Beacon-Morris Twin-Flo III Installation Manual

TFII-11

Beacon/Morris

TWIN-FLOIII® HEATER

INSTALLATION INSTRUCTIONS • TYPES K, W, & F

ATTENTION: READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR

SERVICE THE BEACON MORRIS TWIN-FLO III HEATERS! RETAIN THESE INSTRUCTIONS FOR FUTURE

REFERENCE.

INSPECT THE SHIPMENT IMMEDIATELY WHEN RECEIVED TO DETERMINE IF ANY DAMAGE HAS

OCCURRED DURING SHIPMENT.

PRIOR TO INSTALLATION, CHECK FOR ANY VISIBLE DAMAGE. MAKE CERTAIN THAT ANY

LOOSE PARTICLES ARE REMOVED (ESPECIALLY IN THE BLOWER ASSEMBLY AREA).

GENERAL DESCRIPTION

TWIN-FLO III heaters are for use with forced hot water residential heating systems and consist of a copper tube, aluminum finned heating element, with an electric motor and blower of unique cross flow design. Their purpose is to deliver a

comfortable stream of warmed air, at or near floor level, and their construction is extremely compact so minimum space is

required for installation. The type K heater is primarily used in horizonal floor installation, for example: under a kitchen

counter cabinet, or bathroom sink enclosure. Type W is for verticle mounting, fully recessed in the wall studs, with the air

discharged upward through a flush mounted, louvered front panel. Type F is a surface mounted wall unit, with the air

discharged evenly through a louvered front panel in an upward direction. All types have heating elements with 1/2"

nominal (5/8 O.D.) copper tube connections, and 115V. electric blower motor, interwired with a 120° F (49° C) reverse

acting aquastat that prevents operation until hot water is circulating. These units are NOT intended to be used on one or

two pipe steam systems. See bottom of page 7. For gravity fed systems, it is recommended that a separate circulator pump

be installed for the kick space heater.

INSTALLING TWIN-FLO III TYPE K

1. Select a location under the bottom shelf of a cabinet that meets the minimum dimensions shown in Fig. A.

2. CUT AN ACCESS PANEL THROUGH THE BOTTOM OF THE CABINET AT THIS LOCATION, LARGE ENOUGH

FOR INSTALLATION AND SERVICE. IT IS RECOMMENDED THAT THIS ACCESS PANEL BE CONSTRUCTED

SO ANNUAL CLEANING OF THE BLOWER FAN AND COIL FINS CAN BE EASILY ACCESSIBLE.

3. At this location, center and cut an opening in the toe-space riser 4'' high x 11'' long (model K42) (See figure A)

or 4'' high x 18'' long (model K84) (See figure B) or 4" high x 23" long (Model K120). (See figure C).

4. Set the TWIN-FLO III in the space at finished floor level and check piping and wiring locations. The air outlet

should be facing but not extending beyond the toe-space riser at the opening. The air outlet should also be located at

the bottom portion of the 4'' toe-space riser (See figure A) at finished floor level. Make sure the switch is accessible

through the grille openings. The front of the unit should fit flush to the inside of the toe space riser.

5. Install the wire grille over the 4'' toe-space opening by clamping in place with two end caps and screws provided. The

verticle bars should be on the inside (fig. A).

6. If using the TWIN-FLO "Easy Connect" Flexible Hose Connection Kit, see those installation instructions.

7. Next, prepare the heating element for pipe connections (this procedure will also pertain to Model types W and F).

Remove the 3 screws from the electric conn. box. Unsnap (pull) the thermostat clamp from the return copper U-bend.

Holding down the top cover, remove the 4 element cover screws. Carefully remove this top cover noting the position of

the element and the neoprene side pad. Lift out the element for soldering and fittings. Both ends are sized to accept

1/2'' solder fittings. (Note required fittings for one pipe and two pipe systems on page 6).

8. Replace the heating element in the bottom cover in the proper position. Place the neoprene side pad in position and

replace the top cover using the 4 screws. Tighten enough to keep the element in place between the covers. DO NOT

OVER-TIGHTEN!

9. Place the TWIN-FLO III under the cabinet and connect the piping and wiring. Make sure unit & outlet are free of any

dirt or debris prior to start up. Turn on the system, purge of air, check blower operation and check for any possible

leaks in the piping (run for 2 hrs. minimum). It should then be screwed to the floor through the four resilient mounting

feet (2-inside electrical box and 2 external). Do not over-tighten screws. Secure top of electrical box.

