Page 1

BC Group International Inc

3081 Elm Point Industrial Dr.

St. Charles, MO 63301-4333 USA

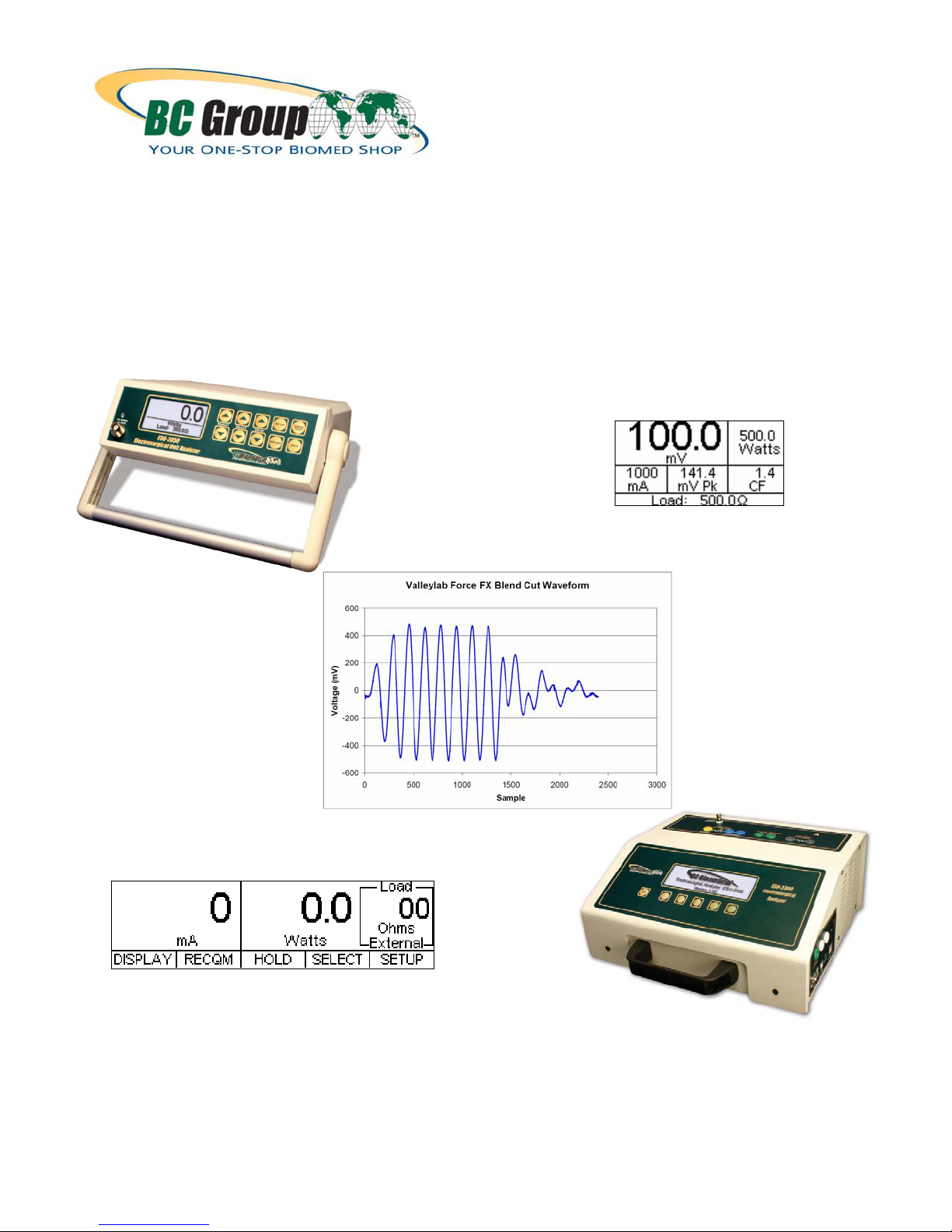

ESU-2000 Series Product Overview

A Paradigm Shift In Electrosurgery Testing

Technology and Capability Is Here

Your current ESU Analyzer just became

obsolete – no matter how new it is!

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

1 Revision 1 – June 13, 2007

Page 2

INDEX

The Next Generation in ESU Testing is Finally Here....................................................................................................................3

Electrosurgery 101 – A Basic Review of Electrosurgery ..............................................................................................................3

ESU Testing 101 – Some Testing History....................................................................................................................................7

ESU-2050: Truly Unique in the Market.........................................................................................................................................9

ESU-2050: A Replacement for the Discontinued Fluke 8920A Instrument.................................................................................11

ESU-2050: Unprecedented 1% Accuracy in ESU Testing..........................................................................................................11

ESU-2300: A More Conventional Approach...............................................................................................................................11

ESU-2400: More High-End Technology to Come.......................................................................................................................11

Common Element: Patent Pending DFA Technology.................................................................................................................11

Up To 32,768 Data Points!.........................................................................................................................................................12

ESU-2050: Precision Load Resistors Are Where Accuracy Starts.............................................................................................13

Product Development In Cooperation with ESU Manufacturers.................................................................................................14

Industry Standard Current Sensing Technology.........................................................................................................................13

Working With The Best In Current Sensing: Pearson Electronics..............................................................................................13

Current Sensing vs. Voltage Measurement................................................................................................................................13

Ensuring Quality By Taking Care Of The Details .......................................................................................................................14

Those Crazy & Exotic Pulsed Waveforms..................................................................................................................................15

ESU-2300: External Load Capabilities – Built In Non-Obsolescence.........................................................................................16

ESU-2000 Series PC Utility Software.........................................................................................................................................16

One Picture is Worth a Thousand Words – Or Up To 32,768 Data Points.................................................................................16

See The Data You Want – The Way You Want .........................................................................................................................17

Easy Setup and Operation.........................................................................................................................................................18

ESU-2050: Graphical Mode .......................................................................................................................................................18

Product Comparison Overview...................................................................................................................................................18

One-Stop-Source: We Make It Easy for You..............................................................................................................................19

Conclusion .................................................................................................................................................................................20

ESU-2050 Product Specifications ..............................................................................................................................................21

ESU-2300 Product Specifications ..............................................................................................................................................22

Technical References.................................................................................................................................................................23

About the Author ........................................................................................................................................................................24

APPENDIX A Fluke Biomedical 454A Instrument Specifications ...............................................................................................26

APPENDIX B Fluke Biomedical RF-303RS Instrument Specifications ........................................................................................27

APPENDIX C Dale Technology DALE3000 Instrument Specifications.......................................................................................31

APPENDIX D Metron QA-ES Instrument Specifications ............................................................................................................33

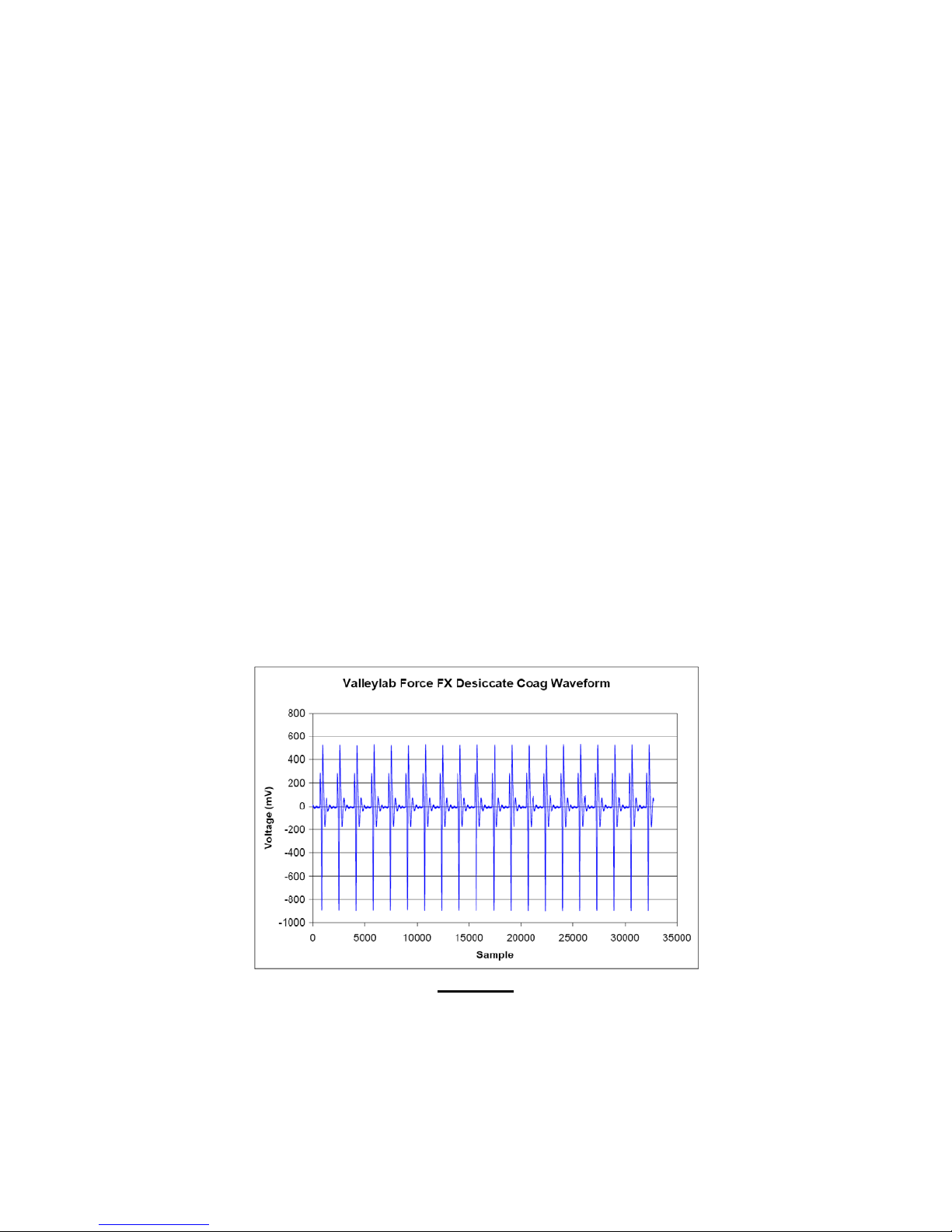

APPENDIX E Valleylab ForceFX Generator Output waveforms ................................................................................................34

APPENDIX F Valleylab Force 2 Generator Output Waveforms .................................................................................................36

APPENDIX G Conmed System 5000 Output Waveforms..........................................................................................................38

APPENDIX H (Pearson Electronics Model 411 Data Sheet)......................................................................................................41

APPENDIX I (Pearson Electronics Model 4100 Data Sheet) .....................................................................................................42

APPENDIX J (Vishay Dale NH-250 Data Sheet)........................................................................................................................43

APPENDIX K (Sample Microsoft Excel® Data Export Workbook) ..............................................................................................45

APPENDIX L (Tyco Healthcare / Valleylab Recommended Test Procedures)...........................................................................46

APPENDIX M (ESU-2000 Series PC Utility Software Screen Shots).........................................................................................49

APPENDIX N (History of BC Group International, Inc.)..............................................................................................................52

2 Revision 1 – June 13, 2007

APPENDICES

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 3

The Next Generation in ESU Testing is Finally Here

With the introduction of the new BC Biomedical ESU-2000 Series of Electrosurgery (ESU) Analyzers (the ESU2050 and ESU-2300 instruments)

technologically significant advances in electrosurgical testing to come about in well over a decade! The new BC

Biomedical ESU-2050 represents an 18-month duration major product design effort in full cooperation with some

of the leading electrosurgery generator manufacturers in the worldwide medical device market. The ESU-2050 is

the very first instrument of its kind to be introduced, specifically designed for electrosurgery generator testing, with

1% of reading accuracy and a testing methodology that is exactly the same as the one that many medical device

manufacturers currently use

2

features and functionality above and beyond competitive analyzers in this “mid-range” class. Both analyzers can

be easily upgraded in the field via the BC Biomedical Flash Update PC Utility Software in the event of a needed

firmware update. Together, these new ESU analyzers from BC Group represent an unprecedented paradigm

shift in electrosurgery testing technology, and set a new baseline for the electrosurgery test device industry. The

long-awaited next generation in ESU testing has finally arrived!

