Page 1

ELECTRICAL

SAFETY ANALYZER

WITH PATIENT SIMULATOR

SA-2010S

USER MANUAL

Page 2

Page 3

BC BIOMEDICAL

SA-2010S

TABLE OF CONTENTS

WARNINGS ................................................................................................................. 3

DESCRIPTION............................................................................................................. 4

LAYOUTS .................................................................................................................... 6

TESTING...................................................................................................................... 10

TEST MATRIX ................................................................................................... 17

ECG WAVEFORMS..................................................................................................... 18

MANUAL REVISIONS.................................................................................................. 19

WARRANTY................................................................................................................. 19

SPECIFICATIONS ....................................................................................................... 20

APPENDIX A -- LABEL .............................................................................................. 22

NOTES......................................................................................................................... 23

1

Page 4

NOTICE

BC GROUP INTERNATIONAL, INC. RESERVES THE RIGHT TO

MAKE CHANGES TO ITS PRODUCTS OR SPECIFICATIONS AT

ANY TIME, WITHOUT NOTICE, IN ORDER TO IMPROVE THE

DESIGN OR PERFORMANCE AND TO SUPPLY THE BEST

POSSIBLE PRODUCT. THE INFORMATION IN THIS MANUAL

HAS BEEN CAREFULLY CHECKED AND IS BELIEVED TO BE

ACCURATE. HOWEVER, NO RESPONSIBILITY IS ASSUMED

FOR INACCURACIES.

CONTACT INFORMATION

BC BIOMEDICAL

BC GROUP INTERNATIONAL, INC.

PO BOX 25125

9415 GENTRY AVE

ST. LOUIS, MO 63125

USA

1-800-242-8428

314-638-3800

www.bcgroupintl.com

sales@bcgroupintl.com

2

Page 5

Manual SA-2010S Copyright © 2006

www.bcgroupintl.com Made in the USA

7/06 Rev 03

All connections to patients must be removed

before connecting the Device Under Test (DUT)

to the Analyzer. A serious hazard may occur if

the patient is connected when testing

Do not connect any leads from the patient

directly to the Analyzer or DUT.

The Analyzer applies 120 or 240 VAC plus 10% to

the Patient leads or External test leads during

the Isolation test. Although this is current

limited by a 121K ohm internal resistor, per

standard test specifications, care should be

taken to prevent contact with this voltage.

Do not touch the test leads, connections or DUT

while depressing the Isolation Test key.

The Analyzer is not a continuous duty device.

Do not leave the device under test (DUT)

connected to this unit for extended periods. It is

intended for short duration testing within the

current limits and duty cycles specified.

WARNING

with the Analyzer.

WARNING

CAUTION

3

Page 6

BC BIOMEDICAL

SA-2010S

ELECTRICAL SAFETY ANALYZER

WITH PATIENT SIMULATOR

The Model SA-2010S is a Microprocessor based Electrical Safety Analyzer with a built in

Patient Simulator. It allows for a multitude of tests to be performed on a device using the

same unit and lead connections. It provides a full Electrical Safety Analyzer, as well as,

ECG Simulation with four waveforms with constant QRS duration and six machine

performance testing waveforms. There is Patient Lead testing for 10 inputs. The following

are highlights of some of the main features:

• LED STATUS INDICATORS

• AUDIO FEEDBACK

• TOUCH CONTROL KEYS – NO KNOBS

• 10 UNIVERSAL PATIENT LEAD INPUTS

• HIGH IMPACT PLASTIC CASE

SAFETY ANALYZER:

