Beacon Morris 61000 BTU - HBB084 User Manual

INSTALLATION INSTRUCTIONS & PARTS LIST

HORIZONTAL STEAM AND HOT WATER UNIT HEATERS

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS! CHECK UNIT DATA PLATE FOR TYPE

OF GAS AND ELECTRICAL SPECIFICATIONS AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT

POINT OF INSTALLATION. RECORD THE UNIT MODEL AND SERIAL No.(s) IN THE SPACE PROVIDED.

RETAIN FOR FUTURE REFERENCE.

HIM-15

J30-05404

Model No.

Serial No.

Improper installation, adjustment, alteration,

service or maintenance can cause property damage,

injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or

servicing this equipment.

INSTALLER’S RESPONSIBILITY

Installer Please Note: This equipment has been tested and

inspected. It has been shipped free from defects from our

factory. However, during shipment and installation, problems

such as loose wires, leaks or loose fasteners may occur. It is

the installer’s responsibility to inspect and correct any

problems that may be found.

RECEIVING INSTRUCTIONS

Inspect shipment immediately when received to determine if

any damage has occurred to the unit during shipment. After

the unit has been uncrated, check for any visible damage to

the unit. Turn fan by hand to determine if damage has occurred.

If any damage is found, the consignee should sign the bill of

lading indicating such damage and immediately fi le claim for

damage with the transportation company.

07/11

260 NORTH ELM ST.

WESTFIELD, MA 01085

TABLE OF CONTENTS

GENERAL SAFETY INFORMATION .......................... 3

SPECIFICATIONS

Dimensional Data ..................................................4

Steam Performance Data .......................................5

Steam Calculations & Correction Factors ............... 6

Hot Water Performance Data .................................7

Hot Water Calculations & Correction Factors ........8

Technical Data ....................................................... 9

Motor Data ...........................................................10

LOCATION ................................................................ 11

INSTALLATION

Unit Mounting .......................................................12

Piping ...............................................................12-16

NOTICE: It is the owner’s responsibility to provide any scaffolding or other apparatus required to perform

emergency service or annual/periodic maintenance to this equipment.

ELECTRICAL CONNECTIONS ................................17

Operation ............................................................. 17

Thermostat Wiring and Location .......................... 17

WIRING INSTALLATION .......................................... 18

OPTIONS .................................................................19

MAINTENANCE .......................................................20

REPLACEMENT PARTS ..........................................21

TROUBLESHOOTING GUIDE .................................. 22

WARRANTY ..............................................................23

INSPECTION SHEET ................................................ 24

DESCRIPTION

Horizontal hydronic unit heaters are available in both

serpentine and header type units. Serpentine units offer

outputs from 8,030 to 35,900 BTU’s (2.4 to 10.5 kW) and

are ideal for hot water (only) installations with limited

clearances. Header type horizontal units range from

18,000 to 360,000 (5.3 to 105.5 kW) and can operate

with either hot water or steam. Both units are furnished

with totally enclosed motors, with explosion proof motors

as optional on header types. The designs are certifi ed

by ETL. Do not alter these units in any way and do

not attach any ductwork to the units. If you have

any questions after reading this manual, contact the

manufacturer.

Figure 1

Serpentine

Type

The following terms are used throughout this manual, in addition to ETL requirements, to bring attention to the

presence of potential hazards or to important information concerning the product:

Indicates an imminently hazardous

situation which, if not avoided, will result in death,

serious injury or substantial property damage.

Figure 2

Header

Type

Indicates an imminently hazardous

situation which, if not avoided, may result in minor

injury or property damage.

Indicates an imminently hazardous

situation which, if not avoided, could result in

death, serious injury or substantial property

damage.

NOTICE: Used to notify of special instructions on

installation, operation or maintenance which are

important to equipment but not related to personal

injury hazards.

2

GENERAL SAFETY INFORMATION

Failure to comply with the general

safety information may result in extensive

property damage, severe personal injury or death.

Do not alter the unit heater in any

way or damage to the unit and/or severe personal

injury or death may occur!

Disconnect all power supplies

before installing or servicing the heater. If the

power disconnect is out of sight, lock it in the

open position and tag it to prevent unexpected

application of power. Failure to do so could result

in fatal electric shock, or severe personal injury.

Insure that all power sources

conform to the requirements of the unit heater

or damage to the unit will result!

Follow installation instructions CAREFULLY to avoid

creating unsafe conditions. All external wiring must

conform to applicable current local codes, and to the

latest edition of the National Electric Code ANSI/NFPA

No. 70. In Canada, all external wiring must conform

to the Canadian Electric Code, Part 1 CSA Standard

C22.1 All wiring should be done and checked by a

qualifi ed electrician using copper wire only. All steam

and hot water connections should be made and leaktested by a suitably qualifi ed individual, per instructions

in this manual. Also follow procedures listed on the “Unit

Equipment Start-Up Sheet” located in this manual.

