Page 1

BECK-O-TRONIC 6

Version: Centronic

en

Assembly and Operating Instructions

Door control unit

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

4005 630 202 0b09/08/2018

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Page 2

Table of contents

General ................................................................................................................ 3

Warranty .............................................................................................................. 3

Safety instructions ................................................................................................ 4

Intended use ........................................................................................................ 6

Product overview .................................................................................................. 7

Assembly ............................................................................................................. 8

Wiring .................................................................................................................. 9

Operator controls & functions/displays ..................................................................10

Parametrisation ...................................................................................................15

Menu table ..........................................................................................................16

Connections & functions.......................................................................................22

Reset / factory setting ..........................................................................................29

Functional description ..........................................................................................30

Remote control....................................................................................................34

Disposal ..............................................................................................................36

Maintenance .......................................................................................................36

Cleaning..............................................................................................................37

Error messages ...................................................................................................37

Complete connecting diagram ..............................................................................40

Electric safety edge and light barrier connecting diagram........................................41

Safety edge OSE connecting diagram ...................................................................42

Technical data .....................................................................................................42

Declaration of conformity .....................................................................................43

2

Page 3

General

This control unit is a high-quality product with many features and advantages:

• Simple, convenient connection

• Easy to handle and highly flexible

• Automatic limit position detection

• Defined buttons for OPEN, STOP and CLOSE, also on the hand-held transmitter

• Design with clear display of operating status and error messages

• Optical safety edge or electric safety edge and additional light barrier can be con-

nected

Please observe these Assembly and Operating Instructions when installing and setting

up the equipment.

Explanation of pictograms

CAUTION

ATTENTION

CAUTION indicates a hazardous situation

which, if not avoided, could result in injury.

ATTENTION indicates measures that must be

taken to avoid damage to property.

Denotes user tips and other useful information.

Warranty

Structural modifications and incorrect installation which are not in accordance with

these and our other instructions can result in serious injuries, e.g., crushing of limbs.

Therefore, structural modifications may only be carried out with our prior approval and

strictly in accordance with our instructions, particularly the information contained in

these Assembly and Operating Instructions.

Any further processing of the products which does not comply with their intended use is

not permitted.

The end product manufacturer and fitter have to ensure that all the relevant current

statutory, official and, in particular, EMC regulations are adhered to during utilisation of

our products, especially with regard to end product manufacture, installation and customer advice.

3

Page 4

Safety instructions

The following safety instructions and warnings are intended to avert hazards and to

prevent property damage and personal injury.

Please keep the instruction manual safe!

Caution

• Work on the electrical equipment may only be carried

out by a qualified electrician.

• The relevant safety and accident prevention regulations

for the specific application must be observed when carrying out assembly, installation, commissioning, testing

and maintenance of the control unit. The following regulations in particular must be observed (not an exhaustive

list):

- Machinery Directive 2006/42/EC

- EN 12453 (safety in use of power-operated doors, requirements)

- EN 12445 (safety in use of power-operated doors,

testing methods)

- EN 12978 (safety devices for power-operated doors,

requirements and testing methods)

- EN 60335 (safety of electrical devices for household or

similar purposes)

- Fire prevention regulations

- Accident prevention regulations ASR A1.7 (power-operated windows, doors and gates)

• The engineer responsible for fitting the system must en-

sure proper installation, instruction of the operator in its

use and issue of the CE mark.

• The operator must ensure that the system is only oper-

ated in perfect condition and that the safety devices are

checked regularly by an expert to ensure they are in full

working order.

• A damaged mains connecting cable must be replaced

immediately by a qualified electrician.

4

Page 5

• If there is no fixed stop, e.g., when using roller doors,

the customer must ensure that the roller shutter curtain

is protected and cannot cause any dangerous situations, e.g., by overrunning a limit position.

• The control unit is designed to have a service life of

100,000 operating cycles.

• Drives with a H05VV-F connecting cable may only be

used indoors. If the cable is installed outdoors, it must

be placed in a protective conduit.

• The person who installs, connects, commissions and

maintains this control unit must have read, understood

and observed these Assembly and Operating Instructions. The manufacturer will not accept liability for damage, consequential damage or malfunctions resulting

from non-compliance with these Assembly and Operating Instructions.

• Before working on the control unit, it must be discon-

nected from the power supply and measures must be

taken to ensure it cannot be inadvertently switched back

on.

• Following installation and commissioning, all users must

receive instruction in the functions and operation of the

system. All users must be briefed on the dangers posed

by the system, as well as the risks and their testing obligations as users. Documentation of these points is recommended.

• Operating personnel who have not received instruction

or children must not operate the door control unit.

• Persons, animals or objects must not be within the

movement range of the door when opening or closing it.

• As the setting options are many and varied, it is also

possible to make settings for the specific system being

operated that are obviously illogical, impermissible or

even dangerous. This is not due to a fault or defect at

5

Page 6

the control unit. In light of this, the installer / person responsible for the system must carefully check the settings made and modify them as necessary.

Intended use

The type of control unit described in these instructions may only be used for the operation of tubular drives in roller doors which have fixed stops at the limit positions or a

cover on the barrel (EN 12453). The radio receiver can be operated using any transmitter of the Centronic range of control units (with the exception of transmitters with a time

switching function and / or sun protection function). For travel in the DOWN direction in

maintained operation, a closing edge safety device is necessary.

This type of control unit must not be used in potentially explosive areas.

Other applications, uses and modifications are not permitted in order to protect the

safety of the users and others, since these actions can impair the system’s safety and

carry the risk of personal injury and property damage. The manufacturer does not accept liability for damage or injury arising from such actions.

Always observe the information in these instructions when operating or repairing the

system. The manufacturer does not accept liability for damage or injury resulting from

improper use.