Electrosurgery 101 – A Basic Review of Electrosurgery

The following basic review on electrosurgery is derived from technical information obtained from various sources

in the public sector, including the Tyco Healthcare/ Valleylab document, Electrosurgery Self Study Guide

Copyright September 1999, Tyco Healthcare / Valleylab. This information is intended for basic review purposes

of some of the terminology and basic principles of electrosurgery technology.

Electrosurgery generally deals with electrical signal frequencies in the range of approximately 200 kHz to 3.3 MHz

(see Figure 1). This is well above the human body’s inherent frequency range of susceptibility to the hazards of

microshock.

1

, BC Group International, Inc. brings to market, the most exciting and

. The new ESU-2300 is a more conventional “mid-range” ESU analyzer, offering

3

4

,

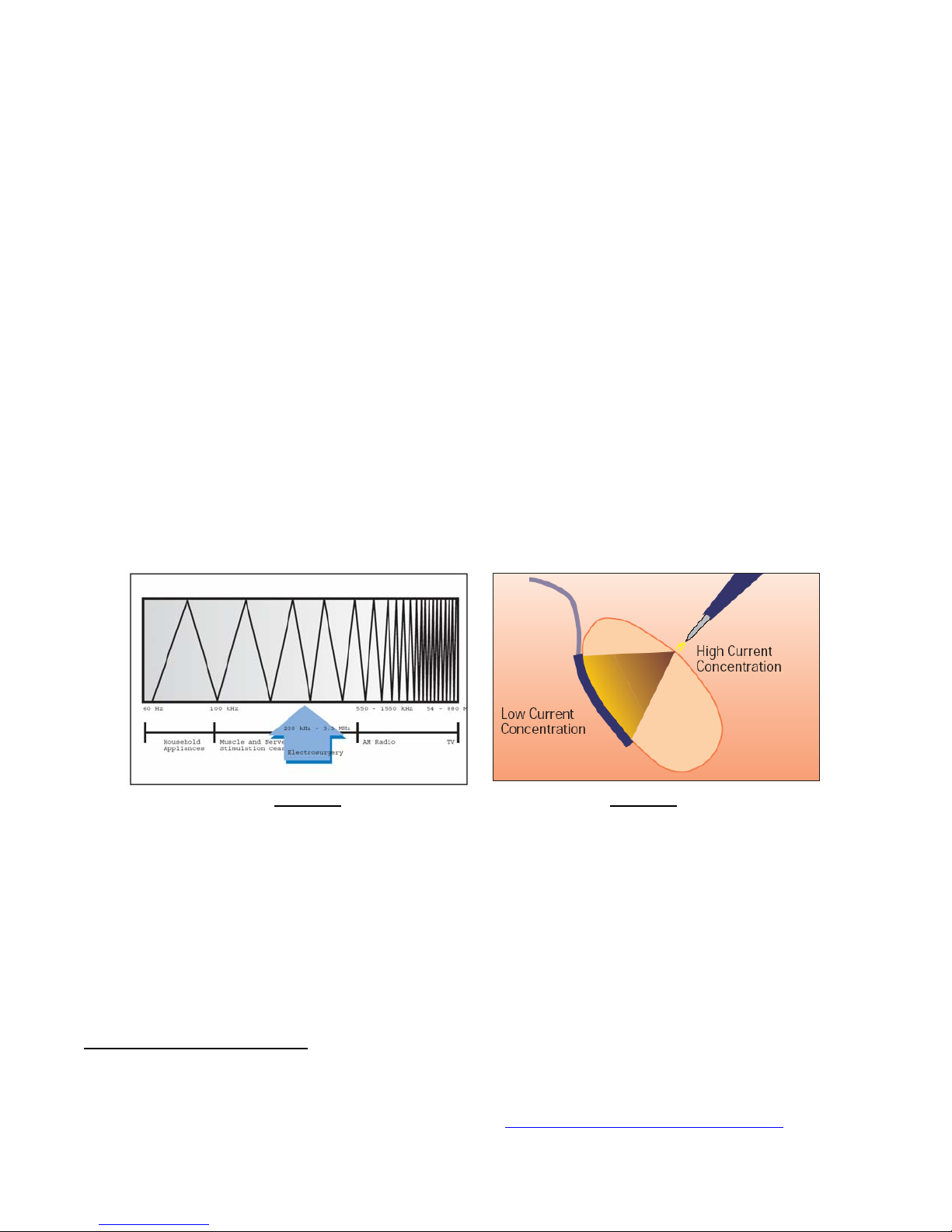

Figure 1 Figure 2

Frequency Spectrum Showing Range Current Density Differences

of Frequencies for Electrosurgery at Surgical Site vs. Return Path

Electrosurgery works based upon heat generated by the density (see Figure 2) of the high frequency current

being passed through human tissue. At the surgical site, the density is typically very high, resulting in high heat

and a cutting or coagulating effect. The “return path” for the high frequency current is much larger and

consequently much less current density exists at this area, which allows the high frequency energy to safely leave

the body without any adverse effects.

There are two basic modes of electrosurgery: bipolar and monopolar. Bipolar surgery (see Figure 3) is

accomplished by using two parallel poles in close proximity, where the flow of high frequency current is restricted

to the two poles, one being the “source” and the other being the “return path”. A patient return electrode is

typically not needed in bipolar electrosurgery applications, and because these two poles are close together, the

1

Commercial availability scheduled for July/August 2007.

2

See Appendix L for specific information regarding Tyco Healthcare / Valleylab recommended test setup procedures and recommended test equipment.

3

Sincere appreciation to Tyco Healthcare / Valleylab for the use of the illustrations in this section. Images and information are based upon the Valleylab

publication Electrosurgery Self-Study Guide, Copyright September, 1999, Authored by Br enda C. Ulmer, RN, MN, CNOR.

4

This Tyco Healthcare / Valleylab publication can be downloaded in PDF format at http://www.valleylabeducation.org/pages/list-book.html

3 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 4

voltage level and resulting applied power are lower than in monopolar electrosurgical applications. This results in

less localized tissue heating and reduced “charring” of tissue. Bipolar electrosurgery is typically used in

neurosurgical and gynecological procedures, and in other procedures where there is concern due to implanted

pacemakers and automatic defibrillators. In general, bipolar electrosurgery is safer that monopolar

electrosurgery, and the subsequent risks of high frequency burns at the return electrode site are avoided.

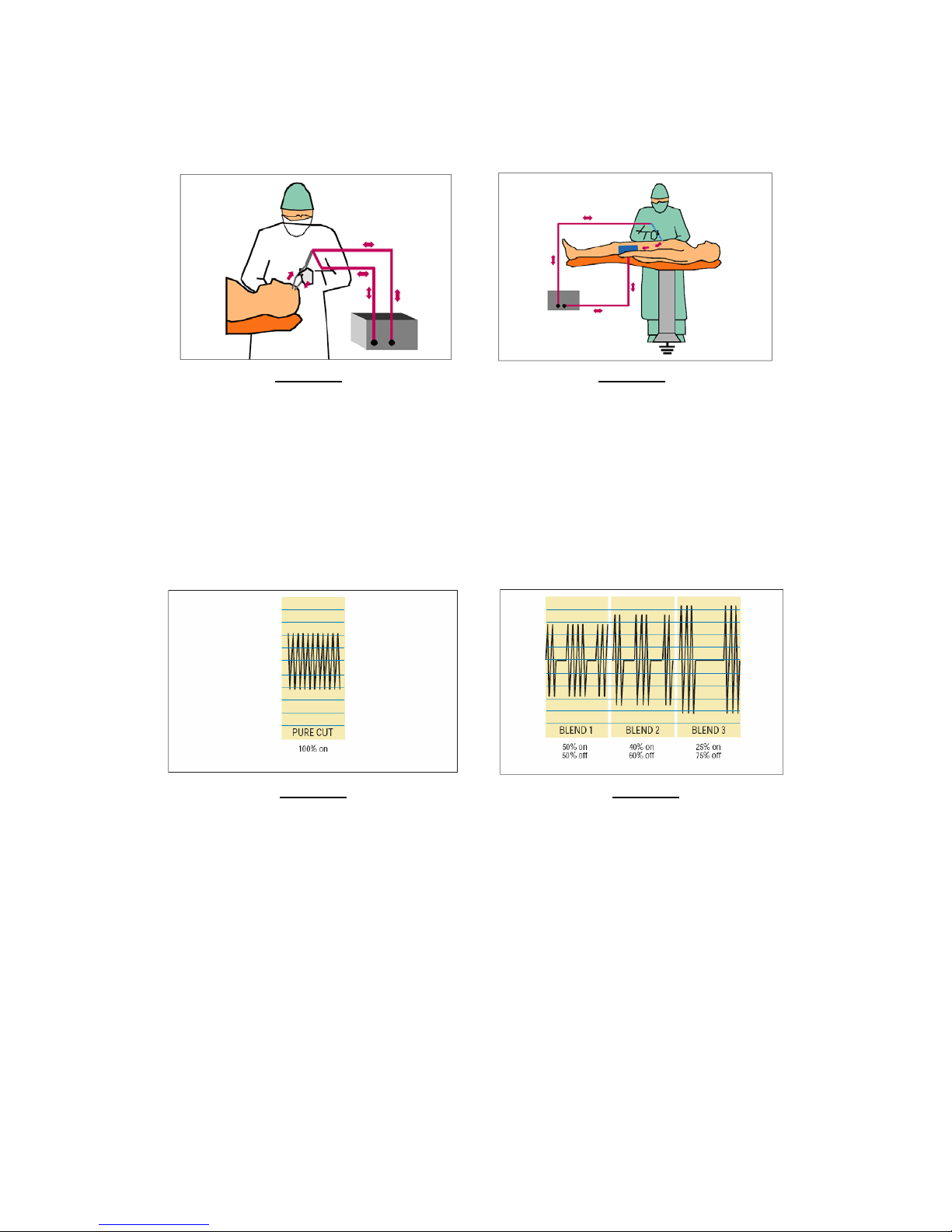

Figure 3 Figure 4

Electrosurgery – Bipolar Mode Electrosurgery – Monopolar Mode

Monopolar electrosurgery (see Figure 4) is a more generalized and more frequently used mode. Monopolar

electrosurgery utilizes higher voltage levels than bipolar, resulting in higher power delivered at the surgical site.

The need for a well prepared and maintained patient electrode site is of paramount concern in monopolar

electrosurgical applications, in order to prevent high frequency burns at the patient return electrode site.