Make certain that the power source conforms to the

electrical requirements of the heater.

Do not depend upon a thermostat

or other switch as sole means of disconnecting

power when installing or servicing heater. Always

disconnect power at main circuit breaker as

described above. Failure to do so could result in

fatal electric shock.

Do not insert fi ngers or foreign objects into the heater

or its air moving device. Do not block or tamper with the

heater in any manner while in operation or just after it

has been turned off, as some parts may be hot enough

to cause injury.

To meet ETL and OSHA requirements, units

mounted below 8 feet (2.4m) from the fl oor must be

equipped with an OSHA fan guard.

It is good practice to have a shutoff switch on the

electrical power lines controlling the heater. Whenever a

unit is serviced, shut power off to the unit.

Since these units are installed in most instances higher

than 8 feet (2.4m), proper type of ladders or scaffolding

should be used, as set up by OSHA requirements (see

Notice on page 2).

In industrial plants, professional maintenance crews

should service this equipment.

All Horizontal Unit Heaters are shipped fully assembled

and may be used for steam or hot water applications.

Coils are factory tested at 250 psig (1723.5 kg).

Each unit is packaged individually and marked for proper

identifi cation. Use normal care in handling and during

installation to prevent damage to the coils fi ns, fan and

casing.

Unless otherwise specifi ed, the following conversions

may be used for calculating SI unit measurements:

1 foot = 0.305 m

1 inch = 25.4 mm

1 psig = 6.894 kPa

1 pound = 0.453 kg

1 gallon = 3.785 L

1 inch water column = 0.249 kPa

meter/second = FPM ÷ 196.8

liter/second = CFM x 0.472

1000 Btu per hour = 0.293 kW

1000 Btu/Cu. Ft. = 37.5 MJ/m

1 cubic foot = 0.028 m

3

3

Special attention must be given to any grounding

information pertaining to this heater. To prevent the

risk of electrocution, the heater must be securely and

adequately grounded. This should be accomplished by

connecting a grounded conductor between the service

panel and the heater. To ensure a proper ground,

the grounding means must be tested by a qualifi ed

electrician.

