CERT. N. 9115 BCEL

INSTRUCTION MANUAL

UNI EN ISO 9001:2000

OD 7685

DISSOLVED OXYGEN CONTROLLER

MICROPROCESSOR BASED

D. Oxygen scales: 0/200.0 %air

0/200.0 mmHg

0/20.00 PPM

0/20.00 mg/l

Temperature scale: -2/+52 °C

Power supply: 110/220 Vac

Software: R2.2x

Option

S/N

REP N°

Valid for options 091.3711 e 091.601

Cod. 28006762 - Rev. D - 12/06

B&C Electronics Srl - Via per Villanova 3 - 20040 Carnate (Mi) - Italy - P.IVA 00729030965

Tel +39 039 63 1721 - Fax +39 039 607 6099 – bc@bc-electronics.it - www.bc-electronics.it

B&C Electronics OD 7685

Index

1 GENERAL .........................................................................................................................................4

1.1 Measuring principle..................................................................................................................5

1.2 Measuring system .....................................................................................................................5

1.3 Functional specifications ..........................................................................................................6

1.4 Physical specifications..............................................................................................................9

2 SPECIFICATIONS..........................................................................................................................10

3 INSTALLATION ............................................................................................................................14

3.1 Controller installation .............................................................................................................14

3.2 Sensor installation...................................................................................................................14

3.3 Electrical connections.............................................................................................................15

3.4 Operating the system ..............................................................................................................18

4 KEYBOARD ...................................................................................................................................20

5 READOUT SEQUENCES ..............................................................................................................21

6 CALIBRATION SEQUENCES ......................................................................................................27

6.1 Manual/automatic mode .........................................................................................................27

6.2 Zero and Sensitivity calibration..............................................................................................28

6.3 Secondary parameters calibration...........................................................................................34

6.4 Set-point A/B setting ..............................................................................................................37

6.5 Alarm setting ..........................................................................................................................39

6.6 Cleaning function ...................................................................................................................40

7 CONFIGURATION.........................................................................................................................43

7.1 Keyboard locked/unlocked .....................................................................................................43

7.2 LCD display contrast ..............................................................................................................43

7.3 Access number........................................................................................................................44

7.4 Cell type..................................................................................................................................44

7.5 Microtransmitter selection......................................................................................................45

7.6 Measuring unit........................................................................................................................45

7.7 Thermocompensation type......................................................................................................45

7.8 Thermocompensation coefficient ...........................................................................................45

7.9 Calibration mode ....................................................................................................................46

7.10 Polarization voltage ................................................................................................................46

7.11 Software filter .........................................................................................................................46

7.12 Input relared to analog output n°1 (Option 091.3711) ...........................................................47

7.13 Analog output n°1 range.........................................................................................................47

7.14 Input related to analog output n°2 (Option 091.3711)............................................................47

7.15 Analog output n°2 range.........................................................................................................48

7.16 Set-point A function ...............................................................................................................48

7.17 Set-point B function................................................................................................................48

7.18 Alarm on set-point A ..............................................................................................................49

7.19 Alarm on set-point B ..............................................................................................................49

7.20 Alarm relay C contacts ...........................................................................................................50

7.21 Cleaning function ...................................................................................................................50

Instruction Manual - Rev. D - 12/06

- 2 -

B&C Electronics OD 7685

7.22 Cleaning time (Relay d on).....................................................................................................50

7.23 Holding time ...........................................................................................................................50

7.24 New access number ................................................................................................................51

8 CALIBRATION...............................................................................................................................52

9 PREVENTIVE MANTENIANCE...................................................................................................54

10 TROUBLESHOOTING...................................................................................................................55

11 APPENDIX Nr. 1 (Valid for option 091.601) .................................................................................59

WARRANTY CERTIFICATE...............................................................................................................62

REPAIRS................................................................................................................................................62

TECHNICAL SUPPORT .......................................................................................................................63

Instruction Manual - Rev. D - 12/06

- 3 -

B&C Electronics OD 7685

1 GENERAL

The instrument structure has been designed considering the three way of use:

1) The user checks measuring values and the proper functioning of the instrument.

The user should consult the Chapters 1 and 2.

2) The user should define the operating parameters and carry out the periodic calibration.

The user can carry out the following choices and operations:

- operating with keyboard locked/unlocked

- manual/automatic operating mode

- selecting the values of Set-point, Hysteresis, and Delay time for the relay switching

- selecting the Minimum/maximum function and the alarm Delay time

- calibrations

- programming the Cleaning function

3) The user should operate the functioning choice required for the system in which the instrument is

used.

After the installation the instrument should be configured for the desired functioning.

Can be carried out:

- selections between possible options

- input numeric values within a fixed range

We suggest to follow the next steps:

1) in the Chapter 2 "Specifications", locate parameters marked with

"*" and the corresponding factory values in the "Default" column

2) make a list of changing in order to fit with the specific application

3) insert the "Configuration" access code to:

** select the Dissolved Oxygen sensor type

** select the measuring unit

- program the two Software Filter response time

- select the calibration mode

- program the Automatic Pressure Compensation (option)

- select the input for the analog output N°1 and N°2

- select the mA output range

- program the measuring value corresponding to 0/4 and 20 mA

** select the Min/Max function for the Set-Point A and B

- program the alarm action on the activation time for Set-point A and B

- program the Max. activation time for Set-point A and B

- select the Activated/Deactivated function for relay C

- program the Cleaning function (relay D)

- select the Access number to the Configuration

(The choice of the parameters marked ** is the minimum required for the use of the instrument).

Refer to the Chapter 7 "Configuration".

Instruction Manual - Rev. D - 12/06

- 4 -

B&C Electronics OD 7685

1.1 MEASURING PRINCIPLE

Polarographic method

The measurement is performed with a Polarographic sensor introduced by Clark and still represents

the more practical measuring system since it allows accurate and fast measurement as well as easy

calibration procedures.

The method consists of the Dissolved Oxygen diffusion through a membrane which divides the

sample from an electrolytic cell with a Silver Anode and a Platinum Cathode.

A suitable polarization Voltage generates a current flow which is proportional to the diffused

Dissolved Oxygen through the membrane.

The Oxygen in the cell will be restored by the continuous diffusion through the membrane. The result

is a great stability of the measurement.

Anyway the method is influenced by two physical factors: the Temperature and the sample speed.

Temperature effect

The membrane is affected by a contraction/dilatation at the Temperature variation, with the

consequence of a variation of the membrane porosity.

This changing modify the diffusion speed of the Dissolved Oxygen through the membrane and

consequently a different measuring.

This effect is compensated by the instrument by means of a Thermoresistance included in the

D.O. sensor.

Sample speed effect

The Oxygen diffusion through the membrane will decrease the concentration close to the membrane,

resulting in a reduction of the measuring value.

For this reason it is necessary to allow a continuous flow of the sample with a speed from 0,3 to 0,7

meter/second close to the membrane.

Avoid air bubbles in the sample that would affect the measuring accuracy.

1.2 MEASURING SYSTEM

The Dissolved Oxygen monitoring system consists of two parts:

- the measuring/regulating instrument which is discussed in this instruction manual

- the Dissolved Oxygen sensor

The system could be implemented with additional devices for field application:

B&C Electronics amplified sensor, Temperature sensor, recorder, remote display, ON-OFF regulators,

PID regulators, sensor Cleaning devices.

Instrument

This instrument carries out the following functions:

1) Dissolved Oxygen measuring when connected to the sensor

Instruction Manual - Rev. D - 12/06

- 5 -

B&C Electronics OD 7685

2) manual or automatic Dissolved Oxygen regulation, if suitable devices are connected to the output

relays

3) Temperature measuring, if an RTD Pt100 is connected

4) manual or automatic compensation of Temperature, Pressure, Salinity and Relative Humidity

effects

5) alarm devices activation when unexpected measuring and Set-point conditions happen

6) D.O. and/or Temperature acquisition, when connected to a Recorder or a Data Logger

7) sending data via a Serial interface, if the option 091.701 "RS232" is installed

8) external device activation for the sensor Cleaning

9) Barometric Pressure measuring if the option 091.601 is installed

Sensor

For the proper functioning of the system it is necessary to use the suitable sensor for each specific

application.

The sensor installation should allow a continuous contact with the sample, in a position with sufficient

stirring and exchange of sample.

In some applications the use of sensor Cleaning devices is suggested.

1.3 FUNCTIONAL SPECIFICATIONS

R2.2x Software specification updates

- Two Software Filter Time depending on the amplitude of the input signal changing

- Selectable access number to the Configuration

- Manual Temperature calibration even with sensor connected

- Sensor cleaning function

- Barometric Pressure reading (option)

- Sensor calibration in Immediate/Postponed mode

- Type of sensor and microtransmitter selection.

Input

The instrument accepts input from three sensors:

- Dissolved Oxygen sensor;

- Temperature sensor (Pt100);

- Barometric Pressure internal sensor (option).

Software Filter

The unit is provided with a programmable software filter, to be inserted when the readout is not stable.

The user may select different filter values for small and large signal fluctuations.

Instruction Manual - Rev. D - 12/06

- 6 -

B&C Electronics OD 7685

D.Oxygen sensor type

The following sensor type can be used:

- 3 polarographic sensor types with different Current in air;

- galvanic sensor;

- B&C Electronics amplified sensor (ST series)

An exclusive feature of the instrument allows to connect ST series sensors, amplified by the 080610.2

microtransmitter, for long distance applications.

