Page 1

INFUSION PUMP ANALYZER

IPA-1000

USER MANUAL

Page 2

Page 3

BC BIOMEDICAL

IPA-1000

TABLE OF CONTENTS

DESCRIPTION............................................................................................................. 3

OVERVIEW.................................................................................................................. 5

KEYS............................................................................................................................ 7

SCREENS.................................................................................................................... 8

MESSAGES ................................................................................................................. 10

SETUP ......................................................................................................................... 12

OPERATIONS.............................................................................................................. 13

CONNECTING CHAMBERS........................................................................... 13

THEORY OF OPERATIONS........................................................................... 14

RUNNING A TEST.......................................................................................... 15

OPTIMIZING MEASUREMENTS .................................................................... 16

MANUAL REVISIONS.................................................................................................. 17

WARRANTY................................................................................................................. 17

SPECIFICATIONS ....................................................................................................... 18

NOTES......................................................................................................................... 20

1

Page 4

iii

CAUTION

iii

ONLY DISTILLED WATER SHOULD BE USED IN THE CHAMBERS WITH THE

IPA-1000. DO NOT USE TAP WATER, GLUCOSE OR ANY OTHER FLUID;

THIS WILL CAUSE THE TUBING TO BECOME CONTAMINATED.

iii

N O T I C E

iii

BC GROUP INTERNATIONAL, INC. RESERVES THE RIGHT TO MAKE

CHANGES TO ITS PRODUCTS OR SPECIFICATIONS AT ANY TIME,

WITHOUT NOTICE, IN ORDER TO IMPROVE THE DESIGN OR

PERFORMANCE AND TO SUPPLY THE BEST POSSIBLE PRODUCT. THE

INFORMATION IN THIS MANUAL HAS BEEN CAREFULLY CHECKED

AND IS BELIEVED TO BE ACCURATE. HOWEVER, NO RESPONSIBILITY

IS ASSUMED FOR INACCURACIES.

Manual IPA-1000 Copyright © 2005

www.bcgroupintl.com

3/05 Rev 01

Made in the USA

2

Page 5

BC GROUP

IPA-1000

INFUSION PUMP ANALYZER

The Model IPA-1000 Series is a Microprocessor based High Precision infusion Pump

Analyzer (IPA). It tests the flow rate of intravenous (I.V.) infusion pumps. The flow rates

are displayed in milliliters per hour. The unit can test two volumetric pumps for output flow

rate simultaneously using two volumetric chambers.

The following are highlights of some of the main features.

IPA-1000 (BASIC FEATURES):

• LARGE GRAPHICS DISPLAY WITH CURSOR SELECTION OF

OPTIONS AND SETUP OF PARAMETERS

• +/- 1% OF READING FLOW ACCURACY

• STANDARD MILLITERS PER HOUR RANGE

• DIGITAL CALIBRATION – NO POTS TO TURN

• SELECTABLE DISPLAY OPTIONS AND DIGIT SIZES

• BATTERY LIFE DISPLAY (0 TO 100%)

• SOFTWARE ADJUSTABLE CONTRAST

• USES ANY COMBINATION OF CHAMBERS

• 3.5 ML & 35 ML CHAMBERS AVAILABLE

• SIMPLE TO MAINTAIN AND CLEAN (NO VALVES)

• REPLACEABLE TUBES

• SEALED LEVEL SENSORS

• AUTOMATIC DETECTION OF CONNECTED CHAMBER TYPE

• PROGRAMABLE END OF TEST AUDIO

• PROGRAMABLE AUTO OR MANUAL TEST START

• OPTIONAL BATTERY ELIMINATOR

3

Page 6

OPTIONAL ACCESSORIES:

• BE2000PU 120 VAC BATTERY ELIMINATOR, U.S.

• BE2000PE 220 VAC BATTERY ELIMINATOR, EUROPE

• BC20-30109 SOFT CARRYING CASE

AVAILABLE MODELS:

The base unit plus one of the volumetric chambers are required to test infusion pumps.