3

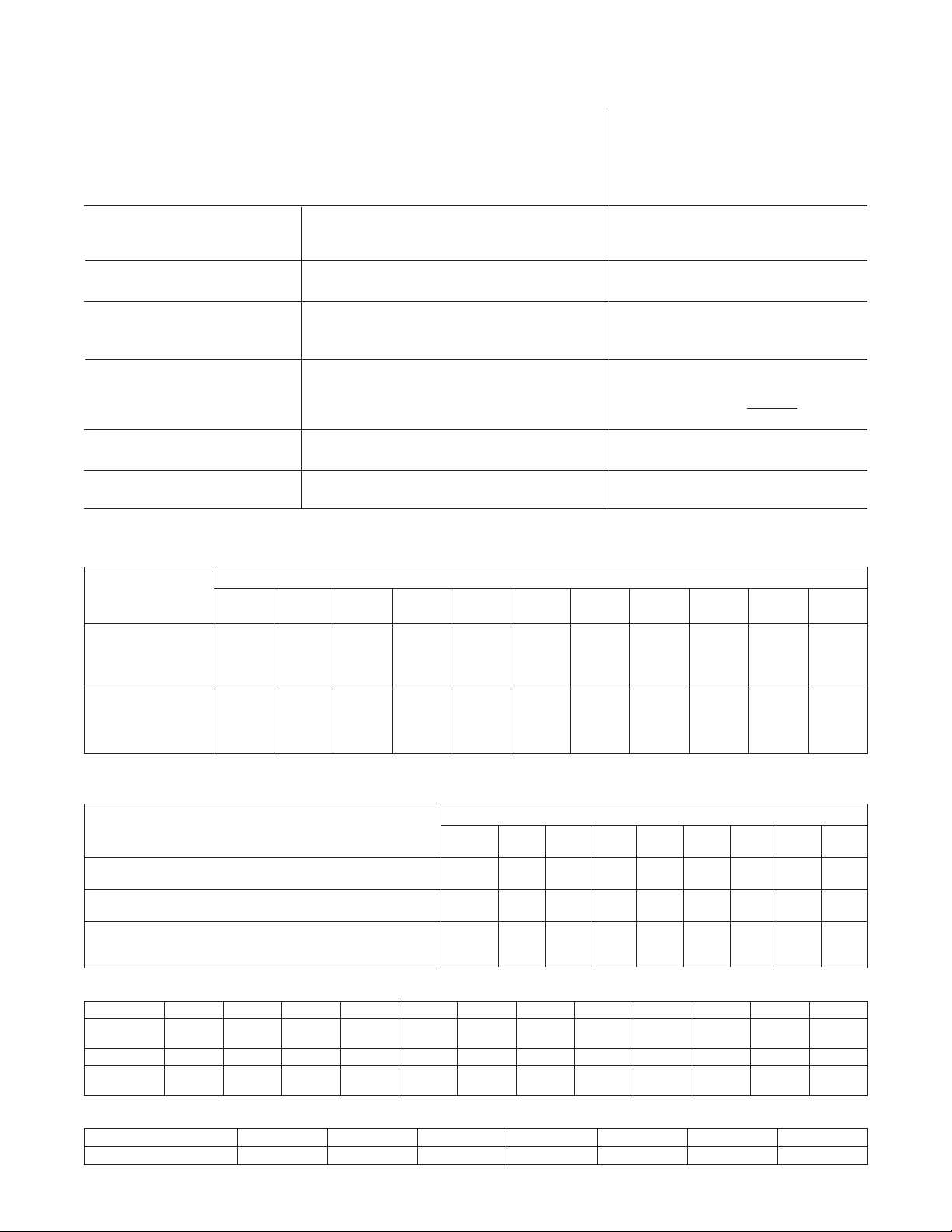

DIMENSIONAL DATA

Figure 3 – Serpentine Type

Models 108A, 118A, 125A, 136A

NOTE: Motors are totally enclosed, thermally protected, sleeve bear-

ing, with 2"(h) x 4"(w) conduit connection boxes. 3/8-16 nutserts are

attached to enclosure for balanced hanging.

Table 1 – Figure 3 Serpentine Models

MODEL

108A

118A

125A

136A

H

inches (mm)

16 (406)

16 (406)

16 (406)

18½ (470)

W

inches (mm)

18 (457)

18 (457)

18 (457)

20½ (521)

A

inches (mm)

7

⁄32 (412)

16

167⁄32 (412)

167⁄32 (412)

1822⁄32 (475)

B

inches (mm)

11¼ (286)

11¼ (286)

11¼ (286)

13¾ (349)

Table 2 – Figure 4 Header Models

A B C D E F G* H* J K L M N

MODEL

* Applies to standard motor with standard fan guard. When optional motors or OSHA fan guards are requested, dimensions will vary according to

the substitutions made.

NOTES: 1. OSHA guard standard on all serpentine models and header models 18 thru 48 supplied with 1 phase motors (dimensions shown in tables).

2. Standard motor and standard guard shown.

3. All 3 phase and explosion proof motors are shelf mounted.

inches inches inches inches inches inches inches inches inches inches inches inches inches

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

145⁄8

18

(371)

145⁄8

24

(371)

36

171⁄8

48

(435)

171⁄8

60

(435)

183⁄8

72

(467)

207⁄8

84

(530)

195⁄8

96

(498)

108

120

132

144

156

180

204

240

280

300

360

207⁄8

(530)

233⁄8

(594)

233⁄8

(594)

245⁄8

(625)

277⁄8

(708)

277⁄8

(708)

333⁄8

(848)

5

⁄16

7

(186)

75⁄16

(186)

89⁄16

(217)

89⁄16

(217)

93⁄16

(233)

107⁄16

(265)

913⁄16

(249)

107⁄16

(265)

1111⁄16

(297)

1111⁄16

(297)

125⁄16

(313)

1315⁄16

(354)

1315⁄16

(354)

1611⁄16

(424)

15

(381)

18

(457)

20½

(521)

20½

(521)

21¾

(552)

24¼

(616)

24

(610)

25¼

(641)

27¾

(705)

27¾

(705)

29

(737)

30¼

(768)

30¼

(768)

37¾

(959)

7½

(191)

9

(229)

10¼

(260)

10¼

(260)

107⁄8

(276)

121⁄8

(308)

12

(305)

125⁄8

(321)

137⁄8

(352)

137⁄8

(352)

14½

(368)

151⁄8

(384)

151⁄8

(384)

187⁄8

(479)

61⁄8

(156)

61⁄8

(156)

57⁄8

(149)

57⁄8

(149)

6

(152)

61⁄8

(156)

65⁄16

(160)

65⁄16

(160)

65⁄16

(160)

65⁄16

(160)

63⁄8

(162)

81⁄8

(206)

81⁄8

(206)

9

(229)

215⁄16

(75)

215⁄16

(75)

215⁄16

(75)

215⁄16

(75)

215⁄16

(75)

215⁄16

(75)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

33⁄16

(81)

3¼

(83)

3¼

(83)

511⁄16

(144)

51⁄16

(129)

51⁄16

(129)

511⁄16

(144)

7½

(191)

611⁄16

(170)

75⁄8

(194)

77⁄16

(194)

77⁄16

(194)

57⁄8

(149)

95⁄8

(244)

95⁄8

(244)

93⁄8

(238)

93⁄8

(238)

117⁄16

(291)

1015⁄16

(278)

111⁄16

(281)

1113⁄16

(300)

1313⁄16

(351)

13

(330)

14

(356)

13¾

(349)

13¾

(349)

14

(356)

17¾

(451)

185⁄8

(473)

12¼

(311)

12¼

(311)

14¾

(375)

14¾

(375)

16

(406)

18½

(470)

17¼

(438)

18½

(470)

21

(533)

21

(533)

22¼

(565)

25½

(648)

25½

(648)

31

(787)

9½

(241)

12½

(318)

15

(381)

15

(381)

16¼

(413)

18¾

(476)

17½

(445)

18¾

(476)

21¼

(540)

21¼

(540)

22½

(572)

23¾

(603)

23¾

(603)

31¼

(794)

Figure 4 – Header Type

Models 18 thru 360

2¼

(57)

2¼

(57)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

1¾

(44)

NO.

