Page 1

HIGH PRECISION / RESOLUTION

DIGITAL PRESSURE METERS

DPM-2300 SERIES

USER MANUAL

Page 2

Page 3

BC BIOMEDICAL

DPM-2300 SERIES

TABLE OF CONTENTS

WARNINGS, CAUTIONS, NOTICES .............................................................................. 2

DESCRIPTION............................................................................................................. 7

OVERVIEW.................................................................................................................. 12

KEYS............................................................................................................................ 19

OPTIONS ..................................................................................................................... 21

COMMUNICATIONS.................................................................................................... 22

MANUAL REVISIONS.................................................................................................. 29

PREVENTIVE MAINTENANCE.................................................................................... 29

WARRANTY................................................................................................................. 29

SPECIFICATIONS ....................................................................................................... 30

NOTES......................................................................................................................... 32

1

Page 4

WARNING - USERS

The DPM-2300 Series Meters are for use by

skilled technical personnel only.

WARNING - USE

The DPM-2300 Series Meters are intended for

testing only and they should never be used in

diagnostics, treatment or any other capacity

where they would come in contact with a patient.

WARNING - MODIFICATIONS

The DPM-2300 Series Meters are intended for use

within the published specifications. Any

application beyond these specifications or any

unauthorized user modifications may result in

hazards or improper operation.

WARNING - CONNECTIONS

All connections to patients must be removed

before connecting the Device Under Test (DUT)

to the Meter. A serious hazard may occur

if the patient is connected when

testing with the Meter.

Do not connect any leads from the patient

directly to the Meter or DUT.

WARNING - BATTERIES

Turn Power Off and unplug any Battery

Eliminator before replacing batteries or cleaning

the surface of the Meter.

WARNING - LIQUIDS

Do not submerge or spill liquids on the Meter.

Do not operate the Meter if internal components

not intended for use with fluids may have been

exposed to fluid, as the internal leakage may

have caused corrosion and be a potential hazard.

2

Page 5

CAUTION - SERVICE

The DPM-2300 Series Meters are intended to be

serviced only by authorized service personnel.

Troubleshooting and service procedures

should only be performed by

qualified technical personnel.

CAUTION - ENVIRONMENT

The DPM-2300 Series Meters are intended to

function between 15 and 30 °C.

Exposure to temperatures outside this range can

adversely affect the performance of the Meter.

CAUTION - MEDIA

The DPM-2300 Series Meter is to be used only

with a pure fluid or gas that is compatible with

Pyrex, Glass, Silicon, Alumina Ceramic, Epoxy,

RTV, gold , aluminum and nickel.

CAUTION – PRESSURE LINE

Purge pressure line with distilled water

following any application that introduces

liquid into the meter.

CAUTION - CLEANING

Do not immerse. The Meter should be cleaned

by wiping gently with a damp, lint-free cloth.

A mild detergent can be used if desired.

CAUTION - INSPECTION

The DPM-2300 Series Meters should be

inspected before each use for wear and

the Meter should be serviced

if any parts are in question.

3

Page 6

NOTICE – CE

The DPM-2300 Series Meters bear the mark

Based on the following testing standards:

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

EMC – Directive 89/336/EEC as amended by 92/31/EEC and 93/68/EEC

EN 61326-1:1997 + A1:1998 + A2:2001 + A3:2003

“Electrical equipment for measurement, control and

laboratory use – EMC requirements”

This equipment has been type tested by an independent, accredited testing laboratory

and compliance was demonstrated to the above standard to the extent applicable.

EMISSIONS

Radiated and Line Conducted Emissions

EN 61000-3-2:2000 Harmonic Current Emissions

EN 61000-3-3:1995 + A1:2001 Voltage Fluctuation and Flicker

IMMUNITY– CLASS C

EN 61000-4-2:1995 + A1:1998 + A2:2001 Electrostatic Discharge

EN 61000-4-3:2002 Radiated Electric Field Immunity

EN 61000-4-4:1995 + A1:2001 + A2:2001 Electrical Fast Transients / Bursts

EN 61000-4-5:1995 + A1:2001 Surge Voltage

EN 61000-4-6:1996 + A1:2000 Conducted Disturbance

EN 61000-4-11:1994 + A1:2001 Voltage Dips and Short Interrupts

LOW VOLTAGE DIRECTIVE

EC – Directive 73/23/EC

EN 61010-1:2001

“Safety requirements for electrical equipment for measurement, control, and

laboratory use – General requirements”

This equipment has been type tested and compliance was demonstrated

to the above standard to the extent applicable.