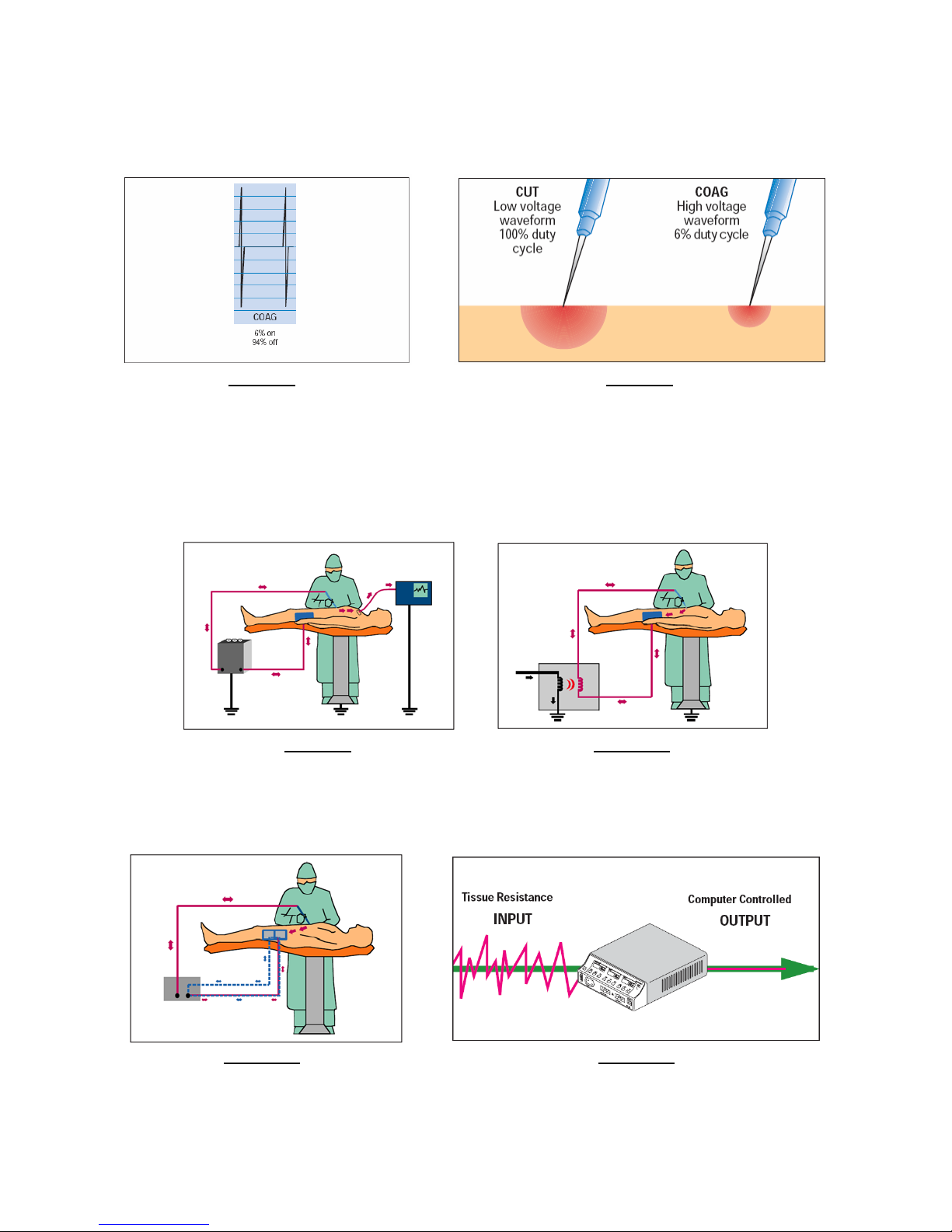

The high frequency waveform produced by the electrosurgical generator determines the physiological effect of the

application of this energy to the tissue in the body. The Cut mode of an electrosurgical generator creates a

continuous waveform, as shown in Figure 5. Different degrees of hemostasis (coagulation) can be achieved by

utilizing varying degrees of “Blended” waveforms as shown in Figure 6.

Figure 5 Figure 6

Pure Cut - Pure Sinusoidal Waveform Blended Waveforms

The Coag mode (see Figure 7) of an electrosurgical generator creates a waveform with large amplitude but short

duration “spikes” to achieve hemostasis (coagulation). The surrounding tissue is heated when the waveform

spikes and then cools down (between spikes), producing coagulation of the cells. Fulguration is achieved in the

Coag mode of the electrosurgical generator, with the tip of the surgical “active electrode” held above (but not in

contact with) the tissue. Electrosurgical Desiccation is achieved in either the Cut or Coag modes of the

generator. The difference between Desiccation and Fulguration is the tip of the “active electrode” must contact

the tissue as in Figure 8 in order to achieve Desiccation. The more desired mode to achieve tissue Desiccation

through direct tissue contact is the Cut mode.

Older electrosurgical generators (those produced prior to around 1968) are generally ground-referenced devices

and must be used with extreme care to avoid unwanted “current division” and possible resulting high frequency

burns at this site (or at multiple sites). This is illustrated in Figure 9 below. Current division can occur at any point

of contact with an earth grounded point, such as the frame of the surgical table or the outer chassis of another

medical device. For the most part, these types of devices are no longer used in surgical procedures, mainly due

to advances in electrosurgical generator technology and concerns over safety.

4 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 5

Advances in electrosurgery generator technology brought about the “solid state” generator around 1968. Along

with this more reliable and more condensed electronics technology came the introduction of the isolated-output

electrosurgical generator (see Figure 10 below), thus eliminating the concern over unwanted current division and

vastly improving patient safety. The outputs of these generators were no longer earth ground-referenced, so

even the best electrical ground-referenced contact made to the patient would not present the risk of high

frequency burns at alternate sites.

Figure 7 Figure 8

The shift in concern now focused on the quality of the patient return electrode and electrode site, and over the

succeeding years, many manufacturers introduced new monitoring techniques designed to constantly measure

the integrity of the patient electrode site in order to minimize the possibility of high frequency burns at the patient

electrode. The varying technologies introduced by the various electrosurgical generator manufacturers over the

years have generically become know in today’s market as the Contact Quality Monitor (CQM) function (see

Figure 11) of the electrosurgical generator.

Coagulation Waveform Tissue Penetration: Cut vs. Coag

Figure 9 Figure 10

Ground-Referenced Electrosurgical Generator Isolated Output Electrosurgical Generator

In more recent years, there has been a steady stream of advances in electrosurgery generator technology, one of

the most significant of which was the introduction by Tyco Healthcare / Valleylab in their Force FX Generator of

“Tissue Response Technology” in the late 90’s. This technology utilizes a constant feedback loop to the

Figure 11 Figure 12

Contact Quality Monitor (CQM) Function Tyco Healthcare / Valleylab Tissue Response Technology

Copyright June, 2007 by BC Group International, Inc.

5 Revision 1 – June 13, 2007

Author: Michael R. Erwine

Page 6

generator’s microprocessor and actually adjusts the power level output of the generator in order to provide

relatively constant power delivery (and thus a consistent surgical effect) at the surgical site, regardless of tissue

impedance.

Electrosurgery generator improvements continue, with new introductions by leading manufacturers like Tyco

Healthcare / Valleylab, Conmed (Electrosurgery Division), Erbe, Bovie, etc. on a regular basis The need for

routine testing and performance verification of these generators has not deceased due to these introductions of

new technologies. In fact, there are more features and safeguards to test for proper operation on today’s average

electrosurgical generator than ever.

Some Common Electrosurgery Terminology

Active Electrode: an electrosurgical instrument or accessory that concentrates the high frequency current at the

surgical site, thus enabling the heating effect at the site and producing the desired electrosurgical effect

Blend: an electrosurgical generator output waveform that combines the features of cut and coag waveforms,

cutting with various degrees of hemostasis (coagulation)

Contact Quality Monitor (CQM): a system that constantly monitors the impedance of the physical connection

between the patient’s body and the patient return electrode and interrupts power form the electrosurgical

generator is the quality of this connection is compromised electrically

Current Density: the amount of electrical current flow per unit of surface area – as current density increases so

does the heating of the tissue in the immediate location

Current Division: high frequency electrical current leaving the intended electrosurgical patient circuit and

following an alternate low impedance path of lesser resistance to earth ground, this introducing the possibility of

high frequency burns at the alternate earth ground contact point – typically a concern in ground-reference

generators and not isolated output generators.

Coagulation: the clotting of blood or destruction of tissue with no cutting effect – electrosurgical fulguration and

desiccation.

Cut Mode: electrosurgical mode that produces a low voltage continuous waveform optimized for tissue cutting

Desiccation: the effect of tissue dehydration and protein denaturation caused by direct contact between the

electrosurgical “active electrode” and the tissue

Fulguration: using electrical arcs (sparks) to coagulate tissue, whereby the sparks jump from the electrosurgical

“active electrode” across an air gap to the tissue

Ground-Referenced Output: an electrosurgical generator with an output that is electrically referenced to earth

ground

Isolated Output: an electrosurgical generator with an output that is not electrically referenced to earth ground

Leakage Current: electrical current that flows along an undesired pathway, usually to earth ground – in an

electrosurgical generator, RF leakage current is high frequency current that regains its ground reference and

seeks earth ground.

Patient Return Electrode: an electrically conductive plate or pad (also known as the dispersive electrode) that

recovers the high frequency current introduced into the patient’s body by the “active electrode” during

electrosurgery. This electrode minimizes the current density of this return current flow in order to minimize the

possibility of high frequency burns at this electrode site.

Radio Frequency (RF): frequencies above 100 kHz that transmit radio signals – the high frequency current

utilized in electrosurgery

Tissue Response Technology: the Tyco Healthcare / Valleylab electrosurgical generator technology that

continuously measures the impedance/resistance of the tissue in contact with the patient return electrode and

automatically adjusts the output of the generator accordingly to achieve a consistent tissue effect.

6 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 7

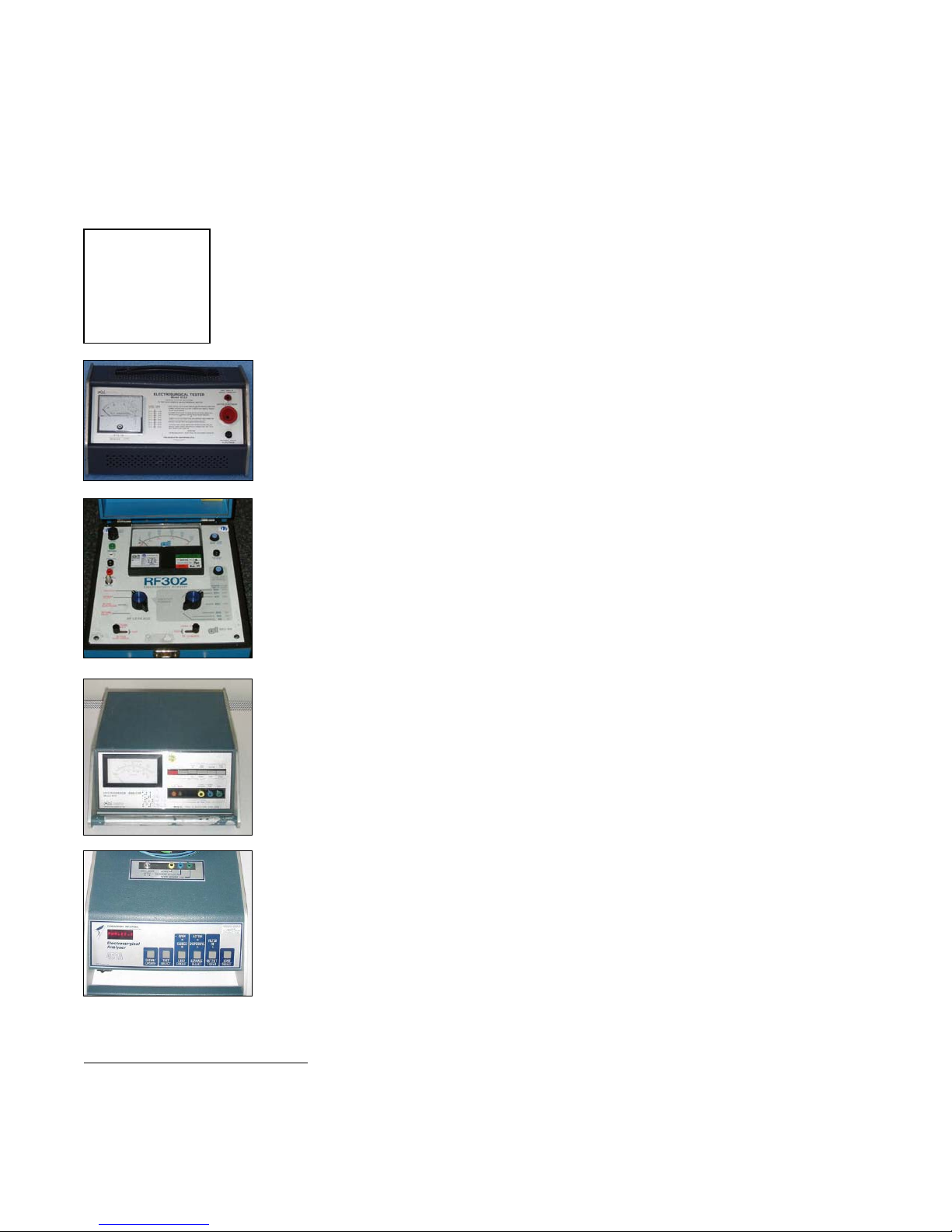

ESU Testing 101 – Some Testing History

Electrosurgery generator technology has undergone tremendous technological advances over the past decade,

but the technology base of ESU analyzers has remained relatively slow-moving over this same time period. The

recently discontinued Fluke Biomedical Model 454A dates back to around 1992 or 1993, and until now,

represents the culmination of research and development efforts on the behalf of competitive companies in the

area of electrosurgery testing. Here is a brief history of ESU testing devices over the past 15 to 20 years.