OF

LOUVERS

5

5

5

6

127⁄8

(327)

127⁄8

(327)

153⁄8

(391)

153⁄8

(391)

165⁄8

(422)

191⁄8

(486)

177⁄8

(454)

191⁄8

(486)

215⁄8

(549)

215⁄8

(549)

227⁄8

(581)

261⁄8

(664)

261⁄8

(664)

315⁄8

(803)

C

inches (mm)

4¼ (108)

4¼ (108)

4¼ (108)

511⁄16 (144)

1¼

(32)

1¼

(32)

1¼

(32)

1¼

(32)

1¼

(32)

1¼

(32)

1½

(38)

1½

(38)

1½

(38)

1½

(38)

1½

(38)

2

(51)

2

(51)

2

(51)

FAN DIAM.

inches (mm)

9 (229)

10 (254)

10 (254)

12 (305)

NO.

OF

LOUVERS

4

5

6

6

7

8

8

8

9

9

9

10

10

13

NOM.

NOM. FAN

DIAM.

inches (mm)

9

(229)

10

(254)

12

(305)

12

(305)

14

(356)

14

(356)

16

(406)

18

(457)

18

(457)

18

(457)

18

(457)

20

(508)

20

(508)

24

(610)

APPROX.

SHIP WT.

lbs. (kg)

22 (10.0)

24 (10.9)

25 (11.3)

31 (14.0)

APPROX.

SHIP WT.

lbs. (kg)

26

(11.8)

30

(13.6)

41

(18.6)

41

(18.6)

44

(19.9)

47

(21.3)

49

(22.2)

59

(26.7)

74

(33.5)

74

(33.5)

90

(40.8)

143

(65)

154

(70)

203

(92)

4

STEAM PERFORMANCE DATA

Table 3 - Header Type Models only

Output

BTU/

Unit

Size

18

24

36

48

60

72

84

96

108

120

132

144

156

180

204

240

280

300

360

Performance based on 2# steam pressure (13.8 kpa) at heater with air entering @ 60°F (16°C).

For Sound Ratings See Pages 7 & 9.

Use conversion Table on page 3 for all metric conversions.

* For the lower output, an optional Speed Controller must be ordered.

†Stated AMP is full load for the standard motors. AMP draw varies by motor manufacturer ± 0.2 AMPS. Please see your unit’s motor

data plate for exact (FLA) Full Load Amp rating. Additional motor data is shown on page 10.

HR*

(kW)

18,000

(5.3)

16,200

(4.7)

24,000

(7.0)

21,600

(6.3)

36,000

(10.5)

32,400

(9.5)

48,000

(14.1)

43,200

(12.7)

60,000

(17.6)

54,000

(15.8)

72,000

(21.1)

64,800

(19.0)

84,000

(24.6)

75,600

(22.2)

96,000

(28.1)

86,400

(25.3)

108,000

(31.6)

97,200

(28.5)

120,000

(35.2)

132,000

(38.7)

144,000

(42.2)

156,000

(45.7)

180,000

(52.7)

204,000

(59.8)

240,000

(70.3)

280,000

(82.0)

300,000

(87.9)

360,000

(105.5)

Cond.

lbs./hr.

(kg/hr)

18.0

(8.2)

16.2

(7.3)

24.5

(11.1)

22.0

(10.0)

37.0

(16.8)

33.0

(14.9)

49.0

(22.2)

44.0

(19.9)

61.0

(27.6)

55.0

(24.9)

73.0

(33.1)

66.0

(29.9)

85.0

(38.5)

76.0

(34.4)

97.0

(43.9)

88.0

(39.9)

110.0

(49.8)

98.0

(44.4)

122.0

(55.3)

134.0

(60.7)

146.0

(66.1)

160.0

(72.5)

190.0

(86.1)

208.0

(94.2)

244.0

(110.5)

280.0

(126.8)

310.0

(140.4)

366.0

(165.8)

E.D.R.

Sq. Ft.