Scales

The following D.O. measuring scales can be selected:

mmHg (partial pressure) - % (air saturation) - PPM - mg/litre.

The instrument holds the calibration data when changing the measuring scale.

Temperature compensation

The unit is supplied with manual or automatic Temperature compensation. The instrument detects of

the absence or malfunctioning of the Temperature sensor and automatically switches to manual

compensation.

Secondary parameters

The D.O. measuring is affected from Barometric Pressure, Salinity and Relative Humidity.

The programming of these parameters values avoids the use of the conversion tables.

As an option the automatic Barometric Pressure compensation can be implemented.

Analog output

Either a 0/20 mA or 4/20 mA programmable and isolated output may be selected, for use as an

interface with computers or data loggers.

The input range corresponding to the output is programmable.

Control relays

The monitor is equipped with two SPST control relays.

Each control relay may be programmed for set-point, high/low, hysteresis or delay time actuation.

The full display indicates the current settings and current status of each relay.

Alarm relay

The unit contains a third SPDT relay designated as an alarm relay.

This relay may be used to warn of conditions that may indicate operational problems.

The relay will activate on either high/low value conditions, or on failure of the control relays to

maintain proper control.

In addition this relay may be programmed for either normal or fail-safe operation.

Instruction Manual - Rev. D - 12/06

- 7 -

B&C Electronics OD 7685

Operating mode

The instrument is provided with 2 programmable modes of operation.

- Automatic operation:

The Automatic mode is the normal operation mode of the unit.

- Manual operation:

This mode of operation would normally be used for control system troubleshooting.

The unit will allow the relays to be manually actuated by pushing up/down keys.

The letter "M" flashing on the display, indicates the instrument is in manual operation mode.

Calibration

The sensitivity calibration in air can be automatically performed.

The manual calibration mode can be selected in two ways:

- immediate calibration;

the user immediately adjusts the measuring value;

- postponed calibration;

the instrument memorizes the sample value;

the user adjusts the memorized value after the laboratory analysis.

Cleaning function

The unit contains a SPST relay designated as an autoclean relay.

This relay may be used to start a manual or automatic autoclean cycle.

The user may select:

- the cleaning time

- the waiting time to turn to the normal operation

- the repetition time of the cycle

During the cleaning and waiting the unit will provide:

- flashing messages

- analog outputs in hold

- control and alarm relays deactivated

Configuration

A number of programming functions are provided in the Configuration menu and are protected by a

selectable access number, which must be entered to allow changes in this setting.

The keys on the front panel of the monitor can be used for both changing the display and for

calibrations and set-point adjustments.

When the monitor is shipped, all functions are accessible.

However, the adjustment and calibration functions may be locked in order to prevent unauthorized

adjustments to the instrument.

Instruction Manual - Rev. D - 12/06

- 8 -

B&C Electronics OD 7685

IMPORTANT NOTE: the factory configuration allows the immediate use of the instrument in main

applications.

Options

091.3711 Dual isolated and programmable output.

Two outputs may be configured for Concentration or Temperature.

091.701 RS232 isolated output.

The output sends the data (Concentration, °C) to the serial port of the computer.

091.404 24 VAC power supply.

091.4143 9/36 VDC power supply.

1.4 PHYSICAL SPECIFICATIONS

The controller enclosure is designed for surface or panel mounting.

It consists of an anodized aluminium case built according to the standard DIN 43700, with an

aluminium panel coated with scratch-proof and non-corrosive polycarbonate membrane.

A transparent waterproof front door SZ 7601 can be added to the housing, in order to protect the unit

from excessive moisture or corrosive fumes.

Signal and power cable connections are made by using two special extractable terminal blocks placed

in the back of the instrument.

This makes wiring, installation and general maintenance of the probes and other devices easier.

The package is supplied complete with fixing clamps for panel-mounting.

Instruction Manual - Rev. D - 12/06

- 9 -

B&C Electronics OD 7685

2 SPECIFICATIONS

The Default values are corresponding to the factory calibration values.

Parameters marked by " * " can be modified in the Configuration procedures.

Default

OPERATING MODE

Automatic/Manual Auto

SENSOR TYPE

* 250nA-P/45nA-P/300nA-P/30mV-G 250nA-P

* Microtransmitter: On/Off Off

Input from POLAROGRAPHIC CELL 250

Current in air input at 20°C: 200/400 nA 250 nA

* Thermocompensation: according to internal table/Coefficient Table

* TC selectable: 0/4 %/°C 2.3%

(table arranged for SZ654.1 cell with Vpol. 675 mV)

Input from POLAROGRAPHIC CELL 45 nA

Current in air input at 20°C: 25/75 nA 45 nA

* Thermocompensation: according to internal table/Coefficient Table

* TC selectable: 0/4 %/°C 2.3%

Input from POLAROGRAPHIC CELL 300 nA

Current in air input at 20°C: 170/510 nA 300 nA

* Thermocompensation: according to internal table/Coefficient Table

* TC selectable: 0/4 %/°C 2.3%

Polarization voltage: 0/1250 mV 675 mV

Input from GALVANIC CELL 30 mV

Voltage in air input at 20°C: 17/51 mV 30 mV

* Thermocompensation: according to internal table/Coefficient Table

* TC selectable: 0/4 %/°C 2.3%

Software filter 90% RT:

* Large signal variation: 0.4/20.0 sec. 2.0 sec

* Small signal variation: 0.4/20.0 sec. 10.0 sec

Ref. Temp. for the Thermocompensation: 20°C

* Scales: % air saturation: 0/200.0 % air % air sat

PPM: 0/20.00 PPM

mg/l: 0/20.00 mg/l

Partial pressure O2: 0/200.0 mmHg

Zero regulation: (+/- 3.00 nA/30 nA) +/- 10% air/20°C 0 nA

Sensitivity regulation: 55/170 % 100 %

Display accuracy at 20°C: 1/1000

Automatic calibration (function of Temp-Press-RH)

Manual calibration (function of the adjusted value)

Signalling of the calibration value stability reached

Instruction Manual - Rev. D - 12/06

- 10 -

B&C Electronics OD 7685

SECONDARY PARAMETERS

Pressure: 500/800 mmHg 760 mmHg

Salinity (Chloride): 0/60000 PPM 0 PPM

Relative Humidity: 0/100 % 50 %

TEMPERATURE

Input: RTD Pt100

Connections: 2/3 wires

Measuring and compensation range: -2/+52 °C

Accuracy: 0.1 °C

Zero adjustment: +/- 2°C 0°C

Manual temperature value range: 0/50°C 20°C

SET-POINT A/B

Set value (function of the scale): 0/200.0 % 0 %

Hysteresis (function of the scale): 0/20.0 % 0 %

Delay time: 0.0/99.9 sec 0 sec

* Function: HI/LO (Max/Min) LO

Relay contact: SPDT 220V 5Amp resistive

ALARM (CONTACT C-D)

Low value (function of the scale): 0/200.0 % 0.0 %

High value (function of the scale): 0/200.0 % 200.0 %

Delay time: 0.0/99.9 sec 0 sec

* Alarm for max. activation time on SA (Set-point A): ON/OFF OFF

* Max. activation time for SA: 0/60 minutes 60 min.

* Alarm for max. activation time on SB (Set-point B): ON/OFF OFF

* Max. activation time for SB: 0/60 minutes 60 min.

* Contact type (activated/deactivated): ACT/DEA ACT

Relay contact: SPST 220V 5Amp resistive

CLEANING (Relay D)

* Action: Disabled/Manual Clean/Auto+Manual Clean Disabled

Auto Clean:

Repetition time: 0.1/24.0h 24.0h

* Cleaning time: 0.5/60.0" 15.0"

* Hold time (hold of analog output,

deactivation of Set-point A and B and Alarm C): 0.1'/20.0' 3.0'

Relay contact: SPST (N.O.)