• LINE VOLTAGE MEASUREMENT

• DEVICE UNDER TEST CURRENT MEASUREMENT

• EARTH / GROUND LEAD RESISTANCE

• EARTH / GROUND LEAKAGE CURRENT

• ENCLOSURE / CHASSIS LEAKAGE CURRENT

• EXTERNAL RESISTANCE

• EXTERNAL LEAKAGE CURRENT

• SOURCE RECEPTACLE WIRING INTEGRITY MONITOR

• TRUE RMS MEASUREMENTS

• AAMI ES1-1993 or IEC 601 SELECTABLE TEST LOADS

• 85 TO 265 VAC OPERATION

• FULL 20 AMP RATING

• SELF TEST POINTS

• EXTERNALLY REPLACEABLE GROUND FUSE

• AUTOMATIC LOAD REVERSAL DELAY

• PATIENT LEAD TO LEAD LEAKAGE CURRENT

• PATIENT LEAD TO EARTH / GROUND LEAKAGE CURRENT

• PATIENT ISOLATION LEAKAGE CURRENT

• EXTERNAL ISOLATION LEAKAGE CURRENT

4

Page 7

PATIENT SIMULATOR:

• ECG: 30, 60, 120 AND 240 BPM

• SINE: 10, 60 AND 100 HZ

• SQUARE: 0.125 AND 2.0 HZ

• TRIANGLE: 2 HZ

• HIGH LEVEL OUTPUT (1 V p-p)