(sq. m)

75

(7.0)

68

(6.3)

100

(9.3)

90

(8.4)

150

(13.9)

135

(12.5)

200

(18.6)

180

(16.7)

250

(23.2)

225

(20.9)

300

(27.9)

270

(25.1)

350

(32.5)

315

(29.3)

400

(37.2)

360

(33.4)

450

(41.8)

405

(37.6)

500

(46.5)

550

(51.1)

600

(55.7)

650

(60.4)

770

(71.5)

850

(79.0)

1000

(92.9)

1100

(102.2)

1250

(116.1)

1500

(139.4)

Final Air

Deg.°F

(Deg. °C)

102

(39)

105

(41)

109

(43)

112

(44)

119

(48)

120

(49)

119

(48)

123

(51)

121

(49)

131

(55)

120

(49)

123

(51)

115

(46)

123

(51)

123

(51)

132

(56)

115

(46)

120

(49)

118

(48)

121

(49)

120

(49)

115

(46)

135

(57)

124

(51)

123

(51)

121

(49)

117

(47)

120

(49)

Motor

HP

(kW)

16 Watts

16 Watts

25 Watts

1/20

(.037)

1/20

(.037)

1/20

(.037)

1/12

(.062)

1/12

(.062)

1/12

(.062)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/2

(.373)

1/2

(.373)

1/2

(.373)

RPM

1550

1350

1550

1350

1550

1350

1000

900

1000

900

1000

900

1000

900

1000

900

1000

900

1140

1140

1140

1140

1140

1140

1140

1100

1100

1100

Nominal

CFM

3

(m

/s)

395

(.186)

330

(.156)

450

(.212)

380

(.179)

550

(.260)

480

(.227)

750

(.354)

630

(.297)

900

(.425)

700

(.330)

1100

(.519)

950

(.448)

1400

(.661)

1100

(.519)

1400

(.661)

1100

(.519)

1800

(.850)

1500

(.708)

1900

(.897)

2000

(.944)

2200

(1.038)

2600

(1.227)

2200

(1.038)

2900

(1.369)

3500

(1.652)

4200

(1.982)

5000

(2.360)

5500

(2.596)

Outlet

FPM

(m/s)

395

(2.007)

330

(1.676)

450

(2.286)

380

(1.930)

550

(2.794)

480

(2.438)

550

(2.794)

460

(2.337)

650

(3.302)

510

(2.591)

800

(4.064)

700

(3.556)

900

(4.572)

750

(3.810)

930

(4.724)

800

(4.064)

1000

(5.080)

900

(4.572)

900

(4.572)

950

(4.826)

1000

(5.080)

1150

(5.842)

800

(4.064)

1000

(5.080)

900

(4.572)

980

(4.978)

700

(3.556)

1000

(5.080)

Nom.

Amps

@

115VAC†

0.80

0.80

1.2

1.4

1.4

1.4

2.2

2.2

2.2

4.5

4.5

4.5

4.5

4.5

4.5

4.5

5.4

5.4

5.4

Nom. Fan

Diam.

Inches

(mm)

9

(228.6)

9

(228.6)

10

(254.0)

10

(254.0)

10

(254.0)

10

(254.0)

12

(304.8)

12

(304.8)

12

(304.8)

12

(304.8)

14

(355.6)

14

(355.6)

14

(355.6)

14

(355.6)

16

(406.4)

16

(406.4)

16

(406.4)

16

(406.4)

18

(457.2)

18

(457.2)

18

(457.2)

18

(457.2)

18

(457.2)

18

(457.2)

20

(508.0)

20

(508.0)

24

(609.6)

24

(609.6)

5

STEAM CALCULATIONS AND CORRECTION FACTORS

EXAMPLE: –

UNIT SIZE: _________ 24

Steam Pressure ___ 10 PSI

Entering Air Temp. __ 40°F

I. CAPACITY

A. For 2 lbs. steam, 60° entering air Read output directly from Table 3, 24,000 BTU/HR.

(Ref., Std. 24).

B. For higher steam pressures Multiply output from Table 3 by appropriate correction

and/or E.A.T.’s above or below 60°F factor from Table 4 (below).

II. FINAL AIR TEMPERATURE

A. For 2 lbs. steam, 60° entering air Read temperature directly from Table 3, 109°F.

(Ref., Std. 24).

24,000 x 1.29 = 30,960 BTU/HR.

B. For capacities calculated in I.B. (above) Output from I.B.

III. FINAL AIR VOLUME

A. For 2 lbs. steam, 60° entering air

Nom. CFM Final

B. For fi nal air temperatures calculated 460 + Final Air Temp from II.B. x from = Air 460+103.4

In II. B. (above) 530 Table 3 Volume 530

IV. CONDENSATE PER HOUR Read lbs. per hour from Table 3, 24.5 LBS./HR.

A. For 2 lbs. steam, 60° entering air (Ref., Std. 24).

B. For capacities calculated in I.B. (above) Output from I.B.

Latent Heat From Table 5 953

1.085 x CFM from Table 3

460 + Final Air Temp from Table 3 x from = Air 460+109

530

+ E.A.T. = Final Air Temp.