Beacon/Morris

260 NORTH ELM STREET, WESTFIELD, MASSACHUSETTS 01085

7555 TRANMERE DRIVE, MISSISSAUGA, ONTARIO L5S 1L4 CANADA

www.beacon-morris.com

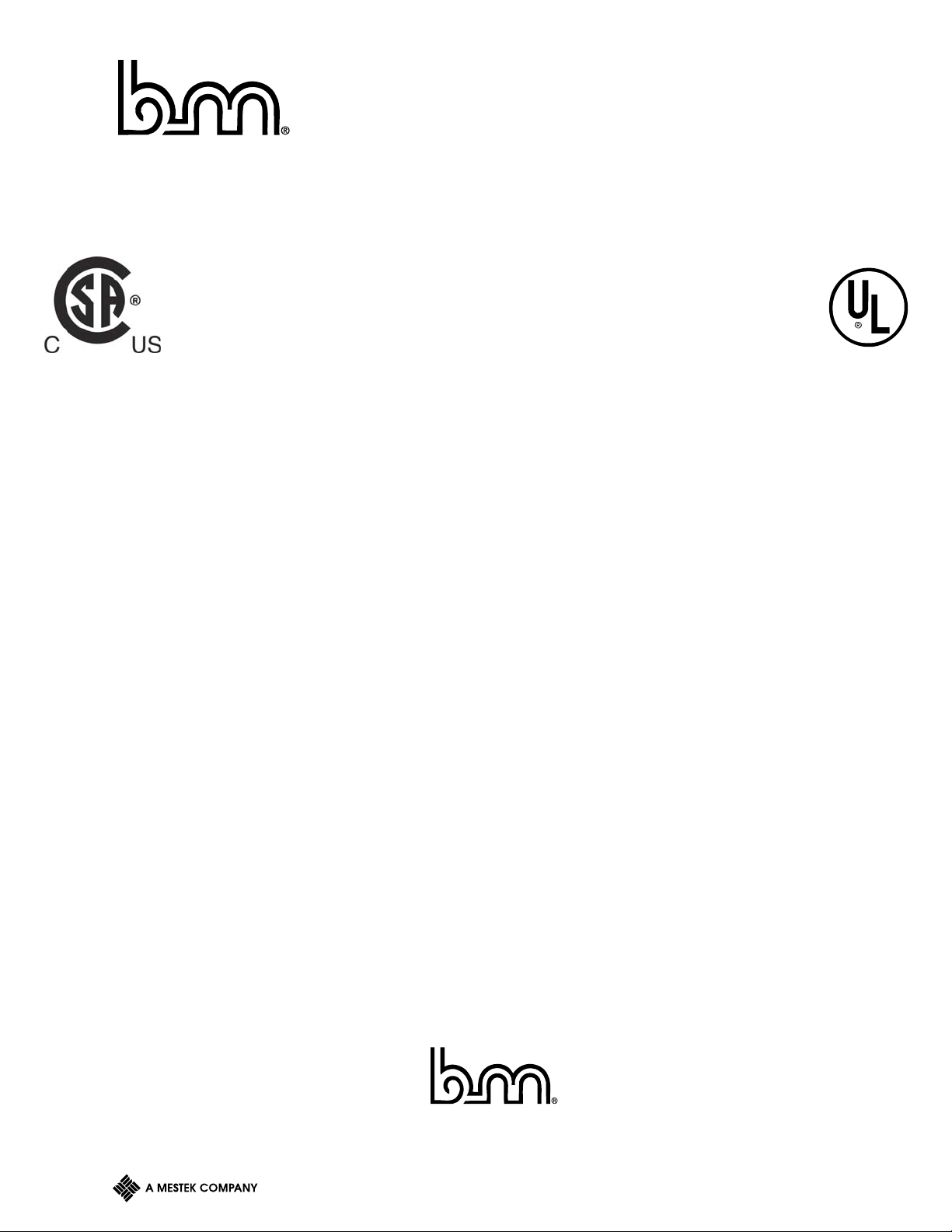

1.