Analyzers are shown in the order of their introduction to the market.

No

Picture

Available

Bio-Tek Instruments RF-301: The very first offering in ESU analyzers by Bio-Tek Instruments. T his

“passive”

301 instruments in use in the field today. The design was basic and rugged.

5

RF thermocouple ammeter type instrument got the job done. There are still quite a few RF-

Neurodyne Dempsey Model 403A: The Neurodyne Dempsey (which later became Dynatech

Nevada Inc.) Model 403A was a very small-sized ESU tes ter with limited functionality. This was

a passive technology device with an RF thermocouple type analo g ammeter and a single fixed

500 Ω internal load. Meter range was 0.2 A to 1.0 A / 20 watts to 500 watts. It was the

company’s first dedicated ESU tester. There are very few of these units left in the market.

Bio-Tek Instruments RF-302: The predecessor to the Bio-Tek RF-303, the RF-302 was a

“passive” RF thermocouple ammeter type instrument. This gave an advantag e to the RF-302

above other competitive “active” type ESU analyzers available at time. T he RF-302 offered a

better high frequency range than some competitive “active” units. Bio-T ek Instruments sold qu it e

a few of these units in the market. This instrument is very similar to the BC Biomedical ESU2000A instrument that is still available today, for those customers who prefer a l egacy type RF

ammeter “passive” instrument approach to ESU generator testing.

Dynatech Nevada Model 443: The Dynatech Nevad a Model 443 was the company’ s very first

“active” type

technology, the Model 443 still utilized an analog meter. The Model 443 was discontinued

shortly after the introduction of the Model 453A.

6

design in ESU analyzers. Despite it’s active internal circuitry and measurement

Dynatech Nevada Model 453A: The predecessor to the 454A, the Dynatech Nevada Model

453A was probably the very first “Hi-Tech” ESU analyzer on the market. It utilized active

technology. Introduced in the mid 1980’s, the Model 453A was in production until the

introduction of the Dynatech Nevada Model 454A , starting in 1992 or 1993. The 453A had a

small LED 7-segment display and was a fairly large instr ument weighing well over 15 pounds.

There are still many 453A ESU analyzers in use in biomedical departments across the U.S.

today.

5

Passive technology in an ESU Analyzer refers to an instrument that does not require any external power source and simply meters the RF energy without

any electronic signal processing.

6

Active technology is an ESU Analyzer refers to an instrument that requires a power supply and has active electronic circuitry including components such as

A/D converters. Operational amplifiers, thermal converters, etc.

7 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 8

Dynatech Nevada Model 454A: Until it was recently discontinued by Fluke Biomedical (the

Model 454A is no longer listed on the Fluke Biom edical web site and customers report having

been informed that the 454A is no longer availabl e from Fluke Biomedical) in favor of the more

recent Metron QA-ES (re-branded as the Fluke Biomedical QA-ES effective March 18, 2007), the

454A was probably the most popular and successful ESU anal yzer on the market. Originally

designed by Dynatech Nevada Inc., the 454A utilized industry standard current sensing

technology and offered accuracies of 5% of reading on RMS current an d 10% of range on RMS

power. For the the past decade, the 454A was considered to be an electrosurgery industry icon,

but despite this status in the market, it never really attained any level of actual customer

recommendation for any of the leading electrosurgery ge nerator manufacturers. See Appendix

A for full specifications on the discontinued Model 454A.

Fluke Biomedical RF-303RS: Originally marketed as the Bio-Tek Instruments RF-303RS, this is

the current “mid-range” ESU analyzer offering from Fluke Biomedical. The RF-303

does not

RS

utilize industry standard current sensing technology, but uses simple voltage measurement

instead. This product was designed during the period of time that Lionheart Technologies owned

and operated Bio-Tek Instruments, DNI Nevada, and Dale Technology. A concurrent compa nio n

product to the RF-303

was originally introduced in 1998 under the DNI Nevada (formerly

RS

Dynatech Nevada) brand as the Model 402A. The 402A was later re-branded as the Dale

Technology DALE3000 following the acquisition of the biomedical holdings of Lionheart

Technologies by Fluke Electronics (Fluke Biomedical) in 1 993. Instrument specifications for the

Fluke Biomedical (Bio-Tek Instruments) RF-303

Technology DALE3000 are (were) essentia lly identical. Current Fluke Biomed ical advertised specifications for the RF-303

are

+ 5% of reading or + 3 watts (whichever is greater) on RMS power and + 2.5% of readi ng or + 15m a (whichever is greater)

on RMS current. See Appendix B for full specifications on the RF-303

RS

.

, the DNI Nevada 402A, and the Dale

RS

RS

DNI Nevada Model 402A: The DNI Nevada Model 402A was the “sister product” to the Bio-Tek

Model RF-303, introduced concurrently with the RF-303 (see information above under the RF-

). Actual design, development, and manufacturing of t he 402A and the RF-3 03 took place

303

RS

at the DNI Nevada Inc. facility in Carson City, NV, under the ownership and management of

Lionheart Technologies, Inc. In order to make the two products look sufficiently different, and in

order to somehow truly differentiate the two, the 402A was given an RS232 communications port

and the RF-303 was given a battery for portable op eration. Slightly different enclosures were

also chosen, and the 402A was given an LED 7-segment display while the RF-303 was given an

LCD 7-segment display. The instrument firmware that operated the 402A and RF-303 was

common between the products, with firmware subroutines that recognized which instrument was being operated by the

microprocessor. The RS232 communications port was added to the RF-303 much later i n time, following the discontinuance

of the 402A. When Fluke Electronics (Fluke Biomed ical) acquired the biomedical holdings of Lionhea rt Technologies in 1993,

the DNI Nevada Model 402A was soon after discontinued and re-branded under the Dale Technology brand as the

DALE3000.

Dale Technology DALE3000: The DALE3000 existed in the market for less than three-years

before it was discontinued. The re-branding of the DNI Nevada Model 402A to the Dale

Technology DALE3000 was concurrent with the relocation of the Dale T echnology business from

its original location in Thornwood, NY to Carson City, NV, in the then-e xisting Fluke Biomedical

manufacturing facilities (the original Dynatech Nevada manufacturing facility and offices) in

Carson City, NV. The discontinuance of the DALE3000 was actually fairly close in time to the

Fluke acquisition of Metron AS of Trondheim, Norway, which brought the Metron QA-ES “highend” ESU analyzer to the Fluke Biomedical family of products.

BC Biomedical ESU-2000A: The BC Biomedical ESU-2000A was originally introduce d in the

year 2000, based upon strong customer dem and for a “simple but effective” legac y tester similar

to the original Bio-Tek Instruments RF-302. With accuracy of

+ 2% of full scale on current and

power, the ESU-2000A remains popular with customers today. It is still available from BC Group

International. Full instrument specifications for the ESU-2000A ESU analyzer c an be found on

the BC Group International web site at:

http://testequipmentandtools.com/acatalog/BCBiomedicalESU2000ADatasheet.pdf.

8 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 9

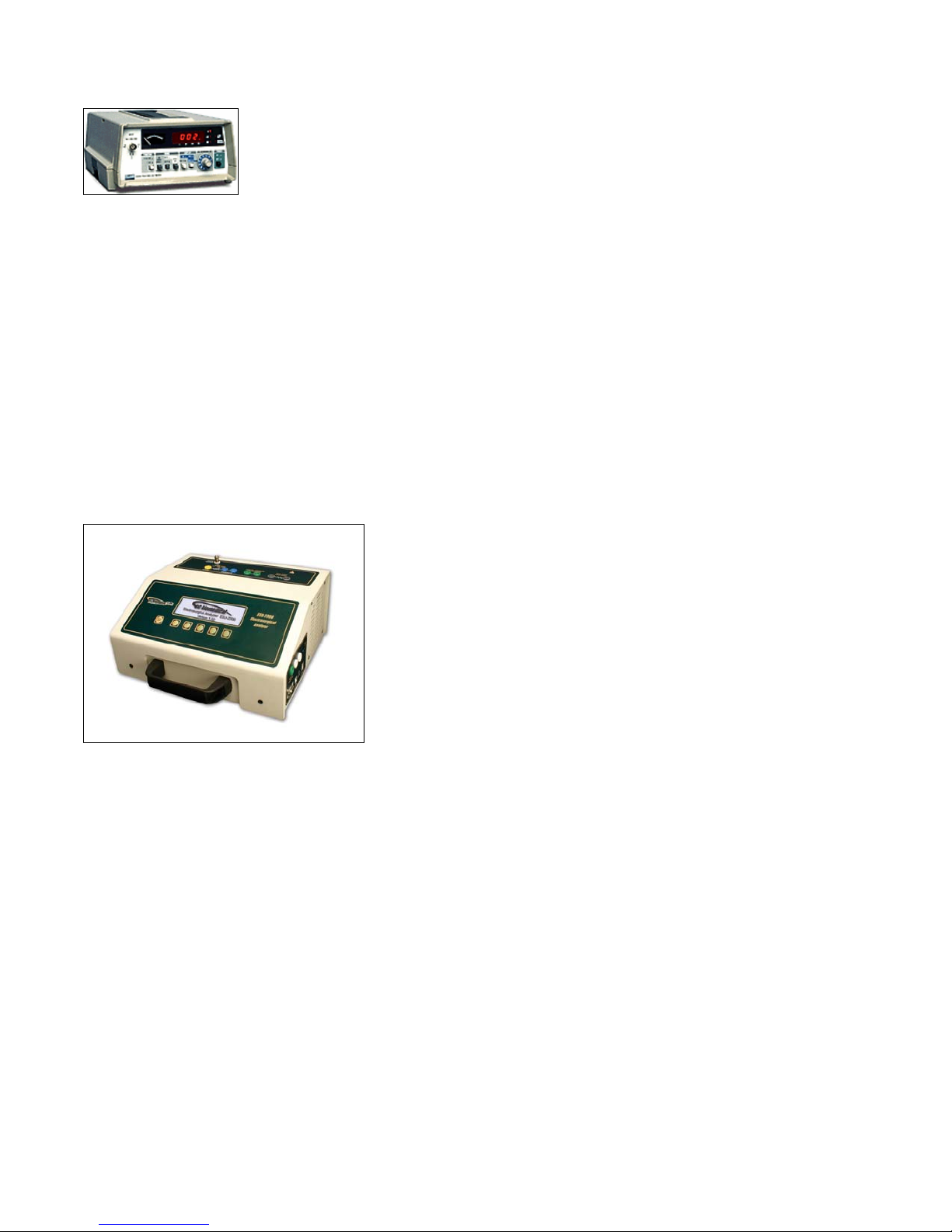

Fluke Biomedical / Metron QA-ES: The re-branded Metron (Trondheim, Norway) QA-ES is

the current “high-end” ESU analyzer offering from Fluke Biomedical, effective March 18,

2007. Originally introduced by Metron AS in Trondheim, Norway, the QA-ES offers accuracy

of 2% of reading for RMS current measurements. RMS power reading accuracy is not

specified by the manufacturer. The QA-ES does not utilize industr y standard c urrent sen sing

technology. See Appendix D for specifications on the Metron QA-ES v ersion of this analyzer.

Fluke Biomedical instrument specifications can be found on the manufacturer’s web site.

BC Biomedical ESU-2050: With commercial availability scheduled for July/August 2007, the

new BC Biomedical ESU-2050 represents a paradigm shift in ESU analyzer technology,

allowing customers to test their electrosurgical generators in exactly the same way as the

electrosurgery manufacturers do! With unprecedented 1% of reading accuracy, the ESU2050 is the most accurate ESU analyzer on the market, offering a dvanced level features and

functionality such as exporting waveform data sets with up to 32,768 data points to Microsoft

®

Excel

for graphing and analysis. Patent pending DFA® Technology.

BC Biomedical ESU-2300: With commercial availability sched uled for July/August 2007, the

new BC Biomedical ESU-2300 is a conventiona l design “mid-range” ESU analyzer utilizing

internal precision load resistors. Unlike other mid-range analyzers on the market, the ESU2300 utilizes industry standard current sensing technology for improved accuracy and

reliability. Like the ESU-2050, the ESU-2300 utilizes paten t pending DFA

ESU-2300 offers the ability to connect an external load resistor, thus ensu ring the availabilit y

of the required test load no matter what the value is. External load resistors can be used in

additive mode (add the external load resistor value to any of the internal load values) or

external only mode (use only the value of the external loa d resistor).

