BD Biosciences FACSAria User Guide

BD FACSAria

User’s Guide

bdbiosciences.com

Part No. 640760 Rev. A May 2006

BD Biosciences |

Asia Pacific |

Brazil |

Canada |

2350 Qume Drive |

Tel (65) 6-861-0633 |

Tel (55) 11-5185-9995 |

Tel (888) 259-0187 |

San Jose, CA 95131-1807 |

Fax (65) 6-860-1590 |

Fax (55) 11-5185-9895 |

(905) 542-8028 |

USA |

|

|

Fax (905) 542-9391 |

Tel (877) 232-8995 |

|

|

canada@bd.com |

Fax (408) 954-2347 |

Europe |

Japan |

Mexico |

|

|||

|

Tel (32) 53-720211 |

Nippon Becton Dickinson Company, Ltd. |

Tel (52) 55 5999 8296 |

|

Fax (32) 53-720452 |

Tel 0120-8555-90 |

Fax (52) 55 5999 8288 |

© 2006, Becton, Dickinson and Company. All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in retrieval systems, or translated into any language or computer language, in any form or by any means: electronic, mechanical, magnetic, optical, chemical, manual, or otherwise, without prior written permission from BD Biosciences.

The information in this guide is subject to change without notice. BD Biosciences reserves the right to change its products and services at any time to incorporate the latest technological developments. Although this guide has been prepared with every precaution to ensure accuracy, BD Biosciences assumes no liability for any errors or omissions, nor for any damages resulting from the application or use of this information. BD Biosciences welcomes customer input on corrections and suggestions for improvement.

BD, the BD logo, BD Calibrite, BD FACS, BD FACSAria, BD FACSDiva, BD FACSFlow, BD FACSRinse, BD Falcon, and BD Trucount are trademarks of Becton, Dickinson and Company.

Clorox is a registered trademark of The Clorox Company. Fluoresbrite is a trademark of Polysciences, Inc. JDS Uniphase is a trademark of the JDS Uniphase Corporation. Kimwipe is a registered trademark of the Kimberley-Clark Corporation. Microsoft and Windows are registered trademarks of Microsoft Corporation. Sapphire is a trademark and Coherent is a registered trademark of Coherent, Inc. SPHERO is a trademark of

Spherotech, Inc. Texas Red, Alexa Fluor, and Cascade Blue are registered trademarks and Pacific Blue is a trademark of Molecular Probes, Inc.

All other company and product names might be trademarks of the respective companies with which they are associated.

FCC Information

For Research Use Only. Not for use in diagnostic procedures.

WARNING: Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his or her own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC limits.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement sur the matériel brouilleur du Canada.

History

Revision |

Date |

Change Made |

|

|

|

333608 |

1/03 |

Initial release |

338645 |

10/04 |

Updated for new instrument and software features: bubble and ND filters, |

|

|

adjustable nozzle, waste cap with baffle and disposable filtered cap, adjustable |

|

|

nozzle, running samples using BD FACSDiva software version 4.1 |

640760 |

5/06 |

Updated for BD FACSDiva software version 5.0 and new ceramic nozzles |

|

|

|

Contents

About This Guide |

ix |

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

x |

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xi |

Safety and Limitations |

xiii |

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiii |

Laser Product Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiv |

Precautions for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiv |

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

Biological Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xvi |

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xvii |

Precaution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xviii |

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xx |

Chapter 1: BD FACSAria Instrument Components |

21 |

Fluidics Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Containers and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Power and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

Flow Cytometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

Fluidics Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

Optics System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

Instrument Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

iii

Chapter 2: Theory of Operation |

45 |

Fluid Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

Sheath Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

Sample Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

Signal Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

Light Scatter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

Fluorescent Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

Signal Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Detector Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

Electronic Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

Pulse Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

60 |

Laser Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

Drop Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

Side Stream Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

Drop Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

70 |

Conflict Resolution During Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

Chapter 3: Using BD FACSDiva Software |

79 |

Workspace Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

80 |

Instrument Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

Fluidics Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

Fluidics Level Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

Instrument Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

Instrument Status Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

Acquisition Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

iv BD FACSAria User’s Guide

Sorting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

Sort Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

Sort Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

Sort Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

Sort Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

100 |

Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

102 |

Chapter 4: Running Samples |

103 |

Instrument Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

104 |

Setting Up the Breakoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

106 |

Setting Up the Fluidics Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

108 |

Instrument Quality Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

Setting Up the QC Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

Running QC Particles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

116 |

Tracking QC Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

Reusing the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

Optimization of Instrument Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

Creating the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

Adjusting the Voltages and Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . |

130 |

Adjusting Area Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

Optimizing Fluorescence PMT Voltages . . . . . . . . . . . . . . . . . . . . . . . . . |

136 |

Calculating Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

Data Recording and Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

Setting Up the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

Recording Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

Analyzing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

Saving the Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

Sample QC Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

147 |

Contents v

Chapter 5: Sorting |

149 |

Setting Up for Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Setting Up for Bulk Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 Determining the Drop Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 Setting Up the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 Sorting Beads to Determine the Drop Delay . . . . . . . . . . . . . . . . . . . . . . 156 Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158 Setting Up the Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 Starting and Monitoring the Sort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 Setting Up for Sorting Into a Plate or Slide . . . . . . . . . . . . . . . . . . . . . . . . . . 163 Installing the Sorting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163 Setting Up the Stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165 Creating a Custom Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Chapter 6: Shutdown and Maintenance |

171 |

Daily Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Fluidics Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

External Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Internal Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Purging Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Changing Fluid Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Changing the Sample Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Changing Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Changing the Bubble Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Unscheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Changing the Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Adjusting the Nozzle Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Cleaning a Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

vi BD FACSAria User’s Guide

Cleaning the Camera Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205 Cleaning Optical Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207 Purging the Bubble Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Chapter 7: Troubleshooting |

211 |

Troubleshooting the Stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Troubleshooting the Breakoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Sorting Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Acquisition Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Fluidics Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Electronics Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Appendix A: Supplies and Options |

231 |

Instrument Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Optical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Other Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Laser Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Instrument Setup Particles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Instrument Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Application Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Two-Laser System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Three-Laser System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

FACSAria Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Defining a Custom Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Index |

249 |

Contents vii

viii BD FACSAria User’s Guide

About This Guide

This user’s guide contains the instructions necessary to operate and maintain your BD FACSAria™ flow cytometer. Because many instrument functions are controlled by BD FACSDiva™ software, this guide also contains basic software information needed for instrument setup. To familiarize yourself with the software, do the tutorials in the BD FACSDiva software Getting Started guide. For detailed information on software features, refer to the BD FACSDiva Software Reference Manual.

The BD FACSAria User’s Guide assumes you have a working knowledge of basic Microsoft® Windows® operation. If you are not familiar with the Windows operating system, refer to the documentation provided with your computer.

New users of the BD FACSAria flow cytometer should read:

•Chapter 1 to become familiar with instrument components

•Chapter 2 to understand how the instrument works and to learn about the software components used to control different subsystems

•Chapter 3 to see where software components are located

Instructions for routine acquisition, analysis, and sorting can be found in Chapters 4 and 5.

Once you become familiar with routine operation and need only a quick reminder of the main steps, use the quick reference guide provided with this user’s guide.

ix

Conventions

The following tables list conventions used throughout this guide. Table 1 lists the symbols that are used in this guide or on safety labels to alert you to a potential hazard. Text and keyboard conventions are shown in Table 2

Table 1 Hazard symbolsa

Symbol Meaning

Caution: hazard or unsafe practice that could result in material damage, data loss, minor or severe injury, or death

Electrical danger

Laser radiation

Biological risk

a.Although these symbols appear in color on the instrument, they are in black and white throughout this user’s guide; their meaning remains unchanged.

Table 2 Text and keyboard conventions

Convention |

Use |

|

|

Tip |

Highlights features or hints that can save time and prevent |

|

difficulties |

NOTICE |

Describes important features or instructions |

Italics |

Italics are used to highlight book titles and new or unfamiliar |

|

terms on their first appearance in the text. |

> |

The arrow indicates a menu choice. For example, “choose |

|

File > Print” means to choose Print from the File menu. |

Ctrl-X |

When used with key names, a dash means to press two keys |

|

simultaneously. For example, Ctrl-P means to hold down the |

|

Control key while pressing the letter p. |

|

|

x BD FACSAria User’s Guide

Technical Assistance

For technical questions or assistance in solving a problem:

•Read the section of the user’s guide specific to the operation you are performing.