• AMPLITUDE ACCURACY: +/- 2%

• FREQUENCY ACCURACY: +/- 0.5%

5

Page 8

LAYOUT

p

A

p

A

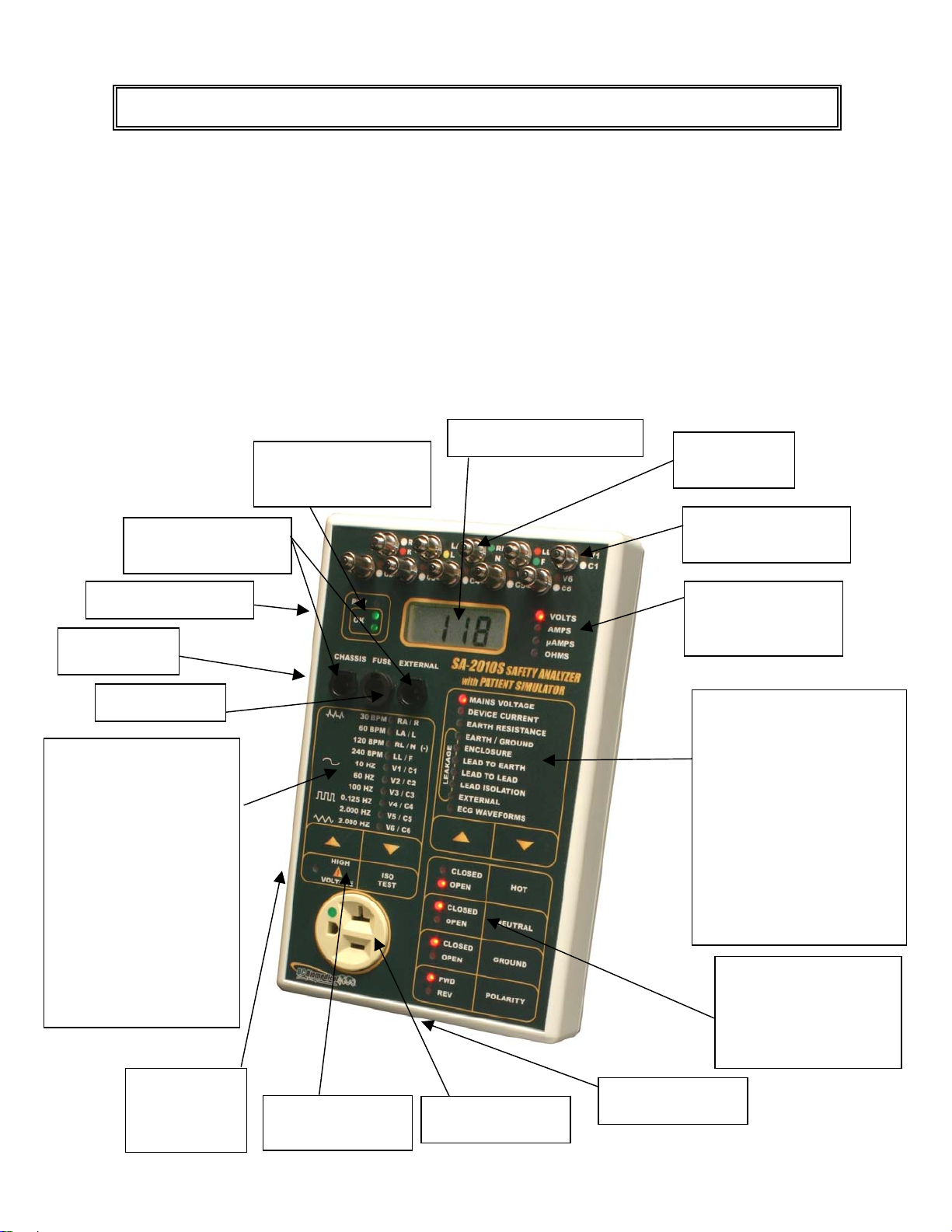

This section looks at the layout of a SA-2010S and gives descriptions of the elements that

are present.

The unit is controlled by 9 light touch keys. They allow the user to perform all the functions

available in the system. There is an audio click when a key is depressed. Note that some

keys are locked out based on the current function setting. If an invalid key is depressed, a

Razz tone is sounded.

There are 33 LEDs and 3 Neon indicators to provide the user with full information about the

test that is being performed and the current setup. This section will review the layout and

operation of each of the elements.

Chassis and

External Connectors

High Level (+) Snap

Test Point

Sna

s

Fuse Access

ECG waveform and

Patient Lead Input

indicators with two light

touch arrow keys for

selection:

ECG— 30 BPM RA/A

60 BPM LA/L

120 BPM RL/N

240 BPM LL/F

Sine— 10 HZ V1/C1

60 HZ V2/C2

100 HZ V3/C3

Sq—0.125 HZ V4/C4

2 HZ V5/C5

Tri— 2 HZ V6/C6

3 Neon indicators for

Power Receptacle

Confirmation

3 1/2 digit LCD Display

High Level (-)

RL/N Snap

10 Universal

Patient Lead Inputs

Unit indicators:

Volts, Amps,

µAmps, Ohms

Function indicators with two

light touch arrow keys for

selection:

Mains Voltage,

Device Under Test Current,

Earth Resistance,

Earth/Ground Leakage,

Enclosure Leakage,

Lead to Earth Leakage,

Lead to Lead Leakage,

Lead Isolation Leakage,

External Leakage

ECG Waveforms

nalyzer Test

Receptacle Control

indicators and keys:

Hot, Neutral, Ground,

Polarity

Load

Selection

switch:

AMI, IEC

ISO Test indicator

and key

Receptacle for

DUT

ower cord

6

Power Cord for

unit

Page 9

Display

The main information in the system is presented in the 3½ digit LCD display. This data is

provided as simple meter readings with the units indicated by one of the four LEDs on the

right of the display. The units LEDs will automatically change to the necessary range

based on the function selected.

Universal Patient Lead Connectors

The 10 Universal Patent Lead Connectors allow for 12 lead ECG simulation with

independent outputs. AHA and IEC color-coded labels are located on the face of the unit to

aid in connecting the corresponding U.S. and International Patient Leads.

AHA Label IEC Label Description

RA R Right Arm

LA L Left Arm

RL N

Right Leg

(reference or ground)

LL F Left Leg

V Leads (V1-V6)

V1

V2

V3

V4

V5

V6

C1

C2

C3

C4

C5

C6

(U.S. and Canada)

also referred to as pericardial,

precordial or unipolar chest leads

Chest Leads (C1-C6)

(International)

Function Selection

Ten LEDs and two keys make up the Function Selection Section. The keys are up and

down arrows. When depressed, they step the Analyzer through the available options. The

LED next to the currently selected option is illuminated.