The part numbers are:

• IPA-1000 INFUSION PUMP ANALYZER BASE UNIT

• MC3.5-1000 3.5 mL VOLUMETRIC CHAMBER

• MC35-1000 35 mL VOLUMETRIC CHAMBER

4

Page 7

)

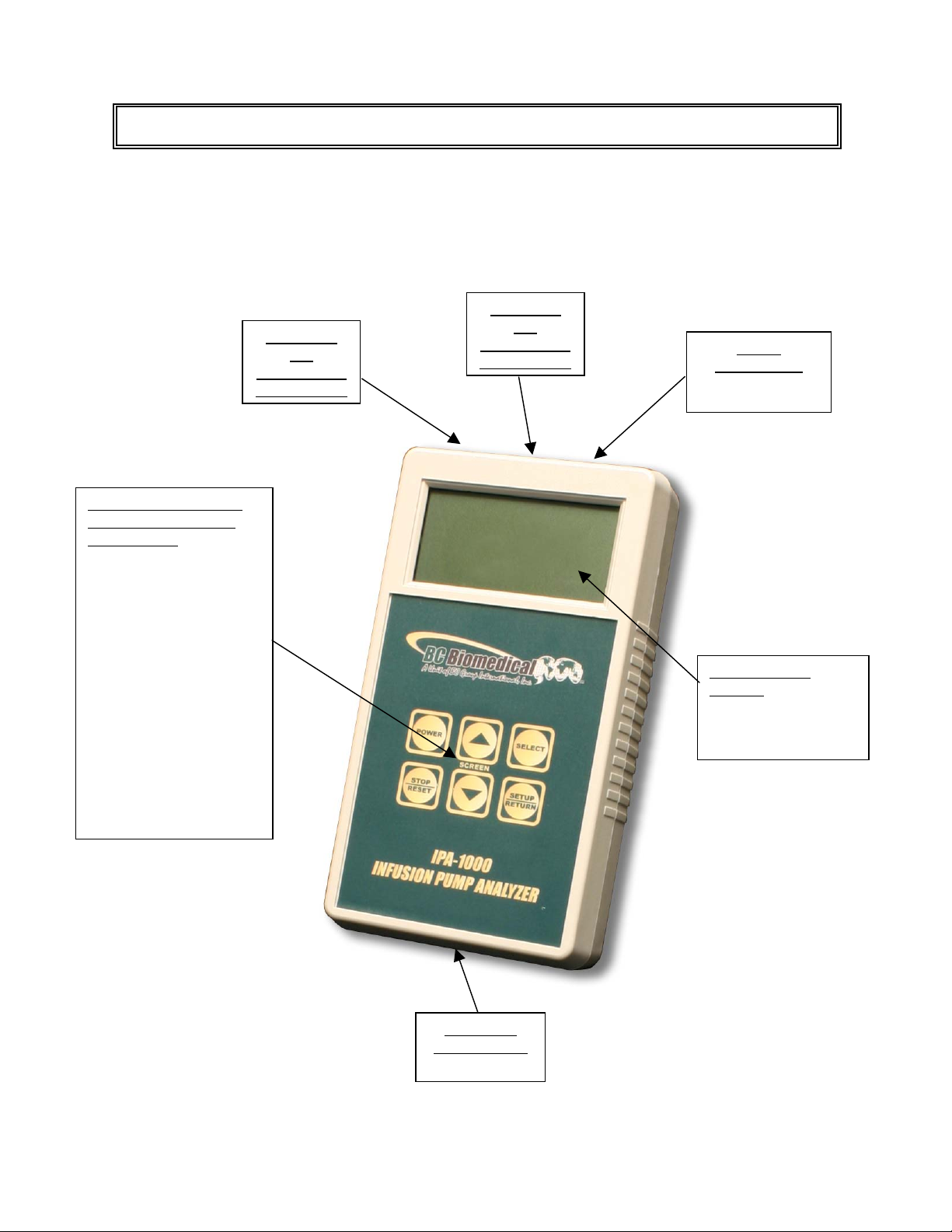

OVERVIEW

This section looks at the layout of the IPA-1000 and its Chambers and gives descriptions of

the elements that are present.

8 pin Mini-

8 pin Mini-

Din

connector for

connection to

6 Light Touch Keys for

Selecting Parameters

and Settings:

POWER for Turning Unit

On and Off

UP and DOWN Arrows

for Scrolling Through

Selected Options.

(When No Options are

Selected, for Changing

Display Screen.)

SELECT for Choosing

Setting or Parameter to

Change

SETUP/RETURN for

Entering and Exiting

Setup Menu

RESET for canceling a

test.