Instruction Manual - Rev. D - 12/06

- 11 -

B&C Electronics OD 7685

ANALOG OUTPUT N°1

* Input related to analog output

(only for option 091.3711): PPM/°C PPM

* Output range: 0-20/4-20 mA 0/20 mA

* Point 1 (corresponding to 0 mA or 4 mA): 0.0%

mmHg/%air: 0.0/200.0

PPM/mg/l: 0.00/20.00

* Point 2 (corresponding to 20 mA): 200.0%

mmHg/%air: 0.0/200.0

PPM/mg/l. 0.00/20.00

Response time: 2.5 sec approx. for 98 %

Isolation: 250 Vca

Rmax: 600 ohm

ANALOG OUTPUT N°2 (only for Option 091.3711) Default

* Input related to analog output: PPM/°C PPM

* Output range: 0-20/4-20 mA 0/20 mA

* Point 1 (corresponding to 0 mA or 4 mA): 0.0%

mmHg/%air: 0.0/200.0

PPM/mg/l: 0.00/20.00

* Point 2 (corresponding to 20 mA): 200.0%

mmHg/%air: 0.0/200.0

PPM/mg/l. 0.00/20.00

Response time: 2.5 sec approx. for 98 %

Isolation: 250 Vca

Rmax: 600 ohm

CONFIGURATION (*) Default

Free calibration (Access number not required):

keyboard locked/Unlocked Unlocked

LCD Display contrast (0/7) 4

Access number required:

Sensor type 250nA-P

Microtransmitter: On/Off Off

D.O. input scales: mmHg/%air/PPM /mg/l % air

Thermocompensation type: Table/Coefficient Table

Thermocompensation coefficient 2,3 %/°C

Calibration mode Immediate

Polarization voltage of the cell 675 mV

RT Large software filter 2.0 sec

RT Small software filter 10.0 sec

Input related to analog output N°1 (Option 091.3711) % air

Analog output N°1 range 0/20 mA

Point 1 (x mA minimum) 0.0

Point 2 (x mA maximum) 200.0

Input related to analog output N°2 (Option 091.3711) % air

Analog output N°2 range (Option 091.3711) 0/20 mA

Point 1 (x mA minimum) (Option 091.3711) 0.0

Point 2 (x mA maximum) (Option 091.3711) 200.0

Relay A function LO

Relay B function LO

Alarm for max. activation time on SA OFF

Max. activation time for SA 60 m

Alarm for max. activation time on SB OFF

Instruction Manual - Rev. D - 12/06

- 12 -

B&C Electronics OD 7685

Max. activation time for SB 60 m

Alarm relay contact function ACT

Cleaning function Disabled

Cleaning time 15.0 sec

Hold time 3.0 min

Configuration access code number: 0/999 0

GENERAL SPECIFICATION

Alphanumeric display: 1 line x 16 character

Acquisition time: 0,1"

Updating time for main measure: 0,4"

Operating Temperature: 0/50 °C

Ambient Humidity: 95% without condensation

Power supply: 110/220 Vac +/- 10% 50/60 Hz

Isolation: 4000 volt between primary and secondary (IEC 348)

Power consumption: 5 VA max.

Terminal boards: extractable

Net weight: 850 gr.

Housing: DIN 43700 96 x 96

Dimension: 96 x 96 x 155 mm.

Instruction Manual - Rev. D - 12/06

- 13 -

B&C Electronics OD 7685

3 INSTALLATION

Packing list

The instrument packaging contain:

- N° 1 instrument with serial number label

- N° 2 brackets for panel mounting

- N° 1 English instruction manual according to IEC N° 278 standard

- N° 1 warranty certificate with Technical Assistance card, included in the instruction manual.

Unpackagin of the instrument

1) Remove from the packaging the instruction manual containing the warranty certificate.

2) Open the packaging and remove the instrument enclosed in a plastic transparent bag.

3) Remove the transparent bag preserving the two brackets.

Storage

For long storage periods hold the instrument in a dry place.

3.1 CONTROLLER INSTALLATION

The instrument can be installed near the sensor or in a distant area, in the electrical cabinet.

The panel mounting should be made in a unbending surface, in a position protected from humidity,

corrosive fumes and casual collisions.

The picture 3 shows the instrument dimensions and the panel cut-out dimensions.

- Introduce the instrument in the cut panel.

- Mount the two fastening brackets on the two sides of the instrument, with the screw head

turned to the back of the instrument.

- Screw on the two fastening brackets until a complete blockage of the housing.

In the field mounting application, the use of a protection cabinet will assure a long time reliability; it is

also available a transparent cover with IP55 protection level (mod. SZ7601).

3.2 SENSOR INSTALLATION

See the instruction manual of the sensor.

Instruction Manual - Rev. D - 12/06

- 14 -

B&C Electronics OD 7685

3.3 ELECTRICAL CONNECTIONS

Safety rules

Before connecting the power supply to the instrument perform the followings check:

- check that the terminal 4 is connected to ground and that all connection are all correct

- check that the connection wires are well fastened to the terminal block

WARNING

The failure coming from erroneous connections is not covered by warranty

Refer to the back panel printing described in Figure 2.

All the connections are made with extractable terminal blocks on the back panel.

The power connections are on the lower terminal block (13 positions).

The input and output signals are on the upper terminal block (12 positions).

Connecting the power

- terminal 4 connect to the ground

- terminals 1-2 connect to the ac power (if power is 110 V)

- terminals 1-3 connect to the ac power (if power is 220 V)

(If 091.404 option is installed, connect 24 VAC to 1-3 terminals)

WARNINGS

- power the device by means of an isolation transformer

- avoid mains-voltage from an auto-transformer

- avoid mains voltage from a branch point with heavy inductive loads

- separate power supply wires from signal ones

- control the mains voltage value

- an internal device protects the unit against power overloads.

Disconnect the power and wait few minutes before powering again.

Connecting the Cell or Microtransmitter

- Use original cables suggested by the sensor manufacturer.

- Avoid interruption on the cable if a high insulation terminal block is not available.

Keep the cable away from power wires on the overall length.

Polarographic cell

- terminal 20_ connect to the cathode (Platinum electrode)

- terminal 19_ connect to the anode (Silver electrode)

- terminals 21-22_ install a jumper

Instruction Manual - Rev. D - 12/06

- 15 -

B&C Electronics OD 7685

Galvanic cell

- terminal 22_ connect to the cathode (Platinum or Silver electrode)

- terminal 21_ connect to the anode (Lead electrode)

- terminals 21-22_ remove the jumper

Sensor with microtransmitter

Refer to operating instruction of this special sensor.

Connecting the RTD

The Temperature readout and the automatic Temperature compensation is provided by connecting the

Pt100.

If the Temperature sensor is not connected or damaged, the unit will operate in manual Temperature

compensation automatically.

3-wire connection

- terminal 23 connect to the Pt100

- terminals 24 - 25 connect to the Pt100 common

2-wire connection

- terminals 23 - 24 connect to the Pt100

- terminals 24 - 25 install a jumper between terminals

Connecting a recorder

Connect to terminals 14-16 for the 1st channel output

Connect to terminals 15-16 for the 2nd channel output (091.3711 option)

- terminal 14 connect to the terminal (+) of the recorder N°1

- terminal 15 connect to the terminal (+) of the recorder N°2

- terminal 16 connect to the terminal (-) of the two recorder

Series connection is required for driving more loads having a total input Resistance lower than 600

ohm for each channel.

Connecting alarms, pumps, valves

Regulators output are available on the instrument terminal block by means of relay contacts relating to

set-point A and B.

RELAY "A" SET-POINT "SA"

terminal 6 marked C common contact

terminal 5 marked NO normally open contact

terminal 7 marked NC normally closed contact

Instruction Manual - Rev. D - 12/06

- 16 -

B&C Electronics OD 7685

RELAY "B" SET-POINT "SB"

terminal 9 marked C common contact

terminal 8 marked NO normally open contact

terminal 10 marked NC normally closed contact

RELAY "C" ALARM

terminal 12 marked C common contact

terminal 11 marked NO normally open contact

Arc suppressor

Install a suitable snubber between relay terminals if the relay activation causes interferences on the

display. (B&C Electronics snubber SX101)

Connecting cleaning system

To activate the external cleaning device, use the following relay contacts.

RELAY "D" SENSOR CLEANING

terminal 12 marked C common contact

terminal 13 marked NO normally open contact

Instruction Manual - Rev. D - 12/06

- 17 -

B&C Electronics OD 7685

3.4 OPERATING THE SYSTEM

Checking

Before connecting the system to the power supply:

- check that all cables are properly fastened to prevent strain on the connections

- check that all terminal-strip connections are mechanically and electrically sound

- check that power voltage is correct

Pre-operation check

The system's controls and indicators are all located on the front panel

(see Fig.1).

The meter has a LCD display 1 indicating that the unit is on.

The cards of the controllers are adjusted at the factory.

If sensors have been connected correctly, as described in the above sections, the system should

function correctly needing only the start up and the parameters calibrations as described in the

following section.

Quick start guide

The unit may be installed for the following purposes:

- measuring

- measuring and regulation

- measuring, regulation and recording

The instrument is shipped with factory calibration and configuration suitable for the most popular

applications.

For this reason the operation may require just the following steps:

measuring

1. Connect the cell to the meter.

2. Power the instrument.

The instrument will show the Display (D0).

3. The instrument is pre-configured for polarographic cell SZ654.1.

Access the Configuration menu to select other cell types.

From Display (D0) press 9 times ù to start the Configuration sequences

Eventually select the secondary parameters.

4. The instrument is pre-arranged for automatic calibration.

Perform the Dissolved Oxygen calibration in air.

Instruction Manual - Rev. D - 12/06

- 18 -

B&C Electronics OD 7685

measuring and regulation

Add the following to the preceding operations:

1. Press § ò £ to go to the manual operation. If the automatic mode is selected,

go to the step 2.

2. A and B relay are configured as LOW (Minimum).

Select HIGH (Maximum) if necessary.

3. Select the Set-point, the Hysteresis and the Delay of A and B relay. From (D0) press 4 times

ù to start the Set-point A selection sequence.

From (D0) press 5 times

4. The alarm on the activation time of A and B relay is deactivated.

Activate this kind of alarm if necessary.

5. Select alarm values of min/max and delay if necessary.

From (D0) press 6 times

measuring, regulation and recording

Add the following to the preceding operations:

1. Analog output is configured as PPM at 0/20 mA corresponding to the input scale.

Select 4/20 mA and a suitable input span if necessary.

2. If option 091.3711 is installed, follow the step 1. for the second output.

This option allows to select the analog output as °C scale.

