CERT. N. 9115 BCEL

OPERATOR’S MANUAL

UNI EN ISO 9001:2000

OD 545.2 - OD 565.2

DIGITAL DISSOLVED OXYGEN

CONTROLLERS

Rev. A – Valid from S/N 28421

Input: from polarographic cells

Scales: 0/19.99 PPM

0/199.9 % O2

0/199.9 % air saturation

0/199.9 mmHg

Power supply: 110/220 Vac

B&C Electronics Srl – Via per Villanova 3 – 20040 Carnate (Mi) – Italy P.IVA 00729030965

Tel +39 039 63 1721 – Fax +39 039 607 6099 bc@bc-electronics.it - www.bc-electronics.it

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

Index

1 GENERAL .................................................................................................................................... 3

2 PRINCIPLES ................................................................................................................................ 3

3 FUNCTIONAL DESCRIPTION .................................................................................................. 4

4 PHYSICAL DESCRIPTION ........................................................................................................ 8

5 SPECIFICATIONS....................................................................................................................... 9

6 PHYSICAL INSTALLATION................................................................................................... 10

7 ELECTRICAL INSTALLATION .............................................................................................. 11

7.1 Connecting the power........................................................................................................ 11

7.2 Connecting the cell (probe) .............................................................................................. 13

7.3 Connecting the microtransmitter ....................................................................................... 13

7.4 Connecting alarms, pumps, valves .................................................................................... 13

7.5 Connecting a recorder........................................................................................................ 14

7.6 Connecting the RTD.......................................................................................................... 14

7.7 Checking............................................................................................................................ 14

8 OPERATING THE SYSTEM .................................................................................................... 15

8.1 Pre-operation check ........................................................................................................... 15

9 NORMAL OPERATION............................................................................................................ 15

10 CALIBRATING THE CONTROLLER ..................................................................................... 16

10.1 Electric zero....................................................................................................................... 16

10.2 Zero cell calibration........................................................................................................... 16

10.3 Slope calibration ................................................................................................................ 16

10.4 Polarization voltage of sensor............................................................................................ 17

11 PREVENTIVE MAINTENANCE.............................................................................................. 18

11.1 Controller........................................................................................................................... 18

11.2 Sensor ................................................................................................................................ 18

12 TROUBLESHOOTING GUIDE ................................................................................................ 19

- 2 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

1 GENERAL

This manual applies to the OD 545.2 and OD 565.2 digital controllers.

It explains the purpose of the equipment, describes the components of the chain and the procedures for

installing the equipment, operating it and calibrating it.

Some suggestions are also given for its maintenance.

2 PRINCIPLES

In a polarographic cell, if a constant tension is applied to the electrodes, the reduction of the oxygen

ions on the cathode generates a current proportional to the oxygen's partial pressure.

The intensity of the current produced at a constant temperature and at a given oxygen pressure

depends on the quantity and composition of the electrolyte, the cathode's area and the sample's state.

Response time depends on the electrolyte's and diaphragm’s characteristics.

The value of the applied voltage to the anode is chosen in a way that only oxygen can react.

In absence of oxygen, the current produced is not exactly zero.

In fact, impurities and other factors generate a "dark current" which can be offset by the amplifier.

The electrode consumes the oxygen diffused through the permeable membrane (PTFE) and the

electrolyte's film, therefore a concentration gradient is established between cathode and sample; the

electrodes with a big cathode, with a high output current, consume a lot of oxygen and are more

sensitive to the sample's flow and therefore request a large flow and an adequate stirring of the sample.

The temperature dependence of the output current is compensated by the automatic temperature

compensation of the meter.

- 3 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

3 FUNCTIONAL DESCRIPTION

This system provides a digital readout of the dissolved oxygen of aqueous solutions.

In order to satisfy the many requests of such measurements, two types of amplifiers with different

ranges have been designed:

The model OD 565.2 for industrial applications and the model OD 545.2 for fermentation.

The mod. OD 565.2 features:

- selectable ranges in PPM, % air, % O2, mmHg.