Din

connector for

connection to

Power

2.1 mm Jack

(Optional Battery

Eliminator

LCD Graphical

Display:

Shows Test Data,

Chamber Status and

Configuration Data

9V Battery

Compartment

(Back)

5

Page 8

3.5 mL Chamber

MC3.5-1000

35 mL Chamber

MC35-1000

8 pin Mini-

Din

connector for

connection to

8 pin Mini-

Din

connector for

connection to

Luer Lock

Connector for

Fluid In

6

Page 9

KEYS

Six tactile-touch keys are provided for system operation:

– This key turns the unit off and on. The unit will return to the screen that was

active when it was turned off.

– In the DISPLAY MODE, these keys toggle the display through the

available main screens.

In the SELECT MODE, if a parameter has been highlighted, these keys with scroll through

the available settings.

– On the Setup screen, there are a number of parameters that may be selected

and changed. This key sequences the cursor (Highlight) through those parameters.

– This key is used to STOP any of the running flow tests or to manually reset the

system if Auto Test Reset is set to NO. (See Setup Section for more details.)

– This key toggles the unit into and out of the Setup Mode. Depressing this key

will enter the Setup screen where the configuration can be viewed and adjusted.

Depressing the key again will exit the Setup Mode and return to the previously viewed

main screen.

7

Page 10

SCREENS

MAIN SCREENS

– There are four main screens: Chamber 1, Chamber 2, DUAL and

Connector. The available screens can be toggled using .

CHAMBER SCREENS

– The Chamber screens have a large time and flow rate display, as

shown below. The arrow at the top of the screen indicates the connector used for that

Chamber. The level indicator at the bottom of the screen identifies the level of water in the

Chamber.

MESSAGE DISPLAY

The display will resemble the following:

Chamber Not Detected

OR DATA

Ready For Flow

CONNECTOR

LOCATION

Chamber 1

Chamber 2

Flow Rate Too High

Invalid Sensor Sequence

Chamber Needs

Calibration

Low Battery

DATA

UNITS

Seconds

mL/hr

LEVEL

INDICATOR

See

Page 11

for special

graphics

8

Page 11

DUAL SCREEN – The DUAL screen shows the status of both Chambers at the same time.

MESSAGE DISPLAY

OR DATA

Chamber Not Detected

Ready For Flow

Flow Rate Too High

CONNECTOR

LOCATION

Chamber 1

Chamber 2

Invalid Sensor Sequence

Chamber Needs

Calibration

Low Battery

LEVEL

INDICATOR

See

DATA

UNITS

Page 11

for special

graphics

Seconds

mL/hr

CONNECTOR SCREEN

– The connector screen indicates the layout of the connectors at

the top of the IPA-1000. Also shown is the volume capacity of any connected Chambers.

VOLUME

3.5 mL

35 mL

Not Detected

9

Page 12

MESSAGES

Several status messages are available to indicate the present state of the system. The

following is a brief description of the available messages:

CHAMBER NOT DETECTED – This message indicates that a Chamber has not been

detected.

READY FOR FLOW– This message indicates that the Chamber is reset and waiting for

fluid to be detected at the bottom sensor. As soon as fluid is detected, the timer will begin

running and the test will begin. The test ends when the fluid reaches the top sensor or

when the Reset key is depressed.

FLOW RATE TOO HIGH – This message indicates that the flow rate is higher than the

resolution of the meter.

INVALID SENSOR SEQUENCE– This message indicates that water is detected at the top

sensor but not at the bottom sensor. This could be caused by either a bad sensor or a

bubble in the tube.

CHAMBER NEEDS CALIBRATION– This message indicates that a Chamber has been

detected, but the calibration data stored in the Chamber is invalid. The Chamber should be

returned for re-calibration.

10

Page 13

LOW BATTERY– This message indicates that the batteries are low and should be

replaced.

LEVEL INDICATOR

A special graphic has been incorporated into the display to identify the level of water in

each Chamber. The graphic is located at the lower right corner of the display for each

channel.

This graphic indicates that water is not present at the lower or upper sensor.

This graphic indicates that fluid is present at the lower sensor.

These graphics are displayed sequentially to indicate that a test is running.

This graphic indicates that water is detected at the top and bottom sensor.

This graphic indicates that water is present at the top sensor, but not the bottom.

This is an invalid condition, indicative of either a bubble at the bottom sensor or a

faulty sensor.

11

Page 14

SETUP

The Setup Mode allows the user to adjust the configuration of the meter. The Setup screen

can be entered using the key. The parameters can be changed by using

key to highlight the line and to toggle the available options.