Manual operation

When the instrument is programmed for the manual operation (see Calibration sequences) the flashing

"M" will appear on the display.

Analog outputs and alarm relay will remain activated.

ù to start the Set-point B selection sequence.

ù to start the alarm selection sequence.

ò while pressing the key, A relay will be activated.

ç while pressing the key, B relay will be activated.

Instruction Manual - Rev. D - 12/06

- 19 -

B&C Electronics OD 7685

4 KEYBOARD

KEY FUNCTION

ù

- it allows the operator to go to the next Display

- it allows to go back to the main Display.

The eventual new parameter values will not be memorized

- it allows the access of calibration sequences

§

- it allows to increase the displayed parameters

- it allows to choose between different functions

ò

- it allows to decrease the displayed parameters

- it allows to choose between different functions

ç

- it allows to enter the selected data and to return to the main Display D0

£

Instruction Manual - Rev. D - 12/06

- 20 -

B&C Electronics OD 7685

5 READOUT SEQUENCES

Applying the power to the instrument the display will shows for 3 seconds the type of cell selected,

then will shows the main Display (D0).

250nA-P nominal Current value for Polarographic cell

(45nA-P) " "

(300nA-P) " "

(30mV-G) nominal Voltage value for Galvanic cell

Press ù to visualize the following Display:

D0

O2 meter 250nAP

XXX %airM àAL ì BH

Dissolved Oxygen value,

set-point status/functions

D1

D2

D3

D4

D5

D6

D7

xxx.x%air xx.x°C

P:xxx sal: xxxxx

TEMP.: xx.x°CM

SA:xxx %air* à LO

SB:xxx %air* à HI

AL xxx/xxx %air

CLEANING OFF

Dissolved Oxygen and Temperature values

Barometric Pressure and Salinity values

for the compensation

Temperature value

Set-point A parameters

Set-point B parameters

Alarm Parameters

Cleaning function

D8

Instruction Manual - Rev. D - 12/06

01 xx.xmA/xxx %a

Analog output Nr.1 /input values

- 21 -

B&C Electronics OD 7685

D8BIS

02 xx.xmA/xxx %a

D9

Configuration

D10

----------------------------------

(D0)

Dissolved Oxygen value, set-point status/functions

xxx %air D.Oxygen value and measuring unit

(PPM)

(mg/l)

(mmHg)

(>>>>) value higher than the full scale (over range)

(<<<<) value is negative (under range)

(flashing) system in alarm

(M flashing) manual operating mode

ì A relay A deactivated

(è A) relay A with delayed activation

(à A) relay A activated

ì B relay B deactivated

(è B) relay B with delayed activation

(à B) relay B activated

L relay programmed for min. function (LO)

H relay programmed for max. function (HI)

MESSAGE MEANING

"CLEANING" cleaning cycle activated

"HOLDING" holding time cycle

OD7685 R2.2x

XXX %airM àAL ì BH

Analog output Nr.2 /input values

Configuration Display

Instrument code and Software release

§ to activate the procedure of the manual/automatic mode selection.

ù to go to

Instruction Manual - Rev. D - 12/06

- 22 -

B&C Electronics OD 7685

----------------------------------

(D1)

Dissolved Oxygen and Temperature values

xxx.x %air Dissolved Oxygen value (with one more digit)

and

measuring unit selected

xx.x°C Temperature value

§ to activate the calibration sequence.

xxx.x%air xx.x°C

ù to go to

----------------------------------

(D2)

Barometric Pressure and Salinity values of the sample

p: xxx Barometric Pressure value (mmHg)

sal: xxxxx Salinity value of the sample (PPM)

P:xxx sal: xxxxx

§ to activate the secondary parameters calibration sequence.

ù to go to

----------------------------------

(D3)

Temperature value

xx.x Temperature value

M Only in manual Temperature

value selection.

§ to activate the Temperature calibration or the procedure of the manual Temperature

TEMP.: xx.x°CM

ù to go to

Instruction Manual - Rev. D - 12/06

- 23 -

B&C Electronics OD 7685

----------------------------------

(D4)

Set-point A parameters

SA set-point A parameters

xxx %air set-point value in % of air

à set-point A status (relay activated)

LO selected function (minimum)

* alarm function on Set-point A is selected

§ to activate the Set-point value, Hysteresis and Delay time programming sequences.

SA:xxx %air* à LO

ù to go to

----------------------------------

(D5)

Set-point B parameters

SB set-point B parameters

xxx %air set-point value in % of air

à set-point B status (relay activated)

HI selected function (maximum)

* alarm function on Set-point B is selected

SB:xxx %air* à HI

§ to activate the Set-point value, Hysteresis and Delay time programming sequences.

ù to go to

----------------------------------

(D6)

Alarm parameters

AL Dissolved Oxygen values alarm (% air)

xxx Low alarm value

xxx.x High alarm value

§ to activate the Alarm value programming sequences.

AL xxx/xxx %air

Instruction Manual - Rev. D - 12/06

- 24 -

B&C Electronics OD 7685

ù to go to

----------------------------------

(D7)

Cleaning function

OFF cleaning function disabled

(ON) cleaning function enabled

MANUAL CLEAN manual cleaning activation

(AUTO CLEAN) automatic cleaning activation

§ to activate the Cleaning function programming sequences.

CLEANING OFF

ù to go to

----------------------------------

(D8)

Analog output N°1 value and input measuring value

01 analog output N°1

xx.xmA: current value output in mA

xxx %air input measuring value in % of air (PPM, mg/l, mmHg)

01 xx.xmA/xxx %a

ù to go to

----------------------------------

(D8BIS)

Analog output N°2 value and input measuring value

02 analog output N°2

xx.xmA: current value output in mA

xxx %air input measuring value in % of air (PPM, mg/l, mmHg, °C)

02 xx.xmA/xxx %a

ù to go to

Instruction Manual - Rev. D - 12/06

- 25 -

B&C Electronics OD 7685

----------------------------------

(D9)

Configuration display

§ to activate the Configuration sequences.

Configuration

ù to go to

----------------------------------

(D10)

Instrument P/N and Software Release

OD7685 instrument Part Number

R2.2x software release installed

OD7685 R2.2x

ù to go back to the main Display (D0)

Instruction Manual - Rev. D - 12/06

- 26 -

B&C Electronics OD 7685

6 CALIBRATION SEQUENCES

The following procedures are accessible only if the Keyboard is unlocked.

To unlock the keyboard follow the instruction of the Chapter 7 "Configuration".

Following procedures allow the operator to perform the sensors calibration and the Set-point/Alarm

parameters programming.

The sequence (1, 2, ....) helps the operator to following the regular calibration sequence.

IMPORTANT NOTE: During the calibration procedure the microprocessor turn the unit to the main

display if no keys have been pressed within 5 minutes (30 minutes for ISE calibration sequences).

6.1 MANUAL/AUTOMATIC MODE

Normally the instrument works in automatic mode.

Follows this procedure only to switch the instrument operating mode.

1. ù to go to

(D0)

2. § to access the operating mode selection

AUTO automatic mode

(MANUAL) manual mode

ù to stop the procedure

3. ò ç to select the operating mode

XXX %airM àAL ì BH

CAL MODE: AUTO

4. £ to confirm the selected operating mode and to go back to (D0)

MESSAGE MEANING

the new parameter is stored

and the instrument goes back to (D0)

Instruction Manual - Rev. D - 12/06

“ UPDATE “

- 27 -

B&C Electronics OD 7685

6.2 ZERO AND SENSITIVITY CALIBRATION

This procedure allows to:

- visualize the Zero Current value, to confirm the value and to go to the visualization of the

Sensitivity.

- access to the Zero calibration sequence

Before calibrating is necessary:

- to verify the correct programming of the Secondary parameters in D2.

- to prepare a solution without Dissolved Oxygen if Zero calibration has to be performed.

ZERO CALIBRATION

1. ù to go to

(D1)

2. § to access the calibration sequences.

x.x nA Zero Current value of the cell

ù to stop the procedure

£ to end the Zero calibration procedure and to go to the Sensitivity calibration

procedure (see next section)

3.

§ to access the Zero calibration procedures

xxx.x%air 20.0°C

Zero: x.xnA

x.x Current value from the cell

CAL Zero: x.x

ù to stop the procedure

ò + ç + £ press the three key to turn to factory calibration (Zero=0)

Instruction Manual - Rev. D - 12/06

- 28 -

B&C Electronics OD 7685

4. £ to end the Zero calibration procedure and to go to the Sensitivity calibration sequence.

MESSAGE MEANING

The calibration is accepted

Error messages

Zero > 10.0 %

£ to stop the error message.

The next message is displayed

The calibration is not accepted.

The instrument goes back to (D1).

See Chapter 10 “Troubleshooting” if error messages turn up.

SENSITIVITY CALIBRATION

The Sensitivity calibration can be performed in one of the three methods:

- immediate automatic calibration in air (procedure A)

- immediate manual calibration (procedure B)

- postponed manual calibration (procedure C)

The selection immediate or postponed is done in the Configuration menu

NOTE 1

Before memorizing the calibration value the instrument check for his stability showing the flashing

message 'R' (READY) until the stability is reached.

When the stability is reached, the instrument shows the steady message 'R' .

