Page 1

Operating Instructions

BC Biomedical SA-2500

Automated Safety Analyzer

User Manual

Page 2

Standard Equipment

Contacts

Standard Accessories (included with Unit)

Product Support

Technical Questions

If required please contact:

1

1

SA-2500 Safety Analyzer

16 A country specific power cable for SA-2500,

not DUT, BC20-20400

Kelvin Coiled Chassis Cable, BC20-20150

Plug-on alligator clip, BC20-20152

CD-ROM with remote control software

USB Cable, BC20-41352

1

1

1

1

BC Biomedical

BC Group International, Inc.

Phone:

E-Mail

1-800-242-8428

1-314-638-3800

sales@bcgroupintl.com

Optional Accessories

•

•

•

•

•

ECG adapters, accepts 3&4 mm plugs, BC20-17024

ECG adapters, accepts 3mm plugs only, BC20-17025

International DUT

Test socket adapter, BC20-20200

Carrying case, BC20-30108

Replacement Fuses, BC80-00829

The accessories available for your instrument are checked for

compliance with currently valid safety regulations at regular intervals, and are amended as required for new applications. Currently

up-to-date accessories which are suitable for your measuring instrument are listed at the following web address along with photo,

order number, description and, depending upon the scope of the

respective accessory, data sheet and operating instructions:

www.bcgroupstore.com

2

BC Biomedical

Page 3

Contact Persons

Calibration Service

We calibrate and recalibrate all instruments supplied by BC

Biomedical, as well as by other manufacturers, at our service

center.

Competent Partner

BC Biomedical is certified in accordance with ISO

9001:2008.

Our calibration lab is accredited in accordance with

ISO/IEC 17025:2005 under registration number L2299 .

We offer a complete range of expertise in the field of metrology:

from test reports and factory calibration certificates, right on up to ISO17025 calibration certificates. Our spectrum of offerings is rounded

out with test equipment management. If errors are discovered during

calibration, our specialized personnel are capable of completing

repairs using original replacement parts. As a full service calibration

lab, we can calibrate instruments from other manufacturers as

well.

Services

Repair and Calibration Center*

If required please contact:

BC Biomedical

Service Center

3081 Elm Point Industrial Drive

St. Charles, MO 63304

Phone:

E-Mail

1-800-242-8428

1-314-638-3800

service@bcgroupintl.com

•

•

•

•

•

•

Device and software updates to current standards

Replacement parts and repairs

Help desk

Calibration lab per ISO/IEC 17025:2005 Service

Contracts and test equipment management

Disposal of old instruments

*

accredited in accordance with ISO/ IEC 17025

Accredited quantities: AC/DC voltage, AC/DC current, resistance,

alternating voltage, alternating current value, capacitance, frequency,

force, pressure, and temperature

BC Biomedical

3

Page 4

Table of contents

Contents

Page

Contents

Page

1

1.1

1.1.1

1.1.2

Applications .................................................................. 5

Classification of Devices Under Test .................................... 6

Protection Classes ............................................................. 6

Applied Parts (electrical medical devices) ............................ 6

8 Index .............................................................................. 37

2 Safety Features and Precautions ..................................... 7

3 Terminals ........................................................................ 9

4

4.1

4.1.1

4.2

4.3

Initial Start-Up ................................................................ 10

Connection to the Mains (90 to 240 V, 50 to 400 Hz) ....................10

Automatic Recognition of Mains Connection Errors ........................10

Switching the Measuring Instrument On ............................. 10

Configuring Device Parameters – Setup Menu ................... 10

5

5.1

5.2

Manually Triggered Measurements .............................. 11

General Procedure ........................................................... 12

Overview ......................................................................... 12

6 Technical Data .............................................................. 30

7

7.1

7.2

7.3

7.4

7.5

Maintenance and Calibration ......................................... 34

Housing Maintenance ....................................................... 34

Replacing the Fuses ......................................................... 34

Recalibration .................................................................... 34

Manufacturer’s Guarantee ................................................ 35

Return and Environmentally Sound Disposal ....................... 35

4

BC Biomedical

Page 5

Applications and Classification of Devices Under Test

1 Applications

Measuring Categories and their Significance per IEC 61010-1

The measuring instrument is intended for quick, safe

measurement of repaired or modified electrical medical devices

and their components (e.g. applications parts) in accordance with

IEC 62353.

Adherence to technical safety requirements assures safe handling

of electrical medical devices for users of the measuring

instrument. The safety of the patient is also assured during use of

tested electrical medical devices.

Use for Intended Purpose

•

The measuring instrument can be used as a benchtop device

which must be isolated and set up on a solid base while

measurements are being performed.

Only those measurements which are descr ibed in the following

chapters may be performed with the measuring instrument.

The measuring instrument, including the measuring probe,

may only be used within the specified measuring category (see

page 8, as well as the table below regarding significance).

Overload limits may not be exceeded. See technical data on

page 30 for overload values and overload limits.

Measurements may only be performed under the specified

ambient conditions. See page 32 regarding operating temperature range and relative humidity.

The measuring instrument may only be used in accordance

with the specified degree of protection (see page 33).

!

Attention!

The measuring instrument may not be used for

measurements within electrical systems!

•

•

• •

•

BC Biomedical

5

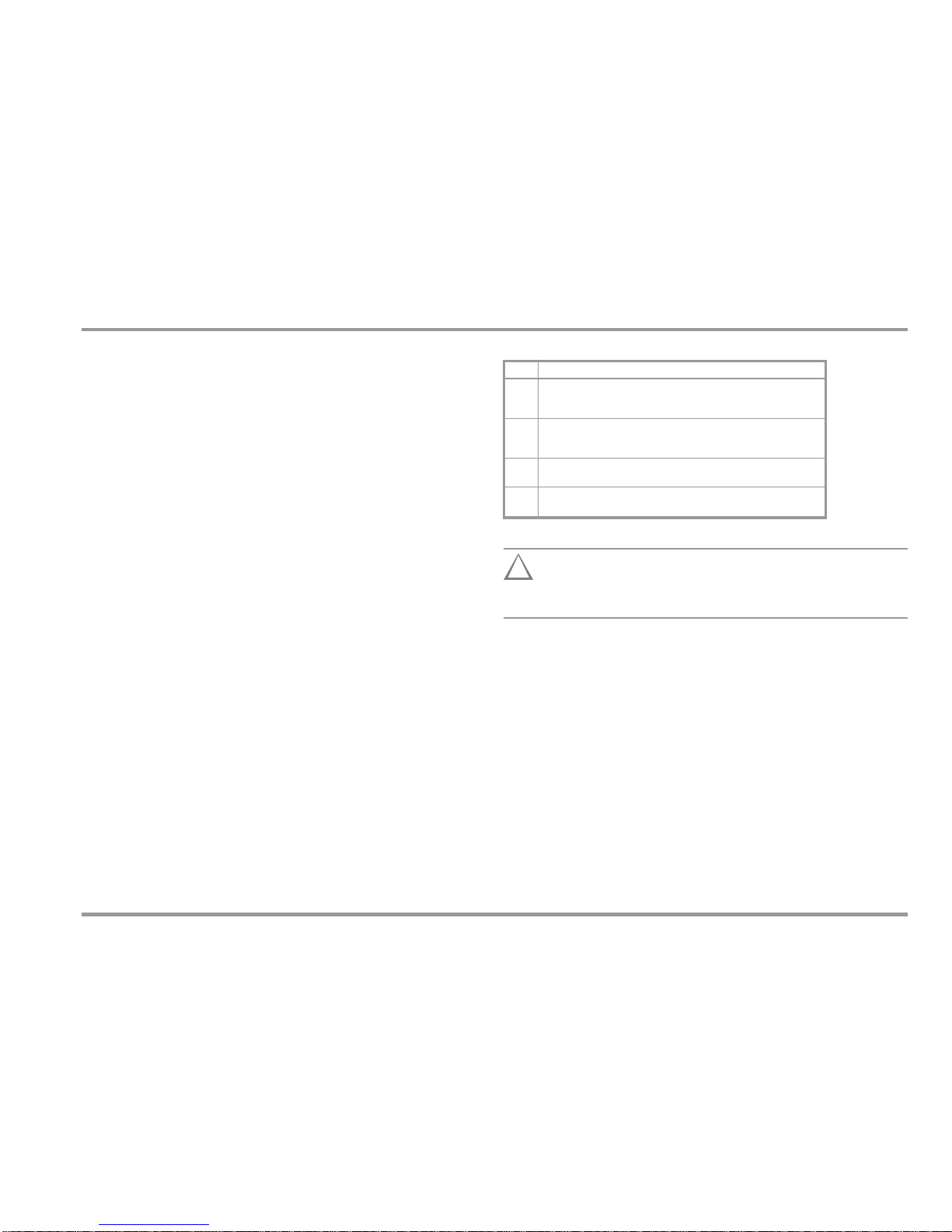

CAT

Definition

I

Measurements in electrical circuits which are not directly connected to

the mains: for example electrical systems in motor vehicles and

aircraft, batteries etc.

