Page 1

SERVICE MANUAL

DV985S

Page 2

CONTENTS

SAFETY PRECAUTIONS

PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES)DEVICES

CONTROL BUTTON LOCATIONS AND EXPLANATIONS

PREVERTION OF STATIC ELECTRICITY DISCHARGE

ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT

OPTICAL PICKUP UNIT EXPLOSED VIEW AND PART LIST

BRACKET EXPLOSED VIEW AND PART LIST

MISCELLANEOUS

ELECTRICAL CONFIRMATION

VI DEO OUTPUT (LUMINANCE SIGNAL) CONFIRMATION

VI DEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION

1

1

2

3

4

4

6

7

8

8

9

MPEG BOARD CHECK WAVEFORM

FLI2300 DIGITAL VIDEO CONVERTER DATE SHEET

AM29LV160D

HY57V641620HG

SiI 164 PANELLINK TRANSMITTER

MT1389

SCHEMATIC & PCB WIRING DIAGRAM

SPARE PARTS LIST

10

11

19

24

27

41

44

60

Page 3

1.1 GENERAL GUIDELINES

1. SAFETY PREAUTIONS

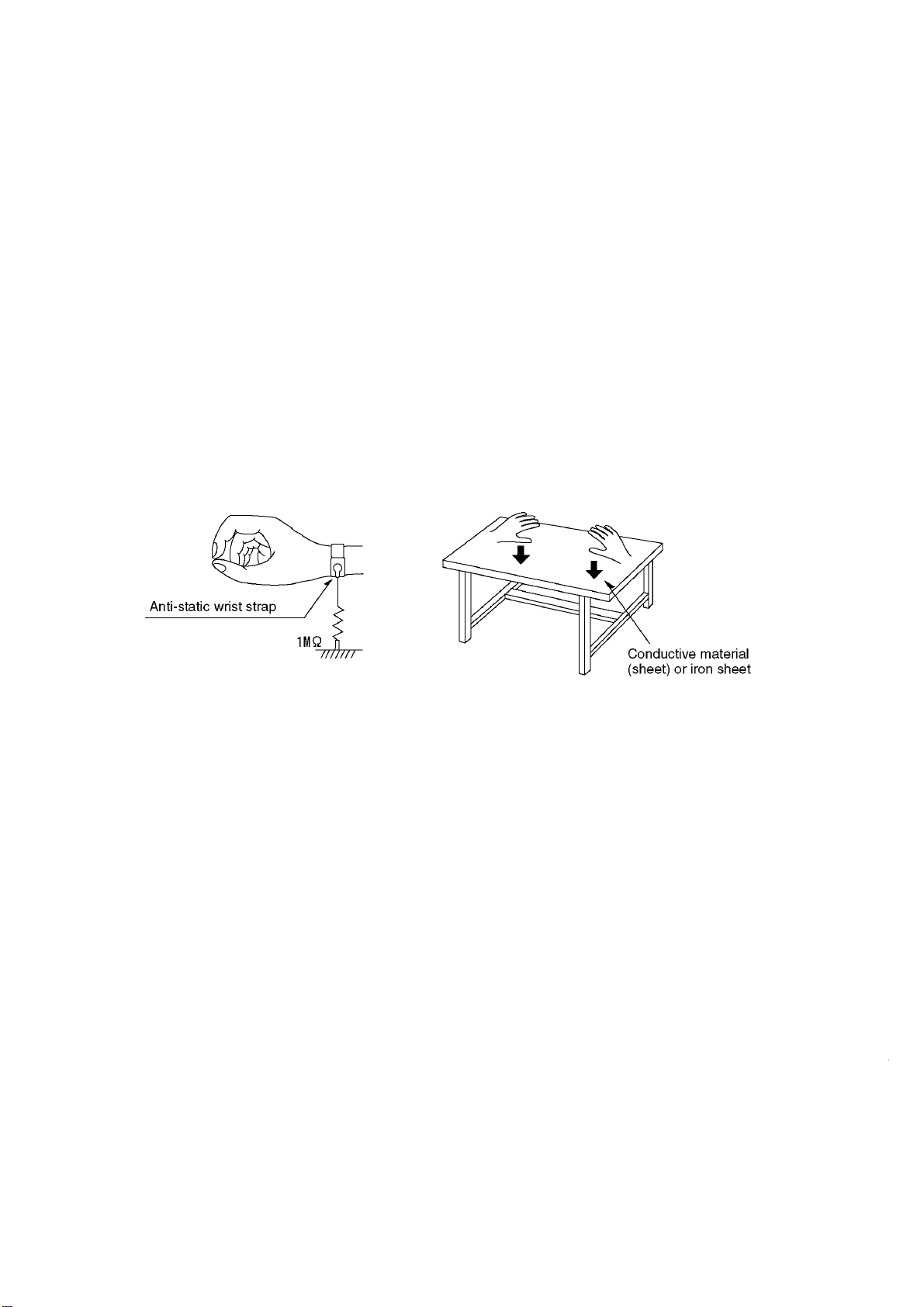

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO

ELECTROSTATICALLY SENSITIVE(ES)DEVICES

1

1. When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have

been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barrier, insulation papers

shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD).

notice (1885x323x2 tiff)

Page 4

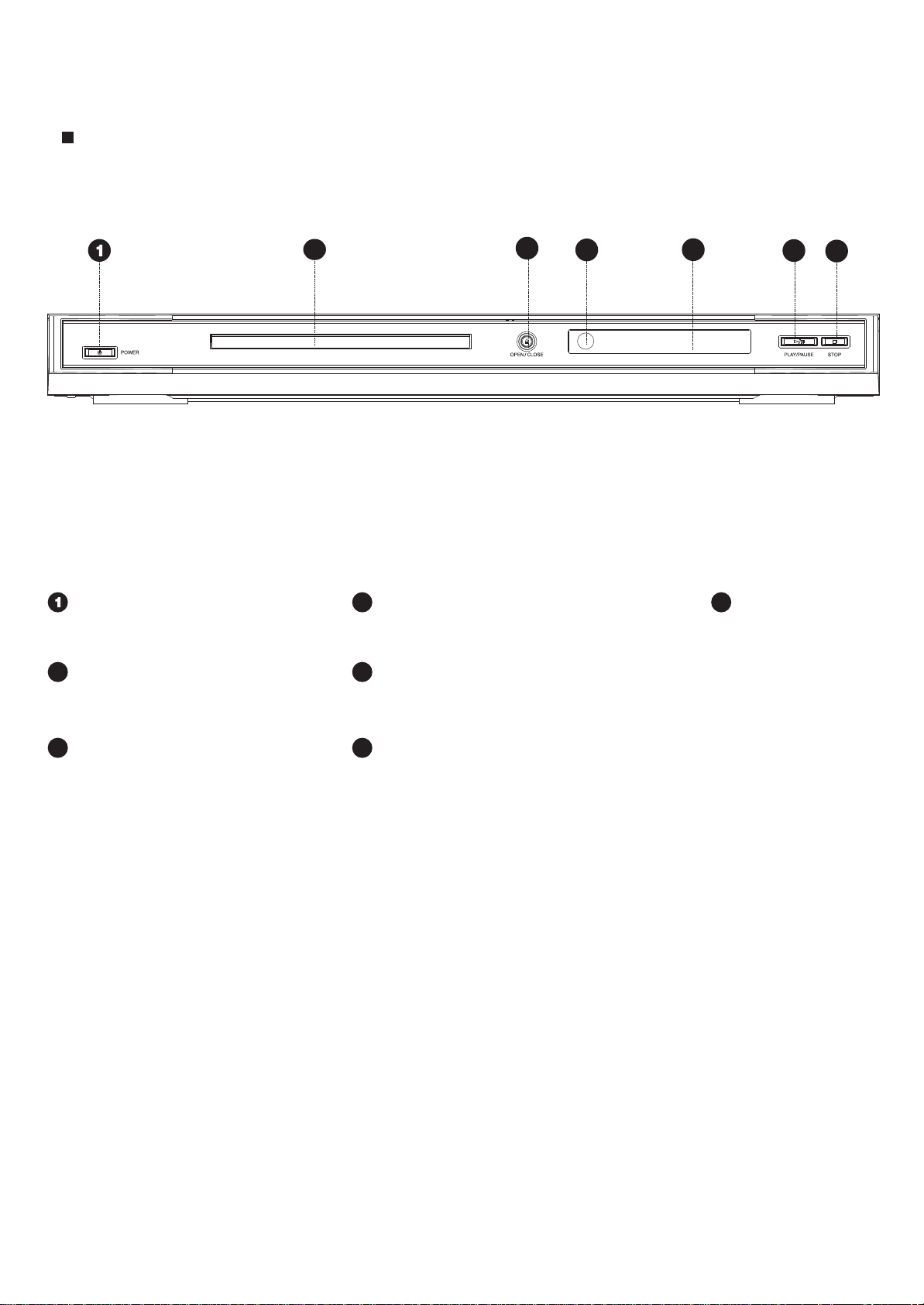

Front Panel Illustration

2

POWER switch

Disc tray

2

2

4

IR SENSOR

5

Display window

3

4

5

7

STOP button

6

7

3

OPEN/CLOSE button

6

PLAY/PAUSE button

Page 5

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1. Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the

3. The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

3

4.PREVENTION OF STATIC ELECTRICITY DISCHARGE

4.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

4.1.1. Worktable grounding

sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

4.1.3.Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before

installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure. (See this Technical Guide).

2. Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2. When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the

optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

Page 6

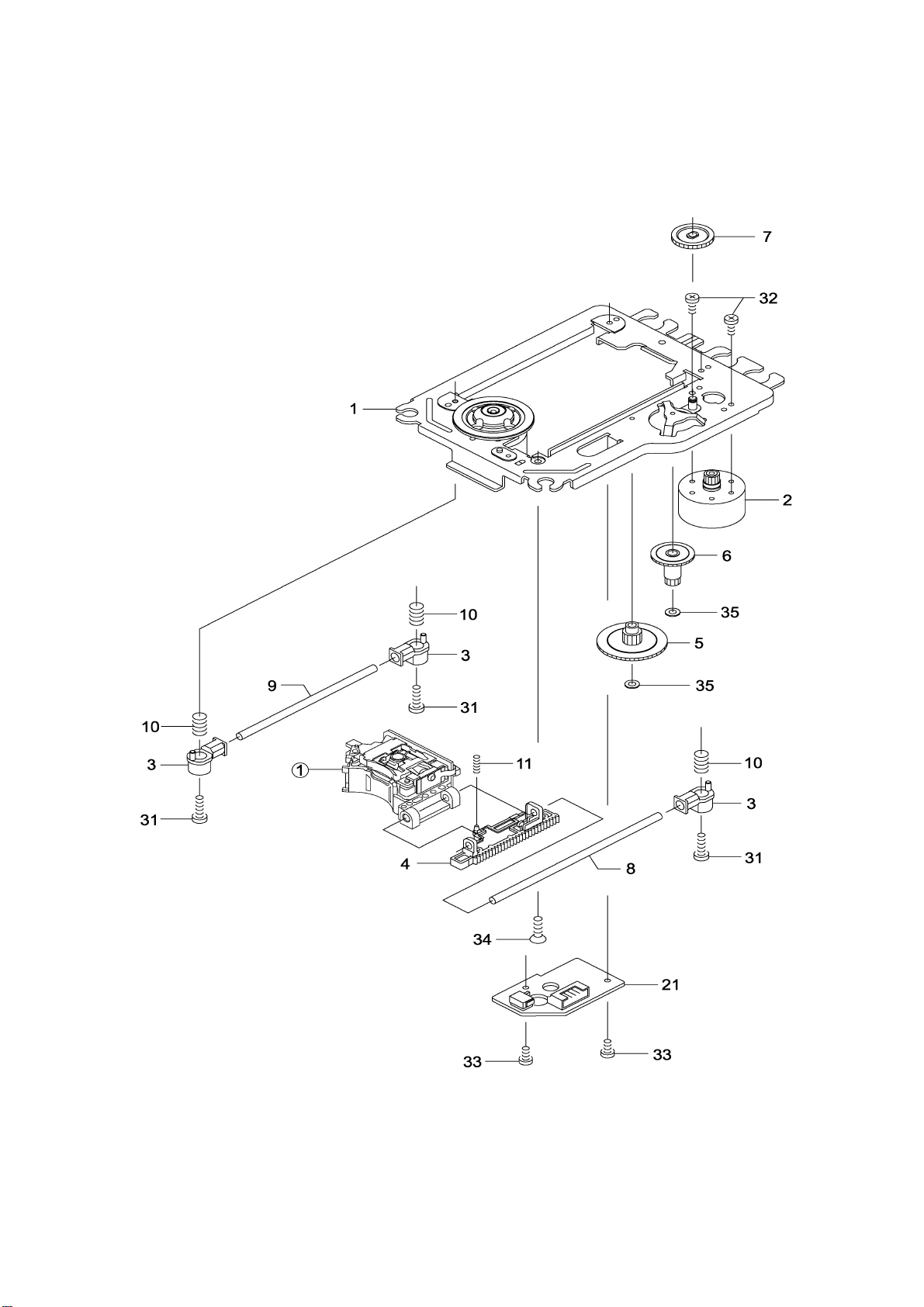

5.1 Optical pickup Unit Explosed View and Part List

5. Assembling and disassembling the mechanism unit

4

Pic (1)

Page 7

Materials to Pic (1)

5

No. PARTS CODE PARTS NAME Q ty

14692200 SF-HD60 1

1

1EA0311A06300 ASSY, CHASSIS, COMPLETE 1

2

Or

3

4

5

6

7

8

9

10

11

21

Or

31

32

1EA0M10A15500 ASSY, MOTOR, SLED 1

1EA0M10A15501 ASSY, MOTOR, SLED 1

1EA2451A24700 HOLDER, SHAFT 3

1EA2511A29100 GEAR, RACK 1

1EA2511A29200 GEAR, DRIVE 1

1EA2511A29300 GEAR, MIDDLE, A 1

1EA2511A29400 GEAR, MIDDLE, B 1

1EA2744A03000 SHAFT, SLIDE 1

1EA2744A03100 SHAFT, SLIDE, SUB 1

1EA2812A15300 SPRING, COMP, TYOUSEI 3

1EA2812A15400 SPRING, COMP, RACK 1

1EA0B10B20100 ASSY, PWB 1

1EA0B10B20200 ASSY, PWB 1

SEXEA25700--- SPECIAL SCREW BIN+-M2X11 3

SEXEA25900--- SPECIAL SCREW M1.7X2.2 2

33

34

35

Note : This parts list is not for service parts supply.