4

Page 7

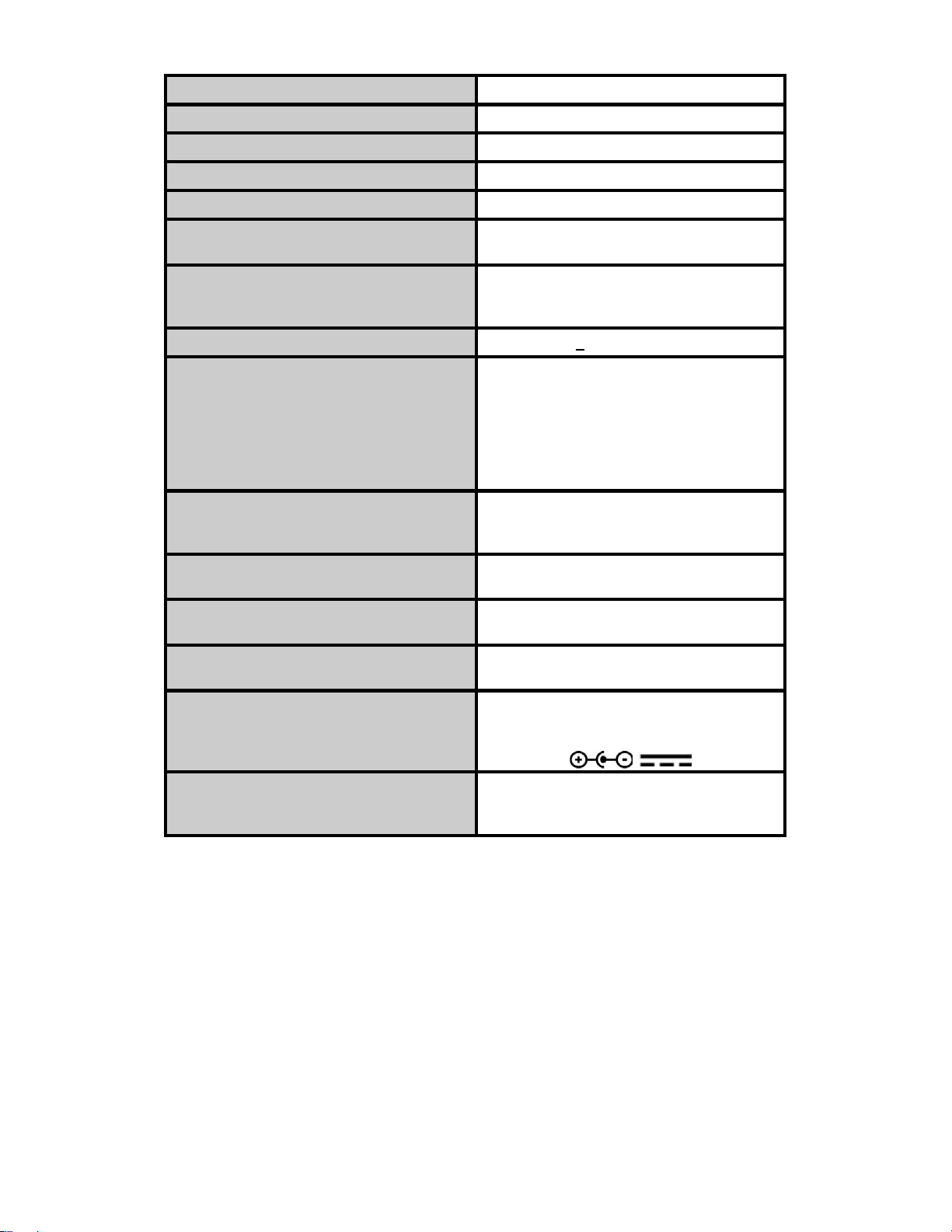

NOTICE – SYMBOLS

Symbol Description

Caution

(Consult Manual for Further Information)

Center Negative

Direct Current

NOTICE – ABBREVIATIONS

c centi- (10-2)

C Celsius

0 centimeter water

cmH

2

° degree

DUT Device Under Test

Euro European

F Fahrenheit

FS Full Scale

hrs hours

Hz hertz

inHg inches mercury

0 inches water

inH

2

k kilo- (10

2

kg/cm

kilograms per centimeter squared

3

)

kHz kilohertz

Kpa kilopascal

-6

µ micro- (10

)

µA microampere

-3

m milli- (10

)

mA milliampere

mBar milliBar

mm millimeter

mmHg millimeter mercury

Ω ohm

Press Pressure

PSI pounds per square inch

PSIG pounds per square inch gauge

Sec seconds

Temp temperature

US United States

V volt

VDC Direct Current Voltage

5

Page 8

USER ASSUMES FULL RESPONSIBILITY FOR UNAUTHORIZED

EQUIPMENT MODIFICATIONS OR APPLICATION OF EQUIPMENT

OUTSIDE OF THE PUBLISHED INTENDED USE AND

SPECIFICATIONS. SUCH MODIFICATIONS OR APPLICATIONS

MAY RESULT IN EQUIPMENT DAMAGE OR PERSONAL INJURY.

BC GROUP INTERNATIONAL, INC. RESERVES THE RIGHT TO

MAKE CHANGES TO ITS PRODUCTS OR SPECIFICATIONS AT

ANY TIME, WITHOUT NOTICE, IN ORDER TO IMPROVE THE

DESIGN OR PERFORMANCE AND TO SUPPLY THE BEST

POSSIBLE PRODUCT. THE INFORMATION IN THIS MANUAL HAS

BEEN CAREFULLY CHECKED AND IS BELIEVED TO BE

ACCURATE. HOWEVER, NO RESPONSIBILITY

IS ASSUMED FOR INACCURACIES.

NOTICE – CONTACT INFORMATION

NOTICE – DISCLAIMER

NOTICE – DISCLAIMER

BC BIOMEDICAL

BC GROUP INTERNATIONAL, INC.

PO BOX 25125

9415 GENTRY AVE

ST. LOUIS, MO 63125

USA

1-800-242-8428

314-638-3800

www.bcgroupintl.com

sales@bcgroupintl.com

Manual DPM-2300 Series Copyright © 2007

www.bcgroupintl.com

Made in the USA

08/07 Rev 03

6

Page 9

BC GROUP

DPM-2300 SERIES

DIGITAL PRESSURE METERS

The Model DPM-2300 Series is a Microprocessor based High Precision High Resolution

Digital Pressure Meter family. These meters measure both gas and liquid pressures and

provide multiple engineering unit displays for the results. The unit may have one or two

pressure sensors and an optional temperature sensor input to measure pressure and

temperature all in one meter.

The DPM-2300 Series meters are intended to be used by skilled technicians in the

evaluation and servicing of a wide variety of medical equipment. The following are

highlights of some of the main features:

DPM-2301 (Basic Features):

• LARGE GRAPHICS DISPLAY WITH CURSOR SELECTION OF

OPTIONS AND SETUP OF PARAMETERS

• 0.05% FS PRESSURE ACCURACY

• STANDARD PRESSURE SCALES INCLUDE 13 DIFFERENT

ENGINEERING UNIT RANGES

(PSI, mmHG@0C, mmHg@20C, inHG@0C, inHg@20C,

cmH

kg/cm

O@20C, inH2O@4C, inH2O@20C, inH2O@60F,

2

2

, Kpa, Bar, mBar)

• MAX and MIN PRESSURE VALUE CAPTURE AND STORAGE

• DIGITAL CALIBRATION – NO POTS TO TURN

• SELECTABLE DISPLAY OPTIONS AND DIGIT SIZES

• BATTERY LIFE DISPLAY (0 to 100%)

• PROGRAMMABLE DIGITAL FILTER

• DISPLAY CONTRAST IS SOFTWARE ADJUSTABLE

• 24 BIT MEASUREMENT

• DIGITAL ZERO ADJUSTMENT – NO POTS TO TURN

• DC ANALOG OUTPUT (OPTIONAL)

