Page 1

Remote Controlled

Manual DV69802.03

Transponder

Mode S Level 2es

BXP6402

BXP6402-1R-(XX) Class 1

BXP6402-2R-(XX) Class 2

Software Versions:

upwards from Software Version

DSP: SCI1026S305 Version 47

FPGA: SCI1039S305 Version 55

Becker Avionics GmbH • Baden-Airpark B108 • 77836 Rheinmünster • Germany

Installatio n and Operation

Issue 04 June 2018

Article-No. 0584.071-071

+49 (0) 7229 / 305-0 • Fax +49 (0) 7229 / 305-217

http://www.becker-avionics.com • E-mail: info@becker-avionics.com

Page 2

Installation and Operation

Contact data for:

Europe, Asia,

Becker Avionics GmbH

Contact data for:

America,

Becker Avionics Inc

industry standards and the requirements of the responsible aviation authority. The product

Approved Production and Maintenance Organization

Certificates see: http://www.becker-avionics.com/company-about/ →Certificates

Oceania and

Africa

Australia, Japan

Baden-Airpark B108

77836 Rheinmünster (Germany)

Tel.: + 49 (0) 7229 / 305-0

Fax: + 49 (0) 7229 / 305-217

Internet: www.becker -avionics.com

Email: info@becker-avionics.com

Customer Service:

Email: support@becker-avionics.com

Email: info@beckerusa.com

WARNING - USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and ot her inform ation from Becker Avionics GmbH prov ide produc t or system opti ons

for further investigation by users having technical knowledge.

The user is responsib le for m ak ing the final se lect ion of the s ystem and com ponents . The us er has to

assure that all perform ance, endurance, m aintenance, safety requirem ents of the app lication are met

and warnings be observed.

For this the user has to include all aspects of the application to be compliant with the applicable

documentations from Becker Avionics GmbH have to be observed.

To the extent that Bec ker Avionics G mbH provide co mponent or system options based up on data or

specifications provided by the user, the user is responsible for determining that such data and

specifications are suit able and sufficient for all applic ations and reasonably fores eeable uses of the

components or systems.

Term definition: User in the sense of user, installer, installation company.

2 BXP6402 DV69802.03 Issue 04 June 2018

Page 3

Installation and Operation

Preface

Dear Customer,

Thank you for purchasing a Becker Avionics product.

We are pleased that you have chosen our product and we are confident that it will meet your

expectations.

For development and m anufacturing of our product, the guidelines for highest quality and reliability

have been borne in m ind, supplemented by selection of high quality material, re sponsible production

and testing in accordance to the corresponding standards.

Our competent customer support department will respond on any technical question you may have.

Please do not hesitate to contact us at any time.

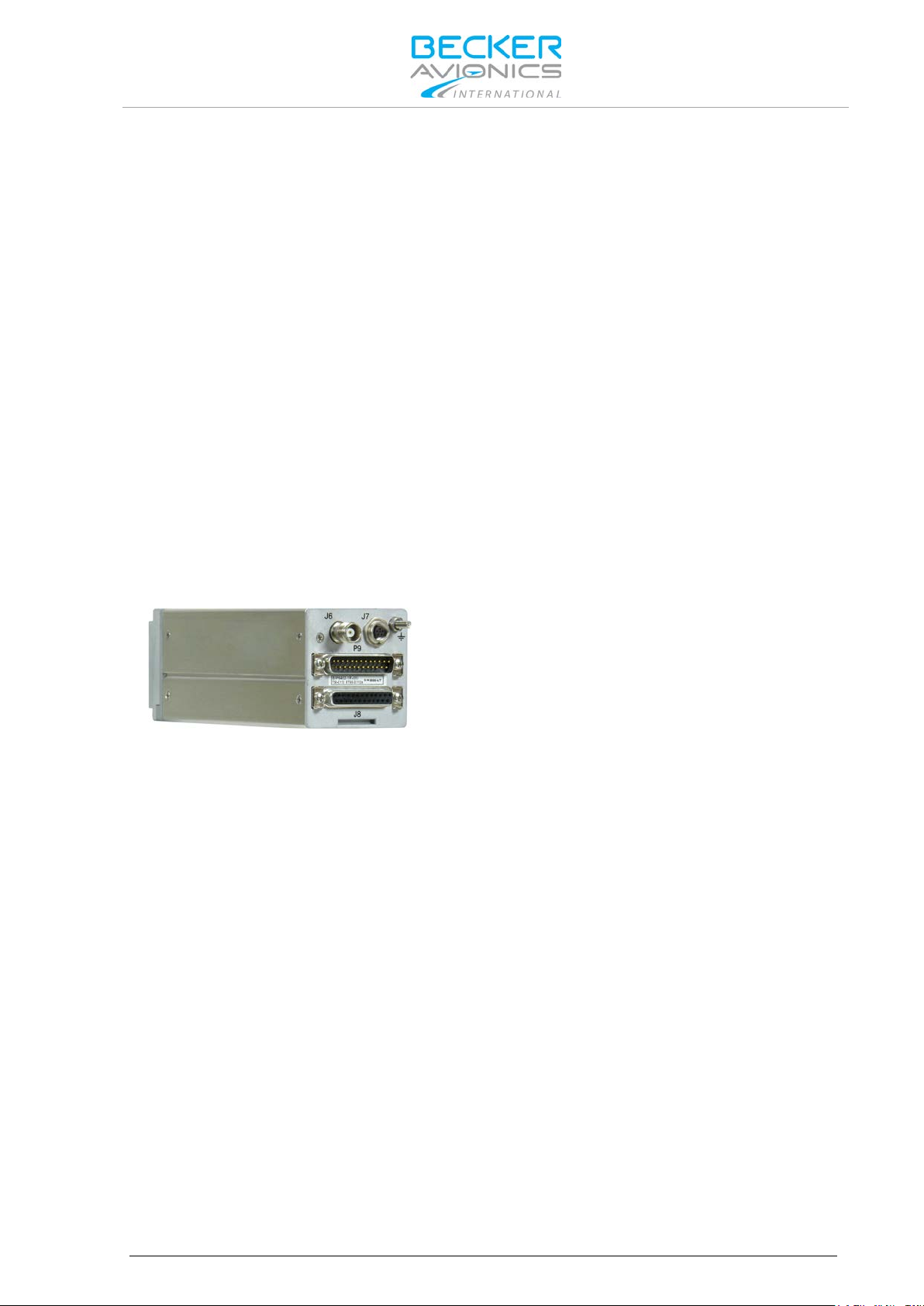

Transponder Design

BXP6402

(Remote controlled Transponder)

