Page 1

BECK-O-TRONIC 4

Version: Centronic

en Assembly and Operating Instructions

Door control unit

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Table of contents

Contents .............................................................................................................. 3

General ............................................................................................................... 3

Warranty .............................................................................................................. 4

Safety instructions ................................................................................................ 5

Intended use ........................................................................................................ 6

Explanation of displays and buttons ....................................................................... 7

Programming the remote control ........................................................................... 8

Deleting transmitters ............................................................................................ 9

Overwriting the master transmitter ......................................................................... 9

Installation .......................................................................................................... 10

Wiring ................................................................................................................. 10

Configuration ...................................................................................................... 11

Maintenance ....................................................................................................... 15

Cleaning ............................................................................................................. 16

Technical data ..................................................................................................... 17

Connecting diagram ............................................................................................ 18

Declaration of conformity ..................................................................................... 19

2

Page 3

Contents

General

This control unit is a high-quality product with many features and advantages:

▪ simple, convenient connection

▪ easy to handle and highly flexible

▪ automatic limit position detection

▪ defined buttons for UP, STOP and DOWN, also on the hand-held transmitter

▪ modular system thanks to plug-in radio and sensors

▪ design with clear display of operating status and error messages

▪ optical safety edge connectable without external sensor

Please observe these Assembly and Operating Instructions when installing and setting

the equipment.

Caution

Denotes a potentially hazardous situation. If this is not

avoided, injuries may result.

Attention

Denotes a potentially hazardous situation. If this is not

avoided, the product or something in its vicinity may be

damaged.

Note

Denotes user tips and other useful information.

3

Page 4

Warranty

Structural modifications and incorrect installation which are not in accordance with

these and our other instructions can result in serious injuries, e.g., crushing of limbs.

Therefore, structural modifications may only be carried out with our prior approval and

strictly in accordance with our instructions, particularly the information contained in

these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is

not permitted.

The end product manufacturer and fitter have to ensure that all the relevant current

statutory, official and, in particular, EMC regulations are adhered to during utilisation of

our products, especially with regard to end product manufacture, installation and cus‐

tomer advice.

4

Page 5

Safety instructions

The following safety instructions and warnings are intended to avert hazards and to

prevent property damage and personal injury.

Please keep the instruction manual safe!

Caution

▪ Work on the electrical equipment may only be carried out by a quali‐

fied electrician.

▪ Ensure compliance with legal provisions (safety, accident preven‐

tion), in particular the provisions of the employers’ liability insur‐

ance associations (BGR 232) and EN 12453 “Safety in use of power

operated doors” as well as the pertinent VDE and EN standards.

▪ The engineer responsible for fitting the system must ensure proper

installation, instruction of the operator in its use and issue of the CE

mark.

▪ The operator must ensure that the system is only operated in per‐

fect condition and that the safety devices are checked regularly by

an expert to ensure they are in full working order.

▪ A damaged mains connecting cable must be replaced immediately

by a qualified electrician.

▪ When using roller doors, the customer must ensure that the roller

shutter curtain is protected and cannot cause any dangerous situa‐

tions, e.g. by overrunning a limit position.

▪ The control unit is designed to have a service life of 100,000 operat‐

ing cycles.

▪ Drives with a H05VV-F connecting cable may only be used indoors. If

the cable is installed outdoors, it must be placed in a protective

conduit.

5

Page 6

Intended use

The type of control unit described in these instructions may only be used for the opera‐

tion of tubular drives in roller doors which have fixed stops at the limit positions or a

cover on the barrel (EN 12453). The radio receiver can be operated using any transmit‐

ter of the Centronic range of control units (with the exception of transmitters with a time

switching function and / or sun protection function). For travel in the DOWN direction in

maintained operation, a closing edge safety device is necessary.

This type of control unit must not be used in potentially explosive areas.

Other applications, uses and modifications are not permitted in order to protect the

safety of the users and others, since these actions can impair the system’s safety and

carry the risk of personal injury and property damage. The manufacturer does not ac‐

cept liability for damage or injury arising from such actions.

Always observe the information in these instructions when operating or repairing the

system. The manufacturer does not accept liability for damage or injury resulting from

improper use.

6

Page 7

Explanation of displays and buttons

FUNK

A

C

E

B

D

F

A) Radio-PRG button

B) Programming button on the radio re‐

ceiver

C) Programming button on the transmit‐

ter

D) LED

E) Channel selection button

F) DIP switch

(DIP ON: Defined travel buttons Up, Stop,

Down

DIP OFF: Pulse sequence Up – Stop –

Down – Stop etc.)

