Page 1

ELECTROSURGICAL

UNIT ANALYZER

ESU-2400 Series

USER MANUAL

Page 2

Page 3

i

WARNINGS, CAUTIONS, NOTICES ........................................................................... iii

DESCRIPTION ............................................................................................................. 1

Accessories .............................................................................................................. 3

OVERVIEW .................................................................................................................... 7

TYPICAL MEASUREMENT CONNECTIONS ................................................................. 8

Monopolar ................................................................ ................................ ................. 8

Bipolar ........................................................................................................................ 9

External Loads ......................................................................................................... 10

Tissue Response Test ............................................................................................. 12

Leakage Mode 1a .................................................................................................... 13

Leakage Mode 1b .................................................................................................... 14

Leakage Mode 2 ...................................................................................................... 15

Leakage Mode 3 ...................................................................................................... 16

GETTING STARTED

ForceTriad™ Preventative Maintenance .................................................................. 17

Measure RF Energy

Scenario 1: Measure mA, 500 ohm load, manual DUT trigger .............................. 18

Scenario 2: Measure mA and Watts, 300 ohm load, footswitch triggers DUT ....... 20

Scenario 3: Measure Hyfrecator mA, 200 ohm load, manual DUT trigger ............ 23

Scenario 4: Measure mA and kHz, 200 ohm load, manual DUT, Pulse Mode 1 ... 25

Scenario 5: Measure V, Delayed Mode ................................................................. 28

Measure RF Leakage

Leakage Test 1a: Active to Ground ....................................................................... 31

Leakage Test 1b: Dispersive to Ground ................................................................ 33

Leakage Test 2: Ground Referenced DUT, Active to Ground ............................... 35

Leakage Test 3: Ground Referenced DUT, Dispersive to Ground ........................ 37

REM/ARM/CQM Test

Scenario 1: Test REM at 35 ohms ........................................................................ 39

Scenario 2: Increase REM by 40% ....................................................................... 40

BC BIOMEDICAL

ESU-2400 SERIES

TABLE OF CONTENTS

Page 4

ii

Load Curves

Scenario 1: Bipolar, 60W, 100 to 1000 ohms, auto trigger DUT ............................ 41

Scenario 2: Pure Cut, 300W, Load List, manual trigger DUT ................................ 44

Autosequence

RF Measure: 200 ohms, 315mA Limit, ±10mA ...................................................... 47

Load Curve: Pure Cut, 300W, 50-5000 ohms, Manual Trigger ............................. 50

Auto CQM ............................................................................................................. 52

MAIN SCREEN ............................................................................................................. 54

AUTOSEQUENCES ...................................................................................................... 57

Running the Autosequence ................................................................................ 74

Autosequence Results ....................................................................................... 78

MEASURE RF ENERGY .............................................................................................. 79

Tissue Response Test ........................................................................................ 80

Parameter Descriptions ...................................................................................... 82

Graph Screen ..................................................................................................... 85

Footswitch Configuration ................................ .................................................... 87

ESU-2400H Advanced Input Modes ................................................................... 89

POWER LOAD CURVES ............................................................................................. 97

REM/ARM/CQM ......................................................................................................... 104

MEASURE RF LEAKAGE .......................................................................................... 105

SYSTEM TOOLS ....................................................................................................... 112

Transfer Files .................................................................................................... 112

Time and Date Setup ....................................................................................... 113

Touchscreen Calibration .................................................................................. 114

System Setup .................................................................................................. 115

System Version and Updates .......................................................................... 116

Networking....................................................................................................... 121

Remote Mode ................................................................................................... 122

Internet Access ................................................................................................ 124

RS-232 Terminal .............................................................................................. 124

Page 5

iii

COMMON DIALOG SCREENS .................................................................................. 126

File Open ......................................................................................................... 126

File Save ......................................................................................................... 127

Keypad ............................................................................................................ 128

Numpad ........................................................................................................... 129

Print ................................................................................................................. 130

KEYBOARD / MOUSE ............................................................................................... 133

BARCODE SCANNER ............................................................................................... 133

ERROR MESSAGES ................................................................................................. 134

SYSTEM INPUTS AND OUTPUTS ............................................................................ 137

DFA® TECHNOLOGY ............................................................................................... 139

FOOTSWITCH CONNECTOR ................................ .................................................... 140

COMMUNICATION PROTOCOL ................................................................................ 141

COMMUNICATION COMMAND SUMMARY .............................................................. 148

FREQUENTLY ASKED QUESTIONS (FAQ) .............................................................. 162

MANUAL REVISIONS ................................................................................................ 164

LIMITED WARRANTY ................................................................................................ 164

SPECIFICATIONS ..................................................................................................... 166

NOTES ....................................................................................................................... 174

CALIBRATION INTERVAL

To ensure the accuracy of the ESU-2400 Series

Analyzers, BC Group International, Inc.

recommends that it be calibrated at least once

every 12 months. Calibration must be done by

qualified personnel. Contact BC Group

International, Inc. for calibration.

Page 6

iv

WARNING - USERS

The ESU-2400 Series is for use by

skilled technical personnel only.

WARNING - USE

The ESU-2400 Series is intended for testing only

and should never be used in diagnostics,

treatment or any other capacity where it would

come in contact with a patient.

WARNING - CONNECTIONS

All connections to patients must be removed

before connecting the DUT to the ESU-2400

Series. A serious hazard may occur if the patient

is connected when testing with the ESU-2400

Series. Do not connect any leads from the patient

directly to the ESU-2400 Series or DUT.

WARNING - POWER ADAPTOR

Unplug the Power Adaptor before

cleaning the surface of the ESU-2400 Series.

WARNING - MODIFICATIONS

The ESU-2400 Series is intended for use within

the published specifications. Any application

beyond these specifications or any unauthorized

user modifications may result in hazards or

improper operation.

WARNING - USE

Never touch exposed metal surfaces on test

leads or other current-carrying parts while the

DUT is activated.

Page 7

v

WARNING - LIQUIDS

Do not submerge or spill liquids on the

ESU-2400 Series. Do not operate the ESU-2400

Series if internal components not intended for

use with fluids may have been exposed to fluid,

as the internal leakage may have caused

corrosion and be a potential hazard.

Page 8

vi

CAUTION - SERVICE

The ESU-2400 Series is intended to be serviced

only by authorized service personnel.

Troubleshooting and service procedures

should only be performed by

qualified technical personnel.

CAUTION - ENVIRONMENT

Exposure to environmental conditions outside

the specifications can adversely affect the

performance of the ESU-2400 Series. Allow ESU-

2400 Series to acclimate to specified conditions

for at least 30 minutes before attempting to

operate it.

CAUTION - CLEANING

Do not immerse. The ESU-2400 Series should be

cleaned by wiping gently with a damp, lint-free

cloth. A mild detergent can be used if desired.

CAUTION - INSPECTION

The ESU-2400 Series should be

inspected before each use for wear and

the ESU-2400 Series should be serviced

if any parts are in question.

CAUTION - VENTILATION

The ESU-2400 Series includes ventilation slots to

help prevent overheating during operation and

should not be blocked.

Page 9

vii

Page 10

viii

NOTICE – SYMBOLS

Symbol Description

Caution

(Consult Manual for Further Information)

Per European Council Directive

2002/95/EC, do not dispose of this

product as unsorted municipal waste.

NOTICE – ABBREVIATIONS

AAMI

Association for the Advancement of Medical Instrumentation

Amps

Amperes

ANSI

American National Standards Institute

ARM™

Aspen Return Monitor

C

Celsius

CF

Crest Factor

CQM

Contact Quality Monitor

°

Degree

DFA

Digital Fast Acquisition

DUT

Device Under Test

hrs

Hours

Hz

Hertz

IEC

International Electrotechnical Commission

kg

Kilogram(s)

kHz

kilohertz

lbs

Pounds

MHz

Megahertz

mA

Milliampere(s)

mm

Millimeter(s)

ms

Millisecond(s)

mV

Millivolt(s)

Ω

Ohm(s)

PC

Personal Computer

Pk

Peak

REM

Return Electrode Monitor

RF

Radio Frequency

RMS

Root Mean Square

USA

United States of America

V

Volt(s)

Page 11

ix

NOTICE – PERFORMING TESTS

REFER TO DUT MANUFACTURER’S SERVICE MANUAL FOR

TEST PROCEDURES AND MEASUREMENT LIMITS.

NOTICE – DISCLAIMER

USER ASSUMES FULL RESPONSIBILITY FOR UNAUTHORIZED

EQUIPMENT MODIFICATIONS OR APPLICATION OF EQUIPMENT

OUTSIDE OF THE PUBLISHED INTENDED USE AND

SPECIFICATIONS. SUCH MODIFICATIONS OR APPLICATIONS

MAY RESULT IN EQUIPMENT DAMAGE OR PERSONAL INJURY.

NOTICE – DISCLAIMER

BC GROUP INTERNATIONAL, INC. RESERVES THE RIGHT TO

MAKE CHANGES TO ITS PRODUCTS OR SPECIFICATIONS AT

ANY TIME, WITHOUT NOTICE, IN ORDER TO IMPROVE THE

DESIGN OR PERFORMANCE AND TO SUPPLY THE BEST

POSSIBLE PRODUCT. THE INFORMATION IN THIS MANUAL

HAS BEEN CAREFULLY CHECKED AND IS BELIEVED TO BE

ACCURATE. HOWEVER, NO RESPONSIBILITY IS ASSUMED

FOR INACCURACIES.

NOTICE – TRADEMARKS

Valleylab™, ForceTriad™, LigaSure™, REM™, and

ForceTriVerse™ are trademarks of Covidien.

Copyright © 2012 Covidien. All rights reserved. Reprinted

with the permission of the Surgical Solutions business unit of

Covidien.

Page 12

x

ESU-2400 Series User Manual Copyright © 2017

www.bcgroupintl.com Made in the USA

11/17 Rev 10

NOTICE – CONTACT INFORMATION

BC BIOMEDICAL

BC GROUP INTERNATIONAL, INC.

3081 ELM POINT INDUSTRIAL DRIVE

ST. CHARLES, MO 63301

USA

1-800-242-8428

1-314-638-3800

www.bcgroupintl.com

sales@bcgroupintl.com

esu.bcgroupintl.com

Page 13

1

This manual covers the model ESU-2400 and ESU-2400H Electrosurgical Unit Analyzers.

Throughout this manual the term ESU-2400 will be used to apply to both models. Sections

that are specific to the ESU-2400H model will use the term ESU-2400H exclusively.

The Model ESU-2400 Electrosurgical Unit Analyzer is a high-accuracy True RMS RF

Measurement system designed to be used in the calibration and routine performance

verification of Electrosurgical Generators. It offers a higher degree of accuracy than

previously attainable with conventional Electrosurgical Unit Analyzer designs. The ESU2400 provides an advanced low reactance internal load bank with a range of 0 to 6400

ohms in 1 ohm increments. It is microprocessor based and utilizes a combination of

unique hardware and software to provide accurate and reliable test results, even from

difficult waveforms such as “Spray”. The DFA Technology® utilized in the ESU-2400 and

DFA2 Technology® (Patent Pending) utilized in the ESU-2400H allow the system to

aggressively digitize the complex RF waveforms produced by Electrosurgical Generators,

analyze each individual digital data point, and provide highly accurate measurement

results.

The ESU-2400, unlike many conventional ESU Analyzers, has internal high voltage setup

relays to control the measurement path, allowing the user to switch between Power

measurements, Leakage measurements, REM/ARM/CQM testing, or even run an

autosequence that could include any or all of these tests – without even moving wires

around!

The current transformer internal to the ESU-2400 senses the RF current flowing through

the internal test load and produces a ratiometric voltage which is digitized and analyzed

by the microprocessor. Combining the standard and low ranges of the ESU-2400 with the

use of the current transformer, the user has full control over the ability to get high accuracy

and high resolution readings from all types of Electrosurgical Generators.

BC BIOMEDICAL

ESU-2400

ELECTROSURGICAL UNIT ANALYZER

Page 14

2

The following are highlights of some of the main features:

• TRUE RMS READINGS USING DFA® TECHNOLOGY

• INDUSTRY STANDARD CURRENT SENSING TECHNOLOGY

• mV, mV PEAK, mA, CREST FACTOR AND POWER (WATTS)

RANGES, LOAD VOLTAGE(ESU-2400H only)

• COLOR QVGA DISPLAY WITH TOUCHSCREEN

• 1% OF READING MEASUREMENT ACCURACY

• DIGITAL CALIBRATION – NO POTS TO TURN

• SELECTABLE DISPLAY OPTIONS

• GRAPHICAL ON-SCREEN REPRESENTATION OF MEASURED

RF SIGNAL

• HIGH RANGE (1000 mV) AND LOW RANGE (100 mV) WITH

AUTOSCALING CAPABILITY

• PULSED RF WAVEFORM MEASUREMENT MODE FOR LOW

DUTY CYCLE PULSED OUTPUTS OFFERED BY SOME

ELECTROSURGICAL MANUFACTURERS

• PROGRAMMABLE AUTOSEQUENCES

• PROGRAMMABLE LOAD CURVES

• BUILT IN CQM TESTING WITH ONE OHM RESOLUTION

• TISSUE RESPONSE TESTING WITH GRAPHING CAPABILITY

• FOOTSWITCH OUTPUTS FOR TRIGGERING THE DUT

• ON-SCREEN DISPLAY OF MEASURMENT CONFIGURATION

• USB PORTS FOR KEYBOARD, MOUSE, PRINTER, OR FLASH

DRIVE.