•See Chapter 7, Troubleshooting.

If additional assistance is required, contact your local BD Biosciences technical support representative or supplier.

When contacting BD Biosciences, have the following information available:

•product name, part number, and serial number

•any error messages

•details of recent system performance

For instrument support from within the US, call (877) 232-8995. For support from within Canada, call (888) 259-0187.

Customers outside the US and Canada, contact your local BD representative or distributor.

About This Guide |

xi |

xii BD FACSAria User’s Guide

Safety and Limitations

The BD FACSAria™ flow cytometer is equipped with safety features for your protection. Operate only as directed in the user’s guide. Do not perform instrument maintenance or service except as specifically stated. Keep this safety information available for reference.

Laser Safety

Lasers or laser systems emit intense, coherent electromagnetic radiation that has the potential of causing irreparable damage to human skin and eyes. The main hazard of laser radiation is direct or indirect exposure of the eye to thermal radiation from the visible and near-infrared spectral regions (325–1,400 nm). Direct eye contact can cause corneal burns, retinal burns, or both, and possible blindness.

There are other potentially serious hazards in other spectral regions. For cytometers that contain UV lasers, excessive ultraviolet exposure produces an intolerance to light (photophobia) accompanied by redness, a tearing discharge from the mucous membrane lining the inner surface of the eyelid (conjunctiva), shedding of the corneal cell layer surface (exfoliation), and stromal haze. These symptoms are associated with photokeratitis, otherwise known as snow blindness or welder’s flash, which results from radiant energy–induced damage to the outer epidermal cell layer of the cornea. These effects can be the result of laser exposure lasting only a fraction of a second.

xiii

Laser Product Classification

Laser hazard levels depend on laser energy content and the wavelengths used. A numbered system is used to categorize laser products according to different hazard levels. The higher the classification number, the greater the potential hazard. The BD FACSAria flow cytometer is a Class I (1) laser product per 21 CFR Subchapter J and IEC/EN 60825-1:1994 + A2:2001. The lasers and the laser energy are fully contained within the instrument structure and call for no special work area safety requirements except during service procedures. These procedures are to be carried out only by BD Biosciences service personnel.

Precautions for Safe Operation

Modification or removal of the optics covers or laser shielding could result in exposure to hazardous laser radiation. To prevent irreparable damage to human skin and eyes, do not remove the optics covers or laser shielding, adjust controls, or attempt to service the instrument any place where laser warning labels are attached (see Precaution Labels on page xviii).

Modification or removal of the optics covers or laser shielding could result in exposure to hazardous laser radiation. To prevent irreparable damage to human skin and eyes, do not remove the optics covers or laser shielding, adjust controls, or attempt to service the instrument any place where laser warning labels are attached (see Precaution Labels on page xviii).

Use of controls or adjustments or performance of procedures other than those specified in the user’s guide may result in hazardous radiation exposure.

Use of controls or adjustments or performance of procedures other than those specified in the user’s guide may result in hazardous radiation exposure.

Keep all instrument doors closed during instrument operation. When operated under these conditions, the instrument poses no danger of exposure to hazardous laser radiation.

Keep all instrument doors closed during instrument operation. When operated under these conditions, the instrument poses no danger of exposure to hazardous laser radiation.

xiv BD FACSAria User’s Guide

Electrical Safety

Lethal electrical hazards are present in some lasers, particularly in laser power supplies. Many portions of the electrical system, including the printed circuit boards, are at a dangerous voltage level. To prevent shock injury, follow these guidelines.

Lethal electrical hazards are present in some lasers, particularly in laser power supplies. Many portions of the electrical system, including the printed circuit boards, are at a dangerous voltage level. To prevent shock injury, follow these guidelines.

•Turn off the power switch and unplug the power cord before servicing the instrument, unless otherwise noted.

•Connect the equipment only to an approved power source. Do not use extension cords. If cords, plugs, or cables are damaged, immediately contact BD Biosciences for a replacement.