7

Page 8

Programming the remote control

Note

Operate the programming button on the transmitter using a suitable

cylindrical tool (e.g. a ballpoint pen).

Programming the first transmitter (master transmitter)

Press the programming button on the radio receiver (B) for 3 seconds.

[ The LED (D) flashes and the radio receiver goes into programming mode for 3

minutes.

Then press the programming button on the transmitter (C) for 3 seconds.

[ The LED on the hand-held transmitter lights up for 3 seconds and the LED (D)

goes out.

Æ Programming is thereby completed and the control unit switches back to the normal

operating status.

Now close the cover of the control unit again using the four cover screws.

Programming additional transmitters

Note

In addition to the master transmitter, up to 7 further transmitters can

be programmed in the radio receiver.

Press the programming button (C) of the master transmitter for 3 seconds.

[ The LED (D) lights up once to confirm.

Now press the programming button of a new transmitter which has not yet been pro‐

grammed in the radio receiver for 3 seconds. This activates the programming mode of

the radio receiver for a new transmitter for 3 minutes.

[ The LED (D) lights up once to confirm.

Now press the programming button of the new transmitter again for 3 seconds.

[ The LED (D) lights up twice to confirm.

Æ The new transmitter has now been programmed.

8

Page 9

Deleting transmitters

Deleting individual transmitters

Note

The programmed master transmitter cannot be deleted. It can only be

overwritten.

Press the programming button (C) on the master transmitter for 3 seconds.

[ The LED (D) lights up once to confirm.

Now press the programming button of the transmitter to be deleted for 3 seconds.

[ The LED (D) lights up once to confirm.

Then press the programming button of the transmitter to be deleted again for 10 sec‐

onds.

[ The LED (D) lights up twice to confirm.

Æ The transmitter has now been deleted from the radio receiver.

Deleting all transmitters (except the master transmitter)

Press the programming button (C) on the master transmitter for 3 seconds.

[ The LED (D) lights up once to confirm.

Press the programming button (C) on the master transmitter again for 3 seconds.

[ The LED (D) lights up once to confirm.

Press the programming button (C) on the master transmitter again for 10 seconds.

[ The LED (D) lights up twice to confirm.

Æ All transmitters (except the master transmitter) have now been deleted from the ra‐

dio receiver.

Overwriting the master transmitter

Press the programming button on the radio receiver (B) for 3 seconds.

[ The LED (D) flashes and the radio receiver goes into programming mode for 3

minutes.

Now press the programming button of the new master transmitter for 10 seconds.

[ This is confirmed by the LED (D) going out.

Æ The new master transmitter has now been programmed and the old master trans‐

mitter overwritten.

9

Page 10

Installation

Open the cover of the control unit. Unplug and remove the keyboard overlay from the

control unit and carefully place the cover to one side.

Remove the required cut-outs in the bottom part of the housing.

Note

Cut in at the edges to make the cut-outs easier to remove.

Use the enclosed cardboard drilling template to drill the holes for attaching the housing

to the wall.

Wiring

Connection of the motor, outdoor light/advance warning light, light barrier, ex‐

ternal key-operated push-button and bottom rail sensor

Connect the individual pieces of equipment as shown in the connecting diagram.

Caution

Electrical work may only be carried out by qualified electricians or

trained personnel. Always disconnect the safety mains plug before

connecting the equipment.

Note

First, pull the insert sleeves over the connecting cable and then push

the insert sleeves into the bottom part of the housing once all of the

wires have been connected.