®

Technology. The

The release of the new BC Biomedical ESU-2000 Series, including the ESU-2050 and ESU-2300 analyzers

represents a paradigm shift in the level of technology offered for electrosurgery generator testing.

ESU-2050: Truly Unique in the Market

From its original product design proposal, the new BC Biomedical ESU2050 analyzer has been a totally different instrument as compared to the

traditional approach to ESU testing. Until now, traditional ESU analyzers

have had the following common elements:

• Internal load resistors (typically the most fragile element of the

conventional ESU analyzer)

• Accuracy on RMS power typically in the 5% to 10% range

• Accuracy on RMS current typically in the 2% to 5% range

• Crest factor (the ratio of V

peak

to V

16 or less

• Measurement technique: typically (less costly) voltage

measurement with the exception of the 454A which utilized

electrosurgical manufacturer industry standard current sensing

• “Active” type instruments typically utilize a thermal converter

The new ESU-2050 is a direct result of extensive collaboration with leading medical device industry

electrosurgery generator manufacturers. The ESU-2050 analyzer was designed to be 100% compatible with the

following mandates of some of the leading manufacturers in this area:

• Accuracy of 1% (give us a calibration quality instrument that can replace the legacy Fluke Electronics

Model 8920A

7

Digital Wide-Band True RMS Voltmeters currently in widespread use)

• Utilize external high-precision (1%) power resistors widely used in the OEM segment

) limitation typically around

rms

7

The Fluke 8920A was discontinued at the end of 1999 due to “product maturity” and electronic component shortages. For the detailed statement on

product discontinuance from Fluke Electronics, simply visit the following url:

9 Revision 1 – June 13, 2007

http://us.fluke.com/usen/support/safetynote/DiscontinuedProductNotice.htm.

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 10

• Utilize external high-accuracy current sensing transformers of 0.1:1 and 1:1 ratio (typically Pearson

Electronics Model 411 and 4100 transformers), thus eliminating the virtual inaccuracies of commercially

available analyzers that utilize voltage measurement techniques

• Eliminate internal test load switching relays that add capacitive leakage at RF frequencies and decrease

the overall level of instrument accuracy

• Add the ability to capture and store in high resolution, the ESU output waveform

• Supply Crest Factor (CF) capability well in excess of the current industry (competitive instrument)

limitation of 16

• Make the new instrument much smaller and lighter, and more resistant to breakage during shipment than

the current industry available ESU analyzers

• In summary, give us an instrument that we can use to test the way we have tested our electrosurgery

generators over the past 10+ years!

The result of these ongoing collaborative efforts over the past 18 months is the new BC Biomedical ESU-2050

analyzer, with never before seen levels of accuracy and functionality in a commercially available ESU analyzer

8

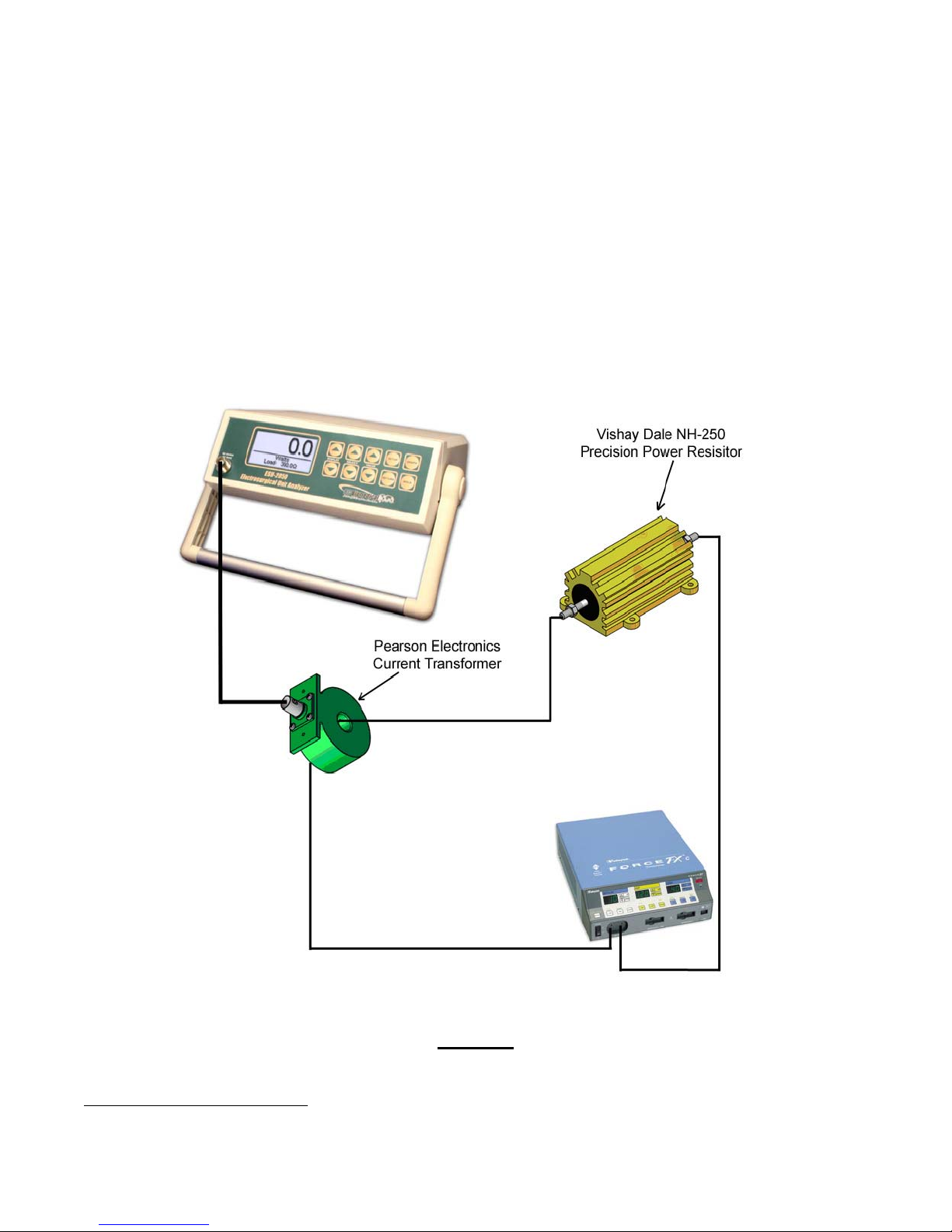

Testing with the new ESU-2050 analyzer is remarkable easy, and requires minimal setup, as can be seen in

Figure 13 below.

.

Typical Test Setup Using the ESU-2050 ESU Analyzer – Test the Way ESU OEMs Test Their Products

8

See complete product specifications for the ESU-2050 on Page 21.

10 Revision 1 – June 13, 2007

Figure 13

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 11

ESU-2050: A Replacement for the Discontinued Fluke 8920A Instrument

The Fluke Electronics Model 8920A Digital Wide-Band True RMS Voltmeter with BNC

Input was widely adopted by electrosurgical generator manufacturers around the world.

Fluke Electronics discontinued this instrument and ceased all shipments by the end of

1999, leaving a void in the industry. Since the formal discontinuance of the 8920A,

several electrosurgical generator manufacturers have searched for a suitable

replacement instrument capable of delivering the same functionality and at the same level of accuracy as the

8920A. But none had been found up to and including the beginning of 2007. The development of the new BC

Biomedical ESU-2050 ESU analyzer was by design, intended to provide a suitable replacement for the Fluke

Electronics 8920A instruments currently in use by these manufacturers.

ESU-2050: Unprecedented 1% Accuracy In ESU Testing

The accuracy specifications (see ESU-2050 spe cifications on Page 21) of the new BC Biomedical ESU-2050 ESU

analyzer are well beyond any competitive ESU analyzer of the market today, meeting the requirements of even

the most demanding electrosurgical manufacturers. The ESU-2050 ESU analyzer allows the customer to test

according to the exact same methodology as the electrosurgery generator manufacturers test their own products.

This is an industry first! Now these manufacturers will be using the exact same instrumentation for test and

measurement that typical electrosurgery generator customers do!

ESU-2300: A More Conventional Approach

For those customers that do not wish to make the quantum leap from

conventional ESU testing methodologies to the new ESU-2050

platform, the new BC Biomedical ESU-2300 analyzer offers a more

conventional approach to ESU testing. The ESU-2300 utilizes some of

the best attributes of the ESU-2050 design:

• Patent pending DFA® Technology

• Industry standard current sensing technology via a custom

design current transformer designed specifically for the BC

Biomedical ESU-2300 by Pearson Electronics

• The latest in microprocessor design, which allows for high

speed digital acquisition and “interrogation” of the

electrosurgery generator waveform

The ESU-2300 is a mid-range analyzer (similar in price point to the Fluke Biomedical RF-303RS), but offers

superior features and accuracy (as result of the implementation of current sensing technology).

ESU-2400: More High-End Technology to Come

Is anything missing form the new BC Biomedical ESU-2000 Series lineup? What about a “high-end” analyzer?

The new BC Biomedical ESU-2400 “high-end” ESU analyzer is currently under active development. Stay tuned to

BC Group International, Inc. for more to come on the new BC Biomedical ESU-2400.

Common Element: Patent Pending DFA® Technology

The common element of all instruments in our new ESU-2000 Series is our patent pending DFA® Technology.

This technology platform allows the instrument to aggressively digitize the RF signal, analyze its components, and

provide highly accurate results. No other ESU analyzer on the market today uses this type of technology

platform. Not even the “high-end” competitive instruments offer this advanced level capability!

11 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 12

In fact, most competitive ESU analyzers on the market today utilize thermal technology, where the ESU generator

signal is fed into a thermal converter of some kind. This component measures the waveform energy through a

temperature change and provides a reading. Most commercially available “active” ESU analyzers have used this

technique for many years. The new BC Biomedical ESU-2000 Series of analyzers breaks this “old technology”

trend and introduces an exciting new level of ESU measurement technology moving forward!

Up To 32,768 Data Points!

For advanced level users, the number of A/D converter samples used in displaying the electrosurgery generator

measurement parameters can be adjusted to any of the following values: 1024, 2048, 4096, 8192, 16,384,

32,768. This setting adjusts the number of A/D converter readings used in each RMS mV computation. A higher

setting requires more computation and is slower, but results in a more stable reading. This setting also

determines the “resolution” of the stored and exported data sets for the captured electrosurgical generator

waveforms. The waveform data sets shown throughout this document and in Appendices E, F, and G all have

32,768 discrete data points.