Load Selection

The unit may either use the AAMI ES1-1993 or IEC 601 Test load for measurements. This

is selected by the Load switch.

7

Page 10

Analyzer Test Receptacle Control

There are four keys and 8 LEDs in the Analyzer Test Receptacle Control Section. They

allow the manual control of the power connections that are made to the DUT. Internally, a

series of relays are switched by the microprocessor based on the keys that are depressed.

The LEDs indicate the current state of the power connections to the Receptacle.

Note: The Forward/Reverse keys have an internal switching delay feature that first turns off

the power to the DUT, delays for a short period, reverses the lines and the turns the unit

back on. This eliminates the need for the user to remember to delay at this point or risk

damage to the Analyzer.

Patient Lead Control

In the maximum configuration, there are ten patient lead inputs. During testing, it is

necessary to select between these leads, select all of them and apply High Voltage to

them. This section provides the control keys to do these test configurations and the LEDs

to indicate the current state.

There is one LED for each input. The markings on the right side of the LEDs are used

during these tests. Internally, there is a relay for each lead. The LEDs indicate when that

relay is on, thus selecting the indicated lead. The Up and Down arrow keys sequentially

select each lead in order and scroll through from None to 1-10 to All and around again.

To apply High Voltage to the leads, the Isolation Test key is depressed. It is only active in

the Isolation mode. It is a momentary key, the voltage is only applied while the key is held

down.

Waveform Selection

When the ECG Waveforms function is selected, the two keys and 10 LEDs become the

Waveform Selection Control Section. The markings o the left side of the LEDS are used

during these tests. The LEDs indicate which waveform is generated. The Up and Down

arrow keys sequentially select each waveform. Internally, the microprocessor has stored in

memory the digitalized waveforms. It sends the selected waveform to a D/A converter that

generates an accurate analog representation. This waveform is then sent through a

resistor network, developing the appropriate signals on the output terminals.

Power Outlet Indicators

These three Neon indicators help verify the polarity and wiring of the wall Receptacle that

the Safety Analyzer is plugged into.

8

Page 11

High Level Output (+)

A High Level snap is located on the side of the unit for connecting to the high level ECG

output signal (1 Volt p-p ). The connection is between High Level (+) and RL (-).

Connectors

There are two connectors for test cables on the unit. One is for the Chassis lead and the

other is for one of two different leads used for external testing. The test cables simply plug

into the sockets. There is a release pin on the cable plug that must be depressed to

remove the cable.

Fuse

There is a fuse in the ground leg of the Analyzer Test Receptacle. This is to help prevent

damage from excess ground current. It is located on the face for ease of replacement.

Test Receptacle

This receptacle is for the connection of the Device Under Test (DUT). It is Hospital Grade,

rated 20 A. An external patch cord is necessary to connect devices utilizing different types

of plugs.

Power Cord

The unit uses a standard Hospital Grade power cord. This cord provides power to both the

Safety Analyzer and the DUT. The connector is designed to plug into a 15A, 125 VAC,

Receptacle. For higher voltage and current applications, an external patch cord is required.

Self Test Points

There are two test points on the side of the unit that allow for a quick self test of the

Analyzer. They provide a fixed 1.0 Ohm resistance to Earth/Ground and a 100 µAmp

source to Earth/Ground.

9

Page 12

SAFETY ANALYZER TESTING

The SA-2000 Family of Safety Analyzers allows the user a great deal of flexibility in testing.

Any of the basic tests can be run and in almost any sequence. The information in this

section presents a systematic approach that is just one way to proceed. It is only

presented as a guide and it is the responsibility of the user to establish which tests are

required based on local codes, facilities practices and equipment manufacturer’s

recommendations.

The Analyzer requires a good Earth/Ground connection for operation. It should be plugged

into a “Hospital Grade” receptacle. This is necessary for both valid test results and

personal safety.