6

Page 7

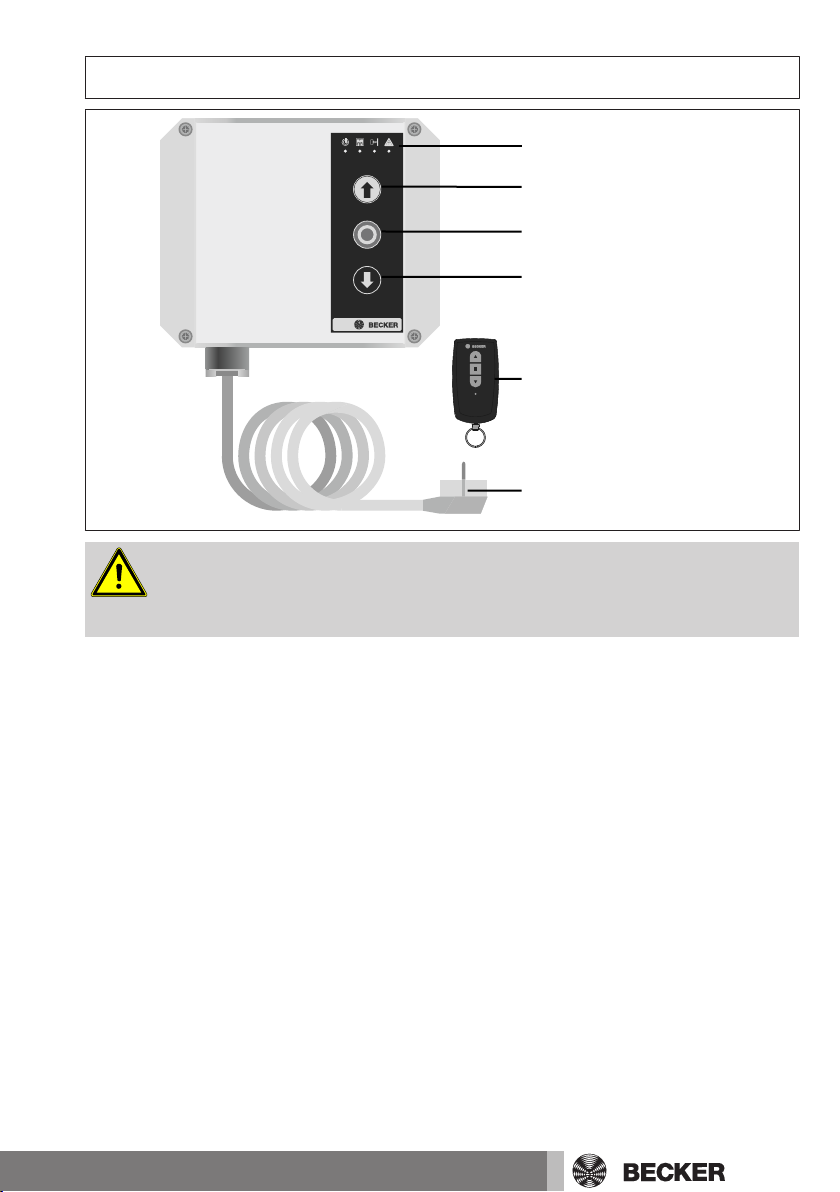

Product overview

Status display

OPEN button

STOP button

CLOSE button

Hand-held transmitter

Mains plug

Caution

Work on the electrical equipment may only be carried out

by a qualified electrician.

7

Page 8

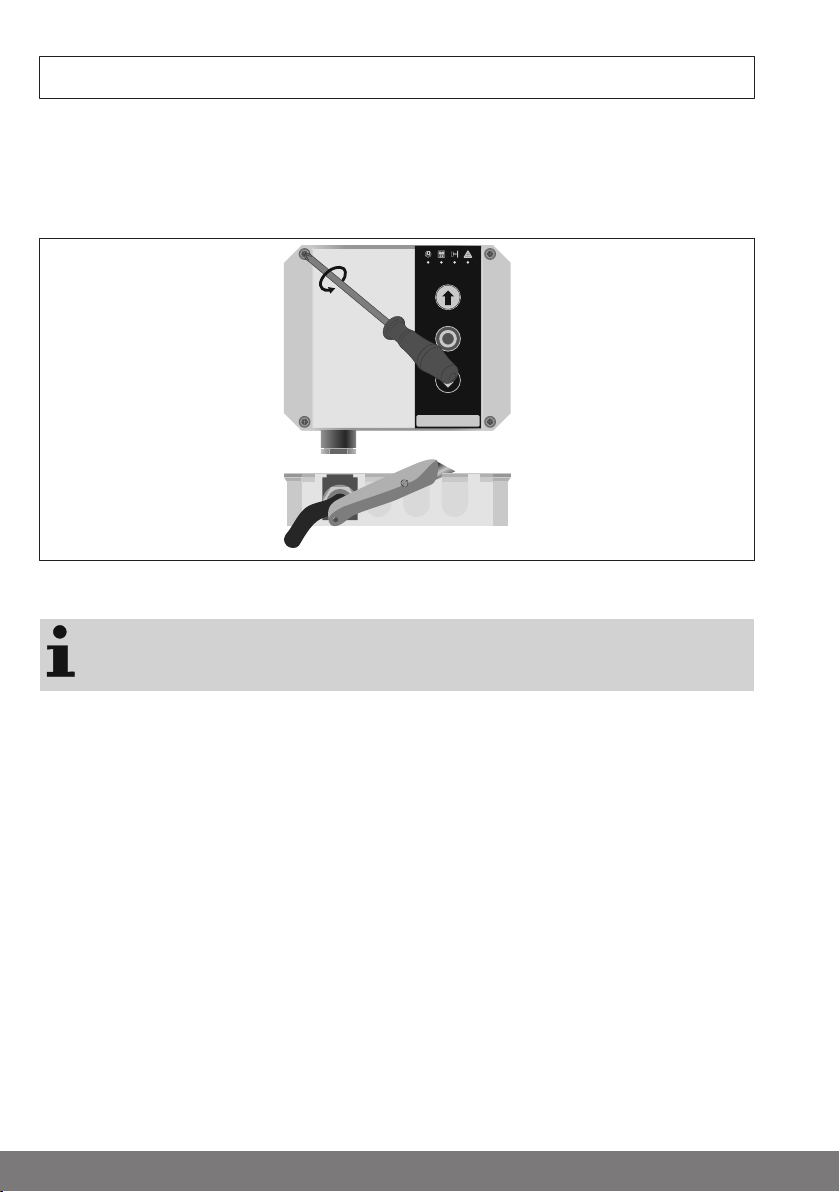

Assembly

Check that the transmitter and receiver are functioning perfectly prior to installation in

the desired location. Do not choose an installation location that is exposed to electromagnetic fields, e.g., in the immediate vicinity of contactors (power relays), mains

transformers, ignition transformers, fluorescent tubes, etc., or their connecting cables.

Protect the control unit against direct solar radiation and driving rain.

Open the cover of the control unit. Pull the cable from the cover off and carefully place

the cover to one side. Remove the required cut-outs in the bottom part of the housing.

Cut in at the edges to make the cut-outs easier to remove.

Install the control unit at a suitable operating height (at least 1500 mm from the

ground). Mount the housing with 4 screws (max. diameter of screw head 7.5 mm) inserted through the holes provided in the corners.

Plug the cable from the cover back on and adjust the parameters. You can now close

the control unit.

8

Page 9

Wiring

Connect the individual pieces of equipment as shown in the connecting diagram.

Caution

Electrical work may only be carried out by qualified electricians or trained personnel. Always disconnect the

safety mains plug before connecting the equipment. The

connection to the building wiring system must be established in accordance with the Machinery Directive using an

adequately sized mains disconnection device. This can be

done by using a plug connection or lockable main switch.

The control unit is protected by a 5 AT, 5 x 20 mm fuse located below the shock-hazard protection cover. Switch the

operating voltage off before replacement!

First, pull the insert sleeves over the connecting cable and

then push the insert sleeves into the bottom part of the

housing once all of the wires have been connected. The

control and drive lines (e.g., pulse, open, stop, close...)

must not exceed a max. length of 30m! This does not apply to the power line. Always route the power line, drive

and control lines in separate cables at a distance from one

another. Non-compliance with the above can lead to malfunctions!