SFBPN204R0SE- SCR S-TPG PAN 2X4 2

SFSFN266R0SE- SCR S-TPG FLT 2.6X6 1

SWXEA15400--- SPECIAL WASHER 1.8X4 X0.25 2

Page 8

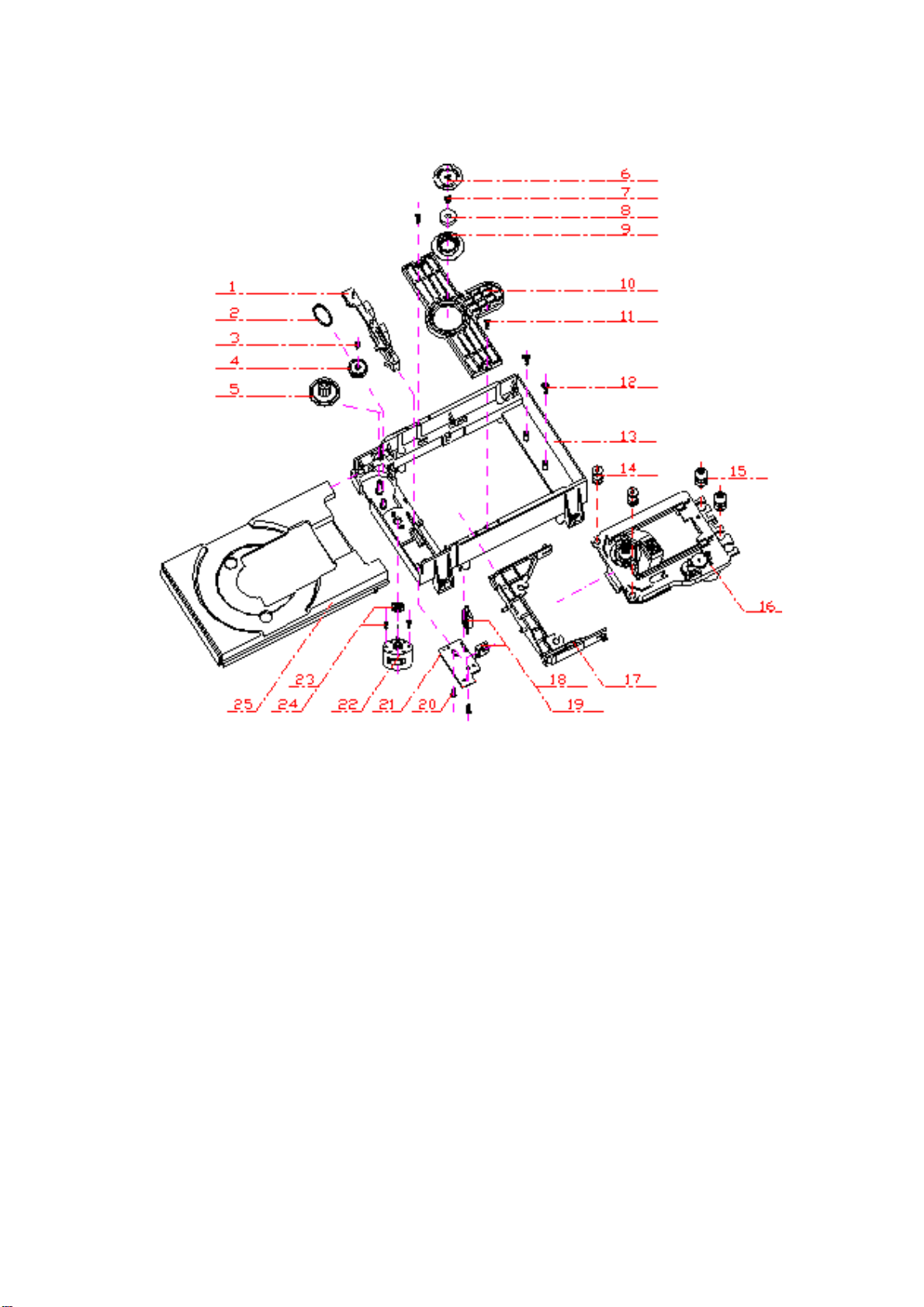

5.2 Bracket Explosed View and Part List

6

Pic (2)

Materials to Pic(2)

1.bracket 14. front silicon rubber

2.belt 15. Back silicon rubber

3.screw 16. Pick-up

4.belt wheel 17. Pick-up

5.gearwheel 18. switch

6.iron chip 19. Five-pin flat plug

7. Immobility mechanism equipment 20. screw

8. Magnet 21. PCB

9. Platen 22. motor

10. Bridge bracket 23. Motor wheel

11. screw 24. screw

12. screw 25.tray

13. Big bracket

Before going process with disassembly and installation, please carefully both

peruse the chart and confirm the materials.

Page 9

5.3 MISCELLANEOUS

7

5.3.1 Protection of the LD(Laser diode)

Short the parts of LD circuit pattern by soldering.

5.3.2 Cautions on assembly and adjustment

Make sure that the workbenches,jigs,tips,tips of soldering irons and measuring instruments are

grounded,and that personnel wear wrist straps for ground.

Open the LD short lands quickly with a soldering iron after a circuit is connected.

Keep the power source of the pick-up protected from internal and external sources of electrical

noise.

Refrain from operation and storage in atmospheres containing corrosive gases (such as H2S,SO2,

NO2 and Cl2)or toxic gases or in locations containing substances(especially from the organic silicon,cyan,

formalin and phenol groups)which emit toxic gases.It is particularly important to ensure that none of the

above substances are present inside the unit.Otherwise,the motor may no longer run.

Page 10

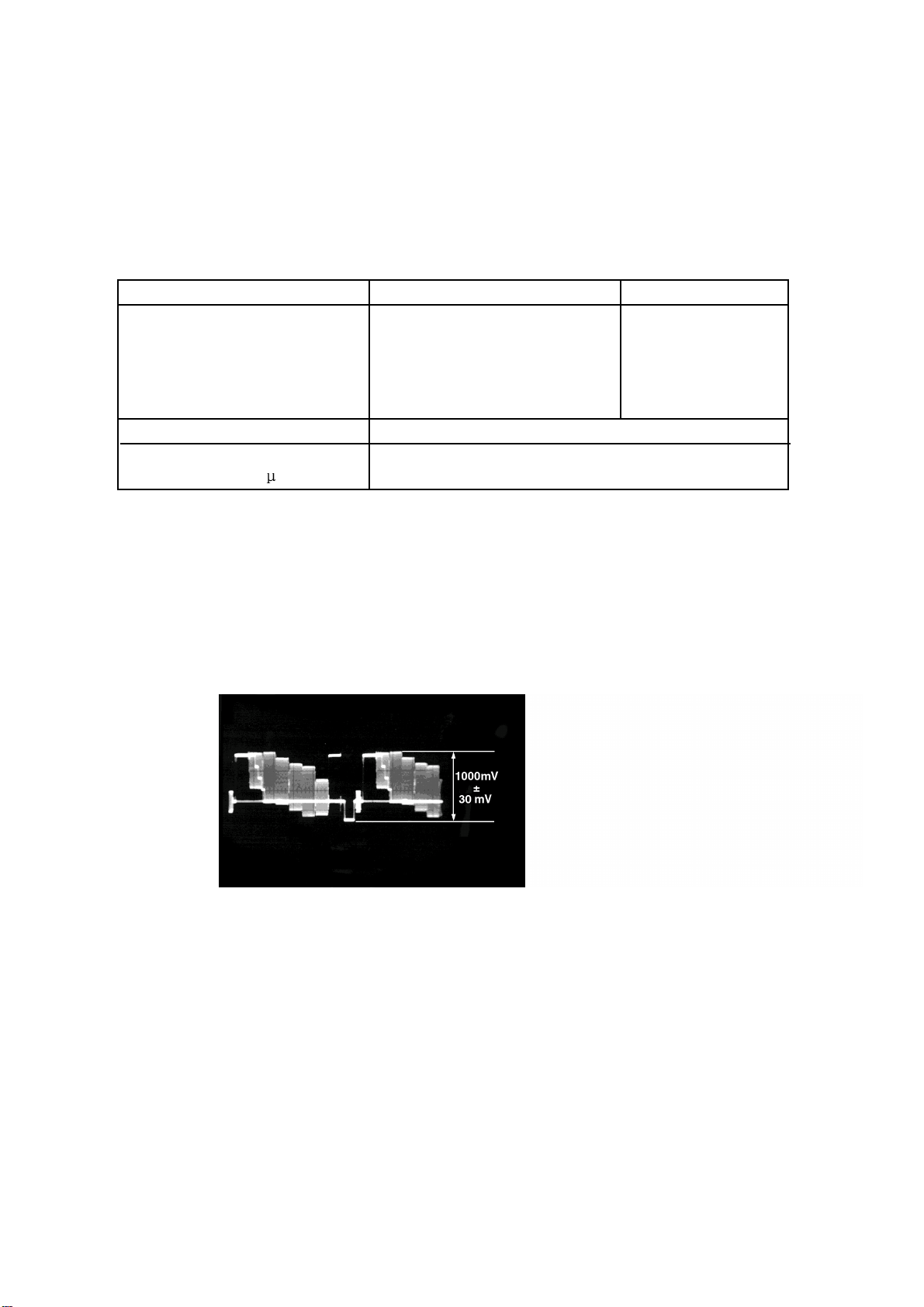

6.1. Video Output (Luminance Signal) Confirmation

6.Electrical Confirmation

8

DO this confirmation after replacing a P.C.B.

