B&C Electronics OD 545.2, OD 565.2 OPERATOR’S MANUAL

CERT. N. 9115 BCEL

OPERATOR’S MANUAL

UNI EN ISO 9001:2000

OD 545.2 - OD 565.2

DIGITAL DISSOLVED OXYGEN

CONTROLLERS

Rev. A – Valid from S/N 28421

Input: from polarographic cells

Scales: 0/19.99 PPM

0/199.9 % O2

0/199.9 % air saturation

0/199.9 mmHg

Power supply: 110/220 Vac

B&C Electronics Srl – Via per Villanova 3 – 20040 Carnate (Mi) – Italy P.IVA 00729030965

Tel +39 039 63 1721 – Fax +39 039 607 6099 bc@bc-electronics.it - www.bc-electronics.it

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

Index

1 GENERAL .................................................................................................................................... 3

2 PRINCIPLES ................................................................................................................................ 3

3 FUNCTIONAL DESCRIPTION .................................................................................................. 4

4 PHYSICAL DESCRIPTION ........................................................................................................ 8

5 SPECIFICATIONS....................................................................................................................... 9

6 PHYSICAL INSTALLATION................................................................................................... 10

7 ELECTRICAL INSTALLATION .............................................................................................. 11

7.1 Connecting the power........................................................................................................ 11

7.2 Connecting the cell (probe) .............................................................................................. 13

7.3 Connecting the microtransmitter ....................................................................................... 13

7.4 Connecting alarms, pumps, valves .................................................................................... 13

7.5 Connecting a recorder........................................................................................................ 14

7.6 Connecting the RTD.......................................................................................................... 14

7.7 Checking............................................................................................................................ 14

8 OPERATING THE SYSTEM .................................................................................................... 15

8.1 Pre-operation check ........................................................................................................... 15

9 NORMAL OPERATION............................................................................................................ 15

10 CALIBRATING THE CONTROLLER ..................................................................................... 16

10.1 Electric zero....................................................................................................................... 16

10.2 Zero cell calibration........................................................................................................... 16

10.3 Slope calibration ................................................................................................................ 16

10.4 Polarization voltage of sensor............................................................................................ 17

11 PREVENTIVE MAINTENANCE.............................................................................................. 18

11.1 Controller........................................................................................................................... 18

11.2 Sensor ................................................................................................................................ 18

12 TROUBLESHOOTING GUIDE ................................................................................................ 19

- 2 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

1 GENERAL

This manual applies to the OD 545.2 and OD 565.2 digital controllers.

It explains the purpose of the equipment, describes the components of the chain and the procedures for

installing the equipment, operating it and calibrating it.

Some suggestions are also given for its maintenance.

2 PRINCIPLES

In a polarographic cell, if a constant tension is applied to the electrodes, the reduction of the oxygen

ions on the cathode generates a current proportional to the oxygen's partial pressure.

The intensity of the current produced at a constant temperature and at a given oxygen pressure

depends on the quantity and composition of the electrolyte, the cathode's area and the sample's state.

Response time depends on the electrolyte's and diaphragm’s characteristics.

The value of the applied voltage to the anode is chosen in a way that only oxygen can react.

In absence of oxygen, the current produced is not exactly zero.

In fact, impurities and other factors generate a "dark current" which can be offset by the amplifier.

The electrode consumes the oxygen diffused through the permeable membrane (PTFE) and the

electrolyte's film, therefore a concentration gradient is established between cathode and sample; the

electrodes with a big cathode, with a high output current, consume a lot of oxygen and are more

sensitive to the sample's flow and therefore request a large flow and an adequate stirring of the sample.

The temperature dependence of the output current is compensated by the automatic temperature

compensation of the meter.

- 3 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

3 FUNCTIONAL DESCRIPTION

This system provides a digital readout of the dissolved oxygen of aqueous solutions.

In order to satisfy the many requests of such measurements, two types of amplifiers with different

ranges have been designed:

The model OD 565.2 for industrial applications and the model OD 545.2 for fermentation.

The mod. OD 565.2 features:

- selectable ranges in PPM, % air, % O2, mmHg.

- auto/manual temperature compensation

- temperature and temperature coefficient readout

- adjustable temperature coefficient

- polycarbonate membrane panel

The mod. OD 545.2 features:

- 0/200.0 % AIR saturation scale

- automatic temperature compensation

A basic dissolved oxygen monitoring system consists of two elements:

a monitor unit, and a probe or O2 cell.

The system can be expanded by adding accessories for field applications, recorders, secondary

regulators, proportional regulators, special probes and temperature probes to suit particular

applications.

The controller contains electronic circuits to control the operation of the entire system.

It provides a digital readout of dissolved oxygen on a 3 1/2 digit display.

There is included an internal circuitry for controlling two alarms, valves, pumps etc.

Set-points are independent and programmed by a front-panel control to trigger at any level within the

range of the meter.