•Do not remove the grounding prong from the power plug. Have a qualified electrician replace any ungrounded receptacles with properly grounded receptacles in accordance with the local electrical code.

•For installation outside the US, use the proper power cord. Contact your local BD representative for more information.

Do not plug the fluidics cart power cord into a wall outlet. Plug the cord into the cytometer only. This ensures proper electrical grounding and protects against electrical shock or damage to the instrument.

Do not plug the fluidics cart power cord into a wall outlet. Plug the cord into the cytometer only. This ensures proper electrical grounding and protects against electrical shock or damage to the instrument.

A 12,000-volt potential exists between the deflection plates when they are on. Contact with the charged plates results in serious electrical shock. Do not touch the deflection plates when the voltage warning light is illuminated, or when the software indicates that the plate voltage is on. The plates remain energized even when the sort block door is opened.

A 12,000-volt potential exists between the deflection plates when they are on. Contact with the charged plates results in serious electrical shock. Do not touch the deflection plates when the voltage warning light is illuminated, or when the software indicates that the plate voltage is on. The plates remain energized even when the sort block door is opened.

The barb and the stream-charging wire conduct electrical charge during sorting. To prevent shock, do not touch the barb or the stream-charging wire when the voltage warning light is illuminated or any time during sorting.

The barb and the stream-charging wire conduct electrical charge during sorting. To prevent shock, do not touch the barb or the stream-charging wire when the voltage warning light is illuminated or any time during sorting.

Safety and Limitations |

xv |

Biological Safety

All biological specimens and materials coming into contact with them can transmit potentially fatal disease. To prevent exposure to biohazardous agents, follow these guidelines.

All biological specimens and materials coming into contact with them can transmit potentially fatal disease. To prevent exposure to biohazardous agents, follow these guidelines.

•Handle all biological specimens and materials as if capable of transmitting infection. Dispose of waste using proper precautions and in accordance with local regulations. Never pipette by mouth. Wear suitable protective clothing, eyewear, and gloves.

•Expose waste container contents to bleach (10% of total volume) before disposal. Dispose of waste in accordance with local regulations. Use proper precaution and wear suitable protective clothing, eyewear, and gloves.

•Prevent waste overflow by emptying the waste container daily and whenever the waste indicator shows the waste is getting full.

•The waste tank can become pressurized when the cytometer is running. Always disconnect the tank from the wet cart before you empty it. Wait at least 1 minute for pressure to dissipate before you remove the waste cap or sensor.

•Replace the waste tank cap every month. Failure to do so could cause the waste tank to malfunction. For tracking, write the date on the waste cap label each time you change the cap.

•Do not wet the waste tank cap. If wet, the filter in the cap will cause the tank to malfunction. To keep the cap dry, place it on the bench label-

side up when it is not on the tank. If you see |

trap |

|

|

liquid in the waste cap trap, remove the drain |

|

plug and fully drain the liquid before you |

|

replace the plug. |

drain plug |

|

xvi BD FACSAria User’s Guide

Cell sorters that use droplet generation methods, like the BD FACSAria, can produce aerosols around the sample stream. When acquiring biohazardous samples, follow universal precautions at all times. Keep the sort block door closed during sorting. If you need to access the sort block, turn off the stream before opening the door.

Cell sorters that use droplet generation methods, like the BD FACSAria, can produce aerosols around the sample stream. When acquiring biohazardous samples, follow universal precautions at all times. Keep the sort block door closed during sorting. If you need to access the sort block, turn off the stream before opening the door.

For information on laboratory safety, refer to the following guidelines. NCCLS documents can be ordered online at www.nccls.org.

•Schmid I, Nicholson JKA, Giorgi JV, et al. Biosafety guidelines for sorting of unfixed cells. Cytometry. 1997;28:99-117.

•Protection of Laboratory Workers from Instrument Biohazards and Infectious Disease Transmitted by Blood, Body Fluids, and Tissue; Approved Guideline-Second Edition. Wayne, PA: National Committee for Clinical Laboratory Standards, 2001. NCCLS document M29-A2.