Measurement point

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 11

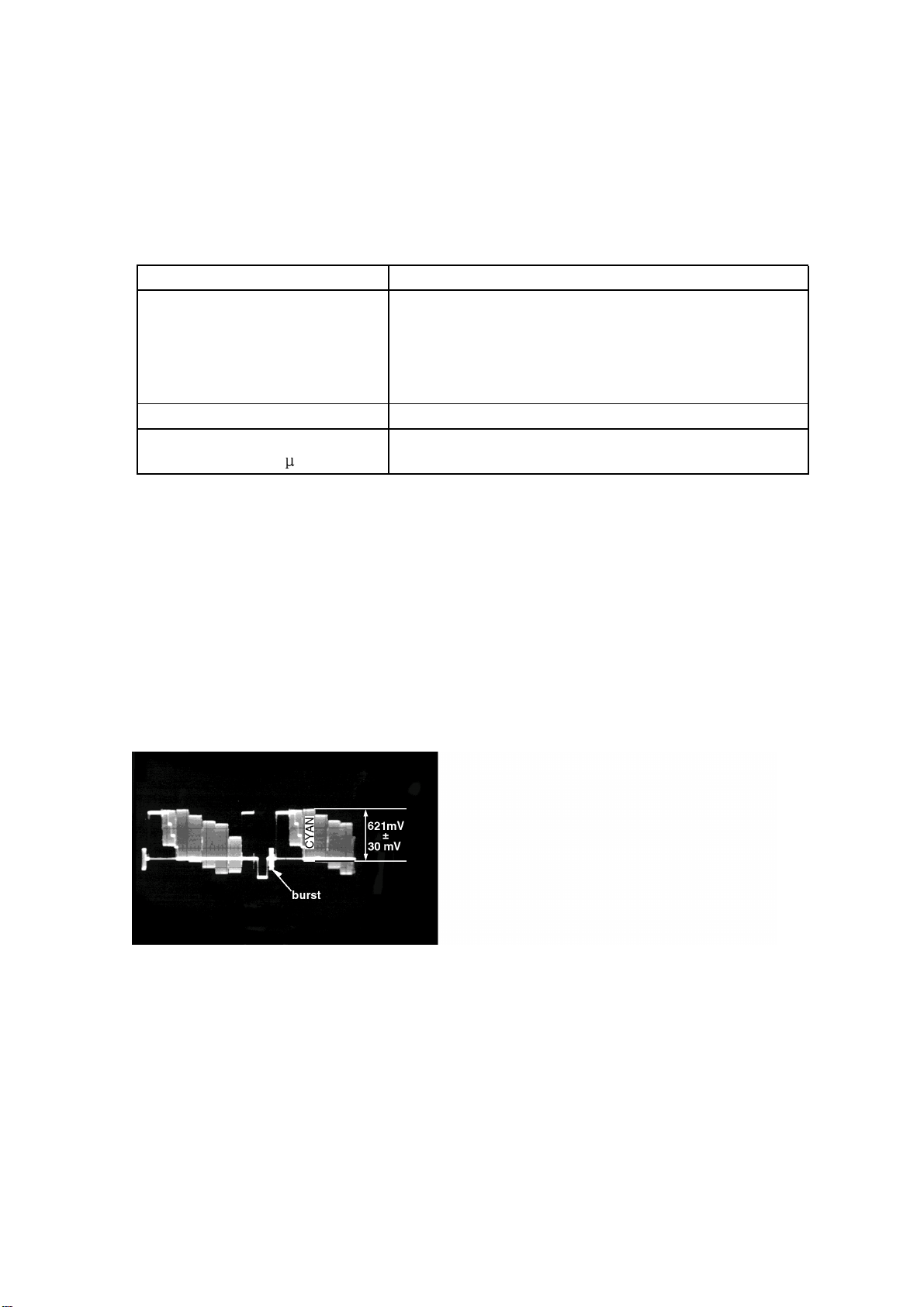

Do the confirmation after replacing P.C.B.

Screwdriver,Oscilloscope

6.2 Video Output(Chrominance Signal) Confirmation

9

Measurement point

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Mode Disc

Color bar 75%

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 12

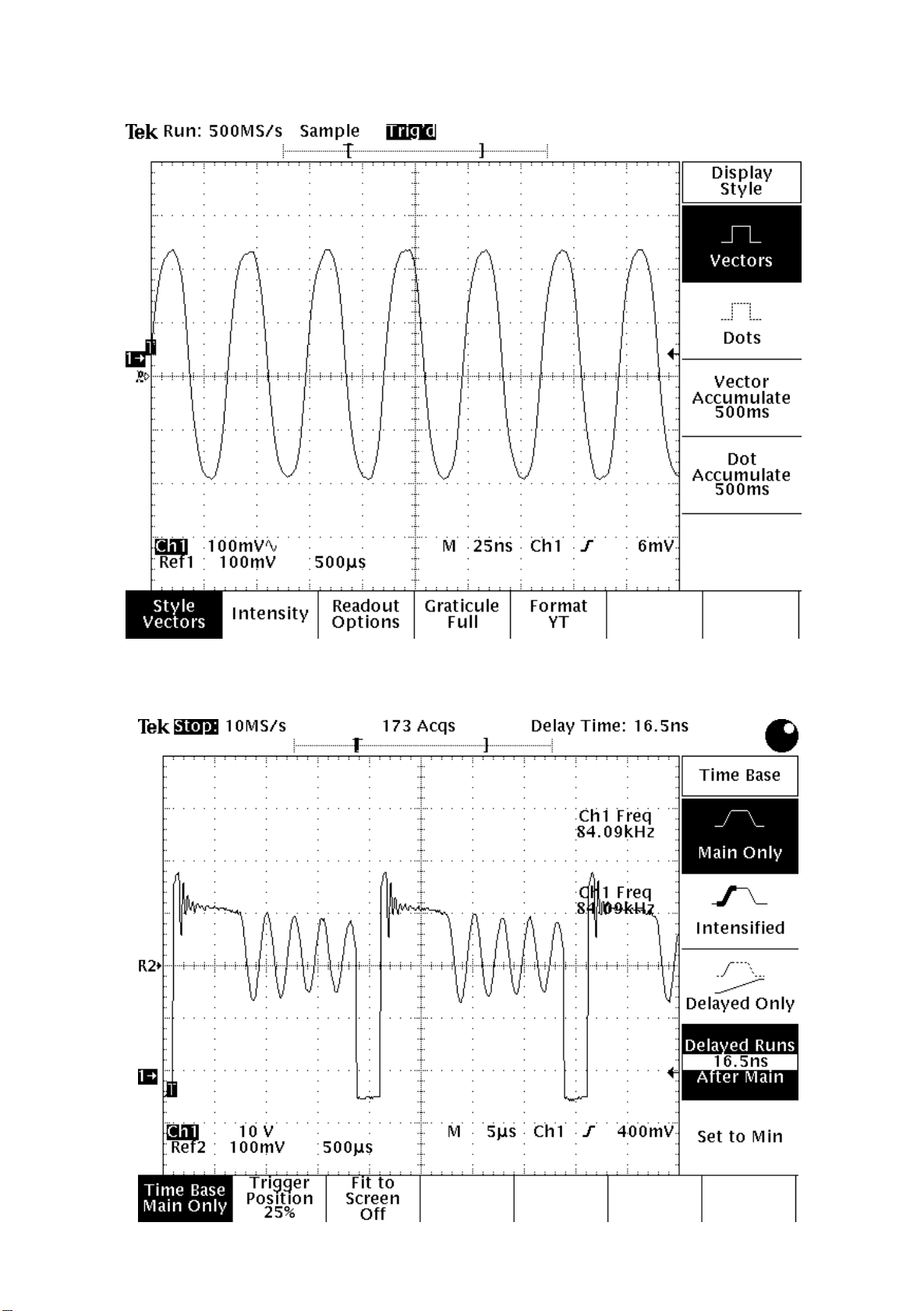

7.MPEG BOARD CHECK WAVEFORM

7.1 27MHz WAVEFORM

7.2 IC5L0380R PIN.2 WAVEFORM DIAGRAM

10

Page 13

FLI2300 Digital Video Converter Data Sheet

11

1 DESCRIPTION

The FLI2300 is a highly integrated digital video

format converter for CRT-TV applications using

patented deinterlacing and post processing algorithms

from Faroudja Laboratories, coupled with highly

flexible scaling, a wide variety of aspect ratio

conversions, and other special video enhancing

features to produce the highest quality image.

1.1 Inputs

• Input all industry standard and non-standard

video resolutions, including 480i (NTSC), 576i

(PAL/SECAM), 480p, 720p, 1080i, and VGA to

XGA

• Digital input, 8-bit Y/Cr/Cb (ITU-R BT656), 8-

bit Y/Pr/Pb, 16-bit Y Cr/Cb (ITU-R BT601), 24bit RGB, YCrCb, YPrPb

• Input pixel rate up to 75MHz maximum

1.2 Outputs

• Output resolutions include 480p, 576p, 720p,

1080i, 1080p, and VGA to SXGA

• Interlaced or Progressive output

• The output can be either analog YUV/RGB

through the integrated 10-bit Digital-To-Analog

Converter (DAC), or digital 24-bit RGB, YCrCb,

YPrPb (4:4:4), or digital 16/20-bit Y Cr/Cb

(4:2:2) Output pixel rate up to 150 MHz

maximum

1.3 Formats

• Input color manipulation matrix supports all

color spaces: RGB, YPrPb, 4:4:4 YCrCb, 4:2:2

YCr/Cb, ITU-R BT656, ITU-R BT601

• Output supports analog RGB, YPrPb, and

YCrCb;

• Output supports digital RGB, YPrPb, 4:4:4

YCrCb and 4:2:2 YCr/Cb

1.4 Frame Rate Conversion

• Tearless Frame Rate Conversion

50/60/72/75/100/120 Hz

1.5 Front End Processing

• Motion Adaptive Noise Reduction - Improves

picture quality for off-air material.

• Cross Color Suppressor (CCS) - Removes cross

color artifacts in composite video signals due to

poor Y/C separation in standard 2-D video

decoders, eliminating the need for expensive 3-D

video decoders.

1.6 Deinterlacing

• Per-pixel Motion Adaptive Deinterlacing

• Patented FilmMode Processing - Used for proper

de-interlacing of 3:2 and 2:2 pulldown material.

• Edit Correction - Film content is continuously

monitored for any break in sequence caused by

“bad edits” and quickly compensates for the

most effective reduction in artifacts.

• DCDi™ by Faroudja - Video is analyzed on a

single pixel granularity to detect presence or

absence of angled lines and edges, which are

then processed to produce a smooth and natural

looking image without visible artifacts or

“jaggies”.

1.7 Scaling

• High Quality Fully Programmable Two

Dimensional Scaler

• Aspect Ratio Conversion for “Anamorphic” or

“Panoramic” (non-linear)

• Display 4:3 images on 16:9 displays and vice

versa, including Letterbox to Fullscreen,

Pillarbox, and Subtitle Display Modes

• Pixel and line dropper to generate PIP windows

1.8 TrueLife™ Enhancer

• Two dimensional, non-linear, luma and chroma

video enhancer brings out details in the picture,

producing a more life-like image.

1.9 Memory

• 32-bit wide SDRAM (i.e. one 2M x 32-bit)

controller, up to 166 MHz operation, for external

SDRAM

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 14

t

12

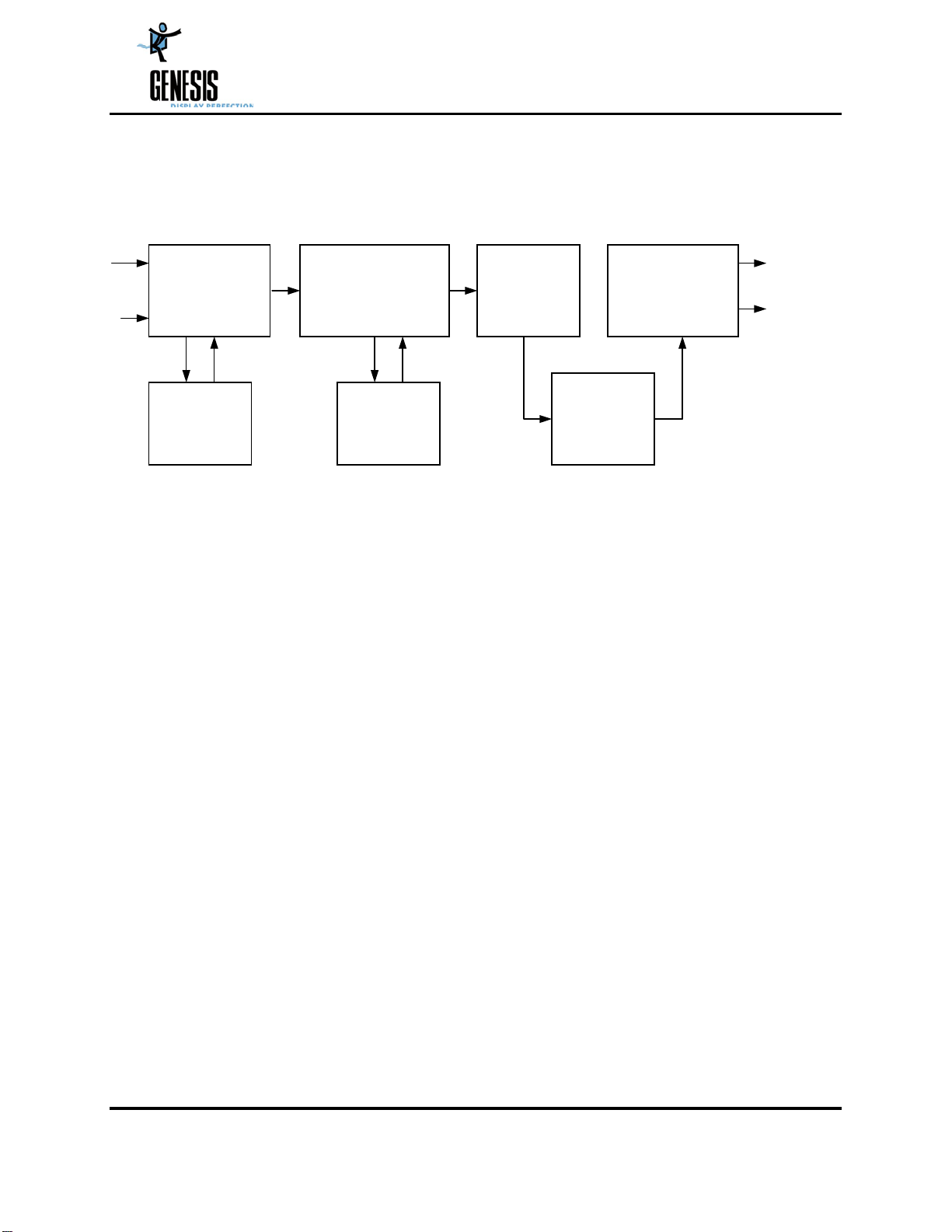

2 BLOCK DIAGRAMS

Port 2

8-bit

656 Input

Port 1

8/16/24-bit

RGB/YCrCb

Input

Input Processor

with Auto Sync

and auto Adjust

Generation

Clock

PLLs

FLI2300 Digital Video Converter Data Sheet

Figure 2.1: FLI2300– Simplified Internal Block Diagram

Noise Reducer,

Deinterlacer, Frame

Rate Converter and

SDRAM interface

Vertical and

Horizontal

Scalers

2Mx32

SDRAM

(external)