Nom. CFM Final

Table 3 Volume 530

= lbs. per hour of condensate

30,960

1.085 x 450

30,960

= 32.5 LBS./HR.

x 450 = 483 CFM

TABLE 4 — STEAM CORRECTION FACTORS BASED ON

2 PSI (13.8 kPa) STEAM AND 60 Deg. F (16 Deg. C) E.A.T.

ENTERING AIR

TEMPERATURE

Deg. F (Deg. C)

30 -(1)

40 (4)

50 (10)

60 (16)

70 (21)

80 (27)

90 (32)

100 (38)

0

(0)

1.19

1.11

1.03

0.96

0.88

0.81

0.74

0.67

STEAM PRESSURE (SATURATED) — LBS. PER SQ. IN. (kPa)

2

(13.8)

1.24

1.16

1.08

1.00

0.93

0.85

0.78

0.71

5

(34.5)

1.29

1.21

1.13

1.05

0.97

0.90

0.83

0.76

10

(68.9)

1.38

1.29

1.21

1.13

1.06

0.98

0.91

0.84

15

(103.4)

1.44

1.34

1.28

1.19

1.12

1.04

0.97

0.89

20

(137.9)

1.50

1.42

1.33

1.25

1.17

1.10

1.02

0.95

30

(206.8)

1.60

1.51

1.43

1.35

1.27

1.19

1.12

1.04

40

(275.8)

1.68

1.60

1.51

1.43

1.35

1.27

1.19

1.12

50

(344.7)

1.70

1.66

1.58

1.50

1.42

1.34

1.26

1.19

75

(517.1)

1.90

1.81

1.72

1.64

1.55

1.47

1.39

1.32

100

(689.4)

2.02

1.93

1.84

1.75

1.66

1.58

1.50

1.42

(861.8)

+ 40 = 103.4°F.

x 450 = 478 CFM

125

2.11

2.02

1.93

1.84

1.76

1.68

1.59

1.51

150

(1,034.1)

2.20

2.11

2.02

1.93

1.84

1.76

1.67

1.59

Steam Pressure

psi (kPa)

Steam Temperature

Deg. F (Deg. C)

Latent Heat of Steam

Btu/lbm (KJ/Kg)

0

(0)

212

(100)

970

(2256)

TABLE 5 — PROPERTIES OF SATURATED STEAM

2

(13.8)

218.5

(103.6)

966

(2247)

5

(34.5)

227.1

(108.4)

961

(2235)

STEAM PRESSURE IN PSIG (kPa)

10

(68.9)

239.4

(115.2)

953

(2217)

15

(103.4)

249.8

(121.0)

946

(2200)

20

(137.9)

258.8

(126.0)

940

(2186)

30

(206.8)

274.0

(134.4)

929

(2161)

40

(275.8)

286.7

(141.5)

920

(2140)

6

50

(344.7)

297.7

(147.6)

912

(2121)

75

(517.1)

319.9

(159.9)

891

(2072)

100

(689.4)

337.9

(169.9)

881

(2049)

125

(891.8)

352.9

(178.3)

868

(2019)

150

(1,034.1)

365.9

(185.5)

857

(1993)

HOT WATER PERFORMANCE DATA

Table 6 - Serpentine and Header Type Models

Nom.

Amps

@

115VAC†

0.80

0.80

1.2

1.4

0.80

0.80

1.2

1.4

1.4

1.4

2.2

2.2

2.2

4.5

4.5

4.5

4.5

4.5

4.5

4.5

5.4

5.4

5.4

Sound

Rating

II

I

II

I

II

I

II

I

II

I

II

I

II

I

II

I

II

I

II

I

III

II

III

II

III

II

III

IV

IV

IV

III

IV

IV

IV

IV

IV

Unit

Size

108A

118A

125A

136A

18

24

36

48

60

72

84

96

108

120

132

144

156

180

204

240

280

300

360

Output

BTU/

HR*

(kW)

8,030

(2.4)

6,800

(2.0)

18,400

(5.4)

15,650

(4.6)

24,800

(7.3)

21,230

(6.2)

35,900

(10.5)

32,300

(9.5)

13,050

(3.8)

11,725

(3.4)

17,400

(5.1)

15,600

(4.6)

26,100

(7.6)

23,500

(6.9)

34,800

(10.2)

31,300

(9.2)

43,600

(12.8)

39,200

(11.5)

52,300

(15.3)

47,000

(13.8)

61,000

(17.9)

54,900

(16.1)

69,700

(20.4)

62,700

(18.4)

78,400

(23.0)

70,500

(20.7)

87,100

(25.5)

95,800

(28.1)

104,000

(30.5)

113,000

(33.1)

118,000

(34.6)

148,000

(43.4)

174,000

(51.0)

209,100

(61.3)

230,000

(67.4)

261,300

(76.6)

Flow

Rate

GPM

(L/s)

0.8

(.050)

1.9

(.120)

2.5

(.158)