• ETHERNET PORT FOR INCREASED ACCESSIBILITY

Page 15

3

STANDARD ACCESSORIES:

BC20 – 00130 Accessory Kit (Test Leads)

BC20 – 21107 Universal Power Supply

BC20 – 41341 Communications Cable (RS-232)

BC20 – 205XX Standard Power Adapter

(International Options, See Page 138 For Details)

Standard Accessory Kit, BC20-00130:

OPTIONAL ACCESSORIES:

BC20 – 00131 ForceTriad PM Accessory Kit

BC20 – 00132 CONMED PM Kit

BC20 – 00133 CONMED Automation Kit

BC20 – 00140 Replacement packaging

BC20 – 41360 Communications Cable, USB Null Modem

BC20 – 00232 BNC To BNC Cable

BC20 – 03000 Footswitch Cable, Unterminated

BC20 – 03001 Footswitch Cable for Covidien ForceFx

BC20 – 03002 Footswitch Cable for CONMED System 5000

BC20 – 03003 Footswitch Cable for Covidien ForceTriad

BC20 – 03004 Footswitch Simulator for Covidien ForceFx and

ForceTriad, triggers Cut, Coag, Bipolar

Ground

Lug

Active

Lead

CQM

Lead

Banana

Jack

Alligator

Clips

Earth/Ground

Lead

RECQM

Lead

Dispersive

Lead

Page 16

4

BC20 – 03005 Monopolar Hand Switch Simulator

BC20 – 03006 Footswitch Cable for Olympus ESG-100

BC20 – 03007 Footswitch Cable for Olympus ESG-400

TRL – 2420 Tissue Response Load

Page 17

5

OPTIONAL ACCESSORIES (continued):

Optional Accessory Kit, BC20-00131, ForceTriad PM Accessory Kit

BC20-03004

Footswitch Simulator

TRL-2420

Tissue Response Load

BC20-03005

Monopolar Handpiece

Simulator

Autobipolar

Lead

Cross Coupling

Lead

Carrying

Case

UFP Port

Adapter

External Cross

Coupling Load

Cross

Coupling

Lead

Page 18

6

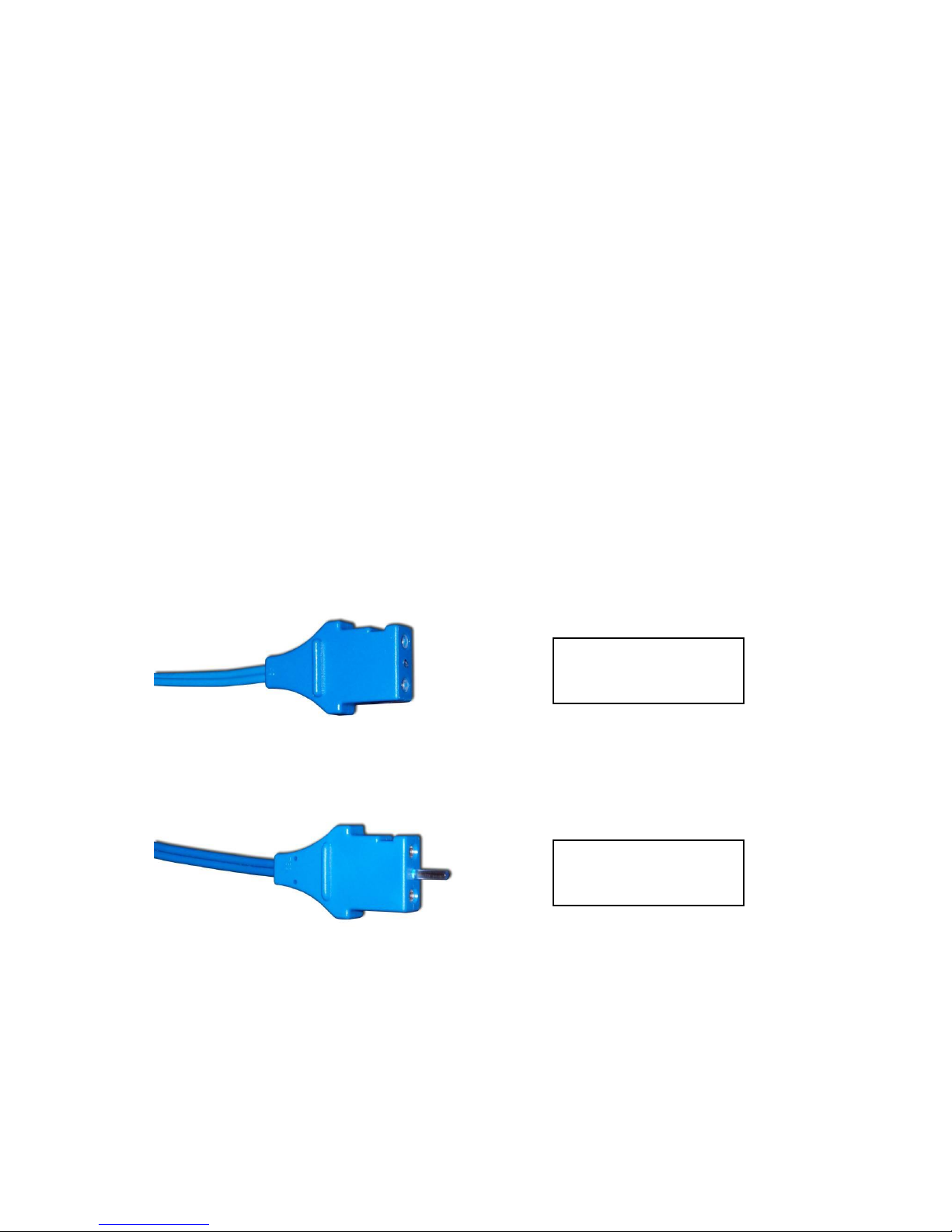

CQM Cable Differences – Two CQM cables are provided in the standard accessory kit.

The only difference between them is that one cable has a small pin and the other does

not. The cable with the pin is used to enable the REM circuitry on the DUT. The cable

without the pin is used to bypass the REM circuit and allow for shorting of the REM leads.

Note that some generators do not allow for the REM circuit to be disabled. For these

generators it does not matter which cable is used.

When using the ESU-2400 CQM test mode, the cable with the pin must be used.

For other modes, the Dispersive ports on the ESU-2400 are shorted together and the

cable without the pin should be used.

Cable Without Pin,

Disabled REM

Cable With Center

Pin, Enables REM

Page 19

7

This section looks at the layout of the ESU-2400 and gives descriptions of the elements

that are present.

Swivel

Carrying

Handle

Computer Interface

Serial Port

2 USB Ports

10/100 Ethernet

Power

Kycon 3 position

locking

receptacle

QVGA

Display with

touchscreen

Durable Powder-Coated,

Custom Aluminum Case

Front USB Port

Power Switch

Rocker Switch

Oscilloscope

Output

Footswitch Interface

Automated DUT

Activation

Safety Jacks

RF Input

OVERVIEW

Page 20

8

The ESU-2400 Series utilizes an internal current transformer and internal precision load

resistors for simple configuration of typical Electrosurgical Generator testing. Many of the

world’s leading Electrosurgical generator manufacturers utilize this exact same technique

when they test, service and calibrate their generators.

Internal configuration relays allow for simple connections to the DUT. When the Measure

RF Energy, Measure RF Leakage, or REM/ARM/CQM mode is selected from the main

menu, the relays configure the internal connections as required. Shown below are

examples of external connections to the DUT.