II

Measurements in electrical circuits which are electrically connected to

the low-voltage mains: via plug, e.g. in household, office and

laboratory applications

III

Measurements in building installations: stationary power consumers,

distributor terminals, devices connected permanently to the distributor

IV

Measurements at power sources for low-voltage installations:

meters, mains terminals, primary overvoltage protection devices

Page 6

Applications and Classification of Devices Under Test

1.1 Classification of Devices Under Test

1.1.1 Protection Classes

Devices assigned to all of the following protection classes are

equipped with basic insulation, and provide for protection against

electrical shock by means of various additional precautions as well.

1.1.2 Applied Parts (electrical medical devices)

Type B Applied Parts

(body)

Devices of this type are suitable for both internal and external

patient applications, except for use in direct proximity to the heart.

These devices provide for adequate protection against shock,

especially as regards:

•

Reliable leakage current

•

Reliable protective conductor connection if utilized

Protection Class I Devices

Exposed, conductive parts are connected to the protective

conductor so that they are not charged with voltage if the basic

insulation should fail.

Type BF Applied Parts

(body float)

Same as type B, but with type F insulated applied parts.

Protection Class II Devices

These devices are equipped with double insulation or reinforced

insulation.

Type CF Applied Parts

(cardiac float)

Devices of this type are suitable for use directly at the heart. The

application pa rt may not be grounded.

Protection Class III Devices

These devices are powered with safety extra-low voltage (SELV).

Beyond this, no voltages are generated which exceed SELV.

These devices may not be connected to the mains.

Note: Only a visual inspection can be conducted for devices of this

protection class with the BC Biomedical SA-2500.

6

BC Biomedical

Page 7

Safety Warnings

2 Safety Features and Precautions

Observe the following safety precautions:

•

The instrument may only be connected to electrical supply

systems with which conform to the valid safety regulations

(e.g. IEC 60364, VDE 0100) and are protected with a fuse or

circuit breaker with a maximum rating of 16 A.

Measurements within electrical systems are prohibited.

Be prepared for the occurrence of unexpected voltages at

devices under test (for example, capacitors may be

dangerously charged).

Make certain that the measurement cables are in proper

working condition, e.g. no damage to insulation, no cracks in

cables or plugs etc.

Insulation Resistance Measurement (alternative leakage current):

Testing is conducted with up to 500 V. Current limiting is

utilized (I < 10 mA), but if the terminals (L and N) are touched,

electrical shock may occur which could result in consequential

accidents.

Leakage Current Measurement

It is absolutely essential to assure that the device under test is

operated with line voltage during performance of leakage

current measurements. Exposed conductive parts may

conduct dangerous contact voltage during testing, and may

not under any circumstances be touched (mains power is

disconnected if leakage current exceeds approx. 10 mA).

Function Test

This instrument fulfills the requirements of applicable European

and national EC directives. This is confirmed by means of the CE

mark. A corresponding declaration of conformity can be

requested from BC Biomedical.

The SA-2500 measuring instrument has been manufactured and

tested in accordance with the following safety regulations:

IEC 61010-1 / DIN EN 61010-1 / VDE 0411-1, DIN VDE 0404

IEC 61577 / EN 61577 / VDE 0413 part 1, 2 and 3

When used for its intended purpose, the safety of the user, the

measuring instrument and the device under test (electrical

equipment or electrical medical device) is assured.

Read the operating instructions carefully and completely before placing

your measuring instrument into service. Follow all instructions contained

therein. Make sure that the ope rating instructions are available to all

users of the instrument.

Tests may only be performed by qualified personnel, or under

the supervision and direction of qualified personnel. The user

must be instructed by qualified personnel in the execution and

evaluation of tests.

•

•

•

• •

Note

Manufacturers and importers of electrical medical devices

must provide documentation for the performance of

maintenance by trained personnel.

•

!

Attention!

The function test may only be performed after the DUT has

successfully passed the safety test!

BC Biomedical

7

Page 8

Safety Warnings

•

Power Consumers with High Inrush Current (> 16 A) – Function Test

(e.g. fluorescent tubes, halogen lamps, headlights etc.):

Observe the following instructions in order to prevent

excessive contact loads.

Meanings of Symbols on the Instrument

300 V CAT II

Maximum permissible voltage and measuring category

between connections 1 through 4, the test socket and

ground

I

System with maximum 16 A nominal current

!

Attention!

Starting the Function Test

For reasons of safety, the device under test must be

switched off before the function test is started. This

precaution prevents inadvertent start-up of a device under

test which may represent a hazard during operation, e.g. a

cetrifuge.

Ending the Function Test

After completion of the function test, devices under test

must be turned off with their own switch – especially

devices with motors or other inductive loads.

Warning regarding dangerous electrical voltage

Warning concerning a point of danger

(attention: observe documentation!)

!

Per European Council Directive WEEE

2012/19/EU, do not dispose of this product as

unsorted municipal waste.

The measuring instrument may not be used:

•

•

If it demonstrates visible damage

With damaged connector cables, measuring cables or

patient ports

If it no longer functions properly

•

In such cases, the instrument must be removed from operation

and secured against unintentional use.