DV69802.03 Issue 04 June 2018 BXP6402 3

Page 4

Installation and Operation

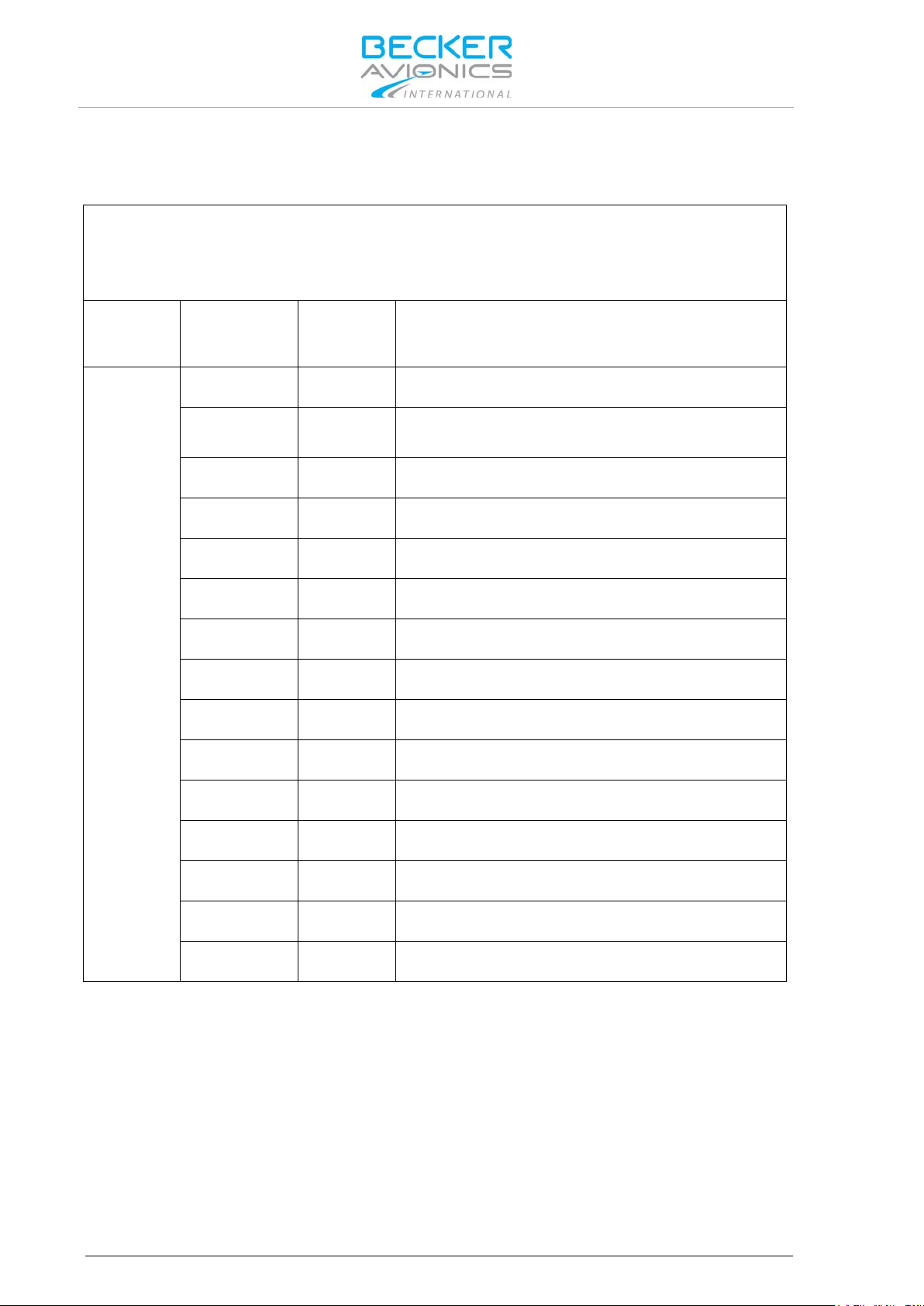

Document: DV69802.03 / issue 04 Article Number 0584.071-071

Added: Address box, User responsibility.

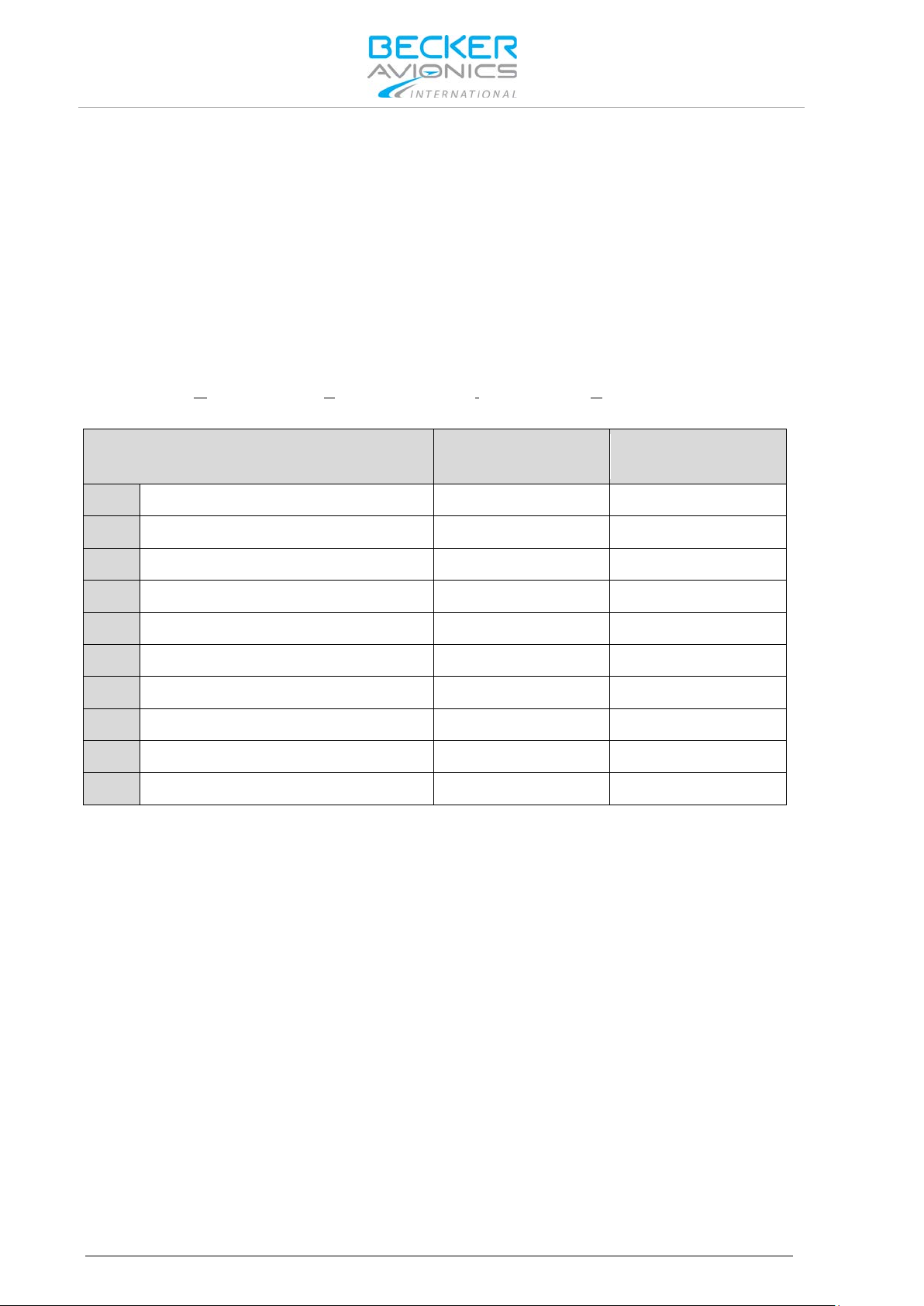

List of Effective Pages and Changes

Only technical relevant modifications are described in this table.

Cover Page 06/2018

Introduction 06/2018

Chapter 1 –4 06/2018

Issue Page No.:

Section /

Chapter

Description

04 all all Changed: Editorial adjustments.

-- Introduction

Updated: User information.

-- 2.4.3 Changed: Dimension drawing AM6400.

-- 2.5.12 Updated: GPS Configuration.

--

--

--

--

--

--

--

--

--

--

--

© by Becker Avionics GmbH / all rights reserved

4 BXP6402 DV69802.03 Issue 04 June 2018

Page 5

Installation and Operation

Table of Contents

1. General Description .................................................................................................................... 11

1.1. Introduction.................................................................................................................................. 12

1.2. Purpose of Equipment ................................................................................................................. 13

1.3. Variants Overview ....................................................................................................................... 14

1.3.1. Software Status ................................................................................................................. 14

1.4. Safety-Conscious Utilization ....................................................................................................... 15

1.5. Restriction for Use ....................................................................................................................... 15

1.6. Technical Data ............................................................................................................................ 16

1.6.1. Electrical Characteristics................................................................................................... 16

1.6.2. Transmitter Data ............................................................................................................... 17

1.6.3. Receiver Data ................................................................................................................... 18

1.6.4. Dimensions & Weight........................................................................................................ 18

1.6.5. Software ............................................................................................................................ 18

1.6.6. Environmental Condition ................................................................................................... 19

1.6.7. Certifications ..................................................................................................................... 20

1.7. Order Code.................................................................................................................................. 21

1.7.1. BXP6402 ........................................................................................................................... 21

1.7.2. Accessories ....................................................................................................................... 21

2. Installation .................................................................................................................................... 23

2.1. Packaging, Transport, Storage ................................................................................................... 24

2.1.1. Packaging Material and Transport .................................................................................... 24

2.2. Device Assignment ..................................................................................................................... 24

2.2.1. Scope of Delivery .............................................................................................................. 24

2.2.2. Additional Required Equipment ........................................................................................ 24

2.2.3. Type Plate ......................................................................................................................... 25

2.2.4. Software/Firmware Status – Functionality ........................................................................ 25

2.3. Mounting Requirements .............................................................................................................. 26

2.3.1. Order of Installation ........................................................................................................... 26

2.3.2. Blind Encoder (BE6400) ................................................................................................... 26

2.3.3. Antenna 1A032 ................................................................................................................. 26

2.4. Dimensions.................................................................................................................................. 27

2.4.1. Transponder BXP6402-XR-(XX) ....................................................................................... 27

2.4.2. Transponder BXP6402-XR-(XX) with Mounting Kit MK4401............................................ 28

2.4.3. Address Module AM6400-1-(01) ....................................................................................... 29

2.4.4. Blind Encoder BE6400 ...................................................................................................... 29

2.4.5. Antenna 1A032 ................................................................................................................. 30

2.5. Electrical Installation ................................................................................................................... 31

2.5.1. Grounding ......................................................................................................................... 31

2.5.2. BXP6402 Connector Layout ............................................................................................. 32

2.5.3. Connector J6 ..................................................................................................................... 32

2.5.4. Connector P9 (Dsub 25-pol male) .................................................................................... 32

2.5.5. Connector J8 (Dsub 25-pol female) .................................................................................. 33

2.5.6. Connector J7 (5-pol female) ............................................................................................. 35

2.5.7. External Suppression ........................................................................................................ 35

2.5.8. External IDENT Push-Button ............................................................................................ 35

2.5.9. Ground Switch .................................................................................................................. 35

2.5.10. Programming of the Address Module ............................................................................... 36

2.5.11. Avionics Data Transfer...................................................................................................... 36