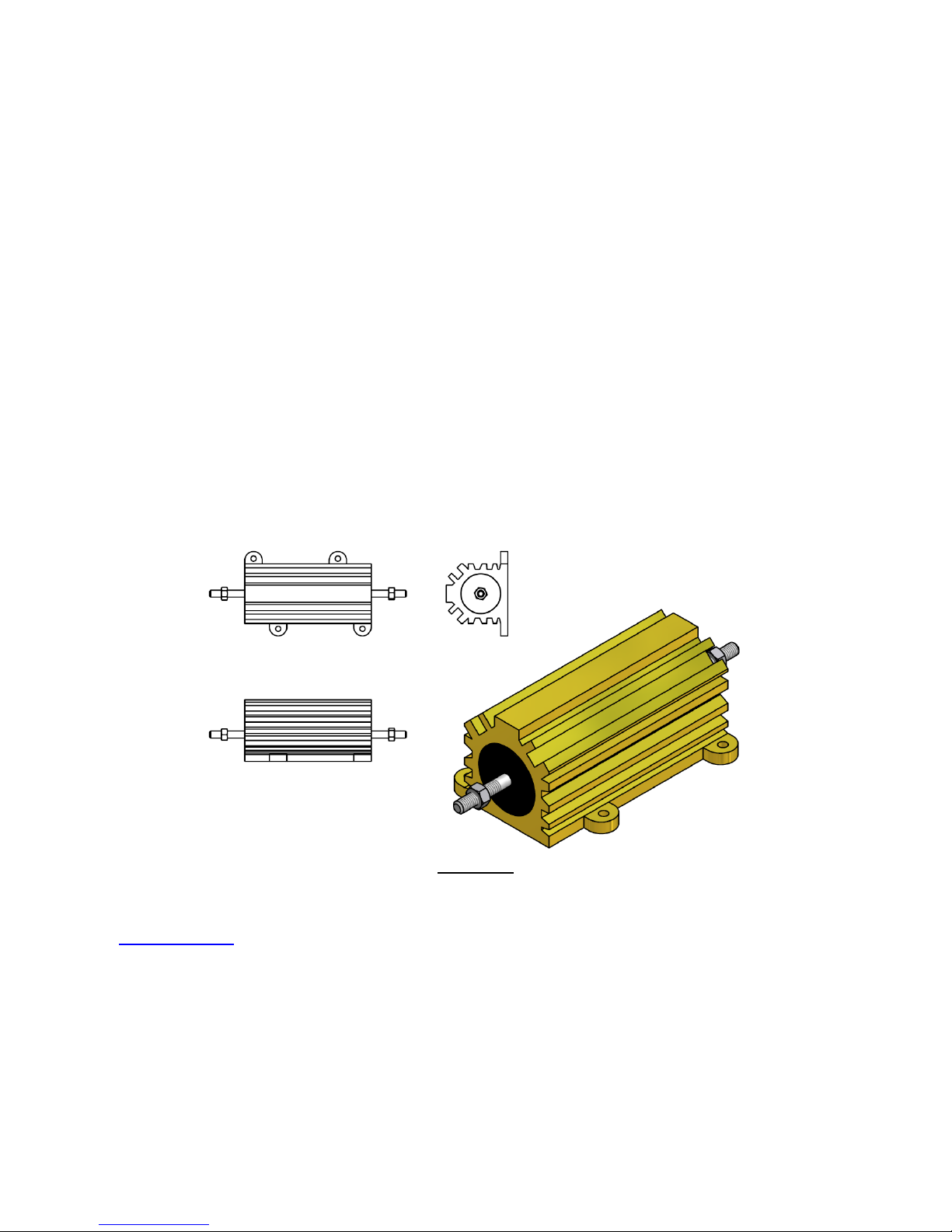

ESU-2050 & ESU-2300: Precision Load Resistors Are

Where Accuracy Starts

If there is another industry standard among manufacturers of electrosurgery generators, it is the precision load

resistors that are commonly used in their manufacturing testing, service, and calibration functions. That is why we

chose the exact same external load resistors for use with our new BC Biomedical ESU-2050 analyzer: the proven

Vishay Dale NH-250 series. See Appendix J for additional information on these precision power re sistors.

Vishay Dale NH-250 Precision Power Resistors Commonly Used With the ESU-2050

The BC Biomedical ESU-2300 ESU ana lyzer also uses 1% precision power resistors manu factured by Riedon

Inc. (

www.riedon.com). These 225-watt rated precision resistors and are of a design that is more suitable for use

as an internal component, and have a superior accuracy specification compared to some of the resistors used in

competitive ESU analyzers.

Product Development In Cooperation with ESU Manufacturers

The product development campaign on the new BC Biomedical ESU-2050 analyzer, and the subsequent design

of the more conventional ESU-2300 analyzer has brought us into contact with some of the leading electrosurgical

manufacturers in the world market.

12 Revision 1 – June 13, 2007

Figure 14

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 13

As we move forward with ongoing product support and possible enhancements to our ESU-2000 Series of ESU

Analyzers, we will remain in contact with these manufacturers.

Industry Standard Current Sensing Technology

Virtually all of the world’s leading electrosurgery generator manufacturers use RF current sensing as their

standard means of measurement when they test, service, and calibrate their electrosurgical devices. This is why

we chose to implement the more costly but more effective current sensing technology in our new ESU-2000

Series products. The simple fact is that current sensing is more accurate and more reliable than voltage

measurement when it comes to ESU analyzers. But don’t just take our word for it. Ask your favorite

electrosurgery manufacturer which technology they approve and use.

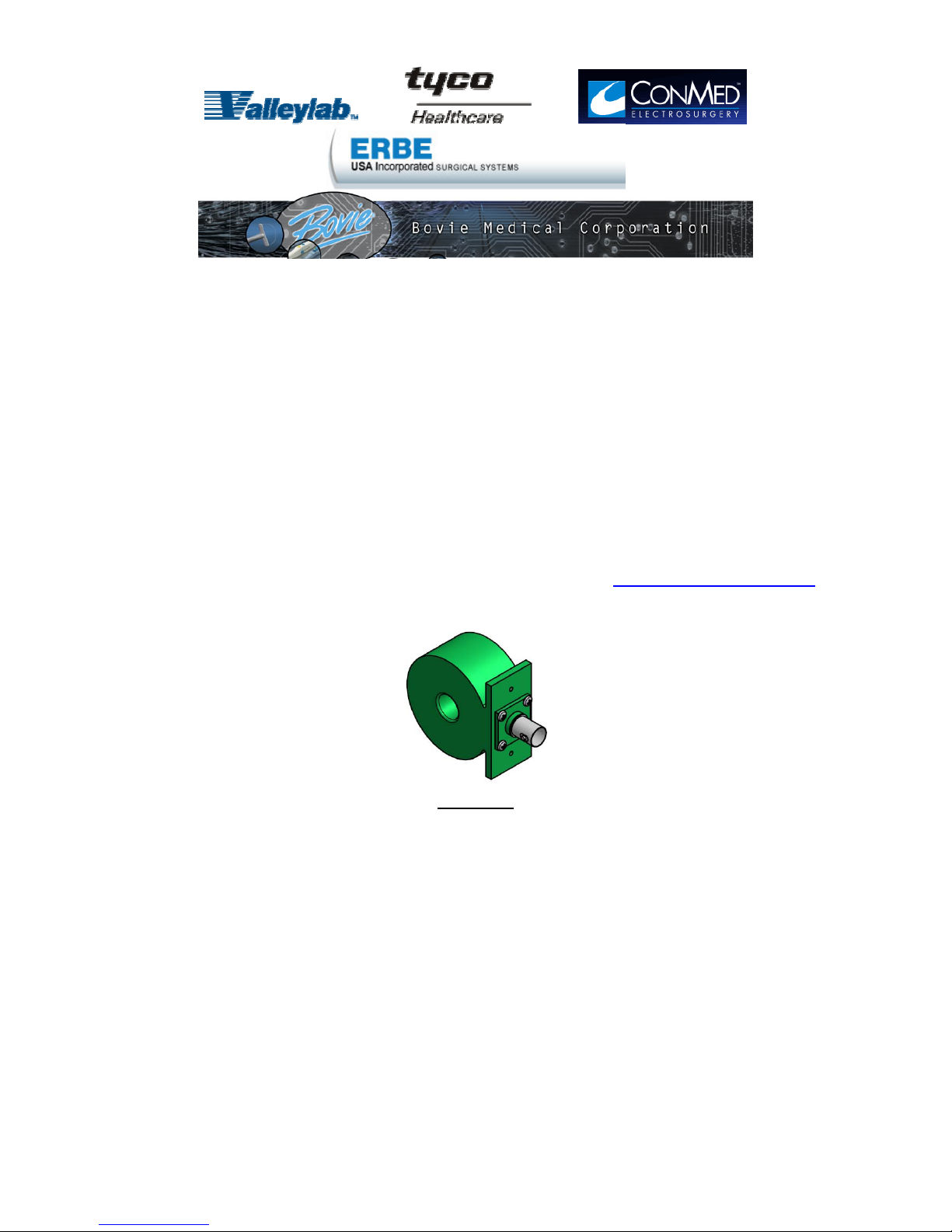

Working With The Best In Current Sensing: Pearson Electronics

When it comes to sensing high frequency current flow, Pearson Electronics (www.pearsonelectronics.com) is one

of the very best companies in the market today. We chose to utilize their current sensing transformers with both

the ESU-2050 and ESU-2300 analyzers.

External Current Sensing Toroid Transformer by Pearson Electronics

The BC Biomedical ESU-2050 utilizes an external transformer. The Pearson Model 411 (0.1:1 ratio) and Model

4100 (1:1 ratio) are the specified transformers for use with the ESU-2050. These are the exact same

transformers currently used by many major electrosurgery generator manufacturers. Data sheets for these

transformers can be seen in Appendices H & I. For customer convenience, these external transformers are

available directly from BC Group International, Inc.

The BC Biomedical ESU-2300 utilizes an internal custom designed current transformer manufactured specifically

for BC Group International, Inc. by Pearson Electronics.

Current Sensing vs. Voltage Measurement

The simple voltage measurement technique utilized by many competitive ESU analyzers introduces several

distinct product attributes as compared to the industry standard current sensing technique:

13 Revision 1 – June 13, 2007

Figure 15

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 14

• reduced manufacturing cost for the test equipment manufacturer

• shorter product development time

• reduced accuracy for the end-user

This is why we chose to utilize the industry standard current sensing methodology in our new BC Biomedical

ESU-2050 and ESU-2300 instruments. The manufacturers of these voltage measurement based ESU analyzers

realize the shortcomings of this technology, and simply try to explain around them. The following statement is

from a User’s Manual Update

9

for a competitive product that utilizes the voltage measurement technique:

The information above is significant in two main areas. First, the explanation clearly indicates that when using the

device in question, the operator should expect measurement errors up to 35% (as compared to the industry

standard current sensing technique)! Secondly, it acknowledges that the industry accepted normal practice

by electrosurgery generator manufacturers is the superior current sensing technique.

With the discontinuance of the Fluke Biomedical Model 454A, the BC Biomedical ESU-2050 and ESU-2300 ESU

analyzers are now the only commercially available analyzers on the market today utilizing industry standard

current sensing technology!

Ensuring Quality By Taking Care Of The Details

Sometimes it comes down to the little things that ensure accuracy and a long-lasting life to your ESU analyzer.

Things like selecting the right load resistors and relays that switch in and out individual load resistors in the

internal load bank can make a big difference. The ESU-2300 utilizes switching relays rated at 10,000 volts

(isolation), 3 amps, 7500 volts (switching). The leading competitive “high-end” analyzer on the market utilizes

relays that are rated significantly lower than this. The ESU-2300 utilizes internal precision load resistors that are

rated at 1% tolerance (DC) with a power dissipation rating of 225 watts. The leading competitive “high-end” ESU

9

The complete User Manual Update can be downloaded in PDF format form the manufacturer’s web site at the following url:

http://global.flukebiomedical.com/busen/support/manuals/default.htm

14 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 15

analyzer on the market utilizes resistors that are rated at 5% tolerance (DC) with a power dissipation rating of only

175 watts. These are just a few of the subtle differences between the new BC Biomedical ESU-2000 Series of

ESU analyzers and competitive analyzers on the market today. Don’t let the perceived “promise” of a particular

brand fool you into making an inferior choice when it comes to selecting your new ESU analyzer, Do your

homework before you purchase!