TWIN-FLO III

TYPE K42

FIGURE A

12 3/4

(324)

ELECTRIC

CONNECTION

BOX

12 1/4

(311)

TWIN-FLO III

TYPE K84

FIGURE B

3 7/8

(98)

3 7/8

(98)

SWITCH

SWITCH

AQUASTAT

12 3/4

(324)

AQUASTAT

MA

X

O

F

F

11" (279) K42

ELECTRIC

CONNECTION

M

I

N

18"

(457)

HEATED

DISCHARGE

BOX

HEATED

DISCHARGE

RETURN

AIR

6 1/4 MIN.

(159)

6" PIPE

CENTERS

(152)

AIR

2" AIR

DISCHARGE

(51)

SUPPLY

RETURN

CAT-55110C

19 1/4

(489)

RETURN

AIR

6 1/4 MIN.

(159)

6" PIPE

CENTERS

(152)

AIR

2" AIR

DISCHARGE

(51)

SUPPLY

RETURN

CAT-55111C

TWIN-FLO III

TYPE K120

FIGURE C

Dimensions shown

in English and metric ( ).

3 7/8

(98)

SWITCH

12 3/4

(324)

AQUASTAT

ELECTRIC

CONNECTION

BOX

DISCHARGE

HEATED

AIR

23"

(584)

2.

RETURN

AIR

19 1/4

(489)

CAT-55112B

8 1/4 MIN.

2" PIPE

CENTERS

(51)

3 1/2 AIR

DISCHARGE

(210)

SUPPLY

RETURN

(89)

INSTALLATION OF TWIN-FLO III WALL MODELS - TYPE “W” AND TYPE “F”

SWITCH

SUPPLY

RETURN

WOLF R

I

A

CAT-55542A

W42 14 1/4 (362)

W84 21 1/4 (540)

W120 21 1/4 (540)

4" (102)

MIN.

22 1/8

(562)

W42 16" (406)

W84 23" (584)

W120 23" (584)

25"

(635)