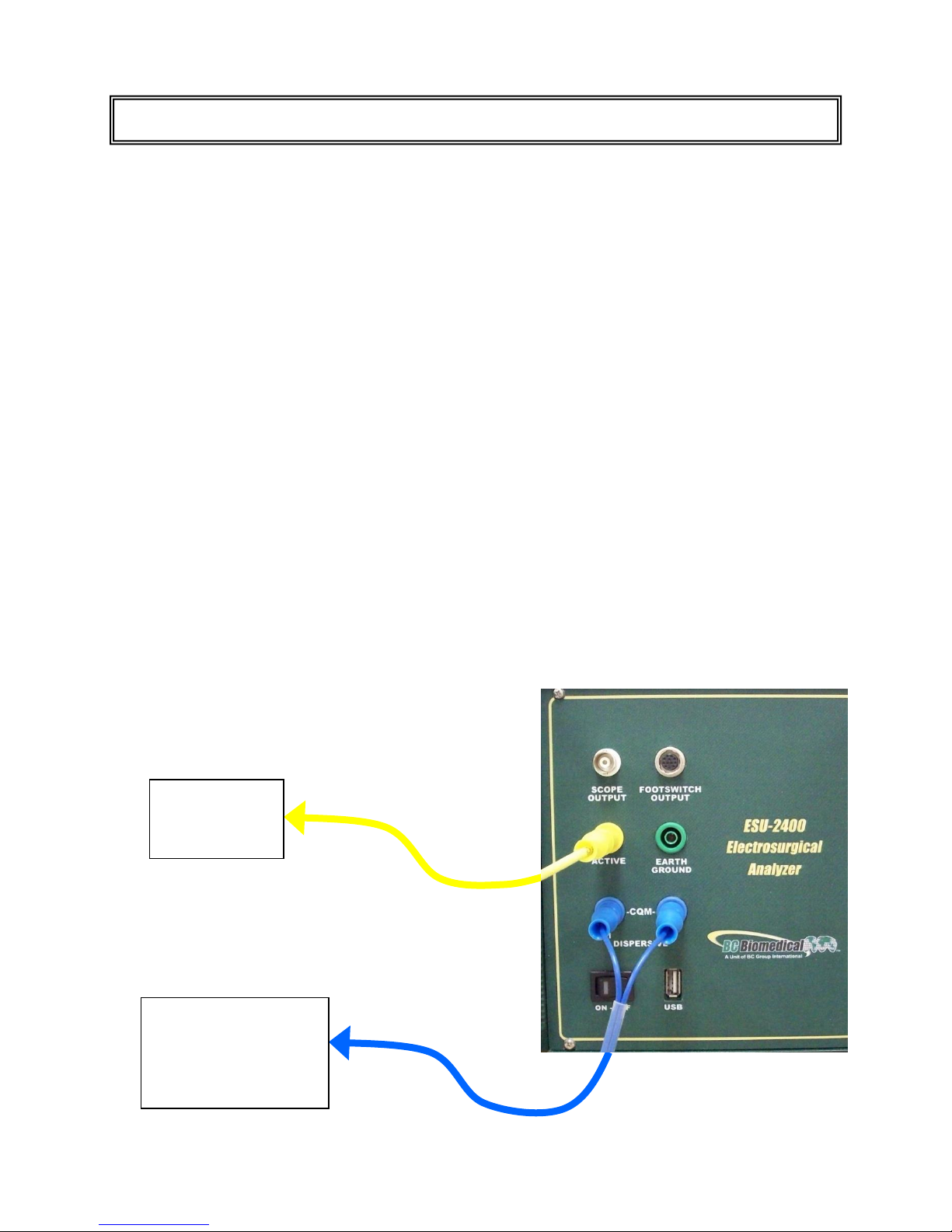

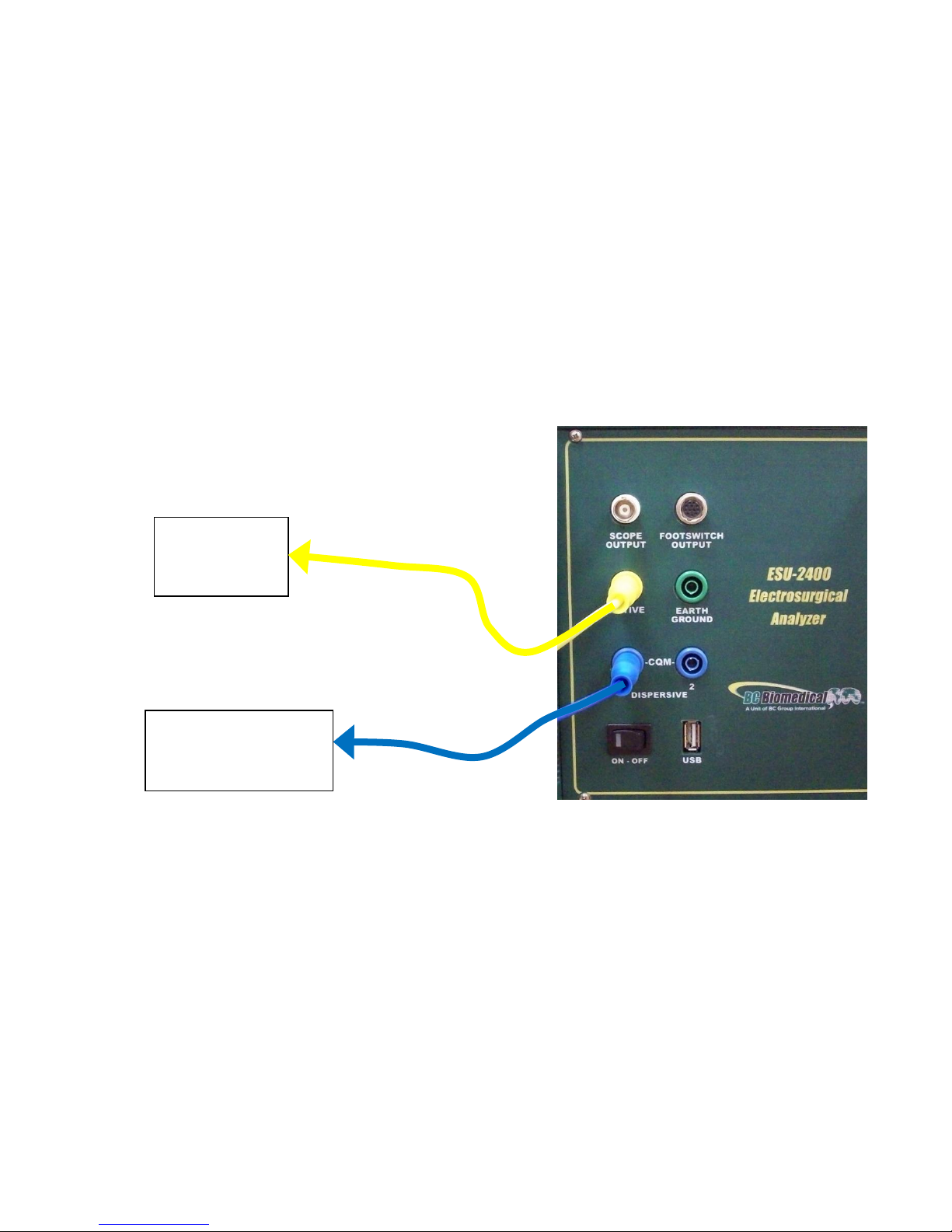

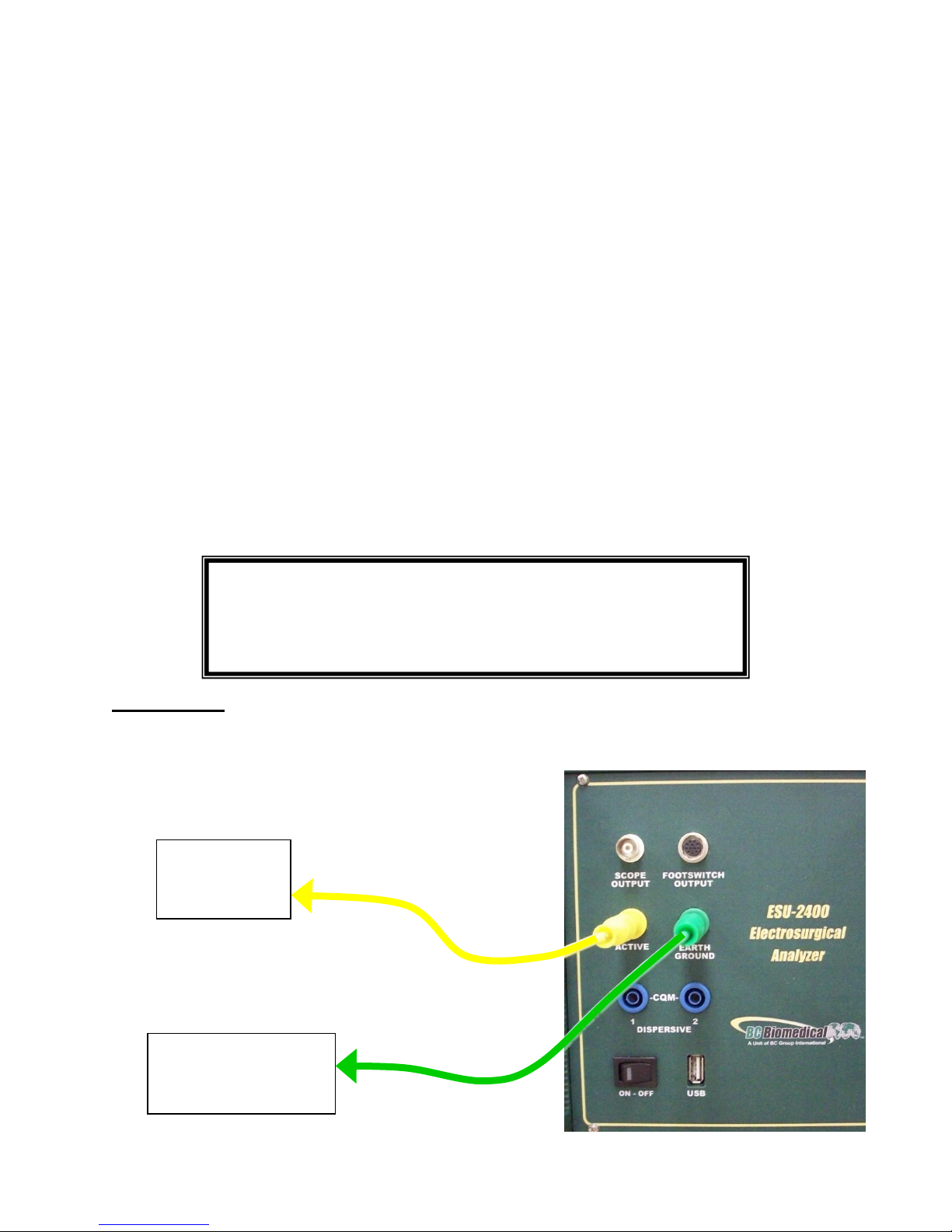

Monopolar:

1. Yellow Active Lead from Active Jack on ESU-2400 to DUT Output.

2. Blue Dispersive Lead from Dispersive Jack on ESU-2400 to DUT Dispersive.

TYPICAL MEASUREMENT CONNECTIONS

ESU (DUT)

Active

Electrode

ESU (DUT)

Patient Return/

Dispersive

Electrode

Page 21

9

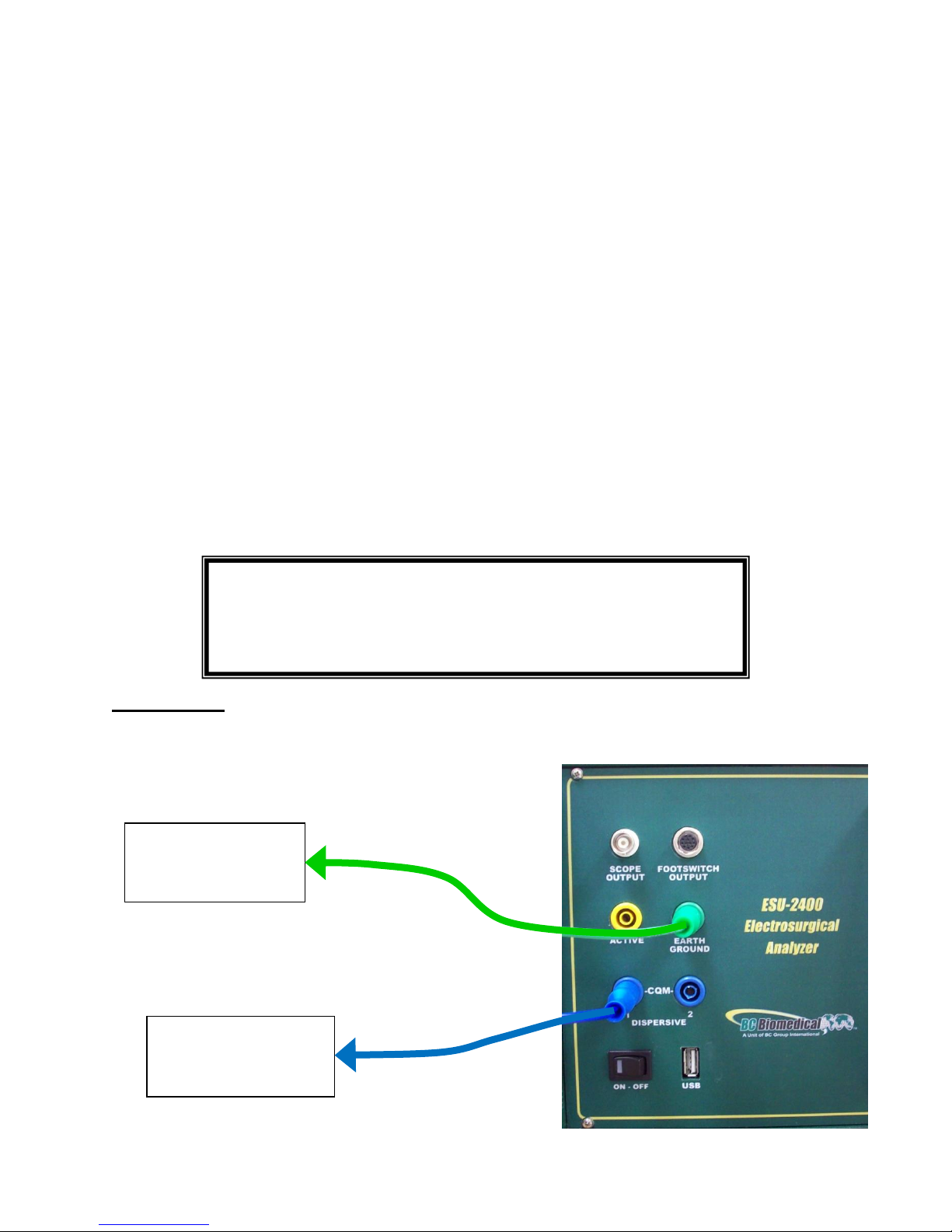

Bipolar:

1. Yellow Active Lead from Active Jack on ESU-2400 to DUT Bipolar Output

Electrode #1.

2. Blue Lead from Dispersive1 Jack on ESU-2400 to DUT Bipolar Output

Electrode #2.