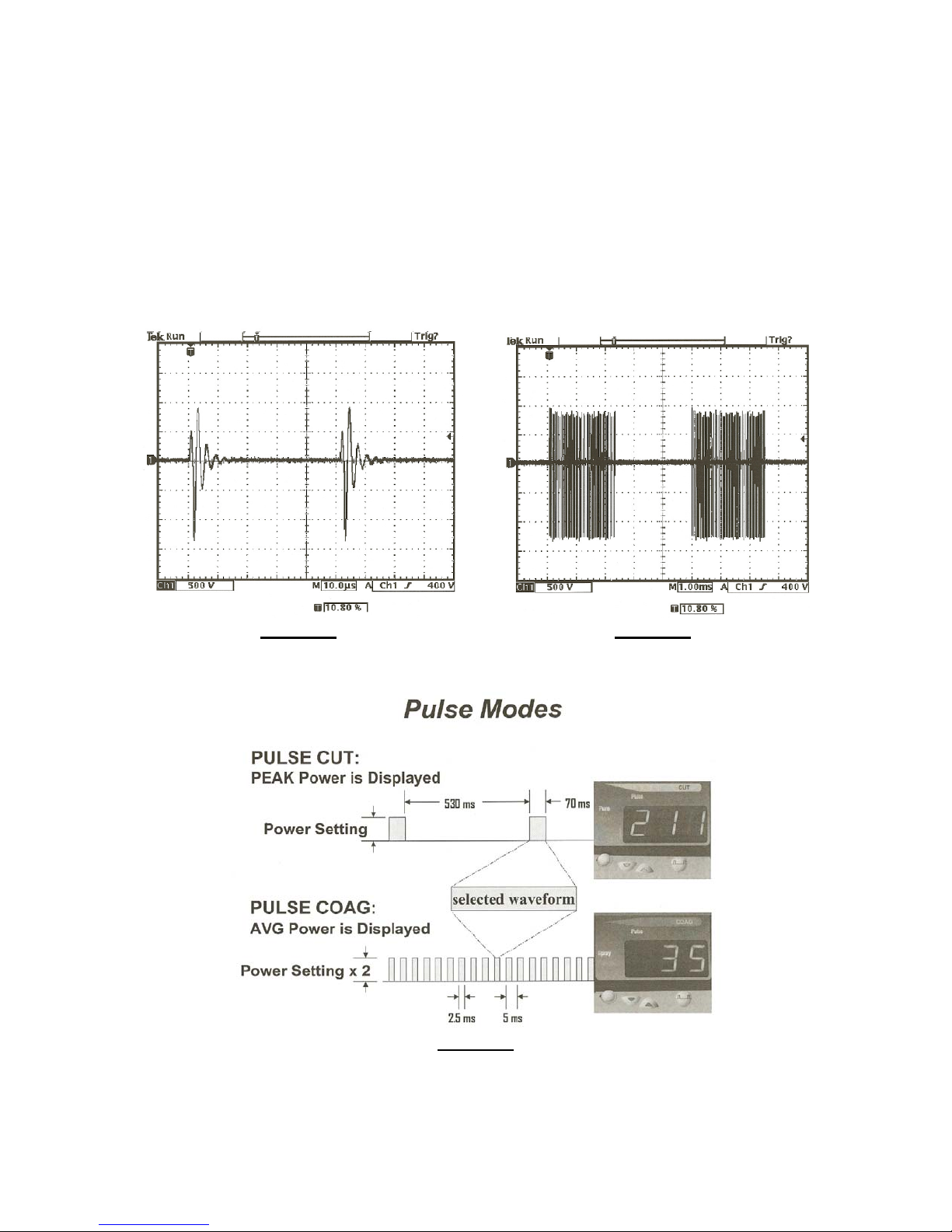

Those Crazy & Exotic Pulsed Waveforms

Conmed and Erbe are two manufacturers that offer electrosurgical generators with pulsed waveforms. Typically,

these pulsed waveforms have long single cycle time periods within which a signal is pulsed for a brief period of

time. This results in a very low duty cycle waveform that is extremely difficult to measure, let alone measure

accurately.

Figure 16 Figure 17

Conmed Spray RF Waveform Conmed Spray Pulsed Waveform

Figure 18

Conmed Pulse Waveform Modes

The BC Biomedical ESU-2050 Analyzer handles these pulsed waveforms easily, and yields accurate results time

after time, leaving all competitive units behind, wondering what hit them.

Copyright June, 2007 by BC Group International, Inc.

15 Revision 1 – June 13, 2007

Author: Michael R. Erwine

Page 16

ESU-2300: External Load Capabilities – Built In Non-Obsolescence

The most common shortcoming of any commercially available ESU analyzer is not having the correct load resistor

value available for the specific electrosurgery generator to be tested. No matter how many internal loads are

designed into a conventional ESU analyzer, you can be sure that one of the electrosurgery generator

manufacturers will eventually come along and specify a load that is not in the mix. That’s why we designed

external load resistor capability into our new ESU-2300 analyzer. Not only does the ESU-2300 allow you to

connect an external load, but you have the option of adding this external load value to the internal load selected

(additive mode) or simply using the external load for its actual value (external only mode).

Our ESU-2050 relies on external load resistors, so obsolescence due to unavailability of a specific test load is not

at all possible.

ESU-2000 Series PC Utility Software

Our BC Biomedical ESU-2000 Series Utility Software enhances the use of your BC Biomedical ESU-2050 and

ESU-2300 analyzers. When used with the ESU-2050, the software allows for export of the saved digitized

waveforms from the ESU-2050 to an Excel

®

workbook for further analysis. It also supports remote operation of

the ESU-2050 and ESU-2300. See Appendix M for sample screen shots form the utility software.

One Picture is Worth a Thousand Words – Or Up To 32,768 Data Points

We’ve all heard the old adage that “one picture is worth a thousand words”. The new BC Biomedical ESU-2050

analyzer puts some technological reality to this statement for the first time in ESU testing history. Through

utilization of the ESU-2000 Series PC Utility Software, now you can export data sets to Microsoft Excel

to 32,768 discrete data points on your electrosurgery generator’s output energy waveform. This export function

automatically creates an Excel

required. The created Excel

®

file that you can name anything you want. No knowledge of Microsoft Excel® is

®

file will automatically include all of the measurement data as well as a graphical

representation such as the one shown in Figure 19 below. See Appendix K for a sample look at the Excel

structure.

®

, with up

®

file

Microsoft Excel® (Automatically Created) Graphical Plot of Exported Electrosurgery Generator Waveform

You can then use the power of Excel

to Excel

®

, you can manipulate this data set to accomplish specific tasks, such as zooming in on a single cycle of a

specific waveform. See an example of this capability in the Figure 20 illustration below. This is a user-created

“zoomed” waveform based on the exported data.

16 Revision 1 – June 13, 2007

Figure 19

®

to analyze the data in any way you choose. Once you export the data set

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 17

Figure 20

Microsoft Excel Graphical Plot of Exported Electrosurgery Generator Waveform

With Zoom Manipulation of the Waveform Cycle

A sample Microsoft Excel® exported data set can be viewed in Appendix K. This example illustrates the

fundamental structure of the resulting Excel

on a single page. The original Excel

®

by a graph of the displayed data. This Excel

Biomedical ESU-2000 Series PC Utility Software. No knowledge of Excel

®

workbook, but has been reduced significantly in size to allow display

workbook contains 32,768 rows of actual measurement data, accompanied

®

workbook is created automatically by the export function of the BC

®

is required.

See The Data You Want – The Way You Want

Both the BC Biomedical ESU-2050 and ESU-2300 offer the capability of multiple parameter screens for viewing

test measurement parameters. The ESU-2050 allows you to select screens with 1 to 5 measurement parameters

for display. You can even select which parameters you want displayed in each window of the screen. For user

convenience, the value of load resistance is always displayed on the screen. See Figure 21 below.

ESU-2050: Display the Number of Measurement Parameters That You Want

The ESU-2300 offers multiple display screens for viewing instrument parameters and setup information. See

Figure 22 below for some examples of the wide screen layout of the ESU-2300’s LCD display with backlighting.

17 Revision 1 – June 13, 2007

Figure 21

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 18

Figure 22

ESU-2300: Multiple Options Are Available for Display of Measurement Parameteters

Easy Setup and Operation

The user interface of both the BC Biomedical ESU-2050 and ESU-2300 is extremely intuitive and easy to learn.

On-screen selection of test loads and other setup parameters is extremely easy.

Figure 23

The “learning curve” for new users of the ESU-2050 and ESU-2300 ESU analyzers is short and both instruments

have an extremely intuitive user interface.

The ESU-2050 and ESU-2300 User Interface is Easy to Learn

ESU-2050: Graphical Mode

The BC Biomedical ESU-2050 offers a graphical mode in which you can easily view the captured electrosurgical

generator waveform. You can even zoom in on the waveform for a closer look, and save it to any one of three

storage locations. Stored waveforms can have up to 32,768 discrete data points.

The ESU-2050 Graphical Mode Offers Advanced Capabilities

Up to three captured waveforms can be saved in the ESU-2050 for export to the ESU-2000 Series PC Utility

Software at any time.

The ESU-2000 Series PC Utility Software also works with the ESU-2300. See Appendix M for some screen shots

of the ESU-2000 Series PC Utility Software in action.

Figure 24

18 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 19

Product Comparison Overview

A brief overview of the BC Biomedical ESU-2000 Series as compared to leading competitive products on today’s

market is as follows:

Feature / Product BC Biomedical

Industry standard current sensing

technology

High-speed digital waveform processing

and analysis

Store digitized high resolution ESU

waveforms

Export ESU waveform data to Microsoft

®

Excel

Internal load resistors No Yes Yes Yes Yes

External load resistor capability Yes Yes Yes

RF Leakage Current Testing Yes

CQM Testing (Internal) No

Displayed parameters Power (watts)

RS232 Communications Port Yes Yes Yes Yes Yes

USB Communications Port Yes Yes No No No

Battery Operation No Yes No Yes No

Pulse waveform compatibility Yes No No No No

Accuracy specification for RMS current

Accuracy specification for RMS power

Easy Flash ROM field upgrades via PC Yes Yes No No No

First introduced to market (year) 2007 2007 1993 1998 2002

Manufactured In (Country) USA USA USA USA Norway

U.S. List Price $ 4,495 $ 3,495 $ 4,442 $ 3,439 $ 4,720

10

11

ESU-2050

Yes Yes Yes No

Yes

Patent Pending

Externally using

Externally per

Specifications

Peak Voltage

RMS Voltage

1% of Reading 2.5% of Reading 5% of Reading 2.5% of Reading 2% of Reading

1% of Reading 5% of Reading 10% of Reading 5% of Reading Not Specified

®

DFA

Technology

Yes No No No No

Yes Yes No No No

Perform Test

1:1 Current

Transformer

Perform

OEM

RMS Current

Crest Factor

Test Load Ω

For a more thorough product comparison, please visit

product comparison sheet on the ESU-2000 Series in Adobe Acrobat PDF format.

BC Biomedical

ESU-2300

Yes

Patent Pending

®

DFA

Technology

Yes Yes Yes Yes

Yes Yes

Power (watts)

RMS Current

Test Load Ω

Fluke

Biomedical

454A

(Discontinued)

No No No

Proprietary Load

Modules Only

Limited

Power (watts)

RMS Current

Peak to Peak

Voltage

Crest Factor

Test Load Ω

Fluke

Biomedical

RF303RS

Voltage

Measurement

No No

Yes

Limited

Power (watts)

RMS Current

Test Load Ω

Metron QA-ES

&

Fluke

Biomedical

QA-ES

No

Voltage

Measurement

Yes

Limited

Power (watts)

RMS Current

Peak to Peak

Voltage

Crest Factor

www.bcgroupintl.com/compare.htm and download the

10

This is an abbreviated specification. See the full specification in the product specifications at the end of this document or in the Appendices.

11

This is an abbreviated specification. See the full specification in the product specifications at the end of this document or in the Appendices.

19 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 20

One-Stop-Source: We Make It Easy for You

BC Group International, Inc. does whatever it takes to make it easy on our customers. Our customers who

purchase the ESU-2050 won’t have to go shopping elsewhere for their Pearson Electronics current sensing

transformers or Vishay Dale NH-250 precision load resistors. BC Group offers these product accessories directly

to the customer, without the standard long lead times from the original manufacturers.

Conclusion

At BC Group International, Inc., we would rather spend our time and effort designing and bringing new and

innovative products such as the new ESU-2050 and ESU-2300 ESU Analyzers to market under the BC

Biomedical brand, than waste it re-branding and re-launching 5 to 10 year old technology base products.

Innovative new products are what we are all about; not new photography and product overlays. We’ll let those

types of “development” efforts up to our competitors. We hold the technology needs of our customers in the

highest regard, and we are confident that our ongoing development efforts, in cooperation with some of the

medical device industry’s most significant players, will be recognized by our customers for what they are – a

sincere desire to lead the biomedical test and measurement industry through a continuous launch of exciting new

products. Our new BC Biomedical ESU-2050 and ESU-2300 ESU Analyzers are simply the most recent evidence

of our real mission. Stay tuned for much more to come!