The unit will power up with the Neutral and Ground Closed, in Forward Polarity and with the

Hot Open. It is recommended that the unit be returned to this condition when plugging and

unplugging the Device Under Test (DUT).

Power Receptacle Confirmation

Once plugged in, the first step is to insure that the wall receptacle that the Safety Analyzer

is plugged into is wired properly (120 VAC Non-Isolated Power Systems Only). There are

three neon indicators in the unit that provide this confirmation. The REV indicator is red

and the other two are green. If the two green indicators are on, the Receptacle is wired

correctly. If not, utilize the following patterns to help determine the problem. Do not

proceed with any testing until you get the two green lights.

NOTE: Neutral/Ground Reversal is not checked.

All connections to patients must be removed

before connecting the Device Under Test (DUT)

to the Analyzer. A serious hazard may occur if

the patient is connected when testing

Do not connect any leads from the patient

directly to the Analyzer or DUT.

WARNING

with the Analyzer.

10

Page 13

Mains Voltage

With the Mains Voltage function selected, the display will show the Voltage that is present

on the incoming power lines. This is measured from Line to Neutral. Insure that this value

is within the specifications for the equipment that is to be tested. Also note that the voltage

may drop when the DUT is turned on. It is the value with the DUT powered that must be

within the DUT specification.

Device Current

With the Device Current function selected, the display will show the current draw of the

DUT. This is measured in hundredths of an Amp up to 19.99 Amps. The Receptacle

should be configure with Hot-Closed, Neutral-Closed, Ground-Closed and Polarity-Fwd, for

this measurement.

Earth Resistance

With the Earth Resistance function selected, the display will show the resistance between

the Chassis Test lead and the Earth/Ground Pin on the Analyzer Test Receptacle. This

resistance is a combination of the resistance within the DUT enclosure and the resistance

in the Earth/Ground Lead in the DUT power cord.

NOTE: This test has no meaning for equipment that does not use a three-wire

(Earth/Grounded) power cord.

The test requires that the Black (Kelvin) test cable be plugged into the Chassis Socket. The

other end should be connected to a solid ground point on the DUT. Consult the equipment

manufacturer’s documentation for the recommended connection point.

Since the Black (Kelvin) cable removes any error from the test lead and the internal

circuitry uses a similar connection at the Analyzer Test Receptacle ground pin (providing a

true 4 wire reading), the value displayed is the actual resistance of interest, without any

compensation. The display is in hundredths of Ohms and will read to 19.99 Ohms.

Overrange shows as 1_ _ _.

11

Page 14

Earth/Ground Leakage Current

With the Earth/Ground function selected and the Ground-Open, the display will show the

leakage current in the ground wire of the DUT. The display is in µAmps and will read from

0 to 1999.

Selecting this function automatically opens the connection to Earth/Ground and passes any

leakage current through a 1000 Ohms load with either AAMI ES1-1993 or IEC 601

frequency compensation as selected by the Load key.

The test should be performed for all receptacle switch combinations as called out in the

Test Matrix, or a subset of these based on the manufacturer’s specifications or local codes

and protocols.

NOTE: This test has no meaning for equipment that does not use a three-wire

(Earth/Grounded) power cord.

Enclosure Leakage

With the Enclosure function selected, the display will show the leakage current between the

Enclosure (Chassis) and Earth/Ground. The display is in µAmps and will read from 0 to

1999.

The test requires that the Black (Kelvin) test cable be plugged into the Chassis Socket. The

other end should be connected to a solid ground point on the DUT. Consult the equipment

manufacturer’s documentation for the recommended connection point.

NOTE: If a non-conductive enclosure is used, a 200 cm2 conductive foil pad should be

used. This foil is to be placed in close contact with the enclosure and connected to the

Black lead.

Any leakage current will flow through the Black lead and then through a 1000 Ohms load

with either AAMI ES1-1993 or IEC 601 frequency compensation as selected by the Load

key.