•Procedures for the Handling and Processing of Blood Specimens; Approved Guideline-Third Edition. Wayne, PA: National Committee for Clinical Laboratory Standards; 2004. NCCLS document H18-A3.

General Safety

Movement of mechanical parts within the instrument can pinch or injure your hands or fingers. To prevent injury by moving parts, follow these precautions.

•Keep your hands and clothing away from the sample injection chamber when a tube is loading or unloading. Do not place objects underneath the sample injection chamber.

•Keep your hands away from the sort aspirator drawer during sorting. The drawer can close at any time without warning if a clog is detected during sorting.

•Keep the sort collection chamber door closed when sorting into a plate. Do not place objects inside the sort collection chamber, and do not attempt to

Safety and Limitations xvii

access the plate until sorting is complete. The microtiter tray stage can move suddenly during the sorting process. Sorting continues even when the sort collection chamber door is open.

Precaution Labels

The following precaution labels appear on the BD FACSAria flow cytometer or fluidics cart to indicate a potential hazard. Do not remove these labels. Use appropriate precautions to avoid injury by the indicated hazard. See the previous sections for more information.

Label |

Location(s) |

Potential Hazard |

||

|

|

|

|

|

|

|

|

Waste tank, waste tank |

Risk of exposure to |

Waste |

connectors on fluidics cart |

biologically transmissible |

||

|

disease |

|||

|

|

|

|

|

|

|

|

|

|

Waste (A) |

Waste tank cap |

Risk of exposure to |

||

|

|

|

|

biologically transmissible |

|

|

|

|

disease |

|

|

|

|

|

|

|

|

|

|

338677 Rev A

Ethanol |

Ethanol tank, ethanol tank |

Highly flammable material |

connectors on fluidics cart |

|

|

|

|

|

|

|

|

|

Ethanol tank cap |

Highly flammable material |

Ethanol

xviii BD FACSAria User’s Guide

Label |

Location(s) |

Potential Hazard |

CAUTION

VISIBLE AND/OR INVISIBLE CLASS 3B LASER RADIATION WHEN OPEN. AVOID

EXPOSURE TO THE BEAM.

335749

CAUTION

VISIBLE AND/OR INVISIBLE CLASS 3B LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED. AVOID EXPOSURE

TO THE BEAM.

335751

On or near all removable |

Risk of exposure to |

covers and any place |

hazardous laser radiation |

where the laser beam can |

|

emerge from the |

|

instrument |

|

|

Sort block door and |

Dangerous voltage |

deflection plates warning |

|

|

|

|

|

|

light |

|

Deflection

Plates

|

|

Behind sample injection |

Risk of crushing or |

! |

|

chamber |

pinching by moving parts |

|

|

|

|

|

|

|

|

|

|

Floor of sort collection |

Risk of crushing or |

! |

CAUTION: |

chamber |

pinching by moving parts |

|

|

||

MOVING PARTS |

|

|

!

WARNING: Before applying power, configure the power input module to the supply voltage. Consult the user's guide for instructions.

Power input on fluidics |

Risk of instrument damage |

cart |

if wrong voltage applieda |

Peel Here

a. NOTE: Voltage is set by your service engineer during installation.

Safety and Limitations xix

Limitations

This instrument is for Research Use Only. Not for use in diagnostic or therapeutic procedures.

BD Biosciences delivers software and workstations that are intended for running the instruments supplied by BD Biosciences. It is the responsibility of the buyer/ user to ensure that all added electronic files including software and transport media are virus free. If the workstation is used for Internet access or purposes other than those specified by BD Biosciences, it is the buyer/user’s responsibility to install and maintain up-to-date virus protection software. BD Biosciences does not make any warranty with respect to the workstation remaining virus free after installation. BD Biosciences is not liable for any claims related to or resulting from the buyer/user's failure to install and maintain virus protection.