9

Page 10

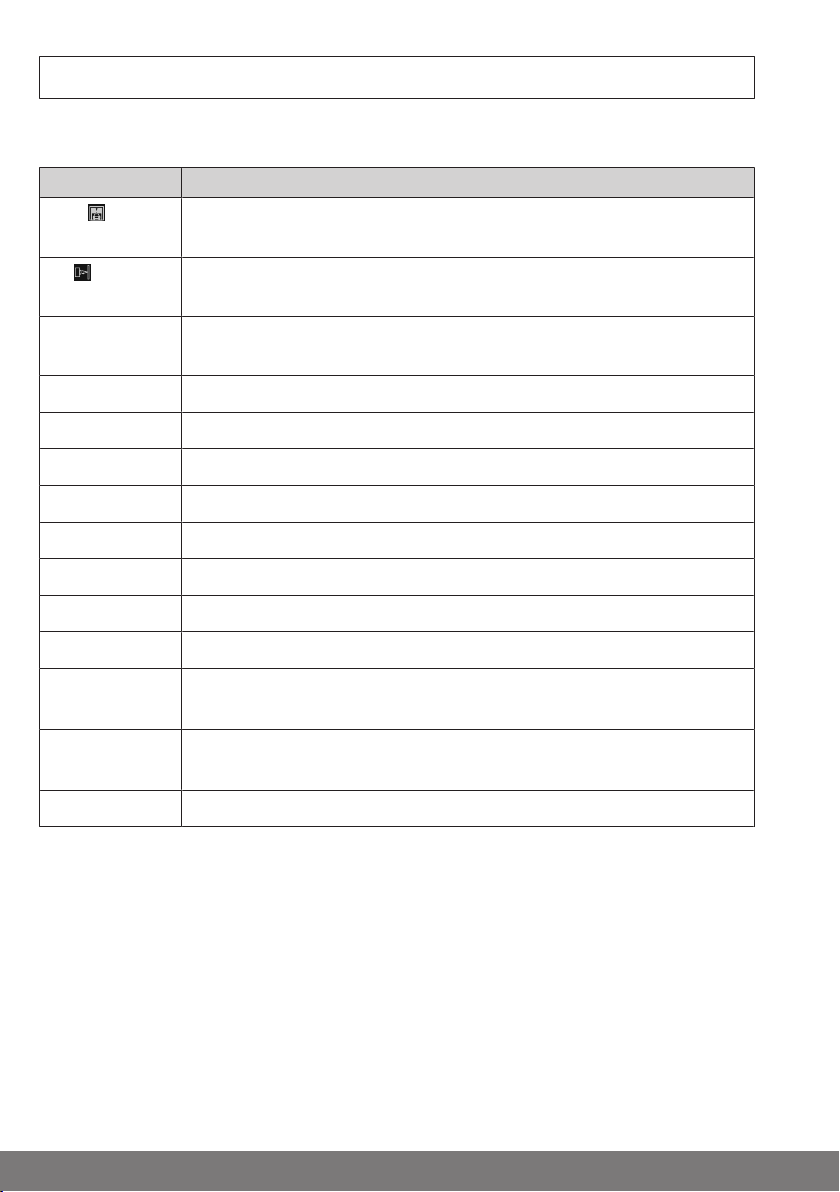

Operator controls & functions/displays

Explanation of abbreviations

Abbreviation Description

USA

Bottom rail sensor; sensor of main closing edge safety device. Detects obstructions when the door is lowering

LS

AWZ

M

[Ta.+]

[Ta.-]

[Ta.F]

[Ta.M]

SE1

SE2

[Kl.1]..[Kl.25]

[M.A0]..

[M.C9]

[Er.01]..

[Er.25]

[F1]..[F2]

Light barrier; for use in buildings as monitoring device for door system and to control the automatic reclosing operation.

Automatic reclosing; the door lowers automatically after the set reclosing time.

Drive

"+" on the PCB

"-" on the PCB

"Radio" button on the PCB

"Menu" button on the PCB

Safety input 1

Safety input 2

Reference to connecting terminals

Menu table "Setting a function", menu items "A0" to "C9"

Error message, shown in the display

Radio module function, shown in the display

10

Page 11

Function of buttons

Display

[Ta.F]

[Ta.M]

[Ta.+]

[Ta.-]

[Ta.+] + value Change menu item and OPEN / STOP in OPEN direc-

tion

[Ta.-] - value Change menu item and CLOSE / STOP in CLOSE dir-

ection

[Ta.F] Radio button For programming / deleting radio settings

[Ta.M] Menu button Menu selection / display of input status

Display on left "Door status"

Display on left Segment status Door status

Lit In the CLOSE limit position

Lit

Lit Between limit positions

Lit In the OPEN limit position

Permanently in the CLOSE limit position

Holiday function: Inputs / radio disabled

Flashes

Permanently in the OPEN limit position

Automatic reclosing off, external inputs

and radio deactivated

11

Page 12

Display on left Segment status Door status

Bars running up Running up

Bars running down Running down

A bar is at a standstill +

flashes with 50% on and

50% off

Lit Automatic reclosing Stay-open time run-

Flashes Stay-open time after exiting light barrier

Advance warning time running

ning

running

Display on right "Status of inputs"

Display on right Segment status Input

Flashes EMERGENCY STOP actuated

Flashes SE1 (LS / SE /OSE) actuated

Flashes SE2 (LS / SE /OSE) actuated

Flashes OPEN actuated

12

Flashes CLOSE actuated

Flashes Pulse actuated

Page 13

Display on right Segment status Input

Flashes Pre-limit switch actuated

Item on right lights up Control unit sends status via transmit

module

Membrane keypad

Labelling Function Function:

short press

OPEN OPEN command Permanently open:

STOP Drive operation in pro-

gress: STOP

If the drive is at a standstill:

Light on/off, if light function

is set with overrun time

CLOSE CLOSE command Permanently closed: Holi-

While the "STOP" button is pressed or a safety device in

the emergency stop circuit has triggered, door travel is

not possible.

Function:

press > 5 s

Automatic reclosing, external inputs and radio disabled.

Steady light:

Light permanently on

day function, external inputs and radio disabled.

13

Page 14

Status indications

The status indicator shows the current status of the control unit. You can find this above

the OPEN button.

Program radio

1-channel operation

Fault in USA circuit On Flashes - Flashes

Internal fault

(no redundancy)

Control unit defective

(replacement necessary)

Error, negative testing

(pre-limit switch possibly too high)

Error

Running time exceeded

AWZ cancelled,

LS actuated and USA

actuated

AWZ cancelled,

USA actuated

Flashes - - -

On Flashes Flashes Flashes

- On On On

On Flashes - -

On - - Flashes

On On On On

On On - On

AWZ cancelled,

LS actuated

AWZ cancelled On - - On

No error,

USA actuated

No error,

LS actuated

No error,

ready

14

On - On On

On On - -

On - On -

On - - -

Page 15

Caution

If an internal error occurs (no redundancy), the system

changes over to dead-man mode for safety reasons.