ESU (DUT)

Bipolar

Electrode #1

ESU (DUT)

Bipolar

Electrode #2

Page 22

10

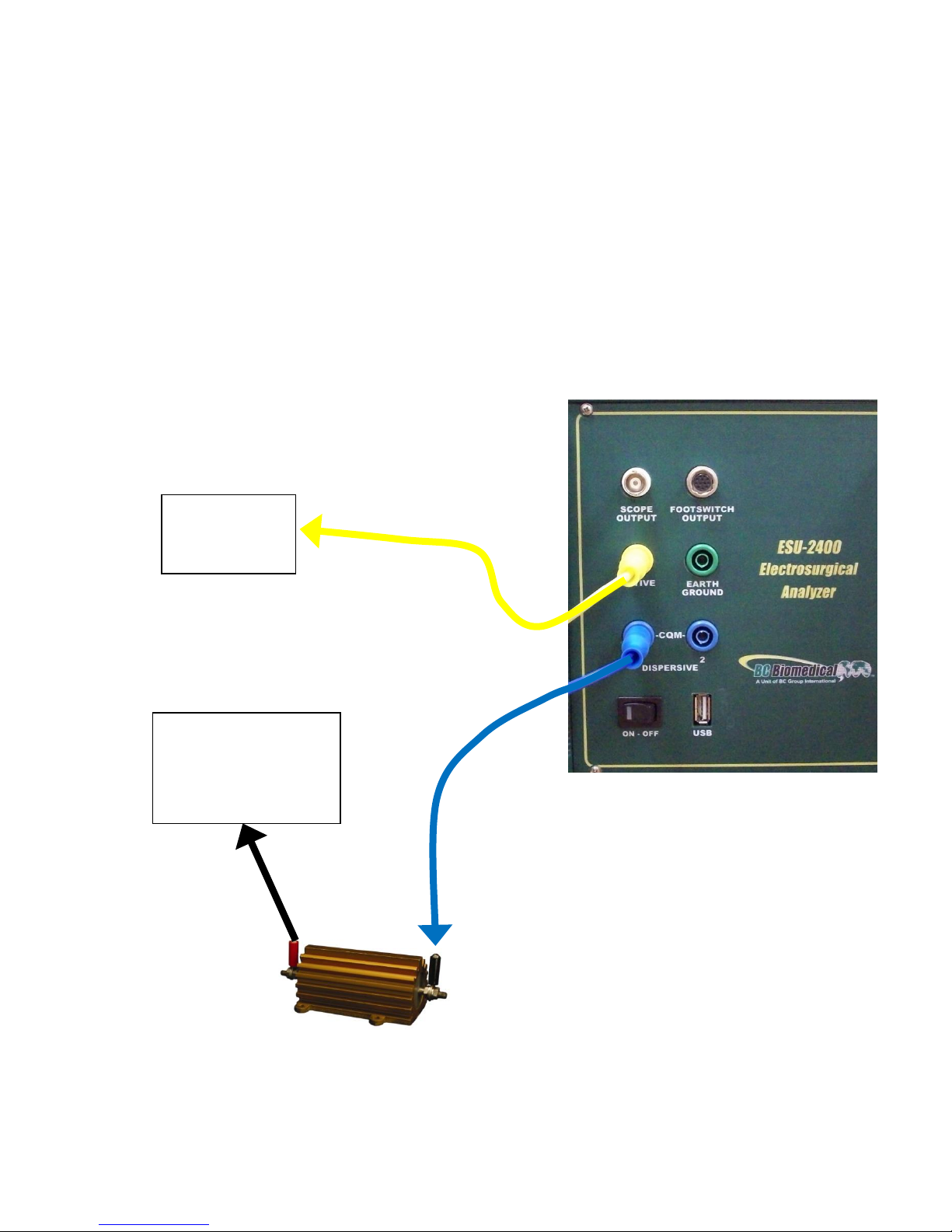

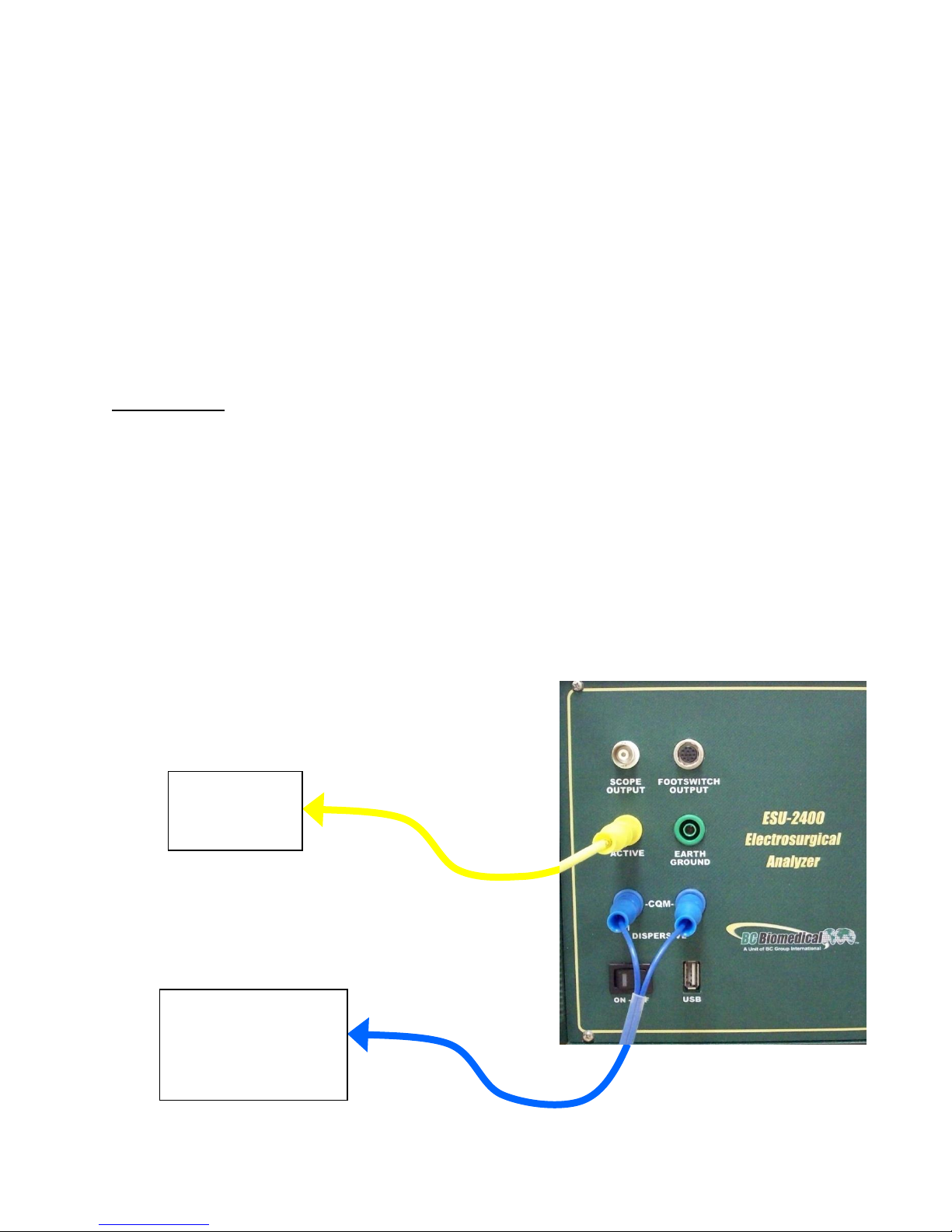

External Loads

Monopolar:

1. Yellow Active Lead from Active Jack on ESU-2400 to DUT Output.

3. Blue Lead from Dispersive 1 Jack on ESU-2400 to External Load.

4. External Load to DUT Dispersive.

ESU (DUT)

Active

Electrode

ESU (DUT)

Patient Return/

Dispersive

Electrode

Page 23

11

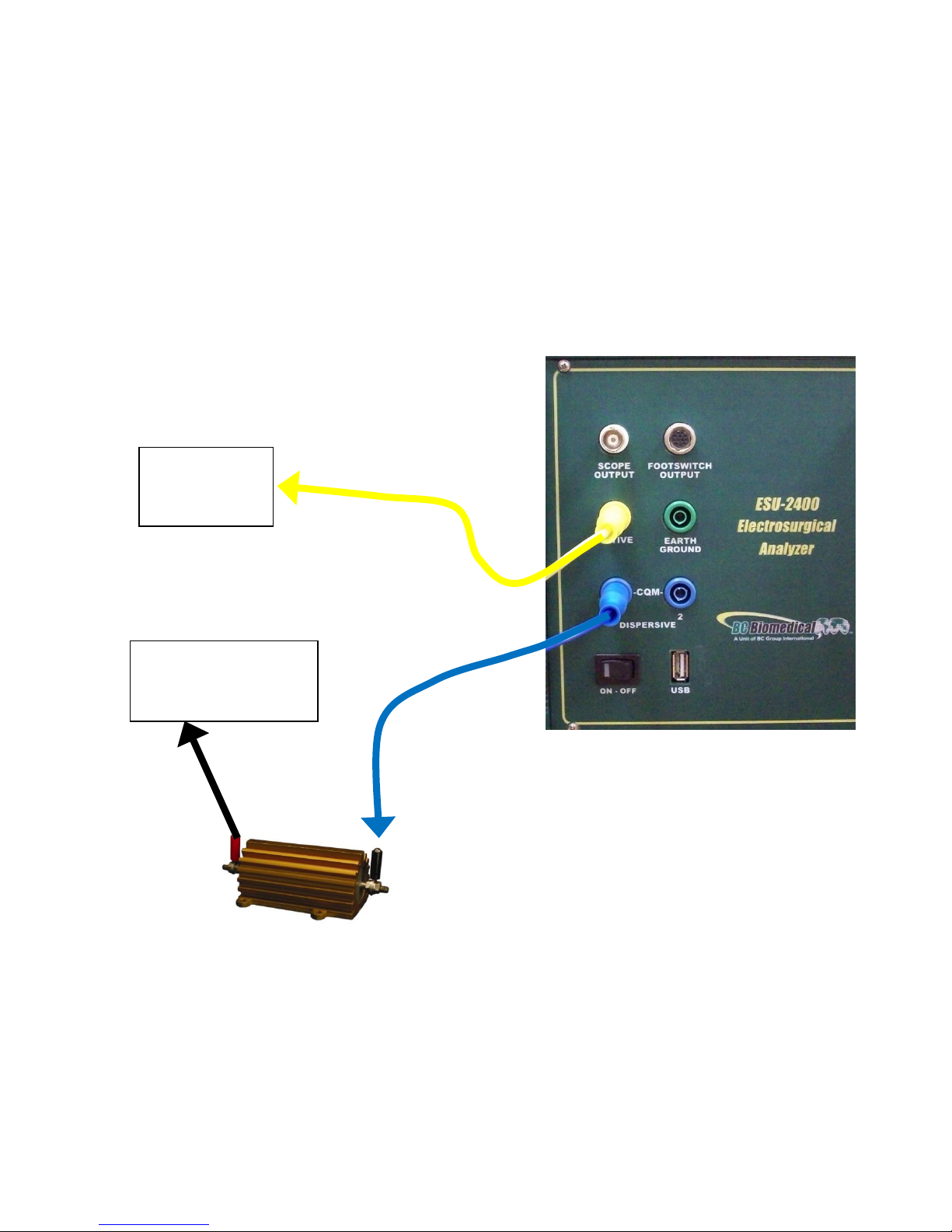

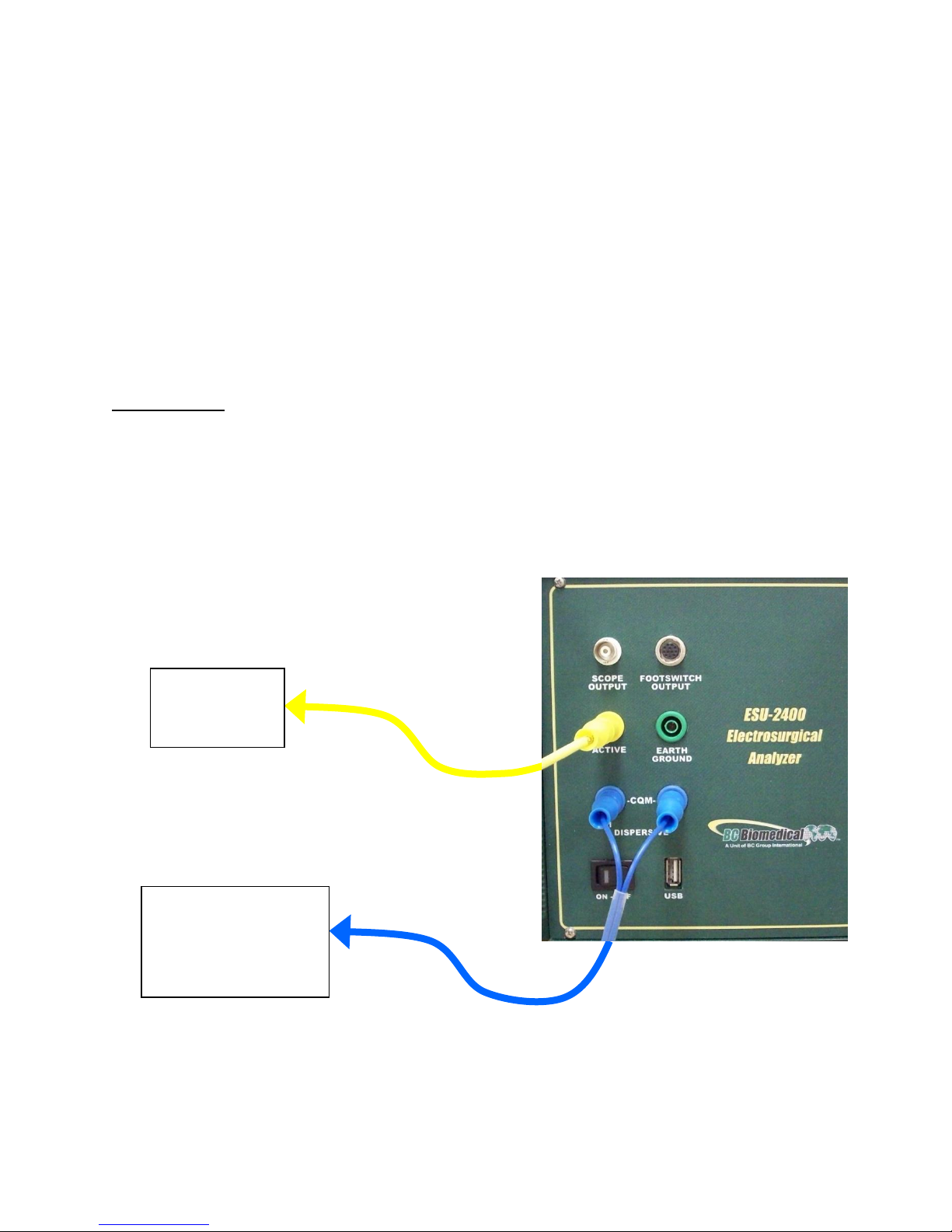

Bipolar

1. Yellow Active Lead from Active Jack on ESU-2400 to DUT Bipolar Output

Electrode #1.