Vertical and

Horizontal

Enhancers

Output

Processor with

Sync Generation

and DACs

16/20/24-bi

RBG/YCrCb

Digital Outputs

RBG/YCrCb

Analog Outputs

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 15

13

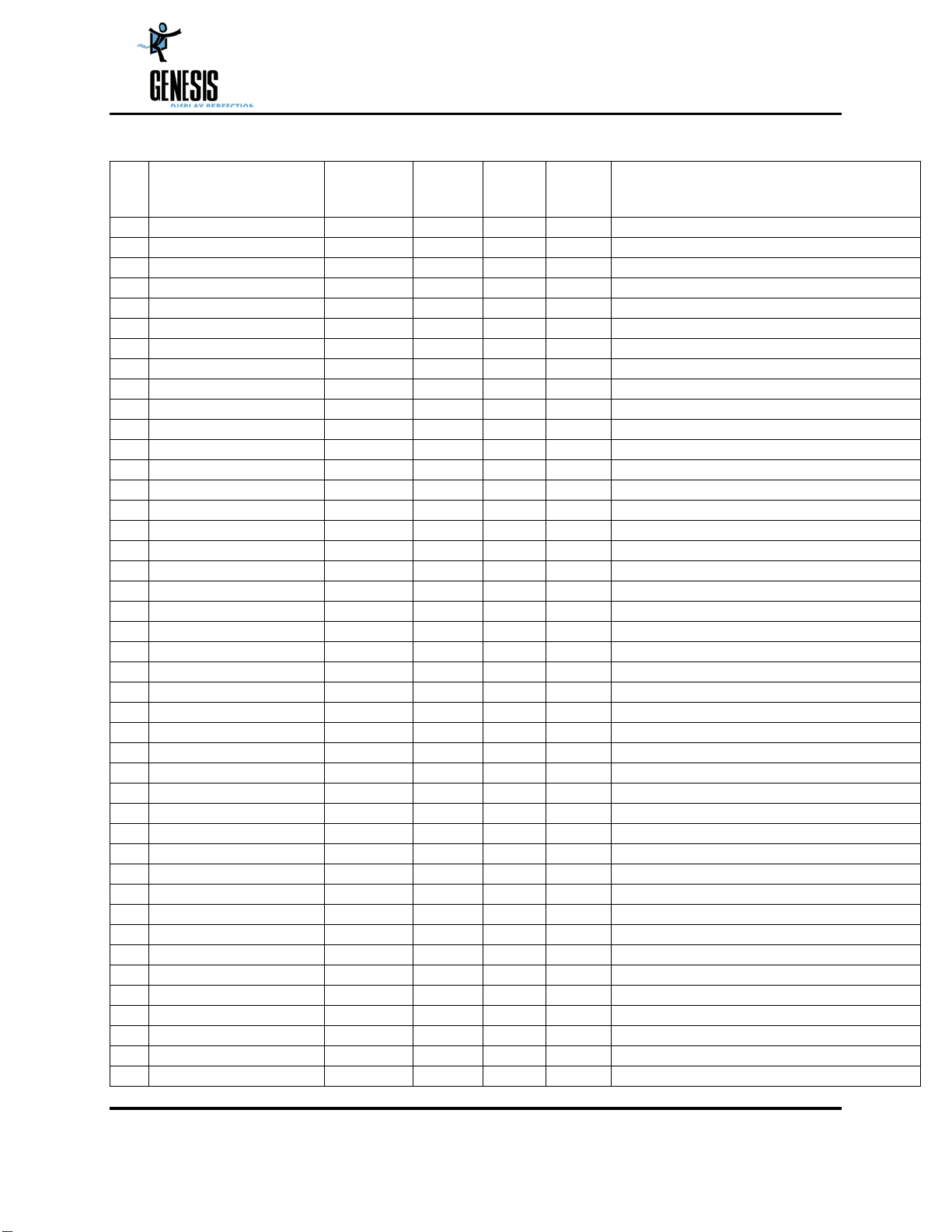

3 PIN INFORMATION

3.1 Pin Diagram

FIELD ID_PORT2

HSYNC_PORT2

VSYNC_PORT2

D1_IN_7

D1_IN_6

D1_IN_5

D1_IN_4

D1_IN_3

D1_IN_2

FLI2300 Digital Video Converter Data Sheet

Figure 3.1: Pinout Information

IN_CLK_PORT2

XTAL IN

XTAL OUT

VDD9

D1_IN_1

VDDcore8

VSScore

TEST2

VSS

D1_IN_0

TEST1

TEST0

DAC_PVDD

DAC_GR_AVDD

DAC_GR_AVSS

DAC_VREFIN

DAC_AVSS

DAC_AVDD

DAC_VREFOUT

DAC_COMP

DAC_RSET

DAC_AVDDR

DAC_AVSSR

DAC_R_OUT

DAC_G_OUT

DAC_AVDDG

DAC_AVSSG

DAC_AVSSB

DAC_B_OUT

DAC_AVDDB

DAC_VSS

DAC_PVSS

DAC_VDD

AVDD_PLL_FE

AVDD_PLL_SDI

AVSS_PLL_FE

AVSS_PLL_SDI

AVSS_PLL_BE2

AVDD_PLL_BE2

AVSS_PLL_BE1

AVDD_PLL_BE1

PLL_PVDD

PLL_PVSS

HSYNC1_PORT1

VSYNC1_PORT1

FIELD ID1_PORT1

IN_CLK1_PORT1

HSYNC2_PORT1

VSYNC2_PORT1

FIELD ID2_PORT1

VDD1

VSS

IN_CLK2_PORT1

B/Cb/D1_0

B/Cb/D1_1

B/Cb/D1_2

B/Cb/D1_3

B/Cb/D1_4

VDDcore1

VSScore

B/Cb/D1_5

B/Cb/D1_6

B/Cb/D1_7

R/Cr/Cb Cr_0

R/Cr/Cb Cr_1

R/Cr/Cb Cr_2

R/Cr/Cb Cr_3

R/Cr/Cb Cr_4

R/Cr/Cb Cr_5

R/Cr/Cb Cr_6

R/Cr/Cb Cr_7

G/Y/Y_0

VDD2

VSS

G/Y/Y_1

G/Y/Y_2

G/Y/Y_3

G/Y/Y_4

VDDcore2

VSScore

G/Y/Y_5

G/Y/Y_6

G/Y/Y_7

IN_SEL

TEST

DEV_ADDR1

DEV_ADDR0

SCLK

SDATA

RESET_N

VDD3

VSS

SDRAM DATA(0)

SDRAM DATA(1)

SDRAM DATA(2)

1 0 0

1 6 0

1 5 5

1 5 0

1 4 5

1 4 0

1 3 5

1 3 0

1 2 5

1 2 0

1 1 5

1 1 0

1 0 5

OE

G/Y/Y_OUT_7

G/Y/Y_OUT_6

G/Y/Y_OUT_5

G/Y/Y_OUT_4

G/Y/Y_OUT_3

G/Y/Y_OUT_2

G/Y/Y_OUT_1

G/Y/Y_OUT_0

VSS

VDD8

R/V/Pr_OUT_7

R/V/Pr_OUT_6

R/V/Pr_OUT_5

R/V/Pr_OUT_4

R/V/Pr_OUT_3

R/V/Pr_OUT_2

VSScore

VDDcore7

R/V/Pr_OUT_1

R/V/Pr_OUT_0

B/U/Pb_OUT_7

B/U/Pb_OUT_6

B/U/Pb_OUT_5

B/U/Pb_OUT_4

B/U/Pb_OUT_3

B/U/Pb_OUT_2

VSS

VDD7

B/U/Pb_OUT_1

B/U/Pb_OUT_0

CLKOUT

VSScore

VDDcore6

CTLOUT4

CTLOUT3

CTLOUT2

CTLOUT1

CTLOUT0

TEST OUT1

TEST OUT0

TEST3

SDRAM CLKIN

VSS

VDD6

SDRAM CLKOUT

SDRAM DQM

SDRAM CSN

SDRAM BA0

SDRAM BA1

SDRAM CASN

SDRAM RASN

1

2 0 5

2 0 0

1 9 5

1 9 0

1 8 5

1 8 0

1 7 5

1 7 0

1 6 5

5

1 0

1 5

2 0

2 5

3 0

3 5

4 0

4 5

5 0

5 5

6 0

6 5

7 0

7 5

8 0

8 5

9 0

9 5

SDRAM DATA(3)

SDRAM DATA(5)

SDRAM DATA(4)

SDRAM DATA(7)

SDRAM DATA(6)

Package: 208-pin PQFP

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

VSS

VDD4

SDRAM DATA(8)

SDRAM DATA(9)

SDRAM DATA(10)

SDRAM DATA(12)

SDRAM DATA(11)

VSScore

VDDcore3

SDRAM DATA(18)

SDRAM DATA(21)

SDRAM DATA(17)

SDRAM DATA(16)

SDRAM DATA(14)

SDRAM DATA(13)

SDRAM DATA(15)

SDRAM DATA(20)

SDRAM DATA(19)

SDRAM DATA(22)

VSScore

VDDcore4

SDRAM DATA(24)

SDRAM DATA(26)

SDRAM DATA(27)

SDRAM DATA(25)

SDRAM DATA(23)

*** Genesis Microchip Confidential ***

VSS

VDD5

TEST IN

SDRAM DATA(31)

SDRAM DATA(28)

SDRAM DATA(30)

SDRAM DATA(29)

SDRAM ADDR(9)

SDRAM ADDR(10)

VSScore

VDDcore5

SDRAM ADDR(6)

SDRAM ADDR(5)

SDRAM ADDR(7)

SDRAM ADDR(8)

SDRAM ADDR(4)

SDRAM WEN

SDRAM ADDR(3)

SDRAM ADDR(0)

SDRAM ADDR(1)

SDRAM ADDR(2)