The door can only be lowered via the CLOSE button at the

control unit.

Testing

Pneumatic safety edges are tested for safety-related reasons during every downward

movement. This process is called testing.

Self-test

The control unit performs a self-test cyclically. CH = Check appears once in the display

and the relays are audibly actuated.

Parametrisation

The operator control is structured in two levels

Level 1 (highest level) = selection of menu item or function

Level 2 (lowest level) = selection of menu values / setting values

Parameter editing Display

1. Control unit in door status

display

Display of current door position and statuses

2. [Ta.M] Press menu button > 3 s Displays the last menu item

called up

3. [Ta.+]

or

[Ta.-]

4. [Ta.M] Briefly press menu button Current menu value 00..99

5. [Ta.+]

or

[Ta.-]

6. [Ta.M] Briefly press menu button Save the menu value and

7. [Ta.M] Press menu button > 3 s Exit the menu

Briefly press + or - value Selection of required menu

item according to select

menu table

Briefly press + or - value Selection of required menu

value

display menu item

no operation for > 15 s Control unit in door status

display

A0

A1

or

A0

A0

15

Page 16

If no changes in the menu values are possible, the entire

control panel is protected against readjustment. Enable

via item "Disable/enable parametrisation".

The drive cannot operate during the adjustment.

Basic values = factory setting

Menu table

Menu

item

A0

A1

A2

Menu

value

RUNNING TIME LIMITATION

00..90 Maximum drive running time 1...90 s, in 1 s increments

91..99 Maximum drive running time 1...9 min, in 1 min increments

LIMIT POSITION DETECTION

00

Running time without drive current monitoring

(observe "Type of limit position detection via running time or limit switch" without fail!)

01 Running time and drive current monitoring 01

SAFETY INPUT SE1: Type

00 No SE safety edge connected

01 LS (without external testing)

02 LS (with external testing)

03 1K2

04 8K2 04

Function / value Basic

Setting

values

60

16

05 OSE

06 OSE (special: 400 Hz / 12 V)

Page 17

Menu

item

A3

Menu

value

Function / value Basic

SAFETY INPUT SE1: FUNCTION

Setting

values

Travel in CLOSE direction:

00 No effect No effect

01 Stop No effect

02 Reverse travel No effect

03 Reopening No effect

04 No effect Stop

05 Stop Stop

06 Reverse travel Stop 06

07 Reopening Stop

08 No effect Reverse travel

09 Stop Reverse travel

10 Reverse travel Reverse travel

11 Reopening Reverse travel

12 No effect Reclosing

13 Stop Reclosing

14 Reverse travel Reclosing

Travel in OPEN direction:

15 Reopening Reclosing

A4

SAFETY INPUT SE2: Type

00 No SE safety edge connected

01 LS (without external testing) 01

02 LS (with external testing)

03 1K2

04 8K2

05 OSE

06 OSE (special: 400 Hz / 12 V)

17

Page 18

Menu

item

A5

Menu

value

Function / value Basic

SAFETY INPUT SE2: FUNCTION

Setting

values

Travel in CLOSE direction:

00 No effect No effect

01 Stop No effect

02 Reverse travel No effect

03 Reopening No effect 03

04 No effect Stop

05 Stop Stop

06 Reverse travel Stop

07 Reopening Stop

08 No effect Reverse travel

09 Stop Reverse travel

10 Reverse travel Reverse travel

11 Reopening Reverse travel

12 No effect Reclosing

13 Stop Reclosing

14 Reverse travel Reclosing

Travel in OPEN direction:

18

15 Reopening Reclosing

A6

01..10 Stay-open time 5...50 s, in 5 s increments, excl.

11..40 Stay-open time 11=1 min, 12=2 min, … 40=30 min

A7

01..20 Stay-open time 1...20 s, in 1 s increments

AUTOMATIC RECLOSING

00 Off 00

advance warning time

excl. advance warning time

STAY-OPEN TIME AFTER EXITING THE LIGHT

BARRIER (SE2)

00 Function switched off 00

Page 19

Menu

item

A8

Menu

value

LIGHT / WARNING LIGHT

00 Only during advance warning time and drive oper-

ation

01..60 Light time 10...600 s, in 10 s increments 12

61

Display: On, if the door is in the OPEN limit position

62

Display: On, if the door is in the CLOSE limit position

63

Display: On, if the door is not in the OPEN limit position (e.g., red traffic light)

64

Display: On, if the door is not in the CLOSE limit

position (e.g., red traffic light)

Off, 5 s after CLOSE limit position

65 Only during advance warning time and motor oper-

ation, 1 Hz flashing

Function / value Basic

values

Setting

A9

01..15 Advance warning time 1...15 s, in 1 s increments

b0

01..15 Advance warning time 1...15 s, in 1 s increments

b1

00..19 Reverse travel time 0.25...5.00 s, in 0.25 s incre-

b2

ADVANCE WARNING TIME PRIOR TO TRAVEL

IN THE OPEN DIRECTION

00 Off 00

ADVANCE WARNING TIME PRIOR TO TRAVEL

IN THE CLOSE DIRECTION

00 Off 00

REVERSE TRAVEL TIME

ments

AUTOMATIC RECLOSING following EMERGENCY STOP

00 Automatic reclosing following EMERGENCY STOP

disabled

01 Rerun of automatic reclosing following EMER-

GENCY STOP release

11

00

19

Page 20

Menu

item

b3

Menu

value

OPEN INPUT & MEMBRANE-TYPE KEY

00 Travel in the OPEN direction with panic function

01 Travel in the OPEN direction without panic function 01

02 Dead-man function

Function / value Basic

Setting

values

b4

b5

b6

CLOSE INPUT & MEMBRANE-TYPE KEY

00 Travel in CLOSE direction with panic function

01 Travel in CLOSE direction without panic function 01

02 Dead-man function

PRE-LIMIT SWITCH

00 Operation without pre-limit switch 00

01 Operation with pre-limit switch

SLAT ADJUSTMENT

00 Operation without slat adjustment 00

01 Operation with slat adjustment

• A short command (< 1 s) via pulse, OPEN,

CLOSE or radio effects a slat adjustment

• A long command (> 1 s) via pulse, OPEN,

CLOSE or radio leads to travel to the relevant

limit position

The slat adjustment is only effective if the OPEN

and CLOSE inputs are also operated in combination with the "with panic function" setting. To do

this, [M.b3] = 00 or [M.b4] = 00 must be set.

b7 00

b8

b9

20

DEAD TIME when reversing/switching the running direction

00..39 0.025...1.000 s, in 0.025 s increments 09

STANDBY for 12 V output (terminal 12)

00 12 V permanently on 00

01 12 V off in standby mode

Page 21

Menu

item

C0 00

C1 00

C2 00

C3 00

C4 00

Menu

value

Function / value Basic

values

Setting

C5

01..99 Maintenance interval 100…9,900 door move-

C6 No function 00

C7

C8

C9

MAINTENANCE INTERVAL

00 No maintenance interval 00

ments, in increments of 100

Disable/enable parametrisation

00 Menu items adjustable 00

01 Menu items not adjustable

Changeover:

Press EMERGENCY STOP, [Ta.+ ] and [Ta.-] simultaneously,

Toggle between 00 and 01 with [Ta.M]

Version number (only readable)

Display of 8-digit version number by running a sequence of digits.