2. Blue Lead from Dispersive 1 Jack on ESU-2400 to External Load.

3. External Load to DUT Bipolar Output Electrode #2.

ESU (DUT)

Bipolar

Electrode #1

ESU (DUT)

Bipolar

Electrode #2

Page 24

12

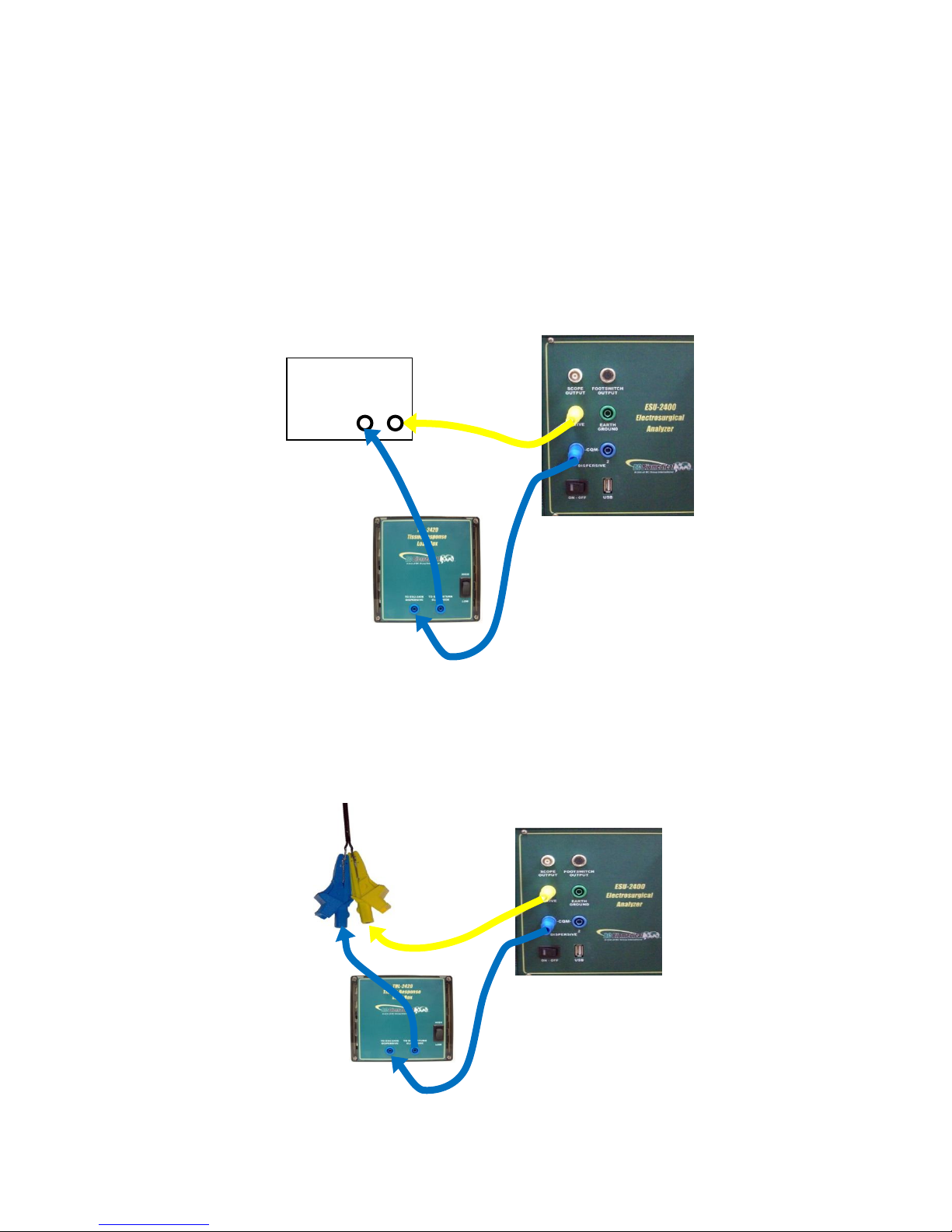

Tissue Test – This mode evaluates the tissue response function of the DUT. In this

mode, the ESU-2400 is configured for an external TRL-2420 lamp load. The ESU-2400

is connected in series with the load as shown below. The terminals are labeled Return

and Active for reference only. The DUT Return terminal shown below is typically not the

Patient Return or REM electrode. Refer to the DUT service manual to determine which

DUT ports are used for the tissue response output.

If the output terminals of the DUT are not compatible with the standard ESU-2400 safety

test leads, the alligator clips supplied with the ESU-2400 accessory kit can be used to

connect directly to the electrosurgical instrument as shown in the connection diagram

below.

ESU Generator

(DUT)

Active

Return

Page 25

13

Leakage 1a: This leakage test, specified by the IEC as Active Electrode to Ground, is for

testing the RF leakage to earth ground of an Isolated Output type CF electrosurgical

generator from a single active or dispersive lead. The test complies with IEC 601.2.2,

sec. 19.101b, fig, 104 and sec. 19.102, adopted by ANSI/AAMI HF18-2001. The purpose

of this test is to verify that open circuit RF leakage of the DUT meets or exceeds the IEC

specification. The ESU-2400 internally connects the load to earth ground. An external

ground is also provided at the front panel.

NOTE: DO NOT TEST AN EARTH REFERENCED TYPE BF ELECTROSURGICAL

GENERATOR WITH THIS TEST, THE RESULTING MEASUREMENT WILL BE

ERRONEOUS.

Connections

1. Active Jack on ESU-2400 to DUT Active Output or Bipolar 1.

WARNING – ONE LEAD AT A TIME

Only test one lead of the ESU Generator at a

time, either Active or Dispersive, not both.

ESU (DUT)

Active

Electrode

Earth Ground to

DUT equipotential

jack.

Page 26

14

Leakage 1b: This leakage test, specified by the IEC as Dispersive Electrode to Ground,

is for testing the RF leakage to earth ground of an Isolated Output type CF electrosurgical

generator from a single active or dispersive lead. The test complies with IEC 601.2.2,

sec. 19.101b, fig, 104 and sec. 19.102, adopted by ANSI/AAMI HF18-2001. The purpose

of this test is to verify that open circuit RF leakage of the DUT meets or exceeds the IEC

specification. The ESU-2400 internally connects the load to earth ground. An external

ground is also provided at the front panel.

NOTE: DO NOT TEST AN EARTH REFERENCED TYPE BF ELECTROSURGICAL

GENERATOR WITH THIS TEST, THE RESULTING MEASUREMENT WILL BE

ERRONEOUS.

Connections

1. Dispersive 1 Jack on ESU-2400 to DUT Dispersive Output or Bipolar 2.

WARNING – ONE LEAD AT A TIME

Only test one lead of the ESU Generator at a

time, either Active or Dispersive, not both.

Earth Ground to

DUT equipotential

jack

ESU (DUT)

Dispersive

Electrode

Page 27

15

Leakage 2: This leakage test, specified by the IEC as Earth Reference Leakage Type BF

(Load Between Electrodes), is for testing the leakage to earth ground of a Ground

Referenced Output type BF electrosurgical generator from the active output. This test

complies with IEC 601.2.2, sec. 19.101a, test 1, fig. 102, and sec. 19.102, adopted by

ANSI/AAMI HF18-2001. The purpose of this test is to verify that the RF leakage of the

DUT meets or exceeds the IEC specification.

Connections

1. Active Lead from Active Jack on ESU-2400 to DUT Active Output.

2. Dispersive Lead from Dispersive Jack on ESU-2400 to DUT Dispersive.

ESU (DUT)

Active

Electrode

ESU (DUT)

Patient Return/

Dispersive

Electrode

Page 28

16

Leakage 3: This leakage test, specified by the IEC as Earth Reference Leakage Type BF

(Load from Active Electrode to Earth) is for testing the leakage to earth ground of a

Ground Referenced Output type BF electrosurgical generator from the active output. This

test complies with IEC 601.2.2, sec. 19.101a, test 2, fig. 102, and sec. 19.102, adopted

by ANSI/AAMI HF18-2001. The purpose of this test is to verify that the RF leakage of the

DUT meets or exceeds the IEC specification.

Connections

1. Active Lead from Active Jack on ESU-2400 to DUT Active Output.

2. Dispersive Lead from Dispersive Jack on ESU-2400 to DUT Dispersive.

ESU (DUT)

Active

Electrode

ESU (DUT)

Patient Return/

Dispersive

Electrode

Page 29

17

This section was written to help you get started with the ESU-2400. Examples are

given for typical configurations of RF Measurement, REM/ARM/CQM testing, Load

Curves and Autosequences. This section will give specific examples of how to

configure the ESU-2400 plus additional modifications that might help fulfill your specific

testing requirements.

Scenario 1 – I need to do a Preventative Maintenance safety check on a Covidien

ForceTriad™ surgical generator.

Solution – The ESU-2400 is capable of automating the ForceTraid™ testing under the

manufacturer’s Preventative Maintenance using the Autosequence feature.

Please see the included ForceTriad™ PM Procedure Using ESU-2400 Autosequence

Manual with your ESU-2400 for detailed instructions. This manual and a tutorial video

can also be found online at http://esu.bcgroupintl.com.

FORCETRIAD™ PREVENTATIVE MAINTENANCE

GETTING STARTED

Page 30

18

Scenario 1 – I need to measure monopolar current with a 500 ohm load. I don’t have a

footswitch cable, so I will trigger the DUT myself.

Solution –

1. Select Measure RF Energy from the main menu.

2. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

3. Connect the Dispersive or Return port on the DUT to the Dispersive 1 and

Dispersive 2 inputs on the ESU-2400. If you are using the cables from the ESU2400 accessory kit, use the Blue cable without the pin.

4. Press the Isolated Generator Type button to configure the ESU-2400 for isolated

generator measurements.

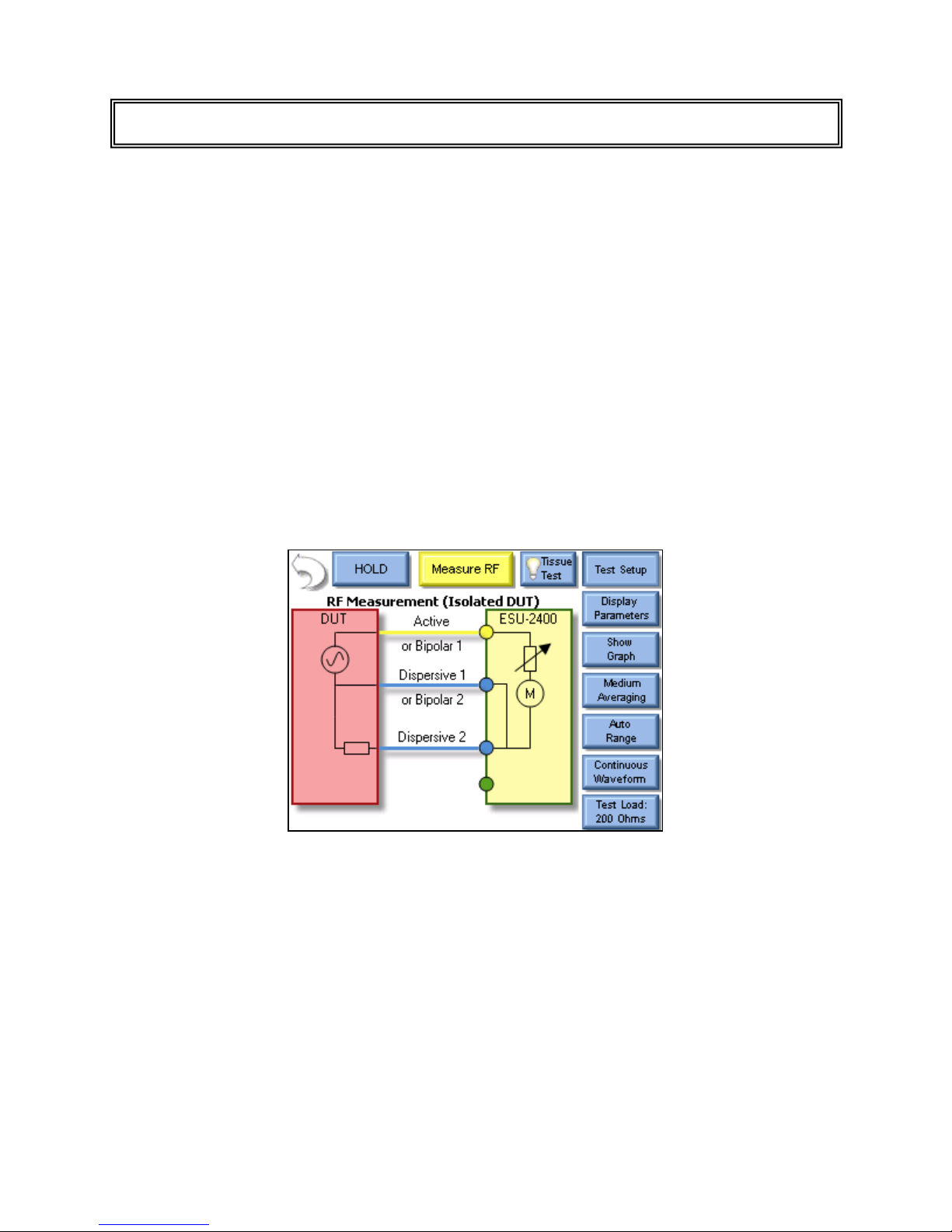

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

MEASURE RF ENERGY

Page 31

19

5. Press the Test Load button to open the load configuration box. The screen

should look like the following:

NOTE: The ESU-2400 can be configured to use internal loads, external loads, or a combination of

both. First select the Load Mode, then enter the desired internal and external loads. The total load

will automatically be updated. For most testing, the internal loads will be sufficient.