Page 16

FLI2300 Digital Video Converter Data Sheet

14

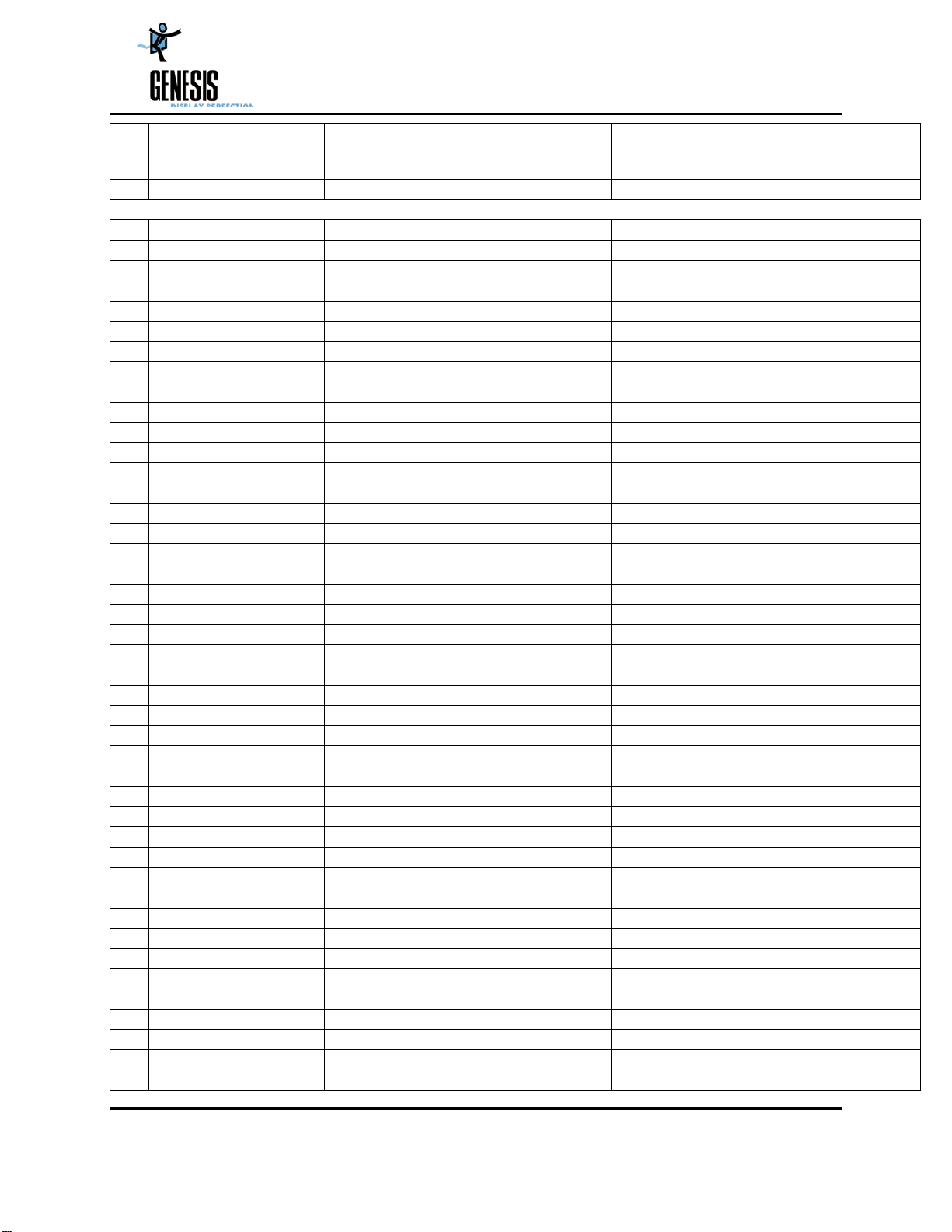

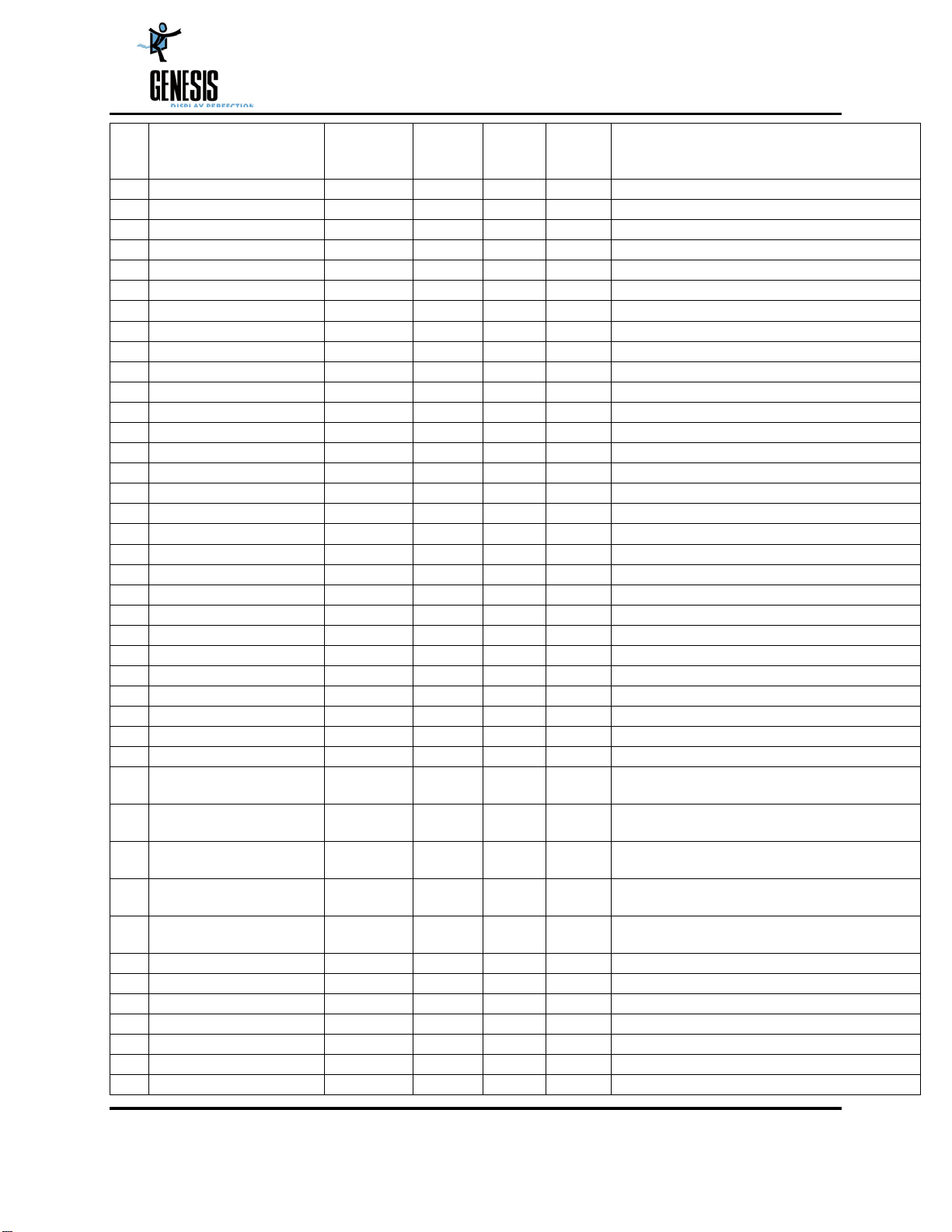

3.2 Pin details

Table 3.1: FLI2300 pin details

Internal

Pull up/

Pulldown

Pin

No

1

HSYNC1_PORT1 Input 5v

2

VSYNC1_PORT1 Input 5v

FIELD ID1_PORT1

3

IN_CLK1_PORT1

4

5

HSYNC2_PORT1 Input 5v

6

VSYNC2_PORT1 Input 5v

FIELD ID2_PORT1

7

VDD1

8

VSS

9

IN_CLK2_PORT1

10

B/Cb/D1_0

11

B/Cb/D1_1

12

B/Cb/D1_2

13

B/Cb/D1_3

14

B/Cb/D1_4

15

VDDcore1

16

VSScore

17

B/Cb/D1_5

18

B/Cb/D1_6

19

B/Cb/D1_7

20

R/Cr/Cb Cr_0

21

R/Cr/Cb Cr_1

22

R/Cr/Cb Cr_2

23

R/Cr/Cb Cr_3

24

R/Cr/Cb Cr_4

25

R/Cr/Cb Cr_5

26

R/Cr/Cb Cr_6

27

R/Cr/Cb Cr_7

28

G/Y/Y_0

29

VDD2

30

VSS

31

G/Y/Y_1

32

G/Y/Y_2

33

G/Y/Y_3

34

G/Y/Y_4

35

VDDcore2

36

VSScore

37

G/Y/Y_5

38

G/Y/Y_6

39

G/Y/Y_7

40

41

IN_SEL Output 5v 8 mA

42 TEST Input 5v

43

DEV_ADDR1 Input 5v

Pin Name I/O Type

Input 5v

Input 5v

Input 5v

Power 3.3 V - Power pin for IO

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Power 1.8 V - Power pin for core

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Input 5v

Power 3.3 V - Power pin for IO

Ground Ground

Input 5v

Input 5v

Input 5v

Input 5v

Power 1.8 V - Power pin for core

Ground Ground

Input 5v

Input 5v

Input 5v

Voltage

Tolerance

Drive

Description

Horizontal sync or reference -CTL1 of Port 1

Vertical sync or reference -CTL1 of Port 1

Odd/Even Field identification -CTL1 of Port 1

Data Clock input -CTL1 of Port 1

Horizontal sync or reference –CTL2 of Port 1

Vertical sync or reference –CTL2 of Port 1

Odd/Even Field identification –CTL2 of Port 1

Data Clock input –CTL2 of Port 1

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Blue/Cb/D1)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Red/Cr/CrCb)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Port 1 – Digital video input (Green/Y)

Output to select external video mux

Connect to Ground

Device address setting 1

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 17

FLI2300 Digital Video Converter Data Sheet

15

Pin

No

44

DEV_ADDR0 Input 5v

45 SCLK

46 SDATA

47 RESET_N

48 VDD3

49 VSS

50 SDRAM DATA(0)

51 SDRAM DATA(1)

52 SDRAM DATA(2)

53 SDRAM DATA(3)

54 SDRAM DATA(4)

55 SDRAM DATA(5)

56 SDRAM DATA(6)

57 SDRAM DATA(7)

58 SDRAM DATA(8)

59 SDRAM DATA(9)

60 SDRAM DATA(10)

61 SDRAM DATA(11)

62 VDD4

63 VSS

64 SDRAM DATA(12)

65 SDRAM DATA(13)

66 SDRAM DATA(14)

67 SDRAM DATA(15)

68 VDDcore3

69 VSScore

70 SDRAM DATA(16)

71 SDRAM DATA(17)

72 SDRAM DATA(18)

73 SDRAM DATA(19)

74 SDRAM DATA(20)

75 SDRAM DATA(21)

76 SDRAM DATA(22)

77 SDRAM DATA(23)

78 SDRAM DATA(24)

79 SDRAM DATA(25)

80 VDDcore4

81 VSScore

82 SDRAM DATA(26)

83 SDRAM DATA(27)

84 SDRAM DATA(28)

85 SDRAM DATA(29)

86 SDRAM DATA(30)

87 SDRAM DATA(31)

88 VDD5

Pin Name I/O Type

I/O

I/O

Input

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Ground

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Tristate I/O

Power

Voltage

Tolerance

5v 8 mA 2-wire serial control bus clock

5v 8 mA 2-wire serial control bus data

5v PU Reset

3.3 V – Power pin for IO

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

3.3 V – Power pin for IO

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

1.8 V - Power pin for core

Ground

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

1.8 V – Power pin for core

Ground

5v 4 mA PD SDRAM data bus *

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

5v 4 mA PD

3.3 V – Power pin for IO

Drive

Internal

Pull up/

Pulldown

Device address setting 0

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

SDRAM data bus *

Description

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 18

FLI2300 Digital Video Converter Data Sheet

16

Pin

No

89 VSS

90 TEST IN

91 SDRAM ADDR(10)

92 SDRAM ADDR(9)

93 SDRAM ADDR(8)

94 SDRAM ADDR(7)

95 SDRAM ADDR(6)

96 VDDcore5

97 VSScore

98 SDRAM ADDR(5)

99 SDRAM ADDR(4)

100 SDRAM ADDR(3)

101 SDRAM ADDR(2)

102 SDRAM ADDR(1)

103 SDRAM ADDR(0)

104 SDRAM WEN

105 SDRAM RASN

106 SDRAM CASN

107 SDRAM BA1

108 SDRAM BA0

109 SDRAM CSN

110 SDRAM DQM

111 SDRAM CLKOUT

112 VDD6

113 VSS

114 SDRAM CLKIN

115 TEST3

116 TEST OUT0

117 TEST OUT1

118 CTLOUT0

119 CTLOUT1

120 CTLOUT2

121 CTLOUT3

122 CTLOUT4

123 VDDcore6

124 VSScore

125 CLKOUT

126 B/U/Pb_OUT_0

127 B/U/Pb_OUT_1

128 VDD7

129 VSS

Pin Name I/O Type

Ground

Input

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Output

Power

Ground

Input

Input

Output

Output

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Voltage

Tolerance

Ground

5V Test input-Connect to ground

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

1.8 V – Power pin for core

Ground

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM address bus *

5v 8 mA SDRAM write enable *

5v 8 mA SDRAM row address select *

5v 8 mA SDRAM column address select *

5v 8 mA SDRAM bank select 1*

5v 8 mA SDRAM bank select 0*

5v 4 mA SDRAM CS *

5v 8 mA SDRAM DQM *

5v 12 mA Clock out to SDRAM *

3.3 V - Power pin for IO

Ground

5v Trace delayed SDRAM Clock in

Test input – Connect to ground

12 mA Test output – leave open

8 mA Test output – leave open

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

1.8 V - Power pin for core

Ground

5v 12 mA Output data rate clock

5v 8 mA

5v 8 mA

3.3 V – Power pin for IO

Ground

Drive

Internal

Pull up/

Pulldown

Description

Control signal output selectable as HSync1/

CSync/HRef/Monitor coast

Control signal output selectable as

VSync1/CRef/VRef/Film Indicator

Control signal output selectable as Monitor

coast/HRef/VDD_en / HSync2

Control signal output selectable as Film

Indicator/VRef/backlight_en/VSync2

Control signal output selectable as CRef/Field

ID/CSync/Monitor coast

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 19

FLI2300 Digital Video Converter Data Sheet

17

Pin

No

130 B/U/Pb_OUT_2

131 B/U/Pb_OUT_3

132 B/U/Pb_OUT_4

133 B/U/Pb_OUT_5

134 B/U/Pb_OUT_6

135 B/U/Pb_OUT_7

136 R/V/Pr_OUT_0

137 R/V/Pr_OUT_1

138 VDDcore7

139 VSScore

140 R/V/Pr_OUT_2

141 R/V/Pr_OUT_3

142 R/V/Pr_OUT_4

143 R/V/Pr_OUT_5

144 R/V/Pr_OUT_6

145 R/V/Pr_OUT_7

146 VDD8

147 VSS

148 G/Y/Y_OUT_0

G/Y/Y_OUT_1

149

G/Y/Y_OUT_2

150

G/Y/Y_OUT_3

151

G/Y/Y_OUT_4

152

G/Y/Y_OUT_5

153

G/Y/Y_OUT_6

154

G/Y/Y_OUT_7

155

156 OE

157 PLL_PVDD

158 PLL_PVSS

159 AVSS_PLL_BE1

160 AVDD_PLL_BE1

161 AVDD_PLL_BE2

162 AVSS_PLL_BE2

163 AVSS_PLL_SDI

164 AVDD_PLL_SDI

165 AVDD_PLL_FE

166 AVSS_PLL_FE

167 DAC_PVSS

168 DAC_VDD

169 DAC_VSS

170 DAC_BOUT

171

DAC_AVDDB

172 DAC_AVSSB

173 DAC_GOUT

174 DAC_AVDDG

Pin Name I/O Type

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Power

Ground

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Tristate O/P

Input

Power

Ground

Ground

Power

Power

Ground

Ground

Power

Power

Ground

Ground

Power

Ground

Output

Power

Ground

Output

Power

Voltage

Tolerance

5v 8 mA Digital video output – Blue/U/Pb

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA Digital video output – Red/V/Pr