2.5.12. GPS Configuration ............................................................................................................ 37

2.5.13. Remote Control ................................................................................................................. 38

2.6. Settings after Installation ............................................................................................................. 39

2.7. Warning and Failure Indications ................................................................................................. 40

2.8. Aircraft Wiring .............................................................................................................................. 40

2.8.1. BXP6402 with Parallel Encoding Altimeter & GPS Receiver............................................ 41

2.8.2. BXP6402 with Serial Encoding Altimeter & GPS Receiver .............................................. 42

DV69802.03 Issue 04 June 2018 BXP6402 5

Page 6

Installation and Operation

2.8.3. BXP6402 with Serial Encoding Altimeter (Cutout) ............................................................ 43

2.8.4. BXP6402 with RS232 GPS Receiver (Cutout) .................................................................. 43

2.9. Check after Installation ................................................................................................................ 44

2.9.1. Pre-Flight Check Using Self -Test ...................................................................................... 44

2.9.2. Check of the Address Module ........................................................................................... 44

2.9.3. Test and Adjustment of Transmit Frequency .................................................................... 44

2.9.4. Check of Transmit Power .................................................................................................. 44

3. Operating Instructions ................................................................................................................ 45

3.1. Device Description....................................................................................................................... 45

3.1.1. Device Assignment ........................................................................................................... 45

3.1.2. Packing, Transport, Storage ............................................................................................. 45

3.1.3. Scope of Delivery .............................................................................................................. 45

3.1.4. Type Plate ......................................................................................................................... 45

3.2. Operating with CU6401 Control ler .............................................................................................. 45

3.3. Operating with OEM Controller ................................................................................................... 45

4. Index .............................................................................................................................................. 48

List of Figures

Figure 1: Type Plate (example) .............................................................................................................................. 25

Figure 2: Transponder BXP6402-XR-(XX) ............................................................................................................. 27

Figure 3: Mounting Kit MK4401 .............................................................................................................................. 28

Figure 4: Address Module AM6400-1-(01) ............................................................................................................. 29

Figure 5: Blind Encoder BE6400 ............................................................................................................................ 29

Figure 6: Antenna 1A032 ....................................................................................................................................... 30

Figure 7: BXP6402 Connector Layout .................................................................................................................... 32

Figure 8: BXP6402 with Parallel Encoding Altimeter & GPS Receiver ................................................................... 41

Figure 9: BXP6402 with Serial Encoding Altimeter & GPS Receiver ..................................................................... 42

Figure 10: BXP6402 - Serial Encoding Altimeter Connection (not for BE6400) ..................................................... 43

Figure 11: BXP6402 - RS232 GPS Receiver Connection (not with BE6400) ......................................................... 43

6 BXP6402 DV69802.03 Issue 04 June 2018

Page 7

List of Abbreviations

AA

Aircraft Address (24-bit ICAO)

ACAS

Airborne Collision Avoidance System

A/D

Analog/Digital

ADLP

Avionics Data Link Processor

ADS

Comm-A Definition Subfield

ADS-B

Automatic Dependent Surveillance-Broadcast

AI

Aircraft Identifier

AICB

Air Initiated Comm-B

ALT

Altitude or Transponder ALT Mode

AM

Address Module

ARINC

Aeronautical Radio Incorpo rat ed

ATC

Air Traffic Control

ATCRBS

Air Traffic Control Radar Beacon System (US only)

BIT

Built-In Test

BITE

Built-In Test Equipment

CBIT

Continuous Built-In Test

Comm-A

112-bit interrogation containing the 56-bit message field (uplink)

Comm-B

112-bit reply containing the 56-bit message field (downlink)

Class 1

XPDR with transmit power ≥ +21 dBW (125 W) at antenna foot and ≥ 250 W at

Class 2

XPDR with transmit power ≥ +18.5 dBW (70 W) at antenna foot and ≥ 140 W at

CU

Control Unit

DC

Direct Current

Diversity

Diversity receiving and transmitting with two antennas

DME

Distance Measurement Equipment

DPSK

Differential Phase Shift Keying

DV

Document Identification Number

EASA

European Aviation Safety Agency

ELS

Elementary Surveillance, XPDR mode S supports the altitude and the downlinked

EHS

Enhanced Surveillance, XPDR mode S supports additional parameters to

es

e = Extended squitter and s = SI capability

ETSO

European Technical Standard Order

EUROCAE

European Organization for Civil Aviation Equipment

FAA

Federal Aviation Administration

FL

Flight Level

FMS

Flight Management System

FN

Flight Number

List of Abbreviations

Installation and Operation

equipment output, altitude up to 50 000 ft., aircraft speed > 175 kt.

equipment output, altitude up to 15 000 ft., aircraft speed > 175 kt.

aircraft identification (unique ICAO-24-bit-address)

e.g. heading, speed and selected vertical intention

DV69802.03 Issue 04 June 2018 BXP6402 7

Page 8

Installation and Operation

List of Abbreviations

GICB

Ground Initiated Comm-B

GND

Ground

GPS

Global Positioning System

IBIT

Initiated Built-In Test

IC

Integrated Circuit

ICAO

International Civil Aviation O r ganizat io n

ID

Identifier

IDT

Ident (Identification)

IFR

Instrument Flight Rules

I/O

Input and/or Output

Level 2es

Surveillance with Comm A/B capability (transmitting and receiving with data block

LCD

Liquid Crystal Display

Mode S

S = Selective Interrogation of the Transponder

MTL

Minimum Triggering Level

ON

Transponder ON mode (without altitude transmission)

PAM

Pulse Amplitude Modulation

PBIT

Power-on Built-In Test

PN

Part Number

PS

Power Supply

R

Reply

RF

Radio Frequency

RX

Receiver

SBY

Standby mode

SEL

Selection

SI

Surveillance Identifier

SPI

Special Position Identification Pulse

SSR

Secondary Surveillance Radar

STO

Store

SUPP

Supply Voltage DC

TCAS

Traffic Alert and Collision Avoidance System (US)

TIS

Traffic Information Service

TIS-B

Traffic Information Service-Broadcast

TNC

Threaded Naval Connector (coaxial)

TSO

Technical Standards Order

TX

Transmitter

VFR

Visual Flight Rules

VSWR

Voltage Standing Wave Ratio

XPDR

Transponder

up to 112 bit). e = Extended squitter and s = SI capability

8 BXP6402 DV69802.03 Issue 04 June 2018

Page 9

Units

Units

A

Ampere

mA

Milliampere

°C

Degree Celsius

cm

Centimetre

dBm

Power Ratio In Decibel referenced to 1 mW

dB

Decibel

g

Gram

kg

Kilogram

Hz

Hertz

kHz

Kilohertz

MHz

Megahertz

mm

Millimetre

Nm

Nautical Mile

Ohm (Ω)

Resistance

s

Second

V

Volt

mV

Millivolt

W

Watt

"

Inch

Indicates a hazardous situation which, if not avoided, will result in death or

Indicates a hazardous situation which, if not avoided, could result in death or

Indicates a hazardous situation which, if not avoided, could result in minor or

Is used to address practices not related to physical injury.

Safety instructions (or equivalent) signs indicate specific safety-related

Installation and Operation

General Safety Definitions

serious injury.

serious injury.

moderate injury.

instructions or procedures.

DV69802.03 Issue 04 June 2018 BXP6402 9

Page 10

Installation and Operation

The packaging material is inflammable, if it is disposed of improperly by

The device(s) may be installed on an aircraft only by an approved aer on aut ical

The user is responsible for protective covers and/or additional safety measures in

Disposal

burning, toxic fumes may develop.

This product contains materials that fall under the special disposal regulation, which corresponds to

the EC directive for dangerous disposal material. We recommend disposing of the respective materials

in accordance with the respectively valid environmental laws.

Dispose circuit boards via a technical waste dump which is allowed to take on e.g. electrolytic

aluminium capacitors. Do under no circumstances dump the circuit boards with normal waste dump.

Warranty Conditions

company (e.g. EASA Part 145) which shall also examine and verify the

User conversions and changes are not permitted.

Any change made by the u ser excludes any liabilit y on our part (excluding th e work described in th is

manual).

• The device must not be opened.

• Do not make any modifications to the device, except for those described in the manual.

• Make connections to the inputs, outputs and interfaces only in the manner described in

the manual.

• Fix the devices according to the mounting instructions.

We cannot provide any guarantee for other mounting methods.

installation.

Conditions of Utilization

General introductory notes

With this device you bought a product whic h was manufactured and tes ted before delivery with th e

utmost care.

Please take your tim e to read the follo wing notes which you ought to follo w closely during ins tallation

and operation.

Otherwise all claim s under the warranty wi ll becom e void and a reduced s ervice life or even d am ages

must be expected.

order to prevent damages to persons and electric accidents.

Additional Conditions of Utilization

Please refer to "Safety-Conscious Utilization", page 15.

Non-Warranty Clause

We checked the co nte nts o f this publication for com pli anc e with th e as soc ia ted h ar d a nd s of t ware. We

can, however, not exclude discrepancies and do therefore not accept any liability for the exact

compliance. The inf orm atio n in this p ublic ation is r egular ly chec ked, neces sar y co rrec tions will be par t

of the subsequent publications.

