECIFICATION 429

PART 1-17

GAMA Pub. No 11

Functional Description, Electrical Interface, Label Assignments and Word

Formats

ARINC 429, GENERAL AVIATION SUBSET

TIA/EIA-422-B

1.8.10.3 FCC Approval Radiofrequency radiation exposure information:

This equipment com plies with FC C rad iatio n exp osure lim its set f orth f or an uncon trolled enviro nm ent.

This equipment should be installed and operated with minimum distance of 50 cm between the

radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate ra dio frequency energ y and, if not installed an d used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this e quipment in a residential ar ea is likel y to cause har mful interfe rence in which c ase

the user will be required to correct the interference at his own expense.

NOTE:

This device complies with Part 15 of the FCC Rules [and with Industry Canada licence-exempt

RSS standard(s)].

Operation is subject to the following two conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may cause

undesired operation.

NOTE:

Changes or modifications made to this equipment not expressl y approved by Beck er Avionics may

void the FCC authorization to operate this equ ipment.

28 RT6512 DV17501.03 Issue 06 April 2018

Page 29

Becker Avionics

General Description

1.9 Order Code

Qty

VHF-AM Transceiver

1

Art.-No.: 0644.927-910

1

Art.-No.: 0637.300-910

1

Art.-No.: 0649.643-910

Qty

Mounting Tray

1

Mounting Tray MT6512-(01)*, vertical position

Article-No. 0644.722-284

Qty

Connector Kit

CK6512-C;

Article-No. 0642.568-954

CK6512-S;

Article-No. 0642.551-954

Qty

Antenna

-

Please use only antennas (50 Ohm, vertically polarized with

--

Qty

Available Documentation

1

DV17501.03 Installation & Operation (English)

Article-No. 0645.702-071

1

DV17501.04 Maintenance & Repair (English)

Article-No. 0645.710-071

RT6512

RT6512-(100)

Frequency Range 118.000-136.975 MHz

RT6512-(200)

Frequency Range 118.000-155.975 MHz

RT6512-(201)

* install RT6512 using MT6512 to meet the conditions for DO160G, section 7 and 8

(see "Environmental Conditions", page 26).

Frequency Range 118.000-155.975 MHz + Emergency Mode

Accessories

Order Code

• Connector D-Sub, 37pin, female (crimp version),

• Connector housing,

1

• Label "COMM",

• SK504; Antenna Connector BNC for coax cable

• Connector D-Sub, 37pin, female (solderin g versio n) ,

• Connector housing,

1

• Label "COMM",

• SK504; Antenna Connector BNC for coax cable

coaxial cable) which are certified to one of the following TSOs:

TSO C37

TSO C38

TSO C169.

DV17501.03 Issue 06 April 2018 RT6512 29

Page 30

General Description

Becker Avionics

Order Code

Blank Page

30 RT6512 DV17501.03 Issue 06 April 2018

Page 31

Becker Avionics

Installation

Packaging, Transport, Storage

The packaging mater ial or parts of it are inf lammable. If disposed improperly,

2 Installation

This manual should be available close to the device when performing the tasks below.

Careful planning should be applied to achieve the desired performance and reliability from the product.

Any deviations from the installation instructions prescribed in this document are under own

responsibility.

In this chapter you can read about:

2.1 Packaging, Transport, Storage ................................................................................................... 31

2.2 Device Assignment ..................................................................................................................... 32

Scope of Delivery .............................................................................................................. 32

Additional Required Equipment (optional) ........................................................................ 32

Type Plate ......................................................................................................................... 33

Meaning of Status LEDs ................................................................................................... 33

2.3 Mounting Requirements .............................................................................................................. 34

Mounting Distance ............................................................................................................ 34

Grounding ......................................................................................................................... 34

Antenna Cables ................................................................................................................ 35

Antenna Installation .......................................................................................................... 36

2.4 Dimensions.................................................................................................................................. 39

RT6512 ............................................................................................................................. 39

RT6512 with Mounting Tray MT6512 ............................................................................... 40

2.5 Connector Pin Assignments ........................................................................................................ 41

Connector P1 (RT6512) .................................................................................................... 41

2.6 Equipment Configuration Samples ............................................................................................. 43

RT6512 with RCU6512 ..................................................................................................... 43

RT6512 with RMU5000..................................................................................................... 43

RT6512 with ARINC 429 Controller .................................................................................. 43

2.7 Aircraft Wiring .............................................................................................................................. 44

RT6512-(XX0) with RCU6512 as Primary Controller ....................................................... 45

RT6512-(XX0) with ARINC 429 Controller ....................................................................... 46

RT6512-(XX1) with ARINC 429 Controller ....................................................................... 47

2.8 Post Installation Tests ................................................................................................................. 48

Mechanical Installation and Wiring Check ........................................................................ 48

Power Supply .................................................................................................................... 48

Receiver / Transmitter Operation ...................................................................................... 48

Antenna Check ................................................................................................................. 48

Interference Check ............................................................................................................ 48

Flight Test Check .............................................................................................................. 50

2.1 Packaging, Transport, Storage

Visually inspect the package contents for signs of transport damage.