The test should be performed for all receptacle switch combinations as called out in the

Test Matrix, or a subset of these based on local codes, facilities practices and equipment

manufacturers recommendations.

12

Page 15

Lead to Earth/Ground Leakage

With the Lead to Earth/Ground function selected, the display will show the leakage current

between the selected Patient Lead and Earth/Ground. The display is in µAmps and will

read from 0 to 1999.

Attach the patient leads to the connectors on the top of the Safety Analyzer. The Up and

Down arrow keys may then be used to select any individual lead or all of the leads.

Internally, relays connect the leads as necessary. The LEDs indicate the selected lead(s).

The test should be performed for all receptacle switch combinations as called out in the

Test Matrix, or a subset of these based on local codes, facilities practices and equipment

manufacturer’s recommendations. This is to be done for each lead individually and all leads

together.

This test measures the leakage current that would flow through the leads if the patient were

to come into contact with Earth/Ground.

Lead to Lead Leakage

With the Lead to Lead function selected, the display will show the leakage current between

the selected Patient Lead and All other patient leads. The display is in µAmps and will read

from 0 to 1999.

Attach the patient leads to the connectors on the top of the Safety Analyzer. The Up and

Down arrow keys may then be used to select any individual lead. Internally, relays

connect the leads as necessary. The LEDs indicate the selected lead.

The test should be performed for all receptacle switch combinations as called out in the

Test Matrix, or a subset of these based on local codes, facilities practices and equipment

manufacturers recommendations. This is to be done for each lead individually.

This test measures the current that would flow from a lead to other leads. Normally these

are Auxiliary currents from bias, measurement and sensing circuits.

13

Page 16

Lead Isolation

With the Lead Isolation function selected and the Isolation Voltage key depressed, the

display will show the leakage current between the selected Patient Lead(s) and

Earth/Ground. The display is in µAmps and will read from 0 to 1999.

Attach the patient leads to the connectors on the top of the Safety Analyzer. The Up and

Down arrow keys may then be used to select any individual lead and all of the leads.

Internally, relays connect the leads as necessary. The LEDs indicate the selected lead(s).

As each lead and then All leads are selected, depress and hold the Isolation Voltage key.

This will apply 110% of the line voltage through a 121K resistor to the selected lead(s) and

measure the current that flows to Earth/Ground through a 1000 Ohms load with either

AAMI ES1-1993 or IEC 601 frequency compensation as selected by the Load key.

The test should be performed for all receptacle switch combinations as called out in the

Test Matrix, or a subset of these based on the manufacturer’s specifications or local codes

and protocols. This is to be done for each lead individually and All leads together.

This test measures the leakage current that would flow through the lead(s) if the patient

were to come into contact with Line voltage. This is referred to as MAP (MAINS on Applied

Parts).

The Analyzer applies 120 or 240 VAC plus 10% to

the Patient leads or External test leads during

the Isolation test. Although this is current

limited by a 121K Ohms internal resistor, per

standard test specifications, care should be

taken to prevent contact with this voltage.

Do not touch the test leads, connections or DUT

while depressing the Isolation Test key.

WARNING

14

Page 17

Point to Point Measurements

The unit has the ability to measure Leakage Current, Isolation Leakage Current and

Resistance between two points, utilizing two test leads. These tests are separated

because they use a slightly different setup than the previous tests.

Point to Point Leakage Current

With the External function selected, the display will show the leakage current between the

test leads. The display is in µAmps and will read from 0 to 1999.

The test requires that the Black test cable be plugged into the Chassis Socket and the Red

test cable be plugged into the External Socket. The other end of the leads are then

attached to the points of interest.

Any current flowing between the test points is passed through a 1000 Ohms load with either

AAMI ES1-1993 or IEC 601 frequency compensation as selected by the Load key.

Point to Point Isolation Leakage Current

With the External function selected and the Isolation Voltage key depressed, the display will

show the isolation leakage current between the test leads. The display is in µAmps and will

read from 0 to 1999.