Example: Rest - 00 - 01 - 05 - 12 - Rest, etc. corresponds to version number 00.010512

Clock counter (only readable)

6-digit display of movements in the OPEN direction

by running a sequence of digits.

Example: Rest - 00 - 35 - 17 - Rest, etc. corresponds to 3,517 movements in the OPEN direction

21

Page 22

Connections & functions

Mains connection

[Kl.1]..[Kl.2] Protective conductor / PE

[Kl.3] L-conduction

[Kl.4] N-conductor

Light / warning light

[Kl.1]..[Kl.2] Protective conductor / PE

[Kl.5] L-conductor (enabled)

[Kl.6] N-conductor (enabled)

• 230 V / AC output, max. 250 VA, all-pole disconnection

• The light function is set via [M.A8]

• With [M.A8] = 00, the light is actuated for the set advance warning time [M.A9] or

[M.b0] and the drive operation time.

• With [M.A8] = 01 to 60, the light is actuated throughout the entire drive operation

and following a drive operation for the selected time. With the setting 04 to 60, the

light goes out briefly once 10 s before the time expires and signals the pending

time rundown.

• With [M.A8] = 61 to 64, a red/green traffic light or door status indicator can be im-

plemented; in this case the light output is actuated according to the door position

(OPEN or CLOSE limit position).

• With [M.A8] = 65 the output flashes with 1 Hz during the advance warning time

and drive operation.

Drive / tubular drive

[Kl.1]..[Kl.2] Protective conductor / PE

[Kl.7] CLOSE direction, 230 V / AC output

[Kl.8] OPEN direction, 230 V / AC output

[Kl.9] N-conductor (enabled)

• 230 V / AC output, max. 500 VA, all-pole disconnection

22

Page 23

Drive / tubular drive

• The drive must travel in the OPEN direction following "Operating voltage / mains

voltage on" and the first pulse command. If the drive travels in the CLOSE direction even though the bars in the display are moving up, the connecting wires

[Kl.7]+[Kl.8] must be swapped round.

EMERGENCY STOP (safety input)

[Kl.10] EMERGENCY STOP input

[Kl.11] EMERGENCY STOP (12 V permanent)

• Safety input category 1 to EN ISO 13849-1/2008 (directly switches the relay for

direction of travel off)

• Input for EMERGENCY STOP control sensor

• NC contact, floating

• Several control sensors can be connected in series.

• If an EMERGENCY STOP input is not used it must be jumpered! The jumper must

be removed when it is in use.

• The automatic reclosing function after an EMERGENCY STOP is adjusted in

[M.b2]

• The EMERGENCY STOP input switches the drive and light relay off directly and is

therefore still effective when the electronics fail!

• After an EMERGENCY STOP command when the drive is in operation, the door

travels in the opposite direction (away from the source of danger) the next time a

pulse command is given.

• After an EMERGENCY STOP command when the door is at a standstill, travel in

the OPEN direction generally occurs the next time a pulse command is given.

12 V DC output (stabilised)

[Kl.11] +12 V DC (stabilised), I

[Kl.12]

• +12 V DC testing of light barriers and/or switching off of LS

< 300 mA (total [Kl.11] + [Kl.12])

max

and OSE at standstill

• [M.b9] = 00, +12 V permanently on, although briefly off dur-

ing self-test

• [M.b9] = 01, +12 V off in standby mode and briefly off dur-

ing self-test

23

Page 24

12 V DC output (stabilised)

[Kl.18] 0V / Earth

[Kl.20] 0V / Earth

Connection for external consumer, e.g., OSE, light barrier, etc.

Attention!The maximum current specified in the "Technical data" must not be

exceeded! Non-compliance can lead to malfunctions, failure, destruction and

property damage.

Safety input

[Kl.11] +12 V (continuous)

[Kl.12] +12 V (with testing)

[Kl.13] SE1 signal input

[Kl.14] Common

[Kl.15] SE2 signal input

[Kl.18] or [Kl.20] 0V / Earth

• Safety input category 2 / Performance Level C to EN ISO 13849-1/2008

• The type of the input is set in [M.A2] for SE1 and [M.A4] for SE2.

∙ Input for safety contact strips (1k2 or 8k2 or OSE) for closing edge safety device

∙ Input for light barriers (LS)

• The function of the input is set in [M.A3] for SE1 and [M.A5] for SE2.

∙ Setting the function of the safety input for travel in the OPEN direction and travel

in the CLOSE direction

∙ Stop: Drive remains at standstill

∙ Reverse travel: When approaching an obstruction, the door is actuated in the

opposite direction for the set reverse travel time [M.b1].

∙ Reopening/reclosing: If a safety device is actuated when the drive is in operation

(e. g., detects obstruction in the active direction of travel) the door then travels

in the opposite direction up to the limit position.

• When the SE input is actuated the drive can only be started if the SE setting is

not effective in the corresponding direction of travel. If effective, travel will not be

possible in the direction of travel.

• When the drive is in operation a command at the SE input effects the following:

stop, reverse travel, reopening, reclosing or no effect, depending on the direction

of travel and setting.

24

Page 25

Safety input

• When the automatic reclosing is active and the SE input is actuated, the stay-

open time is reset until the input is once again enabled.

• The input has a safety function and is monitored by self-testing of the electronics.

If an error is detected in the SE input, door travel is not possible. SE1: Display

{Er.08} / {Er.10} SE2: Display {Er.09} / {Er.11}

• If control sensors (1k2 / 8k2 / OSE / LS) at safety inputs SE1 / SE2 are defective,

the control unit can be manually operated in dead-man mode in the OPEN or

CLOSE direction.

• Actuate the control sensor briefly twice in the required travel direction then

hold actuated. The door now travels in dead-man mode.

• If a pneumatic pressure-wave safety edge (DW edge) is used, its function must

be tested. An external pre-limit switch is needed for this. The pre-limit switch is

only effective in combination with the safety input SE1 and is activated with

([M.b5] = 1). Depending on the type of edge, the safety input SE1 must either be

set as 1k2 ([M.A2] = 3) or as 8k2 ([M.A2] = 4).

Attention

[Kl.14] = Common. Must not be connected to 0 V = [Kl.18]

or [Kl.20] as otherwise the SE input is defective or is not

functioning!

External safety devices must be approved for protection

against personal injury.

The pre-limit switch is only effective in combination with

the safety input SE1!

Light barriers with an OC (open collector output, PNP /

NPN semi-conductor output) cannot be used (malfunction!)