- auto/manual temperature compensation

- temperature and temperature coefficient readout

- adjustable temperature coefficient

- polycarbonate membrane panel

The mod. OD 545.2 features:

- 0/200.0 % AIR saturation scale

- automatic temperature compensation

A basic dissolved oxygen monitoring system consists of two elements:

a monitor unit, and a probe or O2 cell.

The system can be expanded by adding accessories for field applications, recorders, secondary

regulators, proportional regulators, special probes and temperature probes to suit particular

applications.

The controller contains electronic circuits to control the operation of the entire system.

It provides a digital readout of dissolved oxygen on a 3 1/2 digit display.

There is included an internal circuitry for controlling two alarms, valves, pumps etc.

Set-points are independent and programmed by a front-panel control to trigger at any level within the

range of the meter.

Red LEDs on the panel indicate if the measured value is below the set point A level, or if it is above

the set point B level.

Red LEDs also indicate the switching of corresponding relays.

The controller provides an output of 0/20 mA - 4/20 mA selectable by rear switch (on request 0/10 V

or others).

The output is proportional to the meter reading, for driving a recorder, remote readout or regulators

having an isolated input (not grounded).

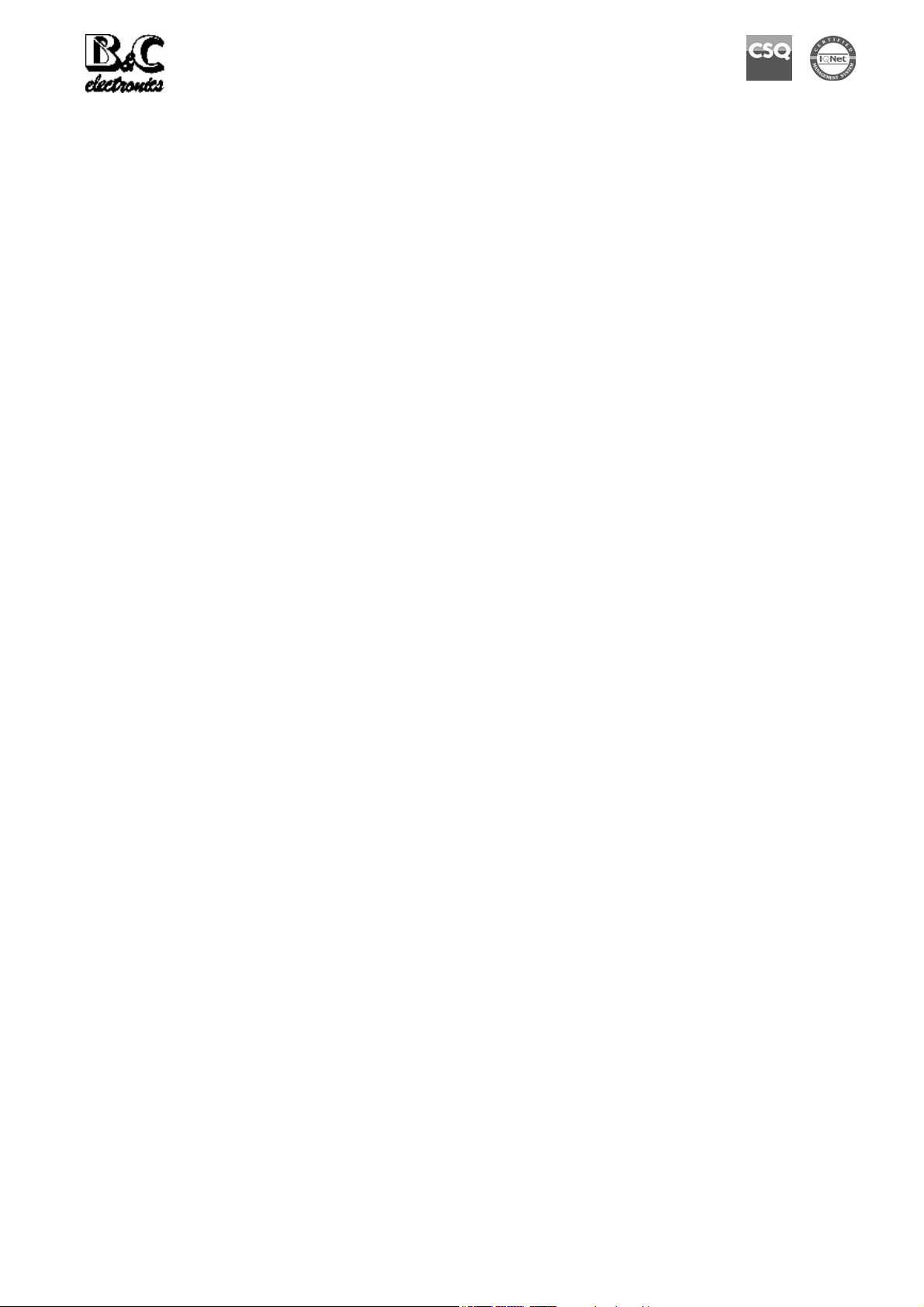

Zero and slope are adjusted by trimmers 2 and 3 on the front panel.