If the stability is not reached for several causes, the operator can go ahead with the procedure by

“ UPDATE “

Z > 10.0%

“ NO UPDATE “

pressing £ . In this case the instrument will show for approx. 1" the message:

NOTE 2

At the end of the Sensitivity calibration procedure the instrument will show one of the following

messages:

Instruction Manual - Rev. D - 12/06

' Skip Stability '

- 29 -

B&C Electronics OD 7685

MESSAGE MEANING

The calibration is accepted

Error messages

Sensitivity > 170.0%

Sensitivity < 55.0%

The above mentioned messages remain

for 5 minutes.

£ to stop the messages readout and to

show:

The calibration is not accepted and the

instrument goes back to (D1).

See Chapter 10 “Troubleshooting” if error messages turn up.

After the Zero calibration, the procedure begins with the following display:

xxx.x Sensitivity value

“ UPDATE “

SENS > 170.0%

SENS < 55.0%

“ NO UPDATE “

SENS: xxx.x%

ù to stop the procedure

£ to end the Sensitivity calibration procedure and to go back to (D1)

1. § to access the selection of manual or automatic calibration mode

AUTO (MANUAL) automatic mode calibration (manual)

ù to stop the procedure and to go back to (D1)

Instruction Manual - Rev. D - 12/06

CAL O2:AUTO/air

- 30 -

B&C Electronics OD 7685

2. ò ç to select the calibration mode

3. £ - to confirm the calibration mode selected

- to go to the Sensitivity calibration sequence in automatic (procedure A) or manual

(procedures B or C).

(procedure A.) AUTOMATIC SENSITIVITY CALIBRATION

It is the regular calibration method, therefore it is automatically proposed at this point of the

procedure.

Refer to the Chapter 8 "Calibration".

Carry out the following operations:

- remove the cell from the sample

- make sure that the sensor is dry

- bring the sensor in air with a known Relative Humidity

xx.x Temperature value

Before proceeding, check for the Temperature value stability, to avoid calibration errors.

CHECK TEMP.:x.xx

ù to stop the procedure and to go back to (D1)

4A. £ to access the calibration procedure

xxx.x Dissolved Oxygen measuring value

R measuring stability indicator

A automatic calibration procedure

ù to stop the procedure and to go back to (D1)

ò + ç + £ press the 3 keys to turn to the Sensitivity factory calibration and to go back to (D1)

5A. £ to end the calibration procedure and to go back to (D1)

See Chapter 10 “Troubleshooting” if error messages turn up.

CAL O2: xxx.xR A

Instruction Manual - Rev. D - 12/06

- 31 -

B&C Electronics OD 7685

(procedures B. and C.) MANUAL SENSITIVITY CALIBRATION

Two types of manual calibration can be selected in the "Configuration" menu:

- Immediate calibration (procedure B.)

- Postponed calibration (procedure C.)

IMMEDIATE CALIBRATION

It is suitable when the D.Oxygen contents are stable or known.

The Display will show for few seconds the message:

then the following Display will be shown:

xxx.x Dissolved Oxygen measuring value

R measuring stability indicator

M: manual calibration procedure

IMMEDIATE CAL

CAL O2: xxx.xR M

ù to stop the procedure and to go back to (D1)

ò + ç + £ press the 3 keys to turn to the Sensitivity factory calibration and to go back to (D1)

4B. ò ç press the keys to adjust the D.O. value

£ to end the calibration and to go back to (D1).

5B.

POSTPONED CALIBRATION

It is suitable when the D.Oxygen contents are not stable or unknown.

The Display will show for few seconds the message:

VAL. REC. sample value memorization

SAMPLE VAL. REC.

Instruction Manual - Rev. D - 12/06

- 32 -

B&C Electronics OD 7685

xxx.x Dissolved Oxygen measuring value

R measuring stability indicator

M: manual calibration procedure

CAL O2: xxx.xR M

ù to stop the procedure and to go to (D1)

ò + ç + £ press the 3 keys to turn to the Sensitivity factory calibration and to go back to (D1)

Withdraw a sample to check the concentration:

4C. £ to memorize D.O. value of the sample; the following message will be displayed:

After few seconds the instrument goes back to Display (D1) and it is ready to continue in the normal

operation.

To end the postponed Sensitivity calibration it is necessary:

- to have the correct Dissolved Oxygen value from the analyzed sample

- to select the Display (D1)

- to access again to the manual Sensitivity calibration procedure

The display will show the message:

Afterwards the Display will show the previous memorized value

xxx.x D.O. value to be changed according to the analyzed sample value

SAMPLE V. UPDATE

SAMPLE V. ADJUST

SAMPLE V.: xxx.x

ù to stop the procedure and to go to (D1)

ò + ç + £ press the 3 keys to turn to the Sensitivity factory calibration

5C. ò ç to adjust the D.O. value

Instruction Manual - Rev. D - 12/06

- 33 -

B&C Electronics OD 7685

6C. £ to end the postponed Sensitivity calibration value and to go back to (D1)

See Chapter 10 “Troubleshooting” if error messages turn up.

6.3 SECONDARY PARAMETERS CALIBRATION

This procedure allows programming the following parameters:

- Barometric Pressure

- Salinity

- Relative Humidity

- Temperature

These parameters will be used by the instrument to access the memorized compensation table.

1. ù to go to

(D2)

xxx Pressure value

xxxxx Salinity value

2. § to access the calibration sequence

Barometric Pressure calibration

p xxx mmHg Barometric Pressure value selected

ù to stop the procedure and to go back to (D2)

P:xxx sal: xxxxx

CAL p: xxx mmHg

3. ò ç to program the Pressure value

4. £ to confirm the new value and to go to the Salinity Calibration procedure

Instruction Manual - Rev. D - 12/06

- 34 -

B&C Electronics OD 7685

MESSAGE MEANING

the new value has been memorized

Salinity calibration

xxxxx PPM Salinity value selected

ù to stop the procedure and to go back to (D2)

ò ç to program the Salinity value

5.

“ UPDATE “

CAL sal:xxxxxPPM

6.

£ to confirm the new value and to go to the Relative Humidity calibration procedure

MESSAGE MEANING

the new value has been memorized

Relative Humidity calibration

xxx% Relative Humidity value selected

ù to stop the procedure and to go back to (D2)

7. ò ç to program the Relative Humidity value

“ UPDATE “

CAL RH: xxx%

8. £ to confirm the new value and to go back to (D2)

Instruction Manual - Rev. D - 12/06

- 35 -

B&C Electronics OD 7685

MESSAGE MEANING

the new value has been memorized

Temperature calibration

This calibration should be performed with a reference Thermometer.

1. ù to go to

(D3)

xx.x Temperature value

M manual Temperature mode

“ UPDATE “

TEMP.: xx.x°CM

2. § to access the Pt100 Zero calibration procedure

T Pt100 Zero calibration

xx.x measuring Temperature value

ù to stop the procedure and to go back to (D3)

3. ò ç to adjust the Temperature value

£ to confirm the new value and to go to manual Temperature value calibration

4.

_

CAL T: xx.x°C

CAL T.M.: xx.x°C

ù to stop the procedure

5. ò ç to program the manual Temperature value

6. £ to confirm and to go back to (D3)

Instruction Manual - Rev. D - 12/06

- 36 -

B&C Electronics OD 7685

MESSAGE MEANING

the new values has been memorized

Error messages

Zero PT100 > 2.00 °C

This message will be shown for 5 minutes.

£ to acknowledge the error message

The calibration is not accepted

The unit goes back to (D3)

“ UPDATE “

Z> 2.00°C

“ NO UPDATE “

6.4 SET-POINT A/B SETTING

For each set-point it is possible:

- to insert the set-point

- to insert the hysteresis

- to insert the delay time

1. ù to go to:

(D4)

(D5)

The following procedures are suitable for both set-point A and B.

Set value

SA:xxx %air* à LO

SB:xxx %air* à HI

2. § to access the calibration sequences

SA Set-point A calibration

xxx.x Set-point value

ù to stop the procedures

Instruction Manual - Rev. D - 12/06

CAL SA S:xxx.x

- 37 -

B&C Electronics OD 7685

3. ò ç to insert the Set-point value

4. £ to confirm and to go to the next step

xx.x Actual Hysteresis value

ù to stop the procedure

5. ò ç to insert the Hysteresis value

CAL SA I: xx.x

6. £ to confirm and to go to the delay time insertion

xx.xs Actual Delay Time value (in seconds)

ù to stop the procedure

7. ò ç to insert the Delay Time value

8. £ to confirm and to go back to (D4)/(D5)

The calibration is accepted.