3.6

(.227)

1.3

(.082)

1.8

(.114)

2.7

(.170)

3.5

(.221)

4.4

(.278)

5.3

(.334)

6.1

(.385)

7.0

(.442)

7.9

(.498)

8.8

(.555)

9.6

(.606)

10.4

(.656)

11.3

(.713)

11.8

(.744)

14.9

(.940)

17.4

(1.098)

21.0

(1.325)

23.0

(1.451)

26.2

(1.653)

Final

Air

Deg. °F

(Deg. °C)

91

(33)

90

(32)

94

(34)

96

(36)

102

(39)

106

(41)

99

(37)

100

(38)

95

(35)

99

(37)

96

(36)

98

(37)

103

(39)

103

(39)

103

(39)

111

(44)

105

(41)

112

(44)

104

(40)

106

(41)

100

(38)

106

(41)

106

(41)

113

(45)

100

(38)

103

(39)

102

(39)

104

(40)

104

(40)

100

(38)

110

(43)

107

(42)

106

(41)

106

(41)

102

(39)

103

(39)

Prssr.

Drop

FT./H

O

2

(m/water)

0.80

(.244)

2.20

(.671)

2.20

(.671)

3.00

(.914)

0.005

(.002)

0.014

(.004)

0.09

(.027)

0.12

(.037)

0.17

(.052)

0.23

(.070)

0.24

(.073)

0.29

(.088)

0.36

(.110)

0.39

(.119)

0.41

(.125)

0.43

(.131)

0.53

(.162)

0.6

(.183)

0.79

(.241)

1.06

(.323)

1.33

(.405)

2.1

(.640)

2.1

(.640)

Motor

HP

(kW)

16 Watts

16 Watts

25 Watts

1/20

(.037)

16 Watts

16 Watts

25 Watts

1/20

(.037)

1/20

(.037)

1/20

(.037)

1/12

(.062)

1/12

(.062)

1/12

(.062)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/3

(.249)

1/2

(.373)

1/2

(.373)

1/2

(.373)

1550

1350

1550

1350

1550

1350

1000

900

1550

1350

1550

1350

1550

1350

1000

900

1000

900

1000

900

1000

900

1000

900

1000

900

1140

1140

1140

1140

1140

1140

1140

1100

1100

1100

Nominal

CFM

3

(m

/s)RPM

245

(.116)

210

(.099)

500

(.236)

420

(.198)

580

(.274)

460

(.217)

850

(.401)

750

(.354)

395

(.186)

350

(.165)

450

(.212)

380

(.179)

550

(.260)

480

(.227)

750

(.354)

630

(.297)

900

(.425)

700

(.330)

1100

(.519)

950

(.448)

1400

(.661)

1100

(.519)

1400

(.661)

1100

(.519)

1800

(.850)

1500

(.708)

1900

(.897)

2000

(.944)

2200

(1.038)

2600

(1.227)

2200

(1.038)

2900

(1.369)

3500

(1.652)

4200

(1.982)

5000

(2.360)

5500

(2.596)

Outlet

FPM

(m/s)

250

(1.270)

215

(1.092)

500

(2.540)

420

(2.134)

590

(2.997)

450

(2.286)

550

(2.794)

480

(2.438)

395

(2.007)

350

(1.778)

450

(2.286)

380

(1.930)

550

(2.794)

480

(2.438)

550

(2.794)

460

(2.337)

650

(3.302)

510

(2.591)

800

(4.064)

700

(3.556)

900

(4.572)

750

(3.810)

930

(4.724)

800

(4.064)

1000

(5.080)

900

(4.572)

900

(4.572)

950

(4.826)

1000

(5.080)

1150

(5.842)

800

(4.064)

1000

(5.080)

900

(4.572)

980

(4.978)

700

(3.556)

1000

(5.080)

Performance based on 200°F (93°C) EWT, 60°F (16°C) E.A.T., 20°F (11°C)TD.

For Fan Diameter See Page 4.

Use conversion Table on page 3 for all metric conversions.

* For the lower output, an optional Speed Controller must be ordered.

†Stated AMP is full load for standard motors. AMP draw varies by motor manufacturer ± 0.2 AMPS. Please see your unit’s motor

data plate for exact (FLA) Full Load Amp rating. Additional motor data is shown on page 10.

7

HOT WATER CALCULATIONS AND CORRECTION FACTORS

EXAMPLE: –

UNIT SIZE: _______________________ 24

Entering Water Temp. ____________ 160°F

Entering Air Temp. _______________ 40°F

Water Temperature Drop __________ 10°F

I. CAPACITY @ 20° TD:

A. For 200° EWT, 60° EAT Read output directly from Table 6,

17,400 BTU/HR (Ref., Std. 24).

B. For EWT and/or EAT above Multiply output from Table 6

or below Standard by factor from Table 7 (below). 17,400 x .878 = 15,277 BTU/HR.