DPM-2302 ADDS:

• RS232 SERIAL COMMUNICATIONS

SECOND PRESSURE SENSOR ADDS:

• INDEPENDENT PRESSURE CHANNEL

• SEPARATE AND COMBINED DISPLAY OPTION

7

Page 10

TEMPERATURE OPTION ADDS:

• YSI 700 OR 100 Ω

RTD TEMPERATURE PROBE INTERFACE

• -20.0 TO100.0 C / -4.0 TO 212.0 F TEMPERATURE RANGE

• 0.5% FS ACCURACY

• MAX and MIN TEMPERATURE VALUE CAPTURE AND STORAGE

OPTIONAL ACCESSORIES:

BC20 - 21100 BATTERY ELIMINATOR (US Version)

BC20 - 21101 BATTERY ELIMINATOR (Euro Version)

BC20 - 41337 COMMUNICATIONS CABLE (7Pin Mini-Din to DB 9 F)

BC20 - 30106 BC BIOMEDICAL SMALL SOFT SIDED CARRYING CASE

BC20 - 01005 UNIVERSAL PRESSURE ADAPTER KIT

BC20 - 01006 YSI TEMPERATURE CABLE

8

Page 11

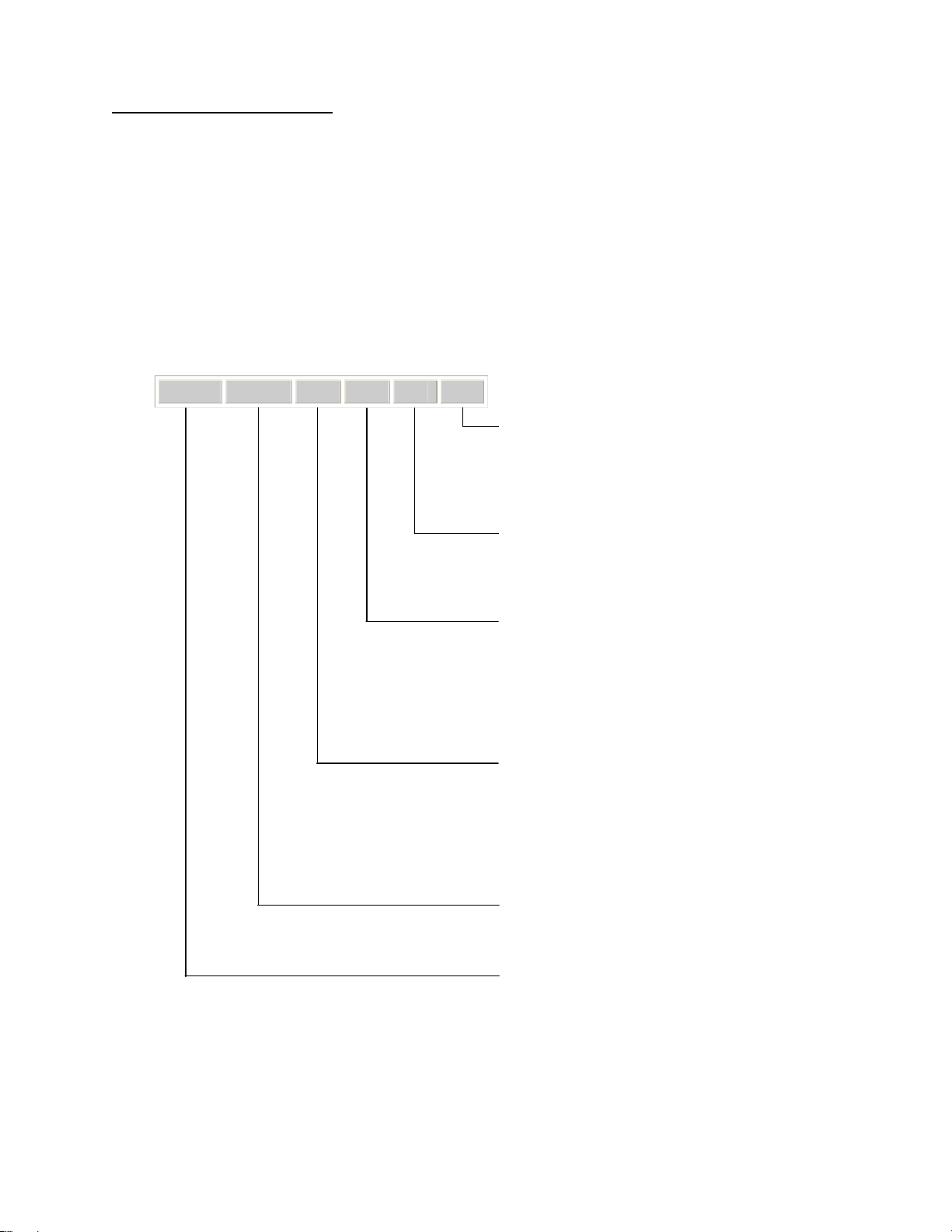

AVAILABLE MODELS:

g

r

There are a numerous possible configurations for the DPM-2300. The meter can have one

or two pressure sensors and an optional temperature sensor input. There are a variety of

pressure transducer full-scale values and two types of temperature sensor inputs available.

It can be configured with or without and RS232 communications port and a Min/Max

pressure and temperature capture and hold function. The optional DC output provides a

DC voltage level output that is proportional to the full scale value of the pressure being

measured. The model number configuration guide below calls out these various options

and configurations. For additional details on the Pressure and Temperature Sensor

Ranges, see next pages.