8

BC Biomedical

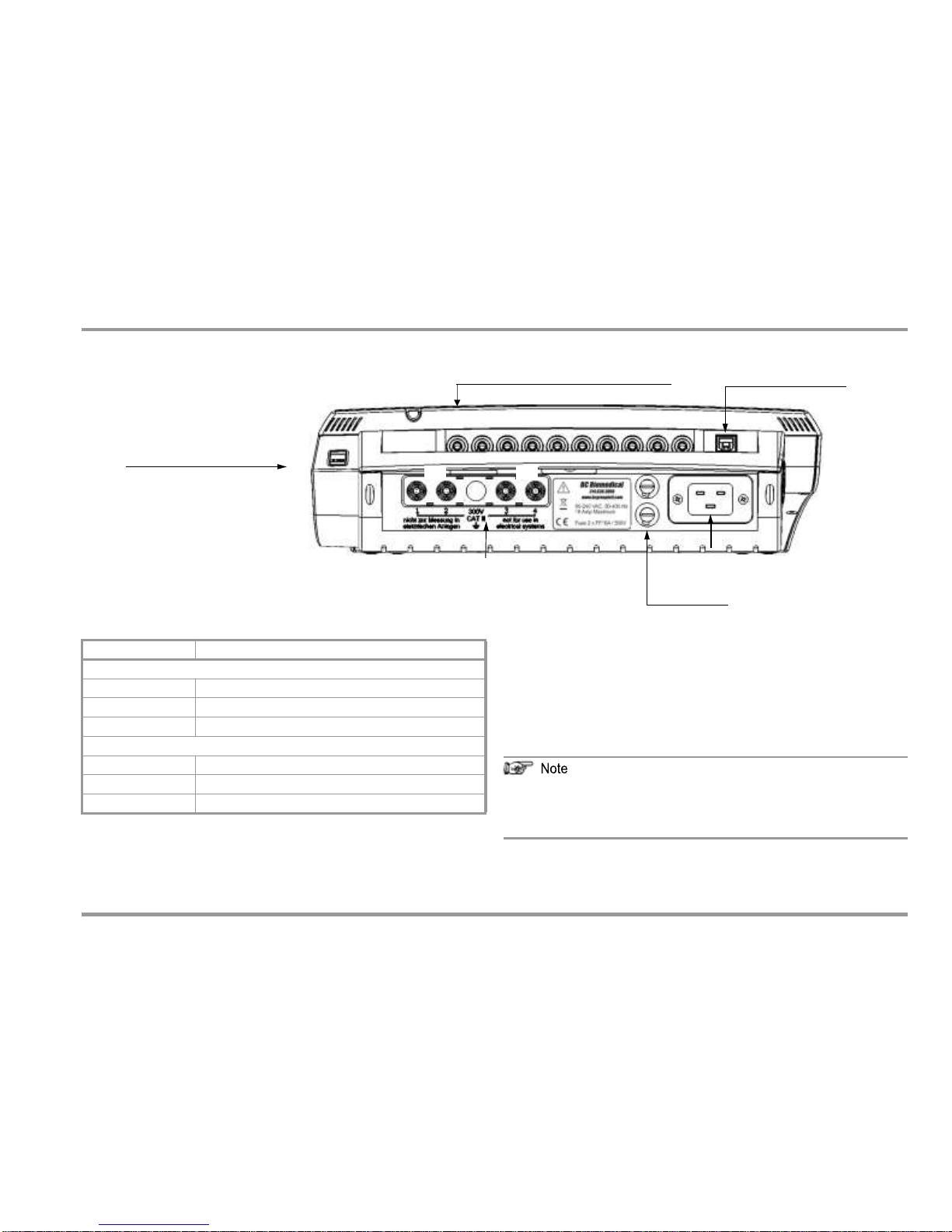

Page 9

Terminals

3 Terminals

Jacks 1 through 10 for Applied Parts

USB Slave, to PC

1

10

Standard Socket (test socket)

for connecting the DUT

S1 S2

nection

Connections for Probes

Insert the double plug of the probe into sockets 1 and 2 such that

the plug with the white ring makes contact with socket 1 (silver

ring).

If 2 probes are used: If the first probe is, for example, the 25 m cable

drum (1-2), the test point is contacted with the second probe (3-4).

1)

For a lot of measurements, the protective conductor of the

test socket is not connected with the protective conductor

of the mains terminal.

1)

4-wire measurement possible

2)

4-wire measurement not provided for, see ”Measuring and Storing an

Offset Value when Using a 2

nd

Probe” on page 15

BC Biomedical

9

Connection

Application

Top Connections

Standard socket

Test socket

Sockets 1 through 10

Applied parts connection

USB-SI

USB slave, to PC

Bottom Connections

Sockets 1 and 2

Test probe connection (max. 300 V CAT II)

Sockets 3/4 (green)

Terminal for second test probe

2)

(max. 300 V CAT II)

Inlet socket

Connection for supply power (90 to 240 V, 50 to 400 Hz)

Mains Con

Fuses

Page 10

Initial Start-Up – Setup

4 Initial Start-Up

4.1 Connection to the Mains (90 to 240 V, 50 to 400 Hz)

➭

Connect the mains plug at the measuring instrument to the

mains power outlet.

4.1.1 Automatic Recognition of Mains Connection Errors

The measuring instrument’s protective conductor connection is

tested each time the start-stop key is pressed.

If a voltage of greater than 25 V is detected between the

protective conductor and the finger contact, no measurements

are possible. Disconnect the measuring instrument from the

mains immediately in the event of a mains connection error, and

arrange for the error to be corrected!

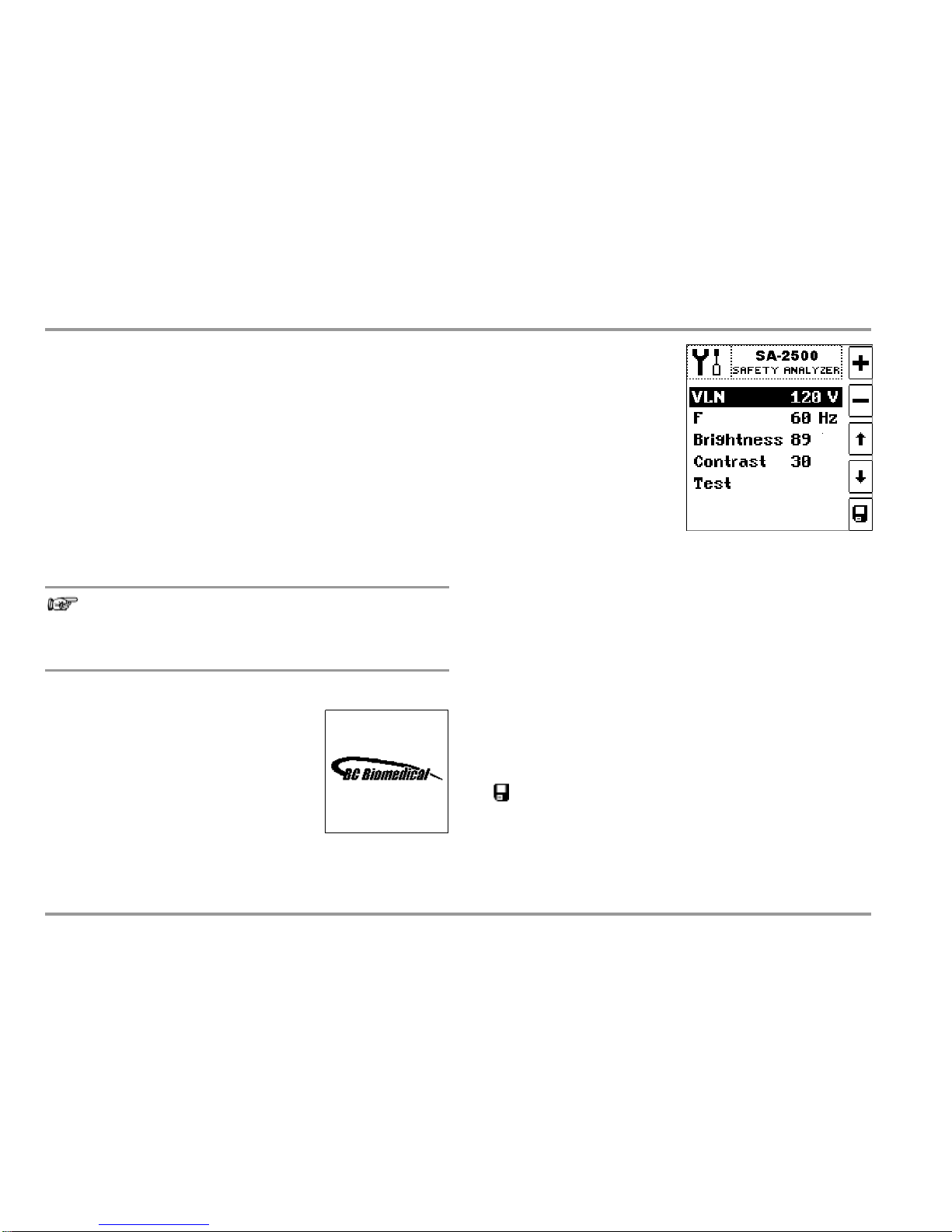

Selecting Nominal Line Voltage VLN

Measured values acquired by

means of leakage current measurement are normalized to the

selected VLN voltage value. Line

voltage parameter VLN (100, 110,

115, 117, 120, 127, 220, 230,

240 or 250 V) can be selected

with the

keys, and adjusted

with the +/– keys. The voltage

value selected here is generated

by the measuring instrument for alternative measurement.

Setting Nominal Frequency

The frequency selected here is generated by the measuring instrument for alternative measurement of leakage cur rent. Nominal

line frequency parameter F (50 or 60 Hz) can be selected with the

keys, and adjusted with the +/– keys. This setting is irrelevant

for direct measurement and differential current measurement.

Setting Brightness and Contrast

Brightness (1 ... 40 ... 100) and contrast (0 ... 40 ... 63) for the LCD panel

can be selected with the

keys, and adjusted with the +/– keys.

Activating Device Parameters

Changed values are permanently saved after acknowledging with

Note

Voltage at the mains protective conductor may cause

erroneous measured values during the measurement of

leakage current.