Packaging Material and Transport

We recommended keeping the packaging material for reuse, in the case of a return shipment.

Improper or faulty packaging may lead to transport damages.

Make sure to transport the device always in a safe manner and with the aid of suitable lifting

equipment, if necessar y. Do never use the electric connecti ons for lifting. Bef ore transport the unit, a

clean and level surface should be prepared. Protect all electrical connections while handling the unit.

First Device Checkup

• Check the device for signs of transport damages.

• Please verify if the indications on the type plate correspond to your purchase order.

• Check if the equipment is complete ("Scope of Delivery", page 32).

DV17501.03 Issue 06 April 2018 RT6512 31

by burning, toxic fumes may develop.

Page 32

Installation

Becker Avionics

Device Assignment

Storage

If you do not wish to mount and insta ll the de vice im medi atel y, mak e sure to stor e it in a dr y and clean

environment. Make sure that the device is not stored near strong heat sources and that no metal

chippings can get into the device connectors.

2.2 Device Assignment

This manual is valid for the following devices:

• RT6512-(100)

• RT6512-(200)

• RT6512-(201)

Scope of Delivery

• Manuals

o Installation & Operation manual (English)

• VHF-AM transceiver

o RT6512 (corresponding to your ordered version)

• Authorized Release Certificate (EASA Form 1)

Additional Required Equipment (optional)

• Mounting tray MT6512 (for RT6512 to meet the conditions for DO-160G section 7 and 8)

• Connector kit + cables

• Antenna + antenna cables

• Control unit (controlling and operating RT6512)

Details see "Accessories", page 29.

32 RT6512 DV17501.03 Issue 06 April 2018

Page 33

Becker Avionics

Installation

Type Plate

S/N:

Unique number of the particular device

A/N:

Article number

DOM:

Date of Manufacturing

Software:

Compliance and Certificat ions

The device type defined by the type plate (on the housing).

Example:

Figure 5: Type Plate (Example)

Explanation:

P/N: Type designation:

RT6512: Remote-Controlled VHF-AM transceiver

Options:

(100): Frequency Range 118...136.9916 MHz

(200): Frequency Range 118...155.975 MHz

(201): Frequency Range 118...155.975 MHz + Em ergency Mode

Device Assignment

Corresponding to the displayed version (see product label)

Corresponding to the displayed text and logos (see product label)

Meaning of Status LEDs

Three front panel LEDs indicate basic information about overall equipment status.

For details, please see "Error Indication" page 55.

DV17501.03 Issue 06 April 2018 RT6512 33

Page 34

Installation

Becker Avionics

The device must not be opened after factory exit.

air circulation min 15 (0.59)

air circulation min 15 (0.59)

6x Ø5.3 (Ø0.21)

Mounting Requirements

2.3 Mounting Requirements

The installation of the device(s ) depends on the t ype of aircraft and its equipment a nd therefore onl y

general information can be given in this sect ion.

•

• When installing the device, make sure the heat dissipator of the device

receive sufficient air. Keep an efficient distance between other heat

producing devices in order to ensure proper circulation of the cooling air.

• Make sure that the mounting support is not exposed to external heat flux.

• The RT6512 is designed for vertical and hor i zo nta l mount in an area, which

provides sufficient convection cooling. A forced cooling is not required if the

RT6512 is installed according to the mounting requirements above.

• Refer to FAA AC 43.13-2B Chapter 2 p. 204 for installation methods.

• Install RT6512 using mounting tray MT6512 to meet the conditions for

DO-160, section 7 and section 8. For details see "Environmental

Conditions", page 26.

Mounting Distance

Dimensions mm (in ch)

Figure 6: RT6512 with MT6512 - mounting area

Grounding

Provide correct radio bonding.

Make sure that the grounding contact area is adequate and that the

connection has low resistance and low inductance. Never use a

grounding point on paint-coated surfaces!

The RT6512 has a threaded grounding bolt at the front side of the unit.

• Use this point as grounding contact.

• Type: Threaded bolt M4 (stainless steel)

For details, please refer to FAA AC 43.13-2B Chapter 2 p. 207.

34 RT6512 DV17501.03 Issue 06 April 2018

Page 35

Becker Avionics

Installation

Antenna Cables

The total attenuation of each antenna conn ection, including cabl es, connectors,

All signal characteristics are defined for antenna port of RT6512.

cable type

maximum loss @ 118 MHz

maximum loss @ 156 MHz

RG400

15.5 dB/100 m

18.1 dB/100 m

RG142

13.6 dB/100 m

15.7 dB/100 m

RG393

7.3 dB/100 m

8.4 dB/100 m

ECS310801

-

4.5 dB/100 m

ECS310701

-

3,5 dB/100 m

microwave switch (if used), etc. shall be as lo w as possibl e.

An aircraf t installation should be verified for rec eiving sensitivity in accordance

with ICAO Annex 10, Vol. 3, Part II, §2.3.2.2.1

Observe manufacturer data for characteristic attenuation of the selected cable

type, connectors, microwave switch, etc.

2.3.3.1 Attenuation: Cable length versus coax cable type

Data below shall be used as guideline only.