DPM 230X XX XX XX XX

Options

DC = DC (Direct Current)

Analog Output

FC = Female Coupler CPC Connectors

MC = Male Insert CPC Connectors

Temperature Sensor

N = Not Applicable

Y7 = YSI 700

R1 = 100 Ω RTD

Pressure Sensor 2 (Port 2 Left)

N = Not Applicable

100 = Max 100 PSI (CPC Connector)

75 = Max 75 PSI (CPC Connector)

10 = Max 10 PSI (Luer Connector)

5 = Max 5 PSI (Luer Connector)

.3 = Max .3 PSI (Luer Connector)

Pressure Sensor 1 (Port 1Right)

N = Not Applicable

100 = Max 100 PSI (CPC Connector)

75 = Max 75 PSI (CPC Connector)

10 = Max 10 PSI (Luer Connector)

5 = Max 5 PSI (Luer Connector)

.3 = Max .3 PSI (Luer Connector)

2300 Series

2301 = Basic Model (Includes Min/Max)

2302 = RS232 Add

Di

ital Pressure Mete

9

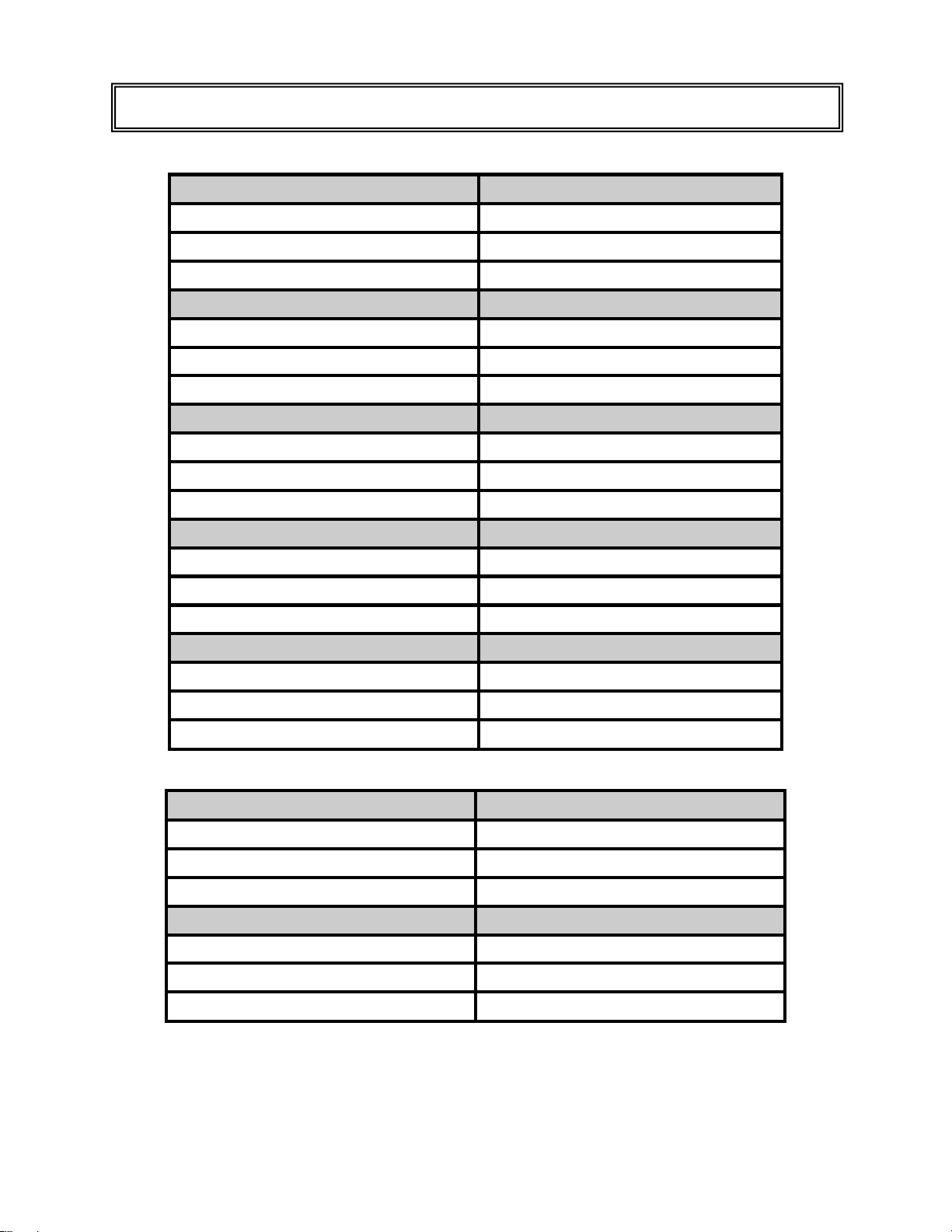

Page 12

Pressure Sensor 100

Units Range

(Accuracy: .05%

FS = +/- 0.05 PSI)

PSI -13.500 to 100.000

mmHg 0C -698.2 to 5171.5

mmHg 20C -700.6 to 5190.3

inHg 0C -27.486 to 203.602

inHg 20C -27.586 to 204.342

cmH2O 20C -951.8 to 7043.2

inH2O 4C -373.6 to 2768.1

inH2O 20C -374.3 to 2772.9

inH2O 60F -374.1 to 2770.8

kg/cm2 -.9491 to 7.0306

kPa -93.08 to 689.48

mBar -930.8 to 6894.8

Bar -.9308 to 6.8948

Pressure Sensor 10

Units Range

(Accuracy: .05%

FS = +/- 0.005 PSI)

PSI -10.0000 to 10.0000

mmHg 0C -517.15 to 517.15

mmHg 20C -519.03 to 519.03

inHg 0C -20.3602 to 20.3602

inHg 20C -20.4342 to 20.4342

cmH2O 20C -704.32 to 704.32

inH2O 4C -276.81 to 276.81

inH2O 20C -277.29 to 277.29

inH2O 60F -277.08 to 277.08

kg/cm2 -.70307 to .70307

kPa -68.948 to 68.948

mBar -689.48 to 689.48

Bar -.68948 to .68948

mmHg 0C -698.2 to 3878.6

mmHg 20C -700.6 to 3892.7

inHg 20C -27.586 to 153.256

cmH2O 20C -951.8 to 5282.4

inH2O 4C -373.6 to 2076.1

inH2O 20C -374.3 to 2079.7

inH2O 60F -374.1 to 2078.1

Pressure Sensor 75

Units Range

(Accuracy: .05%

FS = +/- 0.0375 PSI)