10 BXP6402 DV69802.03 Issue 04 June 2018

Page 11

General Description

Introduction

1. General Description

In this chapter you can read about:

1.1. Introduction.................................................................................................................................. 12

1.2. Purpose of Equipment ................................................................................................................. 13

1.3. Variants Overview ....................................................................................................................... 14

1.3.1. Software Status ................................................................................................................. 14

1.4. Safety-Conscious Utilization ....................................................................................................... 15

1.5. Restriction for Use ....................................................................................................................... 15

1.6. Technical Data ............................................................................................................................ 16

1.6.1. Electrical Characteristics................................................................................................... 16

1.6.2. Transmitter Data ............................................................................................................... 17

1.6.3. Receiver Data ................................................................................................................... 18

1.6.4. Dimensions & Weight........................................................................................................ 18

1.6.5. Software ............................................................................................................................ 18

1.6.6. Environmental Condition ................................................................................................... 19

1.6.7. Certifications ..................................................................................................................... 20

1.7. Order Code.................................................................................................................................. 21

1.7.1. BXP6402 ........................................................................................................................... 21

1.7.2. Accessories ....................................................................................................................... 21

The remote controlled Mode S transponder BXP6402-XR-(XX) forms together with a control unit

(e.g. CU6401) an airborne component of the Air Traffic Control (ATC). It works as a Mode S

Secondary Surveillance Radar system with added ADS-B Transmitting Subsystem functionality.

In the selective m ode (Mode S), the Ground Co ntrol c an inter rogate the transp onder ind ividually using

an ICAO 24-bit address, which is unique to the particular aircraft.

BXP6402-XR-(XX) works as a part of the surveillance system in two ways:

• As Mode S transponder which provides responses to ground station interrogations and

allows air traffic control (ATC) to locate, identify and track aircraft.

• As ADS-B Broadcast-Only System which continuously transmits aircraft information.

DV69802.03 Issue 04 June 2018 BXP6402 11

Page 12

General Description

DV69802.04

DV69802.03

General X X

Installation X X

Operation X X

Theory of Operation

X

N/A

Maintenance and Repair

X

N/A

Illustrated Parts List

X

N/A

Modification and Changes

X

N/A

Circuit Diagrams

X

N/A

Certifications X N/A

Attachments X N/A

Introduction

1.1. Introduction

This manual describes the installation and operation of the Mode S transponder BXP6 402-XR-(XX).

The ID label on your device shows the part number for identification purposes (see "Type Plate",

page 25).

Before starting operation of the unit(s) please read this manual carefully, with particular attention to the

description referring to your device(s). This manual also contains several optional elements of the

system (Blin d encoder for example) that m ay not be contained in your delivery package and in t hat

case are not applicable.

For further descriptions we are using the term BXP6402 instead of writing the complete model

number.

The manuals “Maintenance and Repair” (M&R) and “Installation and Operation (I&O) contain the

following sections:

Section

M&R

I&O

12 BXP6402 DV69802.03 Issue 04 June 2018

Page 13

Actual generation of each ADS-B message type and data within each message

General Description

Purpose of Equipment

1.2. Purpose of Equipment

The BXP6402 transponder is a remote controlled unit designed for installation in the avionic

compartment of aircraft.

• All connectors for connection to the aircraft interwiring, adddress module, antenna and

altitude encoder are located at the rear side of the unit.

• Serial interfaces RS422 are available at the unit connectors.

o Control via: Control unit CU6401.

o Control via: "External" unit (e.g. ADLP).

• Easy mounting; to meet the conditions for certification use the mounting method with

Mode S features:

mounting kit MK4401.

• Individual interrogation of the transponder ICAO 24-bit address.

• Support of the SI code (Surveillance Identifier).

• Register capability for elementary surveillance (ELS) and enhanced surveillance (EHS).

• Extended squitters transmission.

• Data link capability.

• GPS receiver connection capability.

• ADS-B Broadcast-Only System Class B0 e.g. broadcasts following data:

o Airborne Position Message

o Surface Position Message

o Airborne Velocity Message

o Extended Squitter Aircraft Status Message

Inherent features:

• Mode A - in this mode, the 4096 character code set on the control head is sent as a reply

to interrogation from a ground station.

• Mode C - in this mode, the encoded altitude is sent in addition to the mode A reply.

The altitude information must be delivered from an external device (e.g. Becker Blind

Encoder BE6400).

• A special identifier pulse (SPI) can be activated by pressing the IDT button in Mode A/C

and Mode S.

• Selftests (BITs). The Initiated Built-In Test (IBIT), the Continuous Built-In Test (CBIT) and

the Power-on Built-In Test (PBIT) are integrated in the transponder.

depends on availability of navigation data and GPS engine capabilities.

DV69802.03 Issue 04 June 2018 BXP6402 13

Page 14

General Description

BXP

6402

-

X R - (

X X

)

Identifier

Model Number

01= Standard

XPDR Class

1= Class 1

2= Class 2

Design

Variants Overview

1.3. Variants Overview

Within the part number, the meaning of "-XR-(XX) " is:

1.3.1. Software Status

Descriptions see "Software/Firmware Status – Functionality", page 25.

Options

R= Remote Controlled

14 BXP6402 DV69802.03 Issue 04 June 2018

Page 15

Excessive pulses on the DC bus of the aircraft may cause damage on electrical

The BXP6402 is to be used inside the declared limits.

1.4. Safety-Conscious Utilization

For safe operation of the product the following notes have to be observed:

• The installation of the Mode S transponder into an aircraft may be carried

out only by an authorized installation company. The country regulations

always have to be observed.

• Use the product only within the specified conditions, see "Technical Data"

page 16.

Power supply:

• Do not connect the unit to AC sources.

• Make sure that the unit is connected to the mandatory DC source, see

"Technical Data" page 16.

• Do not connect the unit with reversed polarity to the DC source.

Circuit breaker:

• If no load is connected to connector P9, pin 6, the unit should be protected

from the aircraft power supply by a dedicated 3 A circuit breaker.

• If an external load is connected to connector P9, pin 6, the circuit breaker

should be a 5 A type.

Address module:

• The programming of the address module AM6400-1 with the ICAO 24-bit

address of the aircraft must be carried out at an installation company or in

the manufacturer factory. A programming kit is available see "Order Code"

page 21.

General Description

Safety-Conscious Utilization

circuits of any installed instrument.

Do not switch ON the device during engine start or shutdown.

1.5. Restriction for Use

DV69802.03 Issue 04 June 2018 BXP6402 15

Page 16

General Description

BXP6402

Specifications

Power supply

10...33 VDC

Typical consumption

50 Mode S replies/s + Squitter

Serial interfaces

RS422

Data link capability

255 GICB registers

DME suppression

input voltage:

< 2 V (no suppression)

output voltage

< 0.5 V (not active)

External Ident input

"0" (active) ≤ 3.5 V

Ground detection input

"ground" ≤ 0.5 V

Power-up time

2 s (including internal self-test)

Internal fuse protection

F 5 A

External fuse protection

T 3 A (circuit breaker)

Operating temperature

Class 1: -40...+55 °C (short-time +70 °C)

Storage temperature

-55...+85 °C

Operating altitude

50 000 ft. max. (class 1)

Mode S

Class 1 or 2, Level 2es

• surveillance identifier (SI code)

Technical Data

1.6. Technical Data

1.6.1. Electrical Characteristics

0.35 A at 14 V

0.20 A at 28 V

in standby Mode:

0.18 A at 14 V

0.13 A at 28 V

> 8 V (suppression)

> 18 V (active)

"1" (not active) ≥ 4.0 V

Isource (shorted to GND) ≤ 10 mA

"airborne" ≥ 2 V

Isource (shorted to GND) ≤ 10 mA

(5 A circuit breaker if an external load is connected to

P9 pin 6)

Class 2: -20...+55 °C (short-time +70 °C)

16 BXP6402 DV69802.03 Issue 04 June 2018

15 000 ft. max. (class 2)

(Class 1=250 W, Class 2=140 W at unit output)

• extended squitter capability

Page 17

BXP6402 (Transmitter Data)

Specifications

Transmit frequency

1090 MHz ± 1 MHz

Transmit modulation

12MOM1D PAM (Pulse Amplitude Modulation)

Transmitter type

Solid state

Transmit power (class 1)

≥ 125 W (+21 dBW) at antenna end terminal and

Transmit power (class 2)

≥ 70 W (+18.5 dBW) at antenna end terminal and

Reply rate capability

Mode A/C:

Mode S squitter rate (approx.)

Acquisition squitter 4/s

Reply code (mode A)

ICAO coding system with 4096 pulse reply possibilities

Altitude code (mode C)

ICAO coding system 100 ft

Altitude code (mode S)

25 ft. or 100 ft. steps

Transmit pulse shape

Pulse width 0.45 µs ± 0.1 µs (mode A/C)

Nominal output impedance

50 Ω

1.6.2. Transmitter Data

General Description

Technical Data

≥ 250 W at unit output

≥ 140 W at unit output

at least 1200 Mode A/C replies/s for a 15 pulse coded

reply, can be limited to 500...1200

Mode S:

at least 50 Mode S replies/s interval (thereof at least

16 long formats)

Extended squitter 1/s

(octal code)

steps from -1000...62700 ft.