ELECTRICAL

KNOCKOUT

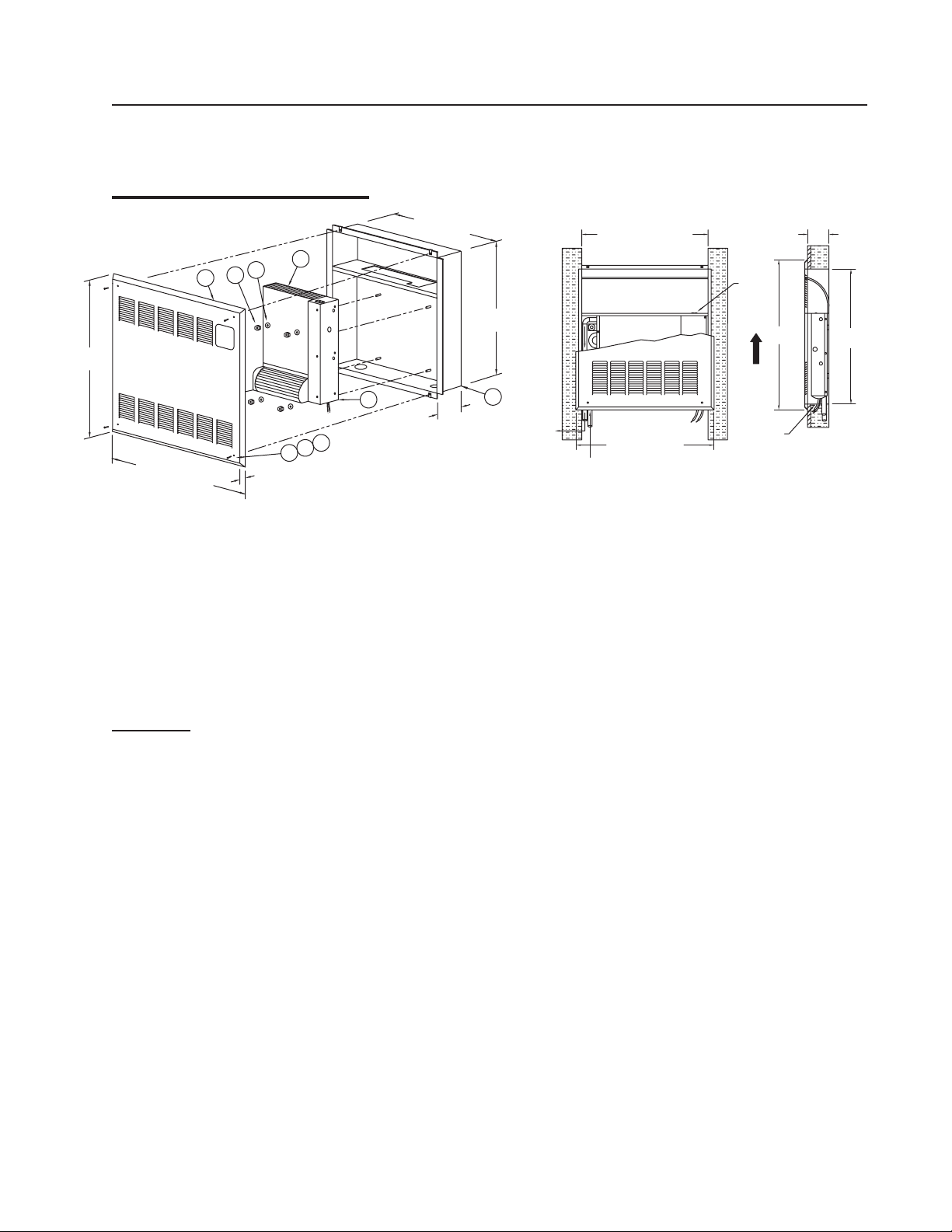

Figures D and F show exploded views of the wall models”W” & “F” Twin-Flo III's. Figure E shows the “W” type

mounted in a wall with an air outlet at the top of the unit. Figure G shows the “F” type mounted. The louvers of

the front panel will direct the air flow as shown. Use the following procedures for installation:

Type W Installation

14" (356) W42

21" (533) W84

21" (533) W120

3

5

6

1W

22 3/32

(561)

25"

(635)

4"

(102)

2W

FIGURE E

6. FLANGED NUTS

7. KICKSPACE ELECTRICAL CONTROL

BOX COVER

8. WASHERS (PLASTIC)

9. SNAP-CAP (PLASTIC)

16" (406) W42

23" (584) W84

23" (584) W120

TYPE W

FIGURE D

PARTS LIST

7

1/2

(13)

9

8

4W

CAT-55524A

FIGURE D

1W. FRONT PANEL ASS'Y

2W. BACK RECESSED PANEL ASS'Y

3. KICKSPACE UNIT

4W. FRONT PANEL MTG. SCREWS

5. LOCKWASHERS

PART #3 (KICKSPACE UNIT) WILL BE SHIPPED IN IT'S OWN CARTON. ALL REMAINING PARTS ARE

INCLUDED IN A SEPERATE CARTON.

TYPE “W” :

1.) Frame an opening between wall studding as shown in

Figure E. Model W42 will fit between studs that are

on 16'' centers. Model 5/B W84 and K120 will require

a small amount of framing to suit the mounting. A 7/8''

diameter hole is provided at the bottom of the cabinet

interior to provide entrances for electrical connections,

and a 7/8'' diameter knockout is provided at the rear

of the motor in the electrical control box. A 2-1/2''

diameter hole is provided at the bottom of the cabinet

interior to provide an entrance for piping connections.

Cut horizonal framing to clear, as necessary.

2.) After removing the front panel mounting screws (Item

4W), remove the front louvered panel (Item 1W).

Notice the direction of the louvers (see the air flow

direction label on inside front label).

3.) Nail the recessed cabinet (Item 2W) to the framed

opening at both sides.

4.) Mount the Kickspace Unit (Item 3) to the recessed

back panel, remove the electrical control box cover

from kickspace unit. Secure the kickspace unit in

place using Items 5 & 6 as shown in Figure D. Do

not over tighten.

5.) Remove the heating element from the kickspace unit

(Item 3) following the procedure described in the

installation of Type “K”, step 6. Hold this element and

fittings temporarily in place in the recessed cabinet

before soldering to check for clearance and length of

tubing required.

6.) After piping connections have been made, return the

element to the cabinet as described in Type K

installation, step 8.

7.) Electrical connections for the wall units are to be

made as shown on page 5.

8.) Make final piping and electrical connections (see

pages 5 & 6) to the system in the cabinet. Secure in

place the kickspace electrical control box cover. Turn

on the system, purge of air, check blower operation,

and check for any possible leaks in the piping.

9.) Replace front panel (Item 1W), place washers (Items 8)

in required positions, screw through holes and tighten.

10.) Place snap-cap

®

(Item 9) over washer at angle. Push

snap-cap® (Item 9) DOWN firmly until it engages with

a snap.

3.

Loading...

Loading...