PSI -13.500 to 75.000

inHg 0C -27.486 to 152.702

kg/cm2 -.9491 to 5.2730

kPa -93.08 to 517.11

mBar -930.8 to 5171.1

Bar -.9308 to 5.1711

mmHg 0C -258.57 to 258.57

mmHg 20C -259.51 to 259.51

inHg 20C -10.2171 to 10.2171

cmH2O 20C -352.16 to 352.16

inH2O 4C -138.40 to 138.40

inH2O 20C -138.64 to 138.64

inH2O 60F -138.54 to 138.54

Pressure Sensor 5

Units Range

(Accuracy: .05%

FS = +/- 0.0025 PSI)

PSI -5.0000 to 5.0000

inHg 0C -10.1801 to 10.1801

kg/cm2 -.35153 to .35153

kPa -34.473 to 34.473

mBar -344.74 to 344.74

Bar -.34474 to .34474

10

Page 13

Pressure Sensor .3

Units Range

(Accuracy: .05%

FS = +/- 0.00015 PSI,

+/- 0.01 cmH2O)

PSI -.30000 to .30000

mmHg 0C -15.514 to 15.514

mmHg 20C -15.571 to 15.571

inHg 0C -.61081 to .61081

inHg 20C -.61303 to .61303

cmH2O 20C -21.129 to 21.129

inH2O 4C -8.304 to 8.304

inH2O 20C -8.319 to 8.319

inH2O 60F -8.312 to 8.312

kg/cm2 -.021092 to .021092

kPa -2.0684 to 2.0684

mBar -20.684 to 20.684

Bar -.020684 to .020684

Temperature Sensor

Units Range

100 Ω RTD

(Accuracy: .5%

FS = +/- 0.5 C)

Degrees C -20.0 to 100.0

Degrees F -4.0 to 212.0

Temperature Sensor

Units Range

YSI 700

(Accuracy: .5%

FS = +/- 0.5 C)

Degrees C -20.0 to 100.0

Degrees F -4.0 to 212.0

11

Page 14

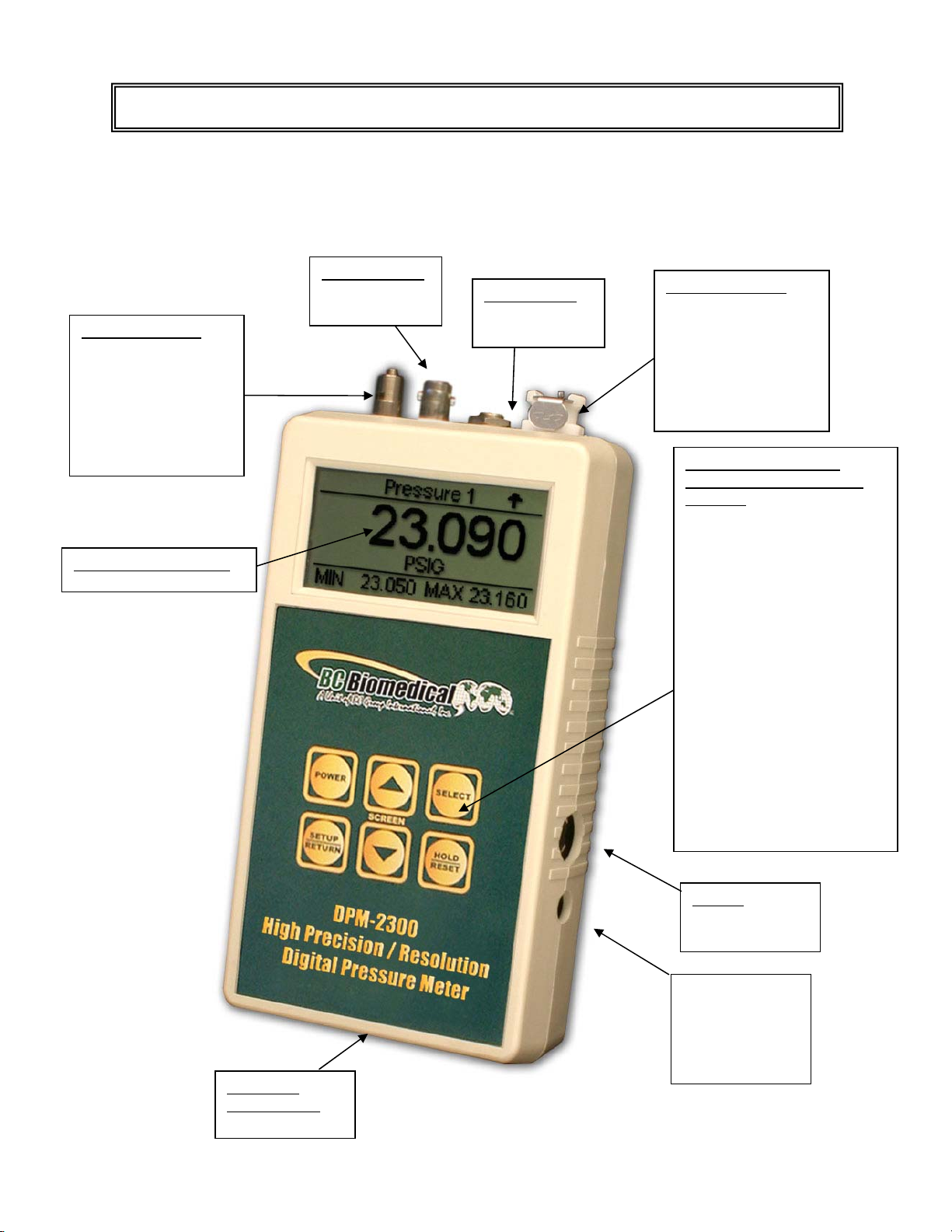

OVERVIEW

This section looks at the layout of the DPM-2300 and gives descriptions of the elements

that are present.