- 4 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

Fig. 1

- 5 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

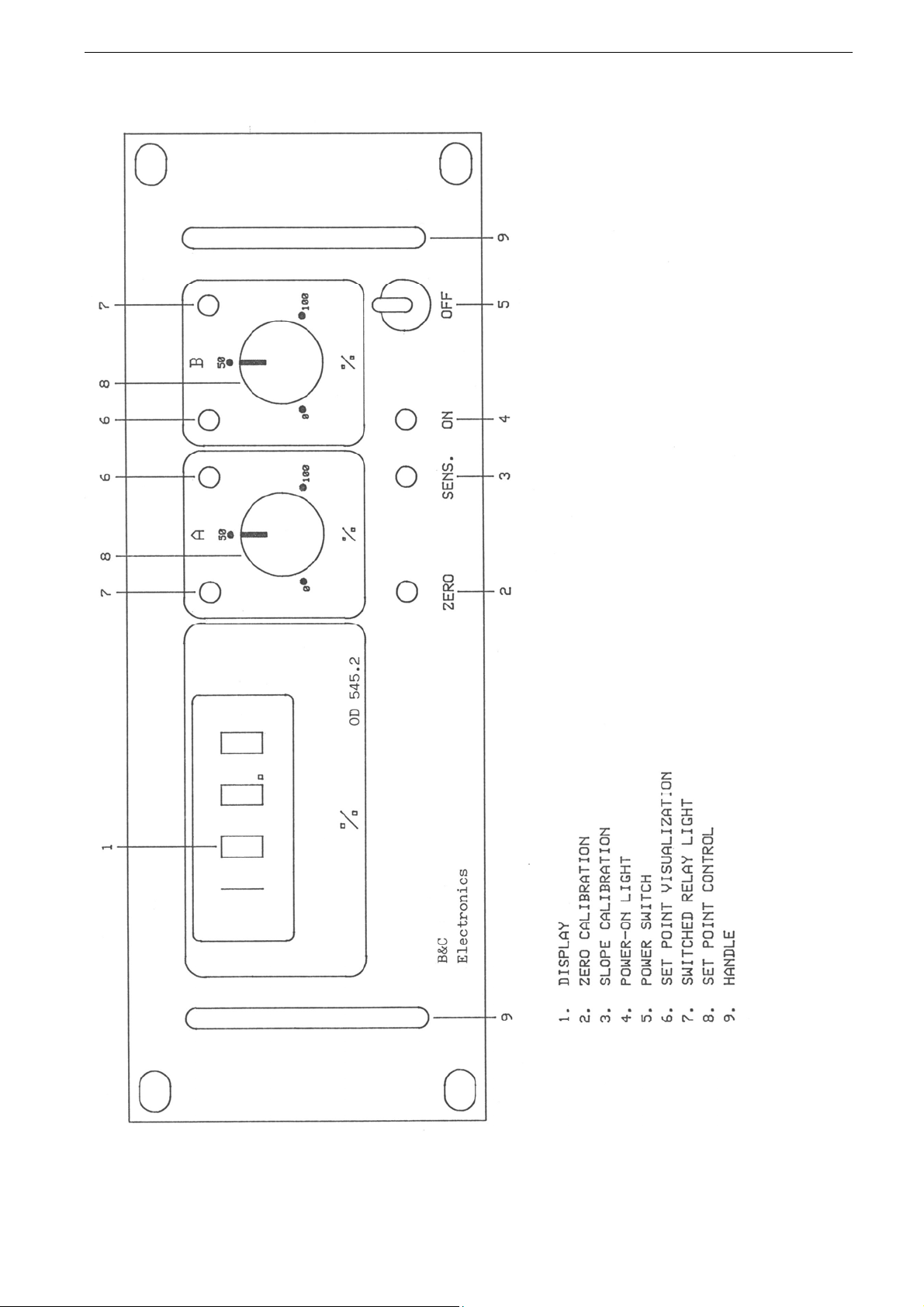

Fig. 2

- 6 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

The following features are available:

- the set point value is visualized by pushing the button 6 on the front panel

- the switching function of relay is inverted by rear switches marked min/MAX

- the regulators have a delay action 0 to 5 seconds by rear trimmers marked DEL A and DEL B

- the B regulator, as an " option ", can be supplied as a " window alarm " working over the set

point A with the delay action included.

- automatic temperature compensation is carried out by means of a 3 wire RTD Pt 100.

- the input of meters is both by electrodes (probes) or by amplified probes (by microtransmitter).

This special probe is completely waterproof and contains the measuring O2 cell and a microtransmitter

which allows a normal electrical cable to be used to receive the signal. With this technical solution, it

is possible to make considerably long connections between the measuring point and the controller

without signal delay or interference.

As a result, fewer additives are consumed and a greater precision of regulation is obtained.

Furthermore, the coupling of the instrument and the probe by means of a 4 wire cable, is protected

against connection errors. (a 7 wire cable is needed when Pt 100 thermo compensator is installed)

Therefore, the installation of the measuring and regulating link can be carried out by non-specialized

staff.

In the model OD 565.2 the digital temperature readout is obtained by pushing a button 10 on front

panel, as measuring and controlling functions of the instrument are not altered.

The digital temperature factor readout is obtained by pushing a button 12.

The value of the temperature factor is adjusted by the trimmer 11.

The scale is chosen by the selector 14.