5v 8 mA Digital video output – Red/V/Pr

1.8 V – Power pin for core

Ground

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

3.3 V – Power pin for IO

Ground

5v 8 mA Digital video output – Green/Y

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v 8 mA

5v Output data enable for Digital video output

1.8 V – Power pin for PLL pads

Ground for PLL pads

PLL Ground

1.8 V – Power pin for PLL

1.8 V – Power pin for PLL

PLL Ground

PLL Ground

1.8 V – Power pin for PLL

1.8 V – Power pin for PLL

PLL Ground

Ground for DAC pads

1.8 V – Digital power pin for DAC

DAC digital Ground

34 mA Analog B/U output

3.3 V – Analog power pin for B channel

Analog Ground for B channel

34 mA Analog G/Y output

3.3 V – Analog power pin for G channel

Drive

Internal

Pull up/

Pulldown

Description

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Blue/U/Pb

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Red/V/Pr

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

Digital video output – Green/Y

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 20

FLI2300 Digital Video Converter Data Sheet

18

Pin

No

175 DAC_AVSSG

176 DAC_ROUT

177 DAC_AVDDR

178 DAC_AVSSR

179 DAC_COMP

180 DAC_RSET

181 DAC_VREFOUT

182 DAC_VREFIN

183 DAC_AVDD

184 DAC_AVSS

185 DAC_GR_AVSS

186 DAC_GR_AVDD

187 DAC_PVDD

188 TEST0

189 TEST1

190 TEST2

191 XTAL IN

192 XTAL OUT

193 VDD9

194 VSS

195 IN_CLK_PORT 2

196 D1_IN_0

197 VDDcore8

198 VSScore Ground Ground

199 D1_IN_1 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

200 D1_IN_2 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

201 D1_IN_3 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

202 D1_IN_4 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

203 D1_IN_5 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

204 D1_IN_6 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

205 D1_IN_7 Input 5v 4 mA Port 2 - ITU-R BT656 digital data input

206 FIELD ID_PORT 2

207 VSYNC_ PORT 2

208 HSYNC_PORT 2

Note: 1) * - The connection of these pins depends on the type of external SDRAM used. See Appendix 3

Pin Name I/O Type

Ground

Output

Power

Ground

Output

Output

Output

Input

Power

Ground

Ground

Power

Power

Input

Input

Input

Input

Output

Power

Ground

Input

Input

Power

Input

Input

Input

2) For 16/20 bit Y and muxed C output modes see Appendix 2 for pin configuration

Voltage

Tolerance

Analog Ground for G channel

34 mA Analog R/V output

3.3 V – Analog power pin for R channel

Analog Ground for R channel

Compensation for video DACs

Current setting resistor for video DACs

External Voltage reference for video DACs

3.3 V – Analog power pin for DAC

Analog Ground for DAC

Ground for DAC Guard ring

3.3 V – Power pin for DAC Guard ring

3.3 V –Power pin for DAC pads

5v Test pin – connect to ground

5v Test pin – connect to ground

5v Test pin – connect to ground

External parallel crystal oscillator

External parallel crystal oscillator

3.3 V - Power pin for IO

Ground

5v 4 mA Port 2 - Data Clock input

5v 4 mA Port 2 - ITU-R BT656 digital data input

1.8 V – Power pin for core

5v 4 mA Port 2 - Odd/Even Field identification

5v 4 mA Port 2 - Vertical sync or reference

5v 4 mA Port 2 - Horizontal sync or reference

Drive

Internal

Pull up/

Pulldown

Description

1.28 V Internally generated voltage reference for

video DACs

*** Genesis Microchip Confidential ***

PRELIMINARY INFORMATION -- SUBJECT TO CHANGE

Page 21

16 Megabit (2 M x 8-Bit/1 M x 16-Bit)

19

8. Am29LV160D

CMOS 3.0 Volt-only Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single power supp ly operation

— Full voltage range: 2.7 to 3.6 volt read and write

operations for battery-powered applications

— Regulated voltage range: 3. 0 to 3.6 volt read and

write operations and for compatibility with high

performance 3.3 volt microprocessors

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Manufactured on 0.23 µm process technology

— Fully compatible with 0.32 µm Am29L V160B de vice

■ High performan c e

— Access times as fast as 70 ns

■ Ultra low power consumption (typical values at

5MHz)

— 200 nA Automatic Sleep mode current

— 200 nA standby mode current

— 9 mA read current

— 20 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

thirty-one 64 Kbyte sectors (byte mode)

— One 8 Kword, two 4 Kword, one 16 Kword, and

thirty-one 32 Kword sectors (word mode)

— Supports full chip erase

— Sector Protection features:

A hardware method of locking a sector to prevent

any program or erase operations within that sector

Sectors can be locked in-system or via

programming equipment

Temporary Sector Unprotect f eature allows code

changes in previously locked sectors

■ Unlock Bypass Program Command

— Reduces overall pr ogramming time when issuing

multiple program command sequences

■ Top or bottom boot block configurations

available

■ Minimum 1,000,000 write cycle guarantee

per sector

■ 20-year data retention at 125°C

— Reliable operation for the life of the system

■ Package option

— 48-ball FBGA

— 48-pin TSOP

— 44-pin SO

■ CFI (Common Flash Interface) compliant

— Provides device-specific information to the

system, allowing host software to easily

reconfigure for different Flash devices

■ Compatibility with JEDEC standards

— Pinout and software compatible with single-

power supply Flash

— Superior inadvertent write protection

■ Data# Polling and toggle bits

— Provides a software method of detec ting program

or erase operation completion

■ Ready/Busy# pin (RY/BY#)

— Provides a hardware method of detecting

program or erase cycle completi on (not av ailable

on 44-pin SO)

■ Erase Suspend/Erase Resume

— Suspends an erase operation t o read data from,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the devic e to reading

array data

This Data Sheet states AMD’s current technical specifications regarding the Product described herein. This Data

Sheet may be revised by subsequent versions or modificat ions due to changes in technical specif ic ations.

Publication# 22358 Rev: B Amendment/+3

Issue Date: November 10, 2000

Page 22

PRODUCT SELECTOR GUIDE

20

Family Part Number Am29LV160D

Speed Option Voltage Range: V

Max access time, ns (t

Max CE# access time, ns (t

Max OE# access time, ns (t

)7090120

ACC

)7090120

CE

) 303550

OE

= 2.7–3.6 V -70 -90 -120

CC

Note: See “AC Characteristics” for full specifications.

BLOCK DIAGRAM

RY/BY#

V

CC

V

SS

RESET#

WE#

BYTE#

CE#

OE#

State

Control

Command

Register

PGM Voltage

Generator

Sector Switches

Erase Voltage

Generator

Chip Enable

Output Enable

Logic

STB

DQ0

–

DQ15 (A-1)

Input/Output

Buffers

Latch

Data

A0–A19

VCC Detector

Timer

STB

Address Latch

Y-Decoder

X-Decoder

Y-Gating

Cell Matrix

Am29LV160D

Page 23

CONNECTION DIAGRAMS

21

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A16

BYTE#

V

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

CE#

A0

SS

CC

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Standard TSOP

Reverse TSOP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC

WE#

RESET#

NC

NC

RY/BY#

A18

A17

A7

A6

A5

A4

A3

A2

A1

Page 24

CONNECTION DIAGRAMS

22

RESET#

A18

A17

A7

A6

A5

A4

A3

A2

A1

A0

CE#

V

OE#

DQ0

DQ8

DQ1

DQ9

DQ2

DQ10

DQ3

DQ11

SS

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

SO

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

WE#

A19

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

FBGA

Top View, Balls Facing Down

A6 B6 C6 D6 E6 F6 G6 H6

A5 B5 C5 D5 E5 F5 G5 H5

A4 B4 C4 D4 E4 F4 G4 H4

A3 B3 C3 D3 E3 F3 G3 H3

A2 B2 C2 D2 E2 F2 G2 H2

A1 B1 C1 D1 E1 F1 G1 H1

Special Handling Instructions

Special handling is required for Flash Memory products

in FBGA packages.

BYTE#A16A15A14A12A13

DQ15/A-1 V

SS

DQ13 DQ6DQ14DQ7A11A10A8A9

V

CC

DQ4DQ12DQ5A19NCRESET#WE#

DQ11 DQ3DQ10DQ2NCA18NCRY/BY#

DQ9 DQ1DQ8DQ0A5A6A17A7

CE#A0A1A2A4A3

OE# V

SS

Flash memory devices in FBGA packages may be

damaged if exposed to ultrasonic cleaning methods.

The package and/or data integrity may be compromised

if the package body is exposed to temperatures above

150°C for prolonged periods of time.

A

Page 25

PIN CONFIGURATION

23

A0–A19 = 20 addresses

DQ0–DQ14 = 15 data inputs/outputs

DQ15/A-1 = DQ15 (data input/output, word mode),

A-1 (LSB address input, byte mode)

BYTE# = Selects 8-bit or 16-bit mode

CE# = Chip enable

OE# = Output enable

WE# = Write enable

RESET# = Hardware reset pin

RY/BY# = Ready/Busy output

(N/A SO 044)

= 3.0 volt-only single power supply

V

CC

(see Product Selector Guide for speed

options and voltage supply toleranc es)

LOGIC SYMBOL

20

A0–A19

CE#

OE#

WE#

RESET#

BYTE# RY/BY#

16 or 8

DQ0–DQ15

(A-1)

(N/A SO 044)

V

SS

= Device ground

NC = Pin not connected internally

Page 26

HY57V641620HG

8.1 HY57V641620HG

24

4 Banks x 1M x 16Bit Synchronous DRAM

DESCRIPTION

The Hyundai HY57V641620HG is a 67,108,864-bit CMOS Synchronous DRAM, ideally suited for the main memory applications which

require large memory density and high bandwidth. HY57V641620HG is organized as 4banks of 1,048,576x16.

HY57V641620HG is offering fully synchronous operation referenced to a positive edge of the clock. All inputs and outputs are synchronized with the rising edge of the clock input. The data paths are internally pipelined to achieve very high bandwidth. All input and output

voltage levels are compatible with LVTTL.

Programmable options include the length of pipeline (Read latency of 2 or 3), the number of consecutive read or write cycles initiated

by a single control command (Burst length of 1,2,4,8 or Full page), and the burst count sequence(sequential or interleave). A burst of

read or write cycles in progress can be terminated by a burst terminate command or can be interrupted and replaced by a new burst

read or write command on any cycle. (This pipelined design is not restricted by a `2N` rule.)

FEATURES

• Single 3.3±0.3V power supply

• All device pins are compatible with LVTTL interface

• JEDEC standard 400mil 54pin TSOP-II with 0.8mm

of pin pitch

• All inputs and outputs referenced to positive edge of

system clock

• Data mask function by UDQM or LDQM

• Internal four banks operation

Note)

• Auto refresh and self refresh

• 4096 refresh cycles / 64ms

• Programmable Burst Length and Burst Type

- 1, 2, 4, 8 or Full page for Sequential Burst

- 1, 2, 4 or 8 for Interleave Burst

• Programmable CAS Latency ; 2, 3 Clocks

.