Pressure Port #2:

Luer Lock Connector

(or Female Coupler

CPC Connector

or Male Insert

CPC Connector,

Range and Option

Dependent)

LCD Graphical Display

Analog Output:

BNC (Optional)

Temperature:

¼” Phone Jack

(Optional)

Pressure Port #1:

Female Coupler

CPC Connector

(or Male Insert

CPC Connector,

Option Dependent

or Luer Lock,

Range Dependent)

6 Light Touch Keys for

Selecting Parameters and

Settings:

POWER for Turning Unit On

and Off

UP and DOWN Arrows for

Scrolling Through Selected

Options. When No Options

are Selected, for Changing

Display Screen

SELECT for Choosing

Setting or Parameter to

Change

SETUP/RETURN for

Entering and Exiting Setup

Menu

HOLD/RESET for Freezing

the Unit at its Current Setting

and for Clearing the Min/Max

Value in Capture Register

RS232:

7 PIN Mini-Din

(Optional)

Power

2.1 mm Jack

(Optional Battery

Eliminator)

9V Battery

Compartment

(Rear)

12

Page 15

MAIN SCREENS

– There can be up to five main screens, depending on the model. They

are PRESSURE 1, PRESSURE 2, TEMPERATURE, COMBINED and INPUTS. The

available screens can be toggled through using .

Pressure Port 1

Display with Min/Max

Option selected

Pressure Port 2

Display with Min/Max

Option selected

Temperature Display

with Min/Max Option

selected

Combined Screen showing:

Pressure Port 1

Pressure Port 2

Temperature

Input Identification Screen

Note: Sensor limits are

displayed based on

selected range.

13

Page 16

PRESSURE SCALE

– The pressure scale is indicated by the units displayed under

the reading. The scale can be changed by using to highlight the unit line and

to toggle the pressure units.

Pressure Units

PSI

mmHg 0C

mmHg 20C

inHg 0C

inHg 20C

cmH2O 20C

inH2O 4C

inH2O 20C

inH2O 60F

kg/cm2

kPa

mBar

Bar

NOTE: If the measured pressure is outside of the range of the instrument, an OVER

RANGE or UNDER RANGE message box will be displayed.

Typical display with

“Over Range”

message box.

14

Page 17

TEMPERATURE SCALE

– The temperature scale is indicated by the units displayed under

the reading. The scale can be changed by using to highlight the unit line and

to toggle the temperature units. The following is a breakdown of the available

temperature units and the measurement range for typical sensors:

Temperature Sensor

Units

Degrees C

Degrees F

NOTE: If the measured temperature is outside of the range of the instrument, an OVER

RANGE or UNDER RANGE message box will be displayed. If a probe is not connected,

the NO PROBE message box will be displayed.

Typical display with

“No Probe” message

box.

15

Page 18

SYSTEM SETUP

– The Setup Mode allows the user to adjust the configuration of the

meter. The Setup screen can be entered using the key. The parameters can be

changed by using to highlight the line and to toggle the available

options. The Setup screen can be exited using the key. The following is a

breakdown of the parameters available in the configuration of the unit and their available

options:

System Setup Configuration

Parameter Description Range

Display Min/Max

Analog Scale

Analog Source

Contrast Adjust

Auto Off Timer (Min)

Battery Life

Beep Length

Filter – Pres 1 (Sec)

Filter – Pres 2 (Sec)

Filter – Temp (Sec)

Software

Selects whether the Min and Max values will be

displayed on the main screens

(except COMBINED).

Analog Output Scaling voltage. This is the

maximum analog output voltage. The output is

scaled to this voltage over the positive input of the

selected source.

Selects the source reading for the analog output

Sets the contrast of the display screen.

Determines the period of inactivity before the meter

is turned OFF. A timer is started when the meter is

turned ON and is reset each time a key is pressed.

When the timer reaches the value set in this

parameter, the power is automatically turned OFF.

(NOTE: Setting this parameter to 0 disables the

Auto Off timer. When running from line power, the

meter does not automatically shut off.)

Displays current life of the battery.

At 10%, a warning screen will appear.

Sets volume for the audio beep.

Determines the number of samples that are

averaged in the digital filter. The software has a

Digital Filter that averages the readings to produce

a stable display.

(NOTE: Increasing this setting will cause a more

stable display. However, it will also cause a slower

response to small changes. The best setting is the

smallest number that provides a stable display.)

Displays current software program.

Yes/No

1.0 to 4.0 Volts

Pres1, Pres2, or

Temp

0-20

0-30 Minutes

0-100%

(Read Only)

0-16

0-10

(Read Only)

16

Page 19

ZEROING PRESSURE SCALES

– When there are no pressure inputs connected to the

unit, the display should read “0.” It may be necessary to zero the pressure scales to

remove any errors due to ambient conditions. This is done by depressing the

key until the zeroing instructions are displayed, then depressing

simultaneously to begin the process. The “ZEROING…” message will flash while the scale

is being zeroed. When the zeroing instructions are displayed again, the process is

complete.

NOTE: Each sensor needs to be zeroed separately.

17

Page 20

LOW BATTERY

– When the battery life reaches 10 percent, the LOW BATTERY message

box will be displayed.

Typical display with

“Low Battery” message

box.

NOTE: The unit is shipped with a red plug in the Power Input that prevents it from

accidentally being turning on, subsequently depleting the battery during transport. This

plug must be removed before use.

LINE POWER – A 2.1 mm jack is provided for the optional 9 VDC power supply

(BC20 - 21100, BC20 - 21101) that may be used for continuous run applications. It

bypasses the internal battery when plugged in.

18

Page 21

KEYS

Six tactile-touch keys are provided for system operation:

– This key turns the unit off and on. The unit will return to the main screen that

was active when it was turned off.

– In the DISPLAY MODE, these keys toggle the display through the

available main screens.

In the SELECT MODE, if a parameter has been highlighted, these keys will scroll through

the available settings.

– On any screen, there are a number of parameters that may be selected and

changed. This key sequences the cursor (Highlight) through those parameters.

– This key is used to Hold (freeze) and Reset (unfreeze) any of the input displays.

Depressing this key will hold the currently displayed Pressure or Temperature reading until

reset. Each input can be held independently.

When active, the word “HOLD” is in the display. Depressing this key on a screen that is

held will reset that input and remove the word “HOLD” from the display.

NOTE: In the composite screen, the hold feature requires that the specific input be

selected using before is used.

19

Page 22

– This key toggles the unit into and out of the Setup Mode. Depressing this key

will enter the Setup screen where the configuration can be viewed and adjusted.

Depressing the key again will exit the Setup Mode and return to the previously viewed main

screen. This will also save any changes to the internal EEPROM memory so they will be

retained even with the power turned off or battery removed.

20

Page 23

OPTIONS

ANALOG OUTPUT

– The unit may be ordered with a DC (Direct Current) Analog Output.