- 7 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

4 PHYSICAL DESCRIPTION

The controller enclosure is designed for surface or panel mounting.

It consists of an anodized aluminium front panel and an epoxy-coated metallic case, to ensure the

maximum anticorrosion characteristics.

(The model OD565.2 has a polycarbonate membrane on the front panel).

However a mounting in a splash proof board is suggested for field applications.

The figures 3 and 4 show the physical details, dimensions and drill plan of this case.

Connections to power supply, loads, recorder, RTD, electrodes/probe are carried out by means of a

detachable terminal block on the rear side.

Fig. 3

- 8 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

5 SPECIFICATIONS

Voltage: 110/220 Vac +/-10 % 50/60 Hz

Input: from polarographic O2 cell

from microtransmitter 080610.2

Output : 0/20 – 4/20 mA dc selectable, nonisolated, 300 Ω max.

Scales OD545.2: 0/199.9 % AIR saturation

Scales OD565.2: 0/19.99 PPM

0/199.9 AIR saturation

0/199.9 % O2

0/199.9 mmHg

Zero: adjustment +/- 15%

Slope: fine adjustment +/- 20%

coarse adjustment

Temperature: 0/50 °C

Cell current in air: 0.030 µA

Temp. comp.: automatic 0/50 °C

Temp. coeff.: 0 to 6 %/K (OD 565.2)

2.3 %/K at 20 °C (others on request) (OD 545.2)

Temp. sensor: RTD Pt100

Temp. readout: 0/100°C (OD 565.2)

Regulators: +/- 0.25% hysteresis (others as requested)

Switching time: < 0.5 s

Regulators delay: 0 to 5 s

Relay contacts: 5 A 220 V resistive load

Fuse : 80 mA T (110 V) 32 mA T (220 V)

Power: 3 VA max

Weight: 1.014 kg

Size: 241 x 89 x 157 mm

Option 091.113 galvanic cell input

Option 091.363 isolated output

Option 091.401 24 Vac power supply

Option 091.201 window B regulator

- 9 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

6 PHYSICAL INSTALLATION

The controller may be installed close to the points being monitored, or it may be located some distance

away in a control area.