10

Page 11

Configuration

1

1

4

72

5

83 6

ON

DIP

1

4

72

5

83 6

ON

DIP

1

2

3

1

4

7

2

5

83 6

ON

DIP

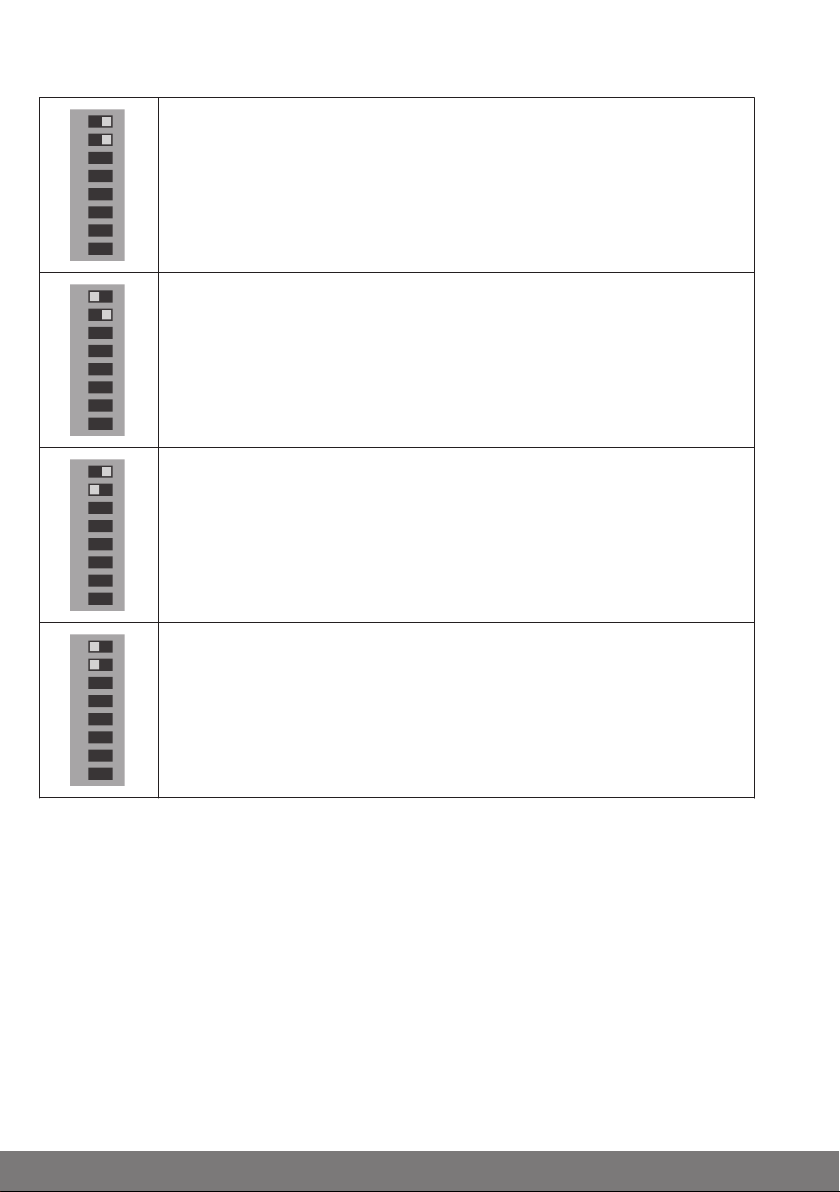

Using the 8 DIP switches (1), you can configure the con‐

trol unit according to your requirements:

▪ Mode

▪ Closing edge safety device

▪ Outdoor light or advance warning light

▪ Automatic closing

Factory settings

Dead-man operating mode factory setting:

Maintained operation mode factory setting:

(only with safety contact rail sensor):

Operating mode

Setting mode

Limit position detection and running time monitoring are off. The con‐

trol unit does not switch off the power to the tubular drive once a limit

position has been reached, so the limit position of the door system can

be adjusted while it is live. This ensures that the door system directly

follows the settings of the limit switches. To disconnect from the power

supply, press the STOP button.

Attention

The setting mode is only suitable for tubular drives with mechanical

limit switching. Once the settings are complete, DIP switch 1 must be

set to OFF (door mode). Operating the door in the setting mode is not

permitted!

11

Page 12

1

4

7

2

5

83 6

ON

DIP

Door mode

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

The control unit is ready for operation. Limit position detection and run‐

ning time monitoring are on.

Closing edge safety device

Caution

In the maintained operation mode, the system must be equipped with a

safety contact rail. The sensor of the safety contact rail must be fitted.

Please ensure that main and auxiliary closing edges are adequately se‐

cured and that the permitted closing edge forces are not exceeded!

Dead-man mode

The door can only be controlled using hard-wired device (e.g. pushbutton). In the DOWN direction, the DOWN button must be permanently

held down. In the UP direction, the door travels in maintained opera‐

tion. The hand-held transmitter can only be used for travel in the UP di‐

rection.

Closing edge stop mode

While the door is closing, the light barrier or safety edge is activated.

The door stops as soon as the safety edge is activated or the light barri‐

er is interrupted. No function in the UP direction. After encountering an

obstruction, the door must first clear the obstruction before it can be

lowered again.

Closing edge reverse travel mode (clearing an obstruction)

While the door is closing, the light barrier or safety edge is activated.

The door stops and reverses as soon as the safety edge is activated or

the light barrier is interrupted. No function in the UP direction.