CAL SA D: xx.xs

“ UPDATE “

Instruction Manual - Rev. D - 12/06

- 38 -

B&C Electronics OD 7685

6.5 ALARM SETTING

This procedure allows to:

- select the min/max alarm value

- select the Delay Time alarm value

1. ù press the key to go to:

(D6)

2. § to access the calibration sequence

AL L low alarm calibration

xxx.x actual low alarm value

AL xxx/xxx %air

CAL AL L:xxx.x

ù to stop the procedure

3. ò ç to insert the alarm value

4. £ to confirm and to go to the high alarm insertion

AL H high alarm calibration

xxx.x actual high alarm value

ù to stop the procedure

5. ò ç to insert the alarm value

CAL AL H: xxx.x

6. £ to confirm and to go to the Delay Time selection

Instruction Manual - Rev. D - 12/06

- 39 -

B&C Electronics OD 7685

AL D Delay alarm calibration

xx.xs Delay Time value (in seconds)

ù to stop the procedure

7. ò ç to insert the Delay value

8. £ to confirm the new value and to go back to (D6)

the calibration is accepted

CAL AL D: xx.xs

“ UPDATE “

6.6 CLEANING FUNCTION

1. ù to go to

(D7)

CLEANING OFF Cleaning function disabled

(MANUAL CLEAN) Cleaning function with manual activation

(AUTO CLEAN) Automatic Cleaning function

2. § to access the Cleaning function parameters calibration

Manual clean

The following message will be shown:

WAITING the unit is waiting to start a Cleaning cycle

(START) cleaning cycle starting

CLEANING OFF

CLEAN C.: WAITING

Instruction Manual - Rev. D - 12/06

- 40 -

B&C Electronics OD 7685

ù to stop the procedure

3A. ò ç to select START or WAITING

4A.£ to confirm the selected option

- By selecting START the instrument begins a manual Cleaning cycle and

the (D0) Display will be shown.

- By selecting WAITING the instrument go back to (D7)

Automatic functioning (AUTO CLEAN)

The instrument will show the waiting time for the next Cleaning cycle

xx.xh Waiting time for the next cycle (hours)

NEXT CYCLE: xx.xh

ù to stop the procedure

ò + ç + £ press the 3 keys to reset the waiting time.

3B. £ visualization of waiting condition for the next cycle

WAITING the unit is waiting to start a Cleaning cycle

(START) the unit begins a manual Cleaning cycle

ù to stop the procedure

4B. ò ç to select START or WAITING

5B. £ to confirm the selected option

CLEAN C.: WAITING

- By selecting START the instrument begins an extra manual cycle and then go to

the (D0) Display.

- By selecting WAITING the instrument will go to the Cleaning cycle repetition

Time calibration

Instruction Manual - Rev. D - 12/06

- 41 -

B&C Electronics OD 7685

REPETITION:xx.xh

xx.xh: Cleaning cycle repetition time (hours)

ù to stop the procedure

6B. ò ç to insert the Cleaning cycle repetition time

7B. £ to confirm the new value and to go back to (D7)

Instruction Manual - Rev. D - 12/06

- 42 -

B&C Electronics OD 7685

7 CONFIGURATION

The following operations are possible:

- keyboard locked/unlocked selection

- display contrast selection

- access number insertion

1. ù to go to

(D9)

2. § to access the Configuration sequences

Configuration

7.1 KEYBOARD LOCKED/UNLOCKED

Unlocked (Locked) Keyboard unlocked (locked)

ù to go back to (D9)

ò ç to select locked or unlocked

3.

4.

£ to confirm and to go to the next step

KB UNLOCKED

7.2 LCD DISPLAY CONTRAST

This procedure allows the operator to select up to 7 different levels of Display Contrast, in a way to

get a better visibility of the Display.

x Contrast level

LCD contrast: x

ù to go back to (D9)

Instruction Manual - Rev. D - 12/06

- 43 -

B&C Electronics OD 7685

1. ò ç to select the Contrast from 0 to 7

2. £ to confirm and to go to the access number insertion

7.3 ACCESS NUMBER

0 Access number request

ù to go back to (D9)

Access Nr.: 0

1. ò ç to insert the access number (when keeping the key pressed the number will scroll

with 3 speed levels)

2. £ to confirm and to proceed with the configuration

MESSAGE MEANING

a wrong number has been selected;

it is only allowed the visualization of the

parameters and not the modification.

‘Cal Inhibition’

7.4 CELL TYPE

250nA-P (polarographic cell with 250 nA in air)

(45nA-P) (polarographic cell with 45 nA in air)

(300nA-P) (polarographic cell with 300 nA in air)

(30mV-G) (galvanic cell with 30 mV in air)

Input: 250 nA-p

Active keys:

ù - ò ç - £

Instruction Manual - Rev. D - 12/06

- 44 -

B&C Electronics OD 7685

7.5 MICROTRANSMITTER SELECTION

By using a sensor with microtransmitter (080610.2) the option ON has to be selected.

OFF Microtransmitter input disabled

(ON) Microtransmitter input enabled

Active keys: ù - ò ç - £

Microt.: OFF

7.6 MEASURING UNIT

%air scale in % of air saturation

(PPM) scale in PPM

(mg/l) scale in mg/l

(mmHg) scale in mm of Mercury

O2 Scale: %air

Active keys: ù - ò ç - £

7.7 THERMOCOMPENSATION TYPE

TABLE the instrument use the memorized tables

(COEFF.) the instrument use the Thermocompensation Coefficient

Active keys:

By selecting COEFF. the instrument will go to the Coefficient selection procedure.

TERMOC.: TABLE

ù - ò ç - £

7.8 THERMOCOMPENSATION COEFFICIENT

x.xx Thermocompensation Coefficient value

CAL TC: x.xx%/°C

Active keys:

Instruction Manual - Rev. D - 12/06

ù - ò ç - £

- 45 -

B&C Electronics OD 7685

7.9 CALIBRATION MODE

IMM Immediate calibration mode

(POST) Postponed calibration mode

Active keys: ù - ò ç - £

MODE OF CAL:IMM.

7.10 POLARIZATION VOLTAGE

xxx Polarization Voltage value

Adjust the Polarization Voltage by means of the trimmer accessible removing the back panel.

CAL Pol.: xxxmV

Active keys: ù - ò ç - £

7.11 SOFTWARE FILTER

Large s RT Response time for wide variations

xx.xs Response time value(sec.)

Active keys: ù - ò ç - £

Small s RT Response time for small variations

xx.xs Response time value (sec.)

Active keys: ù - ò ç - £

Large s RT:xx.xs

Small s RT:xx.xs

Instruction Manual - Rev. D - 12/06

- 46 -

B&C Electronics OD 7685

7.12 INPUT RELARED TO ANALOG OUTPUT N°1 (OPTION 091.3711)

%air (PPM, mg/l, mmHg) input related to output N°1 (°C)

Active keys: ù - ò ç - £

CAL OUT1:%air

7.13 ANALOG OUTPUT N°1 RANGE

0/20mA (4/20mA) output range

Active keys: ù - ò ç - £

P1 begin of the range

xxx.x measuring value related to 0(4) mA.

CAL OUT1: 0/20mA

CAL P1:xxx.x%air

Active keys: ù - ò ç - £

P2 end of the range

xxx.x measuring value related to 20 mA.

Active keys:

IMPORTANT NOTE: If the value related to P1 is lower than the value related to P2, the analog

output will be "Direct", otherwise it will be "Reverse".

CAL P2:xxx.x%air

ù - ò ç - £

7.14 INPUT RELATED TO ANALOG OUTPUT N°2 (OPTION 091.3711)

%air (PPM, mg/l, mmHg) input related to output N°2 (°C)

CAL OUT2: %air

Active keys: ù - ò ç - £

Instruction Manual - Rev. D - 12/06

- 47 -

B&C Electronics OD 7685

7.15 ANALOG OUTPUT N°2 RANGE

0/20mA (4/20mA) output range

Active keys: ù - ò ç - £

P1 begin of the range

xxx.x measuring value related to 0(4) mA

Active keys: ù - ò ç - £

P2 end of the range

xxx.x measuring value related to 20 mA.

CAL OUT2: 0/20mA

CAL P1:xxx.x%air

CAL P2:xxx.x%air

Active keys: ù - ò ç - £

IMPORTANT NOTE: If the value related to P1 is lower than the value related to P2, the analog

output will be "Direct", otherwise it will be "Reverse".

7.16 SET-POINT A FUNCTION

F function

LO (HI) minimum (maximum)

Active keys: ù - ò ç - £

SET A F.: LO

7.17 SET-POINT B FUNCTION

F function

LO (HI) minimum (maximum)

SET B F.: LO

Active keys: ù - ò ç - £

Instruction Manual - Rev. D - 12/06

- 48 -

B&C Electronics OD 7685

7.18 ALARM ON SET-POINT A

ON (OFF) alarm enabled (disabled)

Active keys: ù - ò ç - £

- By selecting OFF the alarm function is not activated.

The unit goes to the next parameter calibration.

- By selecting ON the alarm function is activated. (When the relay B will be active

longer than the time selected in the following procedure).

xx m Activation time selected (minutes)

AL SET A: ON

TIME SET A: xx m

Active keys: ù - ò ç - £

7.19 ALARM ON SET-POINT B

ON (OFF) alarm enabled (disabled)

Active keys: ù - ò ç - £

- By selecting OFF the alarm function is not activated.

The unit goes to the next parameter calibration.

- By selecting ON the alarm function is activated. (When the relay B will be active

longer than the time selected in the following procedure).

xx m Activation time selected (minutes)

AL SET B: ON

TIME SET B: xx m

Active keys: ù - ò ç - £

Instruction Manual - Rev. D - 12/06

- 49 -

B&C Electronics OD 7685

7.20 ALARM RELAY C CONTACTS

Select one of the following Display:

ACT (DEA) relay activated (deactivated) when the alarm is active

Active keys: ù - ò ç - £

IMPORTANT NOTE: By selecting DEA, it is necessary to modify some Jumpers on the Power

supply board (contact the Service Department).