For a distance between sensor (cell/probe) and controller greater than 30 feet the microtransmitter

probe is suggested to avoid signal delay and interferences.

The enclosure is designed for panel-mounting. It should be mounted on a rigid surface, in a position

protected from the possibility of damage or excessive moisture or corrosive fumes.

Immersion probes have a PVC ring to adjust the depth of the cell into the liquid to be tested. Probes

may be fastened by hangers with 36 mm. hole.

The cable from the probe must be protected by a sheath and not installed near to power cables.

Interruption on cables must be avoided or carried out by high insulation terminals.

When installing the cell it is suggested to follow the specific instructions given by the sensor’s

manufacturer.

- 10 -

Fig. 4

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

7 ELECTRICAL INSTALLATION

The electrical installation consists of:

- connecting the power supply to the meter

- connecting the cell or the probe to the meter

- connecting alarms, pumps, valves if necessary

- connecting the monitor output to the recorder or similar devices if required

- connecting other optional accessories (RTD P.I.D. regulators)

All connections within the controller are made on terminal strips (detachable) located on the rear side.

All power and output-recorder connections are made at the 16 pin terminal strip, while input signal

connections are made at the 8 pin terminal strip.

7.1 CONNECTING THE POWER

- connect ground to terminal 1

- connect ac power to 2 and 3 terminals if power is 110 V

- connect ac power to 2 and 4 terminals if power is 220 V

- use 32 mA T fuse for 220 V

- use 80 mA T fuse for 110 V

(connect 24 Vac power to 2 and 4 terminals if option 091.403 is installed)

WARNINGS:

- power the device by means of an isolation transformer

- avoid mains voltage from an auto-transformer

- avoid mains voltage from a branch point with heavy inductive loads

- separate power supply wires from signal ones

- control the mains voltage value

- it is necessary that all ground terminals of each component of the system should be connected

together to a sure ground.

- 11 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

Fig. 5

- 12 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

7.2 CONNECTING THE CELL (PROBE)

Electrode cabling is a critical part of the whole system.

- use a low noise coax cable on overall length between sensor and input terminals of the meter

- avoid interruption on the cable if a coax connector and a high insulation terminal strip are not

available

- keep the cable away from power wires on the overall length

- use microtransmitter in field applications for distance longer than 30 feet between the electrode

and the controller.

- connect the cathode (Pt) to the terminal 30 marked Pt

- connect the anode (Ag) to the terminal 31 marked POL

- connect the shield to the terminal 28 marked 0

Electrodes supplied by B&C Electronics have wires marked for the right connection to the meter.

7.3 CONNECTING THE MICROTRANSMITTER

The controller may operate with signal by microtransmitter mod. 080610.2.

Follow the specific instructions for connections.

7.4 CONNECTING ALARMS, PUMPS, VALVES

The output connections are made at terminal strip and they consist of two independent relay contacts

corresponding to regulator ""A" and regulator "B".

Regulator ''A''

terminal 8 marked C : common contact

terminal 9 marked NO : normal open contact

terminal 10 marked NC : normal closed contact

Regulator ''B''

terminal 5 marked C : common contact

terminal 6 marked NO : normal open contact

terminal 7 marked NC : normal closed contact

To provide an ac-line voltage at the relay commons, install jumpers from the ac power terminal 2 to

the concerned relay commons marked C.

Connect one side of an external line-operated device to the terminal NO/NC according to the

requirements of the device, and connect the other side of the device to the line terminal 3 (110 V) or 4

(220 V).

The device may be powered by an external independent line following the above procedure.

An independent line is suggested if the device consists in a high inductive load.

Remember that relay switching inverted by installing jumpers from terminal 12 to 13 (reg. B) and

from 13 to 14 (reg. A).

Also, the action of relay "B" may be delayed 0 to 5 sec by the trimmer marked DEL B. (rear side)

- 13 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

7.5 CONNECTING A RECORDER

A current output for a remote recorder or P.I.D. regulators is available on terminals 13-14.

Connect the recorder "high" to terminal "14" and connect the recorder low to terminal "13".

Series connection, following the signal's polarity, is required for driving more loads having a total

input resistance lower than 300 Ω. Output drives ground-isolated loads only. Most recorders fulfil this

requirement but it is recommended to control it.