6. Press the Button next to Internal Load and enter 500 in the number pad. The

system should return to the Measure RF screen.

7. Trigger the DUT. The mA measurement will be shown on the ESU-2400 Screen.

NOTE: The displayed measurement can be changed by pressing the mA RMS button. There are

many measurements that can be displayed.

Page 32

20

Scenario 2 – I need to measure mA and Watts of a Bipolar output with a 300 ohm

Load. I want the ESU-2400 to trigger the DUT with the footswitch output.

Solution –

1. Select Measure RF Energy from the main menu.

2. Connect one Bipolar output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

3. Connect the other Bipolar output port from the DUT to the Dispersive 1 input on

the ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use

the Blue cable with banana jacks on each end, not the CQM/RECQM cable.

4. Press the Test Load button to open the load configuration box. The screen

should look like the following:

5. Press the Button next to Internal Load and enter 300 in the number pad. The

load configuration box should automatically close.

Page 33

21

6. Press the Display Parameters button and select Two Readings from the Select

Screen menu.

NOTE: By default mA RMS and Watts RMS are shown when Two Readings are selected. Each

position can display any of the ESU-2400 measurements by pressing the corresponding

measurement button.

Page 34

22

7. Press the Configure Footswitch button to open the Footswitch Setup box.

8. Use the dropdown arrow under Select Output to select the Bipolar output.

9. Use the dropdown arrow under Activation Timeout to select the maximum time

the DUT will be triggered.

NOTE: The footswitch output selection is only valid for footswitch cables that are designed for a

specific DUT, such as the BC20-03001 or BC20-03002. If you are using the unterminated

footswitch cable, BC20-03000, the output selection is dependent on how the cable is wired.

10. Press the footswitch button to trigger the DUT. The mA and Watts

measurements will be shown on the ESU-2400 Screen.

11. You may either wait for the Footswitch Activation Timeout, or press the

Footswitch button again to stop triggering the DUT output.

Page 35

23

Scenario 3 – I need to measure the mA output of a Hyfrecator (ground referenced

generator) with a 100 ohm load. I don’t have a footswitch cable, so I will trigger the

DUT myself.

Solution –

1. Select Measure RF Energy from the main menu.

2. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

3. Press the Gnd Ref generator type button to configure the ESU-2400 to make a

ground referenced measurement.

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

Page 36

24

4. Press the Test Load button to open the load configuration box. The screen

should look like the following:

NOTE: The ESU-2400 can be configured to use internal loads, external loads, or a combination of

both. First select the Load Mode, then enter the desired internal and external loads. The total load

will automatically be updated. For most testing, the internal loads will be sufficient.

5. Press the Button next to Internal Load and enter 100 in the number pad. The

screen should automatically return to the Measure RF screen.

6. Trigger the DUT. The mA measurement will be shown on the ESU-2400 Screen.

NOTE: The displayed measurement can be changed by pressing the mA RMS button. There are

many measurements that can be displayed.

Page 37

25

Scenario 4 (ESU-2400H Model Only) – I need to measure the frequency and mA

output of a generator with a pulsed waveform using a 200 ohm load. I know that the

waveform has a 700 mA pulse but little or no current between pulses. I don’t have a

footswitch cable so I will trigger the DUT myself.

Solution –

1. Select Measure RF Energy from the main menu.

2. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

3. Connect the Dispersive or Return port on the DUT to the Dispersive 1 and

Dispersive 2 inputs on the ESU-2400. If you are using the cables from the ESU2400 accessory kit, use the Blue cable without the pin.

4. Press the Isolated Generator Type button to configure the ESU-2400 for isolated

generator measurements.

5. Press the Input Mode button, which by default reads “Continuous Waveform”,

and select Pulsed from the dialog options.

Page 38

26

6. This will open the Pulsed Mode Configuration screen. Select Pulsed Mode 1 by

clicking on the mode button or the picture.

7. A threshold should be chosen so that the pulse will be over the threshold but not

too close to the maximum value to account for variations in the waveform. In this

scenario 600mA is sufficient to detect the 700mA waveform. See pg 89 for more

information on choosing a threshold.

8. Press the button next to Threshold 1 and enter 600 mA for the threshold.

9. Click the Accept Changes button to enter your settings and return to the

measurement screen.

10. Press the Display Parameters button and select Two Readings from the Select

Screen menu.

Page 39

27

11. By default mA and Watts are displayed when selecting two readings. Press the

button labeled Watts and then press the button labeled kHz to change the

measurement to frequency.

12. Trigger the DUT. The measurements will be displayed on the ESU-2400.

Page 40

28

Scenario 5 (ESU-2400H Model Only) – I need to measure the load voltage of a

generator that has a pulsed waveform with a long settling time of about 2 seconds. I

don’t have a footswitch cable so I will trigger the DUT myself.

Solution –

1. Select Measure RF Energy from the main menu.

2. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

3. Connect the Dispersive or Return port on the DUT to the Dispersive 1 and

Dispersive 2 inputs on the ESU-2400. If you are using the cables from the ESU2400 accessory kit, use the Blue cable without the pin.

4. Press the Isolated Generator Type button to configure the ESU-2400 for isolated

generator measurements.

5. Press the Input Mode button, which by default reads “Continuous Waveform”,

and select Delayed from the dialog options.

NOTE: Delayed Mode is designed for use with pulsed waveforms only.

Page 41

29

6. This will open the Delayed Mode Configuration screen. Press the button below

“Delay Time” and enter 2000 ms as the delay.

7. Click the Accept Changes button to enter your settings and return to the

measurement screen.

Page 42

30

8. By default mA is displayed. Press the button labeled mA and then press the

button labeled V Load to change the measurement to load voltage.

9. Trigger the DUT. The measurements will be displayed on the ESU-2400H.

Page 43

31

Leakage Test 1a – I need to measure the leakage current from an Active lead to

ground of a type CF ESU generator.

Solution –

1. Select Measure RF Leakage from the main menu.

2. If the Leakage selection at the top of the screen does not show Leakage 1a,

press the button and select Leakage 1a from the test mode menu.

3. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

4. Connect earth ground port on the ESU-2400 to the ground lug on the back of the

DUT. If you are using the cables from the ESU-2400 accessory kit, use the

green cable and green alligator clip.

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

MEASURE RF LEAKAGE

Page 44

32

5. Trigger the DUT. The ESU-2400 will show the mA RMS measurement in the

display.

Page 45

33

Leakage Test 1b – I need to measure the leakage current from the dispersive (REM)

port to ground.

Solution –

1. Select Measure RF Leakage from the main menu.

2. If the Leakage selection at the top of the screen does not show Leakage 1b,

press the button and select Leakage 1b from the test mode menu.

3. Connect the Dispersive output from the DUT to the Dispersive inputs on the

ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use the

Blue cable without the clear pin.

4. Connect earth ground port on the ESU-2400 to the ground lug on the back of the

DUT. If you are using the cables from the ESU-2400 accessory kit, use the

green cable and green alligator clip.

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

Page 46

34

5. Trigger the DUT. The ESU-2400 will show the mA RMS measurement in the

display.

Page 47

35

Leakage Test 2– I need to measure the leakage current from the dispersive (REM) port

to ground. I need to have a 200 ohm load from Active to Dispersive during the test.

Solution –

1. Select Measure RF Leakage from the main menu.

2. If the Leakage selection at the top of the screen does not show Leakage 2, press

the button and select Leakage 2 from the test mode menu.

3. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

4. Connect the Dispersive output from the DUT to the Dispersive inputs on the

ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use the

Blue cable without the clear pin.

5. Connect earth ground port on the ESU-2400 to the ground lug on the back of the

DUT. If you are using the cables from the ESU-2400 accessory kit, use the

green cable and green alligator clip.

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

Page 48

36

6. Trigger the DUT. The ESU-2400 will show the mA RMS measurement in the

display.

Page 49

37

Leakage Test 3 – I need to measure the leakage current from the dispersive (REM)

port to ground. I need to have a 200 ohm load from Active to Ground during the test.

Solution –

1. Select Measure RF Leakage from the main menu.

2. If the Leakage selection at the top of the screen does not show Leakage 3, press

the button and select Leakage 3 from the test mode menu.

3. Connect the Active output from the DUT to the Active input on the ESU-2400. If

you are using the cables from the ESU-2400 accessory kit, use the Yellow Lead.

4. Connect the Dispersive output from the DUT to the Dispersive inputs on the

ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use the

Blue cable without the clear pin.

5. Connect earth ground port on the ESU-2400 to the ground lug on the back of the

DUT. If you are using the cables from the ESU-2400 accessory kit, use the

green cable and green alligator clip.

NOTE: To see how the ESU-2400 is internally configured, press the Test Setup button. To close

the image, press Test Setup again.

Page 50

38

6. Trigger the DUT. The ESU-2400 will show the mA RMS measurement in the

display.

Page 51

39

Scenario 1 – I need to test the REM function on my generator. The service manual

says that the REM alarm should be Normal at 35 ohms.

Solution –

1. Select REM/ARM/CQM from the main menu.

2. Press the CQM Resistance button and enter 35 in the number pad. The screen

should look like the following:

3. Connect the Dispersive output from the DUT to the Dispersive inputs on the

ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use the

Blue cable with the center pin.

4. The DUT REM state should be Normal.

REM/ARM/CQM TEST

Page 52

40

Scenario 2 – I need to test the REM function on my generator. The service manual

says that the REM alarm should occur if the resistance increases by 40%.

Solution –

1. Select REM/ARM/CQM from the main menu.

2. Press the CQM Resistance button and enter a resistance that should result in a

normal CQM state, in this example we will use 50 ohms.

3. Press the Change By Percent button and enter 40 in the number pad. The

screen should look like the following:

4. Connect the Dispersive output from the DUT to the Dispersive inputs on the

ESU-2400. If you are using the cables from the ESU-2400 accessory kit, use the

Blue cable with the center pin.

5. The DUT REM state should be Normal.

6. Press the Up arrow under the Change By Percent heading. The resistance will

change to 70 ohms and the DUT should indicate a REM alarm.

Page 53

41

Load Curve Scenario 1 – I need to run a bipolar load curve at 60 Watts with loads from

100 to 1000 ohms, measuring every 100 ohms. I am testing a ForceFx generator and

want the ESU-2400 to automatically configure and trigger the DUT.

Solution –

1. Select Load Curves from the main menu.

2. Select Configure Load Curve from the Load Curve Menu.

3. Press The Setup Loads tab at the top of the screen to configure the Loads

4. Press the Load resistance setting for the First Load and enter 100 in the number

pad.

5. Press the Load resistance setting for the Last Load and enter 1000 in the number

pad.

6. Press the resistance setting in the Step Loads By option and enter 100 in the

number pad. The screen should now look like the following:

LOAD CURVES

Page 54

42

7. Press the Setup Power tab at the top of the screen to configure the power setting

for the test.

8. Select the Single Power Level tab to configure the test for one power setting.

9. Press the DUT Power setting button and enter 60 in the number pad. The screen

should look like the following:

10. Press the DUT tab at the top of the screen to configure the settings for the DUT

trigger.