Page 27

PIN CONFIGURATION

25

HY57V641620HG

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

DD

V

LDQM

/WE

/CAS

/RAS

/CS

BA0

BA1

A10/AP

A0

A1

A2

A3

DD

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54pin TSOP II

400mil x 875mil

0.8mm pin pitch

VSS

54

DQ15

53

VSSQ

52

DQ14

51

DQ13

50

VDDQ

49

DQ12

48

DQ11

47

VSSQ

46

DQ10

45

DQ9

44

VDDQ

43

DQ8

42

SS

V

41

NC

40

UDQM

39

CLK

38

CKE

37

NC

36

A11

35

A9

34

A8

33

A7

32

A6

31

A5

30

A4

29

SS

V

28

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS Chip Select Enables or disables all inputs except CLK, CKE and DQM

BA0,BA1 Bank Address

A0 ~ A11 Address

Row Address Strobe,

RAS, CAS, WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

VDD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

VDDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS activity

Selects bank to be read/written during CAS activity

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS, CAS and WE define the operation

Refer function truth table for details

Page 28

FUNCTIONAL BLOCK DIAGRAM

I/O Buffer & Logic

26

1Mbit x 4banks x 16 I/O Synchronous DRAM

HY57V641620HG

Self refresh logic

CLK

CKE

CS

RAS

CAS

WE

UDQM

LDQM

& timer

Row active

State Machine

refresh

Column

Active

Internal Row

counter

Row

Pre

Decoders

Column

Pre

Decoders

1Mx16 Bank 3

X decoders

1Mx16 Bank 2

X decoders

X decoders

1Mx16 Bank 1

1Mx16 Bank 0

X decoders

Memory

Y decoders

Cell

Array

Sense AMP & I/O Gate

DQ0

DQ1

DQ14

DQ15

Bank Select

A0

A1

A11

BA0

BA1

Address buffers

Address

Registers

Mode Registers

Column Add

Counter

Burst

Counter

CAS Latency

Data Out Control

Pipe Line Control

Page 29

SiI 164 PanelLink

27

PanelLink Transmitter September 2002

PanelLinkPanelLink

Data Sheet

General Description

The SiI 164 transmitter uses PanelLink

technology to support displays ranging from VGA to

UXGA resolutions (25 - 165Mpps) in a single link

interface.

®

Digital

Features

• Scaleable Bandwidth: 25 - 165MHz Flexible

• Graphics Controller Interface: 12-bit or 24-bit

• Flexible Input Clocking: Single clock single

The SiI 164 transmitter has a highly flexible interface

with either a 12-bit mode (½ pixel per clock edge) or

24-bit mode 1 pixel per clock edge input for true color

• I

• Low Voltage Interface: 3.3V with option for 1.0

(16.7 million) support. In 24-bit mode, the SiI 164

supports single or dual edge clocking. In 12-bit mode,

• Monitor Detection supported through hot plug

the SiI164 supports dual edge single clocking or

single edge dual clocking. The SiI 164 can be

programmed though an I

2

C interface. In addition the

SiI 164 also supports Receiver and Hot Plug

• De-skewing Option varies input clock to input

• Low Power: 3.3V operation (120mA max.) and

Detection.

PanelLink Digital technology simplifies PC design by

• Cable Distance Support: over 5m with twisted

resolving many of the system level issues associated

with high-speed mixed signal design, providing the

• Compliant with DVI 1.0 (DVI is backwards

system designer with a digital interface solution that is

quicker to market and lower in cost.

• Standard and Pb-free packages (see pg 29)

mode 1 pixel/clock inputs

edge (24-bit), Single clock dual edge (12-/24bit), Dual clock single edge (12-bit)

2

C Slave Programming Interface up to 100kHz

to 3.0V Low Voltage Signal Mode

and receiver detection

data timing

Power Down mode (1mA max.)

pair and fiber-optics ready

compliant with VESA

®

P&DTM and DFP)

SiI 164 Pin Diagram

AGND

VCC

RESERVED

DKEN

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

GND

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

TX2+

31

50

TX2-

30

51

AVCC

29

52

TX1-

TX1+

27

28

64-Pin TQFP

54

53

TX0-

TX0+

AGND

24

25

26

SiI

164

(Top View)

55

56

57

AVCC

23

58

TXC+

22

59

TXC-

21

60

AGND

20

61

PVCC1

EXT_SWING

18

19

62

63

PGND

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

64

GND

BSEL/SCL

DSEL/SDA

ISEL/RST#

VCC

MSEN

PD#

EDGE/HTPLG

CTL1/A1/DK1

CTL2/A2/DK2

CTL3/A3/DK3

VSYNC

HSYNC

VREF

DE

VCC

D9

D8

D7

PVCC2

D11

D10

D6

IDCK-

IDCK+

D5

D4

D3

D2

D1

D0

GND

Figure 1. Pin Diagram for SiI 164

Page 30

SiI 164 PanelLink Transmitter

G

28

Data Sheet

Functional Description

The SiI 164 is a DVI 1.0 compliant PanelLink transmitter in a compact package. It provides 24 bits for data Input to

allow for panel support up to UXGA resolution. Figure 2 shows the functional blocks of the chip.

TX0+

TX1+

TX2+

EXT_SWIN

I2C

Slave

Machine

MSEN

Registers

&

Configuration

Logic Block

TXC+

PanelLink

PanelLink

PanelLinkPanelLink

Digital

core

SDA

SCL

A[3:1]

ISEL/RST

PD

DSEL/SDA

EDGE/HTPLG

DKEN

BSEL/SCL

CTL/A/DK[3:1]

Data Capture

Logic Block

DE

D[23:0]

VSYNC

HSYNC

IDCK+

VREF

IDCK-

Figure 2. Functional Block Diagram

PanelLink TMDS Digital Core

The PanelLink TMDS core encodes video information onto three TMDS differential data lines and the differential

clock. The video data is input by the Data Capture Logic Block, as a 12- or 24-bit bus, using one or two clocks with

one or two edges per clock. An attached monitor may be sensed using the HTPLG pin or internally with Receiver

Sense. This detected state may be output onto the MSEN pin. The device may be powered down using the PD#

pin or with an internal register. The SiI 164 is reset using the ISEL/RST# pin. A resistor tied to the EXT_SWING

pin is used to control the TMDS swing amplitude.

I2C Interface and Registers

The SiI 164 uses a slave I

the switching levels from the host are not 3.3V, then a voltage level shifter must be used. See Figure 16 and

Figure 17 on page 24 for a system diagram.

2

C interface, capable of running at 100kHz. The slave I2C interface is not 5V tolerant. If

A connected display may be detected using the DVI Hot Plug signal, attached to the HTPLG pin; or with the

Receiver Sense logic internal to the SiI 164. The state of the detection, or an interrupt signal indicating a change of

state, may be sent to the MSEN pin. This is useful to the host controller monitoring the SiI 164.

Page 31

SiI 164 PanelLink Transmitter

29

Data Sheet

Data Capture Logic

Video data is input to the SiI 164 by way of a 12-bit or 24-bit interface. The functionality of this interface is affected

by several of the configuration register settings, as follows.

• BSEL selects between 12-bit and 24-bit input bus widths.

• DSEL selects between single-edge and dual-edge modes for the input clocks.

• EDGE selects between rising and falling edge on the input clocks.

• CLK+ and CLK- provide the one or two clocks required for latching the input data bus.

• The PD# input selects the chip power down mode and allows for disabling of the TMDS outputs.

The ISEL/RST# input resets the HDCP engine and internal registers and is asserted after power up and receipt of

a stable input pixel clock.

Page 32

SiI 164 PanelLink Transmitter

30

Data Sheet

Electrical Specifications

Absolute Maximum Conditions

Absolute Maximum Conditions are defined as the worst case conditions the part will tolerate without sustaining

damage. Permanent device damage may occur if absolute maximum conditions are exceeded. Proper operation

under these conditions is not guaranteed. Functional operation should be restricted to the conditions described

under Normal Operating Conditions.

Symbol Parameter Min Typ Max Units

VCC Supply Voltage 3.3V -0.3 4.0 V

VI Input Voltage -0.3 VCC+ 0.3 V

VO Output Voltage -0.3 VCC+ 0.3 V

TJ Junction Temperature (with power applied) 125

T

Storage Temperature -65 150

STG

Normal Operating Conditions

Symbol Parameter Min Typ Max Units

VCC Supply Voltage 3.0 3.3 3.6 V

V

Supply Voltage Noise 100 mV

CCN

TA Ambient Temperature (with power applied) 0 25 70

θ

Note

1. Airflow at 0m/s.

JA

Thermal Resistance (Junction to Ambient)1 64

P-P

°C

°C/W

°C

°C

Digital I/O Specifications

Under normal operating conditions unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

VIH High Swing High-level Input

V

REF = VCC

Voltage

VIL High Swing Low-level Input

V

REF = VCC

Voltage

2

V

Low Swing Voltage 1 3.0 V

DDQ

VSH Low Swing High-level Input

V

REF = VDDQ

Voltage

VSL Low Swing Low-level Input

V

REF = VDDQ

Voltage

V

Input Clamp Voltage1 I

CINL

V

Input Clamp Voltage1 I

CIPL

= -18mA GND -0.8 V

CL

= 18mA VCC + 0.8 V

CL

IIL Input Leakage Current -10 10

VIH High Swing High-level Input

V

REF = VCC

Voltage

Notes

1. Guaranteed by design. Voltage undershoot or overshoot cannot exceed absolute maximum conditions

2. VDDQ defines the maximum voltage level of Low Swing input. It is not an actual input voltage. Chip characterization for

Low Swing operation is performed at 1.5V only. Voltage level of Low Swing input should never exceed absolute

maximum rating.

2.0 V

0.8 V

/2 V

/2 V

2.0 V

/2 +

DDQ

300mV

V

DDQ

/2 –

V

100mV

µA

Page 33

SiI 164 PanelLink Transmitter

31

Data Sheet

DC Specifications

Under normal operating conditions unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units

VOD Differential Voltage Single ended

R

LOAD

= 50Ω, R

EXT_SWING

peak to peak amplitude

V

Differential High-level Output AVCC V

DOH

Voltage1

I

Differential Output Short Circuit

DOS

I

Power-down Current2 0.2 1.0 mA

PD#

I

Transmitter Supply Current IDCK= 165 MHz, 1-pixel/clock

CCT

Current

1

= 0 V 5

V

OUT

mode, R

EXT_SWING

= 510Ω,

IVCC = VCC,

Worst Case Pattern

Notes

1. Guaranteed by design.

2. Assumes all inputs to the transmitter are not toggling.

3. Black and white checkerboard pattern, each checker is one pixel wide.

3

= 510Ω

510 550 590 mV

µA

85

120

mA

Page 34

SiI 164 PanelLink Transmitter

32

Data Sheet

AC Specifications

Under normal operating conditions unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Units Figure

T

IDCK Period, 1-pixel/clock 6 40 ns

CIP

F

IDCK Frequency, 1-pixel/clock 25 165 MHz

CIP

T

IDCK High Time at 165MHz 2.0 ns

CIH

T

IDCK Low Time at 165MHz 2.0 ns

CIL

T

Worst Case IDCK Clock Jitter

IJIT

T

Data, DE, VSYNC, HSYNC

SIDF

Setup Time to IDCK falling edge

(Default De-skew Setting)

T

Data, DE, VSYNC, HSYNC

HIDF

Hold Time from IDCK falling edge

(Default De-skew Setting)

T

Data, DE, VSYNC, HSYNC

SIDR

Setup Time to IDCK rising edge

(Default De-skew Setting)

T

Data, DE, VSYNC, HSYNC

HIDR

Hold Time from IDCK rising edge

(Default De-skew Setting)

T

Data, DE, VSYNC, HSYNC

SID

Setup Time to IDCK falling/rising edge

(Default De-skew Setting)

T

Data, DE, VSYNC, HSYNC

HID

Hold Time from IDCK falling/rising edge

(Default De-skew Setting)

T

VSYNC, HSYNC Delay from DE falling

DDF

T

VSYNC, HSYNC Delay to DE rising edge1 1T

DDR

T

DE high time1 8191T

HDE

T

DE low time1 128T

LDE

T

De-skew step size increment DKEN = 1 260 ps

STEP

T

Duration of RESET signal Low required for

RESET

edge

1

2,3

2 ns

Single Edge

1.0 ns

(DSEL = 0,

EDGE = 0)

Single Edge

0.9 ns

(DSEL = 0,

EDGE = 0)

1

Single Edge

(DSEL = 0,

1.0 ns

EDGE = 1)

1

Single Edge

(DSEL = 0,

0.9 ns

EDGE = 1)

1

Dual Edge

(DSEL = 1,

0.6 ns

BSEL = 0)

1

Dual Edge

(DSEL = 1,

1.3 ns

BSEL = 0)

1T

ns

CIP

ns

CIP

ns

CIP

ns

CIP

10 µs

valid Reset

I2CDVD

S

HLT

SDA Data Valid Delay from SCL high

to low transition

3

Differential Swing High-to-Low Transition

Time

CL = 10pf 700 ns T

C

= 400pf 2000 ns

L

R

LOAD

R

EXT_SWING

= 50Ω,

=

170 200 230 ps

510Ω

S

Differential Swing Low-to-High Transition

LHT

Time

R

LOAD

R

EXT_SWING

= 50Ω,

=

170 200 230 ps

510Ω

Notes

1. Guaranteed by design.

2. Actual jitter tolerance may be higher depending on the frequency of the jitter.

3. All Standard mode I2C (100kHz) timing requirements are guaranteed by design. Fast mode I2C (400kHz) timing

requirements are guaranteed at 10pf loading.