4.2 Switching the Measuring Instrument On

Initial Window

The initial window shown at the right appears in the event of mains connection.

the key. The display is then switched to the main menu. If the

setup menu is exited with the ESC key, the changed values only remain active until supply power to the instrument is interrupted.

Function Test

For testing the keys, LCD segments and the acoustic warning sig-

nal.

4.3 Configuring Device Parameters – Setup Menu

All of the settings which are required for operation of the

measuring instrument can be entered in the setup menu.

10

BC Biomedical

Page 11

Local Operating Mode

Manual Test

5 Manually Triggered Measurements

Adjustable measuring parameters

are displayed as softkeys.

DIR

DIF

ALT

Direct measurement

Diff. current measurement

Alternative meas. method

PRINT:

Key for hardcopy functions

(in preparation)

L/N

N/L

ESC: Return to previous level

Mains polarity

ARROW

UP HELP:

Access context sensitive help

Select measuring function

ARROW

DOWN:

MENU:

Access the main menu

(R

PE

measuring function)

Select measuring function

STARTSTOP: Start or stop measurement /

function test

SETUP:

Access the setup menu

–

Line voltage

–

Line Frequency

–

LCD brightness

–

LCD contrast

Contact Surface

For finger contact – PE potential check

Main Menu Display

!

Attention!

Remote control of the SA-2500 should always be coordinated

with the user who is in contact with the measuring

instrument at the same time, for example in order to exclude the possibility of contact hazards.

BC Biomedical

11

Operating Mode Display

–

Remote: highlighted display

–

Local: display not highlighted (see below)

Page 12

Local Operating Mode

Manual Test

5.1 General Procedure

5.2 Overview

➭

➭

Select the main menu: MENU key.

Select a menu function:

keys.

Depending upon the measuring function select either

–

Type of test current: DIR / DIF / ALT / DL key.

or

–

Protection class and type of connection: PC1 / PC2 / FIX key.

Connect the device under test in accordance with the

previously selected type of test current.

14

➭

Depending upon the type of test current, it may be necessary to

use the probe.

The device under test is checked for short circuiting for all active

measurements during which the mains are connected to the test

socket (e.g. for leakage current measurements).

➭

Start the test with the STARTSTOP

During measurement, a symbol representing a runner appears

at the upper left-hand corner instead of the measurement icon.

During measurement and after the measurement has been completed, measurement data can be read from the display.

➭

If necessary, repeat the test with reversed mains

power polarity: L/N N/L key.

➭

The display is returned to the main menu by pressing the ESC

key or the MENU key.

26

AP = applied part; PC1/2 = protection class I/II; FIX = permanent connection

12

BC Biomedical

Abbreviation

Measurement Type Parameter

Description

Measured Quantity /

Method

Type of

’Connection

Sockets:

Probe 1–2

AP A ... K

Resistance Measurements

R PE

Protective conductor

resistance

PC1

l

Probe 1–2

Page

R INS

Insulation resistance

PC1

—

Page

16

PC2

l

Probe 1–2

FIX

Leakage Current Measurement

I E

Equipment leakage

current

DIR Direct measurement

Test socket

l

AP A ... K

Probe 1–2

Page

18

DIF

Differential current

measurement

ALT

Alternative measurement

(alternative equipment

leakage current)

I T

Touch current

DIR Direct measurement

Test socket

l

Probe 1–2

Page

20

DIF

Differential Current

Measurement

ALT

Alternative measurement

(alternative equipment

leakage current)

DL

Measurement with 2 probes

(cable drum at 1–2)

Probe 1–2

Probe 3–4

I P

Patient leakage current

DIR

Patient leakage current,

direct

Test socket

l

AP A...K

Page

24

I AP

Applied parts leakage

current

DIR

Direct measurement

(mains at applied part)

Test socket

l

AP A...K

Page

ALT

Alternative measurement

(altern. patient leakage current)

Functions Tests

TEST

Voltage / Load current

Active/apparent power P/A

Power factor PF

Test socket

Page

28

Page 13

This page has been left blank to display the following measurements on opposite pages for better clarity.

BC Biomedical

13

Page 14

R

PE

Protective Conductor Resistance

Measuring Method

Resistance is measured:

•

Between each exposed conductive part of the housing which

is connected to the protective conductor (probe contact) and

the earthing contacts at the mains and the device plug (if a

removable mains connector cable is used).

•

Between the earthing contacts at the mains plug and the

earthing contacts at the device plug for device connector

cables

Test Socket Connection

Applications

Continuity and resistance of the protective conductor must be

measured.

Definition

Protective conductor resistance is the resistance of the

connection of a protection class I device (PC1) between any

exposed conductive parts which are connected to the protective

conductor and the protective contact at the mains plug or the

mains side of the permanent connection.

Protective conductor resistance is the sum of the following

resistances:

The protective conductor of the test socket (which is not

connected with the protective conductor of the mains terminal for this measurement) is permanently connected with

sockets 3 and 4 to which a second probe can be connected.

•

•

•

Connector cable or device connector cable resistance

Contact resistance of the plug and terminal connections

Resistance of the extension cable

14

BC Biomedical

Page 15

R

PE

Protective Conductor Resistance

Measuring and Storing an Offset Value when Using a 2

nd

Probe

When a second probe is used which is connected to sockets 3

and 4, 4-wire measurements are not provided for. However, the

ohmic resistance of the cable for the second probe can be automatically deducted from the measuring result by determining an

offset value. Please proceed as follows to this end:

➭

➭

Start the test: Press the STARTSTOP key.

1

probe: Contact one of the conductive parts of the housing which is con-

nected to the protective conductor with the probe (socket 1–2).

2

probes: A cable drum or extension cable (socket 1–2) is contacted

with the reference point (e.g. overall earth electrode of a unit), the second probe (socket 3-4) is contacted with the test point.

➭

Ð

Connect the two probes to sockets 1 and 2 or 3 and 4,

respectively. The probe extension cable or the probe

cable drum must generally be conne cted with sockets 1

and 2. Contact both probes with the same reference point.

This is equivalent to short-circuiting the two probes. The offset

value established in this way is retained by pressing the key on

the right (only for values < 2 ), displayed briefly and will be

deducted from all future measuring results. You can store this

offset value, see key below.

After measuring the offset value, the latter can be permanently stored with the key on the right so that it is

available after switching the instrument on again.

Press the key on the right for loading a stored offset

value.

During measurement, the connector cable must only be moved to the extent that it is accessible during repair, modification or testing. If a change

in resistance occurs during the manual test step of the continuity test, it

must be assumed that the protective conductor is damaged, or that one

of the connector contacts is no longer in flawless condition.

➭

➭

Measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table of

permissible limit values.

Ð

Examples of Maximum Permissible Limit Values for Protective Conductor

Resistance for Connector Cables with Lengths of up to 5 m

Ð

Cable

Only use this function if you work with extension cables.

When using different extension cables, the procedure

described above must principally be repeated.

Sequence

➭

Select the test:

keys.

➭

Connect the DUT to the test socket and connect the probe.

BC Biomedical

15

Test

Standard

Test current

OpenCircuit

Voltage

R

PE

Housing –

Device Plug

R

PE

Housing –

Mains Plug

Connector

IEC 60601

IEC 61010

Production

Not defined

0.1

0.1

1.1

IEC 62353

(VDE 0751-1)

> 200 mA

4 V < UL <

24 V

1.2 1.3 0.1

VDE 07010702

—

0.3

+ 0.1

for each addi-

tional 7.5 m

Page 16

R

INS

Insulation Resistance

Measuring Method

Protection Class I (PC1)

Insulation resistance is measured between short-circuited mains

terminals and the protective conductor.

Protection Class II (PC2)

Insulation resistance is measured between short-circuited mains

terminals and external conductive parts which can be contacted

with the probe.

Connection of Permanently Installed Protection Class I Devices

!

Attention!

Deactivate the electrical system which supplies power to

the device under test before connecting the test system!

Applications

Insulation resistance must be measured for:

➭

Remove the mains fuses from the device under test and

disconnect neutral conductor N inside the device under test.