The test requires that the Black test cable be plugged into the Chassis Socket and the Red

test cable be plugged into the External Socket. The other end of the leads are then

attached to the points of interest.

Depress and hold the Isolation Voltage key. This will apply 110% of the line voltage

through a 121K resistor to the test leads and measure the current that flows through a 1000

Ohms load with either AAMI ES1-1993 or IEC 601 frequency compensation as selected by

the Load key.

The Analyzer applies 120 or 240 VAC plus 10% to

the Patient leads or External test leads during

the Isolation test. Although this is current

limited by a 121K Ohms internal resistor, per

standard test specifications, care should be

taken to prevent contact with this voltage.

Do not touch the test leads, connections or DUT

while depressing the Isolation Test key.

WARNING

15

Page 18

Point to Point Resistance

With the Earth Resistance function selected, the display will show the resistance between

the two test leads. The display is in hundredths of Ohms and will read to 19.99 Ohms.

Remove any device plugged into the Analyzer Test Receptacle.

The test requires two Black (Kelvin) test cables--one in the Chassis Socket and the other in

the External Socket. The other ends should be connected to the points of interest.

Since the Black (Kelvin) cable removes any error from the test leads (providing a true 4

wire reading), the value displayed is the actual resistance of interest, without any

compensation.

NOTE: If there is a DC voltage present between the two test points, the reading may

contain an error. This can be checked by reversing the connections. If the readings differ,

average the two to get the actual resistance value.

16

Page 19

Test Matrix

DUT

POWER

GROUND POLARITY HOT NEUTRAL

On Closed Forward Closed Closed

On Closed Forward Closed Open

On Closed Forward Open Closed

On Closed Forward Open Open

On Closed Reverse Closed Closed

On Closed Reverse Closed Open

On Closed Reverse Open Closed

On Closed Reverse Open Open

On Open Forward Closed Closed

On Open Forward Closed Open

On Open Forward Open Closed

On Open Forward Open Open

On

On

On

Open Reverse Closed Closed

Open Reverse Closed Open

Open Reverse Open Closed

On

Open Reverse Open Open

Off Closed Forward Closed Closed

Off Closed Forward Closed Open

Off Closed Forward Open Closed

Off Closed Forward Open Open

Off Closed Reverse Closed Closed

Off Closed Reverse Closed Open

Off Closed Reverse Open Closed

Off Closed Reverse Open Open

Off Open Forward Closed Closed

Off Open Forward Closed Open

Off Open Forward Open Closed

Off Open Forward Open Open

Off Open Reverse Closed Closed

Off Open Reverse Closed Open

Off Open Reverse Open Closed

Off Open Reverse Open Open

17

Page 20

ECG WAVEFORMS

The SA-2010S provides ECG Waveforms to aid in the verification of the basic operational

characteristics of cardiac-monitoring equipment. The information in this section presents a

listing of available waveforms. It is the responsibility of the user to establish which

waveform verifications are required based on local codes, facilities practices and equipment

manufacturer’s recommendations.

Pulse Waves

The SA-2010S simulates a Normal Sinus Rhythm pulse at 30, 60, 120 and 240 BPM.

With ECG Waveforms function selected, use the arrow keys under the waveform LEDs to

select the desired pulse. The display is unused in this mode and will show over range. The

LEDs will pulse with the waveform.

Performance Waves

Sine

The SA-2010S sends out Sine waves of 10, 60 and 100 Hz. With ECG Waveforms function

selected, use the arrow keys under the waveform LEDs to select the desired Sine wave.

The display is unused in this mode and will show over range.

Square

The SA-2010S sends out Square waves of 0.125 and 2 Hz. With ECG Waveforms function

selected, use the arrow keys under the waveform LEDs to select the desired Square wave.

The display is unused in this mode and will show over range.