Mounting Requirements

DV17501.03 Issue 06 April 2018 RT6512 35

Page 36

Installation

Becker Avionics

Penetration of the pressurized cabin on a pressurized aircraft requires

Radiation risk:

The aircraft's manual for antenna installation has to be observed.

Mounting Requirements

Antenna Installation

For antenna installation, refer always to the manufacturer´s maintenance documentation for the

aircraft. Carry out the antenna installation in accordance with AC 43.13-2B Chapter 3.

additional data, which are not contained in this installation manual.

A safe distance to the installed antenna must be ensured by corresponding

installation measures around human body damage (e.g. at the eyes) and/or

avoid the inflammation of combustible materials by radiated energy.

2.3.4.1 Required Antenna Type

• Vertical polarized 50 Ω broadband aircraft COM antenna.

• The antenna must be able to radiate RF energy evenly and omnidirectional.

2.3.4.2 Antenna Mounting Location

Careful planning should be applied to achieve the desired performance and reliability of the product.

Any deviations from the installation instructions prescribed in this document are under the installer’s

own responsibility.

• The aircraft-certifying inspector could support you in questions about to achieve best

results into all directions (installation instructions must be fully complied with).

• For aircraft with metal fuselage, we recommend a rod antenna.

o The antenna is mounted vertically (as possible) on or under the fuselage.

o Location should be even and in a safe distance from horizontally screening metal

parts (propeller, undercarriage, vertical metal fins etc.), for maximum radio range

The picture shows a typical location for top and bottom antenna installation.

into all (horizontal) directions.

Figure 7: Antenna Installation

• VHF Com 1 and VHF Com 2 can also be mounted on the top with at least ½ wavelength

(of the antenna operating frequency) distance between antennas and provided an

antenna separation of more than 45 dB.

36 RT6512 DV17501.03 Issue 06 April 2018

Page 37

Becker Avionics

Installation

Mounting Requirements

Carbon fibre is conducting and may shield the antenna!

• Distance to other aircraft antennas (COM, NAV antennas), should be at least 1.5 m/5 ft.

• The antenna mounting area should be as flat as possible.

• When two radios are used:

o It is required to have an antenna separation of at least 45 dB. This needs to be

guaranteed by the installer.

o It could happen that operational degradations ma y apply, this needs to be

documented from the installer and approved for airworthiness

• Make sure that the metallic contact between aircraft surface/structure and the antenna

cable outer conductor (shield) is adequate/solid.

o Never use a location on paint-coated surfaces!

o The electrical contact shall remain with low resistance even under vibration.

• For wood and fiberglass (GRP) aircraft (reinforcing the mounting location):

o 3 or 4 aluminum strips (each 60 cm/2 ft long/5 cm/2 in wide) are recommended.

o The stripes shall be placed (mostly) horizontally with a shape as a star or cross.

o These placed counter weights must be centrally screwed together with the

antenna socket to ensure a continuous, electrically good contact.

• For aircraft with non-metallic surface structure inside the fuselage:

o A metal foil (min. 60x60 cm/2x2 ft) can be used.

o The antenna socket should be placed in the foil center, in add ition with a metallic

ground contact support plate.

• For aircraft with fuselage and/or tail-fin made of non-conductive material:

o A vertical folded top antenna is suitable.

o The installation should be made preferably during manufacturing the tail-fin.

• Careful sealing of all holes/openings of the outer skin is mandatory.

o Make sure, that electrical contacts remain continuously good, even under bad

environmental conditions.

o Use only high quality 50 Ω coax cable type RG400 or higher quality.

o Avoid any sharp cable bend (radius > 50 mm), and any excessive coax cable

length.

o Place all wiring including antenna cable away from other wiring which carries

heavy AC currents and away from any aircraft controls.

• Any operating kinematics, trimming and all control handles must be absolutely free in all

directions.

• Ensure the BNC antenna plug is not shortened between inner and outer connector

(ohmmeter).

• Check the antenna matching:

o Using 50 Ω SWR meter over the whole frequency range and check for

VSWR < 3:1.

o It may be helpful or necessary to change slightly the length of the middle radiator,

or counter weight length for optimized antenna efficiency and matching.

DV17501.03 Issue 06 April 2018 RT6512 37

Page 38

Installation

Becker Avionics

Pin No.

Pin Name

I/O

Function

P1-26

/RX_ATT

IN

Reduces the RF gain of the RX section

Pin No.

Pin Name

I/O

Function

P1-7

/PTT

IN

Push-To-Talk key

Mounting Requirements

2.3.4.3 Recommendation for Installation of two RT6512 in one Aircraft

This information provi des guidance to installers whe n perform ing installations with two RT6512 radios

on-board the same aircraft.

In order to minim ize the risk of cr oss talk issues, s pecial care has to be a pplied during the installation

of the antennas, as described in "Antenna Installation" on page 36 of this document. Becker

recommends to configure the receiver attenuation functionality in the RT6212 and to perform the

related wiring as described here.

2.3.4.4 Radio Setting and Wiring for dual installation

To use the RT651 2 in a dual COM installatio n, an attenuation function can be performed using the

following procedure.