This option provides a filtered Analog Output that matches the displayed pressure or

temperature. Filtering is dependent on the Digital Filter Setting (See System Setup section

for more information). This is for slowly changing inputs. The output is scaled to match the

0 to Full pressure range of the selected sensor. The scaling voltage can be selected from

1.0 to 4.0 VDC in 0.1V increments.

The source for the analog output is selectable in the Setup Mode. The Analog Source

parameter can be selected to track Pressure 1 (Pres1), Pressure 2 (Pres2) or

Temperature (Temp).

21

Page 24

COMMUNICATIONS

Since the meter does not handle any high-bandwidth data links, the RS232 communication

port data link has been optimized to allow the user, through very simple instructions, to

control and interrogate the meter. The following section describes the JPC Protocol used

by the meter.

The JPC Protocol consists of 6 basic commands:

R - READ

W - WRITE

U - UPLOAD

Q - QUICKSEND

V - VERSION

X - CANCEL

The data format is standard ASCII and all data are BCD values.

The following is a breakdown of each of the commands and the way they are accessed.

The meter will echo all characters that are typed to it. When used with a terminal, this will

provide the appropriate display. When used with a computer system, this will provide direct

feedback of the fact that unit has accepted the data.

All commands are completed with a carriage return from the computer. All commands will

be acknowledged by a carriage return, line feed ($0D,$0A). If a command is not valid, the

meter will respond with “??”. All commands are not case sensitive.

22

Page 25

READ/WRITE COMMANDS

The READ command is utilized to read from the meter any of the gathered data. The

command is entered as a letter followed by 2 numbers, followed by a carriage return:

R(Location)(Return)

The 'R' indicates to the meter that the command is to be a READ command.

The Location contains two digits that indicate the data location that is to be read.

The carriage return indicates that the command is to be activated.

The WRITE command allows the user to update the system settings. The write command

is entered as a letter followed by 7 numbers, followed by a carriage return.

W(Location)(Data) (Return)

The 'W' indicates to the meter that the command is to be a WRITE command.

The Location contains two digits that indicate the data location that is to be read.

The Data contains five digits that indicate the data that is to be written at the desired

Location.

The carriage return indicates that the command is to be activated.

23

Page 26

LOCATION ACCESS DESCRIPTION RANGE

01 R

% BATTERY LIFE

REMAINING

0-100

02 R/W CONTRAST 0-20

03 R/W AUTO POWER OFF 0-30

04 R MODEL

0 Not Installed

1 100 PSI Max

05 R

PRESSURE 1 SENSOR

TYPE

2 75 PSI Max

3 10 PSI max

4 5 PSI max

5 0.3 PSI max

0 PSI

1 mmHg 0C

2 mmHg 20C

3 inHg 0C

4 inHg 20C

O 20C

2

O 4C

2

O 20C

2

O 60F

2

2

06 R/W PRESSURE 1 UNITS

5 cmH

6 inH

7 inH

8 inH

9 kg/cm

10 kPA

11 mBar

12 Bar

07 R/W PRESSURE 1 FILTER 0-60

08 R PRESSURE 1 See Note 1

09 R/W PRESSURE 1 MAX See Note 1, 3

10 R/W PRESSURE 1 MIN See Note 1, 3

0 Not Installed

1 100 PSI Max

11 R

PRESSURE 2 SENSOR

TYPE

2 75 PSI Max

3 10 PSI max

4 5 PSI max

5 0.3 PSI max

0 PSI

1 mmHg 0C

2 mmHg 20C

3 inHg 0C

4 inHg 20C

O 20C

2

O 4C

2

O 20C

2

O 60F

2

2

12 R/W PRESSURE 2 UNITS

5 cmH

6 inH

7 inH

8 inH

9 kg/cm

10 kPA

11 mBar

12 Bar

13 R/W PRESSURE 2 FILTER 0-60

14 R PRESSURE 2 See Note 1

15 R/W PRESSURE 2 MAX See Note 1, 3

16 R/W PRESSURE 2 MIN See Note 1, 3

24

Page 27

17 R

18 R/W TEMPERATURE UNITS

19 R/W TEMPERATURE FILTER 0-60

20 R TEMPERATURE See Note 2

21 R/W TEMPERATURE MAX See Note 2, 3

22 R/W TEMPERATURE MIN See Note 2, 3

TEMPERATURE SENSOR

TYPE

0 Not Installed

1 YSI 700

2 RTD 100

0 = C

1 = F

Note 1 – The units for the pressure data are determined by the setting in Location 6 and 12.

This may be set via the Write command or manually using the Range Key. See

Description Page for Ranges.

Note 2 – The units for the temperature data are determined by the setting in Location 18.

This may be set via the Write command or manually using the Range Key. See Description

Page for Ranges.

Note 3 – Writing to Min/Max will reset them to the current value. Any data up to 5 digits will

trigger the reset. This is the same function as selecting the Min/Max item in the display and

pressing the key.

25

Page 28

The following is an example of how the Read/Write commands are used. For display

purposes, the symbol <cR> will be used to identify a carriage return ($0D), and the symbol

<LF> will be used to identify a line feed ($0A).

Read Command Examples

Data Sent

Data Returned Meaning

R08<cR> R08<cR><LF> Echo of Command Sent

10.25 mmHg <cR><LF> 10.25 mmHg measured on Pressure Sensor 1

* End of Transmission

R11<cR> R11<cR><LF> Echo of Command Sent

5<cR><LF> Pressure Sensor 2 is a 0.3 PSI Max Sensor

* End of Transmission

Write Command Examples

Data Sent Data Returned Meaning

W124 <cR> W124<cR><LF> Echo of Command Sent

(Set Pressure Sensor 2 units to “inH2O@20C”)

W1200004<cR> W1200004<cR><LF> Echo of Command Sent

(Set Pressure Sensor 2 units to “inH2O@20C”)

* End of Transmission

W05100<cR> W05100<cR><LF> Echo of Command Sent

??<cR><LF> Invalid Command Response

(Location 05 is Read Only)

* End of Transmission

26

Page 29

UPLOAD COMMAND

The Upload command allows the user to read all of the selected device data from locations

1 through 22 with a single command. The data will be transmitted as a single block with

each location separated by a carriage return, line feed ($0D,$0A).