Connect the probe to phase conductor L at the device under

test in order to measure insulation resistance.

In order to assure that all insulation which is exposed to line

voltage is tested during this measurement, make sure that

switches, temperature regulators etc. are closed.

Definition

Insulation resistance is active resistance between the electrical

circuits of the device and its exposed conductive parts.

➭

The PE contact of the test socket is connected with the protective conductor of the mains terminal.

16

BC Biomedical

PC1: protection class l

Between L + N and PE

PC2: protection class ll

Between L + N and user accessible conductive parts

Page 17

R

INS

Insulation Resistance

PC1 Connection

PC2 ConnectionI

All switches at the device under test must be set to the on position during measurement of insulation resistance, including

temperature controlled switches and temperature regulators as

well. Measurement must be performed in all program steps for

devices equipped with program controllers.

➭

Start the test: Press the STARTSTOP

!

Attention!

Testing is conducted with up to 500 V. Current limiting is utilized (I < 10 mA), but if the terminals (L and N) are touched,

electrical shock may occur which could result in consequential accidents.

Permanent connection

Note: Open-circuit voltage is always greater than nominal voltage.

➭

PC2 connection: Contact exposed conductive parts with the

probe during measurement.

All measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table of

permissible limit values.

➭

➭

Sequence

Protection class I devices: The protective conductor test must already

have been passed as a prerequisite for the insulation resistance test.

Examples of Minimum Permissible Limit Values for Insulation Resistance

➭

➭

Select the test:

keys.

Select the protection class and the type of connection:

PC1 / PC2 / FIX. key.

Connect the DUT to the test socket, and connect the probe if necessary.

➭

BC Biomedical

17

Test

Standard

Test Voltage

R

ISO

PC I PC II PC II I Heat

IEC 62353

(VDE 0751-1)

500 V

2 M

7 M

70 M

70 M

VDE0701-0702

1 M2 M

0.25 M

0.3 M

Page 18

IE Equipment Leakage Current (differential current – protective conductor current – fault current)

Definition of Alternative Measurement (alternative equipment leakage current)

Alternative leakage current is current which flows through the

active conductors of the device which are connected to each

other (L/N) to the protective conductor, or to the exposed,

conductive parts and the applied parts.

Direct Measurement Method

The device under test is operated with mains power. Current

which flows through the PE conductor to earth at the mains side

of the device connection is measured. The value which has been

adjusted to nominal line voltage is displayed (see section 4.3).

The protective conductor is ineffective during measurement!

Differential Current Measurement Method

The device under test is operated with mains power. The sum of

the momentary values of all currents which flow through all active

conductors (L/N) at the mains side of the device conne ction is

measured. The measurements must be performed with mains

plug polarity in both directions. The value which has been adjusted to nominal line voltage is displayed (see section 4.3).

Alternative Measurement Method (alternative equipment leakage current)

The device under test is tested with the nominal voltage which

has been selected in the setup menu. Current which would flow

with this nominal voltage is displayed.

Type of Test Current Parameter

Applications

Equipment leakage current must be measured for all devices.

Definition of Equipment Leakage Current / Protective Conductor Current

IEC 62353 (VDE 0751-1)

Current which flows from a power pack to ground via the protective conductor, and via exposed conductive parts of the housing

and the applied parts.

Definition of Direct Measurement

Total amount of current which flows through the protective con-

ductor, probe and applied parts in the case of housings which are

isolated from ground.

Definition of Differential Current Measurement

Sum of instantaneous current values which flow via the L and N

conductors at the device mains connection. Differential current is

practically identical to fault current in the event of an error. Fault

current: Current which is caused by an insulation defect, and

which flows via the defective point.

–

DIR

–

DIF

–

ALT

Protective conductor current, direct

Differential current

Alternative equipment leakage current

Mains Polarity Parameter

Polarity can be reversed for tests in accordance with the direct

and differential current methods.

18

BC Biomedical

Page 19

IE Equipment Leakage Current (differential current – protective conductor current – fault current)

Equipment Leakage Current with the Direct Measurement Method

Equipment Leakage Current with the Alternative Measurement Method

Sequence

The protective conductor is ineffective during measurement!

➭

➭

➭

➭

➭

Select the test:

keys.

Connect the DUT to the test socket.

Select type of test current: DIR / DIF / ALT key.

Select mains polarity reversal: L/N / N/L key.

Start the test: Press the STARTSTOP key.

Measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table see bel.

Equipment Leakage Current with the Differential Current Measurement Method

Examples of Maximum Permissible Limit Values for Device Leakage

Current / Protective Conductor Current

BC Biomedical

19

Test Standard

Protection Class

Direct / Differential Cur-

rent Measurement

Alternative Measurement

IEC 60601 3rd ed.

PC1 5 mA 10 mA

IEC 62353

(VDE 0751-1)

PC1 0.5 mA 1 mA

PC2 0.1 mA 0.5 mA

VDE 0701/702

PC1

3.5 mA

PC2

0.5 mA

Page 20

IT Touch Current – Testing for Absence of Voltage

Definition of Touch Current

Leakage current that flows from the housing or parts thereof –

with the exception of the patient ports – with which the user or the

patient may come into contact during use for intended purpose,

to ground or another part of the housing via an external

connection, except for the protective conductor.

Definition of Direct Measurement

Current which flows through the probe in the case of housings

which are isolated from ground.

Definition of Differential Current Measurement

Sum of instantaneous current values which flow via the L and N

conductors at the device mains connection. Differential current is

practically identical to fault current in the event of an error. Fault

current: Current which is caused by an insulation defect, and

which flows via the defective point.

Definition of Alternative Measurement (alternative equipment leakage

current)

Alternative leakage current is current which flows through the

active conductors of the device which are connected to each

other (L/N), to the exposed, conductive parts.

Applications

For protection class I devices, it may be necessary to separately

measure leakage current from exposed conductive parts which

are not connected to the protective conductor.

Only methods direct measurement and differential current measurement can be used for devices for which isolation in the power

pack is not taken into consideration by the measurement (e.g. resulting from a relay which is only closed in the operating state).

Leakage current measurement may only be performed at

protection class I devices after the protective conductor test has

been passed.

The device must be measured in all intended functional states

(e.g. switch positions) which influence leakage current. The

highest acquired value, as well as the corresponding function if

applicable, must be documented. The manufacturer’s

specifications must be adhered to.

20

BC Biomedical

Page 21

IT Touch Current – Testing for Absence of Voltage

Direct Measurement Method

The device under test is operated with mains power. Current

which flows to the protective conductor via exposed conductive

parts is measured. The measurements must be performed with

mains plug polarity in both directions. The AC or the DC component of the current is measured. The value which has been adjusted to nominal line voltage is displayed (see section 4.3).

Mains Polarity Parameter (not for 2-probe Measurement)

Polarity can be reversed for measurements during which the

mains are connected to the test socket.

Direct Measurement Method Differential Current Measurement Method

Make sure that the contacted parts are not grounded.

Differential Current Measurement Method

The device under test is operated with mains power. The sum of

the momentary values of all currents which flow through all active

conductors (L/N) at the mains side of the device connection is

measured. The measurements must be performed with mains

plug polarity in both directions. The value which has been adjusted to nominal line voltage is displayed (see section 4.3).

Alternative Measurement Method

The device under test is tested with the nominal voltage which

has been selected in the setup menu. Current which would flow

with this nominal voltage is displayed.

Type of Test Current Parameter

Alternative Measurement Method

2-probe Measurement Method

–

DIR

–

DIF

–

ALT

– DL

Touch current, direct (with probe)

Differential current, (with probe)

Alternative touch current, (with probe)

Contact current with 2 probes (DL = Dual Lead)

BC Biomedical

21

Page 22

IT Touch Current – Testing for Absence of Voltage

Sequence DIR / DIF / ALT

Procedure for DL – 2-probe Measurement

This measurement is performed with 2 probes. The measuring

section is electrically isolated from the mains power supply of the

instrument. Input resistance is 1 k.

➭

➭

➭

➭

➭

➭

➭

Select the test:

keys.

Connect the DUT to the test socket, or connect the probe.