Red LEDs on the panel indicate if the measured value is below the set point A level, or if it is above

the set point B level.

Red LEDs also indicate the switching of corresponding relays.

The controller provides an output of 0/20 mA - 4/20 mA selectable by rear switch (on request 0/10 V

or others).

The output is proportional to the meter reading, for driving a recorder, remote readout or regulators

having an isolated input (not grounded).

Zero and slope are adjusted by trimmers 2 and 3 on the front panel.

- 4 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

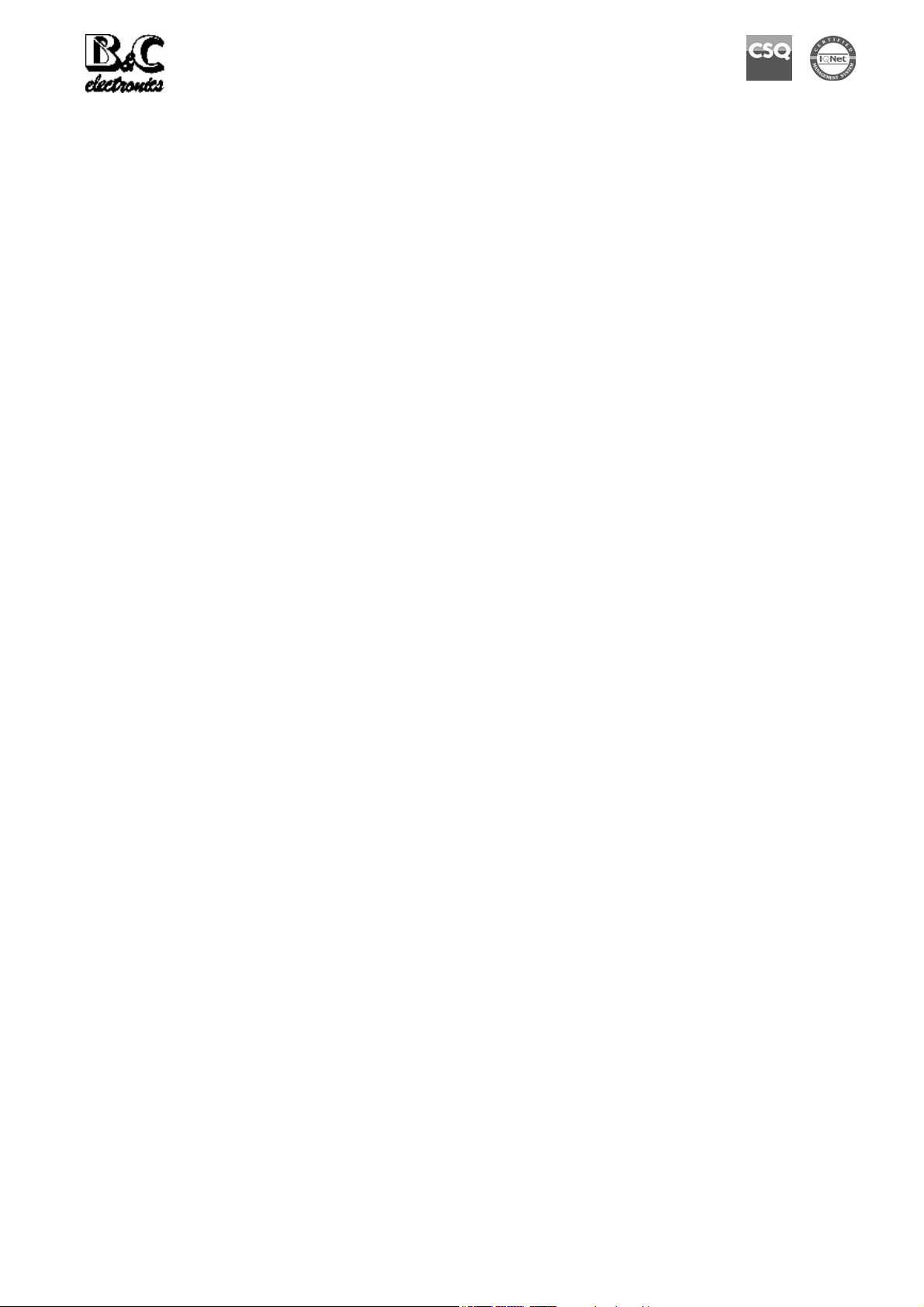

Fig. 1

- 5 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

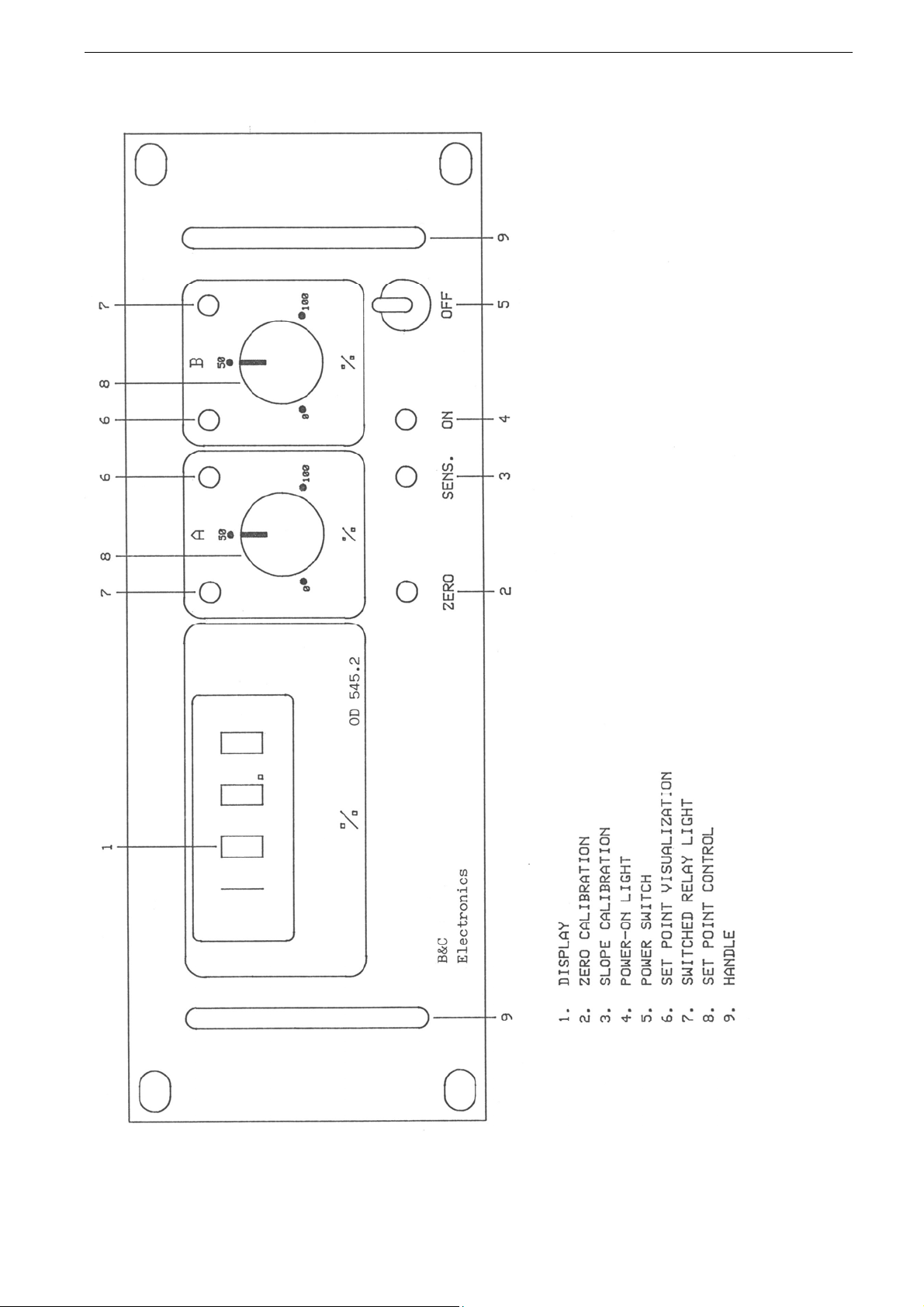

Fig. 2

- 6 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

The following features are available:

- the set point value is visualized by pushing the button 6 on the front panel

- the switching function of relay is inverted by rear switches marked min/MAX

- the regulators have a delay action 0 to 5 seconds by rear trimmers marked DEL A and DEL B

- the B regulator, as an " option ", can be supplied as a " window alarm " working over the set

point A with the delay action included.

- automatic temperature compensation is carried out by means of a 3 wire RTD Pt 100.

- the input of meters is both by electrodes (probes) or by amplified probes (by microtransmitter).

This special probe is completely waterproof and contains the measuring O2 cell and a microtransmitter

which allows a normal electrical cable to be used to receive the signal. With this technical solution, it

is possible to make considerably long connections between the measuring point and the controller

without signal delay or interference.

As a result, fewer additives are consumed and a greater precision of regulation is obtained.

Furthermore, the coupling of the instrument and the probe by means of a 4 wire cable, is protected

against connection errors. (a 7 wire cable is needed when Pt 100 thermo compensator is installed)

Therefore, the installation of the measuring and regulating link can be carried out by non-specialized

staff.

In the model OD 565.2 the digital temperature readout is obtained by pushing a button 10 on front

panel, as measuring and controlling functions of the instrument are not altered.

The digital temperature factor readout is obtained by pushing a button 12.

The value of the temperature factor is adjusted by the trimmer 11.

The scale is chosen by the selector 14.

- 7 -

Loading...

Loading...