11. Select the ESU-2400 option for DUT activation. This will enable features for

configuring the DUT setup. The screen should look like the following:

12. For the DUT setup press the dropdown arrow next to Manual Setup to select Setup

By Model.

13. Use the dropdown arrow to set the DUT Output to Bipolar.

Page 55

43

14. Use the dropdown arrow to set the DUT mode to the desired bipolar output mode.

The screen should now look like the following:

15. Connect the ESU-2400 to the DUT. Connect the Yellow cable from the Active port

on the ESU-2400 to one of the Bipolar outputs on the DUT. Connect the Green

cable from the Dispersive 1 port of the ESU-2400 to the other Bipolar output on

the DUT.

16. Connect the RS-232 cable from the ESU-2400 serial port to the DUT serial port.

17. Connect the BC20-03001 footswitch cable from the DUT to the ESU-2400.

18. Press Save configuration on the ESU-2400 to save the Load Curve settings to a

file for future use, or Press Start Load Curve to begin the test. The DUT power

level and output mode will automatically be configured through the RS-232 port.

Page 56

44

Load Curve Scenario 2 – I need to run a pure cut 300 Watt load curve, but there isn’t a

footswitch cable available for my DUT. I need to test my DUT at 50, 300, 500, 800, and

1500 ohms.

Solution –

1. Select Load Curves from the main menu.

2. Select Configure Load Curve from the Load Curve Menu.

3. Press The Setup Loads tab at the top of the screen to configure the Loads

4. Select the List Based Loads option to configure the list of loads to be used for the

test.

5. Press Clear List to remove all of the previous settings from the list of loads to be

used.

6. Press the Add Load button and enter 50 in the number pad.

7. Press the Add Load button again and enter the values for the other loads to be

used; 300, 500, 800, 1500. The loads do not need to be entered in sequence, they

will automatically be sorted as they are entered. If an incorrect load is accidentally

entered, select the incorrect load by pressing on it and then press the Delete Load

button, it will be removed from the list. The screen should now look like the

following:

Page 57

45

8. Press the Setup Power tab at the top of the screen to configure the power setting

for the test.

9. Select the Single Power Level tab to configure the test for one power setting.

10. Press the DUT Power setting button and enter 300 in the number pad. The screen

should look like the following:

11. Press the DUT tab at the top of the screen to configure the settings for the DUT

trigger.

12. Select the Operator option for DUT activation.

Page 58

46

13. Connect the ESU-2400 to the DUT. Connect the Yellow cable from the Active port

on the ESU-2400 to active output on the DUT. Connect the Blue cable from the

Dispersive ports of the ESU-2400 to the return on the DUT.

14. Press Save Configuration on the ESU-2400 to save the Load Curve settings to a

file for future use, or Press Start Load Curve to begin the test. You will be prompted

when to start and stop triggering the generator.

Page 59

47

RF Measure: I need to configure an Autosequence step to take an RF current

measurement with a 200 ohm load. My measurement tolerance is 315mA, ±25mA.

Solution –

1. From the Autosequence menu, select Create New Sequence. Then press Add

Step.

2. Select the desired location for the new step and press OK.

3. The new step will always default to an instruction type step. Select the RF Energy

/ Leakage option button near the bottom of the screen.

4. Press the title Text box to change the step title as desired. You will need to use

an external keyboard for this.

5. Press the Instructions to Operator text box to enter any instructions that the user

might need to perform at this step of the autosequence.

6. Press the Meter Setup button to configure the measurement mode and tolerance.

AUTOSEQUENCES

Page 60

48

7. Press the Test Load button to open the Load Configuration menu.

8. Press the Internal Load value button to change the internal load to 200 ohms. By

default, the user will not be able to change the load resistance once the test is

running. If you would like for the operator to be able to change the load, check the

box next to Allow Operator to modify load.

9. Press the Test Load button again or the Red X button to close the Load

Configuration menu.

10. Press the Tolerance option button at the bottom of the screen to configure the

tolerance for the RF measurement.

11. The DUT output mode and output type and power setting can be selected at the

top of the screen. These are informational only and do not have any effect on the

test or measurement.

12. Use the dropdown arrow under Expected Reading to change the tolerance mode

to Equal to (Value).

13. Press the number button to the right of the expected reading and enter 315 in the

number pad. Additionally, if the desired reading were watts or any other

measurement taken by the ESU-2400, the red button to the right of the expected

reading can be pressed to change the measurement being tested.

14. Press the number button for High Limit and set the value to 25 with the number

pad.

15. Press the number button for Low limit and set the value to 25 with the number pad.

Page 61

49

16. Additionally, if you would like to allow the user to override the automated limit

testing, you can check the box next to Allow operator to select Pass/Fail status.

17. The screen should look like the following; the configuration is complete for this

step. Press Back to Step Edit and then Done to return to the Autosequence

Summary screen.

Page 62

50

Load Curve– I need to run a pure cut 300 Watt load curve, and there isn’t a footswitch

cable available for my DUT. I need to take 10 measurements with loads from 50 to 5000

ohms.

Solution –

1. From the Autosequence menu, select Add Step.

2. Select the desired location for the new step and press OK.

3. The new step will always default to an instruction type step. Select the Load Curve

option button near the bottom of the screen.

4. Press the Title text box to change the step title as desired. You will need to use

an external keyboard for this.

5. Press the Instructions to Operator text box to enter any instructions that the user

might need to perform at this step of the autosequence.

6. Press the Meter Setup button to configure the load curve.

7. Press The Setup Loads tab at the top of the screen to configure the Loads

Page 63

51

8. Press the Load resistance setting for the First Load and enter 50 in the number

pad.

9. Press the Load resistance setting for the Last Load and enter 5000 in the number

pad.

10. Press the step setting in the Total Steps in Test option and enter 10 in the number

pad. The screen should now look like the following:

11. Press the Setup Power tab at the top of the screen to configure the power setting

for the test.

12. Select the Single Power Level tab to configure the test for one power setting.

13. Press the DUT Power setting button and enter 300 in the number pad. The screen

should look like the following:

14. The configuration is complete for this step. Press Back to Step Edit and then Done

to return to the Autosequence Summary screen.

Page 64

52

Auto CQM– I need to test the CQM input on my generator. My generator service manual

says to increase the CQM resistance starting at 120 ohms until the CQM alarm occurs.

The CQM trip resistance should be 135 ohms +/- 5 ohms.

Solution –

1. From the Autosequence menu, select Add Step.

2. Select the desired location for the new step and press OK.

3. The new step will always default to an instruction type step. Select the

REM/ARM/CQM option button near the bottom of the screen.

4. Press the Title text box to change the step title as desired. You will need to use

an external keyboard for this.

5. Press the Instructions to Operator text box to enter any instructions that the user

might need to perform at this step of the autosequence.

6. Press the Meter Setup button to configure the settings for the REM test.

7. Select the Auto CQM option at the top of the screen.

Page 65

53

8. Select the Step Values tab to configure the CQM resistance to be used. The

screen should look like the following:

9. Press the First Load button and enter 120 in the number pad.

10. Press the Last Load button and enter 145 ohms.

11. Press the Step Loads By button and enter 1 in the number pad.

12. Select the option button for Stop when CQM alarm occurs.

13. Press the Set Tolerance button to configure the Pass/Fail limits for the test. Since

the requirement is to alarm at 135 ± 5 ohms, set the CQM Trip point for 135 ohms.

14. Press the Trip Upper limit button and enter 140 in the number pad.

15. Press the Trip Lower limit button and enter 130 ohms in the number pad. The

screen should look like the following:

16. Press the OK button to close the validation requirements menu.

17. The configuration is complete for this step. Press Back to Step Edit and then Done

to return to the Autosequence Summary screen.

Page 66

54

The ESU-2400 boots to the main screen by default. The power up screen can be changed

in the System Setup screen. The main screen provides a quick way to select the desired

operating mode.

Autosequences

This mode provides for automated DUT testing. Autosequences can consist of any

combination of user instructions, RF measurements, Load Curves, or CQM tests.

Autosequences can be edited, loaded, and saved to either on board memory or external

USB drives.

Measure RF Energy

This mode provides for RF measurements. The user can configure the ESU-2400 for the

desired RF measurement including Pulsed/Continuous waveform measurement, load

setting, etc.

MAIN SCREEN

Page 67

55

Power Load Curves

This mode provides for automated load curve testing of the DUT. Load curves can be

configured for multiple load values and power levels.

REM/ARM/CQM

This mode allows the user to test the REM/ARM/CQM function of the DUT. The

resistance can be manually entered, adjusted by a specific resistance, or adjusted by a

percent of resistance. This mode also has the ability to set the CQM load to an open

circuit.

Measure RF Leakage

This mode provides for RF Leakage measurements. The user can configure the ESU2400 for the desired RF Leakage measurement including Pulsed/Continuous waveform

measurement, load setting, etc. All switching for the leakage modes is performed by

internal relays.

System Tools

This mode provides for configuration of the ESU-2400. In this mode the user can calibrate

the touchscreen, update the system firmware, and adjust settings such as filter rate and

system volume.

Page 68

56

System Information

The system information screen is shown by pressing the ESU-2400 title bar on the main

screen. This window provides the basic information about the system including software

versions and calibration due date.

To exit the system information screen, simply press anywhere on the screen.

Page 69

57

The autosequence is a programmable procedure for performing testing on a generator.

The autosequence can consist of any combination of user instructions, RF

measurements, Load Curves, or CQM tests. Once an autosequence is created, it can be

saved as a secure sequence, which cannot be modified. The following image shows the

main autosequence menu, where the user can load an autosequence, begin a ForceTriad

PM, view previously saved test results, or create new autosequence.

When selecting an autosequence, the user has the option of opening an Autosequence

Setup file (*.seq) or a Secure Autosequence (*.ssq) by selecting the filter type in the File

Open dialog box (see page 126). The Secure Sequence cannot be modified by the user.

AUTOSEQUENCES

Page 70

58

The following screen is shown after opening an autosequence setup file.

When a step is selected, it is highlighted in blue and expanded to show the step details.

When a step is not selected, the background is white and only the essential details of the

step are shown. The following buttons are available in this screen.

New – This button will create a new autosequence.

Open – This button will show the file open dialog box that will open an existing

autosequence.

Save – This button will show the file save dialog box. When saving the autosequence,

the file Filter can be used to select whether the file is to be a standard Autosequence

Setup file (*.seq) or Secure Sequence file (*.ssq) or as a PDF (*.pdf). Once a file is saved

as a secure sequence it cannot be modified.

Print – This button will display the print menu.

Start Test – This button starts the displayed autosequence.

Page 71

59

Add Step – This button will show the add step dialog box, shown below. To add a step

to the autosequence, select where to add the step and then press OK.

Delete Step – This button will delete the selected step from the autosequence.

Copy Step – This button will copy the selected step. When copying a step the user has

the option of where to place the new step.

Page 72

60

Edit Step – This button will show the edit step window, shown below.

Each step has a field for the step title and instructions to the user. These fields must be

entered using an external keyboard or remotely with a PC. Each step can be configured

as an Instruction Only, RF Energy / Leakage, Load Curve, or REM/ARM/CQM step by

selecting the appropriate option button at the bottom of the step edit screen.

Page 73

61

DUT Setup

For RF Energy / Leakage and Load Curve steps, the user needs to configure how the

DUT will be activated. For these measurements, the DUT can be activated by the

Operator or the ESU-2400 as shown below. When Operator is selected, the user will be

prompted when to activate or deactivate the ESU.

Auto Advance on Pass – This setting allows for automatically stepping through the

autosequence if a measurement passes the tolerance limits that are configured for the

selected step.

Auto Capture – When enabled, this setting will automatically capture and validate the

DUT output when the current step is reached during the autosequence. If unchecked,

the autosequence will show instructions to the user and the user must manually select

the meter display and capture an RF measurement.

Page 74

62

When ESU-2400 is selected as the trigger source, the activation can be setup manually

or by DUT manufacturer and model. For Manual Setup, the user selects the desired

footswitch output to be used.

If RS-232 is enabled, the user also selects the baud rate and enters commands to be

used for DUT setup and control. When entering commands, use “%P” to represent the

power level. In the example below, the ESU-2400 would send the command “:FTP300”

when the autosequence power level is set to 300 watts.

When the DUT Setup is set to Setup by Model, the user selects the DUT manufacturer

and model as well as the desired output mode. The ESU-2400 handles all of the RS-232

and footswitch output setup.

Page 75

63

RF Energy / Leakage Step – All of the options in the standard RF measurement and

leakage modes are available in the RF Energy / Leakage step configuration.

The user must configure both the ESU-2400 meter as well as the measurement tolerance.

To setup the tolerance, select the Tolerance option button at the bottom of the screen.