AL RELAY: ACT

7.21 CLEANING FUNCTION

CAL CF Cleaning function calibration

DISABLED Cleaning function disabled

(MANUAL) Manual cleaning function

(AUTO) Automatic cleaning function

CAL CF:DISABLED

Active keys: ù - ò ç - £

7.22 CLEANING TIME (RELAY D ON)

xx.x" Cleaning time (sec.)

Active keys: ù - ò ç - £

CLEANING T:xx.x”

7.23 HOLDING TIME

xx.x' Waiting time between two cleaning cycle (min)

Active keys: ù - ò ç - £

HOLDING T:xx.x’

Instruction Manual - Rev. D - 12/06

- 50 -

B&C Electronics OD 7685

7.24 NEW ACCESS NUMBER

NO (YES) access number changing not required (required)

Active keys: ù - ò ç - £

- By selecting NO the unit will go to the Configuration display

- By selecting YES the unit will go to the following display:

xxx actual access number

Change A Nr.:NO

New Nr.: xxx

Active keys: ù - ò ç - £

The instrument ask the operator to insert again the new access number.

xxx actual access number

The double insertion of the new access number assures the memorization of the

right code.

As soon as the new number is memorized the message "UPDATE" will appear.

Should the operator insert two different numbers, the instrument will not modify the

access number and the message "NO UPDATE" will be shown.

£ Press several time the key to verify the selected parameters before leaving

the Configuration routine.

Confirm Nr.:xxx

ù Press to exit from the Configuration menu.

Instruction Manual - Rev. D - 12/06

- 51 -

B&C Electronics OD 7685

8 CALIBRATION

Zero cell calibration

The Zero cell calibration is necessary at the start up of the system, after the installation of a new cell

and after the cell maintenance is done.

The calibration consists of the Zero Current compensation, setting the cell response to the standard

operating condition of the instrument.

The calibration sequence consists of a Zero value visualization, in order to perform the new Zero

calibration or to maintain the previous one.

Dip the sensor in a 2% of Sodium Sulphite solution. The solution should be made at the time of

calibration to assure the total lack of Dissolved Oxygen during the calibration.

When the measuring is steady and close to Zero, perform the calibration following the instruction in

Chapter 6.2 “Zero and Sensitivity calibration”.

After the calibration rinse the sensor with clean water.

The Zero solution can be stored for few days in a dark bottle, without any trace of air.

Sensitivity cell calibration

This calibration can be manually or automatically performed.

In the usual application the automatic calibration in air is performed.

This method is fast and quite accurate.

Operate as follow:

- Verify that the Pressure, Salinity and Relative Humidity values selected correspond to the real

values.

- Select the automatic mode calibration

- Remove the cell from water, let the Temperature value stabilize in air and press the

- verify the stability of the Dissolved Oxygen value on the Display and press the £ key for the

autocalibration.

If the measured value is not steady it is necessary to evaluate if proceeding with the calibration or

stopping the procedure and check the cell.

As alternative the manual calibration requires the use of a sample with a known D.Oxygen

concentration.

Since it is very difficult to have this type of sample, because of some factors that influence the Oxygen

concentration (Temperature, Salinity, Barometric Pressure, Oxygen concentration in air), this method

is normally used for special applications.

Instruction Manual - Rev. D - 12/06

£ key.

- 52 -

B&C Electronics OD 7685

Temperature calibration

From display (D0) press ù to access the Temperature calibration sequences.

Immerse the sensor in a liquid with a known Temperature value and verify the correspondence of the

measuring.

To adjust the reading, follows the first four points of the procedure described in Chapter 6.3.

“Secondary parameters calibration”

Electrical check

The following procedures can be used to verify the correct operation of the instrument, eventually they

should be performed periodically in the calibration checks.

- Turn back the instrument to Zero and Sensitivity factory calibration and proceed as follows:

Polarographic cell

- Connect to terminals 19-20 of the instrument a cell Simulator

(for instance the mod. OD 105.1 of B&C Electronics).

- Simulate the value 0 nA and check for the value 0.0 on the display.

- Simulate the value 30 nA or 250 nA or 300 nA depending on the type of polarographic cell

installed.

In This condition the display will shows 100 %.

Should the instrument measure different values send it back to B&C Electronics.

Galvanic cell

- Connect to terminals 21-22 of the instrument a mV generator.

- Simulate the value 0 mV and check for the value 0.0 on the display.

- Simulate the value 30 mV and check for the value 100% on the display.

Should the instrument measure different values send it back to B&C Electronics.

Instruction Manual - Rev. D - 12/06

- 53 -

B&C Electronics OD 7685

9 PREVENTIVE MANTENIANCE

Instrument

The use of high quality electronics components, gives to the instrument a great reliability.

The maintenance frequency is depending of each application.

As for any electronic instrument the mechanical components like relays and the terminal blocks, are

the parts subjected to failure.

If the instrument has been supercharged, remove the power supply for 5/10 minutes to allow the reset

of the protections.

Check that connections in the terminal blocks are clean and dry.

Sensor

The sensor maintenance is prescribed by sensors manufacturer.

Store the sensor with the membrane wet in order to avoid the electrolyte loss.

Remove deposits from the membrane by rinsing with water, eventually using detergents, to avoid the

reduction of the membrane life.

Change periodically the membrane and the electrolyte, especially when the measuring response

becomes slow and the Zero Current value is too high.

Normally if the Zero value is reached in more than 30 seconds (when the cell is dipped in Zero

solution) the change of the membrane and the electrolyte is suggested.

During the membrane changing, avoid any touch of the cathode which is located in the centre of the

cell, close to the membrane.

The use of cleaning systems keep the sensor more efficient and reduce the membrane/electrolyte

changing frequency.

Instruction Manual - Rev. D - 12/06

- 54 -

B&C Electronics OD 7685

10 TROUBLESHOOTING

In case of problems in the functioning of the measuring and regulation system it is necessary to locate

were they come from:

- wrong connections

- measuring cell maintenance

- measuring cell failure

- wrong configuration of the instrument

- instrument failure

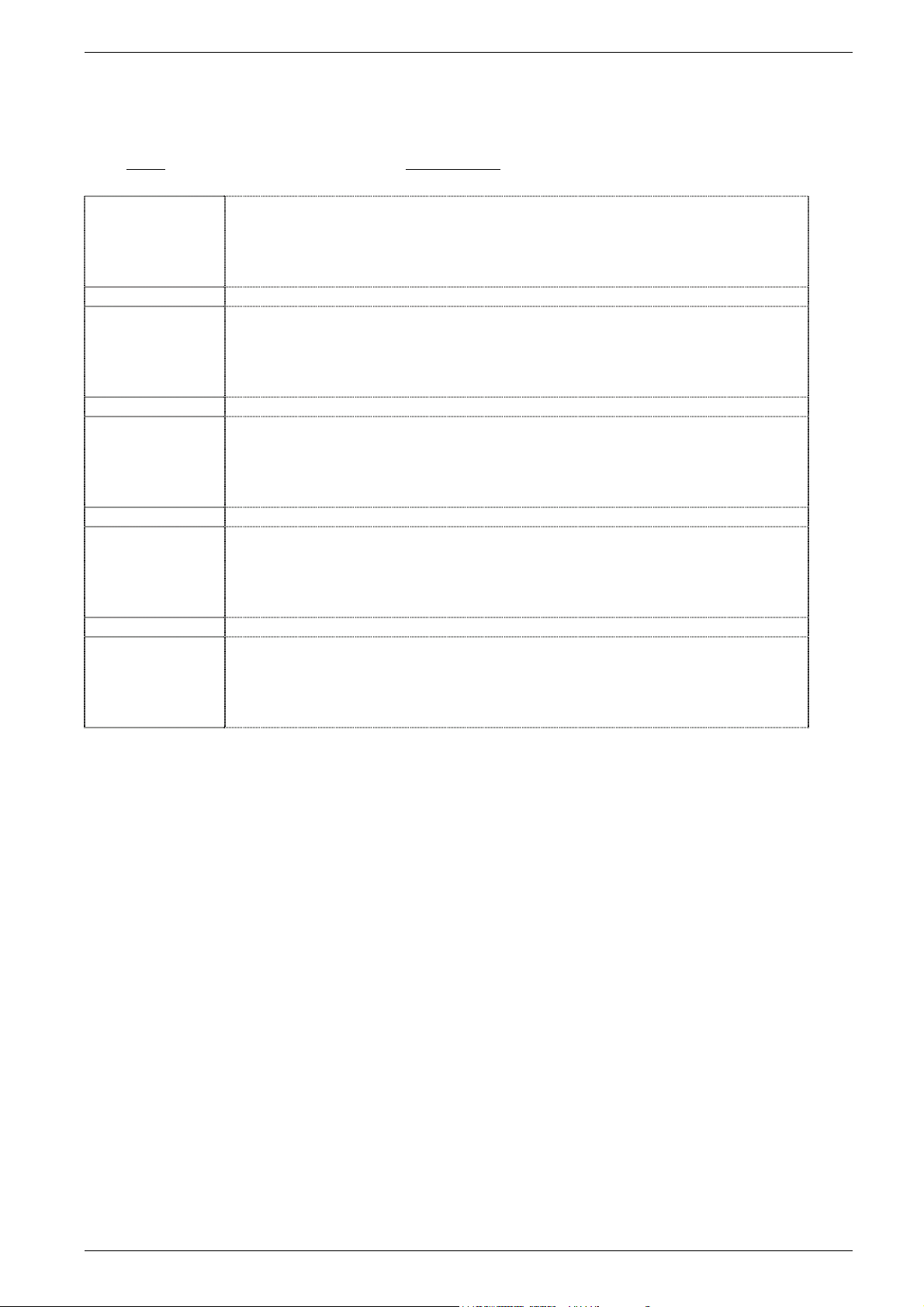

The following table shows the possible cause and relative remedy for the main problems in the

instrument use.