The following is the format for this command:

U (Return)

See the table in the Read Command section for details on the data structure.

QUICKSEND COMMAND

Quicksend is a feature that allows the user to receive an automatic update of all of the

meter data without any user interaction. When the Quicksend feature is turned ON, the

meter will automatically send all of the device data every half second. The Quicksend

feature is toggled ON and OFF with the Quicksend command.

The following is the format for the 'Q' command:

Q (RETURN)

See the table in the Read Command section for details on the data structure.

27

Page 30

VERSION COMMAND

The Version command allows the user to read the Software Version that the unit is running.

To read the Version, the following syntax is used:

V (RETURN)

CANCEL COMMAND

The CANCEL command is simply a way to re-establish proper control, should an error

occur or an incorrect command be transmitted. For the most part, an incorrect command

will simply be ignored and the meter will prepare for an additional command. However, a

command may be cancelled midstream by transmitting an 'X' (ASCII). This command does

not require a carriage return, nor will it acknowledge with a carriage return. However, it will

echo an 'X' to indicate that the CANCEL command has been received.

The command may also be utilized as a clear and/or acknowledgement of the meter being

on line.

28

Page 31

MANUAL REVISIONS

Revision #

Program # Revisions Made

Rev 01 DT7321CA Origination

Rev 02 DT7321CB Min/Max made standard, CPC Connector added

Rev 03 DT7321CB MC and FC option for CPC Connectors added

PREVENTIVE MAINTENANCE

CALIBRATION: Annually

PRESSURE LINE: Purge pressure line with distilled water following any application

that introduces liquid into the meter.

BATTERIES: When a “Low Battery” message is displayed, the battery should be

replaced immediately or the function of the unit may be impaired. The battery

compartment is located on the back of the unit. Use only 9 V Alkaline batteries.

LIMITED WARRANTY

WARRANTY: BC GROUP INTERNATIONAL, INC. WARRANTS ITS NEW PRODUCTS TO BE FREE

FROM DEFECTS IN MATERIALS AND WORKMANSHIP UNDER THE SERVICE FOR WHICH THEY

ARE INTENDED. THIS WARRANTY IS EFFECTIVE FOR TWELVE MONTHS FROM THE DATE OF

SHIPMENT.

EXCLUSIONS: THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

BC GROUP INTERNATIONAL, INC. IS NOT LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

NO PERSON OTHER THAN AN OFFICER IS AUTHORIZED TO GIVE ANY OTHER WARRANTY OR

ASSUME ANY LIABILITY.

REMEDIES: THE PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE: (1) THE REPAIR OR

REPLACEMENT OF DEFECTIVE PARTS OR PRODUCTS, WITHOUT CHARGE. (2) AT THE OPTION

OF BC GROUP INTERNATIONAL, INC., THE REFUND OF THE PURCHASE PRICE.

29

Page 32

SPECIFICATIONS

PRESSURE SENSOR 100

-RANGE

-RESOLUTION

-ACCURACY

PRESSURE SENSOR 75

-RANGE

-RESOLUTION

-ACCURACY

PRESSURE SENSOR 10

-RANGE

-RESOLUTION

-ACCURACY

PRESSURE SENSOR 5

-RANGE

-RESOLUTION

-ACCURACY

PRESSURE SENSOR .3

-RANGE

-RESOLUTION

-ACCURACY

TEMPERATURE SENSOR YSI 700

-RANGE

-RESOLUTION

-ACCURACY

TEMPERATURE SENSOR 100 RTD

-RANGE

-RESOLUTION

-ACCURACY

.05% FS = +/- 0.00015 PSI +/- 0.01 cmH

-13.500 to 100.000 PSI

.001 PSI

.05% FS = +/- 0.05 PSI

-13.500 to 75.000 PSI

.001 PSI

.05% FS = +/- 0.0375 PSI

-10.0000 to 10.0000 PSI

.0001 PSI

.05% FS = +/- 0.005 PSI

-5.0000 to 5.0000 PSI

.0001 PSI

.05% FS = +/- 0.0025 PSI

-.30000 to .30000 PSI

.00001 PSI

-20.0 to 100.0° C, -4.0 to 212.0° F

.1°C, .1°F

.5% FS = +/- 0.5°C

-20.0 to 100.0° C, -4.0 to 212.0° F

.1°C, .1°F

.5% FS = +/- 0.5°C

O

2

30

Page 33

DISPLAY

SETUP MEMORY

MEMORY RETENTION

OPERATING RANGE

STORAGE RANGE

CONSTRUCTION

SIZE

WEIGHT

CONNECTIONS

PRESSURE MEDIA

POWER

Any pure fluid or gas that is compatible with

Pyrex, Glass, Silicon, Alumina Ceramic,

Epoxy, RTV, gold, aluminum and nickel.

POWER CONSUMPTION

BATTERY LIFE

BATTERY ELIMINATOR

(OPTIONAL)

ANALOG OUTPUT

(OPTIONAL)

DC -- Output dependent on Digital Filter

P:\MANUALS\BCGroup\…\DPM-2000\DPM2300_UM_Rev03.doc

LCD Graphical 128 X 64 Pixels

EEPROM, All Parameters

10 Years w/o Power

15 to 30 Degrees C

-40 to 60 Degrees C

Enclosure - ABS Plastic

Face - Lexan, Back Printed

7.09 x 3.94 x 1.56 inches

180 x 100 x 40 mm

(HxWxD)

<

1 lbs. (0.45 kg)

Power - 2.1 mm Center Negative

RS232 - 7 pin Mini Din

Pressure - .3/5/10 Male Luer

75/100 CPC

Coupler or Insert

Temperature - 1/4 inch phone

Analog Output - BNC

LINE: 9VDC, Center Negative

BATTERY

ON: less than 18 mA

OFF: less than 40 µA

CONTINUOUS: ~80 hrs.

BC20 - 21100 -- US

BC20 - 21101 -- Euro

1.0 to 4.0 VDC FS, selectable

: 9V Alkaline

OFF: 12 months

9V, 200 mA DC

+/- .1% FS

31

Page 34

NOTES

32

Page 35

33

Loading...

Loading...