(depending on source)

Pulse width 0.5 µs ± 0.05 µs (mode S)

Rise time 0.05...0.1 µs

Fall time 0.05...0.2 µs

DV69802.03 Issue 04 June 2018 BXP6402 17

Page 18

General Description

BXP6402 (Receiver Data)

Specifications

Operating modes

Mode A/C/S, depending on interrogation

Receive frequency

1030 MHz ± 0.1 MHz (mode A/C)

Sensitivity (MTL)

-74 dBm ± 3 dB (for 90% reply rate in mode A/C and

Selectivity

±15 MHz > 40 dB

Dynamic range

≥ 60 dB

Bandwidth

± 3 MHz < 3 dB

Modulation (mode A/C)

PAM (Pulse Amplitude Modulation)

Modulation (mode S)

DPSK (Differential Phase Shift Keying)

Side lobe suppression

3-pulse method (mode A/C),

Nominal impedance

50 Ω

Specifications

BXP6402-XR-(XX)

Front plate HxW

61x61 mm (2.4x2.4 inch)

Device depth (total)

187.7 mm (7.39 inch)

with antenna socket

186,5 mm (7.34 inch)

with address module

218.5 mm (8.6 inch)

Weight BXP6402

≤ 0.7 kg (1.54 lb)

Address module

01

approx. 0.018 kg (0.04 lb)

Technical Data

1.6.3. Receiver Data

1030 MHz ± 0.01 MHz (mode S)

99% in mode S)

±25 MHz > 60 dB

P5 (mode S)

1.6.4. Dimensions & Weight

Mounting kit MK4401

Blind encoder BE6400-

≤ 0.130 kg (0.27 lb)

approx. 0.1 kg (0.22 lb)

1.6.5. Software

The transponder BPX6402-XR-(XX) is controlled by a micro controller. The software criticality is

determined to be Level C in accordance with EUROCAE/RTCA document ED12B/DO-178B.

18 BXP6402 DV69802.03 Issue 04 June 2018

Page 19

Characteristics

Section

Cat.

Condition

Temperature and Altitude

4.0

D1

Equipment tested to Category D1

Low Ground Survival Temperature

4.5.1

D1

-55 C

Low Operating Temperature

4.5.1

D1

-20 C

High Ground Survival Temperature

4.5.2

D1

+85 C

High Short-Time Operating Temperature

4.5.2

D1

+70 C

High Operating Temperature

4.5.2

D1

+55 C

In-flight Loss of Cooling

4.5.4

Z

No auxiliary cooling required

4.6.1

D1

50 000 ft (class 1) for BXP6402-1R-(XX)

Decompression

4.6.2

X

No test performed

Overpressure

4.6.3

X

No test performed

Temperature Variation

5.0

B

5 °C minimum per minute

Humidity

6.0

A

Up to 95% humidity at 50 °C

Shock and Crash Safety

7.0

B

Equipment tested to Category B

8.0

S

Cat. S, vibration test curve M

Explosion Proofness

9.0

X

No test performed

Water Proofness

10.0

X

No test performed

Fluids Susceptibility

11.0

X

No test performed

Sand and Dust

12.0

X

No test performed

Fungus Resistance

13.0

X

No test performed

Salt Spray

14.0

X

No test performed

15.0

Z

Distance for a deflection of Dc = less

Power Input

16.0

B

Equipment tested to Category B

Voltage Spike

17.0

A

Equipment tested to Category A

Audio Freq. Conducted Susceptibility

18.0

B

Equipment tested to Category B

Induced Signal Susceptibility

19.0

A

Equipment tested to Category A

Radio Frequency Susceptibility

20.0

WW

Equipment tested to Category WW

Spurious RF Emission

21.0

B

Equipment tested to Category B

Lightning Induced Transients

22.0

A3E3X

Equipment tested to Category A3E3X

Lightning Direct Effect s

23.0

X

No test performed

Icing

24.0

X

No test performed

Electrostatic Discharge

25.0

A

Equipment tested to Category A

General Description

Technical Data

1.6.6. Environmental Condition

BXP6402-XR-(XX) was tested in accordance with EUROCAE/RTCA ED-14D/DO-160D under

consideration of below listed environmental categories and conditions:

Altitude

Vibration

Magnetic Effect

A1

15 000 ft (class 2) for BXP6402-2R-(XX)

U

Cat. U, vibration test curve G

than 0.3 m

Susceptibility

DV69802.03 Issue 04 June 2018 BXP6402 19

Page 20

General Description

Conformity

BXP6402-XR-(XX)

EASA.21O.322

ETSO-2C112a, class 1 or 2

FAA

TSO-C112, class 2A or 2B

RTCA

DO-181C

EUROCAE

ED-73B, Level 2es

Software

EUROCAE/RTCA ED12B/DO-178B Level C

In accordance with: EURO CAE/RTCA ED-14D/DO-160D

Operating altitude

50 000 ft. max. (class 1)

In-flight loss of cooling

Cat. Z, no auxiliary cooling required

Humidity

Cat. A/+50 °C; 95%, 48 h

Vibration resistance

Cat. S, test curve M

Operational shocks

6 g in any direction

Crash safety

20 g shocks

Magnetic effect

Category Z

Environmental categories

BXP6402-XR-(XX):

Technical Data

1.6.7. Certifications

15 000 ft. max. (class 2)

Cat. U, test curve G

20 g acceleration

[D1Z]BAB[(SM)(UG)]XXXXXXZBABA[WW]B[A3E3X]X

XA

20 BXP6402 DV69802.03 Issue 04 June 2018

Page 21

Qty

Mode S Transponder (remote controlled)

1 BXP6402-1R-(01), class 1

Article-No. 0588.695-915

1

BXP6402-2R-(01), class 2

Article-No. 0588.717-915

Qty

Control unit for BXP6402

1 CU6401-1-(01)

Article-No. 0572.896-915

Qty

Address module

1

AM6400-1-(01)

Article-No. 0572.942-915

Qty

Programming kit for Address module

1 AMP6400-1, parallel int erface

Article-No. 0584.843-954

1

AMP6400-2, USB interface

Article-No. 0604.054-954

Qty

Blind encoder (altitude encoder)

1 BE6400-1-(01)

Article-No. 0592.137-915

Qty

Antenna

1 1A032 Transponder antenna KEC-KC-89 (BNC)

Article-No. 0707.007-952

Qty

Mounting kit for BXP6402

1 Mounting kit MK4401

Article-No. 0556.726-284

Qty

Connector kit CK4401-S (soldering version)

Article-No. 0552.801-954

1

Connector Dsub 25-s

1 Connector housing

1 Label XPDR

Qty

Connector kit CK4401-C (crimp version)

Article-No. 0552.798-954

1

Connector Dsub 25-s

1 Connector housing

1 Label XPDR

Qty

Connector kit CK6400-S (soldering version)

Article-No. 0586.072-954

1

Connector Dsub 25-s

1 Connector Dsub 25-p

2 Connector housing

1 Label XPDR

Qty

Connector kit CK6400-C (crimp version)

Article-No. 0586.064-954

1

Connector Dsub 25-s

1 Connector Dsub 25-p

2 Connector housing

1 Label XPDR

1.7. Order Code

1.7.1. BXP6402

1.7.2. Accessories

General Description

Order Code

DV69802.03 Issue 04 June 2018 BXP6402 21

Page 22

General Description

Qty

Cable, connectors, ...

1 1K046 Cable harness, length 1 m

Article-No. 0604.615-276

1

1SK504 BNC connector for cable RG58U, soldering

Article-No. 0725.706-277

1

1SK503 TNC connector for cable RG58U, soldering

Article-No. 0725.900-277

1

TNC coaxial connector for RG-58C/U, crimp

Article-No. 0551.694-277

1

TNC coaxial connector for RG-223/U, crimp

Article-No. 0551.732-277

1

TNC coaxial connector for RG-58C/U, soldering

Article-No. 0552.781-277

1

BNC antenna connector for RG-58C/U, crimp

Article-No. 0551.708-277

1

BNC antenna connector for RG-223/U, crimp

Article-No. 0551.740-277

1

BNC antenna connector for RG-58C/U and RG-223/ U, s older ing

Article-No. 0552.771-277

Qty

Available Documentation

1 BXP6402 Installation and Operation Manual, English

Article-No. 0584.071-071

1

BXP6402 Maintenance and Repair Manual, English

Article-No. 0584.088-071

1

BXP6402-XR Control Interface Protocol

Article-No. 0590.241-071

1

BXP640X-XX-(XX) Data Transfer Interface Protocol

Article-No. 0590.258-071

Order Code

22 BXP6402 DV69802.03 Issue 04 June 2018

Page 23

Installation

Order Code

2. Installation

This manual must be available close to the device during the performance of all tasks.