The Setup screen can be exited using the key.

The following is a breakdown of the parameters available in the configuration of the unit

and their available options:

System Setup Configuration

Parameter Description Range

Determines the period of inactivity before the unit is

turned OFF. A timer is started when the unit is

turned ON and is reset each time a key is pressed.

When the timer reaches the value set in this

Auto Off Timer (Min)

Auto Test Reset

End of Test Beeps

Contrast Adjust

parameter, the power is automatically turned OFF.

(NOTE: Setting this parameter to 0 disables the

Auto Off timer. When running from line power, the

unit does not automatically shut off. Auto Off timer

is inactive during a test.)

The auto reset mode automatically resets the

system for a new flow test when the tube is

emptied. If Auto Test Reset is set to NO, the user

must manually press the RESET key to configure

the system for another test.

This determines the number of times that the unit

will beep at the completion of a test. If set to zero,

the unit will not beep.

Sets the contrast of the display screen.

0-30 Minutes

YES/NO

0-15

0-20

Battery Life

Software

Displays current life of the battery.

At 10%, a warning screen will appear.

At 0%, the unit will power down automatically.

Displays current software program.

12

0-100%

(Read Only)

(Read Only)

Page 15

OPERATIONS

CONNECTING CHAMBERS

Chambers are connected to the base unit with a straight through 8Pin Mini Din male

to 8Pin Mini Din Male cable. Chambers can be connected or disconnected at any time.

Disconnecting a chamber while a test is running will cancel the test.

As a chamber is connected or disconnected, the display will change to display the

available chambers. For example, if a test is running on Channel 1 and a second Chamber

is plugged into Channel 2, the display will automatically change to the dual display mode. If

both chambers are connected and Chamber 1 is removed, the display will automatically

change to the large screen displaying Chamber 2.

NOTE: The screen can always be manually changed by using the keys.

13

Page 16

THEORY OF OPERATIONS

Infrared sensors are used to detect the presence of water in the chamber. There are

two sensors in each chamber. As water is detected at the bottom sensor, an internal timer

is started. The timer runs internally in hundredths of seconds but is only displayed in tenths

of seconds. The test automatically ends when water is detected at the top sensor. A

buzzer will sound to indicate that the test is complete. The buzzer can be programmed to

sound for a specific number of beeps (0-15 beeps, see setup).

The flow rate is calculated based on the volume of the chamber and the time

required to fill the tube. The volume of the chamber is calibrated and stored internally in

the chamber. Since the calibration data is stored in the chamber, they are interchangeable

with any base unit.

A test in progress can be aborted by pressing the key, by disconnecting

the chamber or by water not being detected at the bottom sensor.

14

Page 17

RUNNING A TEST

To run a flow test, the chamber must be Ready for Flow, as indicated in the base

unit display (see Messages). When the base unit is setup for Manual Reset, the

key must be used to manually reset the unit after each test. When the base unit is setup

for Automatic Reset, the chamber will be automatically reset when the water level drops

below the bottom sensor.

A flow test can be started whenever the display indicates “Ready for Flow”. The

flow test is started by water being detected at the bottom sensor. Before initiating the flow

on the Infusion pump under test, ensure that the pump is programmed to deliver a sufficient

amount of water to fill the chamber to the top sensor.

NOTE: The chamber volumes of 3.5mL and 35mL are nominal; it is advised that delivery

volume should be about 4 mL and 40 mL respectively.

15

Page 18

OPTIMIZING MEASUREMENTS

To optimize the performance of the IPA-1000, it is recommended that a wetting

agent be used to minimize the surface tension of the test solution. The test solution should

be Distilled water mixed with “MICRO-90.” “MICRO-90” can be purchased from

Cole- Parmer in a 1% solution (Part Number A-18100-01, www.coleparmer.com

,

1-800-323-4340). Further dilute the “MICRO –90” by using one part of “MICRO-90” to

10 parts of Distilled water. If foaming becomes a problem, dilute the “MICRO-90” to a

20:1 solution.

The sheeting action of the test solution has a minor effect on test results. It is

recommended to discard the first reading of a device under test. Run the test and then

repeat the test. Only record data from the second test.