Triangle

The SA-2010S sends out Triangle waves of 2 Hz. With ECG Waveforms function selected,

use the arrow keys under the waveform LEDs to select the desired Triangle wave. The

display is unused in this mode and will show over range.

18

Page 21

MANUAL REVISIONS

A

A

Revision #

Rev 01 DT7338 Preliminary Manual

Rev 02 DT7338CC Photos Updated

WARRANTY

FROM DEFECTS IN MATERIALS AND WORKMANSHIP UNDER THE SERVICE FOR WHICH THEY

RE INTENDED. THIS WARRANTY IS EFFECTIVE FOR TWELVE MONTHS FROM THE DATE OF

SHIPMENT.

EXCLUSIONS: THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

BC GROUP INTERNATIONAL, INC. IS NOT LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

NO PERSON OTHER THAN AN OFFICER IS AUTHORIZED TO GIVE ANY OTHER WARRANTY OR

SSUME ANY LIABILITY.

REMEDIES: THE PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE: (1) THE REPAIR OR

REPLACEMENT OF DEFECTIVE PARTS OR PRODUCTS, WITHOUT CHARGE. (2) AT THE OPTION

OF BC GROUP INTERNATIONAL, INC., THE REFUND OF THE PURCHASE PRICE.

P:\MANUALS\BCGroup\…\SA2010S_UM_Rev03.doc

Program # Revisions Made

LIMITED WARRANTY

: BC GROUP INTERNATIONAL, INC. WARRANTS ITS NEW PRODUCTS TO BE FREE

19

Page 22

SPECIFICATIONS

LINE VOLTAGE

DUT CURRENT

SCALES & RANGES

85 – 265 VAC, 50/60 Hz, RMS

+/- 3% of reading, +/- 1 digit

0 – 19.99 Amps, RMS

+/- 5% of reading, +/- 1 digit

EARTH/GROUND

RESISTANCE

LEAKAGE CURRENT 0-1999 µAmps, RMS

DC and 25 to 1KHz +/- 1.0% of reading, +/- 1 digit

+/- 1% of reading, +/- 1 digit

0-19.99 Ohms

1.00 KHz – 100 KHz +/- 2.5% of reading, +/- 1 digit

100 KHz – 1.00 MHz +/- 5.0% of reading, +/- 1 digit

ISOLATION TEST

LOAD

CAPACITY

110% Line Voltage

+/- 5%

AAMI ES1-1993 or IEC 601

(Selectable)

15 Amps, 30 Minutes

20 Amps, 5 Minutes

NORMAL SINUS

RHYTHM

RATE 30,60,120,240 BPM

PERFORMANCE

SINE WAVE 10,60,100 Hz

SQUARE WAVE 0.125, 2.000 Hz

TRIANGLE WAVE 2.000 Hz

20

Page 23

LEAD 1 1.75 mV

LEAD 2 2.75 mV

LEAD 3 1.00 mV

LEAD TO LEAD

IMPEDENCE

LEAD TEST

IMPEDENCE

OUTPUT

1000 Ohms

< 1000 Ohms

ACCURACY

AMPLITUDE +/- 2 % Lead II

FREQUENCY 0.5 %

PHYSICAL

ENCLOSURE

WEIGHT

DISPLAY .5 inch, 3 ½ digit LCD

FACE PLATE Lexan, Back printed

OPERATING RANGE 15 to 40 C

STORAGE RANGE -20 to 65 C

8.625 x 5.5 x 1.625 Inches

(219 x 140 x 41 mm)

ABS Plastic

<2.5 Lbs

(<1.1 Kg)

POWER

FUSE

ELECTRICAL

85 to 265 VAC, 50/60 Hz

5 VA

250 mA, 250 V

5X20 mm, Fast Acting

Receptacle Ground Leg

21

Page 24

APPENDIX A -- LABEL

The following is a representation of the label found on the back of the SA-2010S:

22

Page 25

NOTES

23

Loading...

Loading...