Figure 3

Figure 3

Figure 3

Figure 6

Figure 6

Figure 6

Figure 6

Figure 7

Figure 7

Figure 8

Figure 8

Figure 5

Figure 9

Figure 4

Figure 4

Page 35

SiI 164 PanelLink Transmitter

33

Data Sheet

Input Timing Diagrams

T

CIP

T

CIH

2.0 V

2.0 V 2.0 V

0.8 V

T

CIL

0.8 V

Figure 3. Clock Cycle High/Low Times

S

LHT

80% V

OD

20% V

OD

S

HLT

VCC

ISEL/RST#

Figure 4. Low Swing Differential Times

T

RESET

Figure 5. ISEL/RST# Minimum Timing

Page 36

SiI 164 PanelLink Transmitter

34

Data Sheet

IDCK

D[23:0], DE,

HSYNC,VSYNC

DE

VSYNC, HSYNC,

CTL[3:1]

50 %

T

SIDF

50 % 50 %

T

SIDR

T

HIDF

50 %

T

HIDR

Figure 6. Input Data Setup/Hold Time to IDCK

0.8 V

T

DDF

0.8 V

DE

VSYNC, HSYNC,

CTL[3:1]

0.8 V

Figure 7. VSYNC, HSYNC and CTL[3:1] Delay Time from DE

T

0.8 V

DDR

DE

SDA

SCL

2.0 V

Figure 9. I

T

HDE

2.0 V

0.8 V

Figure 8. DE High and Low Times

TI2

I2CDVD

2

C Data Valid Delay (driving Read Cycle data)

T

LDE

0.8 V

Page 37

SiI 164 PanelLink Transmitter

35

Data Sheet

Pin Descriptions

Input Pins

Pin Name Pin # Type Description

D[23:12] 36-47 In

D[11:0]

IDCK+ 57 In Input Data Clock +.

IDCK- 56 In

DE 2 In

HSYNC 4 In

VSYNC 5 In

CTL1/A1/DK1

CTL2/A2/DK2

CTL3/A3/DK3

5055,

58-63

8

7

6

Top half of 24-bit pixel bus.

BSEL = HIGH

When

this bus inputs the top half of the 24-bit pixel bus.

When BSEL = LOW,

these bits are not used to input pixel data. In this mode, the state of D[23:16] is input to the

2

C register CFG. This allows 8-bits of user configuration data to be read by the graphics

I

controller through the I

should be tied to ground. D[15:12] are reserved for SiI use only and should be tied to GND.

Bottom half of 24-bit pixel bus / 12-bit pixel bus input.

In

In

BSEL = HIGH

When

this bus inputs the bottom half of the 24-bit pixel bus.

When BSEL = LOW,

this bus inputs ½ a pixel (12-bits) at every latch edge (both falling and/or rising) of the clock.

Input Data Clock –. This clock is only used in 12-bit mode when dual edge clocking is turned

off (DSEL = LOW). It is used to provide the ODD latching edges for dual clock single edge.

If BSEL = HIGH or DSEL = HIGH,

this pin is unused and should be tied to GND.

Input Data Enable. This signal qualifies the active data area. DE is always required by the

transmitter and must be high during active display time and low during blanking time.

Horizontal Sync input control Signal

Vertical Sync input control signal.

The use of these multi-function inputs depends on the settings of ISEL/RST# and DKEN.

These inputs are regular high-swing 3.3V CMOS level inputs. These pins contain weak pulldown resistors so that if left unconnected, they will be LOW.

When ISEL/RST# = LOW, DKEN = LOW

General Purpose Input CTL[3:1] pins are active, for backward compatibility. These pins

must be used to send DC signals only during the blanking time.

When ISEL/RST# = LOW, DKEN = HIGH

DK[3:1] are active, these inputs are used to select the De-skewing setting for the input bus.

When ISEL/RST# = HIGH, DKEN = HIGH

A[3:1] are active, these bits are used to set the lower 3 bits of the I

,

2

C interface (see I2C register definition). When not used D[23:16]

,

This clock is used for all input modes.

2

C device address.

Page 38

Pin Descriptions (cont’d)

36

Configuration Pins

Pin Name Pin # Type Description

MSEN 11 Out

ISEL/RST# 13 In

BSEL/SCL 15 In

DSEL/SDA 14 In/Out

EDGE/

9 In

HTPLG

DKEN 35 In

Monitor Sense. This pin is an open collector output. The behavior of this output depends on

whether I

2

I

C bus inactive (ISEL/RST# = LOW)

2

C interface active:

HIGH level indicates a powered on receiver is detected at the differential outputs.

A LOW level indicates a powered on receiver is not detected.

2

C bus is enabled (ISEL/RST# = HIGH)

I

The output is programmable through the I2C interface (see I2C Register Definitions).

An external 5K pull-up resistor to VDDQ is required on this pin.

2

I

C Interface Select.

ISEL/RST#=HIGH,

2

I

C interface is active.

ISEL/RST#=LOW,

2

I

C is inactive and the chip configuration is read from the configuration strapping pins. This pin

also acts as an asynchronous reset to the I

input is held LOW.

Note

: When the I

Input bus select / I

(ISEL/RST# = HIGH), then this pin is the I

LOW), then this pin selects the input bus width.

Input Bus Select:

HIGH selects 24-bit input mode

LOW selects 12-bit input mode

Dual edge clock select / I

enabled (ISEL/RST# = HIGH), then this pin is the I

(ISEL/RST# = LOW), then this pin selects whether single clock dual edge is used.

Dual Edge clock select:

When HIGH, IDCK+ latches input data on both falling and

When LOW, IDCK+/IDCK- latches input data on only falling or rising clock edges.

In 24-/12-bit mode:

If HIGH (dual edge), IDCK+ is used to latch data on both falling and rising edges.

If LOW (single edge), IDCK+ latches 1

Edge select / Hot Plug input. If the I

used to monitor the “Hot Plug” detect signal (Please refer to the DVI

DFP standards). This Input is ONLY 3.3V tolerant and has no internal de-bouncer circuit.

2

If I

C bus is disabled (ISEL/RST# = LOW), then this pin selects the clock edge that will latch

the data. How the EDGE setting works depends on whether dual or single edge latching is

selected:

Dual Edge Mode (DSEL = HIGH)

EDGE = LOW, the primary edge (first latch edge after DE is asserted) is the falling edge.

EDGE = HIGH, the primary edge (first latch edge after DE is asserted) is the rising edge.

Note: In 24-bit Single Clock Dual Edge mode, EDGE is ignored.

Single Edge Mode (DSEL = LOW)

EDGE = LOW, the falling edge of the clock is used to latch data.

EDGE = HIGH, the rising edge of the clock is used to latch data.

De-skewing enable.

2

I

C mode (ISEL/RST# = HIGH)

DKEN pin must be set to HIGH. DK[3:1] pins are ignored and the De-skewing increments are

selected through the I

2

Non I

C mode (ISEL/RST# = LOW)

DKEN = LOW, then default De-skewing setting is used.

DKEN = HIGH, then DK[3:1] is used as the De-skewing setting. The De-skewing increments

are T

. Please see Data De-skew Feature for an illustration.

STEP

SiI 164 PanelLink Transmitter

2

C interface controller. The reset is active when this

2

C interface is active, DKEN must be set HIGH.

2

C clock. This pin is an open collector input. If I2C bus is enabled

2

C Data. This pin is an open collector input/output. If I2C bus is

2

C interface (see the I2C register definitions).

2

C clock input. If the I2C is disabled (ISEL/RST# =

2

C data line. If the I2C bus is disabled

rising clock edges.

st

half data and IDCK- latches 2nd half data.

2

C bus is enabled (ISEL/RST# = HIGH), then this pin is

TM

or VESA® P&DTM and

Data Sheet

Page 39

SiI 164 PanelLink Transmitter

37

Data Sheet

Pin Descriptions (cont’d)

Input Voltage Reference Pin

Pin Name Pin # Type Description

VREF 3 Analog In Input Reference Voltage. Selects the Swing range of the digital inputs, which include only

D[23:0], IDCK+, IDCK-, DE, VSYNC, and HSYNC. Input pins SCL and SDA, RST, BSEL,

DSEL, EDGE and PD# require 3.3V high swing signals and are not changed by the VREF

input.

To set the digital inputs to 3.3V High Voltage Swing, VREF must be set to 3.3V.

To set the digital inputs to Low Voltage Swing, VREF must be set to ½ of VDDQ where

VDDQ is swing level of input signal. Thus for DVO mode(1.5V Low Voltage Swing) VREF

should be set to 0.75V and BSEL=LOW.

Power Management Pins

Pin Name Pin # Type Description

PD# 10 In

Differential Signal Data Pins

Pin Name Pin # Type Description

TX0+

TX0TX1+

TX1TX2+

TX2-

TXC+

TXC-

EXT_SWING 19 Analog Voltage Swing Adjust. A resistor should tie this pin to AVCC. This resistor sets the

25

24

28

27

31

30

22

21

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Power Down (active LOW). A HIGH level indicates normal operation. A LOW level

indicates Power Down mode. In Power Down mode the Analog core is disabled and Output

buffers/pins are tri-stated however the Input buffer/pins and I

active. PD# pin is disabled during I

TMDS Low Voltage Differential Signal input data pairs.

These pins are tri-stated when PD# is pulled low.

TMDS Low Voltage Differential Signal input clock pair.

These pins are tri-stated when PD# is pulled low.

amplitude of the voltage swing. A smaller resistor value sets a larger voltage swing and

vice versa. For remote display applications a 510Ω resistor is recommended. While for

notebook computers 680Ω is recommended to ensure voltage swing is not overdriven

over a short cable distance.

2

C mode. PD# should be tied low during I2C mode.

2

C Block for read and write are

Reserved Pins

Pin Name Pin # Type Description

RESERVED 34 In

Must be tied LOW for normal operation.

Power and Ground Pins

Pin Name Pin # Type Description

VCC 1,12,33 Power Digital VCC, must be set to 3.3V nominal.

GND 16,48,64 Ground Digital GND.

AVCC 23,29 Power Analog VCC, must be set to 3.3V nominal.

AGND 20,26,32 Ground Analog GND.

PVCC1 18 Power Primary PLL Analog VCC, must be set to 3.3V nominal.

PVCC2 49 Power Filter PLL Analog VCC, must be set to 3.3V nominal.

PGND 17 Ground PLL Analog GND.

Page 40

SiI 164 PanelLink Transmitter

38

Data Sheet

I2C Registers

2

I

C Register Mapping

Addr. Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x09

0x0A

0x0B

0x0C7

0x0D

0x0E

0x0F

Notes

1. All values are Bit 7(MSB) and Bit 0(LSB).

2. Registers that can be written and read from are listed as (R/W) while registers that can be read only are listed with (RO).

3. Actual jitter tolerance may be higher depending on the frequency of the jitter.

4. Contents of this register are dependent on the status of pins D[23:16].

5. After the RESET signal is deasserted in I

programmed value set before the reset. All other registers do not have a default value or retain their value after a reset.

As such all required registers other than PD and MSEL must reinitialized in I

6. Registers listed as RSVD are reserved and for Silicon Image, Inc use only.

7. 0x0C is also called the

applications.

RSVD[1:0] VEN

(R/W)

VLOW (RO) MSEL[2:0] (RW) TSEL (RW) RSEN (RO) HTPLG

DK[3:1] (RW)

SCNT

(RW)

VDJK

RSVD

RSVD[3:0] RSVD[3:0]

Register. Default setting for the VDJK register 0x0C is 89h, which is optimum for most

DKEN (RW)

2

C mode, only PD and MSEL have a default value or can retain their

VND_IDL (RO)

VND_IDH (RO)

DEV_IDL (RO)

DEV_IDH (RO)

DEV_REV (RO)

RSVD[7:0]

FRQ_LOW (RO)

FRQ_HIGH (RO)

HEN

(R/W)

CFG[7:0]4 (RO)

RSVD[7:0]

RSVD[7:0]

DSEL (RW) BSEL (RW ) EDGE (RW) PD (RW)

MDI (RW)

(RO)

CTL[3:1] (RW) RSVD

PLLF[3:1]

(RW)

2

C mode after being powered up or reset.

PFEN

(RW)

Page 41

SiI 164 PanelLink Transmitter

39

Data Sheet

2

I

C Register Definitions

Register Name Access Description

VND_IDL RO Vendor ID Low byte (01h)

VND_IDH RO Vendor ID High byte (00h)

DEV_IDL RO Device ID Low byte (06h)

DEV_IDH RO Device ID High byte (00h)

DEV_REV RO Device Revision (00h)

FRQ_LOW RO Low frequency limit at 1-pixel/clock mode (MHz) (19h)

FRQ_HIGH RO High frequency limit at 1-pixel/clock mode Max frequency minus 65MHz (MHz) (64h)

PD RW Power Down mode (same function as PD# pin)

0 – Power Down (Default after RESET)

1 – Normal operation

EDGE RW Edge Select (same function as EDGE pin)

0 – Input data is falling edge latched (falling edge latched first in dual edge

mode)