xx BD FACSAria User’s Guide

1

BD FACSAria

Instrument Components

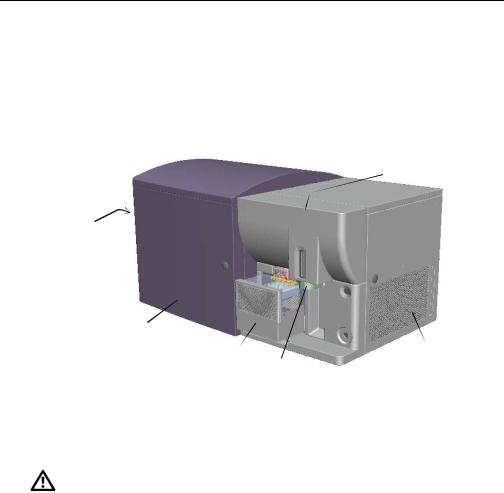

The BD FACSAria flow cytometer is the first fixed-alignment benchtop highspeed cell sorter. The instrument can be operated at varied pressures and can acquire up to 70,000 events per second. With its fixed-optics design and digital electronics, the BD FACSAria flow cytometer enables multicolor analysis of up to 13 fluorescent markers and two scatter parameters at a time.

The BD FACSAria system consists of three major components: a fluidics cart, a benchtop flow cytometer, and a workstation (see Figure 1-1 on page 22). Nearly all instrument functions are operated from within BD FACSDiva software.

For a description of the BD FACSAria system components, see the following sections. For technical information about how the instrument works, see Chapter 2.

•Fluidics Cart on page 22

•Flow Cytometer on page 26

•Workstation on page 44

21

Figure 1-1 BD FACSAria instrument components

flow cytometer

fluidics cart |

workstation |

Fluidics Cart

A separate fluidics cart supplies sheath and cleaning fluids and collects waste from the instrument (Figure 1-2). The self-contained fluidics cart supplies the required air pressure and vacuum, which eliminates the need for an external source (although the cart can be hooked up to an in-house air source, if one is available). The air pumps provide pressure from 2 to 75 psi to accommodate a variety of cell sorting applications. Air pressure is adjusted within BD FACSDiva software.

Figure 1-2 Fluidics cart

10-L container

5-L container

pressure gauge

door access knob

filter

22 BD FACSAria User’s Guide

Containers and Connectors

The fluidics cart holds four 10-L containers (two sheath and two waste), and three 5-L auxiliary cleaning fluid containers (Figure 1-3). The cart can also accommodate up to two BD FACSFlow™ 20-L cubitainers in place of the four 10-L containers.

Figure 1-3 Fluidics cart containers

waste port |

|

|

|

sheath port |

|

||||

|

|

|

waste tank |

sheath tank |

|

To prevent foaming, do not fill the containers with solutions containing a high concentration of detergent.

To prevent foaming, do not fill the containers with solutions containing a high concentration of detergent.

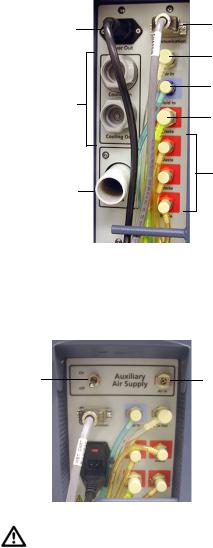

The fluidics cart connects directly to the flow cytometer unit via a power cord, fluid hoses, serial communication cable, and air line (Figure 1-4 on page 24). Receptacles for the aerosol management and temperature control options are also located within the connection panel. The position of the fluidics cart is constrained only by the length of the connecting cables and hoses, which extend up to 9 feet (2.4 m). Typically, the cart is placed to the left or underneath the cytometer.

Chapter 1: BD FACSAria Instrument Components |

23 |

Figure 1-4 Fluidics cart power and fluid line connectors

fluidics cart power cord

connections for temperature control option

AMO connection

serial communication cable

air input (clear tubing)

sheath input (blue tubing)

aspirated fluid output (yellow tubing)

fluid output (orange tubing)

To connect the fluidics cart to an external air source, open the shutter above the Communication port, switch on the Auxiliary Air Supply, and attach the external air line to the air input connector. The external air supply should provide 80–100 psi.

supply

switch air input connector

If your laboratory runs the cytometer continuously and does not shut down at the end of the day, switch on the Auxiliary Air Supply for 15 seconds every 8 hours (every 4 hours in an extremely humid climate). Doing this empties the cart condensation trap and prevents excess moisture from overflowing the trap or causing cart damage.