7.6 CONNECTING THE RTD

The meters have the automatic temperature compensation carried out by means of RTD Pt100.

The temperature sensor, if not included in the electrode, has to be installed in the same solution being

measured, close to the electrode/probe.

The jumpers from 22 to 23 and 24 to 25 terminals keep in action the internal temperature

compensation adjusted at 20 °C.

To operate the automatic temperature compensation, remove the two jumpers and connect the RTD as

shown in Fig. 5.

A three wire connection is suggested to achieve an accurate compensation over a long distance

between the electrode and the controller.

- connect the end of RTD to terminal 23

- connect the common end of the RTD to terminal 24

- connect the common end of the RTD to terminal 25

- The 3-wire cable must not be interrupted on the overall length.

If an extension is needed, the cable must be fastened to the high insulation terminal strip.

- Keep the cable away from power wires.

The RTD connection as above described allows the OD 565.2 controller to provide the temperature

readout and the temperature's factor readout.

The temperature value of a solution is shown by pushing the button 10 marked TEMP. °C on the

front panel.

The temperature readout does not interrupt the measuring and regulating function of the controller.

The temperature coefficient is shown by pushing the button 12 and it is adjusted by trimmer 13.

In manual temperature operation the temperature value is adjusted by trimmer 11.

In the model OD 545.2 the temperature coefficient is adjusted at standard value 2.3 %/K at 20 °C.

(others on request)

7.7 CHECKING

Before connecting the system to the power supply:

- check that all cables are properly fastened to prevent strain on the connections

- check that all terminal-strip connections are mechanically and electrically sound

- check that the fuse value is right

- 14 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

8 OPERATING THE SYSTEM

8.1 PRE-OPERATION CHECK

The system's controls and indicators are all located on the front panel. The meter has a digital display

1 that, together with the green LED 4, indicate that unit is on.

Push the button 6 and rotate the set-point control 8. The display will show the set point values.

The regulators have a set-point check by red LEDs 7 which are part of the circuitry that powers the

relay.

When the monitored value is below the set-point value, the LED of reg. A is alight and the

corresponding relay is pulled in.

When the monitored value is above the set-point value, the LED of reg. B is alight and the

corresponding relay is pulled in.

The cards of the controllers are adjusted at the factory. If sensors and probes have been connected

correctly, as described in the above sections, the system should function correctly needing only the

zero calibration to compensate the dark current of the cell and the slope calibration.

9 NORMAL OPERATION

To operate the system, simply switch on the controller by means of the lever 5 (power switch), and

observe the measured dissolved oxygen of the solution on the meter.

Adjust the set-point control A and the set-point control B to the setting required for each particular

application.

- 15 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

10 CALIBRATING THE CONTROLLER

10.1 ELECTRIC ZERO

This operation may be done, in local or remote applications, only when the electrode or

microtransmitter are not connected to the amplifier.

- remove the cell connections from terminals 30 - 31 (local operation)

- remove the connector from microtransmitter (remote operation)

- adjust the trimmer 2 marked "zero" in order to read the value 0.00 on the display

- repeat the calibration when the measuring has changed.

The display will indicate the value 0.000 (OD 565.2)

10.2 ZERO CELL CALIBRATION

This operation may be effected after the electric zero calibration above described and when the cell is

connected to the amplifier, in order to read zero on the indicator.

This instrumental zero annuls the residual current of the cell zero point, when the cell works in

absence of oxygen.

Immerse the cell in a freshly-prepared 2 % sodium metabisulphyte solution or in an equivalent media

with a total absence of oxygen and operate as follow:

1) local operation

- after balance is reached, adjust the trimmer 2 marked "zero" so as to read zero on the display

- repeat the calibration when the range is changed (OD 565.1)

2) remote operation

- microtransmitter mod. 080610.2 is connected

- after balance is reached, adjust the trimmer marked "zero" on the microtransmitter in order to reach

zero on the display

The repeat of the calibration is not needed when the range is changed (OD 565.2)

10.3 SLOPE CALIBRATION

Zero point adjustment must precede slope calibration. Electrode's manufacturers supply, with the

sensor, the operating instructions for each application. In particular are described the slope calibration

procedures under partial pressure, in % of atmospheric oxygen, in PPM.