Careful planning should be applied to achieve the desired per f ormance and reliability from the product.

Any deviations from the installation instructions prescribed in this document are under own

responsibility.

The BXP6402 transponder is a remote-controlled unit designed for installation in the avionic

compartment of aircraft. The installation of the BXP6402 depends on the type of aircraft and

equipment and therefore only general information can be given in this section.

In this chapter you can read about:

2.1. Packaging, Transport, Storage ................................................................................................... 24

2.1.1. Packaging Material and Transport .................................................................................... 24

2.2. Device Assignment ..................................................................................................................... 24

2.2.1. Scope of Delivery .............................................................................................................. 24

2.2.2. Additional Required Equipment ........................................................................................ 24

2.2.3. Type Plate ......................................................................................................................... 25

2.2.4. Software/Firmware Status – Functionality ........................................................................ 25

2.3. Mounting Requirements .............................................................................................................. 26

2.3.1. Order of Installation ........................................................................................................... 26

2.3.2. Blind Encoder (BE6400) ................................................................................................... 26

2.3.3. Antenna 1A032 ................................................................................................................. 26

2.4. Dimensions.................................................................................................................................. 27

2.4.1. Transponder BXP6402-XR-(XX) ....................................................................................... 27

2.4.2. Transponder BXP6402-XR-(XX) with Mounting Kit MK4401............................................ 28

2.4.3. Address Module AM6400-1-(01) ....................................................................................... 29

2.4.4. Blind Encoder BE6400 ...................................................................................................... 29

2.4.5. Antenna 1A032 ................................................................................................................. 30

2.5. Electrical Installation ................................................................................................................... 31

2.5.1. Grounding ......................................................................................................................... 31

2.5.2. BXP6402 Connector Layout ............................................................................................. 32

2.5.3. Connector J6 ..................................................................................................................... 32

2.5.4. Connector P9 (Dsub 25-pol male) .................................................................................... 32

2.5.5. Connector J8 (Dsub 25-pol female) .................................................................................. 33

2.5.6. Connector J7 (5-pol female) ............................................................................................. 35

2.5.7. External Suppression ........................................................................................................ 35

2.5.8. External IDENT Push-Button ............................................................................................ 35

2.5.9. Ground Switch .................................................................................................................. 35

2.5.10. Programming of the Address Module ............................................................................... 36

2.5.11. Avionics Data Transfer...................................................................................................... 36

2.5.12. GPS Configuration ............................................................................................................ 37

2.5.13. Remote Control ................................................................................................................. 38

2.6. Settings after Installation ............................................................................................................. 39

2.7. Warning and Failure Indications ................................................................................................. 40

2.8. Aircraft Wiring .............................................................................................................................. 40

2.8.1. BXP6402 with Parallel Encoding Altimeter & GPS Receiver............................................ 41

2.8.2. BXP6402 with Serial Encoding Altimeter & GPS Receiver .............................................. 42

2.8.3. BXP6402 with Serial Encoding Altimeter (Cutout) ............................................................ 43

2.8.4. BXP6402 with RS232 GPS Receiver (Cutout) ................................................................. 43

2.9. Check after Installation ................................................................................................................ 44

2.9.1. Pre-Flight Check Using Self Test ...................................................................................... 44

2.9.2. Check of the Address Module ........................................................................................... 44

2.9.3. Test and Adjustment of Transmit Frequency .................................................................... 44

2.9.4. Check of Transmit Power ................................................................................................. 44

DV69802.03 Issue 04 June 2018 BXP6402 23

Page 24

Installation

The packaging material is inf lamm able, if it is dispose d of im properl y by burni ng,

Do not use products with damages!

Packaging, Transport, Storage

2.1. Packaging, Transport, Storage

Visually inspect the package contents for signs of transport damage.

2.1.1. Packaging Material and Transport

The packaging materia l can be kept and reused in the cas e of a return shipment. Improper or f aulty

packaging may lead to transport damages.

Make sure to transport the device always in a safe manner and with the aid of suitable lifting

equipment if necess ary. Do nev er use th e elec tric c onnect ions f or lifting. Befor e the tr anspor t, a cl ean,

level surface should be prepared to place the device on. The electric connections may not be

damaged when placing the device.

First Device Checkup

• Check the device for signs of transport damages.

• Please verify if the indications on the type plate correspond to your purchase order.

• Check if the equipment is complete ("Scope of Delivery", page 24).

toxic fumes may develop.

Storage

If you do not wish to mount and insta ll the de vice im medi atel y, mak e sure to stor e it in a dr y and clean

environment. Make sure that the device is not stored near strong heat sources and that no metal

chippings can get into the device.

2.2. Device Assignment

This manual is valid for the following devices:

• BXP6402-1R-(01) + supplement

2.2.1. Scope of Delivery

2.2.2. Additional Required Equipment

Details see "Accessories", page 21.

• BXP6402-2R-(01) + supplement

• Manuals

o Operating Instructions

• Transponder

o BXP6402 (corresponding t o your ord ered ver sio n)

• Documents of Certifications if available

• Address module AM6400-1-(01) programmed

• Mounting kit

o MK4401

• Connector kit

• Antenna

• Antenna cable

• CU6401 control unit or OEM control unit

24 BXP6402 DV69802.03 Issue 04 June 2018

Page 25

PN:

Example Type designation: BXP6402-1R-(01)

SN:

Unique number of the particular device

AN:

Article number

Software

Compliance and Certifications

Software/Firmware Status

Functionality

CU VER 2x

CU VER 2x

2.2.3. Type Plate

The device type is defined by the type plate (on the housing):

Example:

Figure 1: Type Plate (example)

Explanation:

BXP6402 = Transponder, BXP640X family

Installation

Device Assignment

Options:

-1R-: class 1, remote controlled

-2R-: class 2, remote controlled

(01): standard

Corresponding to the displayed version

Corresponding to the displayed text and logos

2.2.4. Software/Firmware Status – Functionality

The implemented firmware version can be checked with the control unit:

• With control unit CU6401 please see in the "Operating with CU6401 Contro ller ", p age 45.

• With other control unit please see in corresponding user manual.

Units equipped with non-ADS B out capable software can be modified from our Customer Service

Department..

CORE VER 42

FPGA VER 50

CORE VER 47

DV69802.03 Issue 04 June 2018 BXP6402 25

FPGA VER 55

no ADS-B out

ADS-B out

not certified according to TSO-C166b; only

capable for GA Traffic Receiver e.g. FLARM(R)

Page 26

Installation

The device must not be opened.

The installation of the Mode S transponder into an aircraft may be carried out only

The transponder antenna 1A032 is provided with a silicone rubber gasket which

Mounting Requirements

2.3. Mounting Requirements

When installing the device, make sure the heat dissipators of the device receive

sufficient air. Keep an efficient distance of the devices with integrated venti lat or

fans in order to ensure free circulation of the cooling air.

Make sure that the mounting plate is not exposed to external temperature

influences.

The mounting place shall be at least 30 cm from the magnetic aircraft compass, to

avoid any interference to the magnetic compass by the transponder.

2.3.1. Order of Installation

• Installation with MK4401 (mounting kit), first install the mounting frame using three

countersunk screws.

• Loosen the securing-plate from mounting frame.

• Slide the transponder into the mounting.

• Push the security-plate into the locking slot and tighten the securing-plate.

• Carry out removal of the transponder in reversed order.

by an authorized installation company. The country regulations always have to be

observed.

2.3.2. Blind Encoder (BE6400)

For installation of the Becker Avionics Blind Encoder BE6400 the corresponding manual has to be

noticed (BE6400 I&O manual Article-No. 0594.547-071).

• The Blind Encoder BE6400 is intended to be connected to connector J8 of the

transponder.

• The Blind Encoder is direct connected without any interwiring.

• It can be used only in installations that do not require connection of other equipment

utilizing ADLP interface of the transponder.

2.3.3. Antenna 1A032

• Fit the transponder antenna to the bottom of the aircraft at a horizontal, flat location.

o This location should not be in the "shadow" of aircraft structure items.

o The highest range is achieved when the antenna is located at the lo west po int of

the aircraft fuselage.

must also be interposed between the skin of the aircraft and the antenna.

In aircraft having a wooden or plastic airframe an electric counterweight plate or

panel must be located within the fuselage at the antenna location with minimum

dimensions 400x400 mm (15.7x15.7 inch).

2.3.3.1. Antenna Cable

• Cable types RG-58C/U (0.9 dB/m) or RG-223/U (0.6 dB/m) can be used.

o With cable length >2 m between unit and antenna, we recommended cable type

RG-223/U.

• Recommended cable length ≤5 m.

• Complete loss of the antenna cable ≤3 dB.