24 BD FACSAria User’s Guide

Power and Operation

Power to the fluidics cart is supplied by the cytometer—the cart’s fluid pumps are activated when the cytometer main power switch is turned on (see Power Panel on page 42).

Power to the fluidics cart is supplied and controlled through the flow cytometer. The fluidics cart voltage settings have been configured to match the supply voltage by your service engineer. To properly operate the fluidics cart, plug the fluidics cart power cord only into the power receptacle on the instrument (Figure 1-4 on page 24). Do not plug the power cord directly into a wall socket. Do not change the input voltage selection jumpers on the fluidics cart fuse holder.

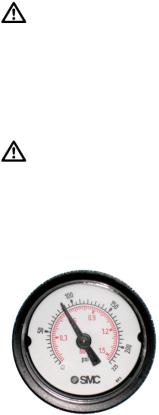

When the stream is on, air pressure fluctuates between 80–100 psi (Figure 1-5). A pressure reading of less than 80 psi or greater than 100 psi indicates that the fluidics cart is not functioning properly. If this occurs, contact your BD Biosciences service representative for assistance. Do not operate the instrument outside the normal air pressure range.

Figure 1-5 Fluidics cart flow gauge

pressure gauge at approximately 88 psi

See the following sections for more information about the fluidics cart.

•Setting Up the Fluidics Cart on page 108

•Refilling Containers on page 109

•Emptying the Waste on page 110

Chapter 1: BD FACSAria Instrument Components |

25 |

•Scheduled Maintenance on page 175

•Fluidics Troubleshooting on page 229

Flow Cytometer

The benchtop flow cytometer contains the major components for all three subsystems (fluidics, optics, and electronics). The BD FACSAria instrument is relatively compact, with a much smaller footprint than most sorters with the same capabilities. The instrument can be set up on a typical laboratory benchtop or table, and it requires only a 20-amp electrical outlet. No special facilities are required.

Figure 1-6 BD FACSAria flow cytometer

flow cell access door

power panel

optics access door

sort collection chamber |

side door |

sample injection chamber |

|

To view the fluidics components, open the side door and lift the flow cell access door; to view the optics components, open the optics access door. The power panel and connectors are found on the left side of the instrument. Other electronic components are embedded within the instrument and do not need user adjustment.

The flow cell access door is equipped with a shutter mechanism that shuts off the laser light when the door is opened. To ensure there is no interruption to data acquisition, do not open the door while sorting or recording.

26 BD FACSAria User’s Guide

See the following sections for more information about the flow cytometer.

•Fluidics Components on this page

•Optics System on page 36

•Instrument Electronics on page 42

Fluidics Components

When the fluidics system is activated, sheath fluid is pumped from the fluidics cart into a plenum reservoir where the fluidics system is pressurized. From the reservoir, fluid is pumped into the cuvette flow cell where hydrodynamic focusing forces particles from the sample injection chamber through the cuvette in a single-file stream.

Within the cuvette flow cell, laser light is focused on the sample core stream. Fluorescent molecules excited by the different laser wavelengths are detected by the optics and analyzed by the electronics. Particles are then either transported to waste reservoirs via the waste aspirator, or sorted into a receptacle within the sort collection chamber.

The following fluidics components are described in this section. For more information about fluidics, see Fluid Movement on page 46.

•Plenum Reservoirs on page 28

•Sample Injection Chamber on page 29

•Cuvette Flow Cell on page 30

•Nozzle on page 31

•Sort Block on page 32

•Sort Collection Chamber on page 35

Chapter 1: BD FACSAria Instrument Components |

27 |

Plenum Reservoirs

Sheath fluid is pumped from the fluidics cart into a plenum reservoir inside the side door of the BD FACSAria flow cytometer (Figure 1-7). From there, the fluid travels to a second reservoir where it is held and pressurized until it flows into the cuvette flow cell. This system eliminates pressure fluctuations by maintaining fluid levels and filtering out pump pulsation. As a result, the fluidics pressure does not vary with the level of fluid in the sheath containers.