Calibration is usually effected at oxygen saturation under operating pressure since it is the simplest.

In calibrating the reading is adjusted to 100 % saturation.

In determining oxygen concentration in PPM, the O2 content of the calibrating solution must be

accurately known. The values applying to pure water, adjusted to the prevailing pressure, are described

on oxygen saturation tables.

- 16 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

1) local operation

The controller is supplied with "coarse" and "fine" adjustment of sensitivity. The coarse adjustment

must be effected when installing the cell, while the fine adjustment is effected during the normal

operation. The coarse adjustment is carried out by the rear sensitivity switch marked LO/HI and by

rear trimmer marked "sens R73", which compensates for the different sensitivity of cells.

When adjusting the coarse sensitivity, check that the "fine" trimmer 3 marked "sens" on the front

panel is set in the middle position.

2) remote operation

The procedure is similar as per the local operation. The "coarse" adjustment of sensitivity is carried out

by trimmer marked "sens" on the microtransmitter, which compensates for the different sensitivity of

cells.

During the normal operation the "fine" adjustment is effected by the trimmer 3 marked "sens" on the

front panel.

10.4 POLARIZATION VOLTAGE OF SENSOR

The controller and the microtransmitter are designed to keep a constant polarization voltage at the

electrode for its correct operating. This value is calibrated at 675 mV and can be adjusted, if

necessary, from 0 to 1.200 mV by rear trimmer marked "pol R87" in local operation, and by trimmer

marked "pol" on the microtransmitter in remote operation.

Use electronic voltmeter to check the polarization voltage on terminals 30-31 of the controller (local

operation), on terminals marked "S" and "Pt" of the microtransmitter (remote operation).

- 17 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

11 PREVENTIVE MAINTENANCE

11.1 CONTROLLER

Quality components are used to give the controller a high reliability.

The frequency of such maintenance depends on the nature of each particular application. As in any

electronic equipment, the mechanical components, such as switches, relays, potentiometers and

connectors, are the most subject to damage.

- check for damage of the electrolytic capacitors if the meter is exposed to temperatures above

80 °C.

- check for damage in all the electronic components if the meter is subjected to excessive voltage

- check for damage of the electronic and mechanical components if the meter is dropped

- repeat periodically the pre-operation check

- check that all the connections are free from moisture and

contamination

Disconnect the power supply to the monitor before performing the following procedures:

Use moisture free air and blow out the interior of the case and terminal board connections as necessary

Inspect the printed circuit boards for dirt and corrosion; clean as necessary and blow dry

Tighten all the terminal-board connections and mounting hardware

Replace the front panel circuit board or the base circuit board

11.2 SENSOR

The state of the cell's membrane is critical for the normal operation of the system and should be

inspected more frequently when using oil and grease containing water, and in bio- applications.

Suggested methods for cleaning the electrode include chemical cleaning and detergent washing (see

the chemical auto cleaning system B&C Electronics). See general instructions given by the cell

manufacturer.

- 18 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

12 TROUBLESHOOTING GUIDE

Symptoms

Neither LED lit nor meter

reading

No meter reading,

but LEDs light

Meter reading too high/low

Meter reading does not change

Alarm circuit does not operate,

meter reading OK

Slope not sufficient

Recorder does not operate

See the peculiar troubleshooting guide of the cell connected to the unit.

Line not connected

Incorrect power wiring

Fuse interrupted

I.C. failure

Inside connector

Electrode fouled

Meter uncalibrated

Electrode damage

Short circuit

Relay contacts

Circuit failure

Electrode damage

Temperature compensation

Recorder not connected

Output circuits damage

Probable cause

Check power

Check wiring

Replace fuse

Replace I.C.

Replace circuit board

Clean electrode

Adjust "sens"

Electrode replacement

Check wiring

Replace base

Return to factory

Electrode replacement

Check jumpers or RTD

Check wiring

Replace base circuit board

Remedy

- 19 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

N O T E

- 20 -

B&C Electronics OD 545.2 – OD 565.2 - Rev. A

N O T E

- 21 -

Loading...

Loading...