26 BXP6402 DV69802.03 Issue 04 June 2018

Page 27

Allowable deviation for dimensions without tolerances: DIN ISO 2768 T1 C

xx...6 (±0.3)

>30...120 (±0.8)

>400...1000 (±2.0)

>6...30 (±0.5)

>120...400 (±1.2)

>1000...2000 (±3.0)

CENTER OF GRAVITY

1

61 (2.4 in)

3.4 (0.13 in)

169.8 (6.68 in)

76.8 (3.02 in)

45.3 (1.78 in)

14.5 (0.57 in)

13.3 (0.52 in)

30.65

(1.21 in)

30.5

(1.2 in)

61

(2.4 in)

J8

P9

J7

J6

1

14 25

13

13

25

14

1

2.4. Dimensions

2.4.1. Transponder BXP6402-XR-(XX)

Installation

Dimensions

Dimensions mm (in ch)

access to TX frequency adjustment

Figure 2: Transponder BXP6402-XR-(XX)

DV69802.03 Issue 04 June 2018 BXP6402 27

"Center of Gravity" without address module.

Page 28

Installation

Allowable deviation for dimensions without tolerances: DIN ISO 2768 T1 C

xx...6 (±0.3)

>30...120 (±0.8)

>400...1000 (±2.0)

>6...30 (±0.5)

>120...400 (±1.2)

>1000...2000 (±3.0)

CENTER OF GR AVITY

236 (9.29 in)

8 (0.31 in)

45 (1.77 in)

8.1 (0.32 in)

218.5 (8.60 in)

32.5

(1.28 in)

32.5

(1.28 in)

50 (1.97 in)

65 (2.56 in)

71.1 (2.8 in)

40.5

(1.59 in)

128 (5.04 in)

Ø5

(Ø0.19 in)

Ø10

(Ø0.39 in)

A

A

Dimensions

2.4.2. Transponder BXP6402-XR-(XX) with Mounting Kit MK4401

Dimensions mm (in ch)

"Center of Gravity" without address module.

28 BXP6402 DV69802.03 Issue 04 June 2018

Figure 3: Mounting Kit MK4401

Page 29

46.4 (1.83 in)

Ø4

(0.16 in)

Ø14

(0.55 in)

3

(0.12 in)

2.4.3. Address Module AM6400-1-(01)

Figure 4: Address Module AM6400-1-(01)

Installation

Dimensions

Dimensions mm (in ch)

2.4.4. Blind Encoder BE6400

Dimensions mm (in ch)

Figure 5: Blind Encoder BE6400

DV69802.03 Issue 04 June 2018 BXP6402 29

Page 30

Installation

Dimensions

2.4.5. Antenna 1A032

Dimensions mm (in ch)

30 BXP6402 DV69802.03 Issue 04 June 2018

Figure 6: Antenna 1A032

Page 31

Radiation risk:

Make sure that the grounding contact area is adequate and that the connection

2.5. Electrical Installat i on

• The installation of the Mode S transponder into an aircraft may be carried out

only by an authorized installation company. The country regulations always

have to be observed.

Power supply:

• Do not connect the unit to AC sources.

• Make sure that the unit is connected to the mandatory DC source, see

"Technical Data" page 16.

• Do not connect the unit with reversed polarity to the DC source.

Circuit breaker:

• If no load is connected to connector P9, pin 6, or if the unit is used with the

retrofit adapter, the unit should be protected from the aircraft power supply by

a dedicated 3 A circuit breaker.

• If an external load is connected to connector P9, pin 6, the circuit breaker

should be a 5 A type.

Address module:

• The programming of the address module AM6400-1 with the ICAO 24-bit

address of the aircraft must be carried out only at an installation company or

in the manufacturer factory.

For installations in a more severe electromagnetically environment use shielded

cable connectors and a common shielding for the transponder inter wiri ng.

Installation

Electrical Installation

A safe distance to the installed antenna must be ensured by corresponding

installation measures around human body damage (e.g. at the eyes) and/or avoid

the inflammation of combustible materials by radiated energy.

2.5.1. Grounding

The transponder has a thr e aded groun di ng b olt at the rear side of the unit. Use this point as grounding

contact.

has low resistance and low inductance. Never use a grounding point on paintcoated surfaces!

DV69802.03 Issue 04 June 2018 BXP6402 31

Page 32

Installation

P9

Pin name

Function

Source

Destination

Recommended

1

A1

Altitude A1

encoding altimeter

BXP6402

AWG24

2*

A2

Altitude A2

encoding altimeter

BXP6402

AWG24

GPS /Enable

aircraft DC supply

AWG26

3

A4

Altitude A4

encoding altimeter

BXP6402

AWG24

4

IDENT_N

IDENT button,

external IDENT

BXP6402

AWG26

5

EXT.

Aircraft suppression

bi-directional

bi-directional

Coaxial cable

6

SWITCHED

Switched supply

BXP6402

encoding

AWG22

7

REPLY OUT

Output for ext. reply

connected to positive

BXP6402

reply lamp

AWG26

8

RX+

RS422 interface

CU6401

BXP6402

AWG26 shielded

9

RX-

RS422 interface

CU6401

BXP6402

AWG26 shielded

11

SUPP

Supply voltage input,

DC supply voltage

BXP6402

AWG20

J8

P9

J7

J6

1

14

25

13

13

2514

1

Electrical Installation

2.5.2. BXP6402 Connector Layout

Figure 7: BXP6402 Connector Layout

2.5.3. Connector J6

Antenna RF connector (from transponder via cable to antenna).

• Type: TNC female.

• Antenna cable: low-loss 50 Ω cable, RG 58C/U or RG 223/U type.

• Signal: bi-directional

J6: Antenna

J7: Address module

2.5.4. Connector P9 (Dsub 25-pol male)

Pin

or

external

SUPPRESSION

POWER OUT

system

voltage Imax = 1 A

lamp, lamp to be

illumination voltage

cable type

(parallel interface)

(parallel interface)

ground*

(parallel interface)

button

altimeter

32 BXP6402 DV69802.03 Issue 04 June 2018

external 5 A fuse for

source 10...33 V

Page 33

P9

Pin name

Function

Source

Destination

Recommended

current protection

12

SUPP

Supply voltage input,

DC supply voltage

BXP6402

AWG20

13

GND

DC supply ground,

DC supply voltage

BXP6402

AWG20

14

B1

Altitude B1

Encoding altimeter

BXP6402

AWG24

15

B2

Altitude B2

Encoding altimeter

BXP6402

AWG24

16

B4

Altitude B4

Encoding altimeter

BXP6402

AWG24

17

C1

Altitude C1

Encoding altimeter

BXP6402

AWG24

18

C2

Altitude C2

Encoding altimeter

BXP6402

AWG24

19

C4

Altitude C4

Encoding altimeter

BXP6402

AWG24

20

D4

Altitude D4

Encoding altimeter

BXP6402

AWG24

21

TX+

RS422 interface

BXP6402

CU6401

AWG26

22

TX-

RS422 interface

BXP6402

CU6401

AWG26

24

ON_N

ON/OFF signal

CU6401

BXP6402

AWG26

25

GND

Ground, additionally

DC supply voltage

BXP6402

AWG20

Note P9:

*If no parallel altimeter is used then pin2 serves as GPS Enable/Disable input (active LOW). If no GPS receiver is

J8

Pin name

Function

Source

Destination

Recommended

1

PSEL

Protocol selection

DC supply voltage

BXP6402

AWG26

2*

GPS_EN

GPS /Enable

Aircraft DC supply

BXP6402

AWG26

3

GND

Ground connection

Aircraft DC supply

BXP6402

AWG24

41)

BSUPP

Supply for BE6400

BXP6402

BE6400

-

5

Not connected

-

- - -

6

RX+

GPS receiver

GPS receiver

BXP6402

AWG26 shielded

Electrical Installation

Installation

Pin

external 5 A fuse for

current protection

additionally

connected to Pin25

cable type

source 10...33 V

ground

(parallel interface)

(parallel interface)

(parallel interface)

(parallel interface)

(parallel interface)

(parallel interface)

connected to Pin13

used Pin2 should be left not connected.

For details see "Aircraft Wiring", page 40.

2.5.5. Connector J8 (Dsub 25-pol female)

Pin

(parallel interface)

ground

cable type

ground

ground

ground

DV69802.03 Issue 04 June 2018 BXP6402 33

Page 34

Installation

J8

Pin name

Function

Source

Destination

Recommended

7

RX-

GPS receiver

GPS receiver

BXP6402

AWG26 shielded

8

Not connected

-

- - -

9

Not connected

-

- - -

10

Not connected

Reserved for SQ

- - -

11

GND SWITCH

"Weigth on wheel"

Aircraft

BXP6402

AWG26

122)

ALTS-

RS422 data interface

Serial encoding

BXP6402

AWG26 shielded

132)

ALTS+

RS422 data interface

Serial encoding

BXP6402

AWG26 shielded

14

TISRX-

RS422 data interface

Avionics Data Link

BXP6402

AWG26 twisted

15

TISRX+

RS422 data interface

Avionics Data Link

BXP6402

AWG26 twisted

16

Not connected

-

- - -

17

TISTX-

RS422 data interface

BXP6402

Avionics

AWG26 twisted

18

TISTX+

RS422 data interface

BXP6402

Avionics

AWG26 twisted

19

Not connected

-

- - -

20

Not connected

-

- - -

21

GND

ground connection

Aircraft DC supply

BXP6402

AWG24

22

Not connected

-

- - -

23

Not connected

-

- - -

24

Not connected

-

- - -

25

Not connected

-

- - -

Note J8:

Electrical Installation

Pin

sensor, active LOW

altimeter

altimeter

Processor

Processor

Data Link

Processor

cable type

pair, shielded all

together

pair, shielded all

together

pair, shielded all

together

ground

1) Do not connect if no BE6400 is used.