Typical Test Setup Using the ESU-2050 ESU Analyzer – Test the Way ESU OEMs Test Their Products

20 Revision 1 – June 13, 2007

Figure 25

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 21

ESU-2050 Product Specifications

12

INPUT RANGE

Voltage (RMS): 2.0 – 700.0 mV RMS

Input Resolution: 0.1 mV RMS

Voltage (Peak): 1000.0 mV

Resolution: 0.1 mV

Frequency: 10 kHz – 10 MHz

Accuracy: 0.5 mV,

< 50 mV

1% of reading, > 50 mV, up to 1 MHz

3% of reading, > 50 mV, 1 to 10 MHz

CALCULATED RANGES

Current (with 0.1:1 CT): 7000 mA RMS

Resolution: 1 mA

Current (with 1:1 CT): 700.0 mA RMS

Resolution: 0.1 mA

Wattage: 999.9 Watts

Resolution: 0.1 Watt

Crest Factor: 1.4 to 500

Resolution: 0.1

INPUT IMPEDANCE

50 Ohms

INPUT COMPATIBILITY

RF Current Transformer (50 ohm): Pearson Electronics 411 or 4100 (Typical)

RF Current Transformer Attenuation: 0.1:1 or 1:1 User Selectable

OTHER

Display: LCD Graphical 128 x 64 Pixels with Backlight

Setup Memory: EEPROM, All Parameters

Memory Retention: 10 Years without Power

Operating Range: 15 to 30 Degrees C

Storage Range: -40 to 60 Degrees C

Construction: Enclosure – ABS Plastic

Face – Lexan, Back Printed

Size: 3.4” H x 9.1” W x 8.0” D

Weight:

Connections: Input: BNC

Output: Serial DB-9 or USB

Power Supply Adapter: 6 VDC, Cen ter Positive, 300 mA

Power Consumption: ON: less than 150 mA

OFF: less than 40 ua

Data Storage (Internal): 3 Sets of 32,768 Data Points

< 3 lbs

12

Specifications are accurate as of the date of release of this document. Specifications are subject to change without prior notice.

21 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 22

ESU-2300 Product Specifications

13

Measurement

Method

Power

Range

Resolution

Accuracy

Industry Standard Current

Sensing Using RF Current

Transformer (Pearson

®

Coil)

Weight

1.0 to 400.0 Watts RMS

0.1 Watts

+ 5% Reading or + 3 Watts

Physical

Enclosure

Electrical

Power Supply

(whichever is greater)

Voltage

Current

Range

Resolution

Accuracy

Frequency

30 to 2500 mA RMS

1 mA

+ 2.5% Reading or + 15 mA

(whichever is greater)

Battery

General

Display

Limits

Bandwidth

Crest Factor

Voltage

Ventilation

10 kHz to 10 MHz

1.4 to 500

10,000 Peak

Oscilloscope Output

Setup Memory

Memory Retention

Operating Range 15 to 35 Degrees C

Loads

Main Test Load

Range

Resolution

Accuracy

Duty Cycle

Auxiliary Test Load

Fixed

Accuracy

Rating

CQM Test Load

Range

Resolution

Accuracy

Storage Range -40 to 60 Degrees C

Humidity Limit

50 to 750 Ω

50 Ω

+ 1% (DC)

50% (1 minute period)

Connections

200 Ω

+ 1% (DC)

225 Watts

(Contact Quality Monitor test

load is an independent variable

load)

1 to 500 Ω

1 Ω

+ 2%

6.0” x 13.5” x 12.0”

12.5 lbs

External Universal Power

Supply: 12 VDC Output

83 to 264 VAC

47 to 63 Hz

Sealed Lead Acid

6 VDC, 7.2 AH

LCD Graphical 256 x 64

Pixels with Backlight

Internal Fan, variable speed,

over-temperature protected,

Fan rotor sensor

Isolated (uncalibrated), BNC

Connector

EEPROM, All Parameters

10 Years without Power

90% Non-Condensing

Oscilloscope: BNC

Communications: USB &

RS232 DB-9

External Loads: 4mm Safety

Sockets

13

Specifications are accurate as of the date of release of this document. Specifications are subject to change without prior notice.

22 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 23

Technical References

• Tyco Healthcare / Valleylab Electrosurgery Self-Study Guide, Copyright Tyco Healthcare Valleylab,

September, 1999 (Author: Brenda C. Ulmer, RN, MN, CNOR)

• Fluke Biomedical / DNI Nevada Model 454A Electrosurgical Analyzer Operating Manual, Copyright Fluke

Electronics / Fluke Biomedical

• Fluke Biomedical / Bio-Tek Instruments RF-303 Electrosurgical Analyzer Operator’s Manu al, Copyright

September, 1998 Fluke Electronics / Fluke Biomedical

• Metron QA-ES Operator’s Manual, Copyright Fluke Electronics / Fluke Biomedical

• DNI Nevada Model 402A Operating Manual, Copyright Fluke Electronics / Fluke Biomedical

• Dale Technology DALE3000 Instruction Manual, Copyright Fluke Electronics / Fluke Biomedical

• Tyco Healthcare / Valleylab Force 2 Electrosurgical Generator Service Manual, Copyright 2004

• Tyco Healthcare / Valleylab Force FX Electrosurgical Generator Service Manual, Copyright 2006

• Tyco Healthcare / Valleylab LigaSure Vessel Sealing System Service Manual, Copyright 2004

• Electrosurgical Generators: Guide to Performance and Safety Testing (ISBN 09661128-1-4), Copyright

Tektran Incorporated (Available for downloading as a PDF at

• Principles of Electrosurgery (ISBN 0-9661128-0-6), Copyright Tektran Incorporated (Available for

downloading as a PDF at

www.tektran.com)

• Understanding Electrosurgery, Bovie / Aaron Medical (Publication # MC-55-049-001 Rev 1), Copyright

July, 2003

• Application Note: Electrosurgical Analyzer Primer, Copyright Fluke Electronics / Fluke Biomedical

(Available for downloading as a PDF from the Fluke Electronics / Fluke Biomedical website at

http://global.flukebiomedical.com/busen/support/appnotes/default.htm#)

• ANSI/AAMI HF18-2001 Standard, Electrosurgical Devices

www.tektran.com)

23 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 24

About the Author

Michael R. Erwine has been involved in the medical device industry since 1975, with his roots being in biomedical

and clinical engineering. Since January, 2006 Mr. Erwine has been employed by BC Group International, Inc.

and is currently fulfilling multiple roles including Strategic Accounts Manager, Worldwide Dealer Network

Manager, Product Manager, as well as other functions. He also manages the BC Group International, Inc.

Western Regional Office in Carson City, NV. Since 1989, Mr. Erwine has worked for or with (under strategic

alliances, marketing partnerships, corporate family structure, etc.), the following major biomedical test and

measurement manufacturers and service providers:

• Spectrum Technologies Inc. (Elysburg, PA)

• Dynatech Nevada Inc. (Carson City, NV)

• Metron AS (Trondheim, Norway)

• Bender GmbH (Grunberg, Germany)

• Datrend Systems (Burnaby, Canada)

• Lionheart Technologies Inc. (Carson City, NV)

• DNI Nevada Inc. (Carson City, NV)

• Bio-Tek Instruments Corp. (Burlington, VT)

• Ultramedic Ltd (Liverpool, England)

• Labatoire Gamida (Eaubonne, France)

• Dale Technology Inc. (Thornwood, NY)

• Fluke Biomedical Corp. (Carson City, NV)

• Fluke Electronics Corp. (Everett, WA)

• Metron USA (Grand Rapids, MI)

During his career track, Mr. Erwine has served in the following capacities, just to name a few:

• Product Manager

• Project Manager

• Product Validation Engineer

• Commercial Manager

• National Sales Manager

• International Sales Manager

• Strategic Accounts Manager

• VP of Sales & Marketing

• Executive Vice President

• General Manager

In the electrosurgery testing specialty area, Mr. Erwine has interfaced and worked with major medical device

manufacturers such as Tyco Healthcare (Valleylab), Conmed (Electrosurgery Division), Erbe USA, Bovie, etc.

While at Dynatech Nevada Inc., Mr. Erwine successfully launched the industry icon Model 454A ESU Analyzer.

Following the acquisition of Dynatech Nevada, Inc. by Lionheart Technologies in 1997, Mr. Erwine launched the

DNI Nevada Model 402A ESU Analyzer and assisted the Bio-Tek Instruments sales and marketing staff in the

launch of their very first “active” ESU testing device in the way of the concurrent Bio-Tek Model RF-303 (currently

offered as the Fluke Biomedical RF-303

Mr. Erwine has worked heavily with Tyco Healthcare / Valleylab and Conmed Electrosurgery Division since

January, 2006 on the development and functionality of the new BC Biomedical ESU-2050 analyzer, and has also

interfaced with Erbe USA, Bovie, Megadyne, and others during the BC Biomedical ESU-2000 Series development

project. Mr. Erwine continues to work with all of these medical device manufacturers in his various roles at BC

Group International, Inc. The design and functionality of the new BC Biomedical ESU-2000 Series of ESU

Analyzers is strongly rooted in these collaborative efforts with some of the same medical device manufacturers

with whom Mr. Erwine has historically worked.

If you have questions concerning anything in this document or on the ESU-2000 Series of Electrosurgery

Analyzers in general, please feel free to e-mail the author at

RS

).

merwine@bcgroupintl.com.

24 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 25

APPENDICES

All documents and information contained in the following Appendices have been

obtained from various sources within the public sector, and do not represent confidential

information or trade secrets of any kind. Recognition of ownership and copyright is

hereby given to the companies and manufacturers whose product and other types of

information are represented here in this document for informational purposes. Original

ownership and copyright of this documentation remains with these companies.

25 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 26

APPENDIX A

Fluke Biomedical 454A Instrument Specifications

(Source: Fluke Biomedical Model 454A Operating Manual)

26 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 27

APPENDIX B

Fluke Biomedical RF-303RS Instrument Specifications

(Source: Fluke Biomedical RF-303 Operator’s Manual)

27 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 28

APPENDIX B (Continued)

Fluke Biomedical RF-303RS Instrument Specifications

(Source: Fluke Biomedical RF-303 Operator’s Manual)

28 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 29

APPENDIX B (Continued)

Fluke Biomedical RF-303RS Instrument Specifications

(Source: Fluke Biomedical RF-303 Operator’s Manual)

29 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 30

APPENDIX B (Continued)

Fluke Biomedical RF-303RS Instrument Specifications

(Source: Fluke Biomedical RF-303 Operator’s Manual)

30 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 31

APPENDIX C

Dale Technology DALE3000 Instrument Specifications

(Source: Dale Technology Product Catalog)

31 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 32

APPENDIX C (Continued)

Dale Technology DALE3000 Instrument Specifications

(Source: Dale Technology Product Catalog)

32 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 33

APPENDIX D

Metron QA-ES Instrument Specifications

(Source: Metron QA-ES Product Data Sheet)

33 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 34

APPENDIX E

Valleylab Force FX Generator Output Waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export14)

14

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

34 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 35

APPENDIX E (Continued)

Valleylab Force FX Generator Output Waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export15)

15

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

35 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 36

APPENDIX F

Valleylab Force 2 Generator Output waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export16)

16

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

36 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 37

APPENDIX F (Continued)

Valleylab Force 2 Generator Output waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export17)

17

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

37 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 38

APPENDIX G

Conmed System 5000 Output Waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export18)

18

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

38 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 39

APPENDIX G (Continued)

Conmed System 5000 Output Waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export19)

19

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

39 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 40

APPENDIX G (Continued)

Conmed System 5000 Output Waveforms

(Source: BC Biomedical ESU-2000 Series PC Utility Software Excel® File Export20)

20

Graphed data shown in the left hand set of illustrations above was automatically created by Excel® as part of the normal data export from the ESU-2000

Series PC Utility Software. No user knowledge of Excel

within Excel

40 Revision 1 – June 13, 2007

®

by the user, based upon the data exported from the ESU-2000 Series PC Utility Software.

®

for graphing purposes is required at this level. The graphs on the right were individually created

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 41

APPENDIX H

Pearson Electronics Model 411 Data Sheet

(Source: www.pearsonelectronics.com)

41 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 42

APPENDIX I

Pearson Electronics Model 4100 Data Sheet

(Source: www.pearsonelectronics.com)

42 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 43

APPENDIX J

Vishay Dale NH-250 Data Sheet

(Source: www.vishay.com)

43 Revision 1 – June 13, 2007

Copyright June, 2007 by BC Group International, Inc.

Author: Michael R. Erwine

Page 44

APPENDIX J (Continued)

Vishay Dale NH-250 Data Sheet