Select type of test current: DIR / DIF / ALT key.

Select mains polarity reversal: L/N / N/L key.

Start the test: Press the STARTSTOP key.

Measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table of

permissible limit values.

➭

➭

Select test: key

Connect probe 1 (e. g. the 25 m cable drum) to sockets 1-2

and connect the probe tip with the reference measuring point.

Select test current type: key DL

Scan the test point with probe 2 (socket connectors 3-4).

Start test: press key STARTSTOP.

Measured values are displayed.

Quit test: Press key STARTSTOP.

Read off measured value and compare it with the table of per-

missible limit values.

➭

➭

➭

➭

➭

Examples of Maximum Permissible Limit Values for

Touch Current in mA

22

BC Biomedical

Test Standard

Protection

Class

Direct /

Differential Current

Measurement

Alternative Measurement

IEC 62353

(VDE 0751-1)

PC2 0.1 mA

0.5 mA

VDE 0701-702

PC2

0.5 mA

Page 23

This page has been left blank to display the following measurements on opposite pages for better clarity.

BC Biomedical

23

Page 24

IP Patient Leakage Current

When testing measuring instruments with several applied parts,

each must be connected, one after the other, and measuring results must be evaluated on the basis of the limit values. Applied

parts which are not included in the

measurement must be kept potential-free.

Definition of Patient Leakage Current

Current which flows from power packs and exposed conductive

parts of the housing to the applied parts.

The AC and the DC component of the current is measured.

Direct Measurement Method

The device under test is operated with mains power. Current

which flows through the applied parts to earth at the mains side of

the device connection is measured. The value which has been

adjusted to nominal line voltage is displayed (see section 4.3).

Type of Test Current Parameter

Applications

As a rule, measurement of leakage current from the applied part

to PE must be performed in accordance with IEC 60601.

No separate me asurement is normally required for type B

applied parts. The applied parts are connected to the housing

(see figures), and are also measured during housing

leakage current measurement, to which the same permissible

values apply.

Separate measurement of leakage current from type B applied

parts only has to be performed if it is specified by the

manufacturer (see accompanying documentation).

For type BF or CF applied parts, measurement is required for all

interconnected patient ports used for a single function of the

applied part, or measurement must be executed as specified by

the manufacturer.

– DIR

Patient leakage current, direct (applied parts plugged in)

Mains Polarity Parameter

Polarity can be reversed for measurements during which the

mains are connected to the test socket.

24

BC Biomedical

Page 25

IP Patient Leakage Current

Examples of Maximum Permissible Limit Values for Patient Leakage

Current in mA

Sequence

➭

➭

Select the test:

keys.

Connect the device under test to the test socket, and the

applied parts to the patient ports. The test probe has to be

connected but without applying electrical contact (potentialfree).

Select mains polarity reversal: L/N / N/L key.

Select applied parts 1 through 10: key.

Start the test: Press the STARTSTOP key.

Measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table of

permissible limit values.

➭

➭

➭

➭

➭

BC Biomedical

25

Test Standard

I

P

Type B

Type BF

Type CF

NC SFC NC SFC NC SFC

EN 60601

DC

0.01 0.05 0.01 0.05 0.01 0.05 AC 0.1 0.5 0.1 0.5 0.01 0.05

IEC 60601 3rd ed.

Total Patient

Leakage Current

DC

0.05 0.1 0.05 0.1 0.05 0.1

AC 0.5 1 0.5 1 0.05 0.1

Page 26

I

AP

Leakage Current from the Applied Part (alternative patient leakage current, mains at applied part)

tient ports for a type BF or CF applied part.

Definition of Alternative Measurement

Alternative patient leakage current is current which flows through

the conductors of the device which are connected to each other

(L/N/PE) to the patient ports.

Prerequisites:

A high-impedance power supply is connected between one

patient port at a time, and the exposed metallic parts of the

housing (which are connected to each other). The mains terminals

are short-circuited and are connected to the same point on the

housing.

Direct Measurement Method (mains at applied part)

The current which flows over the insulation of the device under

test is measured separately for each applied part.

The device under test is operated with mains power in this case.

The value which has been adjusted to nominal line voltage is displayed (see section 4.3).

Alternative Measurement Method (alternative patient leakage current)

The current which flows over the insulation of the device under

test is measured separately for each applied part.

Measurement is always performed using an AC source with

current limiting. Differing mains voltages are taken into

consideration.

Type of Test Current Parameter

Applications

This measurement is only performed for types BF and CF applied

parts. For type BF and CF applied parts, measurement is required

for all interconnected patient ports used for a single function of

the applied part, or measurement must be executed as specified

by the manufacturer.

When testing measuring instruments with several applied parts,

each must be connected, one after the other, and measuring results must be evaluated on the basis of the limit values shown in

table 2. Applied parts which are not included in the measurement

must be kept potential-free.

Definition of Leakage Current from the Applied Part

Current which flows from power packs and exposed conductive

parts of the housing to the applied parts.

Definition of Direct Measurement

Current which is caused by an undesired interference voltage at

the patient, and which flows from the patient to ground via the pa-

–

DIR

–

ALT

Mains at applied part (applied parts plugged in)

Eq. patient leakage current (applied parts plugged in)

26

BC Biomedical

Page 27

I

AP

Leakage Current from the Application Part (alternative patient leakage current, mains at applied part)

Mains Polarity Parameter

Polarity can be reversed for measurements during which the

mains are connected to the test socket.

Can only be used for types BF and CF applied parts.

➭

➭

Select the test:

keys.

Connect the device under test to the test socket and the applied parts to the patient ports. The test probe has to be connected but without applying electrical contact (potential-free).

Select type of test current: DIR / ALT key.

Select mains polarity reversal: L/N / N/L key.

Select applied parts 1 through 10: key.

Start the test: Press the STARTSTOP key.

Measured values are displayed.

End the test: Press the STARTSTOP key.

Read the measured value and compare it with the table of

permissible limit values.

➭

➭

➭

➭

➭

➭

➭

Examples of Maximum Permissible Limit Values for Leakage

Current in mA

BC Biomedical

27

Test Standard

AP

Direct Measurement

(mains at AP)

Alternative Measurement

(alternative patient leakage

current)

IEC 62353

(VDE 0751-1)

BF 5 mA 5 mA

CF 0.05 mA

0.05 mA

IEC 60601

BF 5 mA —

CF 0.05 mA —

IEC 60601 3rd ed.

Total Patient

Leakage Current

BF 5 mA —

CF 0.1 mA —

Page 28

Function Test with Line Voltage

Measuring Method

The device under test can be subjected to a function test with line

voltage via the integrated test socket.

The function test includes the following measurements:

–

–

–

–

–

Voltage VLN between the L and N conductors

Load current I

L

Active power P

Apparent power S (calculated)

Power factor PF (calculated cos , display > 10 W)

Power factor is calculated from active power and apparent power.

Power factor corresponds to cos for sinusoidal quantities (line

voltage and load current).

Applications

Functions which are relevant with regard to device safety must be

tested in accordance with the manufacturer’s recommendations,

if necessary with the support of a person who is familiar with

operation of the measuring instrument or measuring system.

Test Socket Connection

Refer to BC Biomedical function testers and light analyzers for

further function tests.

28

BC Biomedical

Page 29

Function Test with Line Voltage

Prerequisites

•

It is only permissible to execute the function test after the

device under test has passed the safety test, i.e. all safety

measurements must first be executed and passed.

The device under test must be connected to the test socket.

If no device under test has been connected, momentary line

voltage are measured if the measuring

instrument is connected to the mains.

No short-circuits may exist at the DUT.

•

•

!

Attention!

Starting the Function Test

For reasons of safety, the device under test must be

switched off before the function test is started. This

precaution prevents inadvertent start-up of a device under

test which may represent a hazard during operation, e.g. a

centrifuge.

Ending the Function Test

After completion of the function test, devices under test

must be turned off with their own switch – especially

devices with motors or other inductive loads.

Sequence

➭

➭

➭

Select the test:

keys.

Connect the DUT to the test socket.

Start the test: Press the STARTSTOP key.

All measured values are displayed.