Figure 1-7 Plenum reservoirs

Note that the plenum reservoirs can be unscrewed and removed for cleaning, if needed. See Cleaning the Plenum Reservoirs on page 184.

28 BD FACSAria User’s Guide

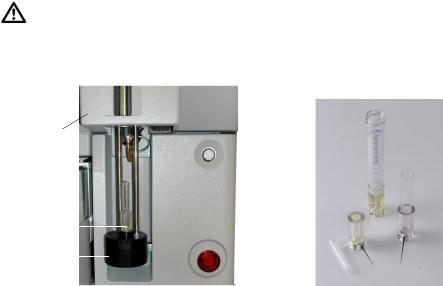

Sample Injection Chamber

The sample injection chamber is where sample is introduced into the flow cytometer. During acquisition, the chamber is pressurized to force sample toward the cuvette flow cell.

Samples can be agitated and temperature-controlled within the sample injection chamber using controls in the software (see Fluidics Controls on page 81). You can view the amount of fluid remaining in your sample tube by pressing the chamber light button shown in Figure 1-8.

Do not use the chamber light for long periods with samples stained with light-sensitive reagents.

Figure 1-8 Sample injection chamber and tube holders

sample |

|

|

|

|

|

injection |

|

|

|

|

|

chamber |

|

|

|

|

15 mL |

|

|

|

|

|

chamber |

|

|

|

|

|

|

|

|

|

|

|

light |

|

|

|

|

|

12 x 75 mm |

tube holder |

|

|

|

|

|

|

|

|

|

|

|

loading port |

|

|

|

|

1 mL |

|

|||||

|

|

|

|

|

microtube |

|

|

|

|

|

tube holders |

A variety of tube holders are provided with the instrument to accommodate tubes from 15-mL centrifuge tubes to 1.0-mL microtubes (Figure 1-8). (For a list of compatible tubes, see Labware on page 240.) To load a tube, install the appropriate-size tube holder in the loading port, and place a tube in the holder. When the Load button is clicked in the software (see Acquisition Controls on page 89), the loading port rises to enclose the tube within the chamber.

After a tube is loaded, the Load button changes to Unload. Use the Unload button to lower the loading port after data has been recorded. After each tube is unloaded, sheath fluid flushes the sample tubing inside and out to reduce

Chapter 1: BD FACSAria Instrument Components |

29 |

potential sample carryover. Using a special cleaning mode, the entire sample injection chamber can be decontaminated with ethanol. See Clean Bulk Injection Chamber on page 185 for more information.

To prevent injury from moving parts, keep your hands and clothing away from the loading port when a tube is loading or unloading. Do not place objects under the loading port.

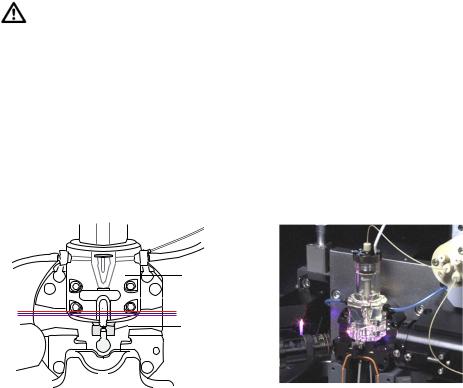

Cuvette Flow Cell

The cuvette flow cell is the heart of the BD FACSAria instrument (Figure 1-9). Within the flow cell, hydrodynamic focusing forces particles through the cuvette in a single-file stream, where laser light intercepts the stream at the sample interrogation point.

Figure 1-9 Cuvette flow cell

flow cell

interrogation point

interrogation point

nozzle

laser light intercepting flow cell

The unique flow cell design permits particles to flow through the cuvette at a low velocity (approximately 13 cm/sec for the high Sort Setup), allowing longer exposure to laser energy. The cuvette is gel-coupled to the fluorescent objective lens to transmit the greatest amount of emitted light from the interrogation point to the collection optics (see Optics System on page 36). After passing through the cuvette, the stream is accelerated (to approximately 69 cm/sec with the 70-µm nozzle) as it enters the nozzle tip, where the drop drive breaks the stream into droplets for sorting.

30 BD FACSAria User’s Guide

Loading...

Loading...