Any droplets remaining in the chamber after a test run will affect the accuracy of the

test results. Adjust the drain rate to minimize the droplets.

iii

ONLY DISTILLED WATER SHOULD BE USED IN THE CHAMBERS WITH THE

IPA-1000. DO NOT USE TAP WATER, GLUCOSE OR ANY OTHER FLUID;

THIS WILL CAUSE THE TUBING TO BECOME CONTAMINATED.

CAUTION

16

iii

Page 19

A

A

MANUAL REVISIONS

Revision #

Program # Revisions Made

Rev 01 DT7312CA Preliminary Manual

Rev 02 DT7312CA Page Numbers adjusted

LIMITED WARRANTY

WARRANTY

FROM DEFECTS IN MATERIALS AND WORKMANSHIP UNDER THE SERVICE FOR WHICH THEY

RE INTENDED. THIS WARRANTY IS EFFECTIVE FOR TWELVE MONTHS FROM THE DATE OF

SHIPMENT.

EXCLUSIONS: THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

BC GROUP INTERNATIONAL, INC. IS NOT LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

NO PERSON OTHER THAN AN OFFICER IS AUTHORIZED TO GIVE ANY OTHER WARRANTY OR

SSUME ANY LIABILITY.

REMEDIES: THE PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE: (1) THE REPAIR OR

REPLACEMENT OF DEFECTIVE PARTS OR PRODUCTS, WITHOUT CHARGE. (2) AT THE OPTION

OF BC GROUP INTERNATIONAL, INC., THE REFUND OF THE PURCHASE PRICE.

: BC GROUP INTERNATIONAL, INC. WARRANTS ITS NEW PRODUCTS TO BE FREE

17

Page 20

SPECIFICATIONS

IPA-1000 UNIT

FLOW RANGE

3.5 mL CHAMBER

FLOW RANGE

35 mL CHAMBER

FLOW RESOLUTION

FLOW ACCURACY

TIME RESOLUTION

INTERNAL

DISPLAY

SETUP MEMORY

MEMORY RETENTION

OPERATING RANGE

STORAGE RANGE

CONSTRUCTION

SIZE

WEIGHT

CONNECTIONS

FOR BASE UNIT

INTERCONNECT CABLE

POWER

POWER CONSUMPTION

BATTERY LIFE

BATTERY ELIMINATOR

(OPTIONAL)

0.0 to 999.9 mL/hr

15.0 to 9999.9 mL/hr

0.1 mL/hr

+/- 1% RDG, +/- LSD

0.01 Seconds

LCD Graphical 128 X 64 Pixels

EEPROM, All Parameters

10 Years w/o Power

0 to 50 Degrees C

-40 to 60 Degrees C

Enclosure - ABS Plastic

Face - Lexan, Back Printed

7.09 x 3.94 x 1.56 inches

180 x 100 x 40 mm

(HxWxD)

<

1 lbs. (0.45 kg)

Power - 2.1 mm Center Negative

Chamber - 8 pin Mini Din Female

8 pin Mini Din Male to 8 pin Mini Din

Male Straight Through

LINE: 9VDC, Center Negative

BATTERY

ON:

No Modules - 8 mA, 1 Module - 12 mA,

2 Modules - 16 mA

OFF:

less than 60µA

CONTINUOUS: TBD

OFF: 12 months

BE2000PU (120 VAC) - US

BE2000PE (220 VAC) - Euro

9V, 200 mA DC

: 9V Alkaline

18

Page 21

3.5 mL and 35mL CHAMBERS

FLOW RANGE

3.5 mL CHAMBER

FLOW RANGE

35 mL CHAMBER

FLOW RESOLUTION

FLOW ACCURACY

15.0 to 9999.9 mL/hr

0.1 mL/hr

+/- 1% RDG, +/- LSD

OPERATING RANGE

STORAGE RANGE

CONSTRUCTION

0 to 50 Degrees C

Enclosure - ABS Plastic

SIZE

14.0 x 5.0 x 3.5 inches

356 x 127 x 89 mm

(HxWxD)

WEIGHT

CONNECTIONS

FOR CHAMBERS

INTERCONNECT CABLE

FLOW MEDIA

<

Unit - 8 pin Mini Din Female

Flow Media - Luer Lock

8 pin Mini Din Male to 8 pin Mini Din

Male Straight Through

Distilled Water

P:\MANUALS\BCGroup\…\IPA-1000_UM_rev02.doc

0.0 to 999.9 mL/hr

-40 to 60 Degrees C

2.2 lbs (1 kg)

19

Page 22

NOTES

20

Loading...

Loading...