Safety input SE1 (LS / 1k2 / 8K2 / OSE)

1k2 / 8k2 connection

[M.A2] 03: 1k2

[M.A2] 04: 8k2

[Kl.13] Electric safety edge

[Kl.14] Electric safety edge

OSE connection

25

Page 26

Safety input SE1 (LS / 1k2 / 8K2 / OSE)

[M.A2] 05: Standard OSE

[M.A2] 06: 400 Hz

[Kl.11] +12 V (brown)

[Kl.18] or [Kl.20] Earth (white)

[Kl.13] Signal (green)

LS connection without external testing

[M.A2] 01

[Kl.11] LS: +12V

[Kl.18] or [Kl.20] Earth

[Kl.13] and [Kl.14] Relay output LS

LS connection with external testing

[M.A2] 02

[Kl.12] LS transmitter: +12V

[Kl.18] or [Kl.20] Earth

[Kl.11] LS receiver: +12V

[Kl.13] and [Kl.14] Relay output LS

During the self-test of the control unit, the +12 V = [Kl.12] to the LS transmitter is

briefly interrupted. The LS receiver must detect this and switch the relay output

[Kl.13] and [Kl.14].

Safety input SE2 (LS / 1k2 / 8K2 / OSE)

1k2 / 8k2 connection

[M.A4] 03: 1k2

[M.A4] 04: 8k2

[Kl.15] Electric safety edge

[Kl.14] Electric safety edge

OSE connection

[M.A4] 05: Standard OSE

[M.A4] 06: 400 Hz

[Kl.11] +12 V (brown)

26

Page 27

Safety input SE2 (LS / 1k2 / 8K2 / OSE)

[Kl.18] or [Kl.20] Earth (white)

[Kl.15] Signal (green)

LS connection without external testing

[M.A4] 01

[Kl.11] LS: +12V

[Kl.18] or [Kl.20] Earth

[Kl.14] and [Kl.15] Relay output LS

LS connection with external testing

[M.A4] 02

[Kl.12] LS transmitter: +12V

[Kl.18] or [Kl.20] Earth

[Kl.11] LS receiver: +12V

[Kl.14] and [Kl.15] Relay output LS

During the self-test of the control unit, the +12 V = [Kl.12] to the LS transmitter is

briefly interrupted. The LS receiver must detect this and switch the relay output

[Kl.14] and [Kl.15].

Light barrier (LS)

• Light barriers can be connected to the safety inputs SE1 and SE2.

• Light barriers with a semiconductor / open collector output cannot be used.

• The connection is established according to item Safety input SE1 (LS /

1k2 / 8K2 / OSE) or Safety input SE2 (LS / 1k2 / 8K2 / OSE).

• When the automatic reclosing is active and the LS input is actuated, the stay-open

time is reset until the input is once again enabled.

• The function " Stay-open time after exiting the light barrier" is set in [M.A7]

and only applies for the light barrier at SE2! If the light barrier is exited when the

door is open, the door closes after the set stay-open time [M.A7]. During this time

the item in the left-hand display flashes. An LS command (e.g., a car driving

through) while the door is still travelling in the OPEN direction is saved (only with

setting [M.A3] = 00 to 03). As soon as the door is in the OPEN limit position, the

set stay-open time [M.A7] runs down and automatic travel in the CLOSE direction

starts.

27

Page 28

OPEN input

[Kl.16] OPEN input

[Kl.18] 0V / Earth

• Input for push-button, key-operated push-button, external radio, etc.

• NO contact, floating

• Several control sensors can be connected in parallel.

• With [M.b3] = "dead-man function", radio operation for the corresponding direc-

tion of travel is disabled.

• The door stops when the OPEN and CLOSE inputs are simultaneously actuated.

Further running direction commands (radio, pulse, membrane keypad) are not

executed.

• When the advance warning time is set [M.A9], the door start is delayed.

CLOSE input

[Kl.17] CLOSE input

[Kl.18] 0V / Earth

• Input for push-button, key-operated push-button, external radio, etc.

• NO contact, floating

• Several control sensors can be connected in parallel.

• The function of the input is set in [M.b4]

• With [M.b4] = "dead-man function", radio operation for the corresponding direc-

tion of travel is disabled.

• The door stops when the OPEN and CLOSE inputs are simultaneously actuated.

Further running direction commands (radio, pulse, membrane keypad) are not

executed.

• When the advance warning time is set [M.b0], the door start is delayed.

28

Page 29

Pulse input

[Kl.19] Pulse input

[Kl.20] 0V / Earth

• Input for push-button, key-operated push-button, external radio, etc.

• NO contact, floating

• Several control sensors can be connected in parallel.

• If the door is in the OPEN limit position, only the stay-open time is reset via a pulse

or OPEN command. The stay-open time remains reset for as long as a pulse or

OPEN command is applied. The stay-open time only starts to run down when an

OPEN/pulse command is no longer applied.

• When the automatic reclosing is active ([M.A6] > 0 or [M.A7] > 0), a pulse com-

mand always effects travel in the OPEN direction. The same applies if the door is

already travelling in the CLOSE direction. The stay-open time restarts.

• Commands for specific OPEN / CLOSE are also effective when the automatic re-

closing is active.

Pre-limit switch

[Kl.21] Pre-limit switch signal input

[Kl.20] 0V / Earth

When the safety input (SE1) is actuated < 2 s after actuation of the pre-limit switch,

travel in the CLOSE direction continues up to the limit position. Deactivation is effected via the internal limit switch in the tubular drive [M.A1] = 01 or via running time

[M.A1] = 00. If the safety input (SE1) is not actuated (active testing e.g., for pneumatic safety edge) < 2 s after actuation of the pre-limit switch, reverse travel or reopening occurs depending on the setting in the menu [M.A3].

The pre-limit switch is only effective in combination with safety input SE1!

No effect in combination with SE2.

Reset / factory setting

The factory setting of the control unit can be restored if required (basic values in accordance with menu table). Press and hold the buttons [Ta.+] and [Ta.-] for approx. 5 s

until the display changes from "r E" to "CH". The entire control unit must be subsequently readjusted!

Programmed hand-held transmitters are not deleted during this process.

29

Page 30

Functional description

Type of limit switch detection via running time or limit switch

During commissioning, the type of limit position detection must be set in [M.A1].

• Running time switch off [M.A1] = 00

∙ This operating mode may only be used with systems where there is no risk in-

volved in doing so, or where this risk is safeguarded by another means. The drive

cut-off is not monitored during the self-test!

∙ The maximum running time can be set in [M.A0] to increments of 1 - 90 s and 91 -

99 min.

∙ With limit position detection based on running time [M.A0] = 00, an error message

is not displayed if the set running time is exceeded; instead, the drive is stopped

and this is interpreted as the limit position.

∙ The door position is not determined, i.e.: every run continues until the total run-

ning time has elapsed. This is also the case if the door was at an "intermediate position" and therefore reaches the limit position before the running time has

elapsed. This operating mode can be used for hydraulic drives with mechanical

limit stop, for example.