Closing edge reopening travel mode

While the door is closing, the light barrier or safety edge is activated.

The door stops and travels to the upper limit position as soon as the

safety edge is activated or the light barrier is interrupted. No function in

the UP direction.

12

Page 13

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

Outdoor light or advance warning light

Outdoor light mode

The light is switched on for 2 minutes at every door movement. The

light can also be switched on via the stop or radio light button (with the

4-channel hand-held transmitter).

Automatic staircase lighting

A connected automatic staircase light is triggered for 2 seconds at ev‐

ery door movement. The light can also be switched on via the stop or

remote light button (with the 4-channel hand-held transmitter).

General advance warning

An advance warning is given for 3 seconds before every door move‐

ment. The warning light is only switched off again once a limit position

has been reached.

Advance warning for automatic closing

An advance warning is given for 3 seconds before every automatic clo‐

sure. The warning light is only switched off again once a limit position

has been reached.

Type of warning light: Automatic flashing warning light

e.g.: Rotating beacon.

Type of warning light: Pulsed warning light

The warning light does not flash automatically, so in order to create a

flashing effect, the output is pulsed at 1 Hz.

13

Page 14

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

1

4

7

2

5

83 6

ON

DIP

Automatic closing

Automatic closing deactivated.

Automatic closing without light barrier reduction

The door closes after a delay of 1 minute. If the door encounters an ob‐

struction, automatic closing is aborted after 5 unsuccessful attempts.

The door must then be moved to the lower limit position using the but‐

tons on the control unit or a hard-wired device.

Automatic closing with light barrier reduction to 3 seconds

The door is closed after a delay of 1 minute. This time is reduced to 3

seconds by passing the light barrier. If the door encounters an obstruc‐

tion, automatic closing is aborted after 5 unsuccessful attempts. The

door must then be moved to the lower limit position using the buttons

on the control unit or a hard-wired device.

Automatic closing with light barrier reduction to 15 seconds

The door is closed after a delay of 1 minute. This time can be reduced

to 15 seconds by passing the light barrier. If the door encounters an

obstruction, automatic closing is aborted after 5 unsuccessful at‐

tempts. The door must then be moved to the lower limit position using

the buttons on the control unit or a hard-wired device.

14

Page 15

Sensors for safety edges

12

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1. DIP switch

USA (bottom rail sensor)

configuration

2. Sensor

Safety edge with 1k2 Ohm terminating resistor without testing

Safety edge with 1k2 Ohm terminating resistor with testing

The safety edge is tested during every closing movement: Once the

pre-limit switch is activated, the safety edge must be activated within 2

seconds (positive testing)

These settings are only possible if the plug-in sensor for

the safety edges is fitted.

Pneumatic safety edges are tested for safety-related

reasons during every downward movement. This proc‐

ess is called testing.

Safety edge with 8k2 Ohm terminating resistor without testing

Safety edge with 8k2 Ohm terminating resistor with testing

The safety edge is tested during every closing movement: Once the

pre-limit switch is activated, the safety edge must be activated within 6

seconds (positive testing)

Optical edge from Fraba

Note

With pneumatic safety edges (testing), a pre-limit switch (Item no.

4932 100 012 0) must always be connected.

Maintenance

This control unit is maintenance-free.

15

Page 16

Cleaning

Only clean the outside of the housing with a suitable cloth. Do not use cleaning agents,

as these may damage the plastic.

16

Page 17

Technical data

Dimensions of the housing (W x H x D) 155 x 130 x 50 mm

Housing material PC

Degree of protection IP54, only for installation indoors

Supply voltage 230 V / 50 Hz (connection type Y)

Input power 6 V A

Fuse 2 A slow-blow

Drive switching capacity 1 drive 230 V / 50 Hz maximum 260 V A

Light switching capacity 230 V / 50 Hz maximum 100 W

Control voltage 24 V maximum 100 mA

Temperature range -10°C to +50°C

Radio frequency 868.3 MHz

17

Page 18

Connecting diagram

Radio

USA sensor

Electric

safety edge

Pneumatic safety

edge contact

Pre-limit switch

Light barrier

Motor

white

green

brown

Outdoor light

Warning light

e.g.,

key switch

Emergency stop circuit

or anti-unrolling device

Optical safety edge

from FRABA

External pre-limit switch

for the initiation of testing

at the pneumatic safety edge contact.

Keypad

Radio PRG Em. Stp.

18

Page 19

Declaration of conformity

19

Page 20

4005 630 034 0 30/01/2013

Loading...

Loading...