Page 76

64

DUT Output Mode – This setting is for display only, to identify to the user the output

mode used.

DUT Output Type – This setting is for display only, to identify the type of output to be

measured.

DUT Power Setting – This setting represents what the DUT should be set to for the

current step.

Expected Reading – This sets how the ESU-2400 determines whether a measurement

passes or fails. Available settings are Equal To (%), Less Than, Greater Than, or Equal

To (Value).

Measurement Units – The user can press the red units button to select what is to be

measured for the current step. Available measurements can be found in the Measure RF

Energy chapter, page 79.

High / Low Limit – These settings determine the limits of the measurement. If Expected

Reading is set to “Equal To (%)”, the limits will be based on a percentage of the expected

reading. If the Expected Reading is set to “Equal To (Value)”, the limits will be based on

a measurement offset from the expected reading. The numbers in parenthesis below the

measurement units display the reading limits based on expected value settings and

High/Low Limits.

Allow Operator to Select Pass/Fail – The tolerances configured on this screen will

determine the pass or fail status of the captured measurement during the autosequence.

In some cases, it may be useful to allow the user to select the pass/fail status of a

particular measurement. If this box is unchecked, the operator will not be allowed to

modify the pass/fail status of the measurement.

Page 77

65

Load Curve Step – All of the options in the standard load curve are available to the load

curve step configuration.

The tabs across the top of the screen allow the user to configure the Loads, Power

settings to be used, and the Meter configuration for the Load Curve.

Setup Loads Tab – The loads can be configured as either a step based load change or

a list based load change. For the step based loads, the user enters the first load to be

used and the last load to be used. Then the ESU-2400 steps the loads by either a fixed

resistance or by a calculated amount to achieve a fixed number of steps for the test. In

the previous picture, the load curve would start at 50 ohms, and increment the load by 35

ohms

2050750

to provide 20 total steps in the test.

Page 78

66

For list based loads, the following screen is shown, allowing the user to select specific

resistances to be used for the test.

The load configuration list can be saved to a file or loaded from a previously saved list.

The loads are automatically sorted by value as they are added to the list.

Page 79

67

Single Power Level Tab – For the load curve power configuration, the user can set the

ESU-2400 to run the load curve at a single power level or multiple power levels. The

following screen shows the configuration for a single power level.

By pressing on the power setting, the user will be able to enter the desired power level

for the load curve test.

Page 80

68

Multiple Power Levels Tab – When using multiple power levels, the configuration

options are similar to the Load config. The user can select either step based power levels

based on a fixed change in watts or based on the number of desired steps in the test.

For list based power levels, the user can enter any combination of power settings to use

for the load curve, as shown below. The power configuration list can be saved to a file or

loaded from a previously saved list. The power settings are automatically sorted by value

as they are added to the list.

Page 81

69

Setup Meter Tab – The measurement mode for the load curve can be configured in the

Setup Meter Tab. This screen allows for the selection of the Input Range, Input Mode,

and Averaging Rate. These settings are adjustable to match the waveform or device

being tested. For the ESU-2400 model analyzer the load curve will always display

measured power in Watts. With the model ESU-2400H analyzer the load curve can be

configured to measure specific units.

ESU-2400 Model ESU-2400H Model

For more information on measurement modes, refer to the RF Measurement chapter of

the manual on page 79.

Page 82

70

Manual CQM Step – CQM autosequence steps can be configured as manual or

automatic tests. For manual CQM autosequence steps, the user configures the initial

CQM resistance and selects whether the operator will be allowed to modify the CQM

resistance. When the test is running, the operator will need to determine whether the

CQM test passes or fails.

Page 83

71

Auto CQM Step – Auto CQM steps allow for greater automation of the autosequence.

Auto CQM steps can be configured as a single resistance test point or as an automatic

sweep of CQM resistances where the CQM status is tested for normal or alarm conditions.

Auto Advance on Pass – This setting allows for automatically stepping through the

autosequence if the CQM status matches the expected setting.

Auto Start CQM Test– When this setting is enabled the ESU-2400 will automatically

trigger the CQM state evaluation to determine if the step passes or fails. If this option is

disabled, the operator will have to trigger the CQM test.

Single Value Tab – The single Value Auto CQM step (shown above) will apply a single

resistance to the DUT CQM circuit and determine whether the step passes or fails based

on the expected status.

Page 84

72

Step Values Tab – This tab allows the user to configure a series of CQM resistances to

be stepped through. The CQM resistance can be configured to step by a fixed resistance

amount or by a fixed number of steps across a range or resistances. At each step, the

DUT CQM state is evaluated. The test can be configured to stop when either an alarm

or normal CQM state occurs.

The Set Tolerance button is used to determine the pass / fail parameters. The CQM

resistance will be stepped until the CQM state is either normal or alarm as programmed

in the step. This point is called the trip resistance. The tolerance configuration allows the

user to configure the trip points that result in a pass or fail status for the test.

Page 85

73

List Values Tab – This allows the user to configure a list of CQM resistances that are

used in the test. During the test the CQM resistance will be sequentially set to the values

shown in the CQM resistance list. The step can be configured to stop when the CQM

state is either alarm or normal.

The Set Tolerance button is used to determine the pass / fail parameters. The CQM

resistance will be stepped until the CQM state is either normal or alarm as programmed

in the step. This point is called the trip resistance. The tolerance configuration allows the

user to configure the trip points that result in a pass or fail status for the test.

Page 86

74

Running the Autosequence:

When an autosequence is started, the user is first prompted to enter information about

the DUT. The data can be entered by pressing on one of the fields and entering the

information from the onscreen keyboard, external keyboard, or barcode scanner.

Instruction Only Steps – These steps will display the instructions that the user is

supposed to follow before proceeding to the next step. Once the instructions have been

performed, the status must be updated to identify if the step passed or failed. Notes can

be added by pressing the paperclip icon at the bottom of the screen.

Page 87

75

RF Energy / Leakage steps – These steps will begin by showing the operator the step

title and instructions. After the instructions are read, pressing the Show Meter button will

allow the operator to perform the measurement. If the step is setup for the operator to

trigger the DUT, the operator must activate the DUT and then press Capture to analyze

the measurement and validate the step. If the step is setup to automatically trigger the

generator, the operator simply presses the Capture button and the DUT will automatically

be activated and the measurement analyzed.

The step can be re-run by pressing the New Capture button after a reading has been

taken.

Page 88

76

Load Curve Steps – This step will begin by showing the operator the step title and

instructions. After the instructions are read, pressing the Show Meter button will allow the

operator to perform the load curve.

At the end of the load curve, the operator can view the measurements or rerun the load

curve. The operator must manually validate the test by pressing the Pass or Fail box.

Page 89

77

Manual CQM Step – This step shows both the instructions and the step configuration. If

the step has been configured to allow the user to adjust the CQM resistance, the following

screen will be shown. The user must manually determine the pass or fail status of this

step.

Auto CQM Step – The automated CQM step also shows the instructions to the user as

well as the CQM resistance. When the Run Auto CQM step button is pressed, the CQM

status of the DUT is evaluated to determine whether the step passes or fails.

Page 90

78

Autosequence Results – After all of the steps have been completed, the result screen

will be shown. This screen indicates whether the test passed or failed.

Save Results – This button allows the user to save the autosequence results to a file.

Print Summary – This button allows the user to print only the test header and test

summary sections.

Print Details – This button allows the user to print the test header, test summary, and

details of each autosequence step.

Autosequence Menu – This button returns the user to the main autosequence menu.

Next DUT – This initiates a new autosequence and returns the user to the DUT

information screen.

Back Arrow – This takes the user back a step, allowing the full test to be reviewed.

Page 91

79

This screen configures the ESU-2400 to measure the RF output of an Electrosurgical

Generator. From this screen the user can configure the measurement, the test load, the

parameters on the screen, and even trigger the DUT.

The measurement mode can be configured using the keys around the top and right side

of the screen. The buttons are described below in a clockwise sequence starting with the

back arrow.

Back Arrow – Pressing the back arrow takes the user to the Main Screen.

Hold Key – The Hold key toggles the Hold mode. Measurements are not updated while

in the Hold mode.

MEASURE RF ENERGY

Page 92

80

Measure RF – This button allows the user to select whether the DUT being tested has

an isolated output or ground referenced output. Some generators such as Hyfrecators

do not have a return pad and rely on earth ground as the current return path. When

testing these generators, select Ground Referenced Output and the ESU-2400 will

configure the variable load to measure current from the active input to earth ground.

Tissue Test – This button is used to initiate the Tissue Test mode. This mode evaluates

the tissue response function of the DUT. In this mode, the ESU-2400 is configured for an

external TRL-2420 lamp load. The ESU-2400 is connected in series with the load as

shown below.

The Tissue Response Test will monitor the current in the load as the lamp heats up.

When the current reaches the Tissue Response Trip point in the DUT, the generator

output will automatically deactivate. At this point, the display will change to show the trip

current as well as a graph of the current during the test. See page 12 for typical

connections.

Page 93

81

Test Setup – This button shows the connection diagram for the RF Measurement mode.

Display Parameters – This key allows the user to select the number of measurements,

or zones, that are shown on the screen. 6 Screen configurations are available, 5 Display

Screens which have 1, 2, 3, 4 and 5 display zones respectively, and a sixth screen which

shows all measurements available for signals that are Continuous or Pulsed Mode 1 for

the ESU-2400H model analyzer (Pulsed Mode for the ESU-2400 model analyzer).

Each Display Zone can be customized to show any desired parameter available for the

current input mode.

Page 94

82

Available Parameter Descriptions

ESU-2400 Model Only

Mode

Parameter

Abbreviation

Description

Pulsed and Continuous Mode

mV RMS

mV

This is the mV measured directly from the RF current

transformer.

mA RMS

mA

This is the converted mA measurement based on the RF

transformer mV to mA attenuation ratio.

Power in Watts

Watts

This is the computed power based on load setting and mA

measured.

mV Peak

mV Pk

This is the maximum mV measured in the buffer.

NOTE: This is shown as an absolute value.

mV Peak – to –

Peak

mV P-P

This is the difference between maximum mV measured and

min mV measured.

mV Peak /

Peak – to – Peak

Vp/P-P

This is the ratio of Peak divided by

Peak to Peak millivolts.

mV Positive Peak

Only

mV Pk+

This is the maximum positive mV measured in the buffer.

For asymmetric waveforms this can determine if the output

polarity is reversed.

Crest Factor

CF

This is the ratio of peak to rms of the measured waveform.

Frequency

kHz

This the frequency of the measured waveform

Pulsed Mode Only

Time – Pulse On

Ton

This is the duration that the pulsed waveform is on in ms.

(See Diagram 1)

Time – Pulse Off

Toff

This is the duration that the pulsed waveform is off in ms.

(See Diagram 1)

Time – Total Cycle

Tcyc

This is the total cycle time of the pulsed waveform in ms.

(i.e. Ton + Toff). (See Diagram 1)

% Duty Cycle

%Duty

This is the ratio of the pulse on time (Ton)

versus cycle time (Tcyc). (See Diagram 1)

V Pulse

mV cyc

This represents the RMS mV over one pulsed cycle.

(See Diagram 1)

mA Pulse

mA cyc

This represents the RMS mA over one pulsed cycle.

(See Diagram 1)

Watts Pulse

Wcyc

This represents the RMS Watts over one pulsed cycle.

(See Diagram 1)

Ton

Toff

Tcyc

mV

mA

Watts

mVcyc

mAcyc

Wcyc

CF

Diagram 1 Pulsed mode (ESU-2400)

Page 95

83

ESU-2400H Only

Mode

Parameter

Abbreviation

Description

Pulsed Mode 3

Pulsed Mode 2

Pulsed Mode 1

Continuous

and Delayed

Mode

V Load

V

This is the load voltage calculated by the load resistance and current

measurement.

mA

mA

This is the converted mA measurement based on the RF transformer mV

to mA attenuation ratio.

Power in Watts

Watts

This is the computed power based on load setting and mA measured.

V Peak

V Pk

This is the maximum V measured in the buffer.

NOTE: This is shown as an absolute value.

V Peak – to –

Peak

V P-P

This is the difference between maximum V measured and min V

measured.

V Peak /

Peak – to – Peak

Vp/P-P

This is the ratio of Peak divided by

Peak to Peak volts.

V Positive Peak

Only

V Pk+

This is the maximum positive V measured in the buffer. For asymmetric

waveforms this can determine if the output polarity is reversed.

Crest Factor

CF

This is the ratio of peak to rms of the measured waveform.

Frequency

kHz

This the frequency of the measured waveform

Time – Pulse On

P1

Ton

This is the duration that the pulsed waveform is on in ms.

(See Diagram 2)

Time – Pulse Off

Toff