• Internal limit switch [M.A1] = 01

∙ If the door travels to the internal limit switch (tubular drive), this is detected as the

limit position and the drive is switched off. To do this, the running time limit [M.A0]

set must be longer (normally +5 s) than the actual running time.

Dead time during reversal

• The minimum dead time for which every drive must be at a standstill before the op-

posite direction can be actuated is set in [M.b8].

• This function is particularly important when changing the running direction in com-

bination with reverse travel/reopening via SE1 / SE2.

Attention

Drives exist that do not run in the opposite direction and

continue running in the original direction instead if the

dead time is too short (especially drives with low selfblocking capability). With these drives, the time must be

increased until start-up in the opposite direction can be

ensured during reversal.

If necessary, check that the force values have been observed once the dead time has been increased!

30

Page 31

Drive / tubular drive operation

• The control unit is ideally designed for tubular drives with internal limit switches that

switch off the corresponding direction of travel directly. The control unit evaluates

the drive current and can thus identify the limit positions.

• Operation with external limit switches is possible. External limit switches must be

approved for 230 V and be able to switch the drive current. The connection is established in the corresponding drive cable. The installation must be 230 V capable.

When operated with tubular drives, the internal limit switches must be set so that

they do not trigger a deactivation at any point on the required travel distance! To do

this, the switch-off point can be set approx. 3 revolutions before the starting point

and after the end of the travel distance.

Attention

When operating with external limit switches, special attention must be paid to the safety regulations!

Panic function

• When the "panic function" is active and the door is in motion, the door travel stops

the first time the input is actuated. The second time the input is actuated, the door

starts moving in the actuated direction.

• If actuation occurs when the door is running in the opposite direction and a "panic

function" is not set, the door stops and immediately starts moving in the opposite

direction. If actuation occurs in the same direction (current travel direction), this

has no effect.

Automatic reclosing

• If the door is not in the CLOSE limit position, the automatic reclosing operation

takes effect after the stay-open time expires [M.A6]. The warning light output is

active for the set advance warning time [M.b0] before the door travels to the

CLOSE limit position.

• If the door is in the OPEN limit position, only the stay-open time is reset via a pulse

or OPEN command. The stay-open time remains reset for as long as a pulse or

OPEN command is applied. The stay-open time only starts to run down when an

OPEN/pulse command is no longer applied.

• When the automatic reclosing is active, a pulse command always effects travel in

the OPEN direction. The same applies if the door is already travelling in the CLOSE

direction. The stay-open time restarts.

• Commands for specific OPEN / CLOSE are also effective when the automatic re-

closing is active.

31

Page 32

• If switch-off via SE1 / SE2 occurs three times in succession during travel in the

CLOSE direction, the automatic reclosing is blocked after the third unsuccessful attempt to travel in the CLOSE direction until the next pulse, OPEN, CLOSE or radio

command. However, this only applies for setting type = 1k2 / 8k2 or OSE.

• If [M.b2] = 00, following actuation of the EMERGENCY STOP the automatic reclos-

ing is blocked until the next pulse, OPEN, CLOSE or radio command. If the drive is

at a standstill, only the stay-open time is reset when SE1 or SE2 is actuated (no

switch-off). The stay-open time only starts running down once the inputs have no

longer been actuated. When the automatic reclosing is active, it is always effective

if the door is not in the CLOSE limit position. While SE1 or SE2 is actuated, travel in

the CLOSE direction does not occur.

• A continuous signal at the OPEN input blocks/interrupts the automatic reclosing.

Once the OPEN signal is removed, the stay-open time runs down, then the door

closes. The potential-free contact of a timer allows the automatic reclosing operation to be controlled.

Standby power / standby operation

• In order to save the standby power, the control unit enters standby mode 15 s after

the last function (door travel or light off). All internal consumers (display, etc.),

apart from the radio module, are switched off or their power reduced.

• External control sensors (LS, OSE, etc.) can also optionally be switched off [M.b9]

via the 12 V output [Kl.12]. However, following standby mode it takes around another +0.5 s to restart the drive.

Holiday function / door permanently open / door permanently

closed / steady light

• Functions only possible in combination with membrane keypad

∙ Door permanently open (all control inputs and the automatic reclosing are dis-

abled). Press OPEN at membrane keypad for longer than 5 s.

∙ Door permanently closed (holiday function, all control inputs are disabled). Press

CLOSE at membrane keypad for longer than 5 s.

∙ Light permanently on. Press Stop at membrane keypad for longer than 5 s.

• Switching off: Press OPEN, STOP or CLOSE at the membrane keypad

• The permanently OPEN and permanently CLOSE functions are also retained when

the operating voltage fails.

32

Page 33

Emergency operation - dead-man

• If control sensors (1k2 / 8k2 / OSE / LS) at safety inputs SE1 / SE2 are defective,

the control unit can be manually operated in dead-man mode in the OPEN or

CLOSE direction.

• Emergency operation can be controlled via the OPEN and CLOSE inputs, [Ta.+] /

[Ta.-], and also the membrane keypad.

• Actuate the control sensor briefly twice in the required travel direction then hold ac-

tuated. The door now travels in dead-man mode.

Disable/enable parametrisation

• All menu items can be disabled in [M.C7] to prevent readjustment. (recommended)

• [M.C7] = 00 menu items can be modified (as-delivered condition)

• [M.C7] = 01 no changes possible

• Disable/enable parametrisation

∙ Continuously actuate EMERGENCY STOP

∙ Select menu [M.C7] and access menu item with [Ta.M]

∙ Press and hold buttons [Ta.+] and [Ta.-]

∙ You can now toggle between the values 00 and 01 with [Ta.M]

Clock counter

• The number of previous door movements can be read out as 6 digits in [M.C9].

• Every start in the OPEN direction is counted.

• After [M.C9] is selected, a sequence of digits runs down 6 times in the display. This

sequence of digits shows the number of OPEN movements, starting after the rest.

Example: Rest - 00 - 35 - 17 - Rest, etc. corresponds to 3,517 movements in the

OPEN direction.

• The travel counter cannot be reset or modified (read-only memory).

33

Page 34

Maintenance interval

• The number of door movements (movements in OPEN direction) that elapse before

the next maintenance message is displayed; set in [M.C5].

• The light output flashes when the drive is in operation to indicate that maintenance

is due.

• To switch off the maintenance message, [M.C5] must be changed. (i.e. if the main-

tenance interval is to remain the same, the menu item must be changed once and

reset to the old value). When [M.C5] is changed, the maintenance counter is set to

the value that is currently set.

• [M.C5] only shows the set maintenance interval. The counter itself cannot be read

out.

• A maintenance message is also retained when the operating voltage fails.

• The maintenance interval is independent of the clock counter [M.C9] and cannot

be reset.

Remote control

Caution

If a radio control system is used, the person operating the

door must have full view of the door and its surroundings

while the door is moving and ensure that he/she is clear of

all hazardous areas.

It is only possible to operate the control unit with one

transmitter when a safety device is connected. A programmed transmitter is indicated by the value F1 or F2.