2) Serial encoding altimeter connection (not for BE6400).

*If no GPS receiver is used then Pin2 should be left not connected.

For details see "Aircraft Wiring", page 40.

Data Link

Processor

pair, shielded all

together

34 BXP6402 DV69802.03 Issue 04 June 2018

Page 35

J7 Pin

Pin name

Function

Source

Destination

1

VCC

Power supply

BXP6402

AM6400

2

I2C_CLK

Clock

AM6400

BXP6402

3

Not connected

Reserved

-

-

4

I2C_DAT

Data

AM6400

BXP6402

5

GND

Power supply return

BXP6402

AM6400

2.5.6. Connector J7 (5-pol female)

Electrical Installation

Installation

2.5.7. External Suppression

External suppression s hould be connected if another tr ansponder or DME is installed in t he aircraft.

The suppression pulses may not be compatible with all models of DME. In this case, leave the

suppression pin open (e.g. P9 pin 5).

In cases when the DME has onl y a suppression output ( e.g. Bendix/King KN62, KN64 and KNS80)

inserted a diode in the suppression line. Details see "Aircraft Wiring" page 40.

2.5.8. External IDENT Push-Button

If this input (unit c onn ector P9 pin 4) is br ief ly connected to GND (e. g. by an external push-button), the

IDENT function (SPI ) is started in the sam e way as when using the ID ENT push-button on the f ront

panel.

2.5.9. Ground Switch

• If required, connect an automatic ground switch ("Weight on Wheel" sensor) at unit

connector J8 pin 11.

DV69802.03 Issue 04 June 2018 BXP6402 35

Page 36

Installation

Electrical Installation

2.5.10. Programming of the Address Module

The 24-bit ICAO address once allocated b y the local authority is stored f or the assigned tr ansponder

in the Address Module AM6400.

The address module pr ogrammer kit AMP6400 is for reading a nd storing fixed aircraft data into th e

Address Module. This to ol is for service and maintenance only. The CD-ROM, which is part of the

address module programmer kit, includes a description of the programming procedure. Insert the

CD-ROM into a PC and follow the instructions. If auto start is disabled on your PC, please start

"setup.exe" manually.

2.5.11. Avionics Data Transfer

• The BXP6402 is a "data link transponder" according to RTCA DO-181C, respectively a

"level 2" transpo nder ac c ordin g to Eurocae ED-73B.This stands for the capability to

transfer data from the ground to a connected ADLP or a similar device and vice versa.

• The transponder transmits information as reply on a Ground Initiated Comm-B (GICB)

request or by means of the extended squitter function. In both cases the valid information

must be available in the GICB registers in the transponder.

• The transponder also transmits information by means of the Air Initiated Comm-B (AICB)

function. In this case the information must be available in a special register in the

transponder. The transponder announces the message and transmits it after authorisation

from the ground station.

• In the other direction, the transponder is able to receive information within a Comm-A

format from the ground station, which is then buffered and transfer red to the connected

device.

• In the BXP6402 a "storage design" is implemented for uplink- as well as for downlink

messages. This means that all information that might be transferred from the transponder

is buffered inside the transponder first.

• The buffers can be accessed from an ADLP or a similar device via the interface on the

rear connector J8. The interface is marked with "TISRX" and "TISTX" in the aircraft wiring

diagram (see page 40).

• The related protocol is specified in the attachment document "Data Transfer Interface

Protocol BXP640X-XX-(XX)". This manual is available at the Becker Product Support

under Article-No. 0590.258-071.

36 BXP6402 DV69802.03 Issue 04 June 2018

Page 37

FreeFlight 1201

NexNav

NMEA

Baud Rate:

19200 bps

19200 bps

4800 bps

#Data Bits: 8 8

8

Parity:

none

none

none

Stop Bits: 1 1

1

Code:

binary

binary

ASCII

Electrical Installation

Installation

2.5.12. GPS Configuration

• If a GPS receiver is used, connect “GPS_EN” to DC supply ground.

o BXP6402 “GPS_EN” J8 pin2 DC supply ground.

• GPS receiver data line connection to BXP6402 see:

o “BXP6402 with Parallel Encoding Altimeter & GPS Receiver” page 41.

o “BXP6402 with Serial Encoding Altimeter & GPS Receiver” page 42.

• GPS receiver supply connection to BXP6402:

BXP6402 “SWITCHED POWER OUT” P9 pin6* ≙ supply voltage P9 p in 11, 12.

(if its current consumption ≤1 A, otherwise it should be connected directly to aircraft

supply).

*when the BXP640X is switched ON the output voltage P9 pin6 corresponds to the supply voltage (P9 pin11, 12).

The equipment is capable to operate with following certified GPS receivers:

• FreeFlight System GPS/WAAS 1201 Sensor, part number 84100-02-XXXX

• NexNav miniGNSS/ GPS-SBAS Sensor/ Receiver.

The equipment is capable to operate with GPS receivers providing EIA-232C or EIA-422 interface with

serial asynchronous transmission parameters: 4800, n, 8, 1 and transmit data with continuous

NMEA-0183 protocol GGA and VTG sentences.

2.5.12.1. GPS Device Protocols

Electrical format – RS232 with the following characteristics:

DV69802.03 Issue 04 June 2018 BXP6402 37

Page 38

Installation

Electrical Installation

2.5.13. Remote Control

• BXP6402 is a remote-controlled transponder and needs an additional controlling device.

o Use the control unit CU6401 from Becker Avionics; a special designed control unit,

which offers the complete set of control functions and indications.

o Use another device (e.g. FMS).

• Two interfaces are available for that purpose.

o "RX", "TX" on connector P9 of the transponder.

The transponder accepts and transmits only control messages via this interface.

o "TISRX", "TISTX" on connector J8 of the transponder.

A combined interface which handles control and data transfer in parallel.

The protocol for both interfaces is described in the document: "BXP6400 Extended Protocol".

This document is available at the Becker Product Support.

38 BXP6402 DV69802.03 Issue 04 June 2018

Page 39

Select with button

Select with rotary encoder

Store button (STO)

ALTM SELECT

GARMIN / TRIMBLE

store

PARALLEL

default

store

DIMMING INPUT

None

default

store

+5 VDC

store

SQUITTER

Short ACQ SQU *

default on

off/on

REPLY RATE LIMIT

RPL RATE LMT

store

SPECIALS

DATA LINK **

store

Error Latch

LOW VOLT

view only

Settings after Installation

Installation

2.6. Settings after Installation

Following description is valid for the BXP6402 remote transponder with the control unit CU6401.

With another contr ol unit the control pr otocol se ttings must be car ried out as they are des cribed in the

document "Control Interface Protocol BXP6402-XR" see ”Order Code”, page 21.

Installation mode is available from SBY mode only.

• Press button SEL,

• Turn the rotary encoder until "INS" appears in the bottom line of the display.

• Select by pressing rotary encoder/push-button.

The installation setup is protected by password "6435".

• Enter password and press store button (STO).

Information front panel see "Operat i ng with CU6401 Cont rol l er", page 45

NORTHSTAR

UPS AT (BECKER BE6400)

UPS AT LORAN

MAGELLAN

SHADIN

ARNAV

(set illumination intensity manually in

the configuration menu)

+14 VDC

+28 VDC

500-1200 replies/s in Mode A/C (setting

in steps of 50)

DEFAULT CONFIG ***

ALT HIGH RESOL

store

store

store

store

store

store

store

store

store

store

*Transponders equ ipped for extended squitter operation should have a means to disab le acquisition

squitters to fac ilitate the s u ppr ess ion of ac quisit ion s q uitt ers when a ll T C AS units have been converted

to receive extended squitter.

DV69802.03 Issue 04 June 2018 BXP6402 39

HIGH TEMP

ANTENNA

RF POWER

DME ERR

SQRT ERR

CORE EE

RECEIVER

FIX DATA

ALTIMETER

DATA LINK

Clear latch

view only

view only

view only

view only

view only

view only

view only

view only

view only

view only

clear latch

Page 40

Installation

*** Default configuration:

Dimming input

none

Brightness

50%

Altitude displayed in ALT mode

AI in SBY

AI in ON

IIlumination characteristics

max. range

Code

0000

VFR

0000

Flight number

eight blanks

Flight number

not active

Installation of the unit varies according to aircraft and equipment design. It

Warning and Failure Indications

**Shall be disabled if no ADLP or similar device is connected.

2.7. Warning and Failure Indications

It is possible to read out t he error latches. If m ultiple failures are listed pleas e keep in your mind the

listed failures and delete the latches with the "Clear Latch" store sequence.

2.8. Aircraft Wiring

is therefore only possible to provide general guidelines in this section.