PROBLEM

LCD extinguished Power not connected.

Unacceptable measure Instrument calibration

Error messages in the

Zero calibration

Error messages in the

Sensitivity calibration

Error messages in the

Pressure calibration

The regulation doesn't

work

Relay chattering if the

measuring is close to the

Set-point

The recorder doesn't

work properly

PROBABLE CAUSE

Over Voltage

Wrong compensation value.

Instrument failure

Cell maintenance.

Cell failure

Cell maintenance.

Cell failure.

Wrong type of cell selected

Pressure sensor failure Send back the instrument to B&C

Relay contacts wrong

selection.

Instrument failure

Interferences on the signal Connect to the ground the instrument

Recorder not connected or

damaged.

Wrong configuration of the

analog output.

Instrument failure.

REMEDY

Check the power supply.

Wait 10 Sec. for the reset of the

protections

Calibrate the instrument.

Check the compensation of °C-P-UR.

Send back the instrument to B&C

Regeneration of the cell.

Change the cell.

Regeneration of the cell.

Change the cell.

Verify the configuration of the cell type

Verify the relay operating mode

selection.

Send back the instrument to B&C

and the sample.

Increase the RT filter SW.

Increase the Delay time.

Increase the Hysteresis.

Check the connections.

Check the analog output configuration.

Send back the instrument to B&C

Instruction Manual - Rev. D - 12/06

- 55 -

B&C Electronics OD 7685

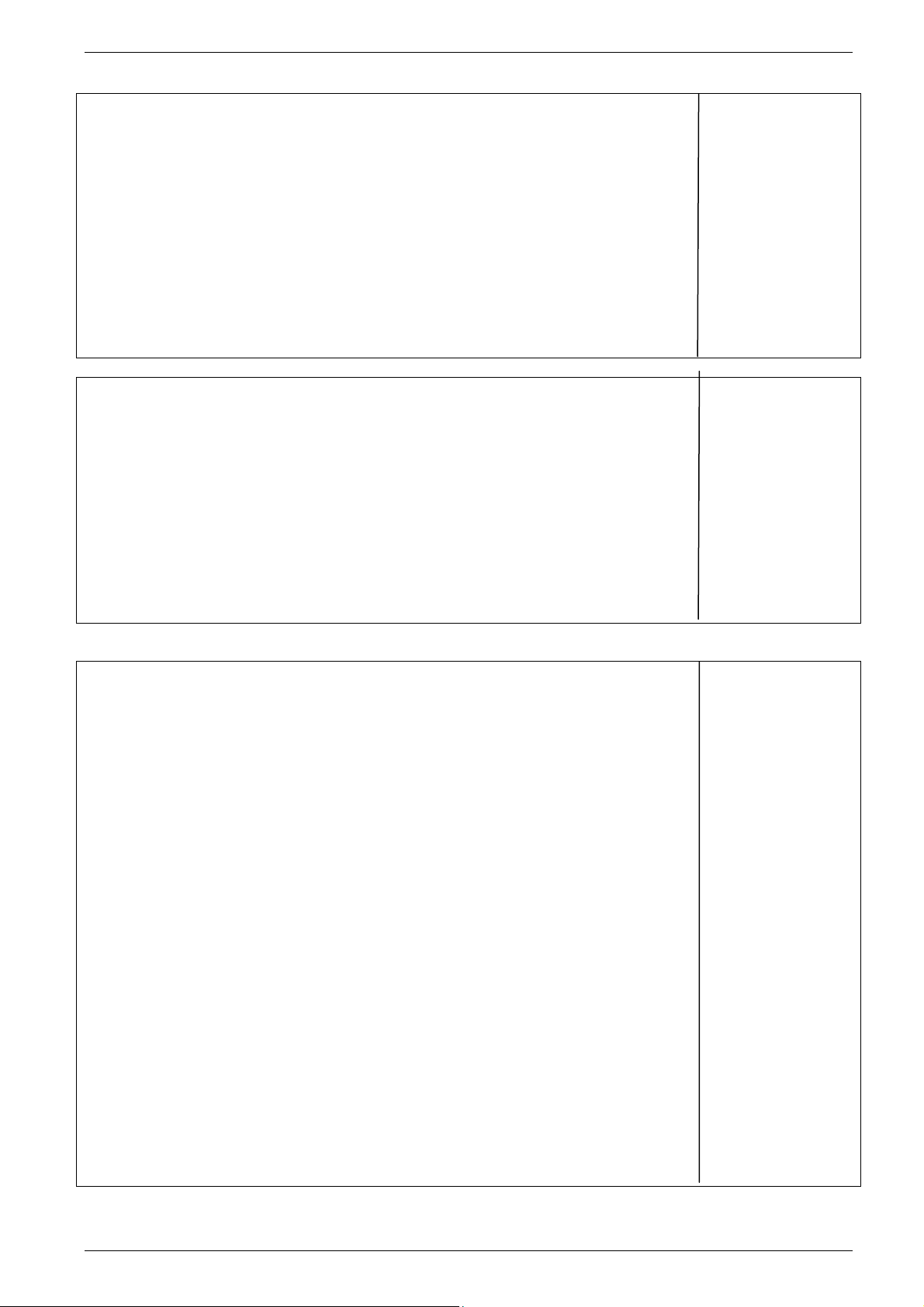

FRONT PANEL

electronics

1. Display

2. Mode-display key

3. Calibration key

4. Increase key

5. Decrease key

6. Enter key

Fig. 1

Instruction Manual - Rev. D - 12/06

- 56 -

B&C Electronics OD 7685

REAR PANEL CONNECTIONS

1.2. Power supply 110 V

1.3. Power supply 220 V

4. Ground

5.6. Relay A – contact N.O.

6.7. Relay A – contact N.C.

8.9. Relay B – contact N.O.

9.10. Relay B – contact N.C.

11.12. Relay C – contact N.O. (alarm)

12.13. Relay D – contact N.O. (cleaning)

14. Analog output N°1 (+)

15. Analog output N°2 (+)

16. Analog output (-) common

17.18.21.22. Microtransmitter input

23.24.25. Pt100 input

POLAROGRAPHIC CELL GALVANIC CELL

19. Input Ag (anode) 21. Input Pb (anode)

20. Input Pt (cathode) 22. Input Ag (cathode)

21.22. External jumper

Fig. 2

Instruction Manual - Rev. D - 12/06

- 57 -

B&C Electronics OD 7685

DIMENSIONS

electronics

DRILL PLAN

Fig. 3

Instruction Manual - Rev. D - 12/06

- 58 -

B&C Electronics OD 7685

11 APPENDIX NR. 1 (VALID FOR OPTION 091.601)

The instrument equipped with this option can measure the Barometric Pressure.

The measuring value can be used to access the conversion table.

The measuring sensor is installed inside the instrument.

In the Configuration procedure it is possible to disable the Pressure measurement and to use the

selected manual value.

In case of sensor failure, the instrument automatically switch to manual Pressure value.

Technical specifications

Change the secondary parameters technical specification with the followings:

Default

SECONDARY PARAMETERS

Barometric Pressure measuring:

Sensor type: absolute (40 mV/760 mmHg)

Sensor sensitivity: 80%/120% 100%

Measuring range: 500/800 mmHg

External Pressure measuring: Auto/Manual Auto

Manual Pressure value: 500/800 mmHg 760mmHg

Salinity (Chloride): 0/60000 PPM 0PPM

Relative Humidity: 0/100 % 50%

Pressure calibration

The calibration is performed in the factory.

The operator can periodically check the calibration.

To calibrate the Sensitivity of the sensor, the operator should access to the procedures and program the

correct Pressure value.

1. ù to go to

xxx Pressure value

M Manual Pressure value xxxxx Salinity value

Instruction Manual - Rev. D - 12/06

P:xxxMsal:xxxxx

- 59 -

B&C Electronics OD 7685

2. § to access the secondary parameters calibration

xxx Barometric Pressure measuring

(>>>>>) Pressure value over the range

ù to stop the procedure

ò + ç + £ press the 3 keys to turn the Pressure to factory calibration

ò ç to modify the Barometric Pressure value

3.

CAL p: xxx mmHg

4.

£ to confirm and to go to the manual Pressure value calibration

MESSAGE MEANING

data has been memorized

Error messages

Sensitivity sensor too high

Sensitivity sensor too low

See Chapter 10 “Troubleshooting” if error messages turn up.

Manual Barometric Pressure value calibration

p M manual value

xxx manual Pressure value

“ UPDATE “

S > 120%

S < 80%

CAL p M:xxx mmHg

ù to stop the procedure

Instruction Manual - Rev. D - 12/06

- 60 -