Operate the programming button on the transmitter using

a suitable cylindrical tool (e.g. a ballpoint pen).

Transmitters with a timer cannot be programmed. It is not

possible to program intermediate positions. Automatic

timer control functions are not executed via the transmitter. A central command must be programmed into the control unit separately.

The function of the radio remote control is determined when programming the transmitter. Up to 27 codings (27 transmitters) with different functions can be programmed.

Operation via a transmitter is not possible with dead-man.

34

Page 35

Value Function

Open button

Stop/Light button

Close button

Button with

pulse sequence

{F1} Triple push-button, Open-Stop/Light-Close

{F2} Pulse (Open-Stop-Close-..)

Transmitter:

{F1} Open-Stop/Light-Close {F2} Pulse

Programming a transmitter:

1. Press [Ta.F] < 1 s until {F1} flashes in the display

2. Select the required function with [Ta.+] or [Ta.-]

3. Now press and hold the operating or programming button on the transmitter until

the selected function {F1}, {F2} is permanently displayed (no longer flashes). The

transmitter has now been programmed.

4. If a transmitter is not programmed, learning mode is automatically exited after 3

minutes.

Deleting a transmitter

1. Press [Ta.F] < 1 s until {F1} flashes in the display.

2. Now press and hold the programming button of the transmitter until {FL} appears

permanently in the display.

35

Page 36

Deleting all transmitters

1. Press and hold the button [Ta.F] until {FL} flashes in the display after which the {FL}

display goes off.

2. All codings have now been deleted.

Antenna connection

1. An antenna wire must be connected to [Kl.23].

2. When using a stick antenna, the shielding of the coaxial cable and inner conductor

must be connected to [Kl.22] and [Kl.23] respectively. The cable can be fed into

the housing via a free cable bushing.

You can maximise the range by routing the antenna wire or

coaxial cable as far as possible from mains, control and

drive cables. Routing in cable ducts alongside other

cables will reduce the range and possibly lead to malfunctions!

If the dead-man function has been set via [M.b3] / [M.b4],

the corresponding direction of travel cannot be radio controlled!

If a programmed radio signal is received, the programmed

function {F1}, {F2} appears in the display.

Radio communication is blocked while a button on the

control unit or membrane keypad is actuated.

Disposal

This product is made of various materials which must be disposed of properly. Find out

about the applicable regulations on recycling or disposal for this product in your country.

The packaging material must be disposed of properly.

Maintenance

This control unit is maintenance-free.

36

Page 37

Cleaning

Only clean the outside of the housing with a suitable cloth. Do not use cleaning agents,

as these may damage the plastic.

Error messages

"Er" (Error) and the relevant error number flash alternately in the display to signal an error.

Error no. Description of error Comment / measure

01 EEprom data Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, the saved menu

parameters are no longer correct. The

control unit must be reset (item Reset /

factory setting) and readjusted.

02 Motor current detection Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, the motor current

detection is faulty. The control unit must

be replaced.

03 N-relay cutoff Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, a short-circuit

has occurred in the N-relay. The control

unit must be replaced.

04 OPEN/CLOSE relay Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, a short-circuit

has occurred in the OPEN or CLOSE relay.

The control unit must be replaced.

05 Watchdog test Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, there is an error

in the control unit hardware. The control

unit must be replaced.

37

Page 38

Error no. Description of error Comment / measure

06 ROM test Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, there is an error

in the controller hardware. The control

unit must be replaced.

07 RAM test Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists, there is an error

in the controller hardware. The control

unit must be replaced.

08 LS / SE1 (internal test-

ing)

09 LS / SE2 (internal test-

ing)

Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists:

a) Check setting [M.A2] when the closing

edge safety device is connected.

b) Check connection of the closing edge

safety device, especially earth connection

at terminal [Kl.14].

c) If a) and b) are correct, an error possibly exists in the control unit hardware.

The control unit must be replaced.

The door can be operated in emer-

gency mode.

Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists:

a) Check setting [M.A4] with regard to

connected closing edge safety device.

b) Check connection of the closing edge

safety device, especially earth connection

at terminal [Kl.14].

c) If a) and b) are correct, an error possibly exists in the control unit hardware.

The control unit must be replaced.

The door can be operated in emer-

gency mode.

38

Page 39

Error no. Description of error Comment / measure

10 LS / SE1 (external test-

ing)

Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists:

a) Check setting [M.A2] (external LS test)

with regard to connected light barrier.

b) Check connection of LS transmitter in

accordance with item Safety input SE1

(LS / 1k2 / 8K2 / OSE).

c) If a) and b) are correct, an error possibly exists in the control unit hardware.

The control unit must be replaced.

The door can be operated in emer-

gency mode.

11 LS / SE2 (external test-

ing)

20 SE1 The last door operation was stopped via

21 SE2 The last door operation was stopped via

22 EMERGENCY STOP The last door operation was stopped via

23 Pre-limit switch The pre-limit switch was actuated without

Switch off operating voltage, wait 10 s,

switch operating voltage back on. If the

error message persists:

a) Check setting [M.A4] (external LS test)

with regard to connected light barrier.

b) Check connection of LS transmitter in

accordance with item Safety input SE2

(LS / 1k2 / 8K2 / OSE).

c) If a) and b) are correct, an error possibly exists in the control unit hardware.

The control unit must be replaced.

The door can be operated in emer-

gency mode.

an SE1 command.

an SE2 command.

an EMERGENCY STOP command.

SE1 being actuated within 2 s.

39

Page 40

Complete connecting diagram

PE

L

N

Outdoor light

Drive

Emergency Stop

Electric safety edge

Travel command OPEN

Pre-limit switch

Travel command pulse

Travel command CLOSE

Light barrier

3 4 5 6 7 8N9

230V

AC

Licht

230V

PE

NL

M

NOT-

12V

10 11 12 13 14 15 16 17 18 19 20 21 22

LS/SE/OSE

SE1 SE2C

Test

Auf Zu

Impuls

24

0V Vor-ES

23

0V

25

ANT.

1

2

8K2

40

Page 41

Electric safety edge and light barrier connecting

C

8K2

C

NO

NC

-

+

+

Light barrier transmitter

Light barrier receiver

Electric safety edge

diagram

41

Page 42

Safety edge OSE connecting diagram

brown

green

white

Technical data

Dimensions of the housing (W x H x D) 155 x 130 x 50 mm

Housing material PC

Degree of protection IP54, only for installation indoors

Supply voltage 230 V / 50 Hz (connection type Y)

Input power 6 V A

Fuse 5 A slow-blow Si3, 5 x 20 mm

Drive switching capacity 1 drive 230 V / 50 Hz maximum 500 V A

Light switching capacity 230 V / 50 Hz maximum 250 V

Control voltage 12 V maximum 300 mA

Temperature range -20°C…..+50°C

Radio frequency 868.3 MHz

Weight approx. 0.5 kg (without connecting cable)

42

Page 43

Declaration of conformity

43

Page 44

Loading...

Loading...