End the test: Press the STARTSTOP key.

BC Biomedical

29

Page 30

Technical Data

6 Technical Data

(2.5% rdg. + 1 d)

(2.5% rdg. + 1 d)

monit

1)

Remote control: 40 ... 200 Hz

2)

Remote control: 100 ... 500 V

30

BC Biomedical

Measured

Quantity

Measuring Range

/ Nominal Range

of Use

Reso-

lution

Additional

Info

OpenCircuit

Voltage

U

0

Addi-

tional

Info

ShortCircuit

Current

I

K

Int.

Resist.

R

I

Ref.

Resist.

R

REF

Measuring Error

Intrinsic Error

Overload

Capacity

Value Time

R

PE

Protective earth

resistance

man: 1

...

999 m

man: 0.01

...

9.99

1 m

10 m

Electronic

fuse + fuse

link

4.0 4.5 V

AC TRMS

where I

PE

= 200

mA~

where

48 Hz

1)

220 ...

270 mA

AC TRMS

—

—

10 % rdg.

within a rage of

0.1 ... 10

for IP = 200 mA

(2.5% rdg. + 10 m)

within a rage of

0.1 ... 10

where IP = 200 mA

240 V

AC/DC

Cont.

auto: 0.01

...

30.00

0.01 ... 3.30

0.1 ... 10.0

10 m

10 m

100 m

R

INS

Insulation

resistance

10

...

300 k

10 k

Test

voltage:

500 V DC

2)

UN < U <

1.2 U

N

Nominal

current

> 1 mA

where

R

ISO

=

500 k

2 mA

—

—

0.01 ... 100 M:

10% rdg.

> 100 M

20% rdg.

where UP = 500 V

each

0.1 ... 30 M:

(2.5% rdg. + 1 d)

> 30 M

(5 % rdg. + 1 d)

where UP = 500 V

each

240 V

AC/DC

Cont.

0.01

...

3.0 M

10 k

0.1

...

30.0 M

100 k

1

...

300 M

1 M

Leakage Current Measurements – Direct Method (DIR/DL)

I

E

Equipment

leakage current

10

...

300 A

0.01

...

3.00 mA at

0.1

...

30.0 mA at

1 A

10 A

100 mA

= Protective earth current, direct (between L and N)

Residual current monitoring,

Mains shutdown: > 20 mA~ (25 ms)

0.5

...

20.0 mA:

10% rdg.

20

...

300 A:

(5% rdg. + 1 d)

> 300 A:

240 V

AC/DC

Cont.

I

T

Touch current

10

...

300 A

0.01

...

3.00 mA at

1.1

...

30.0 mA at

1 A

10 A

100 A

Probe current monitoring:

Probe shutdown: IT > 10 mA~ (5 ms)

Residual current monitoring

Mains shutdown: I

DIF

> 10 mA~ (25 ms)

1 k

10

—

1.2

...

10 mA at:

10% rdg.

20

...

300 A at:

(5% rdg. + 1 d)

> 300 A at:

240 V

AC/DC

Cont.

I

P

Patient leakage

current

2

...

300 A

0.01

...

3.00 mA at

1 A

10 A

Probe current monitoring:

Probe shutdown: IP > 10 mA~ (5 ms)

Residual current oring

Mains shutdown: I

DIF

> 10 mA~ (25 ms)

1 k

10

—

0.01

...

3 mA at:

10% rdg.

10

...

300 A at:

(7.5% rdg. + 1 d)

0.30

...

3.00 mA at

±(2.5% rdg. + 1 d)

240 V

AC/DC

Cont.

I

AP

Applied parts

leakage current

10

...

300 A~

0.01

...

3.00 mA~

0.1

...

30.0 mA~

1 A

10 A

100 mA

Test

voltage:

110/220/

230/240 V

AC

110 ... 240 V~

–15 /

+10%

Fre-

quency

50/60/

200/400

Hz

< 1.5 mA

> 150

k

1 k

10

20 A

...

15 mA AC:

10% rdg.

> 15.0 mA AC:

15% rdg.

20 A

...

15 mA AC:

(5% rdg. + 1 d)

> 15.0 mA AC:

(10% rdg. + 1 d)

240 V

AC/DC

Cont.

Page 31

Technical Data

(10% rdg. + 1 d)

temperature > 70 C

f < 100 Hz

f 100 Hz

f < 100 Hz

3)

Remote control: 50 ... 400 Hz

BC Biomedical

31

Measured

Quantity

Measuring Range

/ Nominal Range

of Use

Reso-

lution

Addi-

tional

Info

OpenCircuit

Voltage

U

0

Addi-

tional

Info

ShortCircuit

Current

I

K

Int.

Resist.

R

I

Ref.

Resist.

R

REF

Measuring Error

Intrinsic Error

Overload

Capacity

Value Time

Leakage Current Measurements – Differential Method (DIF)

I

E

I

T

Residual current

between L and N

10

...

300 A~

0.01

...

3.00 mA~

0.1

...

30.0 mA

1 A

10 A

100 A

= Protective earth current, direct

Residual current monitoring

Mains shutdown: > 20 mA~ (25 ms)

0.5

...

20.0 mA:

10% rdg.

20

...

300 A:

(5% rdg. + 1 d)

> 300 A:

(2.5% rdg. + 1 d)

240 V

AC/DC

Cont.

Leakage Current Measurements – Alternative Method: Alternative leakage current (ALT)

I

E

I

T

I

AP

2

...

300 A~

0.01

...

3.00 mA~

0.1

...

30.0 mA~

1 A

10 A

100 A

Test

voltage:

110/220/

230/240 V

AC

110 ... 240

V~

–15 /

+10%

Fre-

quency

50/60 Hz

3)

< 1.5 mA

> 150

k

1 k

10

20 A

...

15 mA AC:

10% rdg.

> 15.0 mA AC:

15% rdg.

20 A

...

15 mA AC:

(5% rdg. + 1 d)

> 15.0 mA AC:

240 V

AC/DC

Cont.

Function test

VLN

Line voltage (RMS)

90 ... 240 V AC

(50 ... 400 Hz)

0.1 V

5.0% rdg.

(2.5% rdg. + 1 d)

240 V

AC

Cont.

I

V

Load current

(RMS)

0.02 ... 16.00 A AC

(50 ... 400 Hz)

10 mA

Shutdown by mains relay at: IV > 16 A~ where t > 0.5 s

Shutdown by mains relay at: IV > 4 A~ where internal

5.0% rdg.

(2.5% rdg. + 1 d)

4 A

Cont.

P

Active power

10 ... 4000 W

1 W

Measured value P and calculated value S are compared, and

the smaller of the two is displayed.

Shutdown at internal temperature > 70 C

f < 100 Hz

7.5% rdg.

P > 10 W, PF > 0,5

(5% rdg. + 10 d)

<1000W

<4000W

Cont.

10 min

f 100 Hz

10% rdg.

P > 10 W, PF > 0,5

(7.5% rdg. + 10 d)

S

Apparent power

10 ... 4000 W

1 VA

Calculated vale U

L–N

•

I

V

Shutdown at internal temperature > 70 C

f < 100 Hz

7.5% M

P > 10 W

f < 100 Hz

(5% rdg. + 10 d)

<1000W

<4000W

Cont.

10 min

f 100 Hz

10% rdg.

P > 10 W

f 100 Hz

(7.5% rdg. + 10 d)

LF

Power factor

with sinusoidal

waveshape: cos

0.00 ... 1.00

inductive

0.01

Calculated value P / S, display as of P > 10 W

f < 100 Hz

7.5% M

P > 10 W, PF > 0.5

(5% rdg. + 10 d)

—

—

f 100 Hz

10% rdg.