II. CAPACITY AT OTHER TD’s Multiply output obtained in IA. or IB. IA - 17,400 x 1.15 = 20,010 BTU/HR.

A. For TD’s from 5 to 60°F (above) by appropriate factor from Table 8 – OR –

(below) IB - 15,277 x 1.15 = 17,569 BTU/HR.

III. GPM AT OTHER TD’s Multiply GPM of unit for 20° TD, from Table 6

A. For TD’s from 5 to 60°F by appropriate factor from Table 8 (below).

IV. CAPACITY AT OTHER RATES Multiply output from Table 6 by factor

OF WATER FLOW from Table 10 (below).

V. PRESSURE LOSS AT OTHER TD’s Multiply P.D. of unit for 20° TD, from Table 6

A. For TD’s from 5 to 60°F by appropriate factor from Table 8 (below). .014 x 5.00 = .07 Ft. H

TABLE 7 — HOT WATER CONVERSION FACTORS BASED ON 200° (93°C) ENTERING WATER,

60° (16°C) ENTERING AIR AND 20° (11°C) TEMPERATURE DROP

ENTERING AIR

TEMPERATURE

°F (°C)

30 -(1)

40 (4)

50 (10)

60 (16)

70 (21)

80 (27)

90 (32)

100 (38)

100°

(38)

0.518

0.439

0.361

0.286

0.212

0.140

0.069

0.000

120°

(49)

0.666

0.585

0.506

0.429

0.353

0.279

0.207

0.137

140°

(60)

0.814

0.731

0.651

0.571

0.494

0.419

0.345

0.273

ENTERING WATER TEMPERATURE — °F (°C)

160°

(71)

0.963

0.878

0.796

0.715

0.636

0.558

0.483

0.409

180°

(82)

1.120

1.025

0.941

0.857

0.777

0.698

0.621

0.546

200°

(93)

1.268

1.172

1.085

1.000

0.918

0.837

0.759

0.682

1.8 x 2.30 = 4.14 GPM (Applies only to units with

Std. 200° EWT, 60° EAT.) For all others calculate

BTU

260°

500 x TD

O

2

280°

(138)

1.850

1.755

1.663

1.571

1.483

1.397

1.311

1.230

using formula – GPM =

220°

(104)

1.408

1.317

1.231

1.143

1.060

0.977

0.897

0.818

240°

(116)

1.555

1.464

1.375

1.286

1.201

1.117

1.035

0.955

(127)

1.702

1.609

1.518

1.429

1.342

1.257

1.173

1.094

300°

(149)

1.997

1.908

1.824

1.717

1.630

1.545

1.462

1.371

TABLE 8 — HOT WATER OUTPUT, FLOW RATE AND PRESSURE LOSS FACTORS BASED ON STANDARD

CONDITIONS OF 200°F (93°C) ENTERING WATER, 60°F (16°C) ENTERING AIR & 20°F (11°C) WATER DROP

USE FACTORS FROM THIS TABLE TO OBTAIN

APPROXIMATE RESULTS

To obtain output for other Water Temperature Drops,

multiply basic output rating by applicable Factor.

To obtain fl ow for other Water Temperature Drops,

multiply basic rate rating by applicable Factor.*

To obtain Pressure Loss Feet (Meters) of Water

for other temperature Drops, multiply Basic loss

at 20°F (11°C) drop by Factor.

5

(3)

1.25

5.00

10.00

10

(6)

1.15

2.30

5.00

TEMPERATURE DROP °F (°C)

25

15

(8)

1.08

1.44

2.00

20

(11)

1.00

1.00

1.00

(14)

.94

.74

.60

30

(17)

.90

.59

.40

40

(22)

.83

.40

.20

50

(28)

.76

.30

.13

60

(33)

.72

.24

.07

*TABLE 9 — MINIMUM WATER FLOW

MODEL No.

MINIMUM

GPM (L/s)

MODEL No.

MINIMUM

GPM (L/s)

108A

0.125

(.008)

108

3.35

(.211)

118A

0.125

(.008)

120

3.60

(.227)

125A

0.125

(.008)

132

4.09

(.258)

136A

0.125

(.008)

144

4.09

(.258)

18

0.750

(.047)

156

4.09

(.258)

24

1.240

(.078)

180

4.34

(.274)

36

1.240

(.078)

204

4.34

(.274)

48

1.490

(.094)

240

4.59

(.290)

60

1.490

(.094)

280

4.59

(.290)

72

1.620

(.102)

300

6.08

(.384)

84

1.860

(.117)

360

6.08

(.384)

96

3.350

(.211)

*TABLE 10 — HEATING CAPACITY FACTORS FOR VARIOUS RATES OF WATER FLOW

% of Rated Water Flow

Heating Capacity Factor

25%

.80

50%

.89

75%

.96

100%

1.00

125%

1.04

150%

1.07

175%

1.10

8

Loading...

Loading...