P > 10 W, PF > 0.5

f 100 Hz

(7.5% rdg. + 10 d)

Page 32

Technical Data

Reference Conditions

Line voltage

Line frequency

Waveshape

Influencing Quantities and Influence Error

230 V 0.2%

50 Hz 0.1%

Sine (deviation between effective and

rectified value < 0.5%)

70 to 77 °F

40 60%

Linear

Ambient temperature

Relative humidity

Load resistance

Ambient Conditions

Operating temperature

Accuracy range

Storage temp. range

Relative humidity

Elevation

Deployment

-32 F... + 104 F

-32 F... + 104 F

– 4 F ... + 140 F

max.75%, no condensation allowed

max. 2000 m

Indoors, except within specified ambient

conditions

Power Supply

Broad Range Variable Power Pack

Line voltage

Line frequency

Power consumption

90 ... 240 V

50 Hz ... 400 Hz

Measuring Leakage Current

Frequency response is

taken into consideration in accordance

with the diagram to the

right when

leakage current is

measured.

Internal consumption

Permissible DUT power consumption

Permissible DUT power consumption, cont. operation

< 20 VA

4000 VA

1000 VA

Permissible DUT current consumption, cont. operation 4 A~

Switching capacity

16 A, AC1 max. 20 A / 600 ms

32

BC Biomedical

U(

f

)

U(

f

=10

)

at

i

ve

M

a

gni

t

ud

e

(dB):

20

l

og

+20

0

–20

–40

–60

10

10

2 103 104 105 106

Rel

Frequency (f) in Hz

Influencing Quantity /

Sphere of Influence

Designation per

IEC 61557

Influence Error

% of Measured Value

Test instrument position

E1 2.5 at I PE (diff)

Test instrument supply voltage

E2 1

Ambient temperature

(-32 F... + 104 F)

E3

1

DUT current consumption

E4 2.5 Low frequency magnetic fields

E5 3.0 at I PE (diff)

DUT impedance

I6 2.5

Conductance leakage capacity

during insulation measurement

E7

0.5

Waveshape of the measured test

current

E8

2.5 at I PA

1 Other measuring ranges

Page 33

Technical Data

Electrical Safety

Fuses

Mechanical Design

Display

2 x FF (UR) 500 V/16 A AC;

6.3 mm x 32 mm;

(BC80-00829)

50 kA breaking capacity at 500 V AC

monochrome backlit dot matrix display,

128 x 128 pixels

(W x D x H) 325 x 250 x 90 mm

approx. 2 kg

Housing: IP 40, connections: IP 20

per DIN VDE 0470 part 1/EN 60529

Dimensions

Weight

Protection

Safety class

Nominal voltage

Test voltage

Measuring category

Fouling factor

Safety Shutdown

Disconnection from mains per SC II

230 V

2.2 kV AC or 3.3 kV DC

300 V CAT II

2

With following differential current at DUT

during:

Table Excerpt Regarding Significance of the

IP Code

penetration by water

–

Function test

–

Touch current meas.

10 mA~ / < 25 ms

direct current meas. 10 mA~ / < 25 ms

Residual current meas. 20 mA~ / < 25 ms

–

Protective conductor

direct current meas. 10 mA~ / < 25 ms

Residual current meas. 20 mA~ / < 25 ms

with following probe current during:

–

Touch current meas. 10 mA~ / < 5 ms

–

Protective conductor

resistance measurement 300 mA~ / < 1ms

Data Interface

USB Slave

Electromagnetic Compatibility, EMC

Interference Emission EN 61326-1:2006 class B

Interference Immunity EN 61326-1:2006

BC Biomedical

33

IP XY

(1

st

digit X)

Protection against pene-

tration of solid particles

IP XY

(2

nd

digit Y)

Protection against

0 Not protected

0 Not protected

1

50.0 mm dia.

1 vertically falling drops

2

12.5 mm dia.

2

vertically falling drops with

enclosure tilted 15

3

2.5 mm dia.

3 spraying water

4

1.0 mm dia.

4 Splashing water

Page 34

Maintenance – Calibration

7 Maintenance and Calibration

7.1 Housing Maintenance

No special maintenance is required for the housing. Keep outside

surfaces clean. Use a slightly dampened cloth for cleaning. Avoid

the use of cleansers, abrasives or solvents.

7.2 Replacing the Fuses

All fuses are accessible from the outside.

If a fuse should blow, eliminate the cause of overload before

placing the instrument back into service!

and great temperature fluctuations, we recommend a relatively

short calibration interval of 1 year.

During recalibration* in an accredited calibration laboratory

(DIN EN ISO/IEC 17025) the deviations of your instrument in relation to traceable standards are measured and documented. The

deviations determined in the process are used for correction of

the readings during subsequent application.

!

Attention!

Disconnect the instrument from the measuring circuit before

removing the fuse!

!

Attention!

Use specified fuses only!

If fuses with other blowing characteristics, other current

ratings or other breaking capacities are used, the operator

is placed in danger, and protective diodes, resistors and

other components may be damaged.

The use of repaired fuses or short-circuiting the fuse holder

is prohibited.

By having your measuring instrument calibrated regularly, you fulfill the requirements of a quality management system per

DIN EN ISO 9001.

Standards DIN VDE 0701-0702 and IEC 63353 (VDE 0751) stipulate that only measuring instruments which are regularly tested

and calibrated may be used for testing.

7.3 Recalibration

The respective measuring task and the stress to which your mea-

suring instrument is subjected affect the ageing of the components and may result in deviations from the guaranteed accuracy.

*

Verification of specifications or adjustment services are not part of the

calibration. For products from our factory, however, any necessary adjustment is frequently performed and the observance of the relevant

specification is confirmed.

If high measuring accuracy is required and the instrument is frequently used in field applications, combined with transport stress

34

BC Biomedical

Page 35

Maintenance – Calibration

7.4 Manufacturer’s Guarantee

The measuring instrument BC Biomedical SA-2500 is guaranteed for

a period of 1 year after date of shipment. The manufacturer’s

guarantee covers materials and workmanship. Damages resulting

from use for any other than the intended purpose, as well as any

and all consequential damages, are excluded.

Calibration is guaranteed for a period of 12 months.

The manufacturer’s guarantee expires if the seal has been

damaged.

7.5 Return and Environmentally Sound Disposal

We identify our electrical and electronic devices in ac-

cordance with WEEE 2012/19/EU and ElektroG using

the symbol shown at the right per DIN EN 50419.

These devices may not be disposed of with the trash.

Please contact our service department regarding the return of old

devices (see page 3).

BC Biomedical

35

Page 36

36

BC Biomedical

Page 37

Index

8

A

Index

Maintenance

Housing

......................................................... 34

Manufacturer’s Guarantee

...................................35

Measuring Categories and their Significance

.......5

O

Overview

Individual Measurements (manual test)

...... 12

P

Patient Leakage Current

Limit Values

.................................................. 25

Product Support

......................................................2

Protective Conductor Resistance

Limit Values

.................................................. 15

R

Recalibration

.........................................................34

Recalibration Service

..............................................3

Repair and Replacement Parts Service

.................3

S

Safety Precautions

..................................................7

Scope of Delivery

....................................................2

Symbols

On Devices Under Test

.................................. 6

On the Instrument

.......................................... 8

T

Terminals

Overview

......................................................... 9

Touch Current

Limit values

.................................................. 22

Training

...................................................................2

U

Use for Intended Purpose

...................................... 5

Accessories

............................................................ 2

C

Classification of Devices Under Test

According to Application Part

.........................6

According to Safety Class

..............................6

Configuring Device Parameters

........................... 10

E

Equipment Leakage Current

Limit Values

..................................................19

F

Frequency Response

........................................... 32

Function Test

........................................................ 28

Fuses

Position

............................................................9

Replacing the Fuses

.....................................34

Technical Data

..............................................33

I

Individual Measurements

General Procedure

........................................12

Initial Window

....................................................... 10

Insultation Resistance

Limit Values

..................................................17

L

Leakage Current from the Application Part

Limit Values

..................................................27

M

Mains Connection Error

....................................... 10

BC Biomedical

37

Page 38

38

BC Biomedical

Page 39

BC Biomedical

39

Page 40

Phone 1-800-242-8428

1-314-638-3800

E-Mail info@bcgroupintl.com

Web

www.bcgroupstore.com

BC Biomedical

3081 Elm Point industrial Drive

St. Charles, MO 63301

09-15 Rev 03

LM-7339-UM

3-349-444-74

Edited in USA • Subject to change without notice • PDF version available on the Internet

Loading...

Loading...